Patents

Literature

83results about How to "Sufficient operating space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

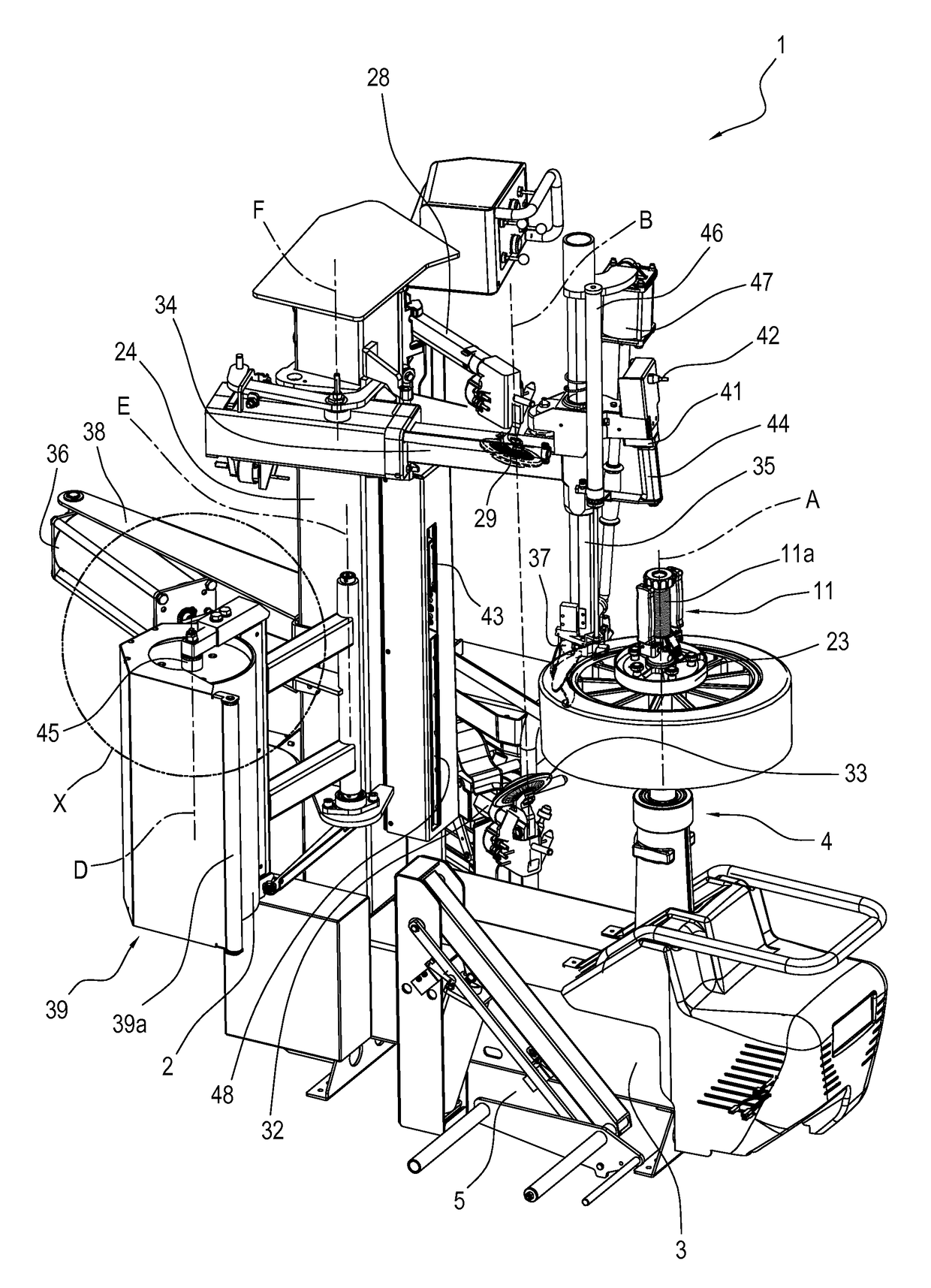

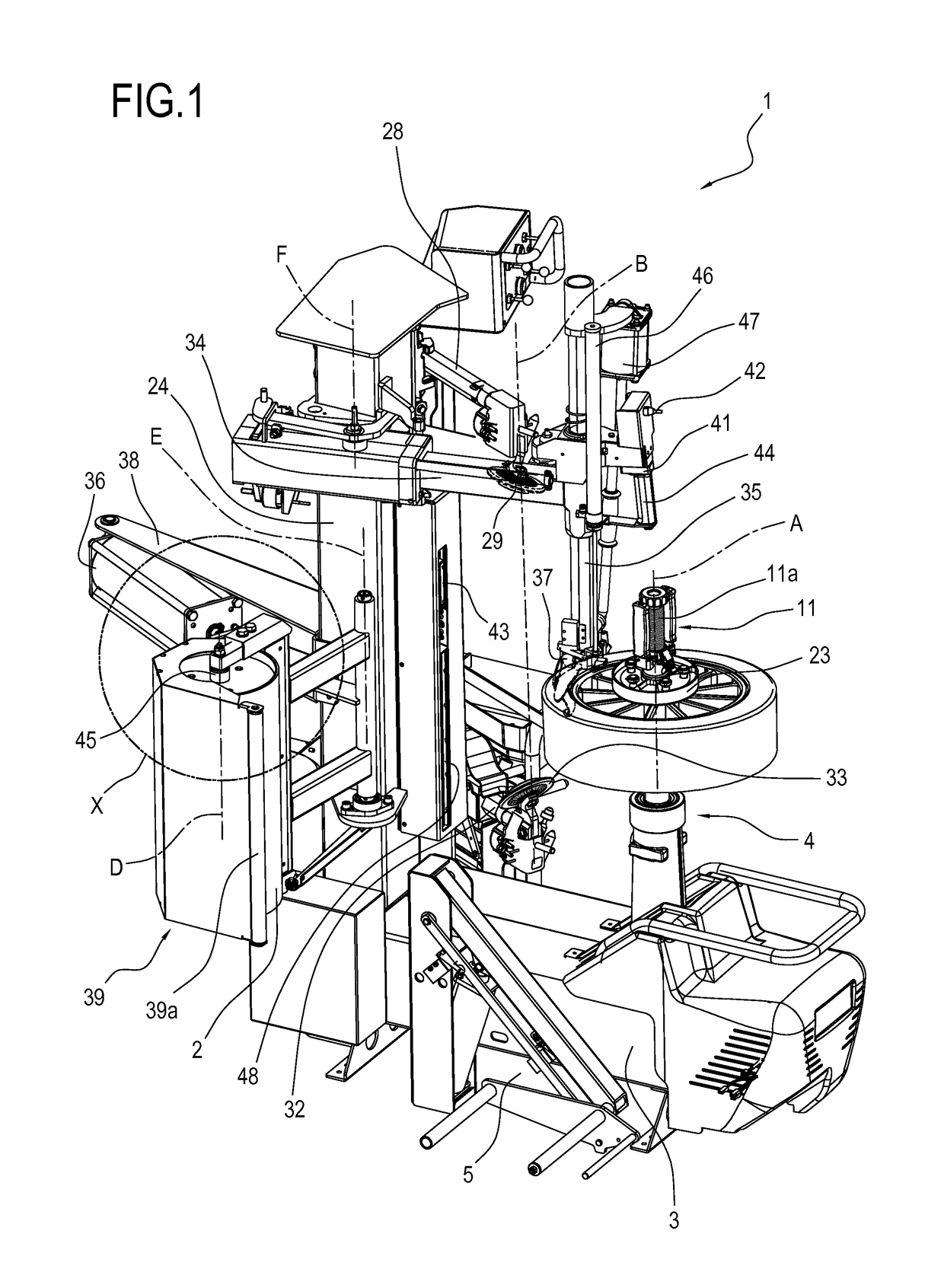

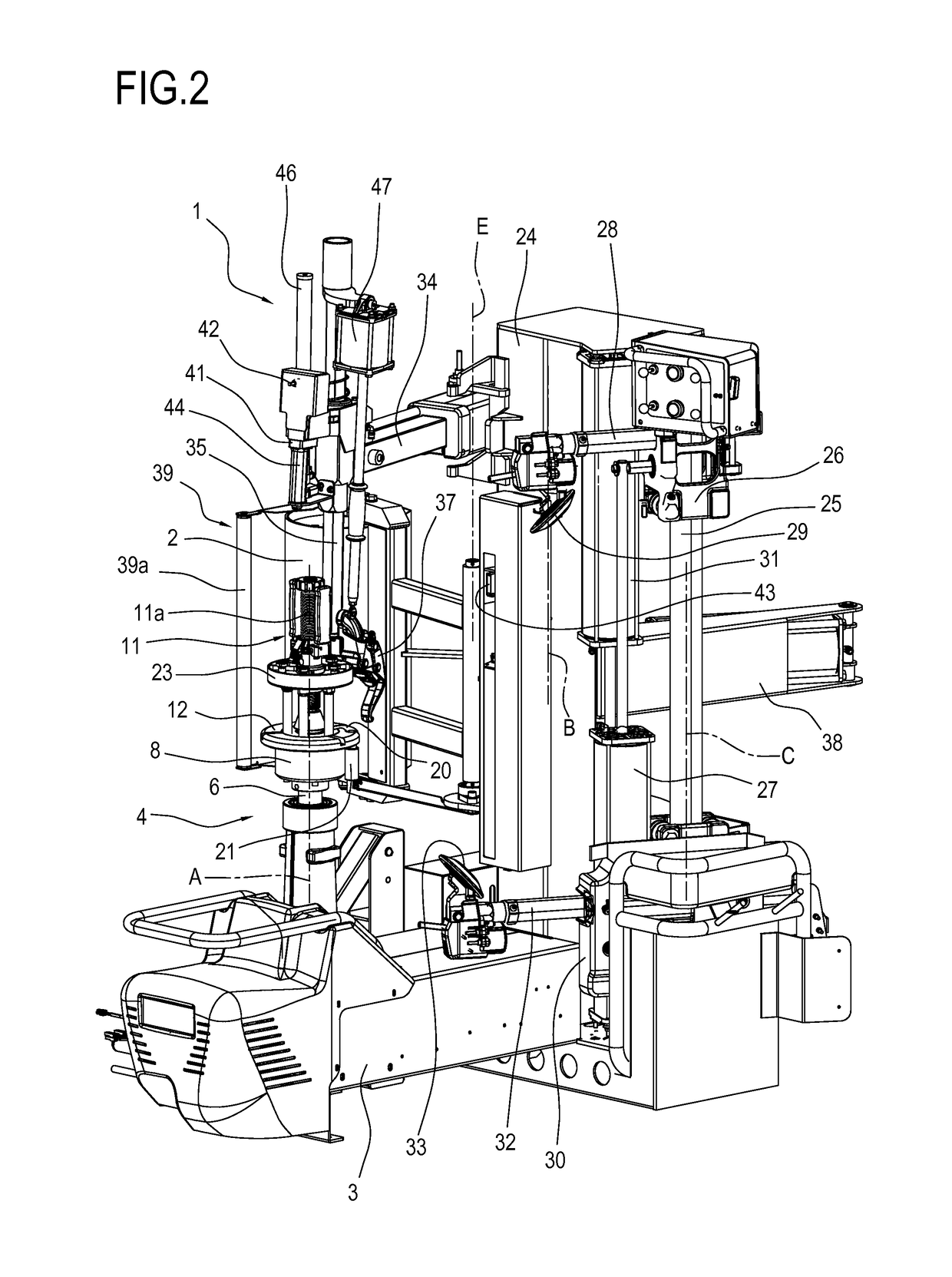

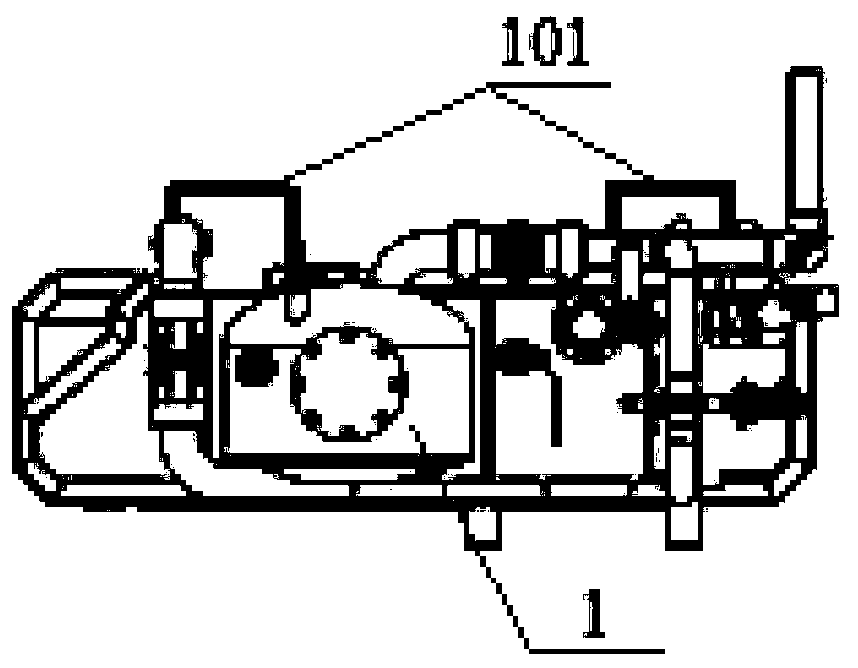

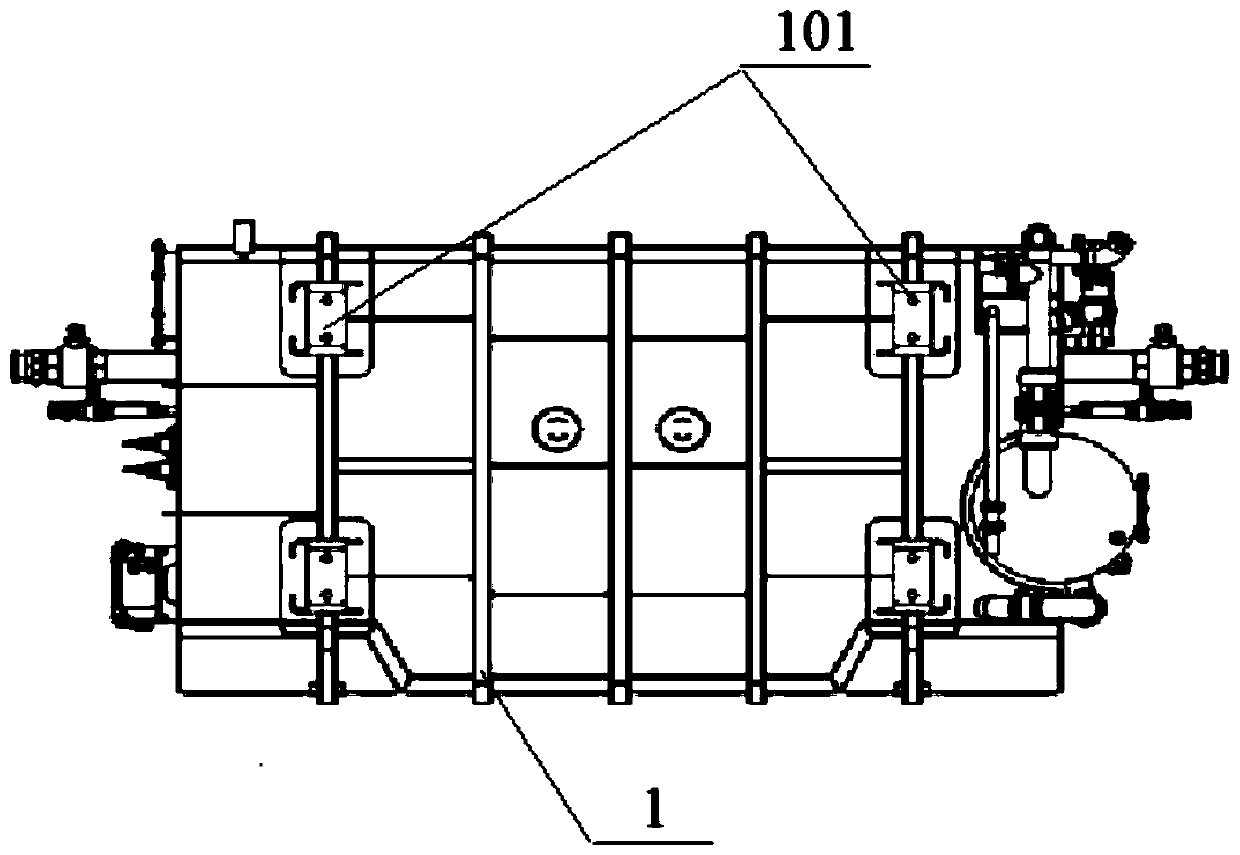

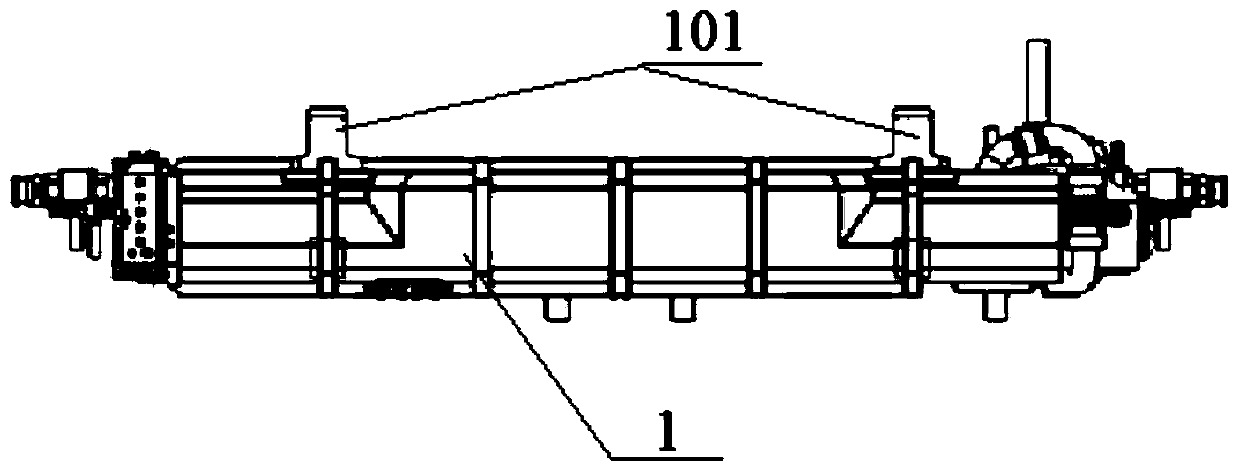

Machine for fitting and removing a tyre and method for operating the machine

ActiveUS10000101B2Sufficient operating spaceWay fastStatic/dynamic balance measurementVehicle tyre testingEngineeringScroll wheel

Described is a machine (1) for fitting and removing a tire from a corresponding wheel rim of a vehicle, comprising: a wheel-holder unit (4), which rotates about a first axis (A); at least one bead breaker tool (29), movable along a second axis (B) parallel to the first axis (A); a roller (2) rotating about a fourth axis (D) parallel to the first axis (A) and configured to move by rotation about a fifth axis (E) spaced from the fourth axis (D), between an active position where it is in contact with a tire tread of the wheel mounted on the wheel-holder unit (4), to a position of non-interference relative to the tire; at least one sensor (40) connected to the roller (2) for detecting a signal representing a force transmitted to the roller (2) by the tire; a removal tool (37), which is movable by rotation about a sixth axis (F) parallel to the first axis (A) and spaced from it, between a first position proximal to the first axis (A) and a second position distal from the first axis (A), which is movable in a direction parallel to the first axis (A) and movable towards and away from the sixth axis (F).

Owner:NEXION SPA

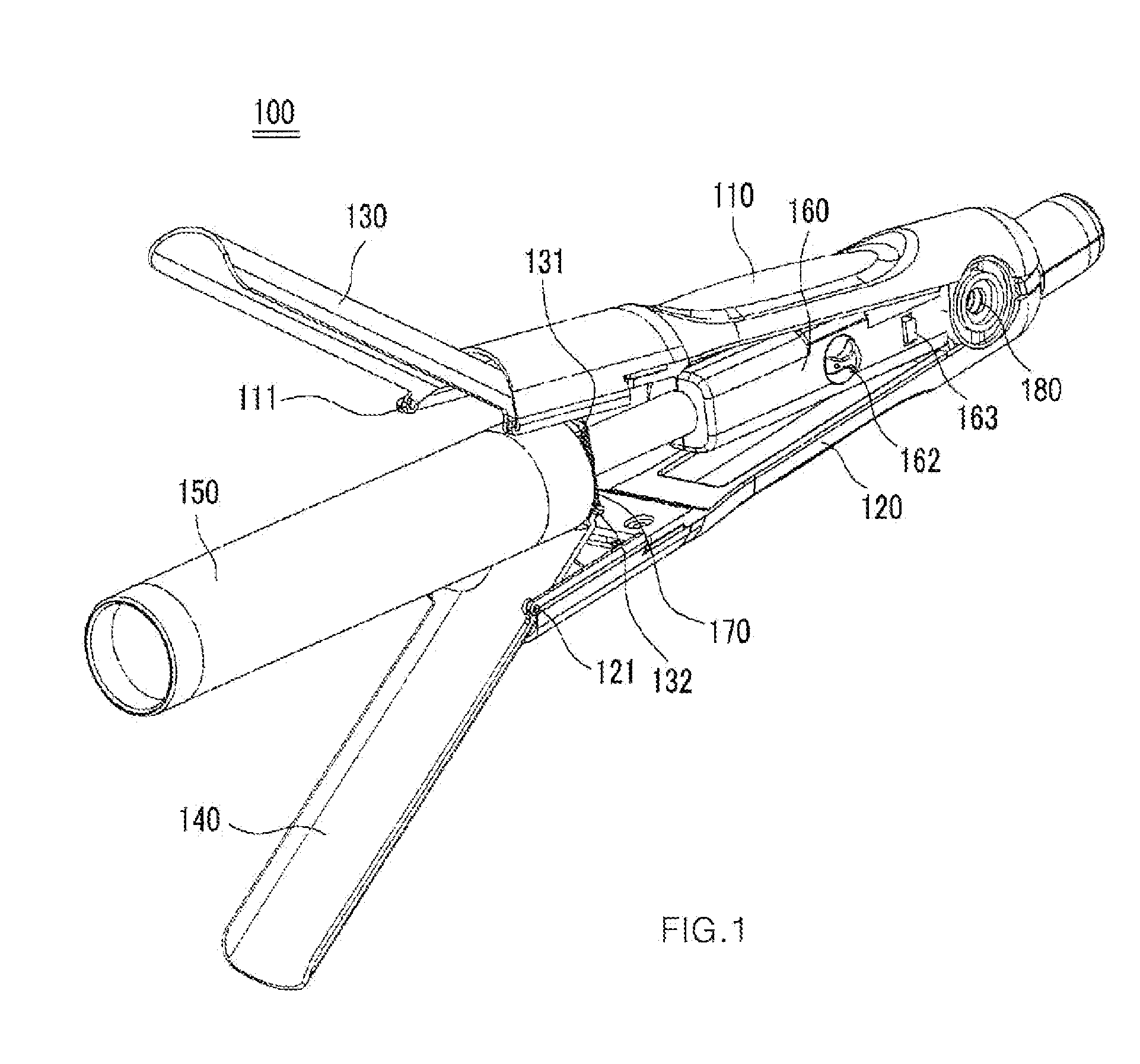

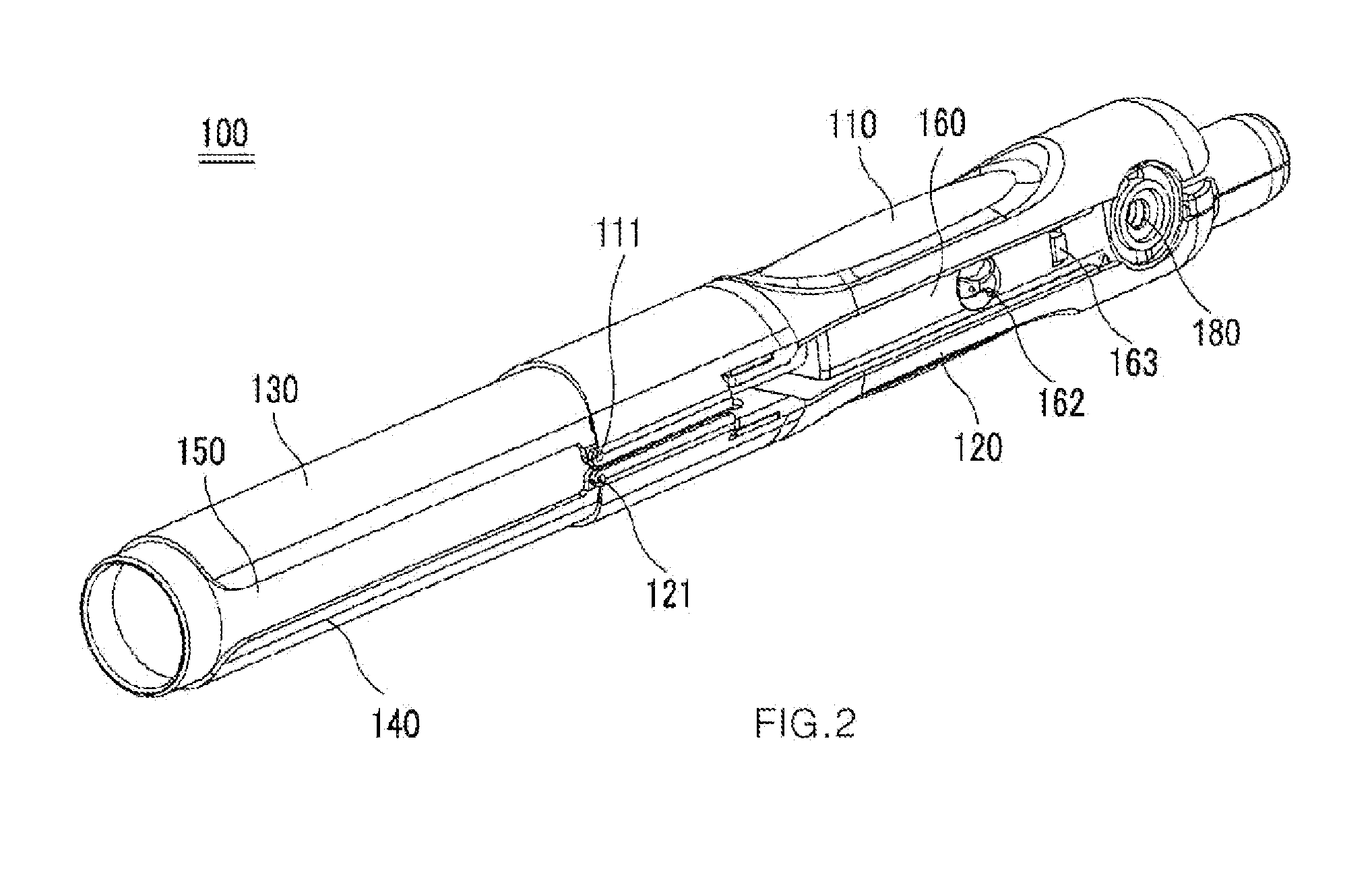

Electric curling iron

InactiveUS20120138081A1Shorten the time periodPrevent diseaseCurling-ironsCurling-tongsEngineeringMechanical engineering

Disclosed therein is an electric curling iron. The electric curling iron includes: a body part; a heating rod arranged at a side of the body part and having a heat ray heater disposed therein; an upper handle and a lower handle hinge-coupled on a hinge shaft formed at the other side of the body part, the upper and lower handles being movable in a tong shape; and an upper pressing member and a lower pressing member whose end portions are respectively overlapped and hinge-coupled to front ends of the inner faces of the upper and lower handles, the upper and lower pressing members respectively having a shape corresponding to the outer circumferential surface of the heating rod, wherein the upper and lower pressing members are opened wider than the upper and lower handles, so that a user can rapidly and convenient do hair styling.

