Process for producing anode copper by adoption of four connected furnaces

An anode copper and process technology, applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of high sulfur content and impurities in blister copper, inability to digest cold materials, and high copper content in blowing smelting slag. The effect of resolving damage and high SO2 concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

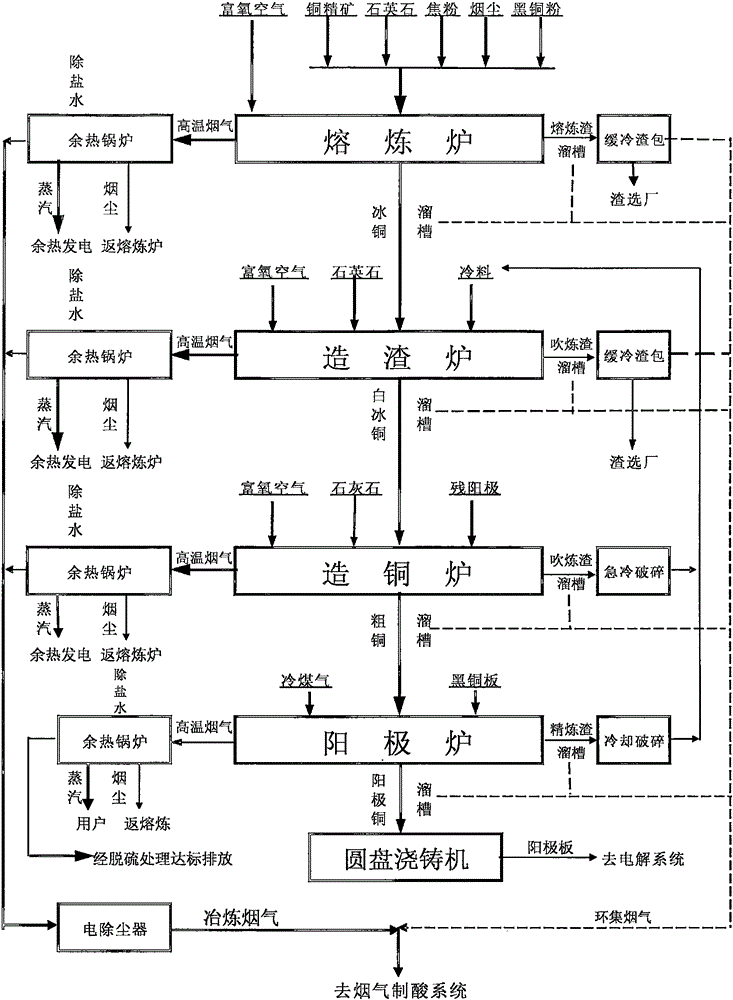

[0045] Such as figure 1 Shown, a kind of technology that adopts four consecutive furnaces to produce anode copper comprises the following steps:

[0046] (1) According to the proportion of ingredients and accurate measurement, the mixed copper concentrate containing 18.5% copper and 7% water content, quartz stone flux and coke powder with a particle size of 2 high temperature flue gas. The smelting slag and matte are separated in the furnace, and the matte containing 50% copper sinks in the lower layer of the melt, is discharged through the siphon channel, and flows into the slagging furnace through the chute; the copper content is less than 0.90%, Fe / SiO 2 =1.55 smelting slag The smelting slag is continuously discharged from the electrode slag chamber, enters the slow cooling slag bag through the chute, and goes to the slag removal plant for flotation; 1220°C high-temperature flue gas containing SO2 enters the waste heat boiler through the vertical flue, and comes out of the ...

Embodiment 2

[0051] Such as figure 1 Shown, a kind of technology that adopts four consecutive furnaces to produce anode copper comprises the following steps:

[0052] (1) According to the proportion of ingredients and accurate measurement, the mixed copper concentrate containing 19.5% copper and 8% water content and quartz stone flux and coke powder with a particle size of 2 =1.65 smelting slag The smelting slag is continuously discharged from the electrode slag chamber, enters the slow cooling slag bag through the chute, and is flotation in the slag removal plant; 1240°C contains SO 2 The high-temperature flue gas enters the waste heat boiler through the vertical flue, and the 330°C low-temperature flue gas from the waste heat boiler enters the acid system through the electric dust collector.

[0053] (2) Hot matte containing 55% copper is produced by smelting, which flows into the slagging furnace continuously and stably through the matte chute, and at the same time, quartz stone flux an...

Embodiment 3

[0057] Such as figure 1 Shown, a kind of technology that adopts four consecutive furnaces to produce anode copper comprises the following steps:

[0058] (1) According to the proportion of ingredients and accurate measurement, the mixed copper concentrate containing 20.5% copper and 9% water content and quartz stone flux and coke powder with a particle size of 2 high temperature flue gas. The smelting slag and the matte are separated in the furnace, and the matte containing 60% copper sinks in the lower layer of the melt, is discharged through the siphon channel, and flows into the slagging furnace through the chute; the smelting slag containing less than 1.2% copper and Fe / SiO2=1.75 is smelted The slag is continuously discharged from the electrode slag chamber, enters the slow cooling slag bag through the chute, and is flotation in the slag removal plant; 1250°C contains SO 2 The high-temperature flue gas enters the waste heat boiler through the vertical flue, and the 340°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com