Brine wastewater advanced treatment and efficient recovery utilization technology

A technology for advanced treatment and waste water, which is applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of concentrated salty waste water seepage, non-recyclable, large footprint, etc. Achieve the effects of long-term stable operation, recycling, low operating costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

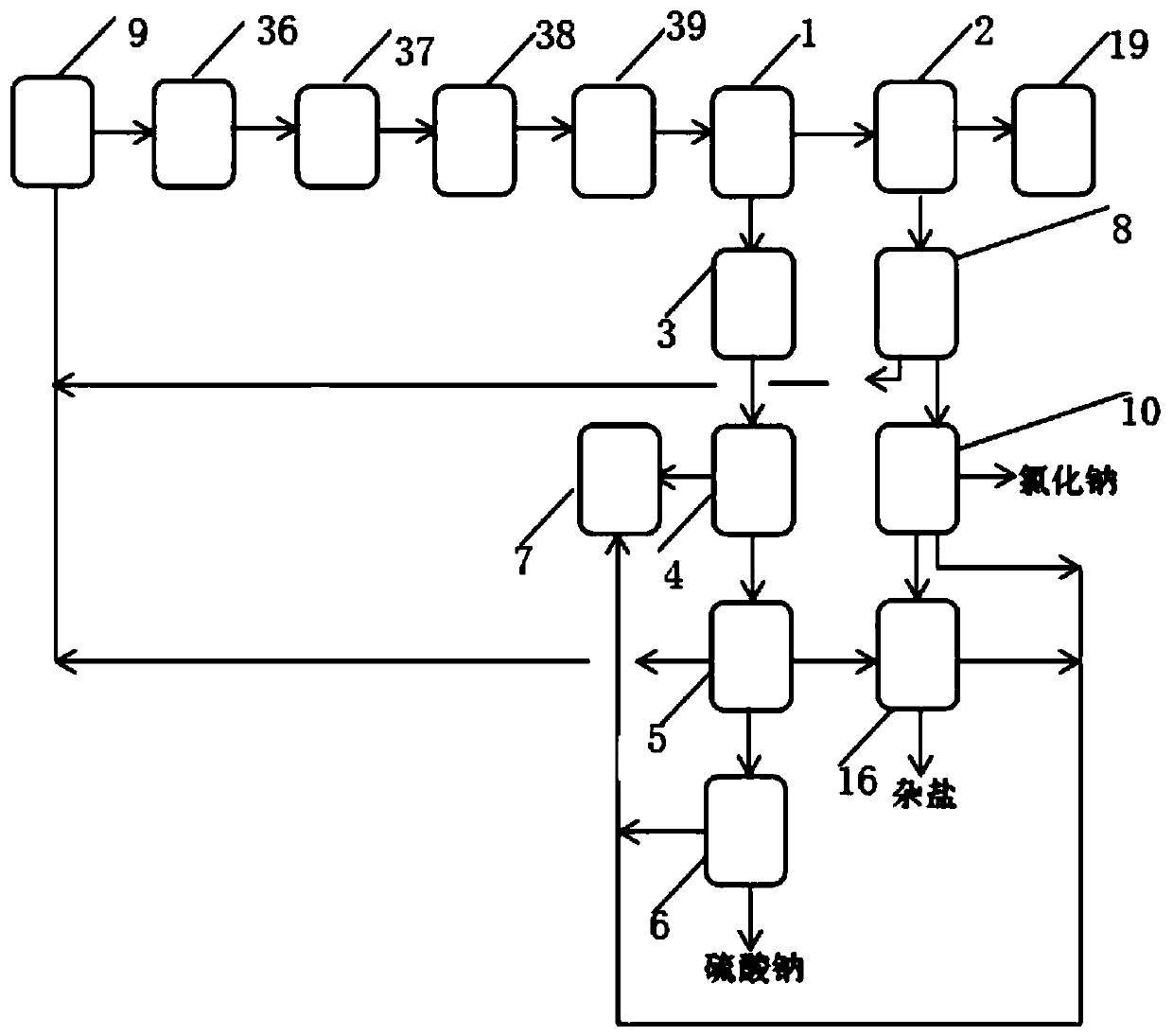

[0061] Example 1 Deep treatment of concentrated salt wastewater and efficient recycling process

[0062] Combine figure 1 , The advanced treatment and efficient recycling process of concentrated salt wastewater, the specific steps are as follows:

[0063] (1) The concentrated salt wastewater from the concentrated water recovery unit enters the nanofiltration unit 1, and is processed by the nanofiltration unit.

[0064] (2) After the concentrated salt wastewater is processed by the nanofiltration unit, the nanofiltration purified water, which accounts for 80% of the total weight of the concentrated salt wastewater, enters the reverse osmosis unit 2, and the reverse osmosis purified water is recycled to the circulating water system through the treatment of the reverse osmosis unit , The recovery volume accounts for 59.5% of the total weight of concentrated salt wastewater.

