The construction method of the station guide tunnel and underground excavation of the existing operating station under zero distance

A construction method and zero-distance technology, applied in the field of rail transit, can solve problems such as settlement control and risk control of unfavorable operating stations and newly-built stations, poor self-stabilizing ability of soil structures, and poor force forms, so as to avoid major operation accidents. and construction safety accidents, improving speed and efficiency, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

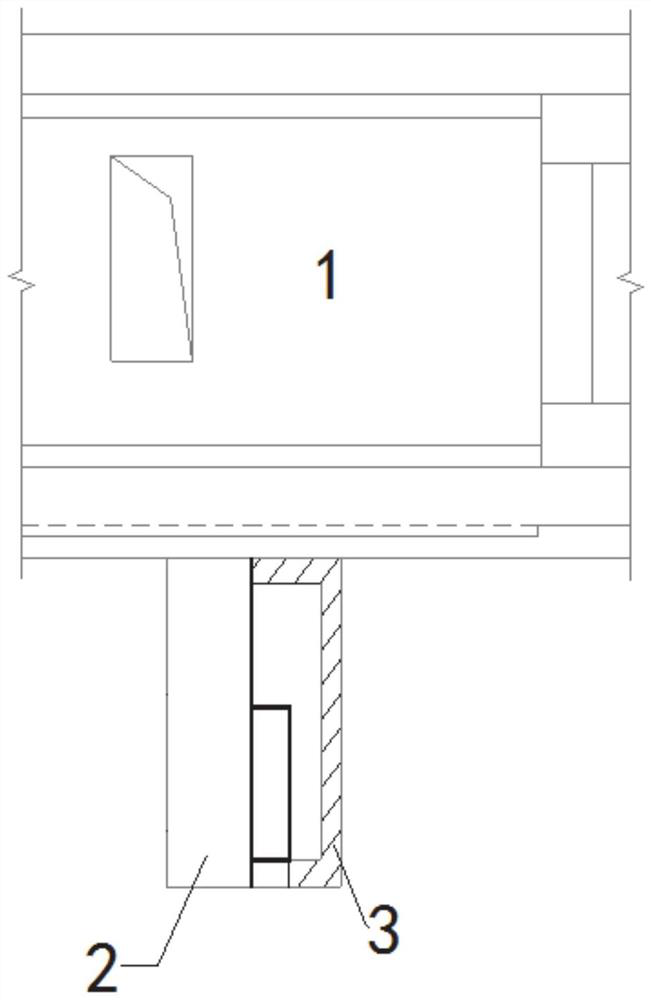

[0039] In an exemplary embodiment of the present invention, reference Figure 1 As shown, the construction method of the station guide hole that passes through the existing operating station at zero distance is carried out, and the construction of the guide hole is carried out by the pipe jacking machine.

[0040]Specifically, it includes the following:

[0041] Use of underground excavation cross-channel as pipe jacking work well;

[0042] As the first step of the excavation of the guide hole, in order to carry out the smooth progress of the pipe jacking machine, the underground excavation of the horizontal channel is carried out first, and the role of the guide hole is to provide the construction surface for the construction of the vertical support system;

[0043] After the hole door is chiseled, the jacking operation of the rectangular pipe jacking machine is carried out in the horizontal passage; the hole door is the hole door to be excavated, that is, the hole door of the g...

Embodiment 2

[0050] The construction method of tunneling stations with zero distance down through existing operating stations includes the following:

[0051] Pipe jacking machine is used to construct multiple guide holes at the same time or one by one;

[0052] After the completion of the construction of the guide hole, in the two guide holes on the upper side side, the crown beam and the side pile are constructed, the side pile goes down, and the side pile is perpendicular to the crown beam, where the straight thread sleeve reserved for the pipe segment structure during the construction of the crown beam is connected with the steel bar of the crown beam;

[0053] And in the upper and lower middle guide holes to install steel pipe columns, respectively, the construction of the top and bottom longitudinal beams;

[0054] Excavate the upper soil between the two guide holes in the middle of the upper layer, apply the top initial lining, and then excavate the upper soil between the upper middle g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com