Gas mixture ratio control apparatus and method implementing low-nitrogen combustion by oxygen-deficient CO2-rich gas

A carbon dioxide-rich, low-nitrogen combustion technology, applied in combustion methods, combustion equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of wasting fuel, high nitrogen oxide concentration and temperature, and ineffective utilization of waste heat from boiler exhaust flue gas. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a non-limiting description of the device and method for controlling the gas mixing ratio of oxygen-deficient and carbon dioxide-enriched gas described in the application of the present invention to realize low-nitrogen combustion in conjunction with specific examples.

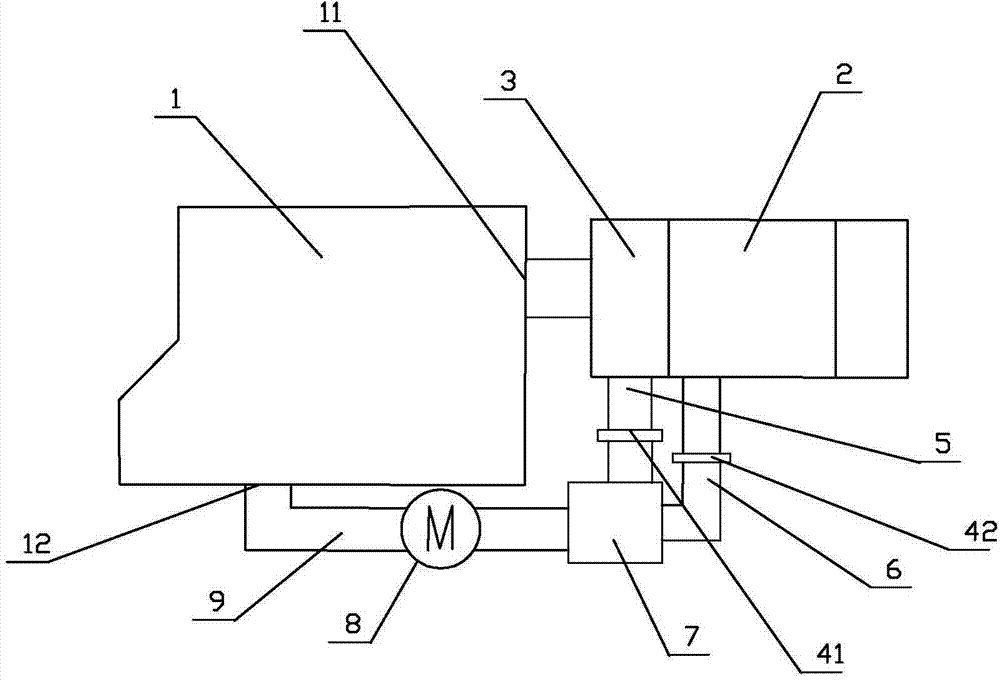

[0020] Such as figure 1 As shown, the equipment for realizing the gas mixing ratio control of low-nitrogen combustion described in the application of the present invention includes an air preheater 2, a mixed gas box 7, a blower 8, a boiler flue gas return pipe 5, a fresh air duct 6 and The air blower duct 9, one end of the flue gas inlet chamber 3 of the air preheater 2 communicates with the flue gas outlet 11 of the boiler 1, and communicates with the mixed gas box 7 through the boiler flue gas return pipe 5, and the air preheater 2 The fresh air outlet of the fresh air is communicated with the mixed gas box 7 through the fresh air duct 6, the mixed gas box 7 is communicated with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com