[0065] (3) The nanofiltration concentrated water of the cashier unit 1 accounting for 20% of the total weight of ...

Embodiment 2

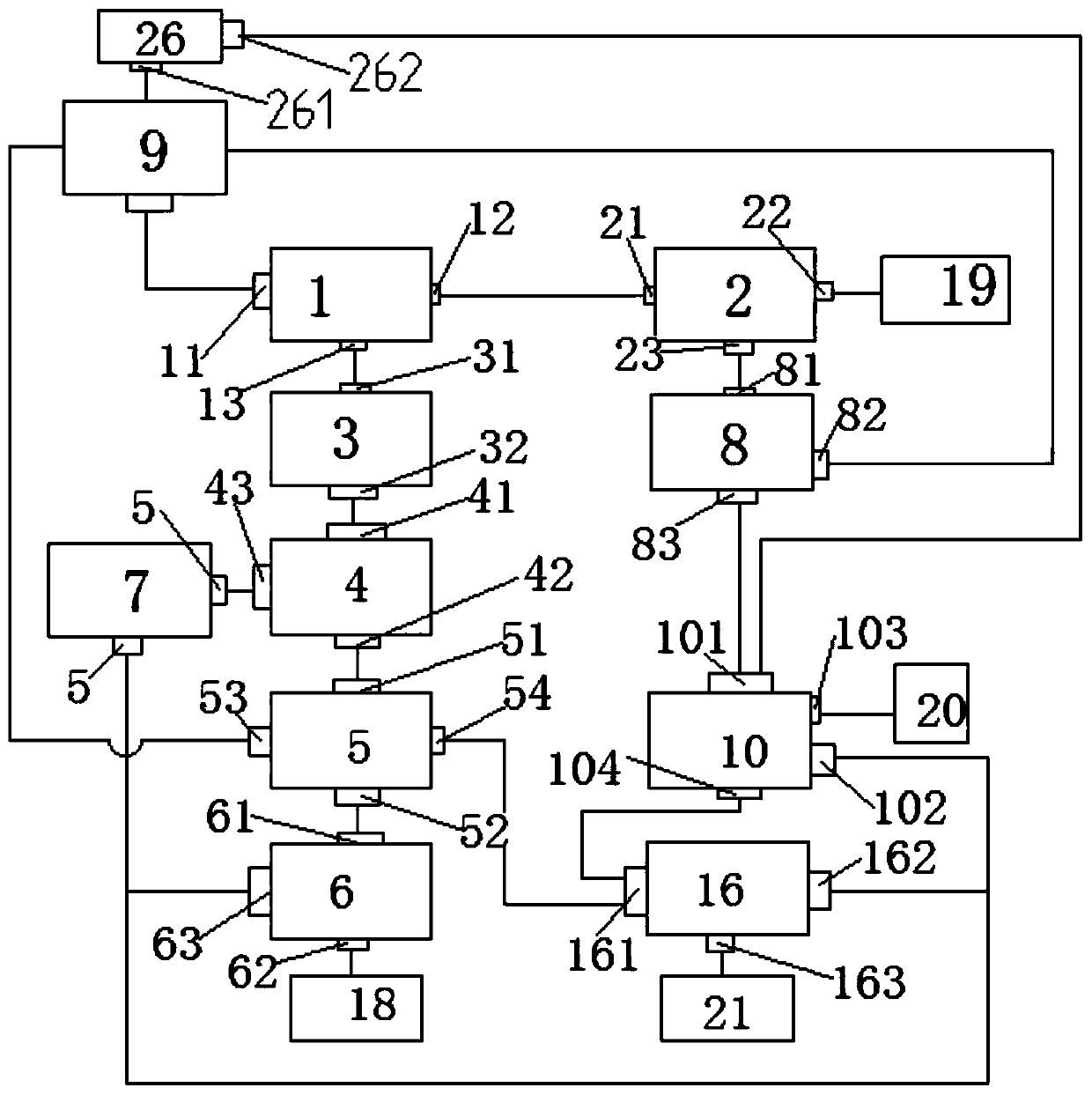

[0071] Example 2 Deep treatment of concentrated salt wastewater and efficient recycling process

[0072] Combine figure 1 Further, in the process for advanced treatment and efficient recycling of concentrated salt wastewater of the present invention, the detailed steps are as follows:

[0073] (1) The concentrated salt wastewater from the concentrated water recovery unit 9 enters the material inlet 11 of the nanofiltration unit and is processed by the nanofiltration unit 1;

[0074] (2) After the concentrated salt wastewater is processed by the nanofiltration unit 1, the nanofiltration purified water, which accounts for 80% of the total weight of the concentrated salt wastewater, enters the water inlet 21 of the reverse osmosis unit through the clean water outlet 12 of the nanofiltration unit, and passes through the reverse osmosis unit 2. Recovered reverse osmosis purified water passes through the purified water outlet 22 of the reverse osmosis unit to the circulating water system 9...

