Manually-operated louver valve

A louver valve and vane technology, which is used in lift valves, valve devices, engine components, etc., can solve problems such as defects in details, and achieve the effect of ensuring sealing performance, good leakage rate, and reducing air leakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

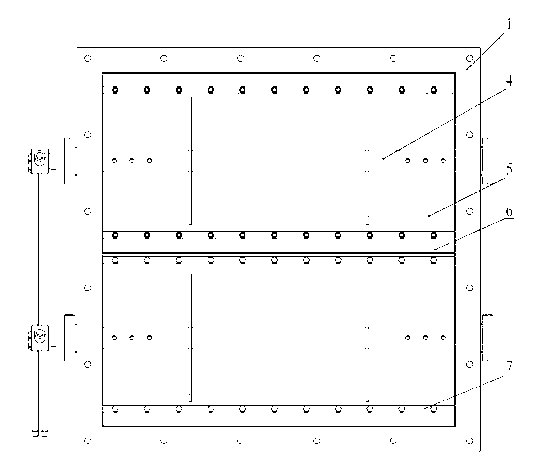

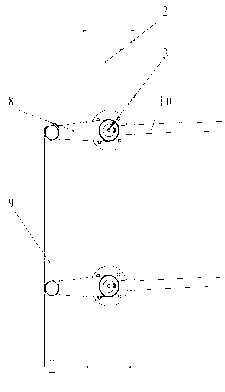

[0012] Such as figure 1 and 2 As shown, a manual louver valve includes a blue 1, a housing 2, a rotating shaft 3, a hollow shaft 4, a blade 5, a high temperature wear-resistant rubber 6, a bead 7, a crank 8, a connecting rod 9 and a handle 10, the method The flange 1 is connected with the shell 2, and the rotating shaft 3 is placed in the shell 2, the blade 5 is fixedly connected with the hollow shaft 4, the rotating shaft 3 is inserted into the hollow shaft 4 and connected by bolts, and the edge of the blade 5 is equipped with a high-temperature wear-resistant rubber 6, The bead 7 is pressed against the rubber 6 to connect the housing 1 with bolts, and the handle 10 is connected to the outside of the housing 2 and connected to the rotating shaft 3 through the crank 8 and the connecting rod 9 .

[0013] It should be pointed out that those skilled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com