A method for calculating the tooth-cutting motion trajectory of a split equal-base bevel gear

A technology of motion trajectory and calculation method, applied in the field of bevel gear cutting, which can solve problems such as the inability of machine tools to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

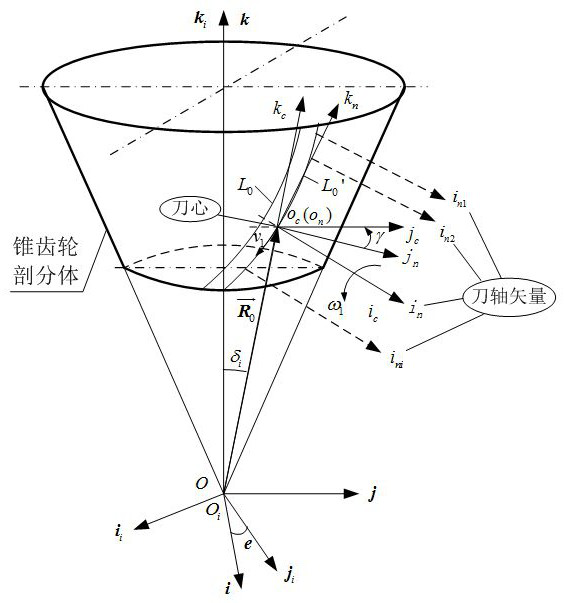

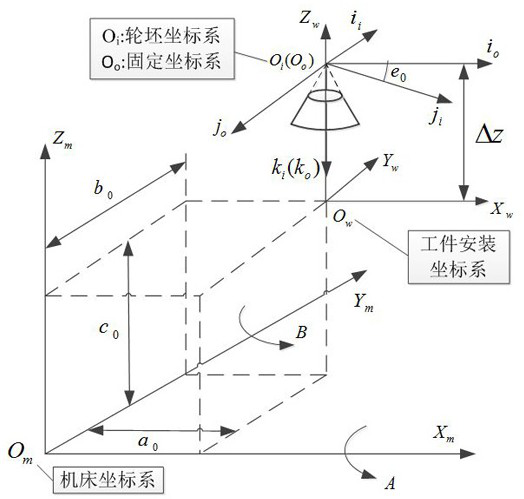

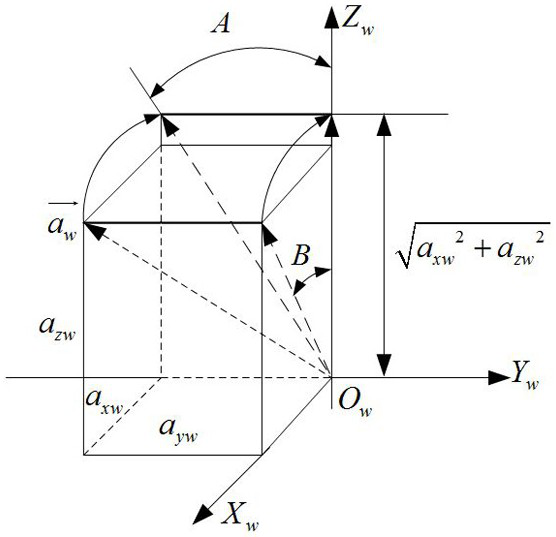

[0093] As shown in the figure, the specific implementation method is as follows:

[0094] Taking the processing of the large wheel in the gear pair shown in Table 1 as an example, a method for calculating the tooth cutting motion track of the split equal base bevel gear of the present invention will be further described in detail in conjunction with the accompanying drawings. In the present embodiment, the number of processed teeth of the bull wheel split body is 3.

[0095] Table 1 Basic geometric parameters of gear pair

[0096]

[0097] Step 1: Solve the included angle e for different processing sequences and different tooth surfaces

[0098] In the equibasic bevel gear cutting coordinate system (attached figure 1 ), the wheel blank coordinate system Axis and Space Fixed Coordinate System The value of the included angle e of the axis determines the relative positional relationship of each convex and concave tooth surface under fixed spatial coordinates. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com