Sewing material thickness modular detection device and sewing machine

A detection device and a modular technology, which is applied in the field of sewing machines, can solve problems such as detection component jamming, failure, and complex structure, and achieve the effects of easy disassembly, low cost, and large operating vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

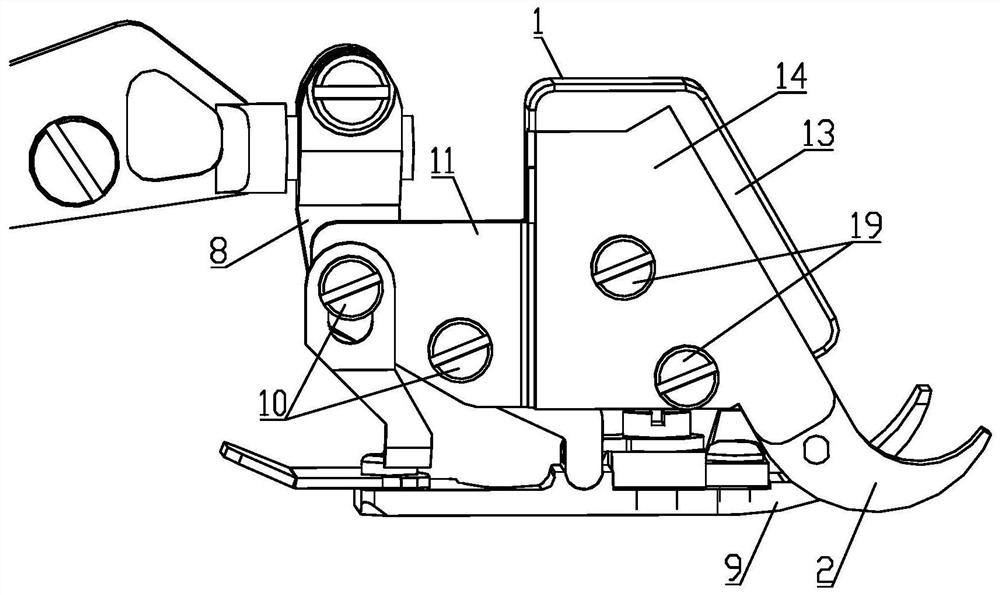

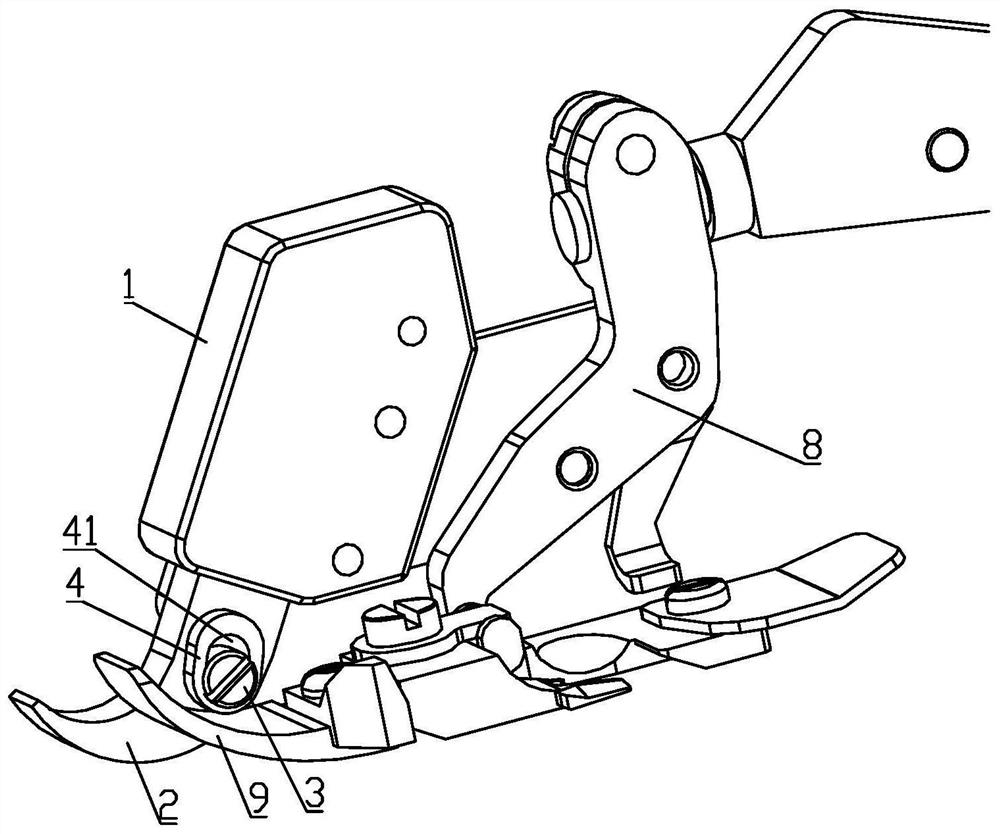

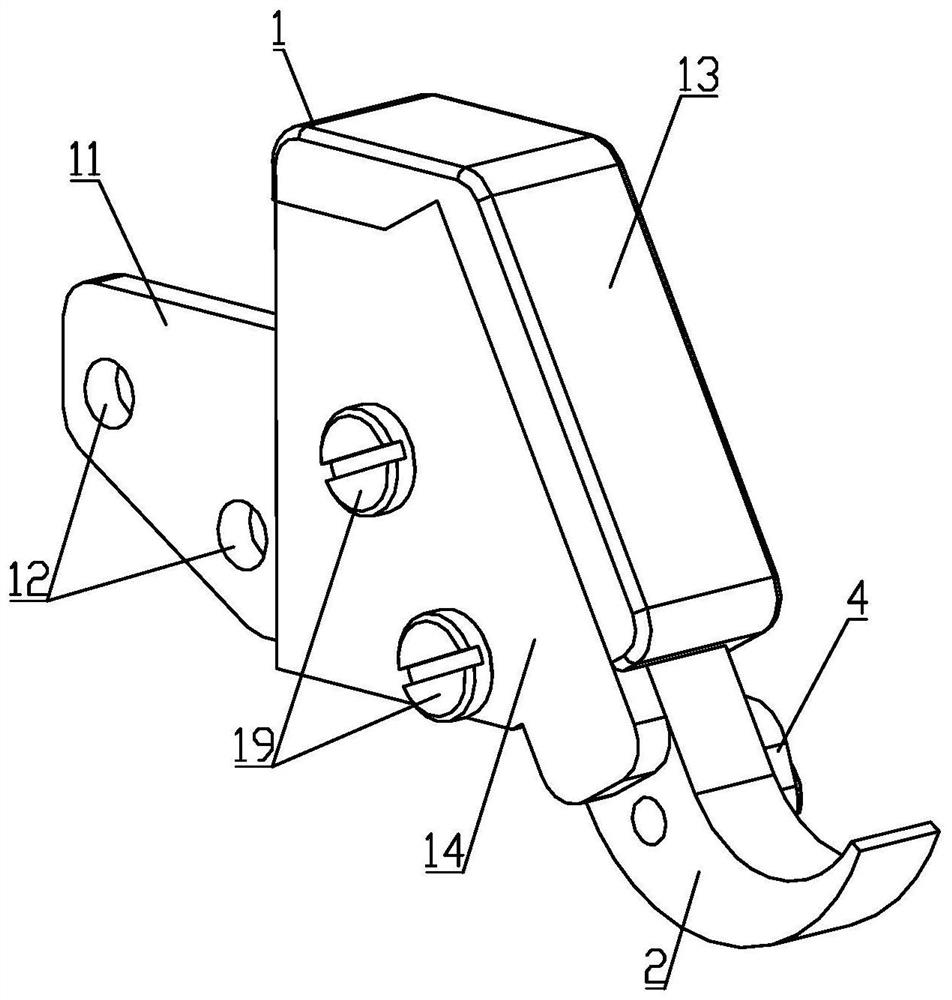

[0053] Such as Figures 1 to 8 As shown, the first embodiment provides the first embodiment of the sewing material thickness modular detection device of the present invention.

[0054]The sewing material thickness modular detection device in the first embodiment includes: a supporting body 1, a movable body 2 and a detection mechanism. The support body 1 and the sewing machine body are separate parts, and the support body 1 has a mounting portion 11, which is used for detachable connection with the sewing machine body, so that the support body 1 can be quickly disassembled on the sewing machine body. A closed accommodating space is formed inside the supporting body 1 . The movable body 2 is movably arranged in the accommodation space of the supporting body 1, and the accommodation space of the supporting body 1 is provided with an opening for the movable body 2 to protrude from, and one end of the movable body 2 extends out of the accommodation space of the supporting body 1 ...

Embodiment 2

[0069] Such as Figures 9 to 11 As shown, the second embodiment provides the second embodiment of the sewing material thickness modular detection device of the present invention.

