Filtering equipment for realizing separation of catalyst in production of polytetramethylene ether glycol

A technology of polytetramethylene and filtration equipment, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of wasting catalyst, restricting the improvement of stable product quality, performance failure, etc., to ensure sedimentation and collection, improve Operational efficiency, the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

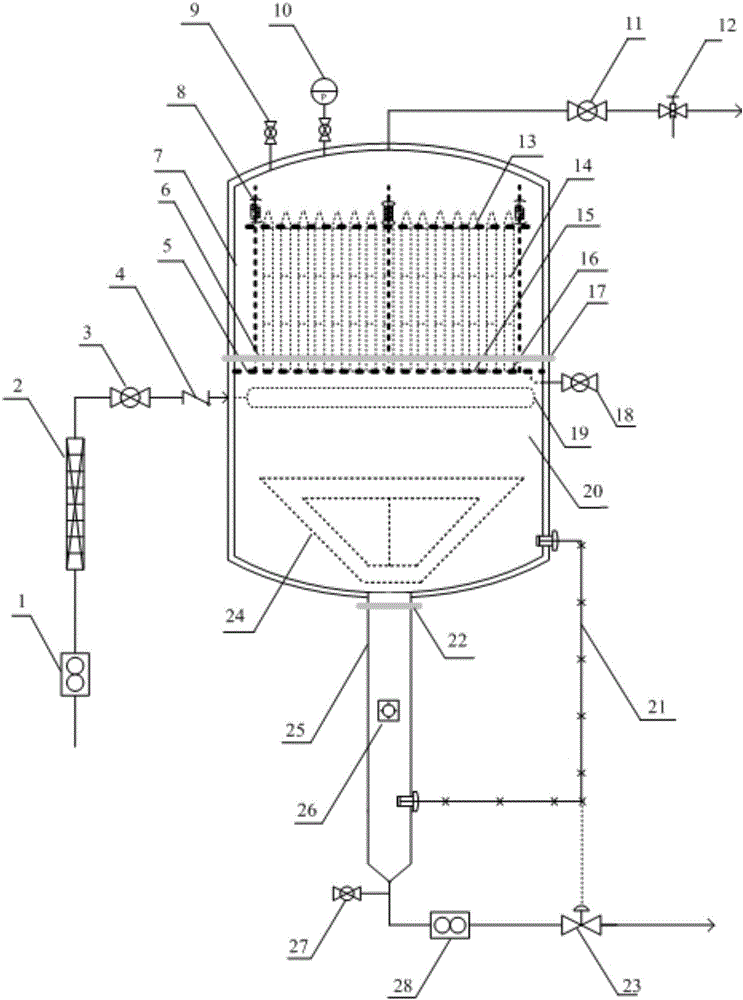

[0020] figure 1 , including the first mass flow meter 1, static mixer 2, feed valve 3, feed check valve 4, tube sheet 5, second PTFE gasket 6, upper cylinder 7, spring 8, reverse Washing feed valve 9, pressure gauge 10, discharge valve 11, sampling valve 12, pressure plate 13, filter element 14, external thread joint 15, first polytetrafluoroethylene gasket 16, first flange 17, emptying valve 18 , distributor 19, lower cylinder 20, interface meter 21, second flange 22, control valve 23, collector 24, stratifier 25, sight glass 26, backwash discharge valve 27, second mass flow meter 28 Wait.

[0021] Such as figure 1 Shown, the present invention is a kind of filter equipment that realizes catalyst separation in the polytetramethylene enigmatic glycol production, comprises the upper cylinder body 7 and lower cylinder body 20 that seal conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com