Owner:LEE SUNG JUN

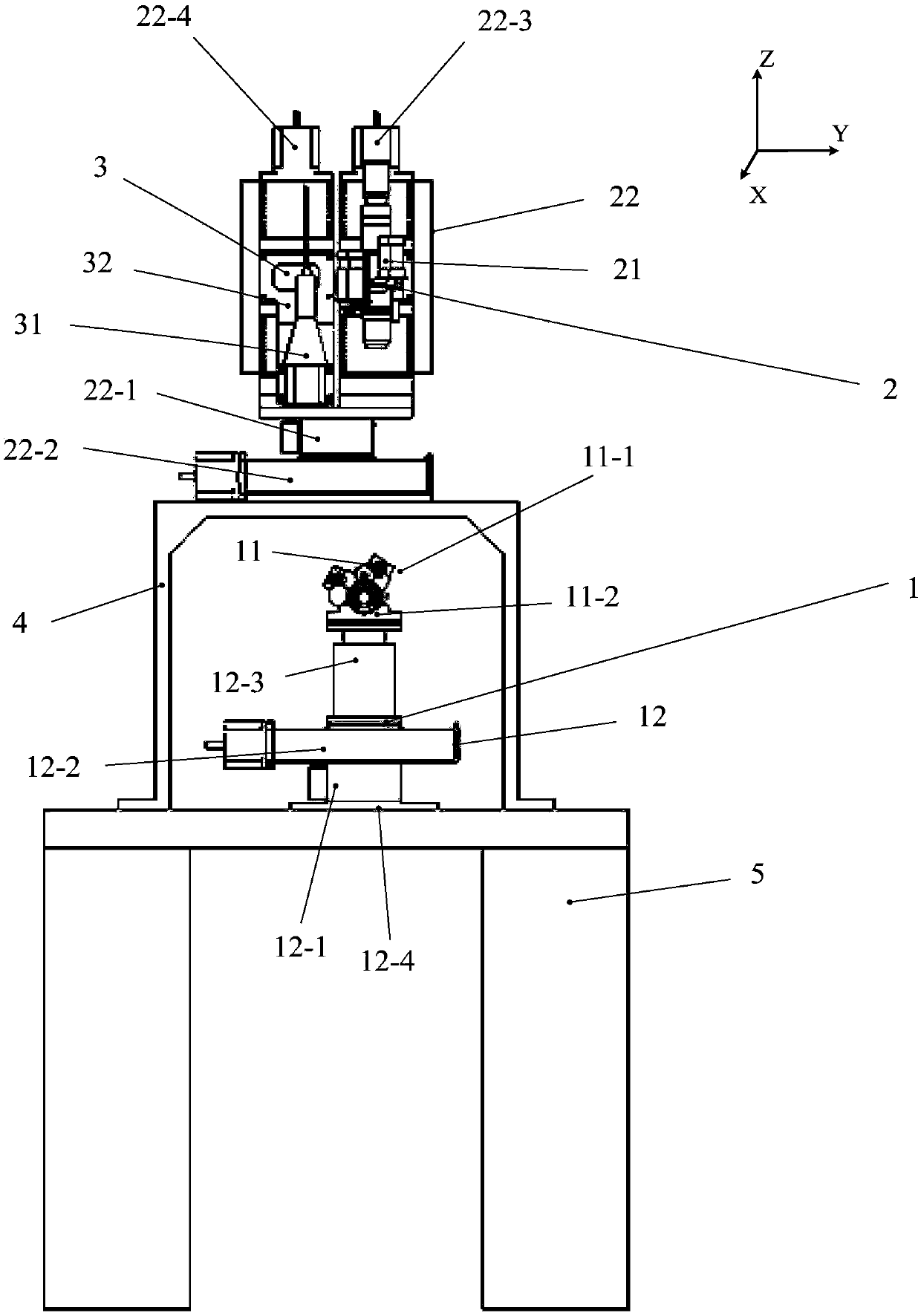

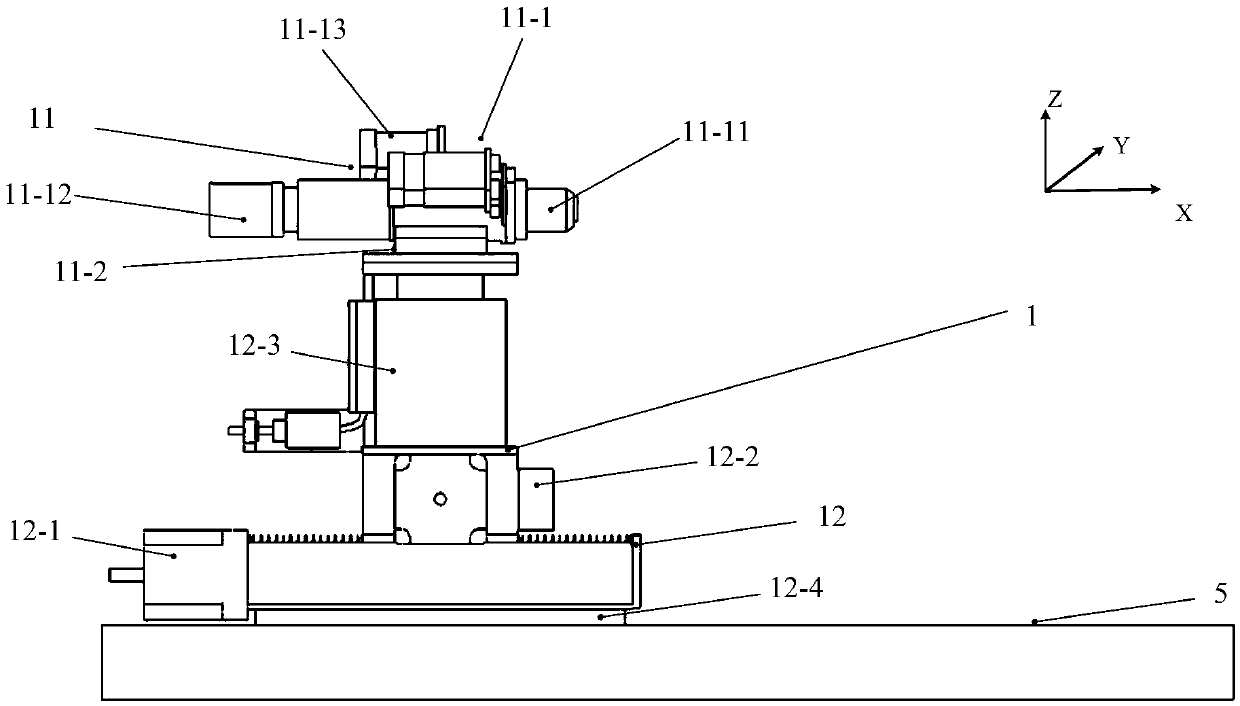

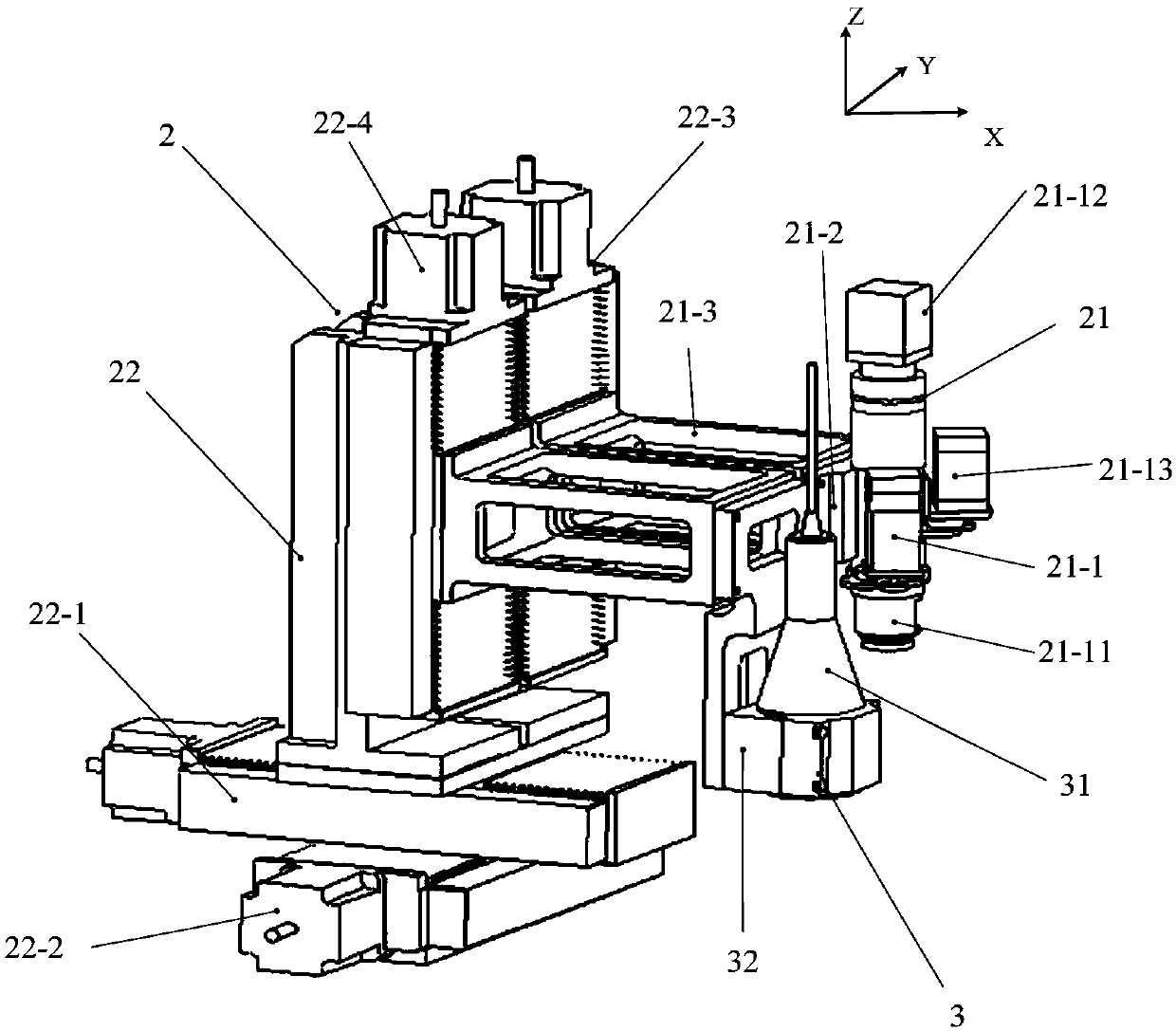

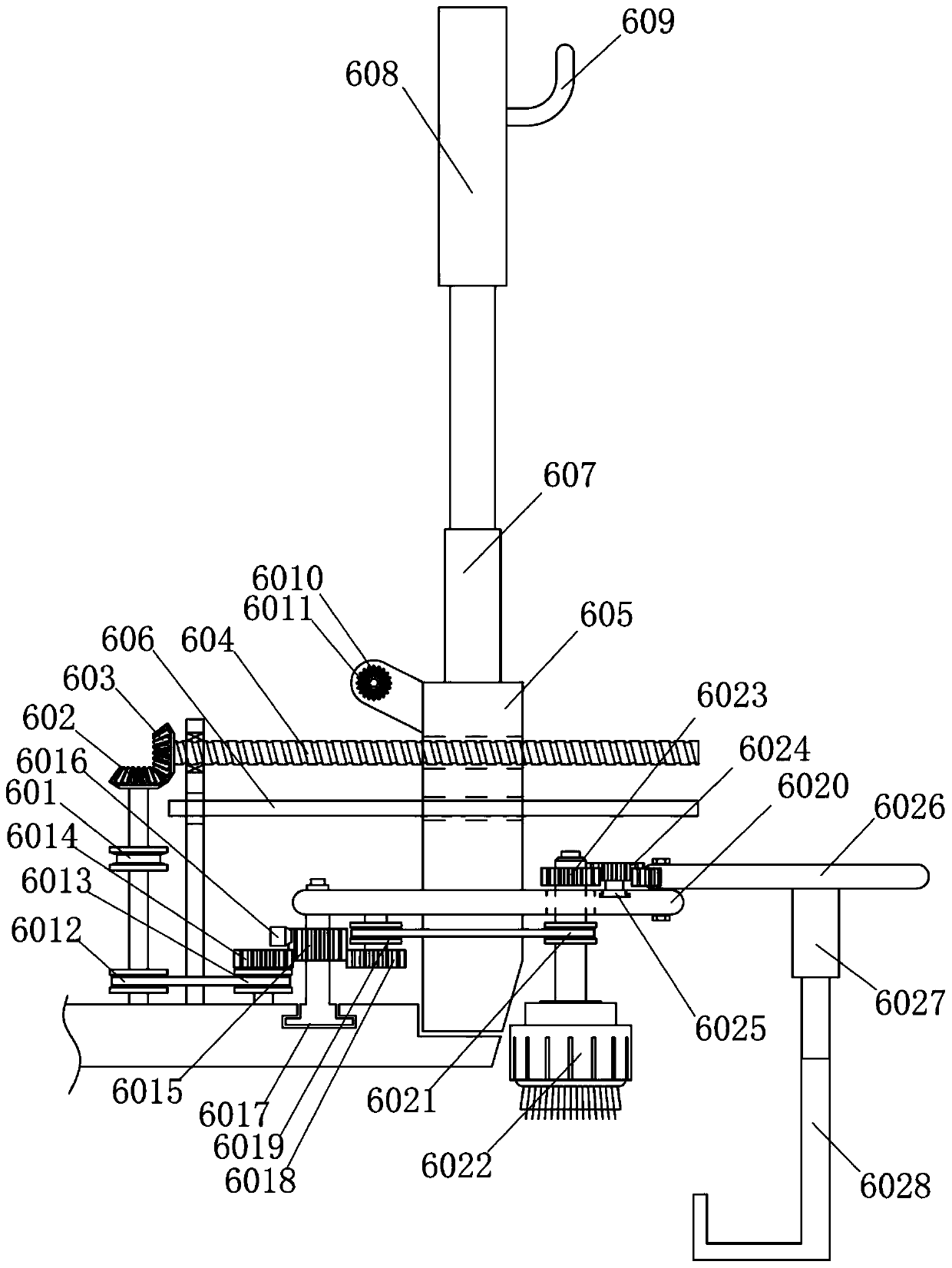

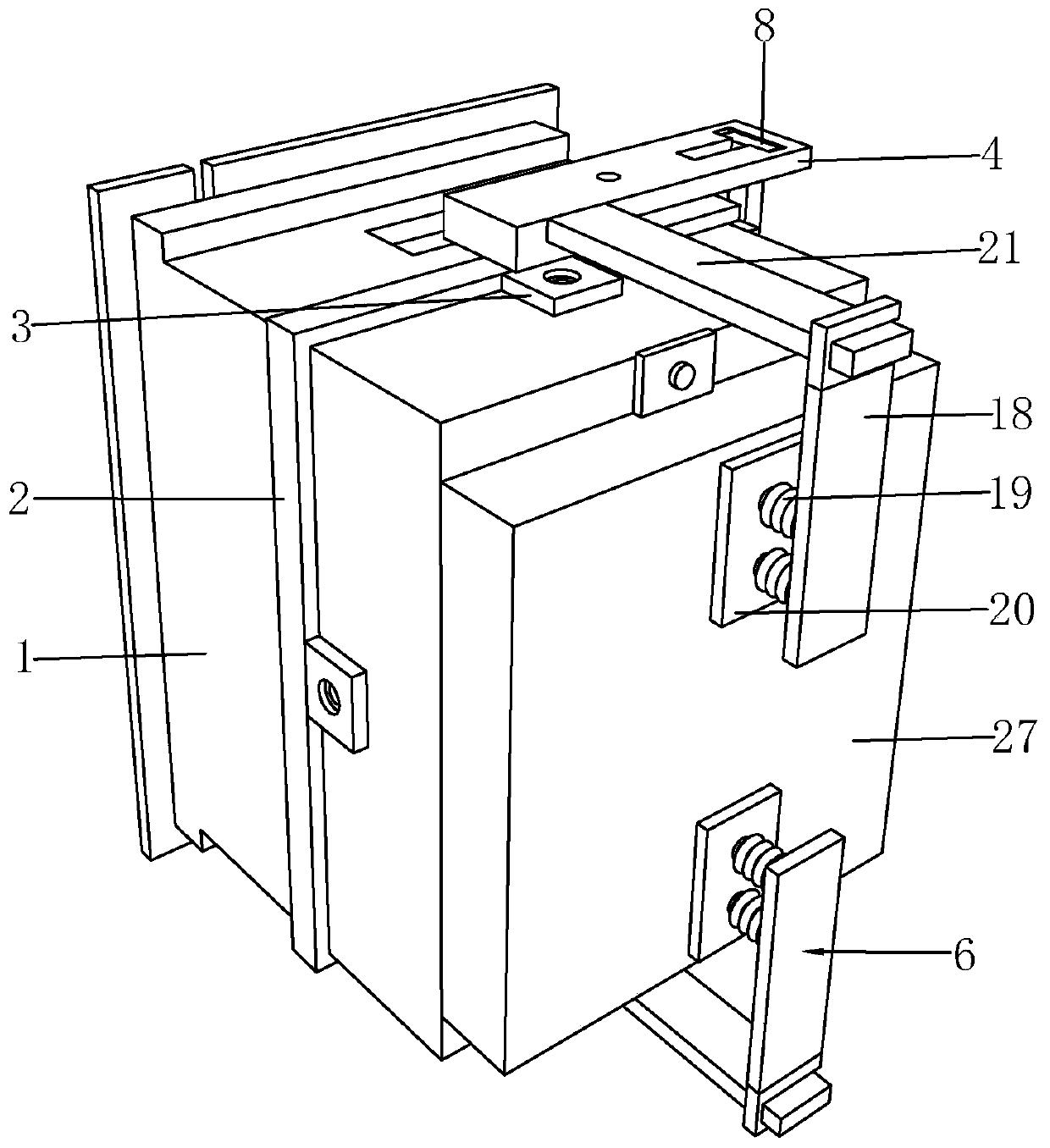

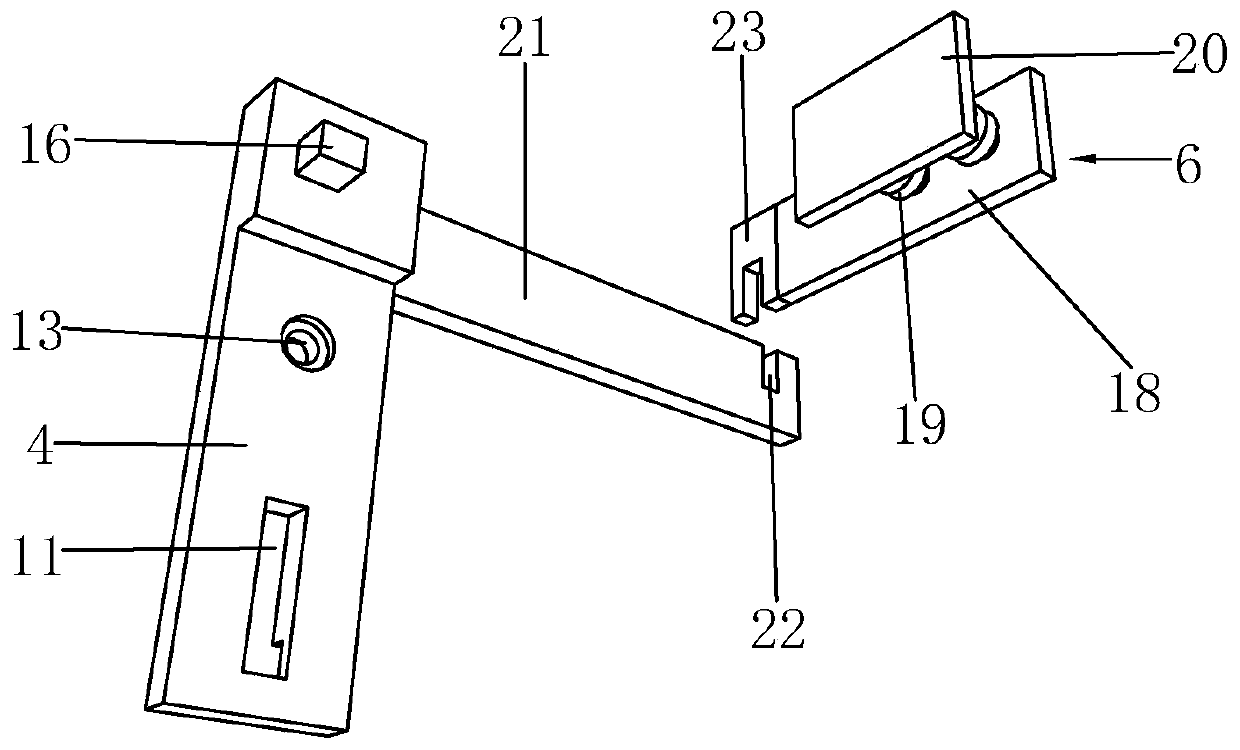

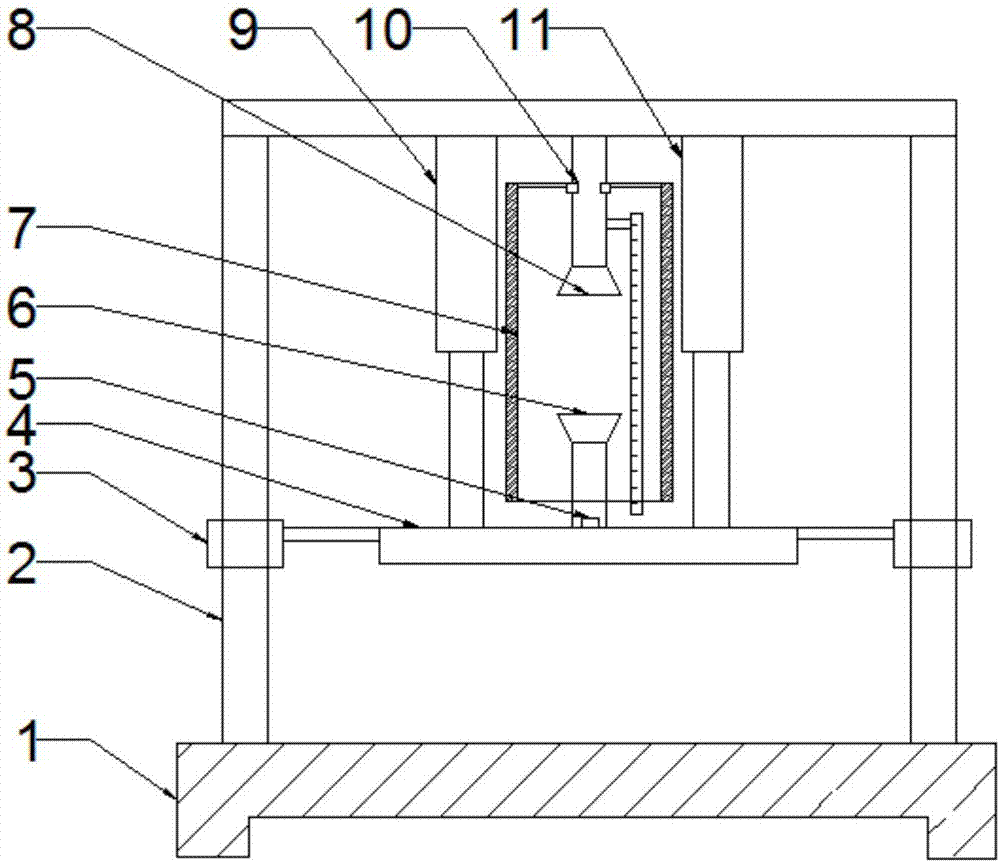

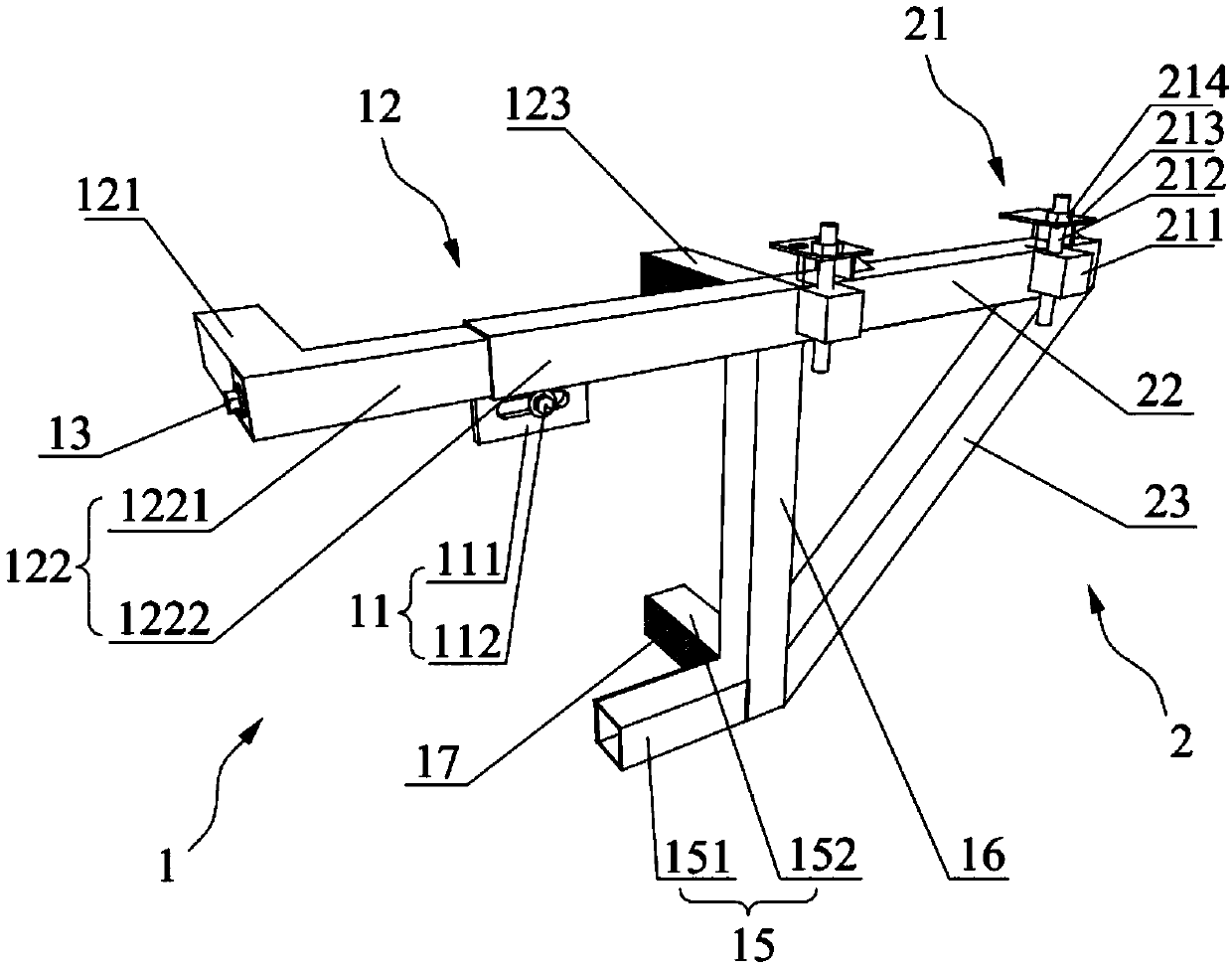

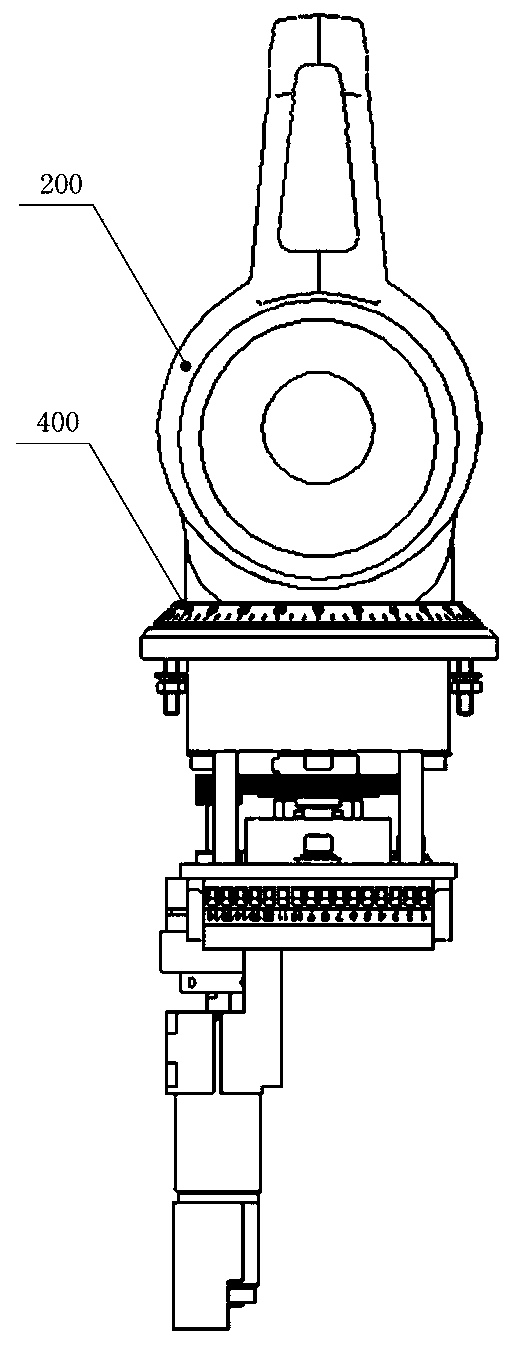

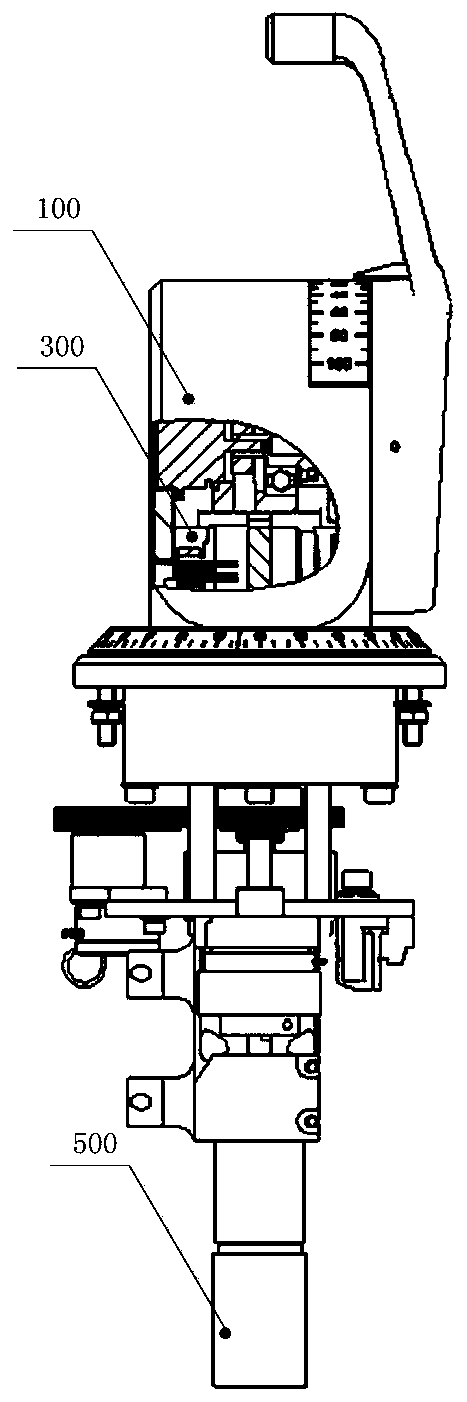

Online detection system applied to automatic assembly of complex multi-configuration micro-parts