[0070] Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference lies in that the function of the clamping fit between the stopper 16 and the upper end of the stopper groove 21 is the same as that of the stopper 3 and the presser foot. 9. The abutment of the upper surface plays the same role. Only one of the stopper 16 and the stopper 3 can reach the lowest position to which the movable body 2 can move downwards, so that the detection device can match the sewing machine as a whole. The purpose of lifting and lowering the presser foot 9 of the main body is synchronous action. Therefore, the second embodiment adopts the method that the elastic member 7 elastically presses between the lower end of the limiting groove 21 and the limiting part 16, that ...

Embodiment 3

[0075] Such as Figures 12 to 16 As shown, the third embodiment provides the third embodiment of the sewing material thickness modular detection device of the present invention.

[0076] Embodiment 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that in this embodiment 3, the thickness of the sewing material changes so that the movement mode of the movable body 2 is to swing back and forth, and the movable body 2 can be relatively The supporting body 1 is arranged in the accommodation space to swing back and forth. In this way, the movement of one end of the movable body 2 protruding from the accommodation space of the supporting body 1 at the opening of the accommodation space for the movable body 2 to protrude is to swing back and forth at the opening, so refer to Figure 12 , Figure 13 with Figure 16 , the opening should consider the swing range of the movable body 2, and expand the opening range appropriately along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com