Conical top cover pull type recycling sub-orbital carrier rocket

A launch vehicle and sub-orbital technology, applied in the field of aerospace rockets, can solve the problems of difficulty in recovery, uncontrollable landing point, failure to achieve recovery, etc., and achieve the effect of reducing construction costs, reducing the number of configurations, and reducing supporting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Two fixed "non-swing tube" recovery power engine solutions:

[0059]Two recovery power engines 661 are fixedly installed on the outer side of the shell section 612 of the cone-top cover 61. The thrust of the recovery power engines 661 is preferably 10t. The recovery power engine 661 and its engine nozzle 662 do not swing, providing rocket boost, recovery power and attitude control thrust; the rocket separation force is symmetrically installed on the outer edge of the bottom of the first-stage rocket body 1. Push rocket provided. Its working mechanism: (1) Recover power attitude control function: set the engine with an angle of 30° to the rocket body and control the rocket pitch attitude by adjusting the thrust of the two engines (by installing a simple "pneumatic attitude control system" to control the rocket yaw and roll attitude). (2) Recovery power thrust function: During the ascent of the rocket, the recovery power engine 661 starts to provide forward t...

Embodiment 2

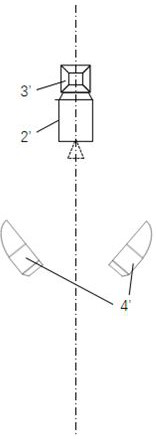

[0060] Example 2: Two "circumferential pendulum" recovery power engines scheme:

[0061] Two unidirectional swing (circumferential) recovery power engines 661 are installed on the outer side of the shell section 612 of the conical top cover 61. The thrust of the recovery power engines 661 is preferably 10t. Recovery power and attitude control thrust; rocket separation force is provided by two reverse thrust rockets symmetrically installed on the outer edge of the bottom of the first-stage rocket body 1. Among them, "circumferential" is relative to the overall columnar launch vehicle, which refers to, please refer to Figure 2B , the engine nozzle 662 can rotate in the direction perpendicular to the plane of the drawing with the swing mechanism 663 as the axis. Its working mechanism: (1) Recovery power attitude control function: the recovery power engine yaw in the same direction to control the pitch attitude, and the opposite direction yaw to control the roll attitude; set th...

Embodiment 3

[0062] Example 3: Two "radial pendulum" recovery power engines scheme:

[0063] Two unidirectional swing (radial) recovery power engines 661 are installed outside the shell section 612 of the cone dome 61. The recovery power engines 661 preferably have a thrust of 10t to provide rocket boost, recovery power and attitude control thrust. Among them, "radial" is relative to the overall cylindrical launch vehicle, which refers to, please refer to Figure 2B and Figure 2C , the engine nozzle 662 can be rotated in the drawing plane with the oscillating mechanism 663 as the axis, for example, from Figure 2B Turn to Figure 2C The state is inclined upward. Its working mechanism: (1) The recovery power attitude control function: the recovery power engine 661 yaw in the same direction to control the pitch attitude, and the recovery power engine 661, which is at an angle of 30° to the arrow body, can also control the pitch attitude by adjusting the thrust (attitude control system). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com