Embodiment 3

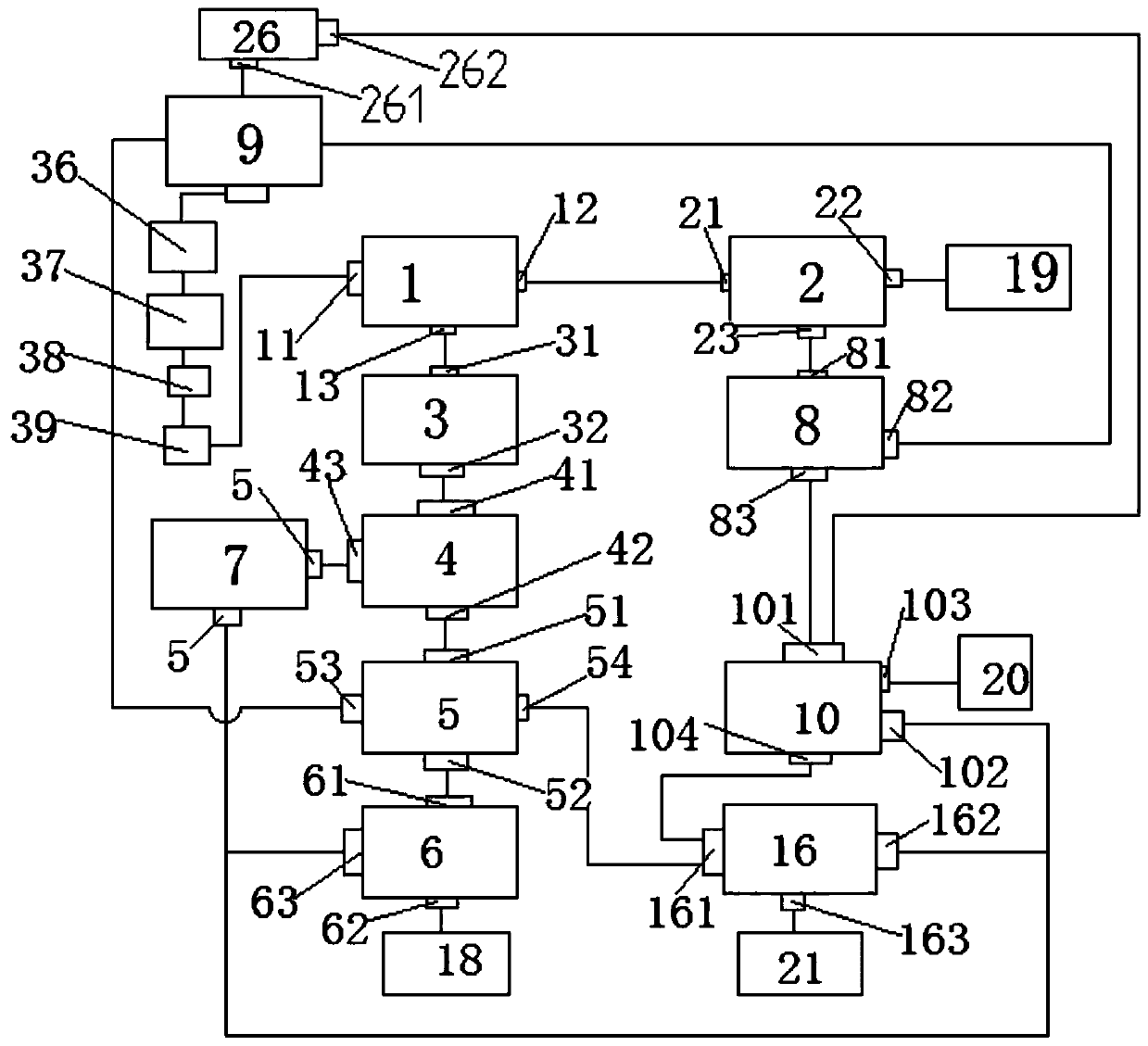

[0082] Combine figure 1 The detailed steps of the advanced treatment and high-efficiency recycling process for concentrated salt wastewater of the present invention are as follows:

[0083] (1) The concentrated salt wastewater from the concentrated water recovery unit 9 first enters the multi-media filter 36, the activated carbon filter 37, the ultrafiltration device 38, and the weak acid anode 39 in sequence. The concentrated salt wastewater after the above treatment enters the nanofiltration unit The material inlet 11 is processed by the nanofiltration unit 1;

[0084] (2) After the concentrated salt wastewater is processed by the nanofiltration unit 1, the nanofiltration purified water, which accounts for 80% of the total weight of the concentrated salt wastewater, enters the water inlet 21 of the reverse osmosis unit through the clean water outlet 12 of the nanofiltration unit, and passes through the reverse osmosis unit 2. Recovered reverse osmosis clean water passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com