Composite type labyrinth compression resistant air-conditioning cabinet

An air-conditioning box and labyrinth technology, which is applied in the field of compound labyrinth pressure-resistant air-conditioning boxes, can solve the problems of high air leakage rate, poor sealing performance, insufficient rigidity, etc., and achieve the effect of reducing air leakage rate, eliminating cold bridges and overcoming cold bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

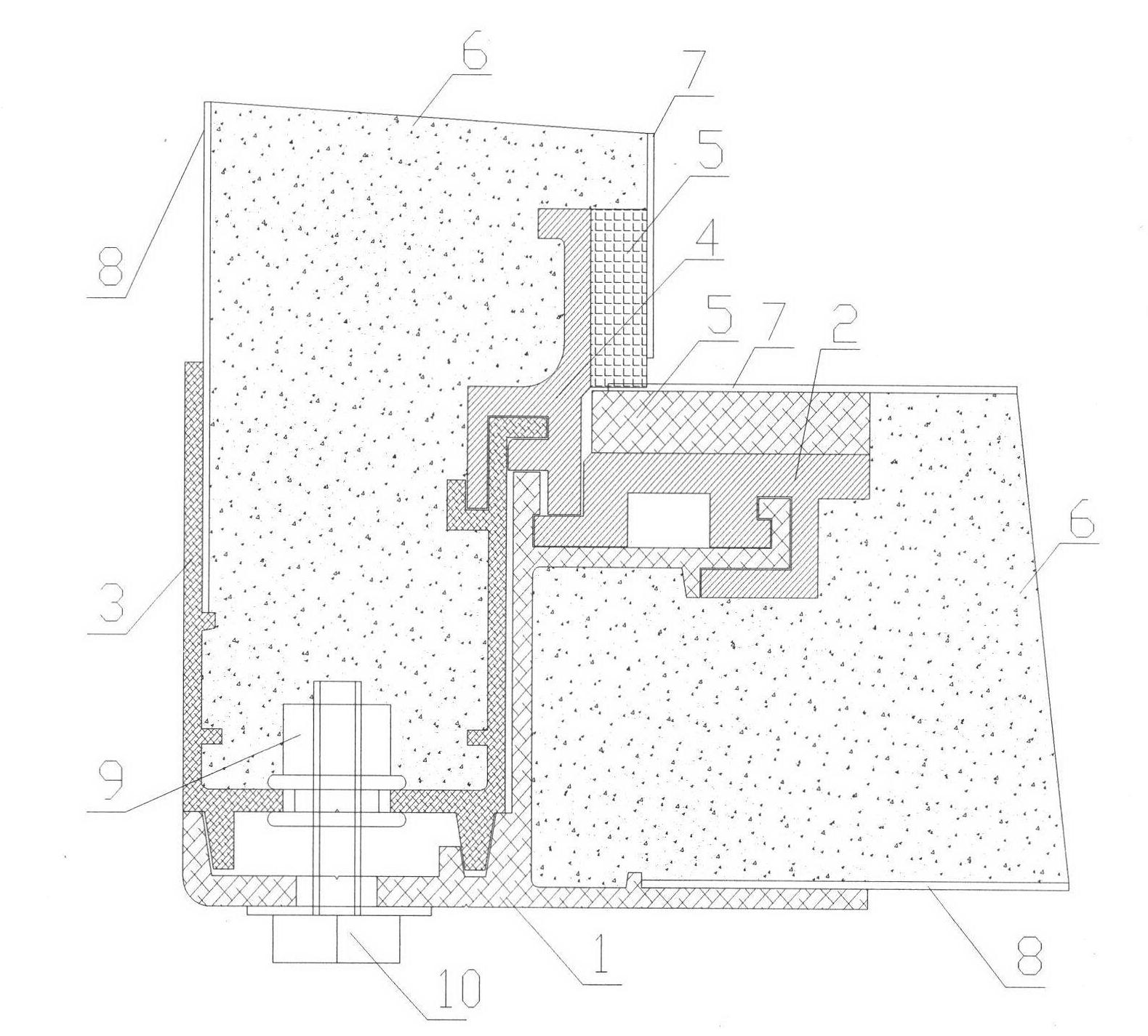

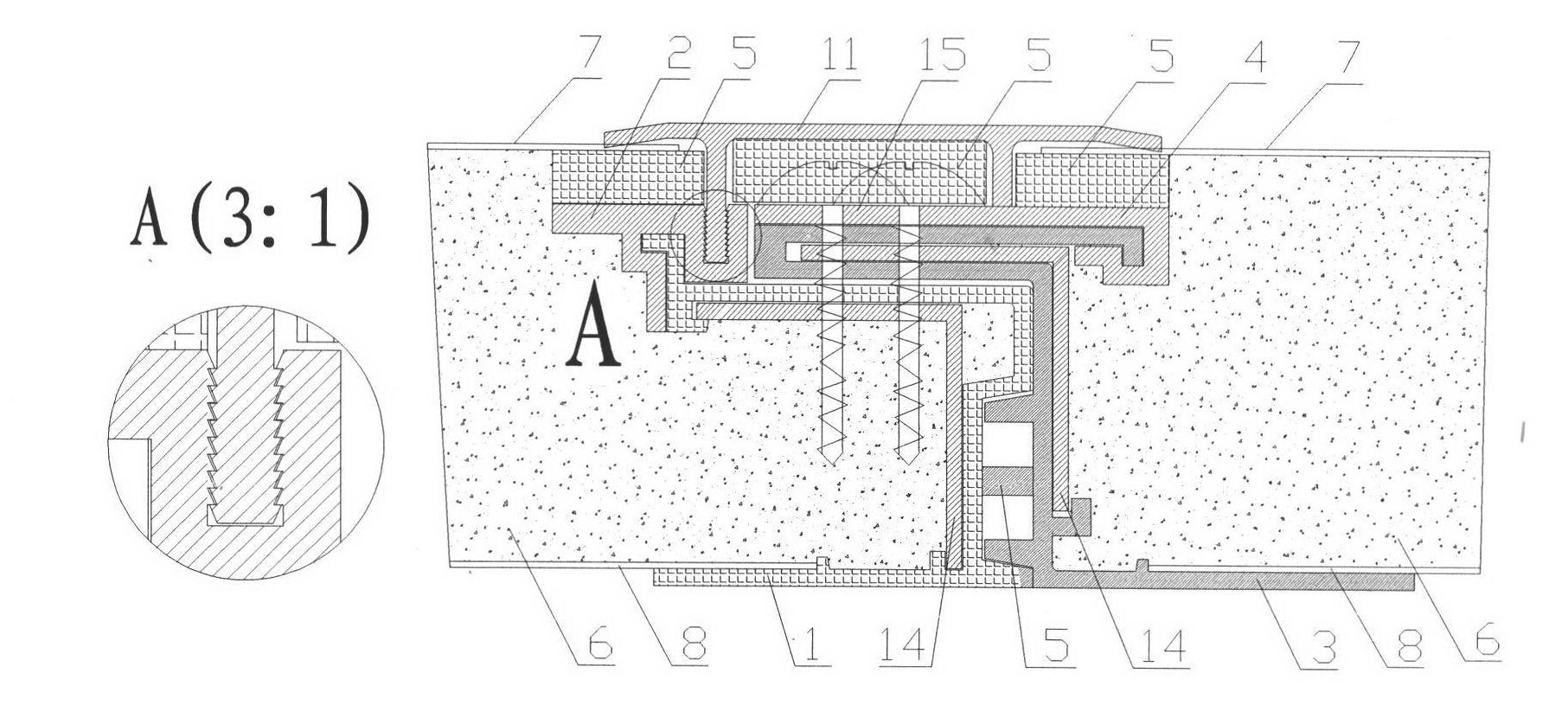