PendingCN109539989AImprove stabilityImprove assembly efficiencyUsing optical meansComputer visionPortal frame

The invention provides an online detection system applied to automatic assembly of complex multi-configuration micro-parts, and relates to the technical field of micro-part detection. The system comprises a micro-assembly horizontal visual detection module, a micro-assembly vertical visual detection module, a micro-assembly vertical photoelectric detection module, a heavy-load portal frame and anequipment workbench, wherein the micro-assembly horizontal visual detection module comprises a horizontal visual optical assembly and a horizontal visual motion assembly; the horizontal visual opticalassembly is installed on the horizontal visual motion assembly and used for detecting a first direction; the micro-assembly vertical visual detection module comprises a vertical visual optical assembly and a vertical visual motion assembly; the vertical visual optical assembly is installed on the vertical visual motion assembly and used for detecting a second direction; and the micro-assembly vertical photoelectric detection module is installed on the vertical visual motion assembly. The system is compact in structure and high in space utilization rate; and real-time detection can be carriedout from multiple directions and multiple angles, thereby improving the assembly efficiency and the assembly precision of the micro-parts.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

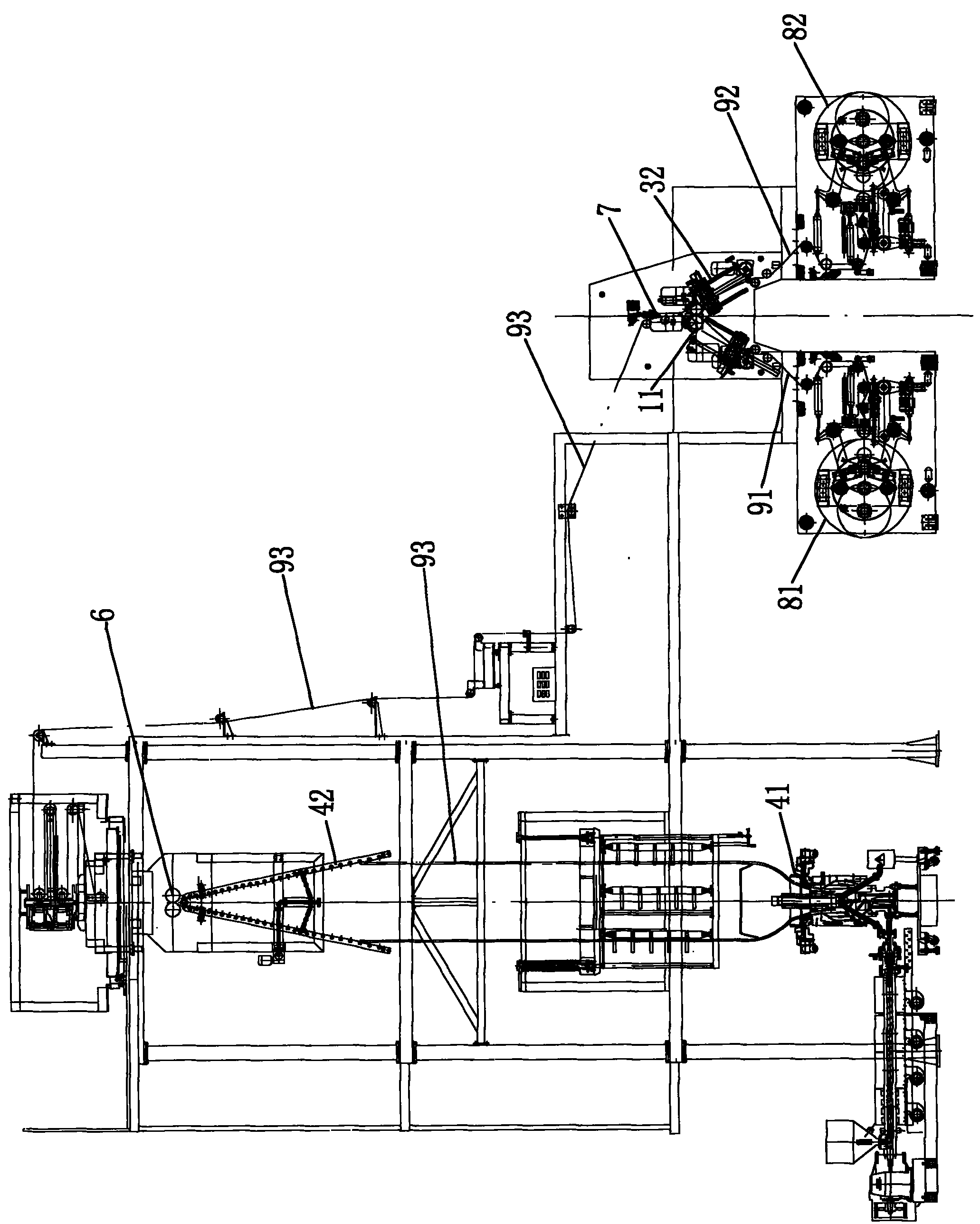

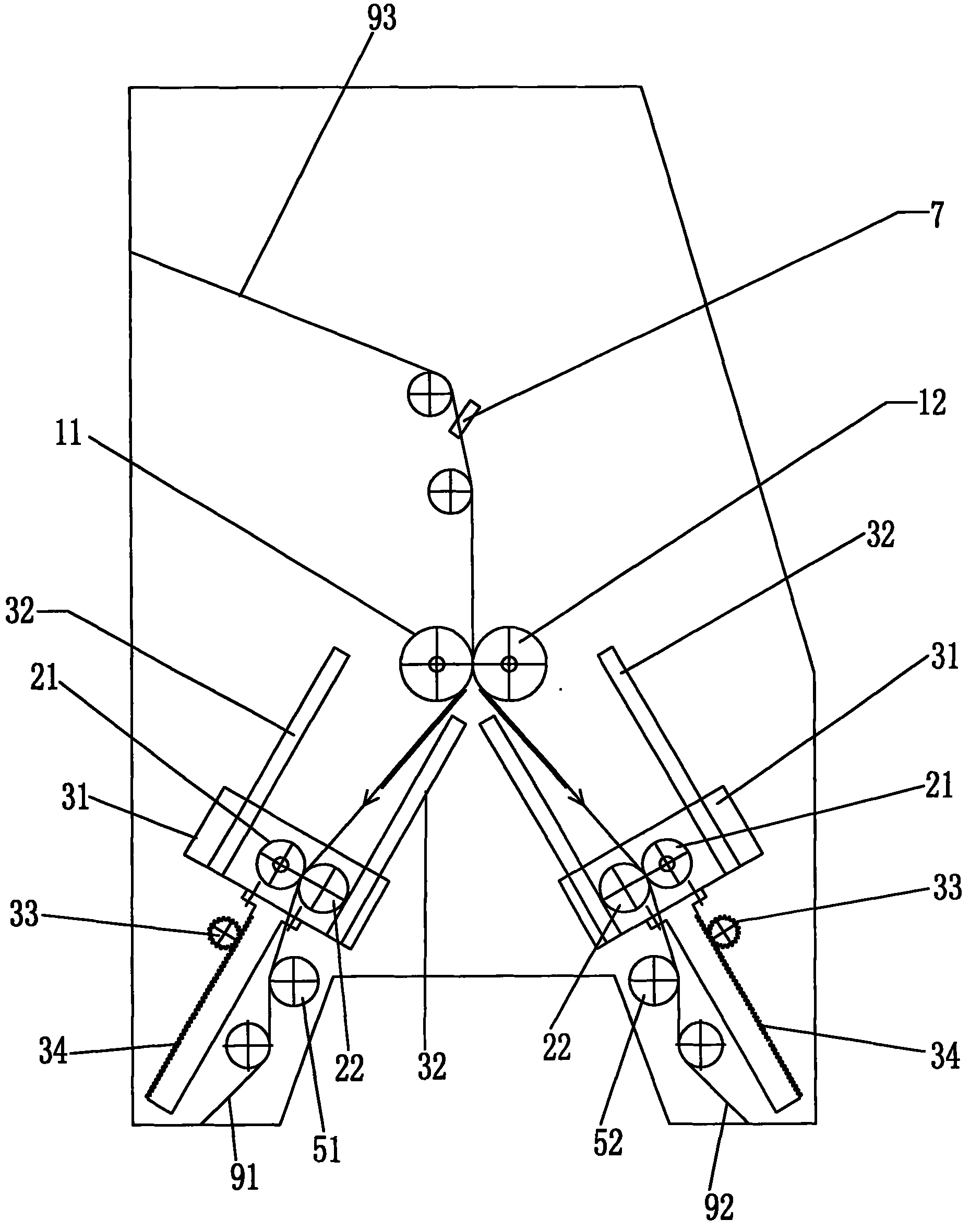

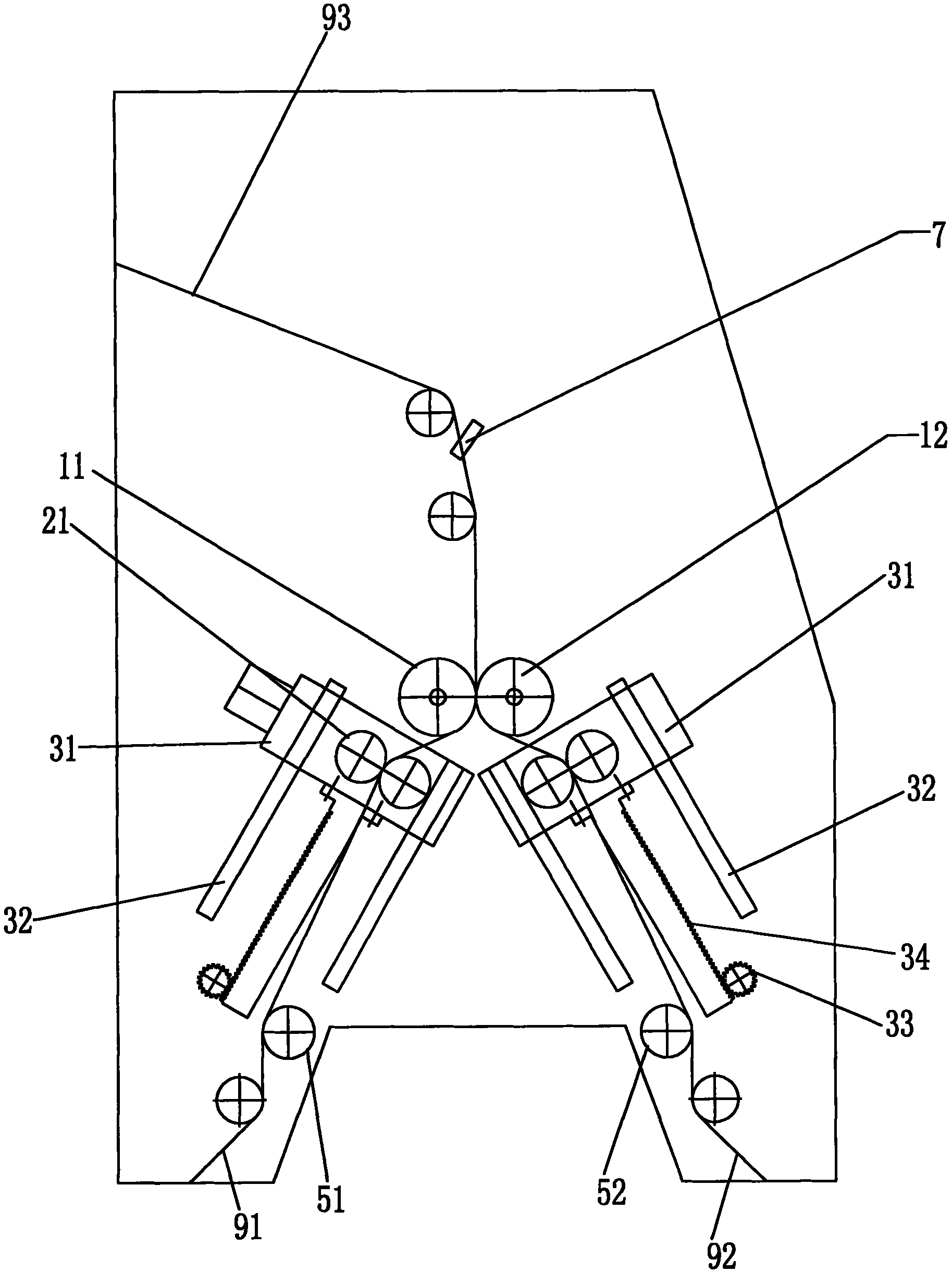

Self-adhesion membrane blowing production equipment and production method

The invention provides self-adhesion membrane blowing production equipment. The equipment comprises a nose, a herringbone splint, membrane tube traction pinch rolls, a sectioning cutter, a left set of membrane coiling mechanism and a right set of membrane coiling mechanism, wherein the herringbone splint is positioned above the nose; a membrane tube traction pinch roll is positioned above the herringbone splint; the left set of membrane coiling mechanism and the right set of membrane coiling mechanism are positioned under the sectioning cutter; and a pair of membrane traction pinch rolls are arranged under the sectioning cutter, two pairs of opening pinch rollers are bilaterally and symmetrically arranged under the membrane traction pinch rolls, the left opening pinch rollers are positioned above the left membrane coiling mechanism, and the right opening pinch rollers are positioned above the right membrane coiling mechanism. The production equipment can smoothly coil the self-adhesion membrane, protects the self-adhesion membrane against wrinkle and fluctuation due to adhesion to the surfaces of a foam stabilizing device, the herringbone splint and the membrane tube traction pinch rolls, and ensures enough adhesion of the self-adhesion membrane finished product. The invention also provides a self-adhesion membrane blowing production method.

Owner:GUANGDONG JINMING MACHINERY

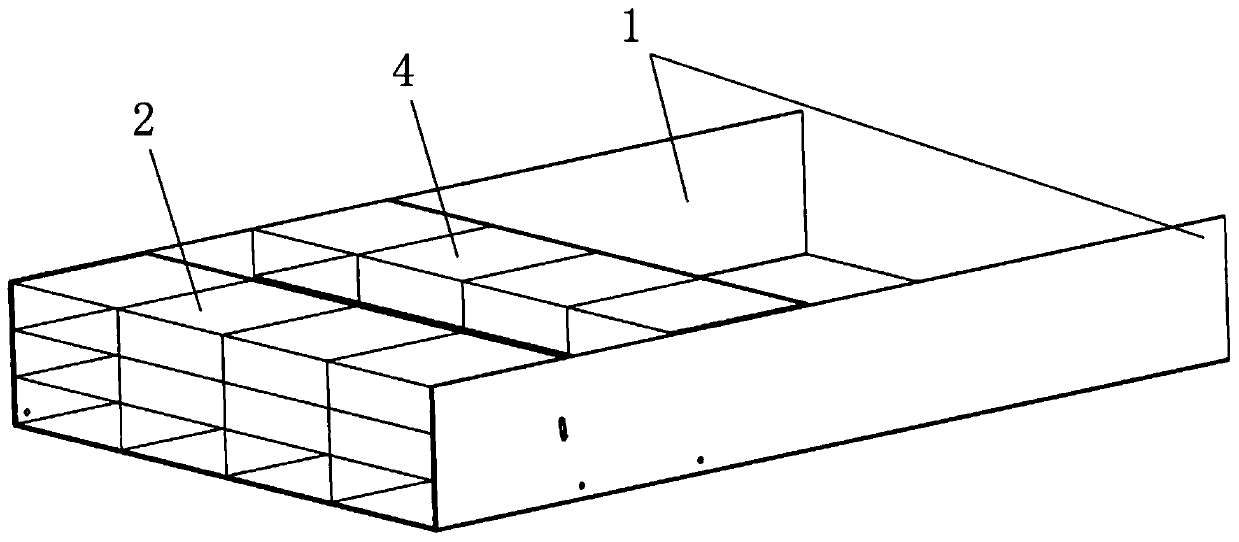

Planting method for cane shoots

InactiveCN107125011AGuaranteed normal growthSufficient operating spaceCultivating equipmentsHorticultureShootNormal growth

The invention discloses a planting method for cane shoots. The method comprises the following steps: (a) selecting a cane shoot field and a cane shoot variety; (b) fertilizing the cane shoot field and breeding seed plants; (c) transplanting the seedlings; (d) erecting a positioning frame in the cane shoot field; (e) erecting a support frame in the cane shoot field; (f) putting in planting pots; (g) digging planting holes; (h) moving the planting pots into the planting holes; and (i) managing the field. According to the invention, seedlings are planted into the planting pots, and the planting pots are lifted away from the cane shoot field for a certain altitude; the distance between two adjacent planting pots is adjusted according the size of the seedlings, and then the positions of the planting pots are fixed; the planting holes are formed in the corresponding positions of the cane shoot field according to the placement positions of the planting pots; the seedling planting space is adjusted according to the size of the seedlings; the planting space of the cane shoot field is fully utilized; the normal growth of the seedlings is guaranteed; and in the transplanting process, a plurality of planting pots are simultaneously planted into the corresponding planting holes, so that the labor is saved, the transplanting time is shortened and the survival rate of the seedlings is increased.

Owner:湖州桑农生态农业有限公司

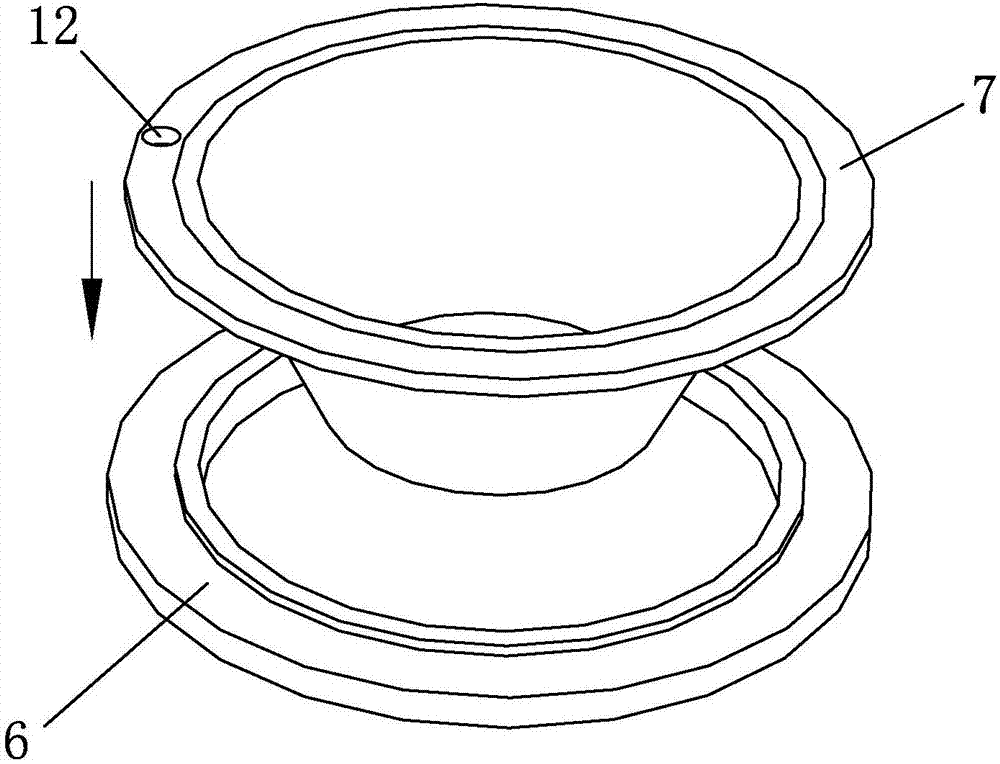

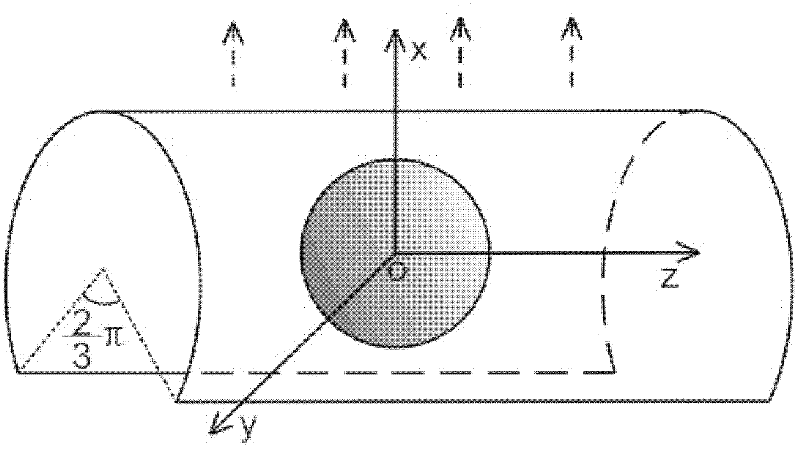

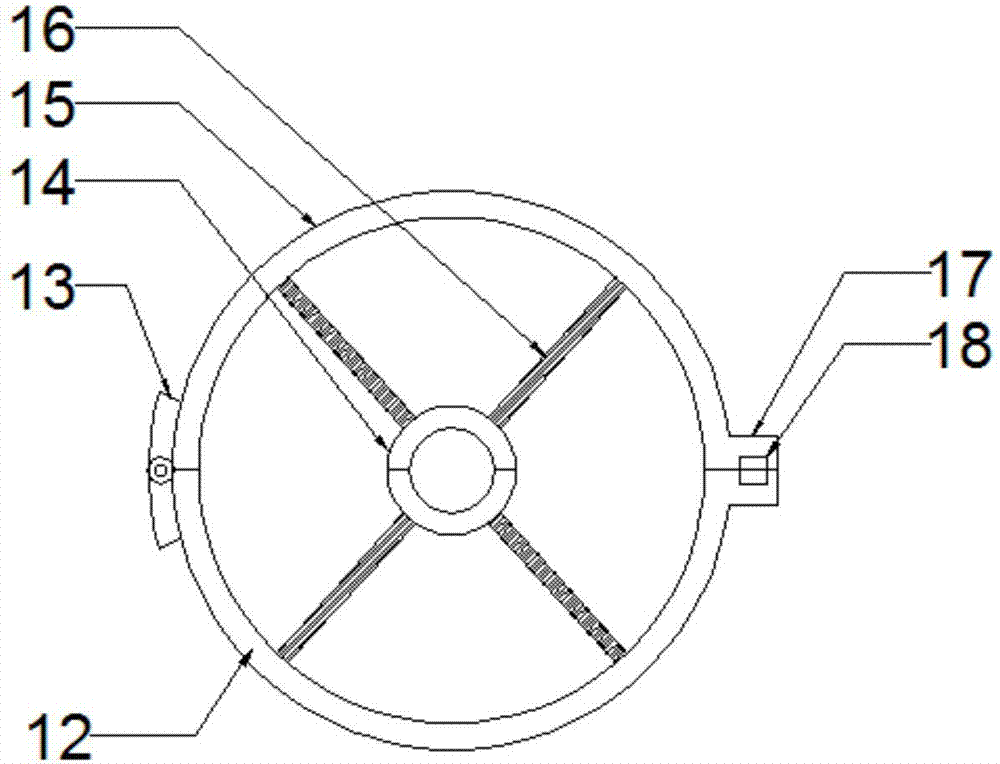

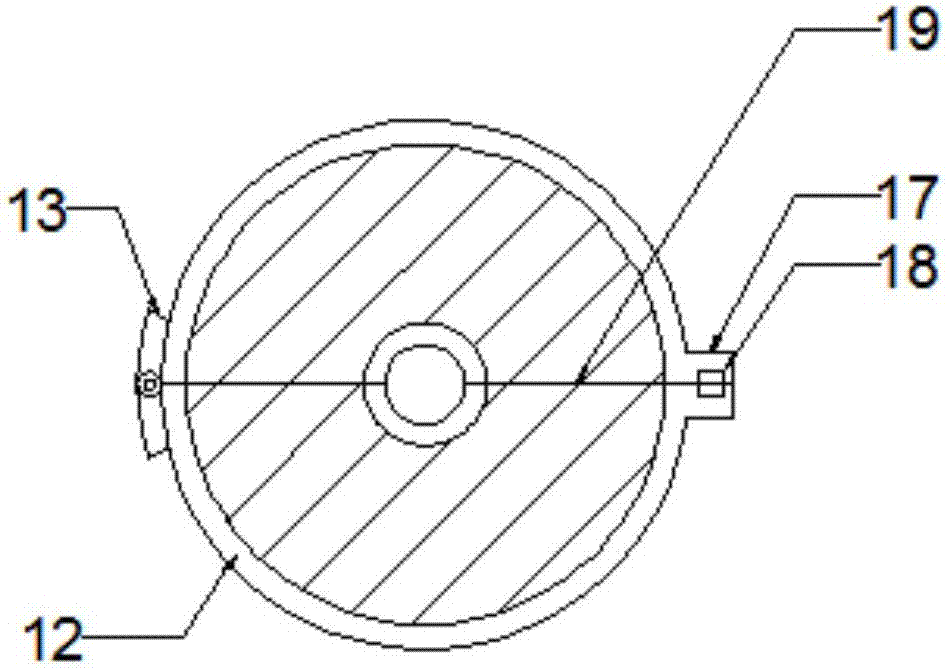

Radio frequency coil for guiding ultrasonic focusing system and design method thereof

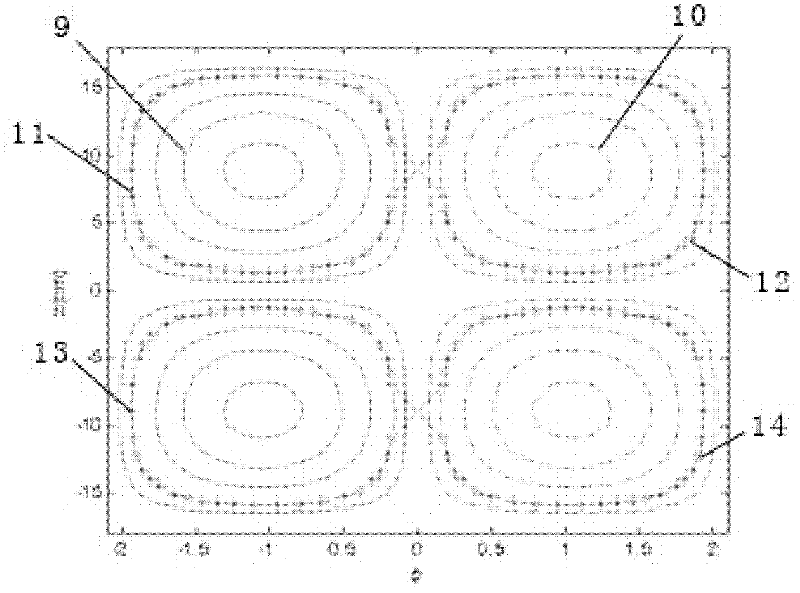

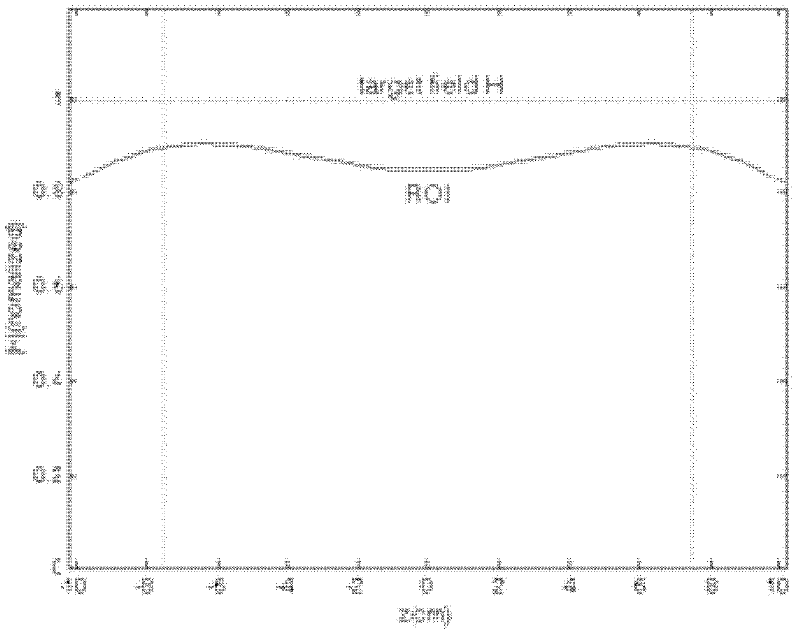

InactiveCN102565730AReal-time non-invasive monitoring of temperatureSufficient operating spaceUltrasound therapyDiagnostic recording/measuringSurgical operationResonance

The invention provides a radio frequency coil for guiding an ultrasonic focusing system and a design method thereof, and belongs to the technical field of magnetic resonance imaging. A coil support housing used by the radio frequency coil is of a cylindrical surface; furthermore, the cylindrical surface is radially provided with an arc-surface gap alpha; a coil loop is arranged on the support housing and comprises two groups of 8-shaped loops and a group of annular compensation loop; the two groups of the 8-shaped loops are arranged in parallel along the axial direction of a cylinder, and two rings in the same 8-shaped loop are arranged along the circumferential direction of the cylinder; the annular compensation loop is arranged in the middle of the two groups of the 8-shaped loops; insulating pads are arranged at the intersected parts of the 8-shaped loops; the two groups of the 8-shaped loops are connected in parallel to form a channel; and the annular compensation coil constitutes the channel alone and is connected with an output circuit board for sending out signals. The radio frequency coil device can enable a low-field magnetic resonance device to be matched with the ultrasonic focusing system for use, provide a sufficient surgical operation space for a doctor and realize real-time non-invasive monitoring of temperature of tissues of a human body during a thermal ablation operation.

