Booms for large tonnage forklifts/loaders

A technology for loaders and tonnage forks, which is applied in the field of composite booms, can solve the problems that the support beams are easy to block the line of sight, it is difficult to meet the load demand, and the workload of production calibration is large, so as to improve work efficiency and work safety and reduce calibration. The effect of reducing the workload and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described below with reference to the drawings.

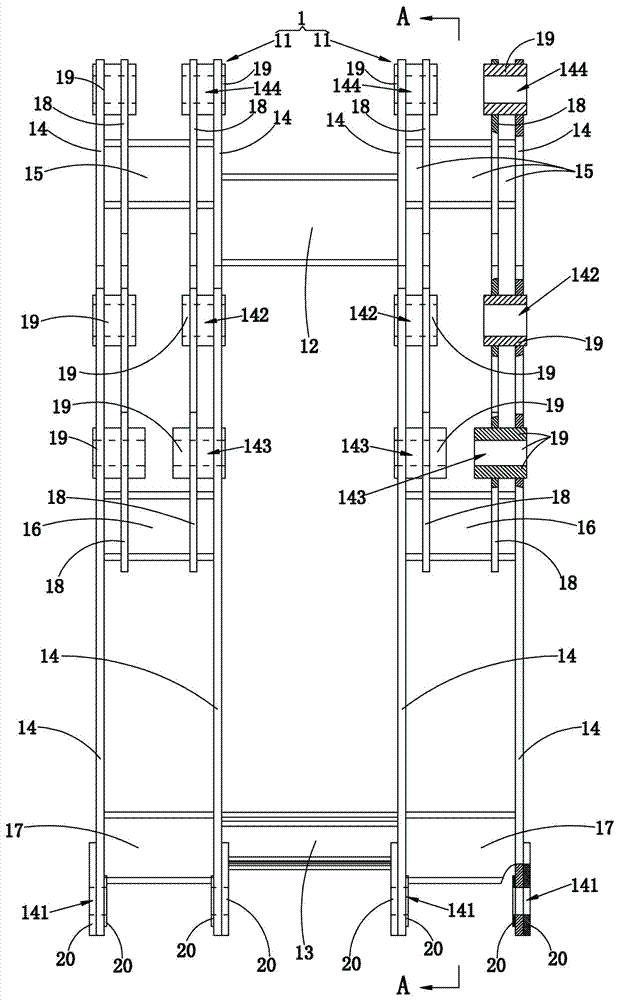

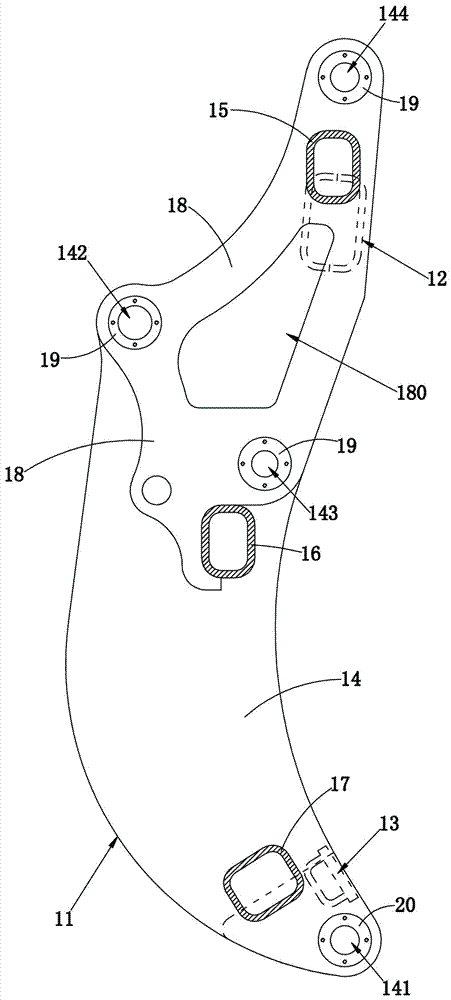

[0019] Reference figure 1 , figure 2 , The boom of a large-tonnage forklift / loader includes a boom body 1, which is composed of two boom units 11, which are connected as a whole through a front cross beam 12 and a rear cross beam 13 , The front cross beam 12 and the rear cross beam 13 are arranged at the two ends of the boom unit 11, and the positions of the front cross beam 12 and the rear cross beam 13 can be flexibly adjusted as needed to reduce the impact on the line of sight. The boom unit 11 is formed by integrally connecting two boom plates 14 through a connecting beam. The boom plates 14 of the same boom unit 11 are connected by a front beam 15, a middle beam 16 and a rear beam 17 into one body. All boom plates 14 are provided with frame connection holes 141, rocker arm connection holes 142, cylinder connection holes 143, and attachment connection holes 144...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com