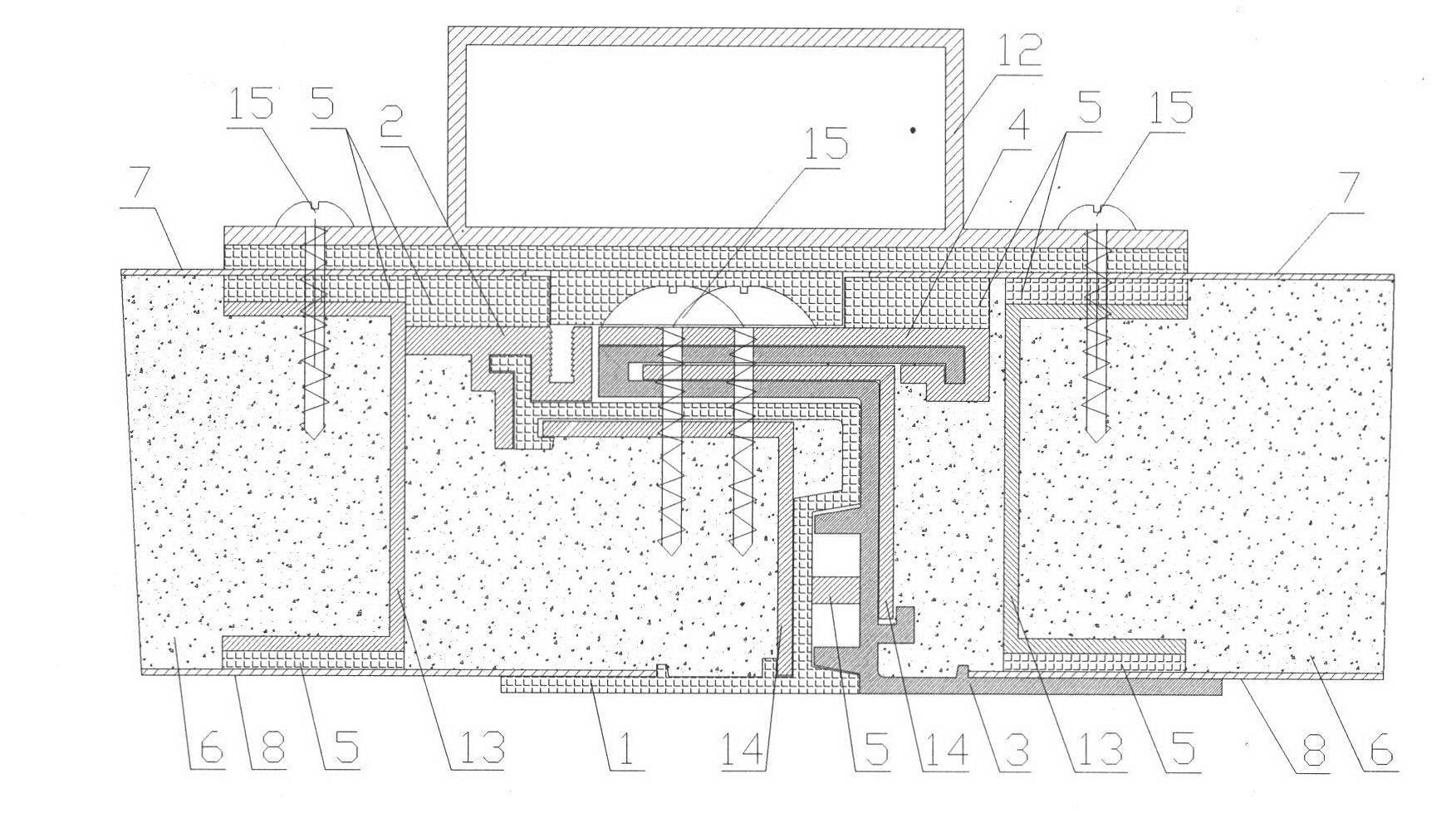

[0020] Such as figure 1 Shown:

[0021] The No. 1 frame aluminum profile 1 and the No. 2 frame plastic profile 2 are fastened into an integral profile, which forms an air-conditioning box panel with the outer panel 8, inner panel 7, foamed polyurethane 6, and foamed rubber 5; the No. 3 frame aluminum Profile 3 and No. 4 frame plastic profile 4 are fastened into one profile and form another air-conditioning box panel with outer panel 8, inner panel 7, foamed polyurethane 6, and foamed rubber 5; the two air-conditioned box panels pass through nuts 9, The cooperation and locking of the bolt 10 makes the two air-conditioning box panels fastened together to form an air-conditioning box; the joint of the concave-convex groove at the corner of the No. 1 frame aluminum profile 1 and the No. 3 frame aluminum profile 3 forms the first part of the air-conditioning box body. The first seal (layer); the contact surface of the No. 2 frame plastic profile 2 and the No. 4 frame plastic profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com