Bale filling machine

A filling machine and straw bale technology, applied in the field of agricultural production equipment, can solve the problems of low production efficiency, long production cycle and high transportation cost, and achieve the effects of improving passability, high degree of automation and improving field passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

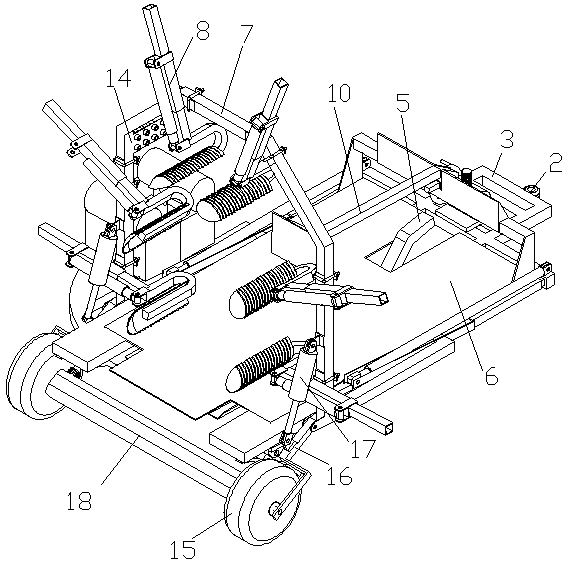

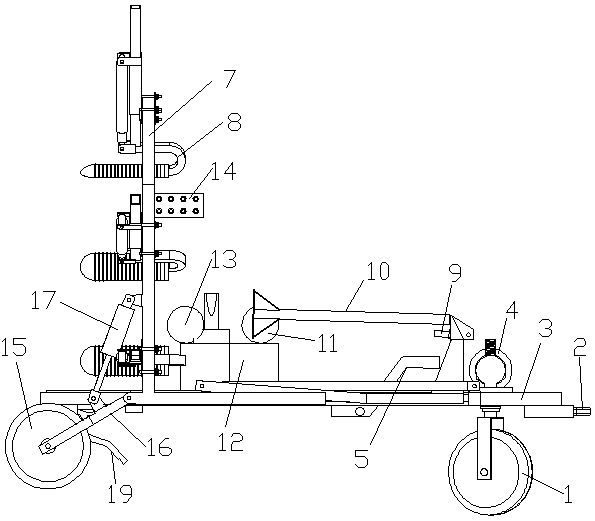

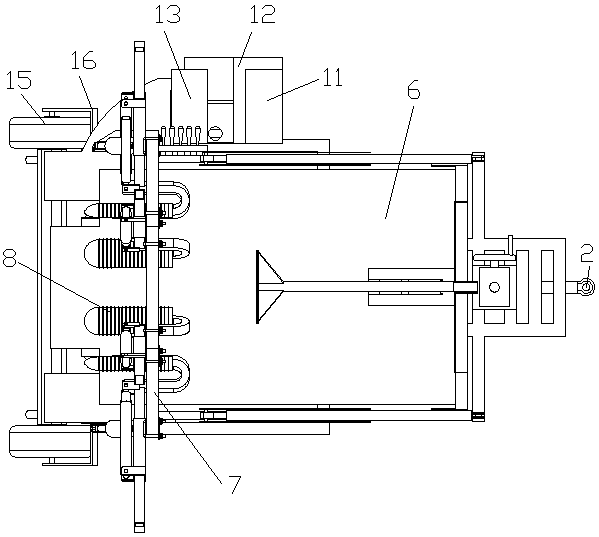

[0032] A bale filling machine, such as Figures 1 to 10 As shown, including vehicle frame 3, front wheel 1 and rear wheel 15, the front end of vehicle frame 3 is provided with traction head 2, and vehicle frame 3 is provided with hand lifter 4, pushing tray mechanism, gantry frame 7, hydraulic oil tank 12 , the hydraulic pump 11 and the power mechanism 13 that provides power for the hydraulic pump 11, the front wheel 1 is fixed on the front wheel bracket, the hand lifter 4 is connected with the front wheel bracket to control the lifting of the front wheel, and the vehicle frame 3 is provided with a power supply The sliding guide rail 31 of the push tray mechanism is provided with a trigger 5 in the push tray mechanism, and the gantry 7 is arranged at the rear of the push tray mechanism. The gantry 7 is provided with a bag support mechanism 8 and a hydraulic manual valve assembly 14. The control valve assembly 14 is connected to the hydraulic system. The rear wheel 15 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com