Continuously variable transmission

A continuously variable transmission, jointless technology, applied in the direction of transmission, belt/chain/gear, transmission parts, etc., can solve the problem of reduced driving force transmission efficiency, inability to narrow the gap between metal elements 101, and difficulty in air acting on metal elements effectively 101 and other problems to achieve the effect of improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

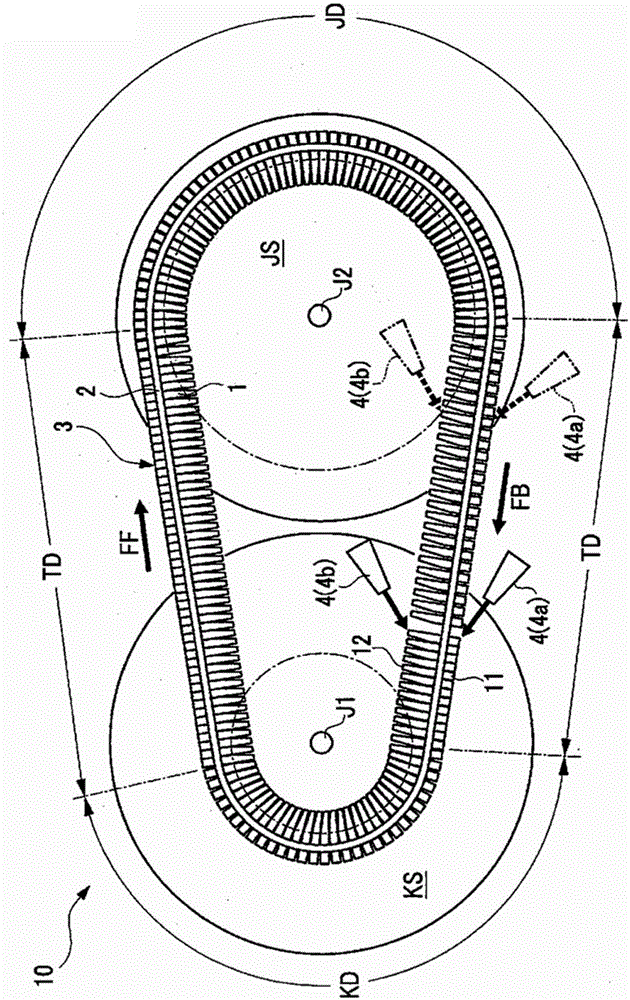

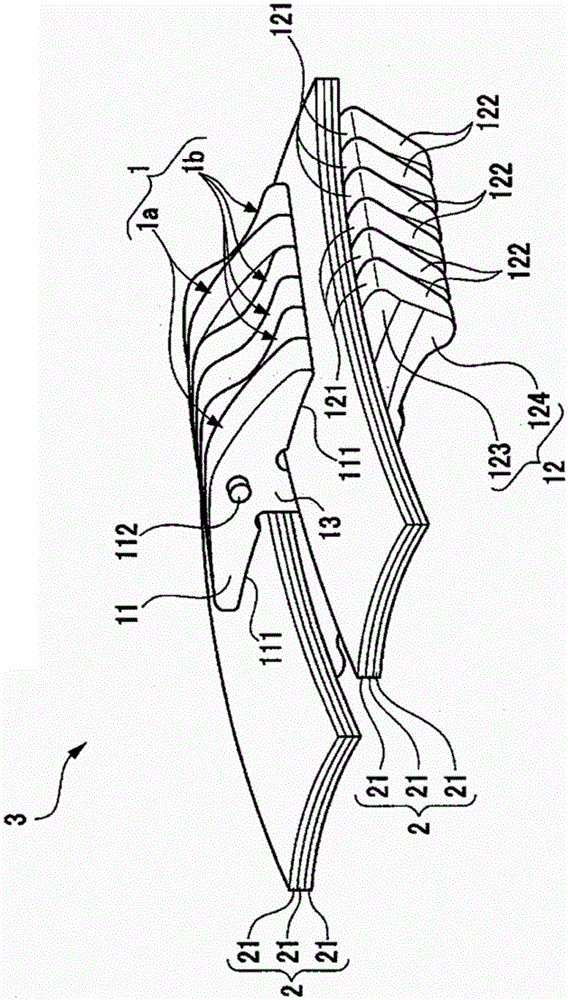

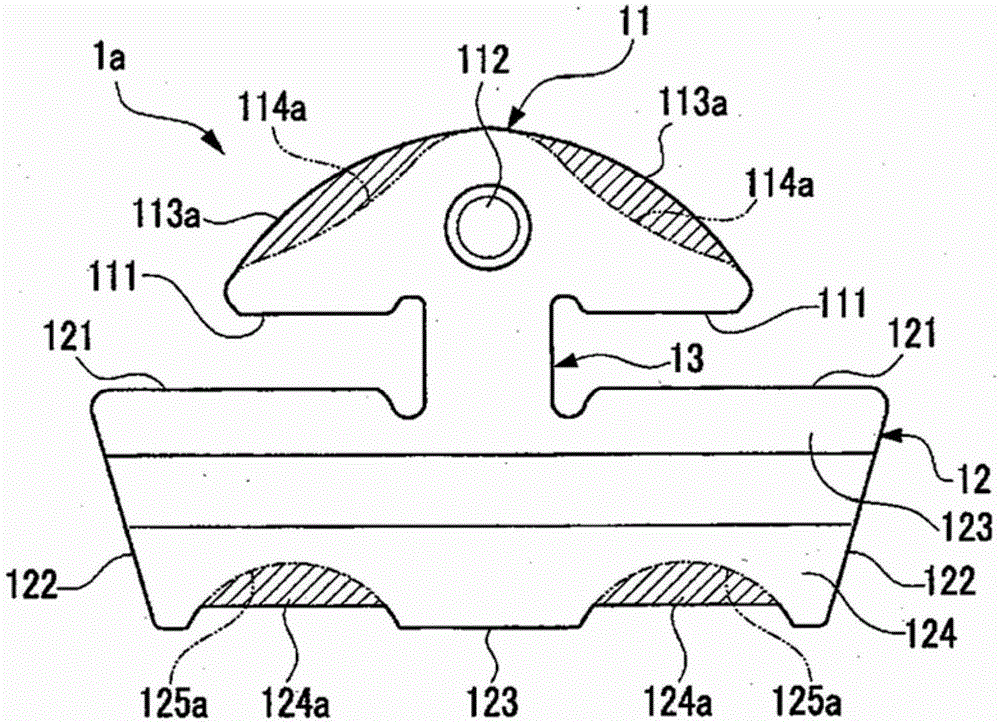

[0046] Such as Figure 6 As shown, the first embodiment is an example in which a first flange portion 113a is formed on the head portion 11 of one metal element 1a, and a second flange portion 124a is formed on the main body portion 12. On this basis, the continuously variable transmission While the belt 3 is moving from the driven pulley to the driving pulley (direction of arrow FB), from the injection ports 4a, 4b toward the first flange portion 113a and the second flange portion 113a along the moving direction of the continuously variable transmission belt 3. The two flange parts 124a blow fluid (lubricating oil) 4aw, 4bw. In this case, the first flange portion 113a and the second flange portion 124a formed on one metal element 1a protrude outward from the inclined side 113b and the arcuate side 124b of the other metal element 1b. Therefore, the fluids (lubricating oils) 4aw, 4bw blown from the ejection ports 4a, 4b of the fluid supply device 4 directly act on the first fl...

no. 2 example