Owner:SOUTHERN MEDICAL UNIVERSITY

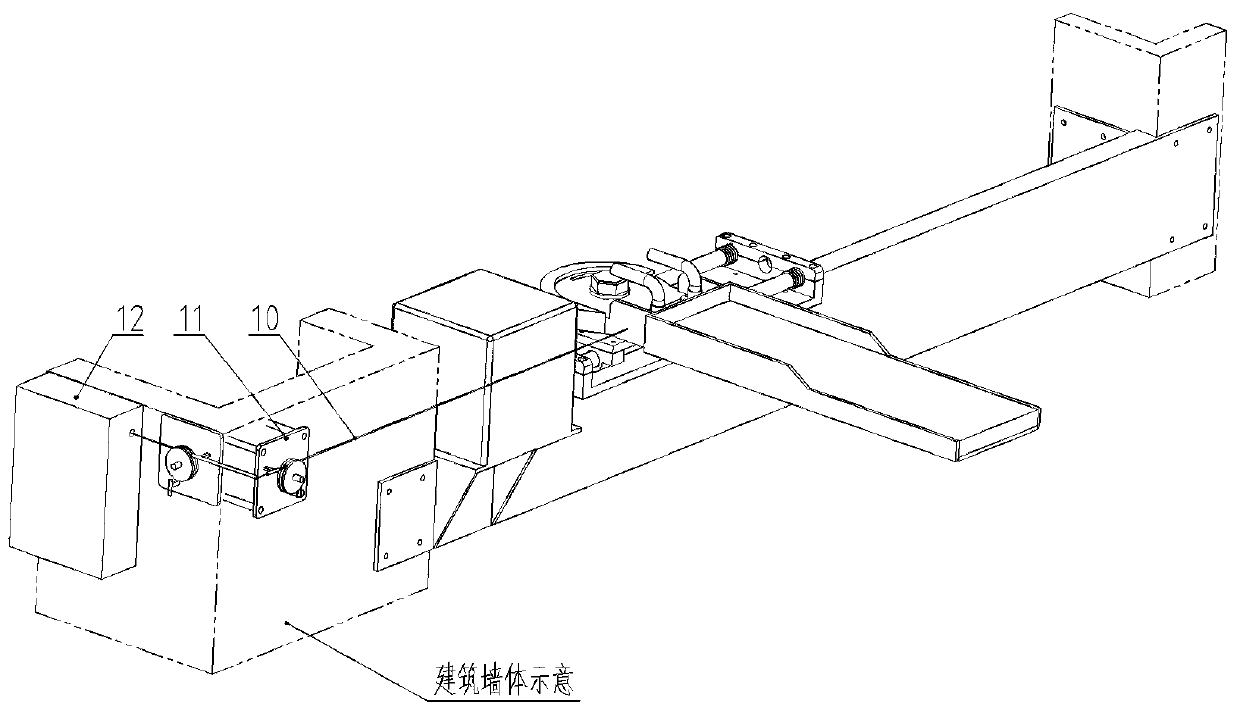

Prefabricated panel installation device

ActiveCN110821187AProtection from falling events and falling objectsSave operating spaceBuilding material handlingRebarElectric machinery

The invention relates to a prefabricated part, in particular to a prefabricated panel installation device. The invention aims to solve the technical problem so as to provide the prefabricated panel installation device which comprises a diagonal bracing and locking mechanism, a first bottom lifting ring, a second bottom lifting ring, a stepping motor, a control display, an installation posture adjusting mechanism and a reinforcing steel bar straightening mechanism. The first lifting ring is arranged on the left part of the bottom end of the diagonal bracing and locking mechanism. According to the prefabricated panel installation device provided by the invention, the diagonal bracing and locking mechanism and a floor are tightly connected, and then the installation posture adjusting mechanism carries out garbage collection on a wallboard placement area, so that objects such as stone blocks are prevented from influencing a level condition of a wallboard; and then reinforcing steel bars inserted into the wallboard are straightened through the reinforcing steel bar straightening mechanism, so that the wallboard can be directly butt-jointed with the reinforcing steel bars when being installed. According to the prefabricated panel installation device provided by the invention, the effects on reducing the aerial edge work of working personnel, preventing the occurrence of falling accidents and falling objects, installing and moving conveniently, and providing an enough operation space for the working personnel are achieved.

Owner:SHANDONG ZHENGSHUN CONSTR GRP

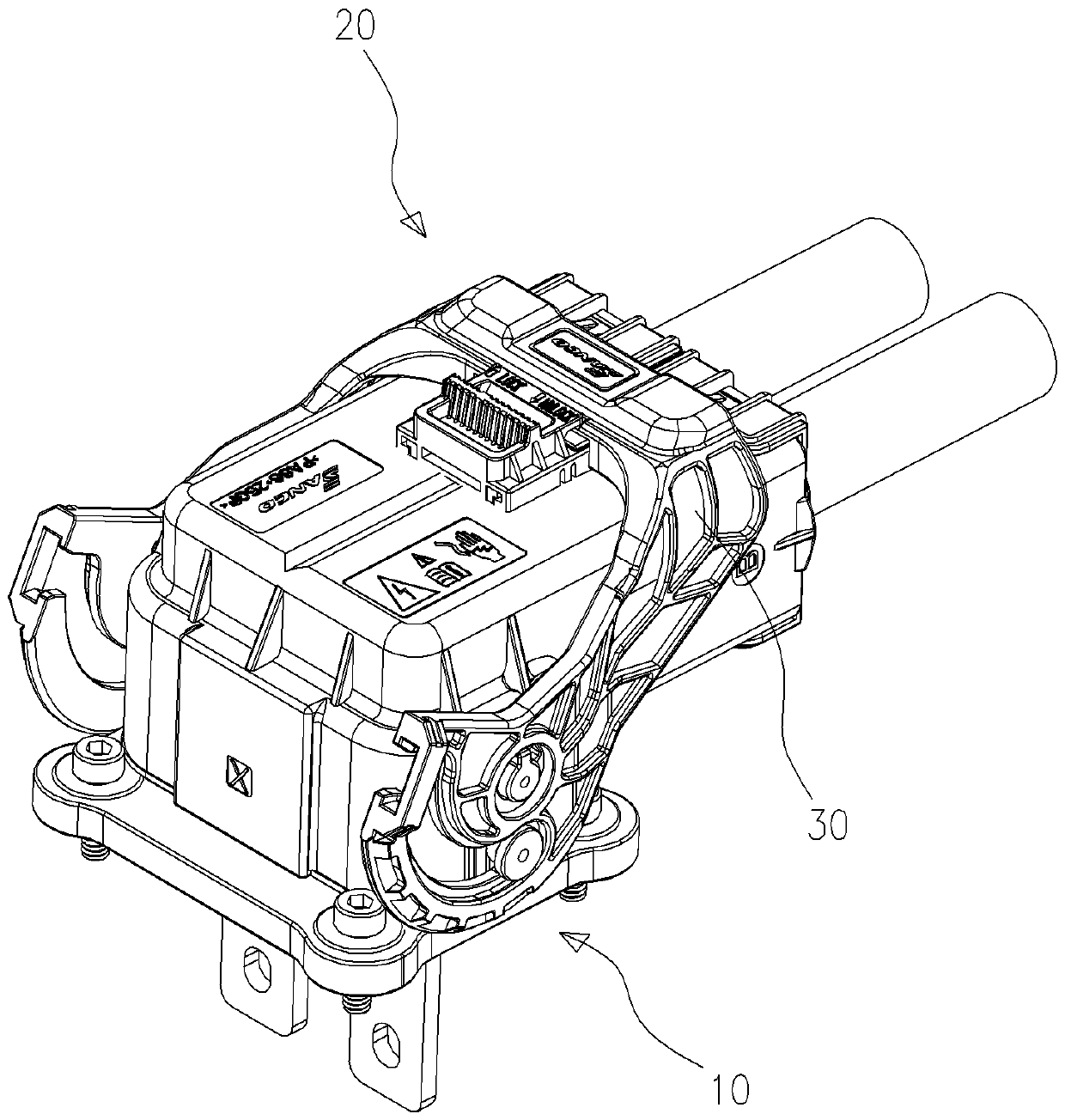

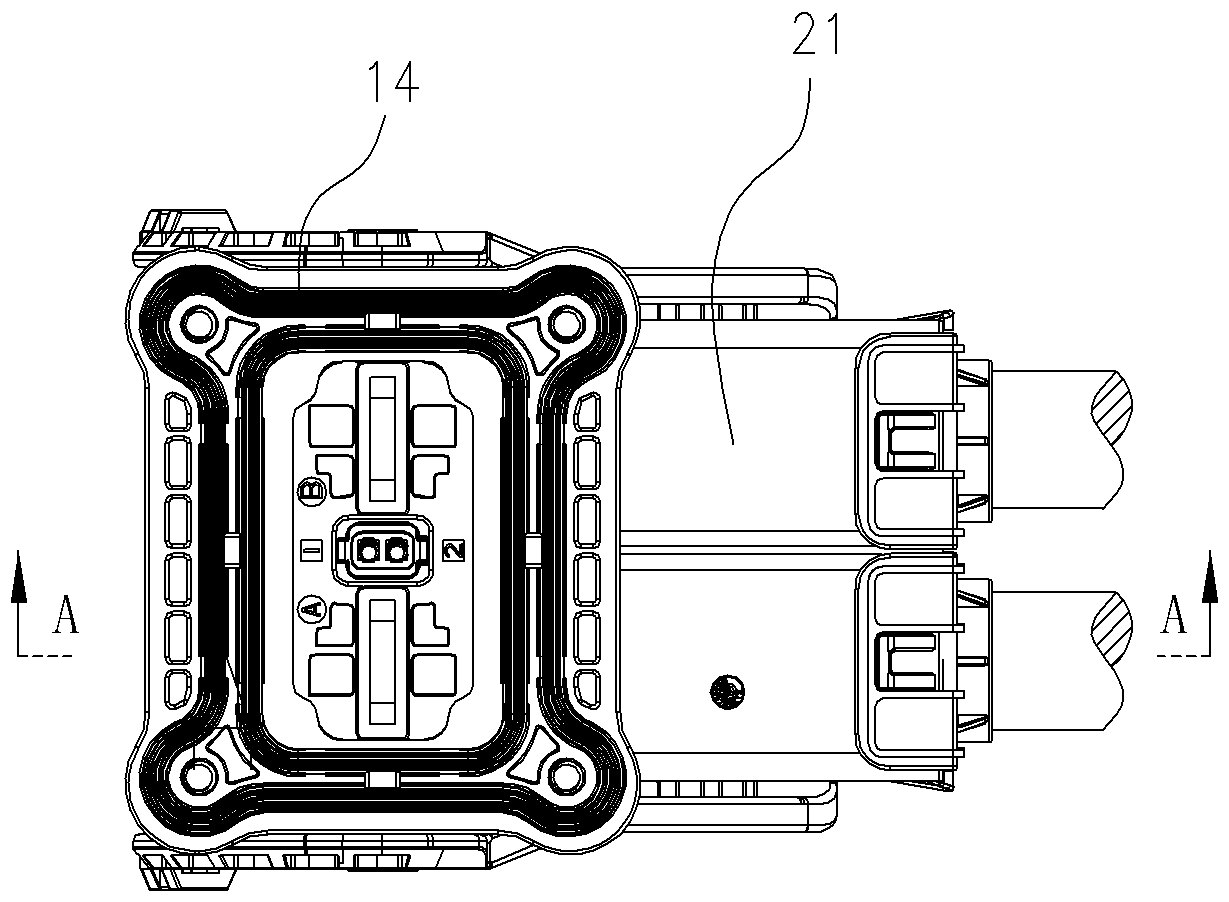

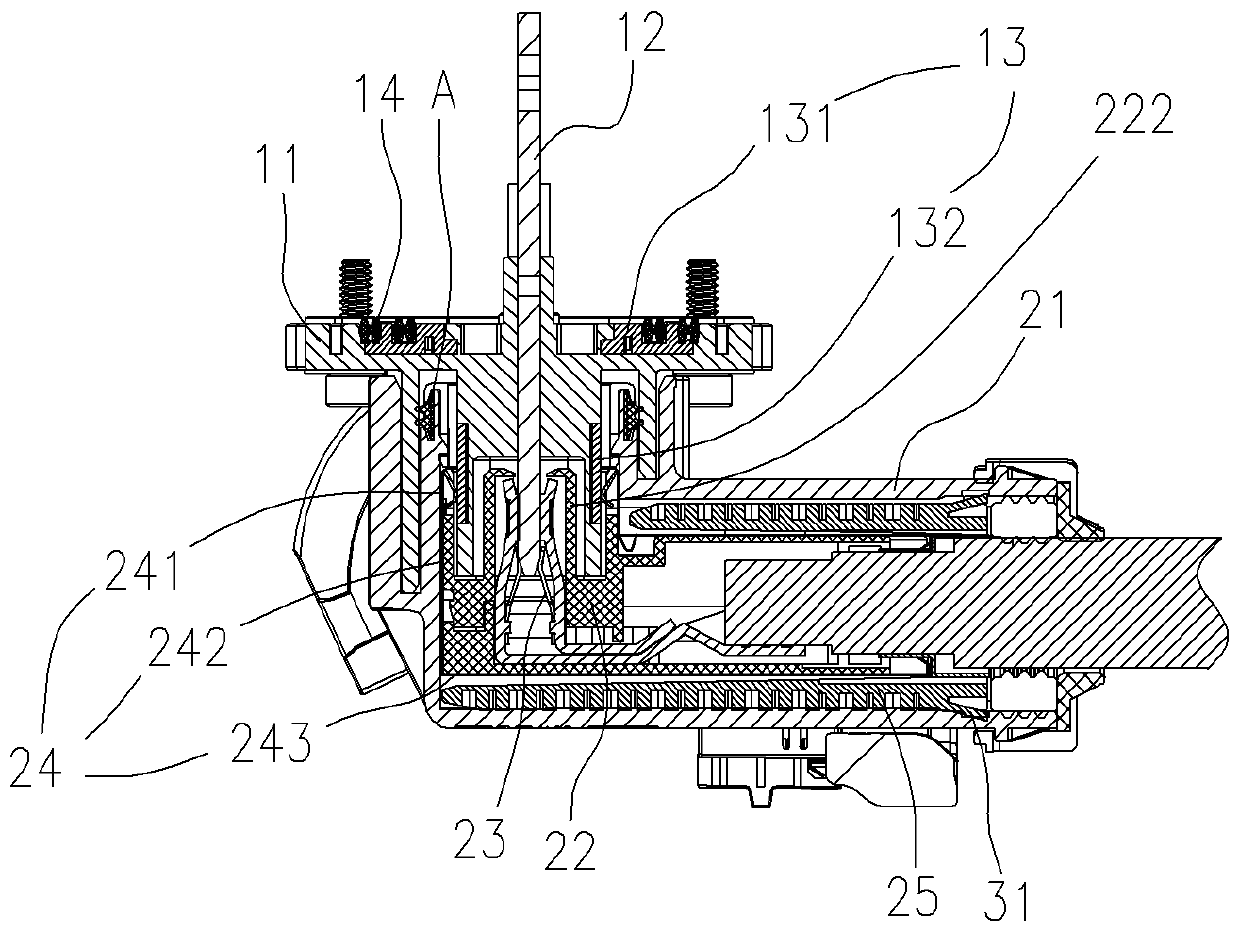

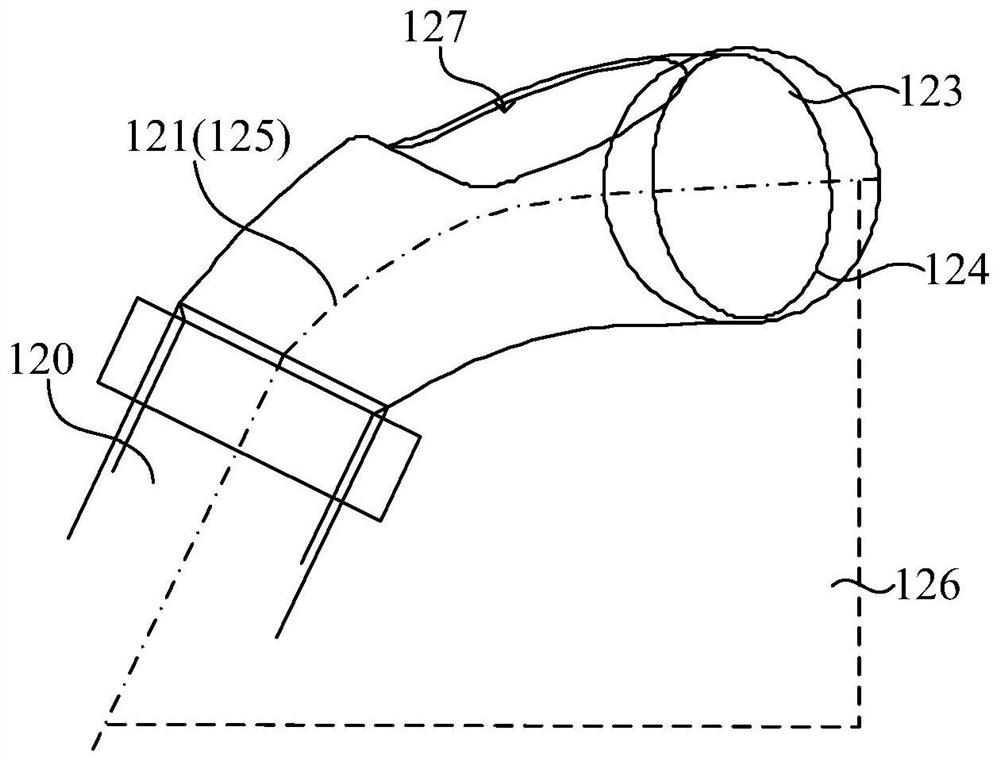

90-DEG bent connector

PendingCN110459901ARealize the electrical structureReduce system costCoupling contact membersCouplings bases/casesCopperElectrical structure

The invention provides a 90-DEG bent connector, which includes a socket and a plug, wherein the socket includes a socket insulator, a copper male terminal inserted in the socket insulator, and a socket shielding seat inserted in the socket insulator. The plug comprises an L-shaped plug housing, a rubber core assembly fixed inside the L-shaped plug housing, a flat female terminal assembly fixed inside the rubber core assembly, and a plug shielding cover fixed on the outer surface of the rubber core assembly. The plug shielding cover is composed of an upper shielding ring, a middle shielding ring, and a lower shielding ring. By adopting the structure of a flat female terminal assembly, the electrical structure when the plug and the socket are plugged can be realized, the flat terminal is cheaper to be made than the previous round terminal, has a simpler structure and is more practical. By adopting a 90-DEG wire outgoing mode, the operating space required when the product is used is moresufficient. By adopting a novel shielding mode, the shielding is more reliable.

Owner:顺科智连技术股份有限公司

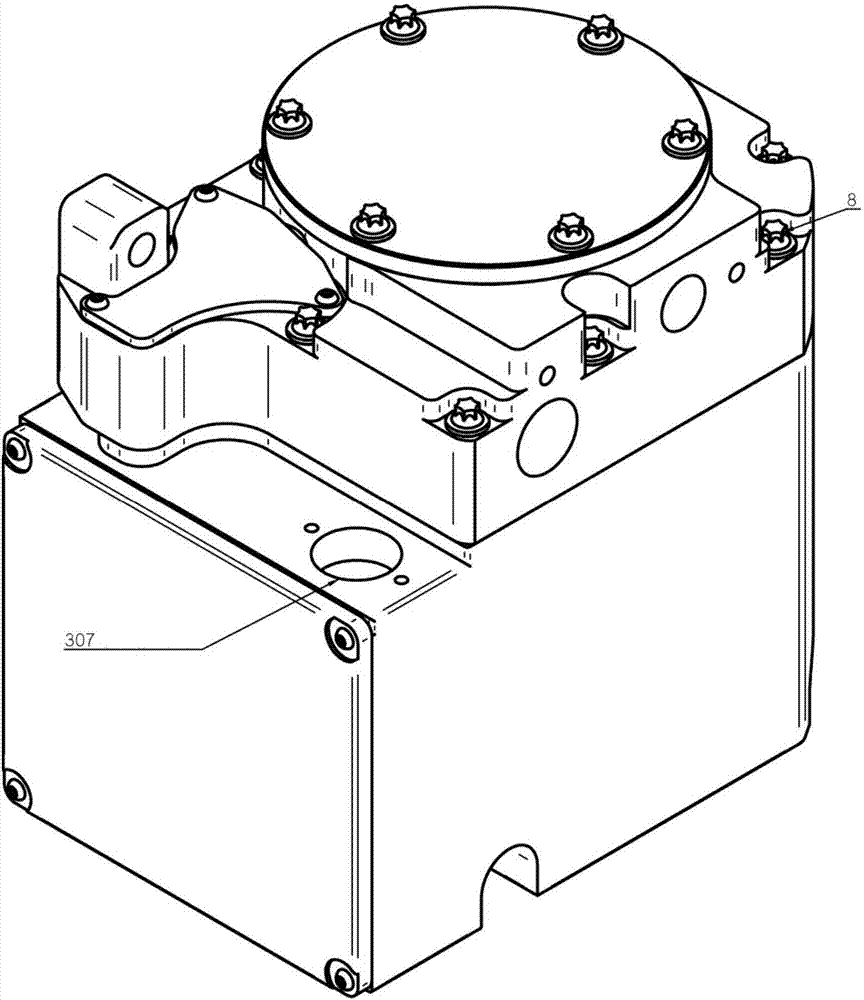

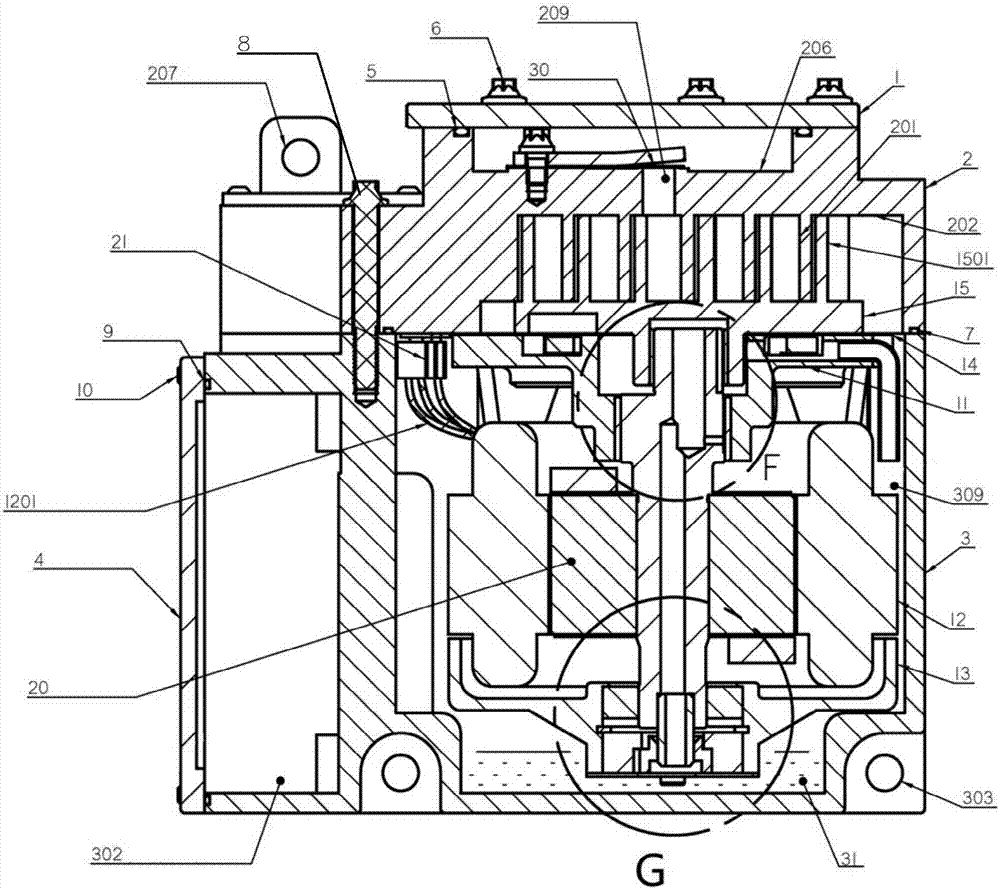

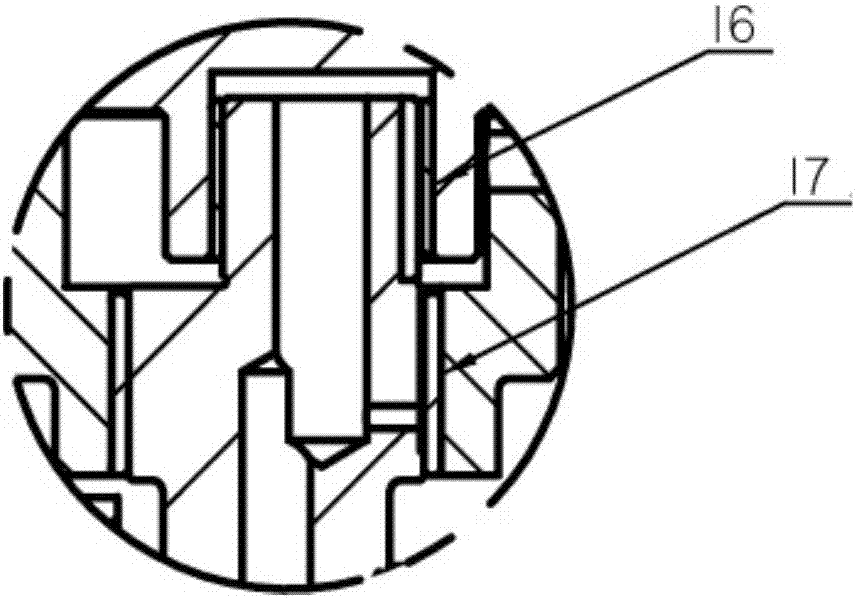

Vortex compressor for vehicle

ActiveCN107100846AEliminate shakingImprove insulation performanceRotary/oscillating piston combinations for elastic fluidsAir-treating devicesControl theoryBinding post

The invention provides a vortex compressor for a vehicle. The vortex compressor comprises a shell which is provided with a first opening to form an accommodating space, a compression mechanism, a motor mechanism which comprises a motor rotor and a motor stator, an upper bracket, and a lower bracket which is fixedly connected with the upper bracket through the motor stator, wherein the motor stator is connected to a binding post through a motor lead-out wire; the binding post is located between the inner wall of the shell and the outer wall of the motor stator and is far away from the bottom wall of the shell; the motor stator is directly or indirectly mounted on the same component together with the wiring post; a distance between an outgoing line of the motor lead-out wire and the binding post is fixed; furthermore, a connection and assembling process is completed before the same component and the shell form a closed cavity. The vortex compressor for the vehicle is favorable for assembling of the binding post.

