A missile hanging separation mechanism

A separation mechanism and hanging technology, which is applied to self-propelled projectiles, projectiles, offensive equipment, etc., can solve the problems of difficult control and low safety of the hanging separation mechanism, and achieve improved flight safety, high action synchronization, Simple and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

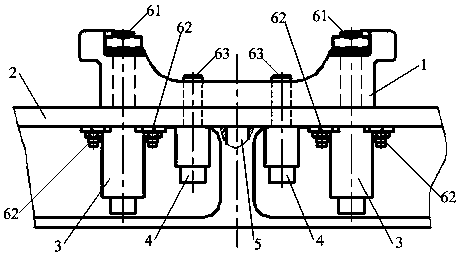

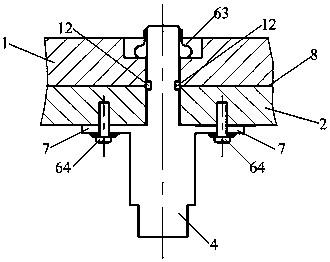

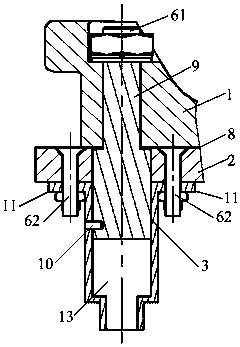

[0025] See attached Figures 1 to 4 , a missile suspension separation mechanism, including a suspension 1, an actuator 3, an explosive bolt 4, a projectile body 2 and a positioning pin 5, and one end of the actuator 3 is connected to the projectile body 2 through a second fastener 62 , the other end is connected to the hanger 1 through the first fastener 61; one end of the explosive bolt 4 is connected to the projectile body 2 through the fourth fastener 64, and the other end is connected to the hanger 1 through the third fastener 63; The hanger 1 is fixed on the body 2 through the positioning pin 5, and the surface of the body 2 in contact with the hanger 1 is a separation surface 8; the upper end of the explosion bolt 4 is provided with a "U"-shaped groove 12, so that The central plane of the "U"-shaped groove 12 is on the separation surface 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com