[0048] Such as Figure 7 As shown, the second embodiment is an example in which the plate thickness t1 of one metal element 1a in the first embodiment is made larger than the plate thickness t2 of the other metal element 1b. By making the thickness t1 of one metal element 1a larger than the thickness t2 of the other metal element 1b, the inertial force of the one metal element 1a pressed by the fluids (lubricating oil) 4aw, 4bw can be increased. As a result, from the position where the fluid (lubricating oil) 4aw, 4bw is blown to the position where it is wound around the drive pulley KS, the metal layered in front of the metal element 1a on one side of the fluid (lubricating oil) 4aw, 4bw to be blown can be made The posture of the group of elements 1a, 1b is continuously maintained stable. In addition, a plurality of one metal element 1a having increased plate thickness t1 may exist, and may be arranged at an appropriate interval between the other metal element 1b.

no. 3 example

[0050] Such as Figure 8 As shown, the third embodiment is an example in which a first groove portion 114a is formed in the head portion 11 of one metal element 1a, and a second groove portion 125a is formed in the main body portion 12. 3 While moving from the driven pulley to the driving pulley (direction of arrow FB), from the injection ports 4a and 4b to the first groove portion 114a and the second groove portion along the moving direction of the continuously variable transmission belt 3 125a blows fluid (lubricating oil) 4aw, 4bw. In this case, the first groove portion 114a and the second groove portion 125a formed in one metal element 1a are recessed inwardly than the inclined side 114b and arcuate side 125b of the other metal element 1b. Therefore, the fluids (lubricating oils) 4aw, 4bw blown from the ejection ports 4a, 4b of the fluid supply device 4 directly act on the metal element 1a stacked in front of one of the first grooves 114a and the second grooves 125a. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com