External expansion joint type glass-metal sealing-in end socket structure with internal shielding cover

A metal sealing and shielding cover technology is applied in the field of grooved photothermal high temperature heat collecting tubes, which can solve the problems of poor reliability of sealing parts, difficult implementation and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

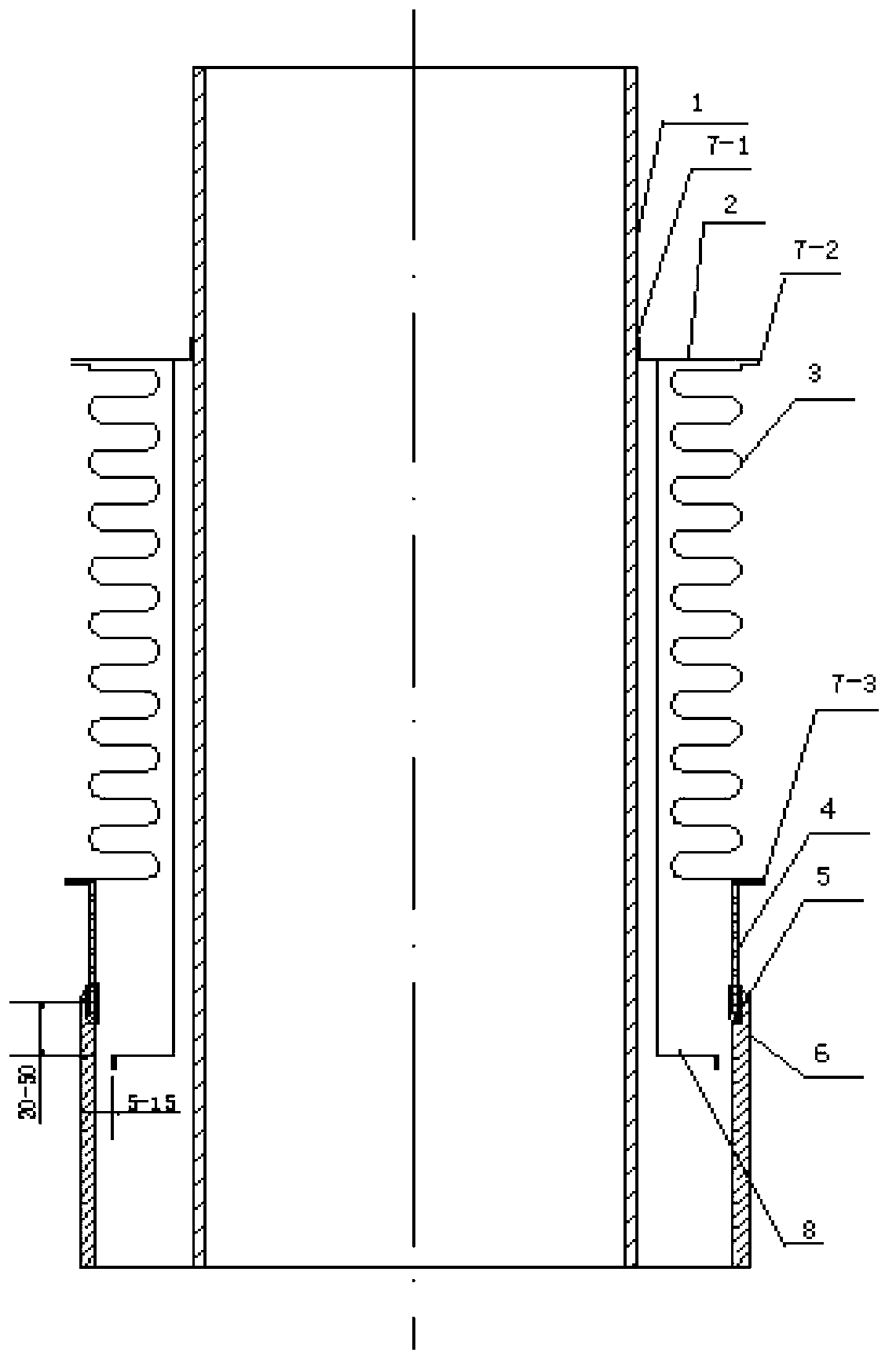

[0027] The shielding cover 8 is connected to the metal end cap 8, so that it is placed between the metal tube 1, the external expansion joint 3 and the sealing part (that is, the connection part of the Varalloy ring 4, the transition glass 5, and the glass tube 6). It can effectively shield the high-temperature heat radiation from the metal pipe 1 and reduce the heat reaching the glass-metal sealing part.

[0028] The structure of the shield is similar to that of a top hat, that is, the main body of the shield is a cylinder, and the part near the glass-metal seal is connected by a ring and the cylinder, like a top hat. One end of the ring of the shielding cover is located on the side of the glass-metal sealing part, 5-15mm away from the inner side of the glass tube to ensure that it does not touch the inner side of the glass tube to avoid conduction and heat transfer. The length of the shielding cover exceeds the glass - Metal sealing part 20-50mm (see figure 1 ), to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com