Owner:SHANGHAI HIGHLY NEW ENERGY TECH CO LTD

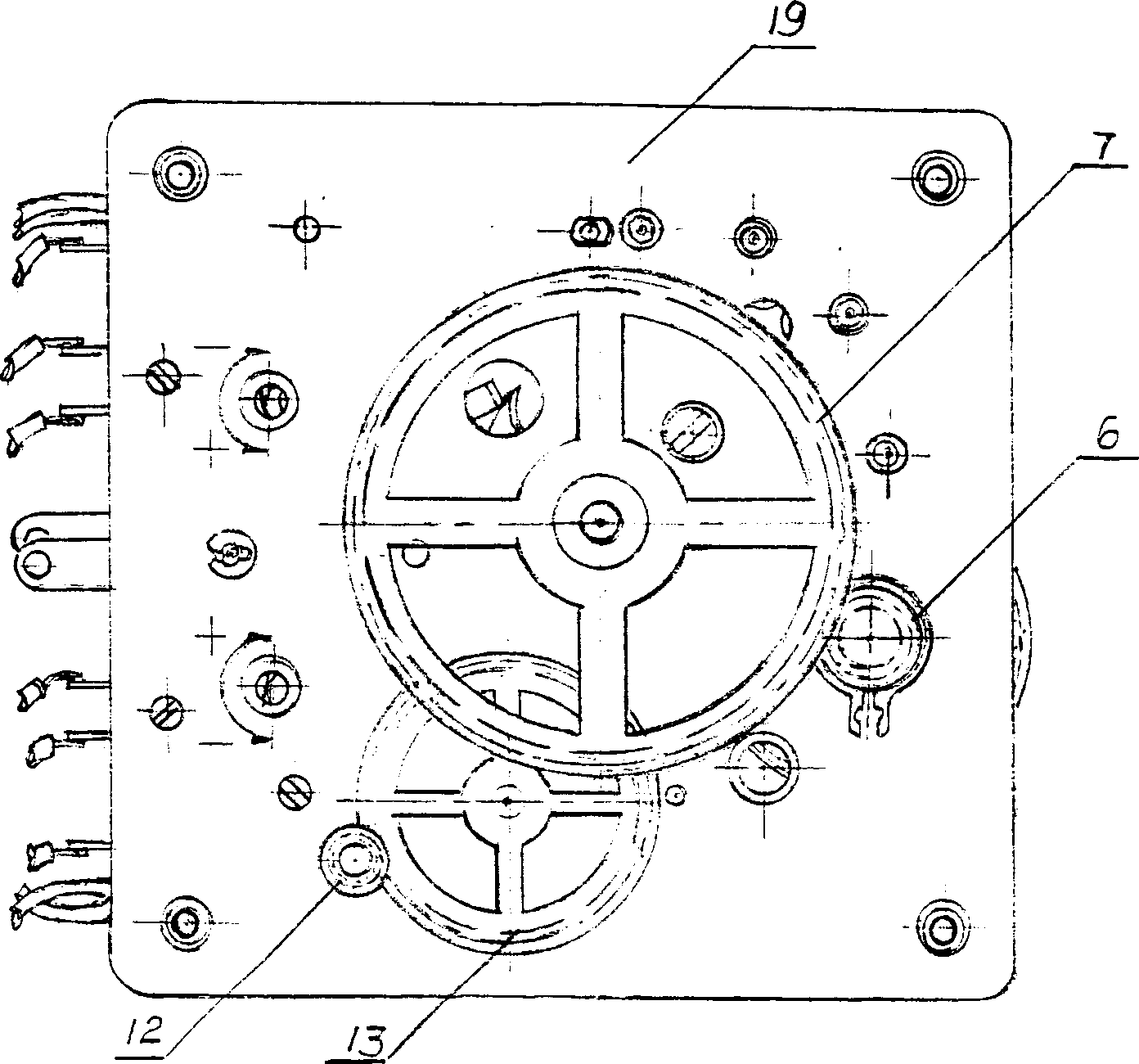

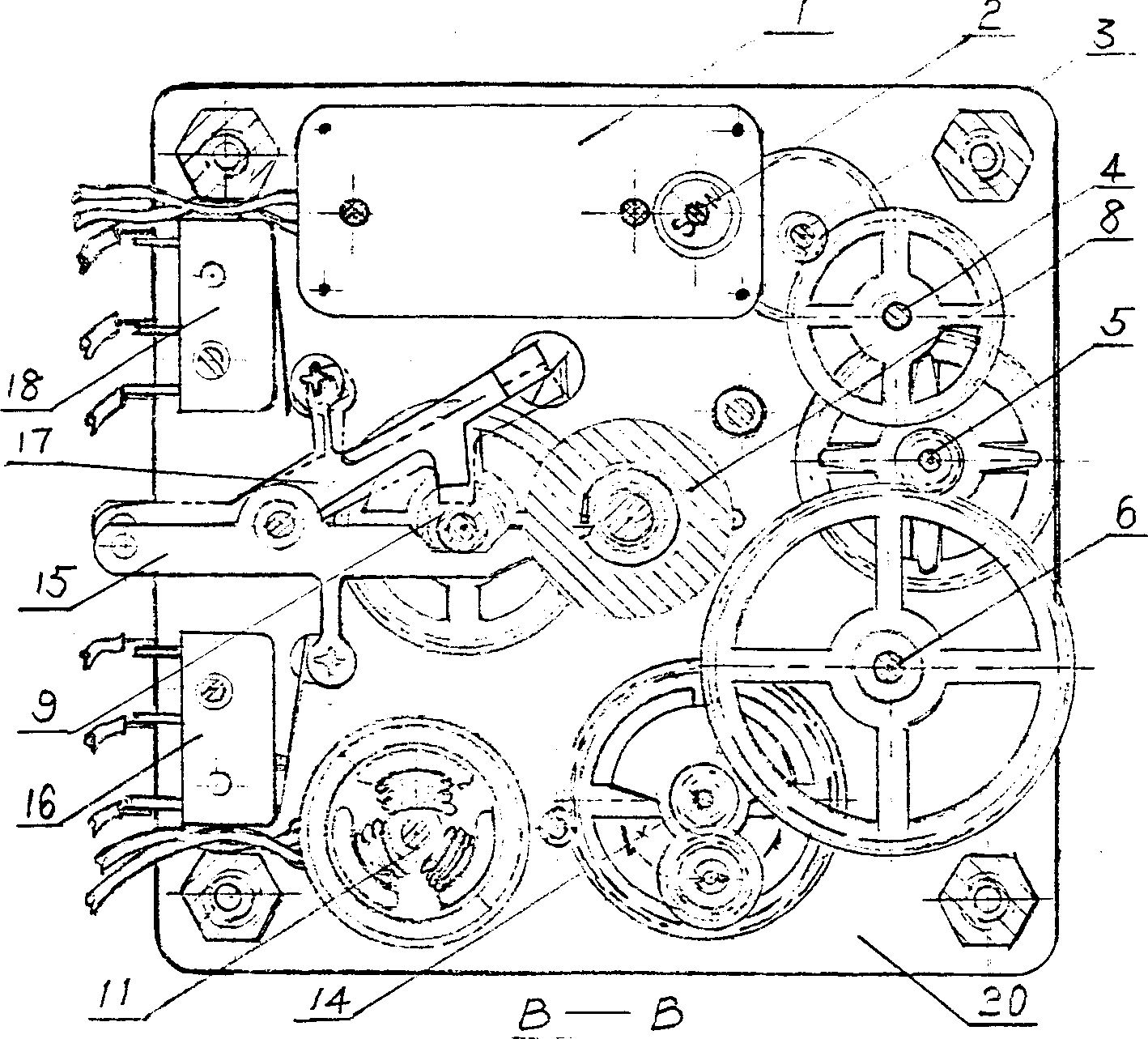

Large electromechanical pointer clock

InactiveCN1399175ASelf-lubricatingCorrosion resistanceVisual indicationElectric indicationWear resistantWear resistance

The present invention relates to the movement structure, calendar display, clock face installation and rotating shaft structure. The movement structure consists of four parts including pulse stepped motor, pointer transmission wheel system, pointer setting mechanism and hour and day reporting trigger signal output mechanism. The minute wheel in backward design is set outside the back clevice assembly for saving space. The calendar display is a micro power consumption and large width one and the clock face is float installed with springs for lasting flatness. The rotating shaft structure is of self-lubricating corrosive and wear resistant material. The large clock of the present invention is not affected by power failure, whether and environment, and is corrosive, wear resistance, accurate, reliable and durable.

Owner:王明德

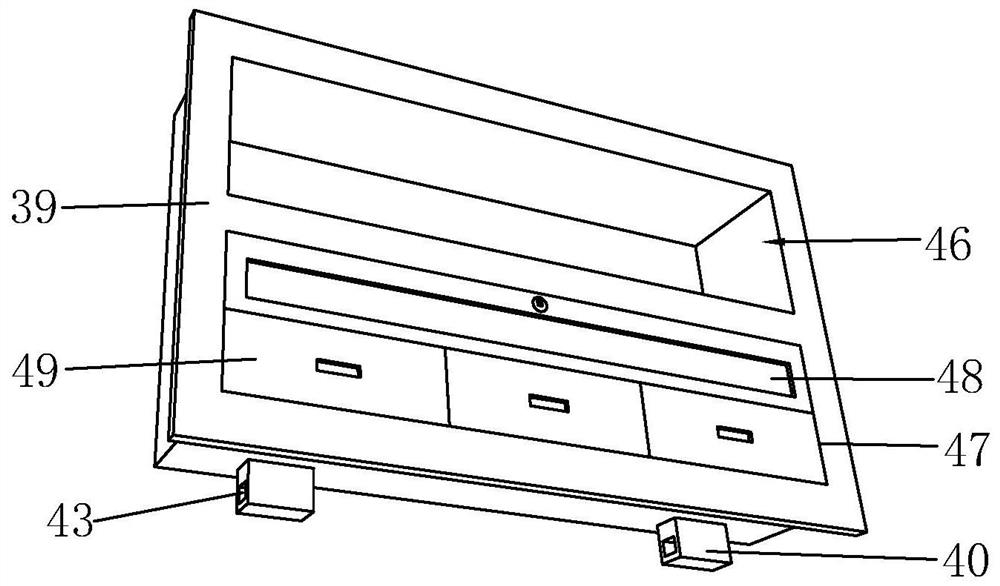

Embedded steaming oven and installation method thereof

PendingCN110123173AStrong applicabilityEasy to assemble and disassembleSteam cooking vesselsRoasters/grillsWaste management

The invention discloses an embedded steaming oven and an installation method thereof. The steaming oven comprises a body and installation supports, wherein an installation ring sleeves the body, and each installation support comprises an installation side plate, a telescoping bottom plate and an elastic assembly. The telescoping bottom plates are arranged between the installation side plates, thetelescoping bottom plates and the installation side plates are connected with the installation ring, each elastic assembly is arranged on one side of the corresponding installation side plate, and theelastic assemblies abut against the back side of the body. The installation method comprises the following steps that a, the installation supports are installed; b, the installation supports are fixed; c, the installation ring is assembled; d, the body is installed in a cabinet. The steaming oven is novel in structure, convenient to install, stable, reliable, suitable for different installation environments and high in applicability; the installation method is simple in operation, saves energy and is convenient to use, stepwise and orderly, a sufficient operation space is ensured, the installation difficulty is reduced, in the installation process, control and adjustment are facilitated, the flexibility is high, and therefore, the installation quality is ensured.

Owner:浙江蓝炬星电器有限公司

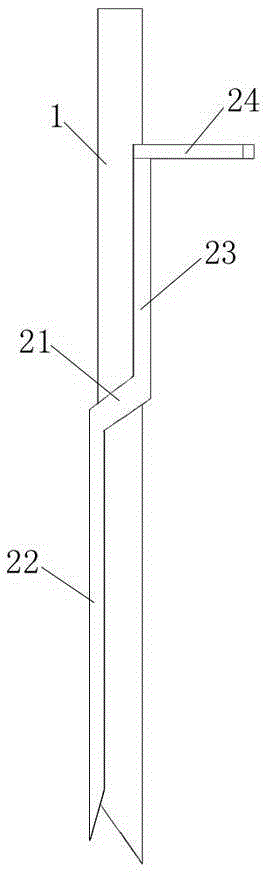

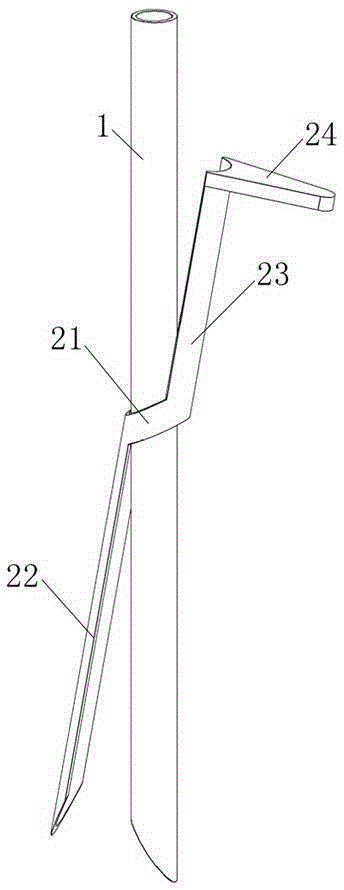

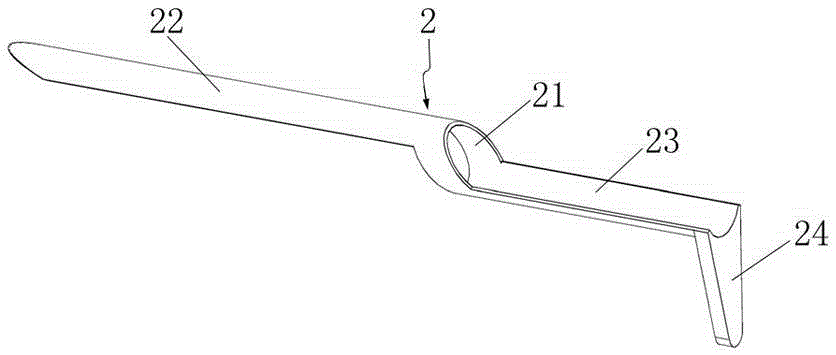

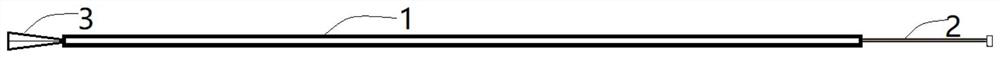

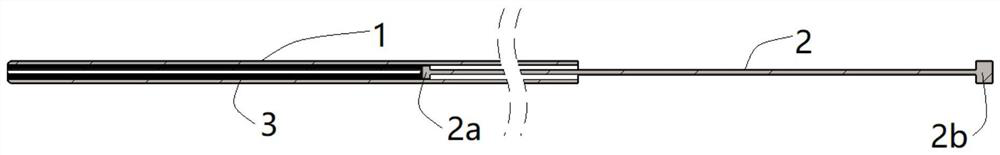

Operation angle changeable type zygopophysis osteotome capable of avoiding image covering

The invention relates to an operation angle changeable type zygopophysis osteotome capable of avoiding image covering. The zygopophysis osteotome comprises a working sleeve and an osteotome shifting rod connected to the outer side of the sleeve in a sleeving mode, wherein the osteotome shifting rod comprises a chiseling part, a connecting part, a driving part and a clamping part, the chiseling part and the driving part are both straight grooves with arched surfaces, the arched surface of the chiseling part protrudes upwards, and the front end of the chiseling part is a pointed end; the arched surface of the driving part protrudes downwards, and the rear end of the driving part is connected with the clamping part; the connecting part is a round tube, and the two end faces of the round tube incline to one side; the rear end of the chiseling part is in smooth butt joint with the upper edge of one end of the connecting part, the driving part is in smooth butt joint with the lower edge of the other end of the connecting part, and the chiseling part, the connecting part and the driving part form a Z-shaped body. According to the zygopophysis osteotome, the working sleeve and a foraminal mirror connected in the working sleeve in a penetrating mode can not be damaged, the front end of the foraminal mirror can not be blocked, and then visual bone chiseling operation is realized.

Owner:HEBEI RUIHE MEDICAL DEVICES CO LTD

Mechanical tensile experiment testing device

ActiveCN106969970AGuaranteed levelGuaranteed to move normallyNuclear energy generationMaterial strength using tensile/compressive forcesEngineeringMechanical engineering

The invention discloses a mechanical tensile experiment testing device. A door-shaped frame is fixedly arranged at the top end of a base; a sliding lantern ring which is in sliding connection with the door-shaped frame is arranged on a vertical column of the door-shaped frame; a first oil cylinder and a second oil cylinder are fixedly arranged at the bottom end of the transverse beam of the door-shaped frame; the first oil cylinder and the second oil cylinder are arranged downwards vertically; the top end of a platform is fixedly arranged at the tail ends of the piston rods of the first oil cylinder and the second oil cylinder; the left end and the right end of the platform are fixed on a left sliding lantern ring and a right sliding lantern ring through a bracket; an upper clamp is fixedly arranged at the bottom end of the transverse beam of the door-shaped frame; the upper clamp is arranged between the first oil cylinder and the second oil cylinder; a lower clamp is fixedly arranged at the top end of the platform; the upper clamp and the lower clamp are coaxially arranged up and down; a load sensor is arranged at the bottom of the lower clamp; a detachable protection cylinder is arranged on the upper clamp; the upper clamp and the lower clamp are covered inside the protection cylinder. The mechanical tensile experiment testing device has the beneficial effects of being high in testing precision and high in security coefficient.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Large-span concrete-filled steel tube tied bar arch bridge construction method

ActiveCN111021222AFast constructionConstruction progress is easy to controlBridge erection/assemblyArch-type bridgeArchitectural engineeringBridge deck

The invention discloses a large-span concrete-filled steel tube tied bar arch bridge construction method and relates to a concrete-filled steel tube tied bar arch bridge construction method, thereby solving problems of long bracket occupation time and the like caused by the existing pre-built bracket assembling method. An arch springing and a continuous beam block 0 are constructed together, and the 2 / 3 of the length of an arch rib of a section 1 is pre-buried in the arch springing; concrete is poured into a first-section arch rib steel tube; and a first arch rib is firmly welded to a temporary support. A bridge deck girder is constructed and a lower anchor box is pre-buried at a corresponding position of a suspender; and construction from the inside to the two ends is simultaneously carried out according to the sequence of erecting a next support and installing a next section of arch rib. For a closure section, the arc rib on the right side of the closure section is closed and then the arc rib on the left side of the closure section is closed and temporary fixation is performed. The seams between the adjacent sections of arch ribs are welded and fixed; arch rib concrete pouring iscarried out; the support is removed; the suspender is mounted; the suspender is expanded; and steel structure finish paint coating is carried out. The method has the advantages of high construction speed, support proceeding along with the installation progress and sufficient on-bridge operation space.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

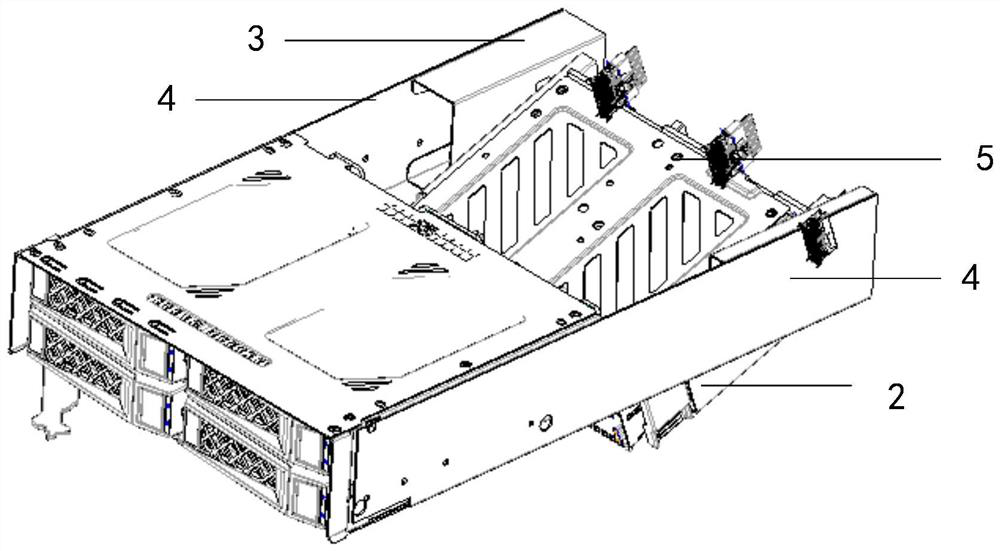

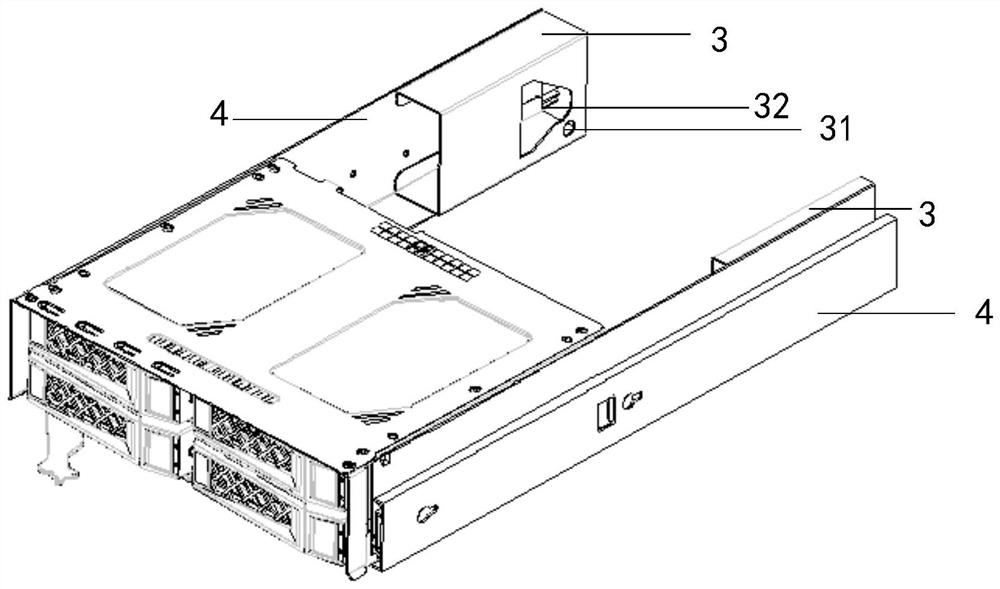

Server and horizontal expansion structure of hard disk bin thereof

InactiveCN110471507AEasy to installEasy to operateDigital processing power distributionComputer engineering

The invention discloses a horizontal expansion structure of a hard disk bin. The horizontal expansion structure comprises a basic hard disk bin arranged in a case, a deflection assembly attached to the side wall of the case in a deflectable mode, and an expansion hard disk bin connected to the tail end of the deflection assembly. According to the horizontal expansion structure of the hard disk bin, the installation position of the expansion hard disk bin in the case can be changed through the change of the deflection state of the deflection assembly, the hard disk bin can be expanded in the horizontal direction in the case, and installation and hot plug operation of a hard disk can be conveniently carried out. The invention also discloses a server, and the beneficial effects of the serverare as described above.

Owner:INSPUR BUSINESS MACHINE CO LTD

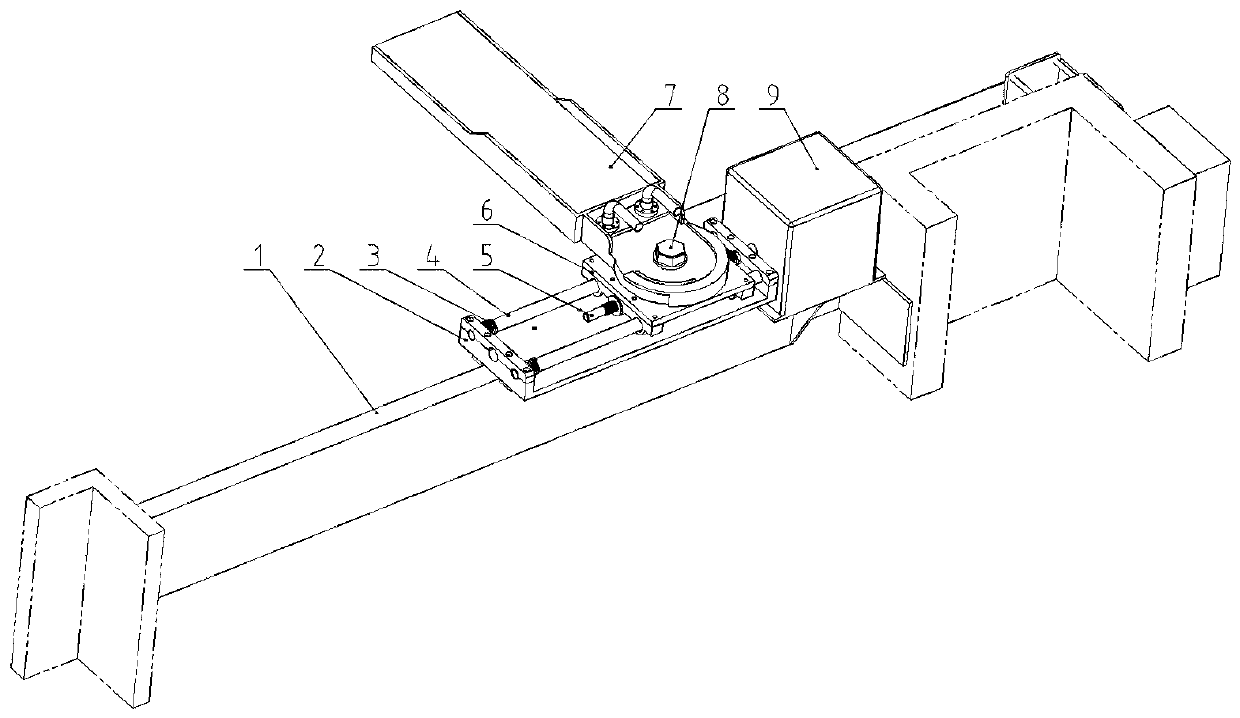

Beam shielding device for industrial electron accelerator

The invention discloses a beam shielding device for an industrial electron accelerator and relates to the industrial electronic accelerator technology. The beam shielding device for the industrial electron accelerator is characterized by comprising twelve parts such as a main body bracket, a stroke base, a stroke guide rod, a stroke transmission rod, a water absorber mounting seat, a water absorber, a motor box, a stroke cable and a control box, wherein the stroke base is fixed with an upper edge of the main body bracket, the water absorber mounting seat penetrates through the stroke guide rod and the stroke transmission rod through a sliding sleeve and a wire sleeve structure, the stroke transmission rod is driven by a motor through a coupling to rotate to make the water absorber move, the stroke information of the water absorber is transmitted by the stroke cable to a stroke switch, and the water absorber is made to reliably move and position. The beam shielding device is advantaged in that the motor can be shielded, electrical components can be mounted at the position with a small electron beam radiation dose radiation dose, the service life of devices is significantly prolonged, a beam blocking device can be easily turned to the far place, and the sufficient maintenance space is reserved.

Owner:SHANDONG LANFU HIGH ENERGY PHYSICS TECH CO LTD

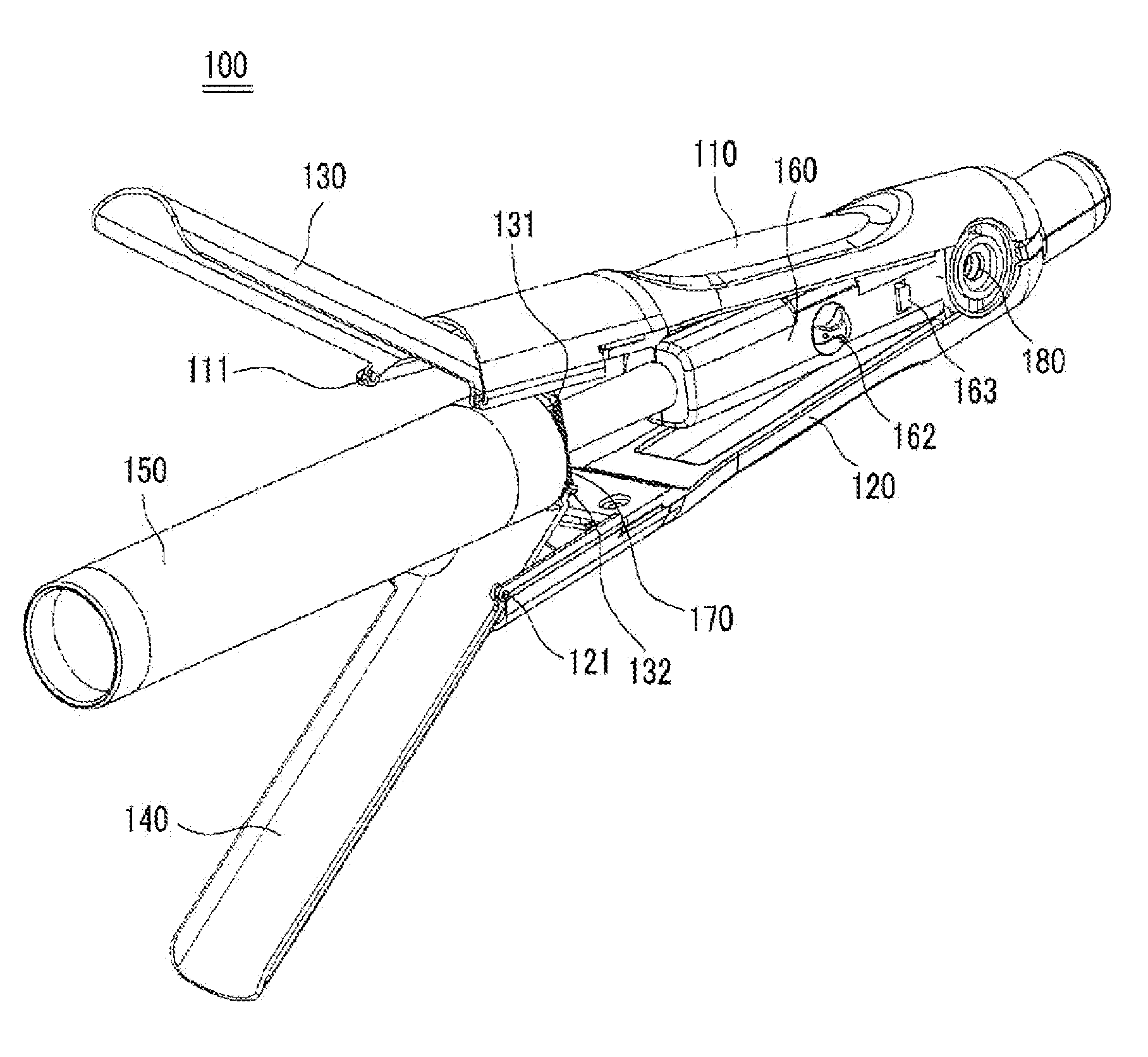

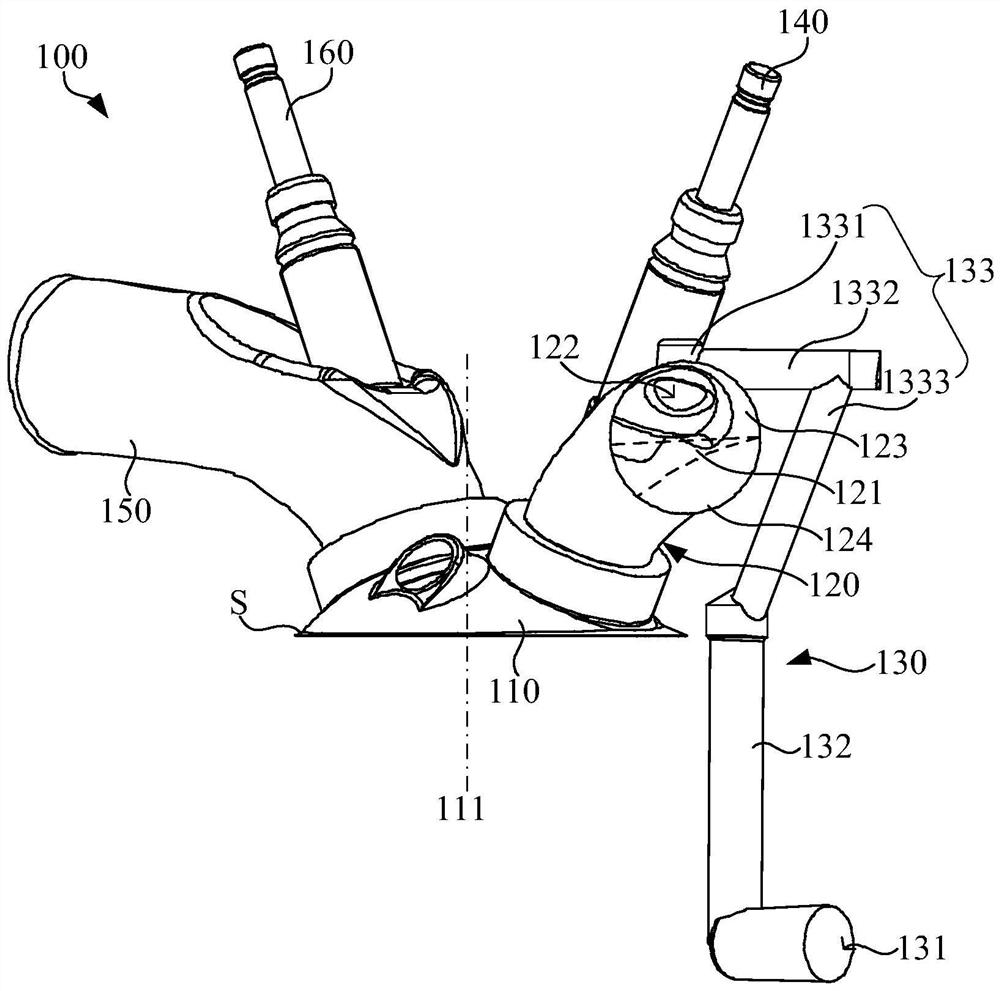

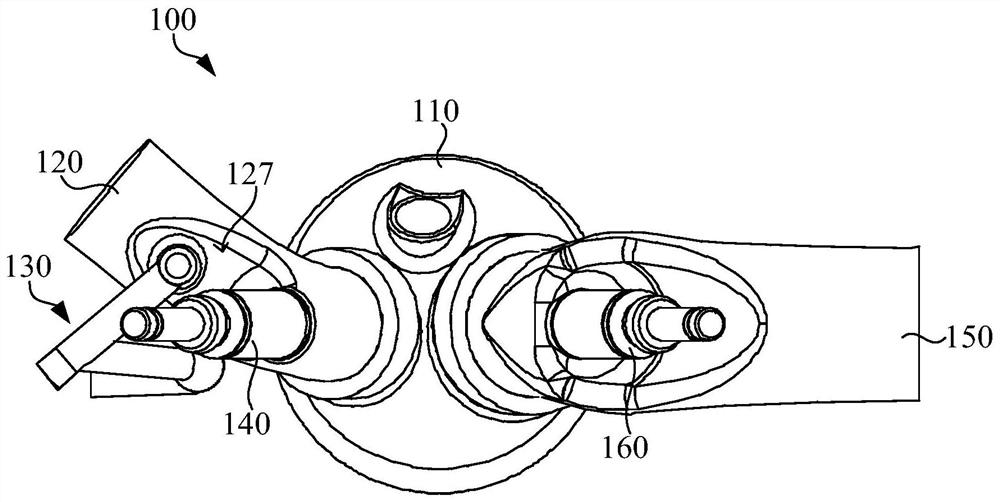

Retractor assembly and retractor

The invention provides a retractor assembly and a retractor. The retractor assembly includes: a catheter extending from a proximal end side toward a distal end side; a retractor which is rolled in thecatheter in a rolled state, is restrained by the inner circumferential surface of the catheter and can slide along the catheter; and a retractor pushing-out component which is partially inserted intothe catheter and can push the retractor to slide from the near end side to the far end side along the catheter, wherein when the retractor is pushed by the retractor pushing-out component to be gradually disengaged from the catheter, the retractor is automatically expanded to gradually expand the tissue. According to the invention, extra surgical risks caused by the difference of retraction operation levels of operators can be avoided; even if the surgical site is deep in the tissue, the tissue can be smoothly retracted at low risk; and the conditions of glare and the like can be avoided.

Owner:泰升医疗有限公司

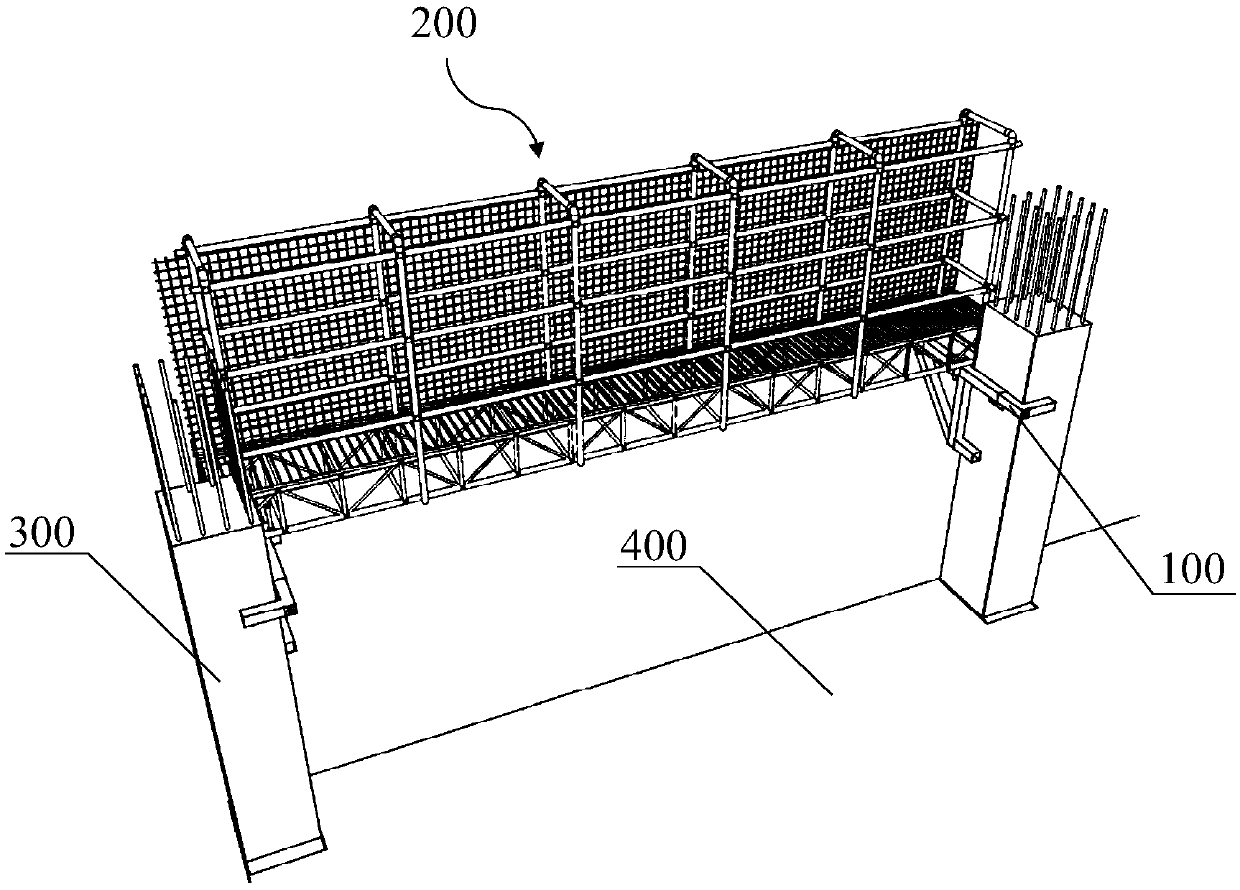

Externally-hanging rack operating platform

PendingCN109610802ASimple structureEasy to assemble and disassembleScaffold accessoriesBuilding support scaffoldsBiochemical engineeringWork space

The invention relates to the technical field of scaffoldings, and discloses an externally-hanging rack operating platform. The externally-hanging rack operating platform comprises a supporting leg andan externally-hanging rack, the supporting leg comprises a fixing part and a supporting part which are connected to each other, and the fixing part comprises a first fixing part and a first clampingpart, the supporting leg can be fixed to a precast column through the first fixing part and clamped to the precast column through the first clamping part, and the clamping length of the first campingpart clamping the precast column can be adjusted according to the size of the precast column; the supporting part is provided with a second clamping part, the externally-hanging rack can be fixed on the supporting part through the second clamping part; a work platform is arranged on the externally-hanging rack to provide a working space for an operator. The externally-hanging rack operating platform has the simple structure, disassembly and assembly is convenient, cost is low, revolution is convenient and flexible, and work efficiency can be greatly improved.

Owner:CHINA HUASHI ENTERPRISES

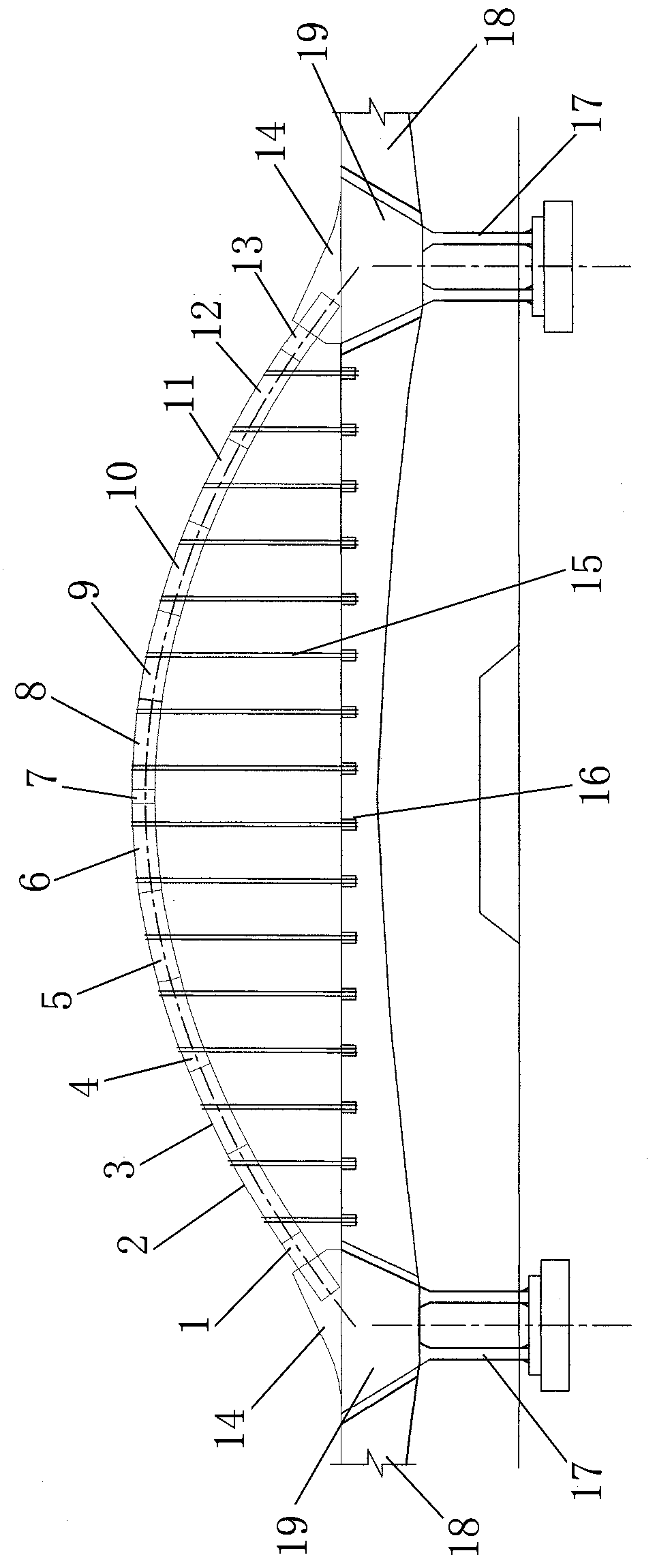

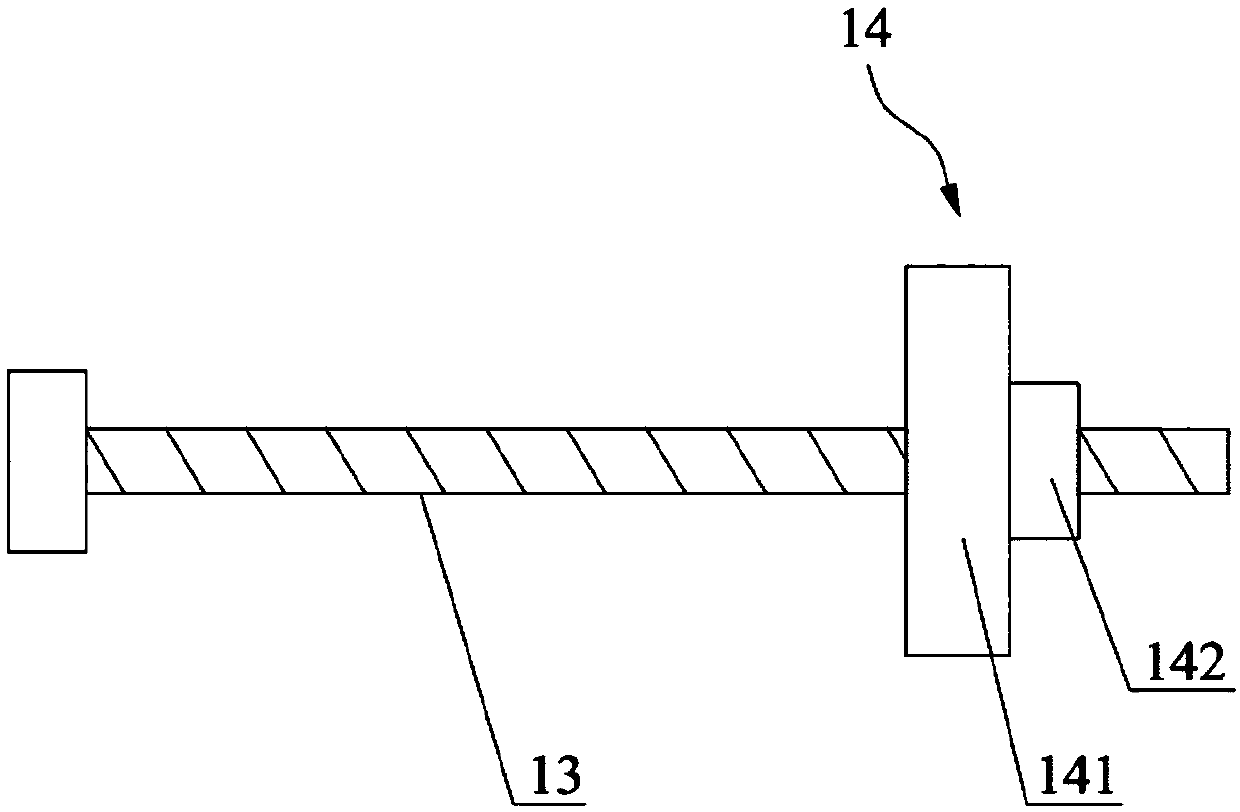

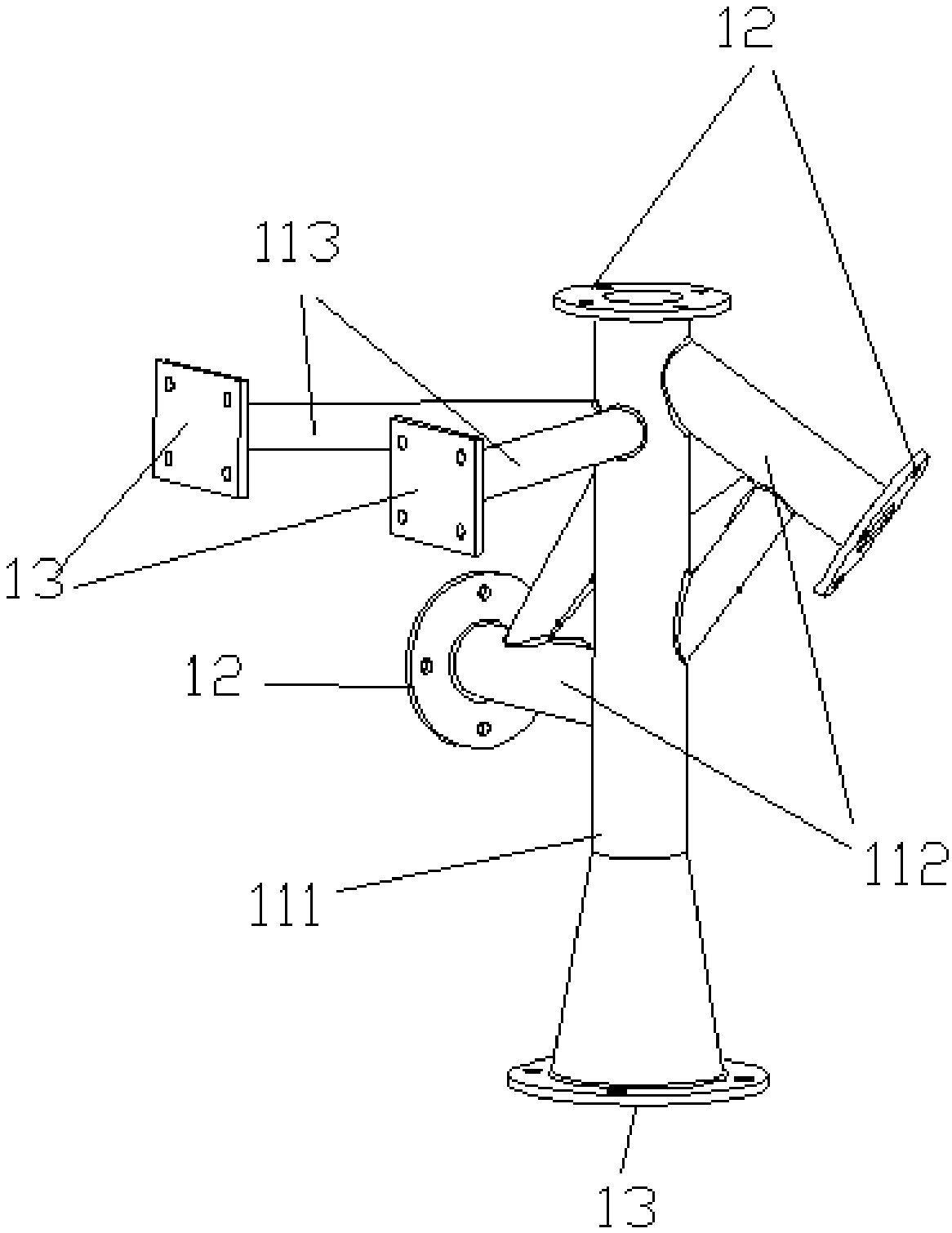

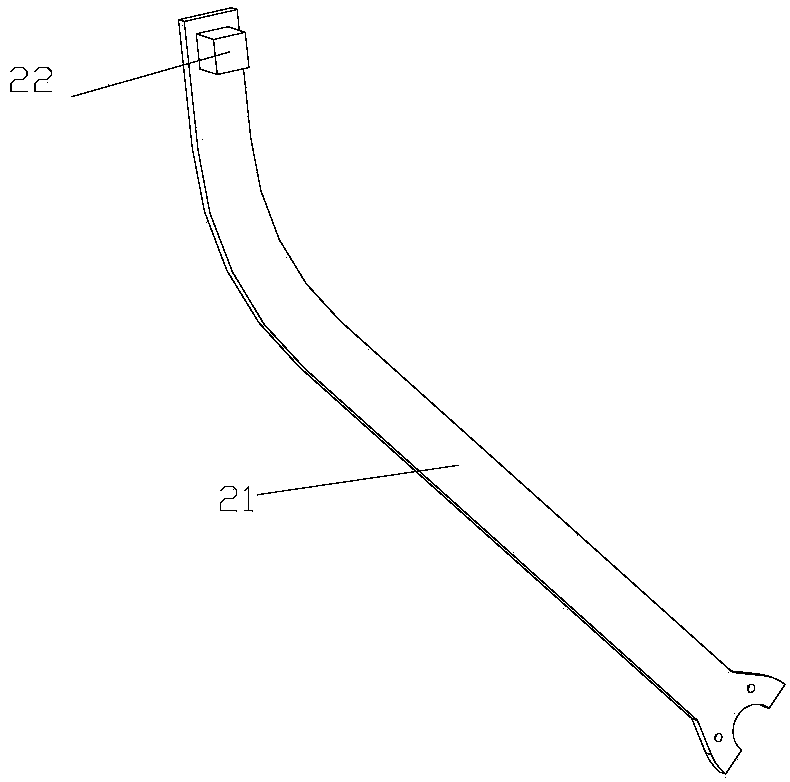

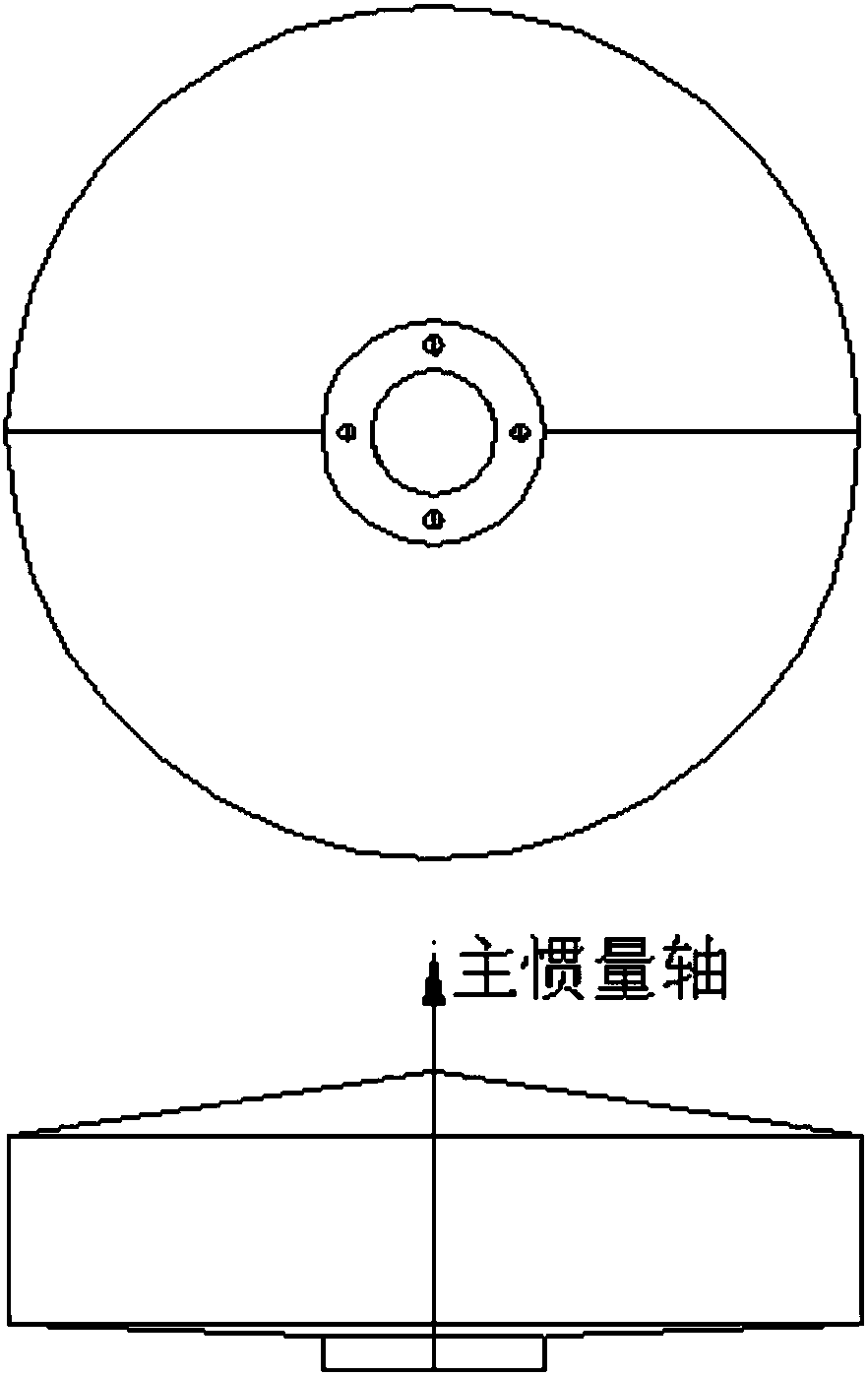

Three-flywheel integrated arrangement device and installation and adjustment method thereof

ActiveCN107933968ARealize layoutSave layout spaceCosmonautic vehiclesSpacecraft guiding apparatusEngineeringFlywheel

The invention discloses a three-flywheel integrated arrangement device and an installation and adjustment method of the three-flywheel integrated arrangement device. The three-flywheel integrated arrangement device comprises a tree-like support and flywheels; the tree-like support comprises a support body; the longitudinal flywheel is installed at one end of a main supporting rod, and the other end of the main supporting rod is connected with an air vehicle; the main supporting rod is in the Y-axis direction of a coordinate system of an air vehicle body, and a main inertia axis of the longitudinal flywheel is in the Y-axis direction of the coordinate system of the air vehicle body; the transverse flywheel and the slant flywheel are installed on the end portions of slant supporting rods, the slant supporting rod connected with the transverse flywheel is perpendicular to the main supporting rod and is in the Z-axis direction of the coordinate system of the air vehicle body, and a main inertia axis of the transverse flywheel is in the Z-axis direction of the coordinate system of the air vehicle body; and all structure connecting rods are perpendicular to the main supporting rod, and the end portions of the structure connecting rods are connected with the air vehicle. The problems that the space in a cabin of the aerospace air vehicle is compact, three flywheel sets are difficult to arrange, meanwhile due to the poor openness of the space in the cabin, the installation and operation space is insufficient, and a measurement light path is poor in accessibility are solved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Motor train unit and chassis end integration device thereof

PendingCN109720369AIncrease storage spaceAvoids deterioration of directional strength for transmitting longitudinal forcesSanitationEngineeringUltimate tensile strength

The invention discloses a motor train unit and a chassis end integration device thereof. The chassis end integration device comprises a dirt box and dirt box lifting points, wherein the dirt box is aspecially-shaped dirt box and used for containing dirt, and when installed at the end of a vehicle chassis, the dirt box can be attached to the end of the vehicle chassis; and the dirt box lifting points and a traction beam at the end of the vehicle chassis are integrally formed, and the dirt box is installed at the end of the vehicle chassis through the dirt box lifting points. Due to the fact that the dirt box containing the dirt is of a specially-shaped structure and the dirt box can be attached to the end of the vehicle chassis when installed at the end of the vehicle chassis, the containing space of the dirt box is enlarged; and in addition, the dirt box lifting points and the traction beam of the vehicle chassis are integrally formed, and the situation that the direction strength oflongitudinal force transmission of the vehicle chassis becomes poor due to the fact that holes are formed in the traction beam is avoided. In conclusion, the containing space of the dirt box is enlarged, and the situation that the direction strength of longitudinal force transmission of the vehicle chassis becomes poor is avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

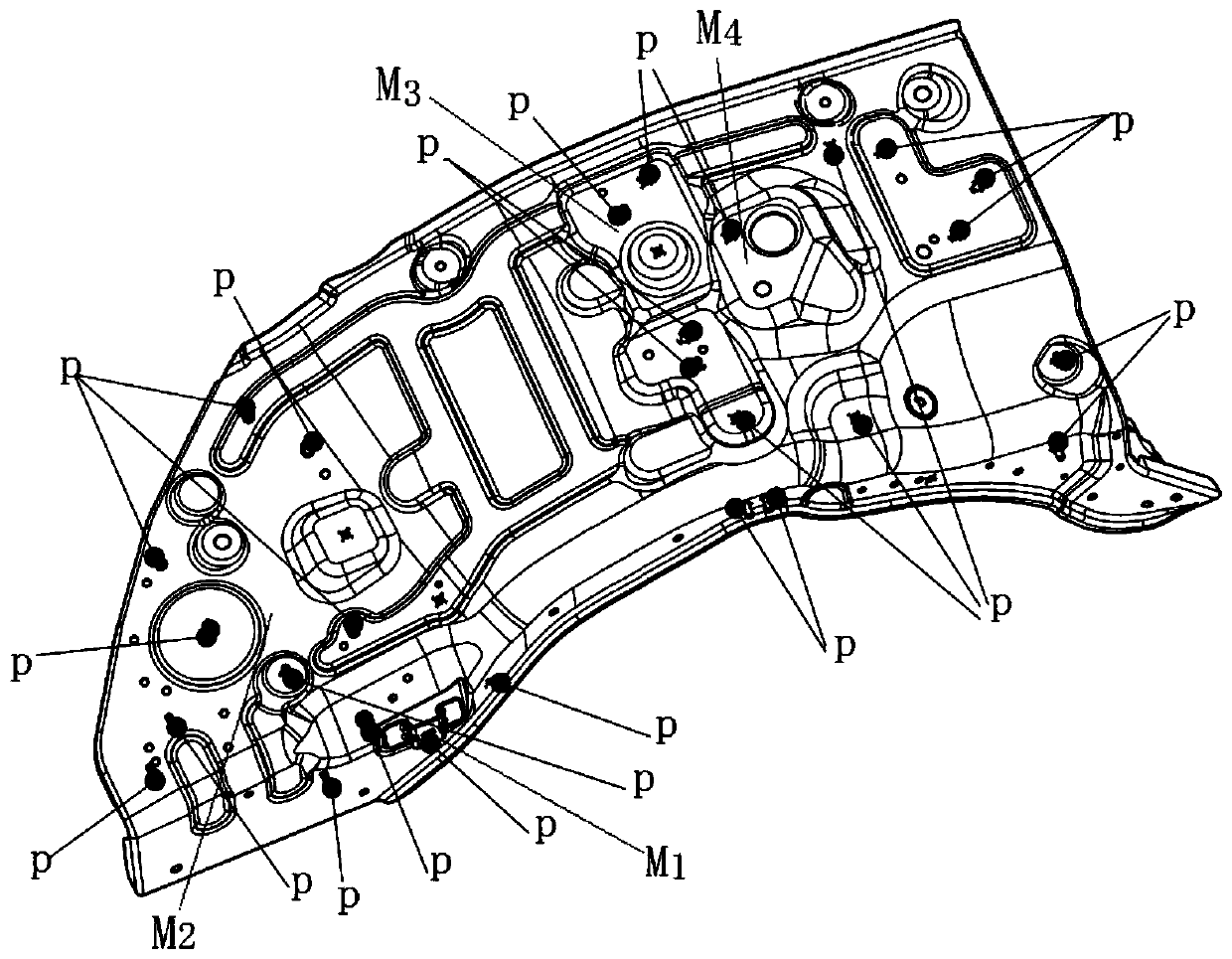

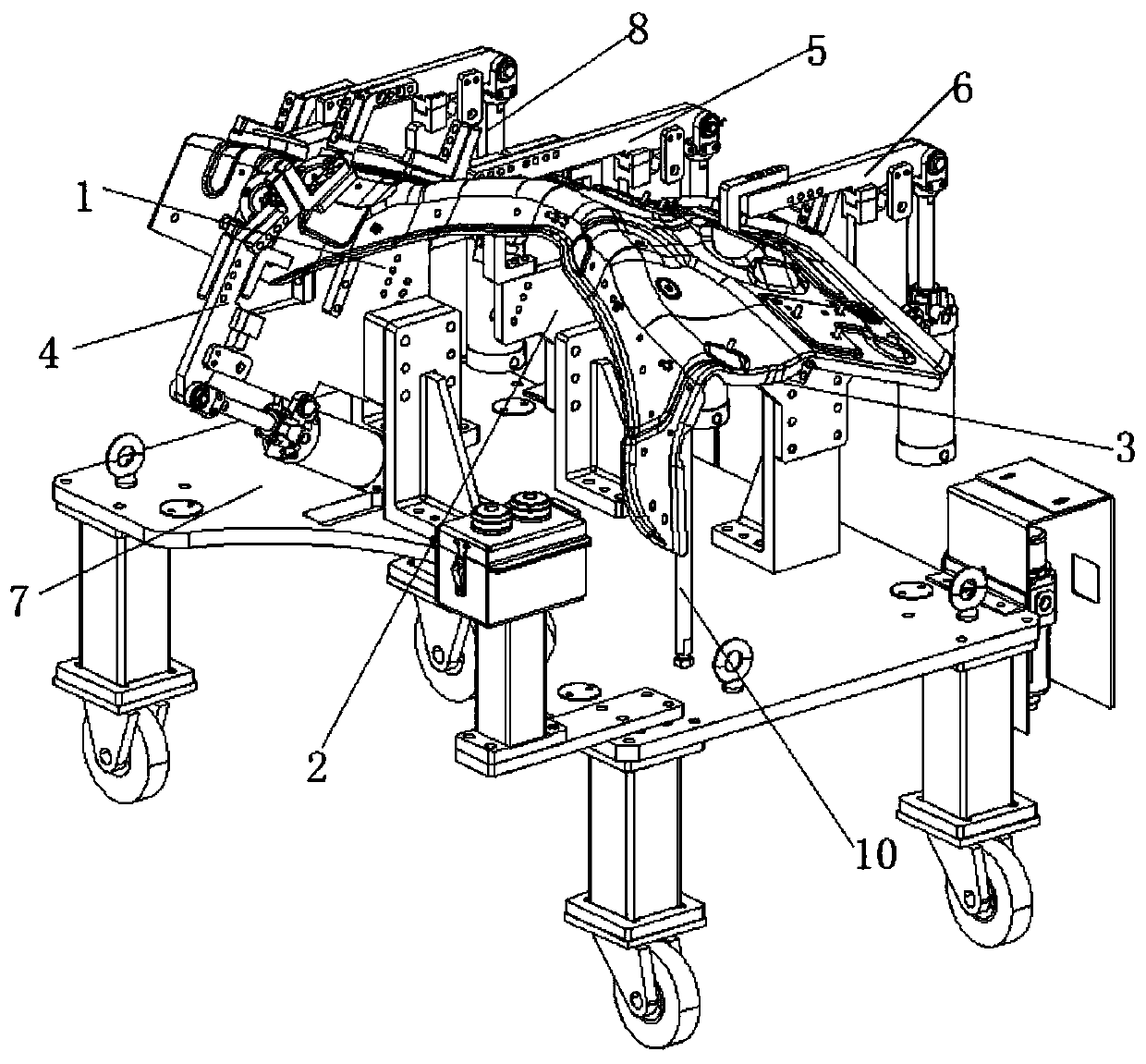

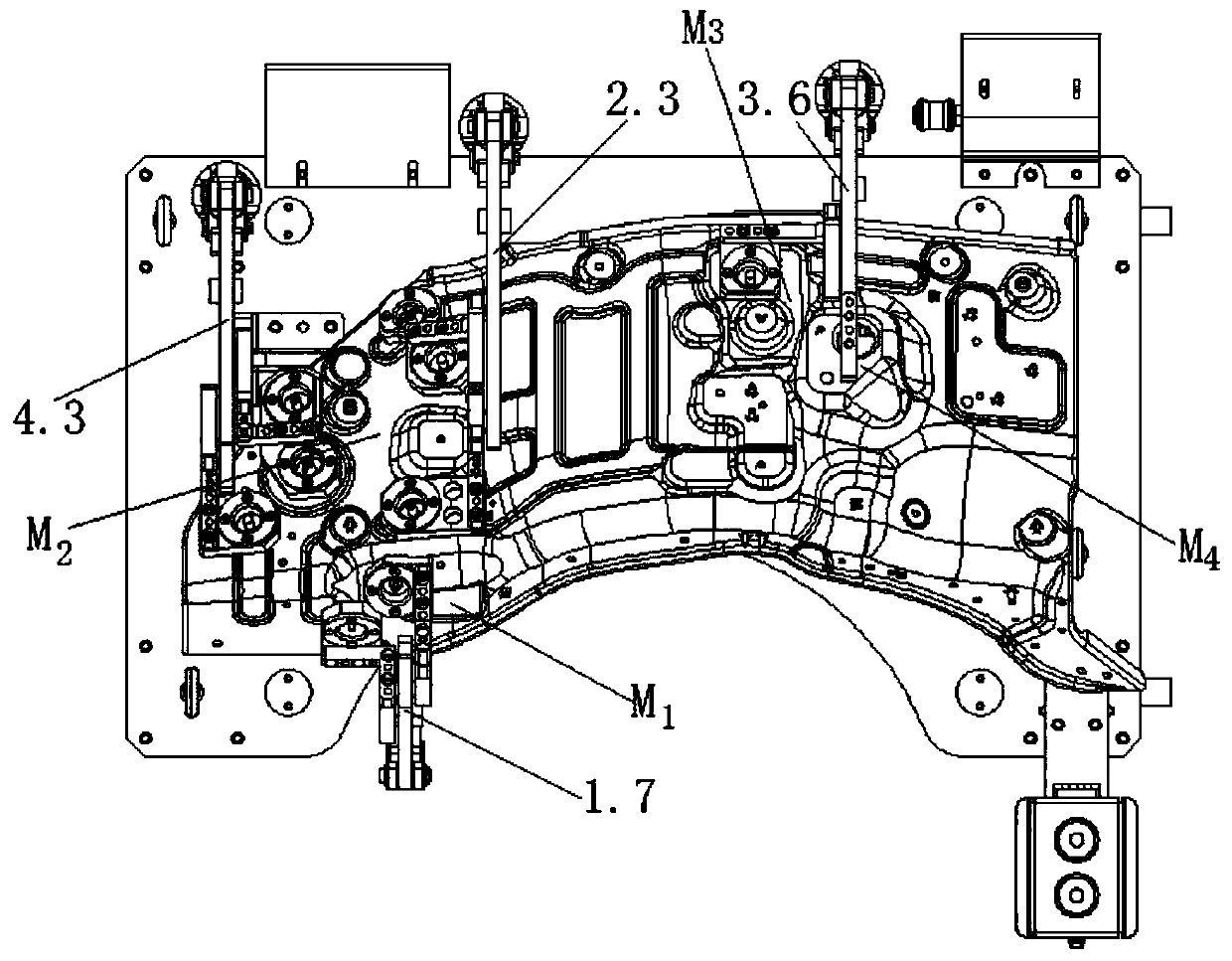

Automobile right front wheel cover screw-implanting cover plate assembly positioning and welding tool

ActiveCN110052759AEasy to installEasy accessWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention discloses an automobile right front wheel cover screw-implanting cover plate assembly positioning and welding tool which comprises a welding support platform and at least one group of supporting and clamping mechanisms arranged above the welding support platform along the length direction of a cover plate assembly. Each supporting and clamping mechanism comprises a fixed supporting mechanism and a movable clamping mechanism; the fixed supporting mechanisms support the cover plate assembly; the movable ends of the movable clamping mechanisms are located above the cover plate assembly; the movable ends of the movable clamping mechanisms of the multiple groups of supporting and clamping mechanisms clamp or are deviated from the cover plate assembly on the corresponding fixed supporting mechanisms; the fixed supporting mechanisms are supported on the inner side surfaces of multiple binding faces M of the cover plate assembly; and the movable ends of the movable clamping mechanisms correspondingly press and cover the outer side surfaces of the multiple binding faces M. Therefore, the cover plate assembly can be accurately positioned and clamped, and high-quality screw-implanting welding is ensured.

Owner:WUXI DAWN DIE & STAMPING

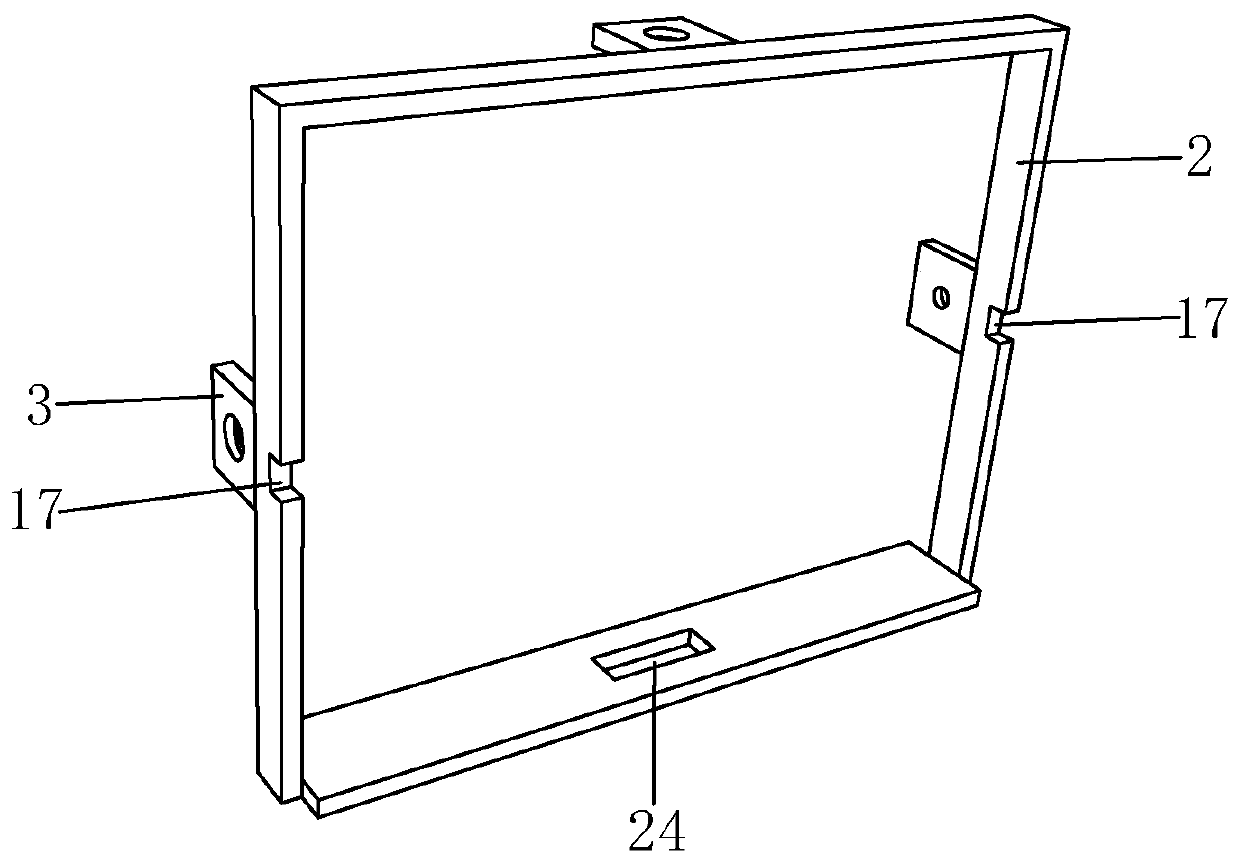

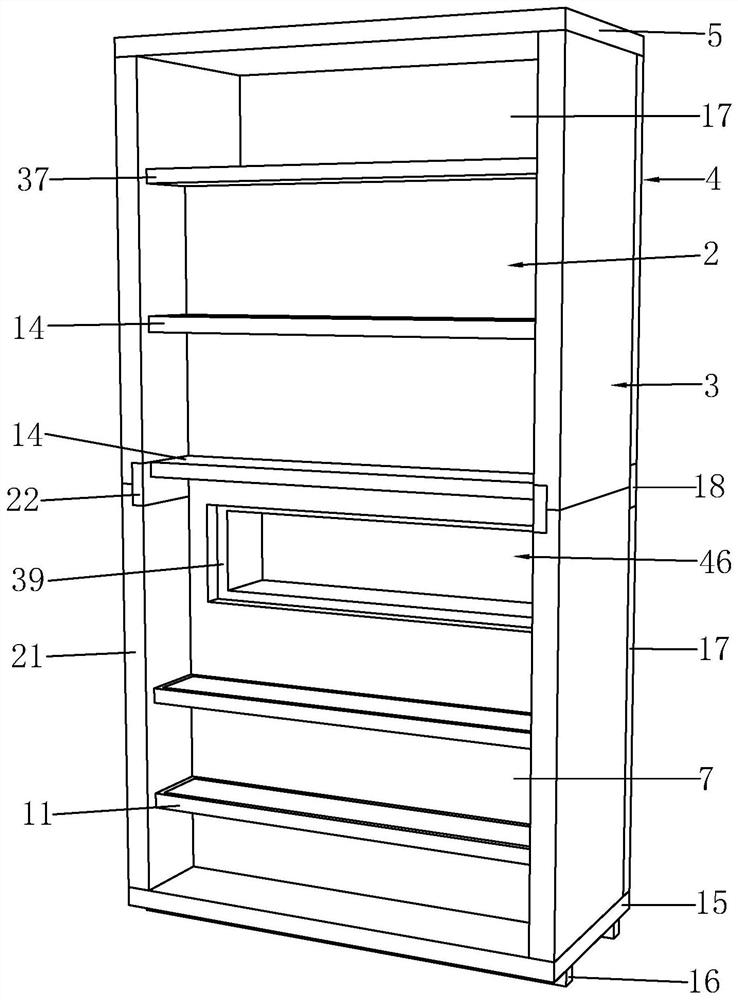

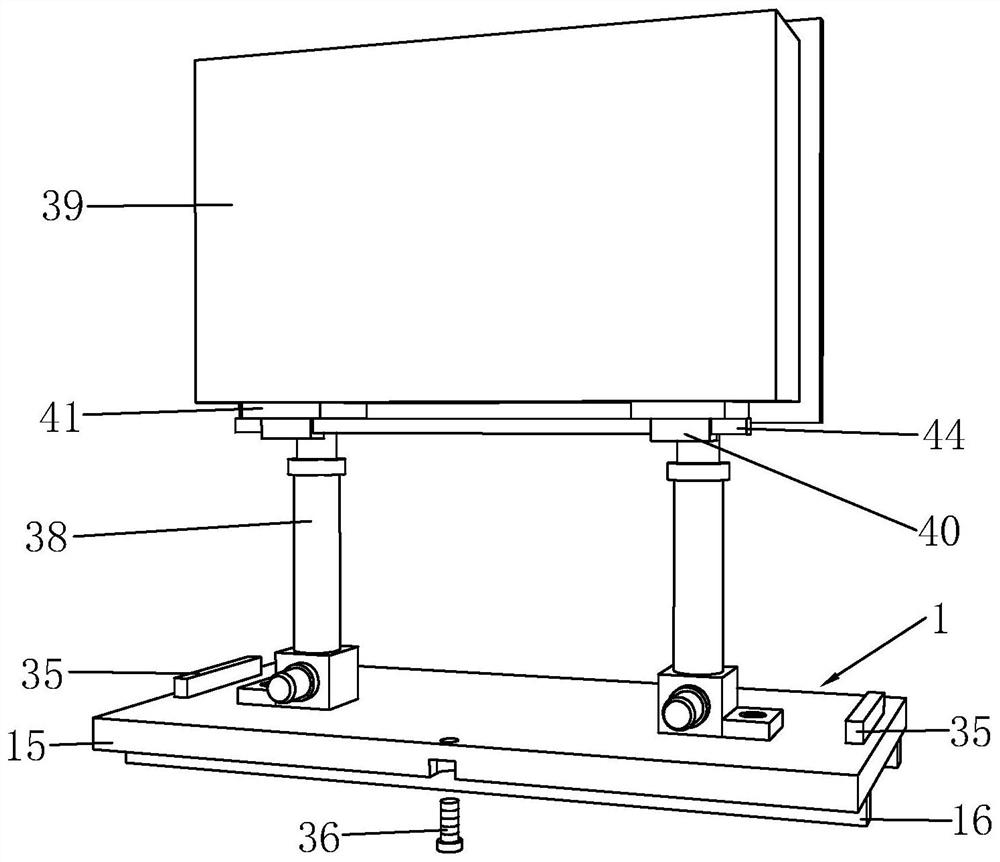

Lifting wardrobe and mounting method thereof

PendingCN112603057AFlexible assemblyReduce shipping costsWardrobesDismountable cabinetsStructural engineeringIndustrial engineering

Owner:浙江图森定制家居股份有限公司

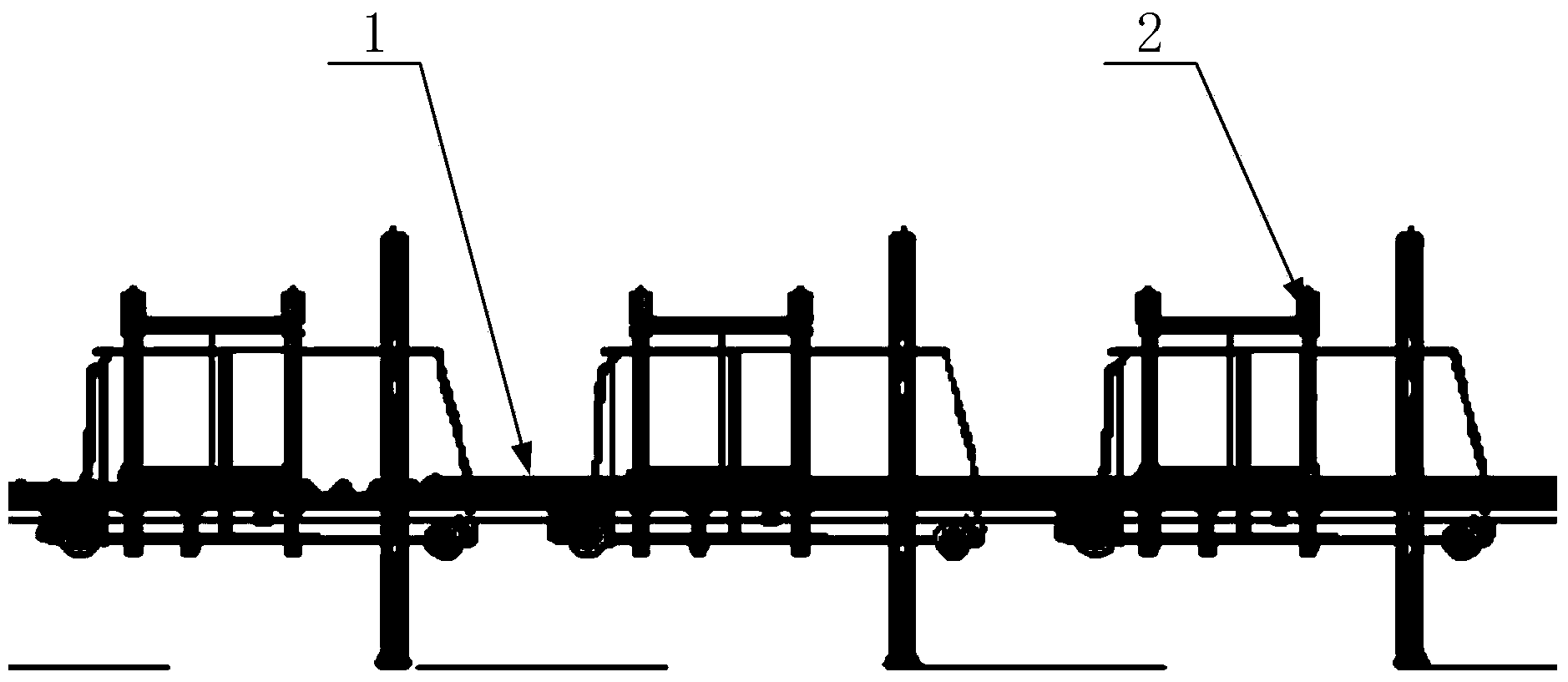

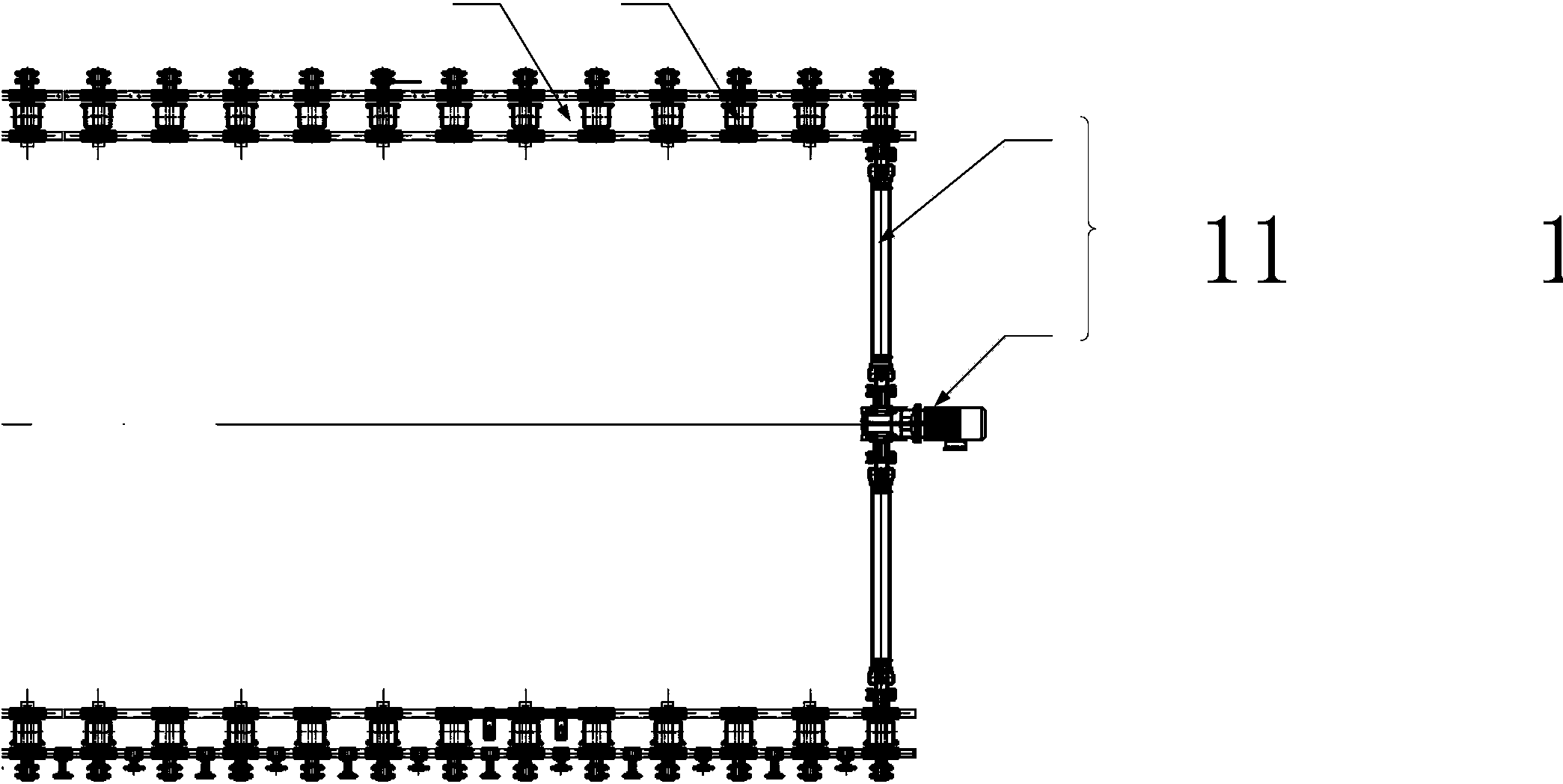

Air roller bed conveyor line

ActiveCN103754585AImprove carrying capacityStable deliveryMechanical conveyorsIndustrial engineeringWheel drive

The invention discloses an air roller bed conveyor line. The air roller bed conveyor line comprises fixed air roller beds and lifting devices arranged on the fixed air roller beds through skids in an erected mode, wherein the fixed air roller beds include two fixed roller beds which are parallel to each other, and rolling wheels driven by driving devices are arranged on the fixed roller beds. Each lifting device comprises an n-shaped frame, a bracket and the skids, wherein the bracket is arranged at the bottom of the n-shaped frame, and the skids are arranged on the two sides of the n-shaped frame. The air roller bed conveyor line provides insufficient operation space for assembly operators at the bottom of a passenger car. Meanwhile, the lifting devices loaded with the passenger car through the skids are directly arranged on the fixed air roller beds in the erected mode, and a lifting structure is adopted to replace a suspension type structure, so that carrying capacity of the air roller bed conveyor line is promoted; the rolling wheels are adopted to drive the skids to drive the lifting devices to move, so that the passenger car is conveyed more stably, and the potential safety hazards caused by shaking of movable hinges are eliminated; consequently, the problem that an existing conveyor line can not assist in completing bottom assembling of the passenger car is solved.

Owner:LIUZHOU WULING MOTORS +1

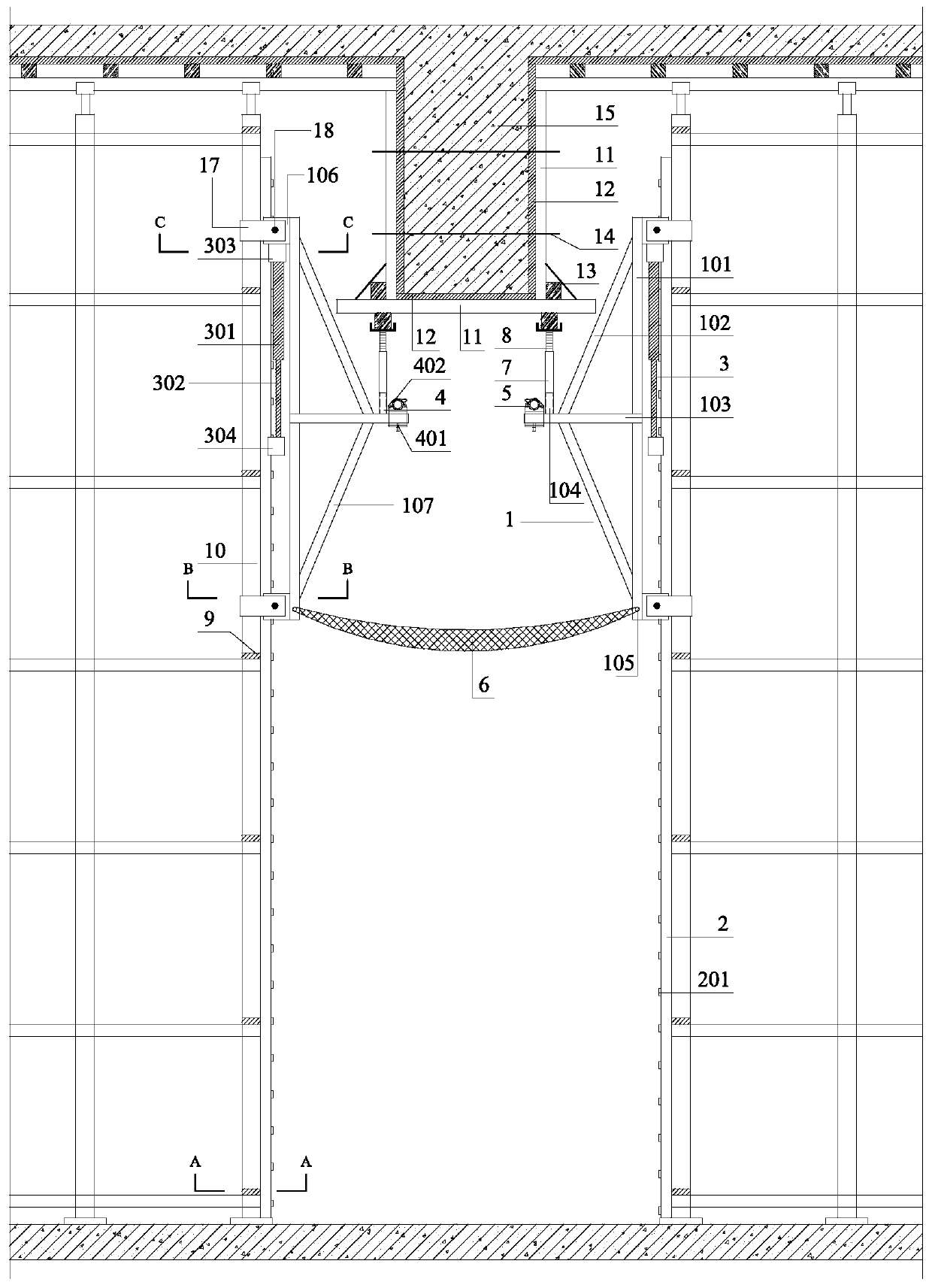

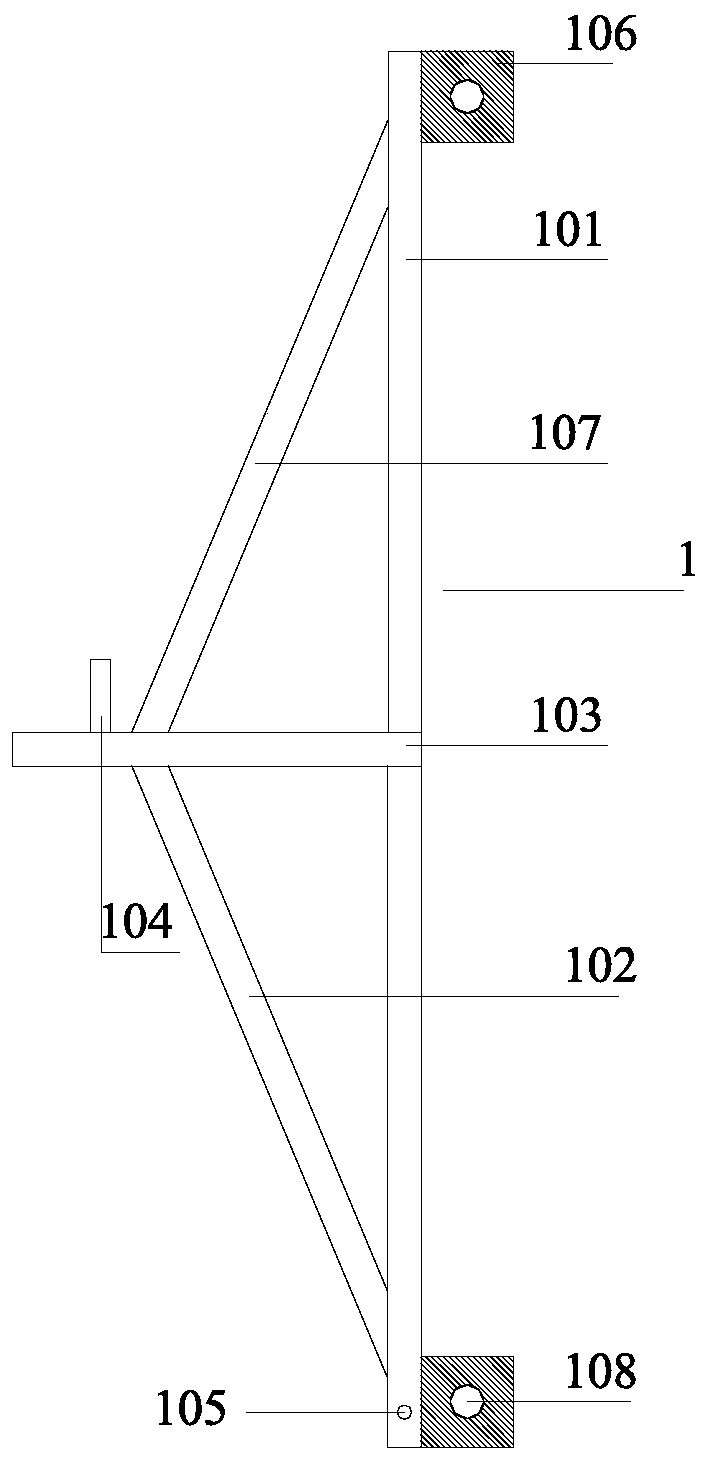

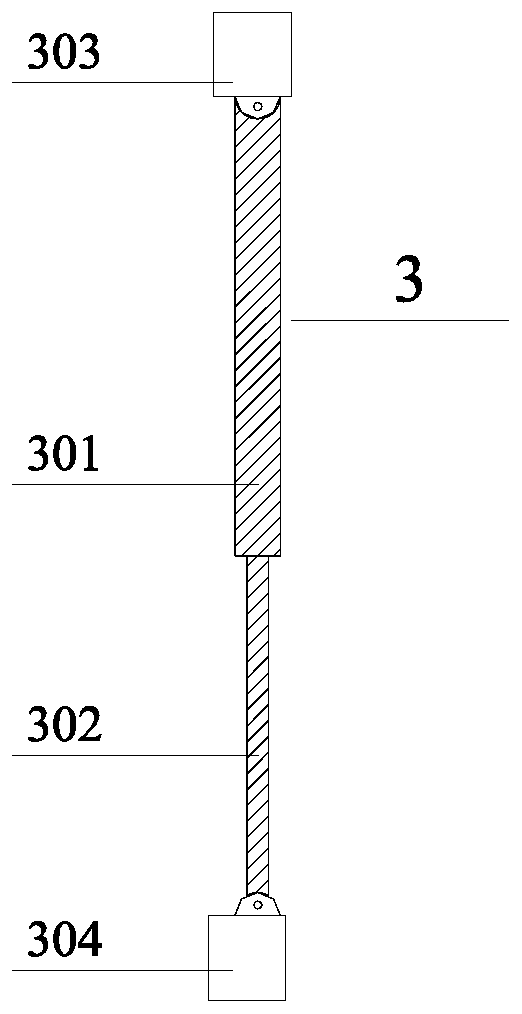

Construction method of tall formwork symmetrical suspension climbing triangular truss support system

InactiveCN109797967AReduce dosageSet up fastAuxillary members of forms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention relates to a construction method of a tall formwork symmetrical suspension climbing triangular truss support system. The main construction steps include vertical slideway installation, triangular truss assembly, triangular truss installation, triangular truss climbing, and beam formwork and support installation. An under beam scaffold in the traditional formwork support system is substituted by a tripod which is symmetrically suspended and combined with pulling and bracing, a plurality of tripods are pulled and combined to form a triangular truss, and a hydraulic climber is further applied to realize an automatic lifting of the triangular truss. The operation space beside and under the beam is large, the construction safety is high, the consumption of steel pipes and fasteners is less, the operation is convenient and the recycling rate of components is high, thereby overcoming the problems such as large supporting and disassembling workload, small operation space, long construction period and unsafe security in the construction of the traditional formwork support system, and the economic and technical benefit is remarkable.

Owner:杭州昂创科技有限公司

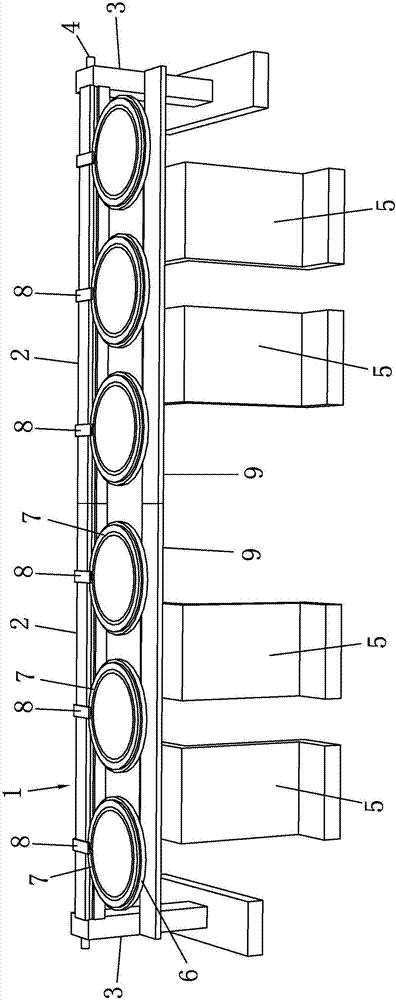

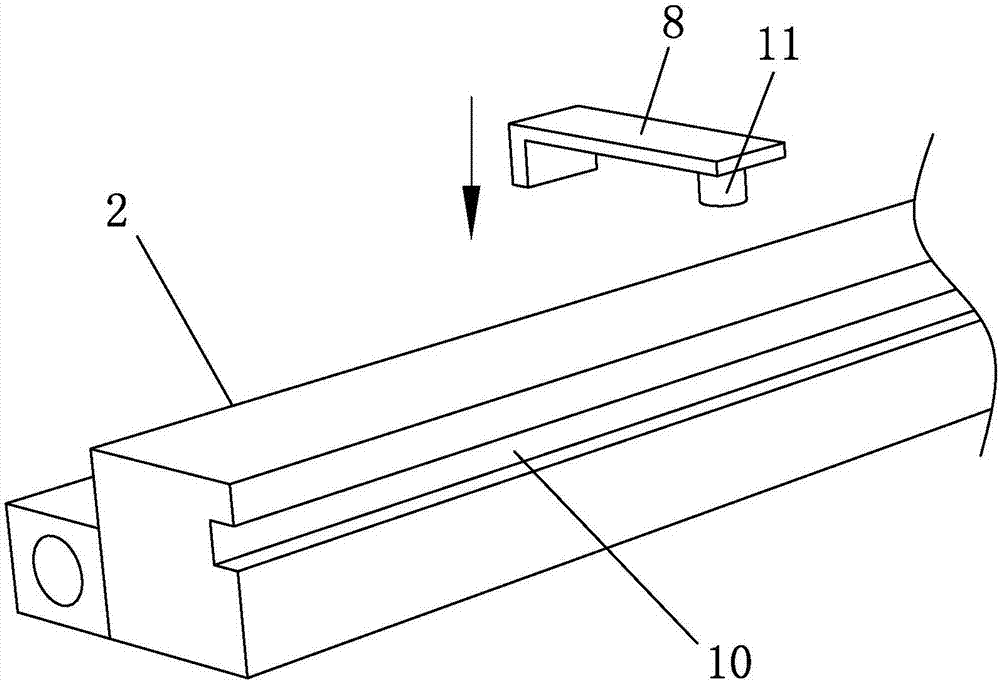

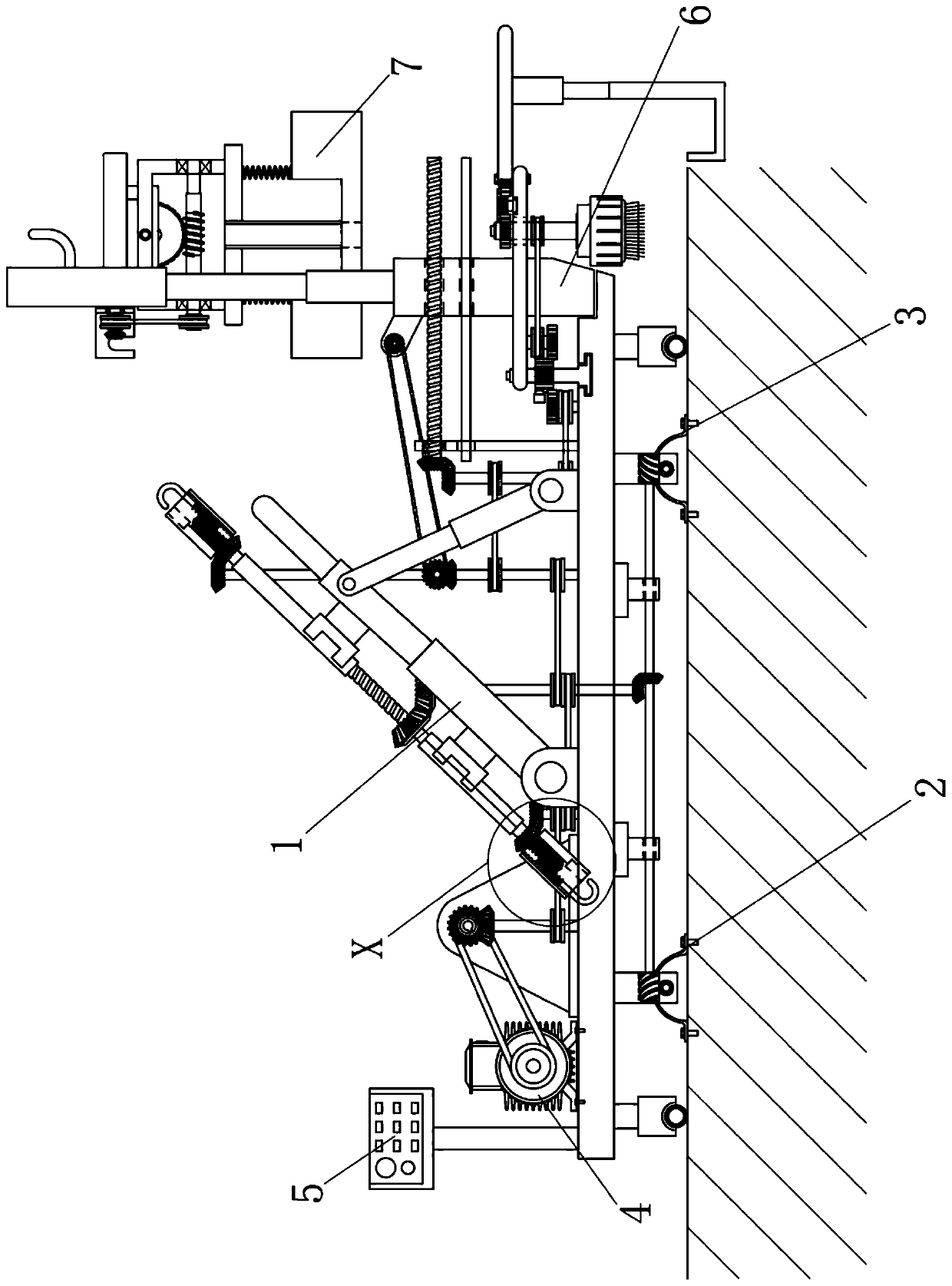

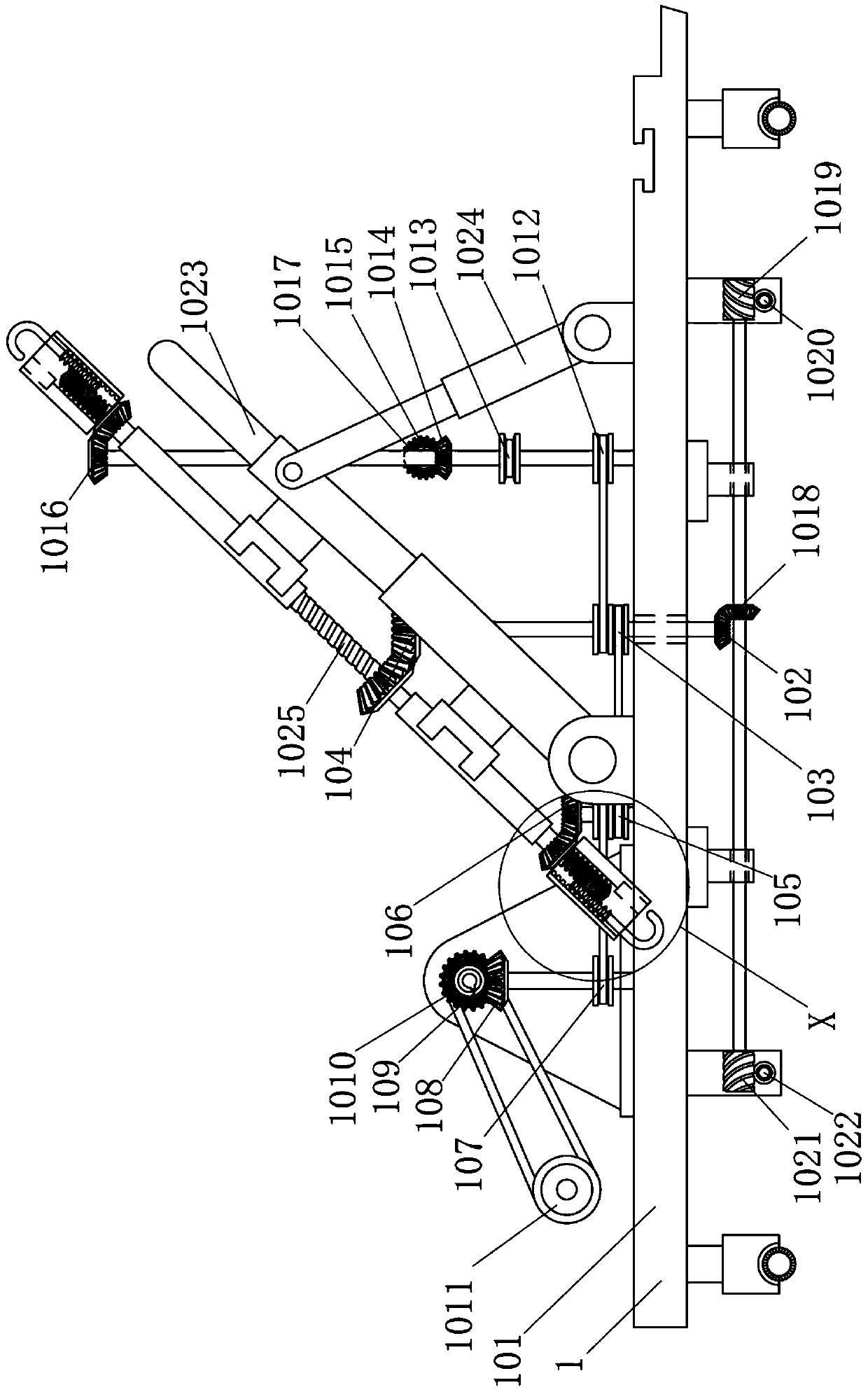

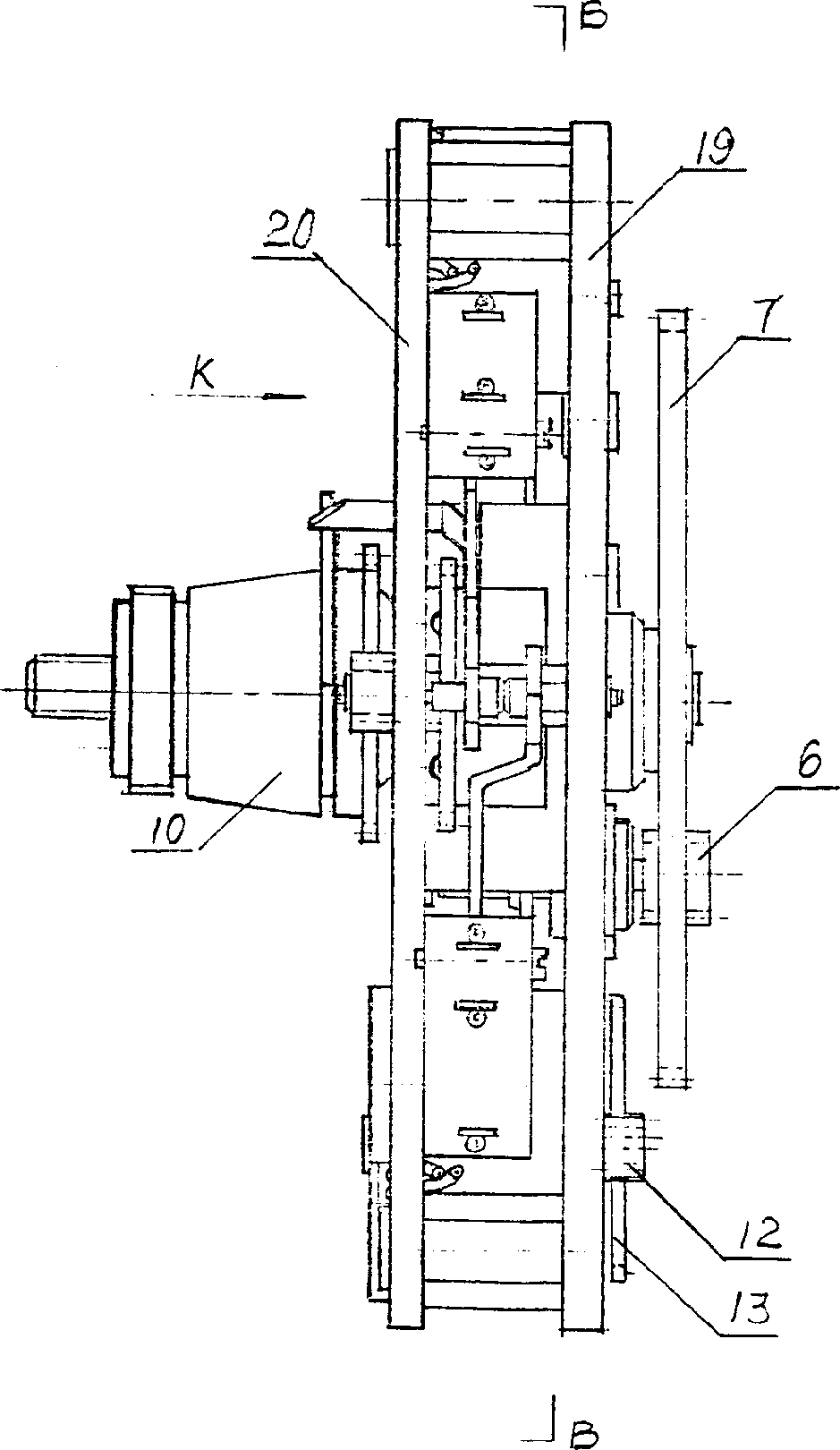

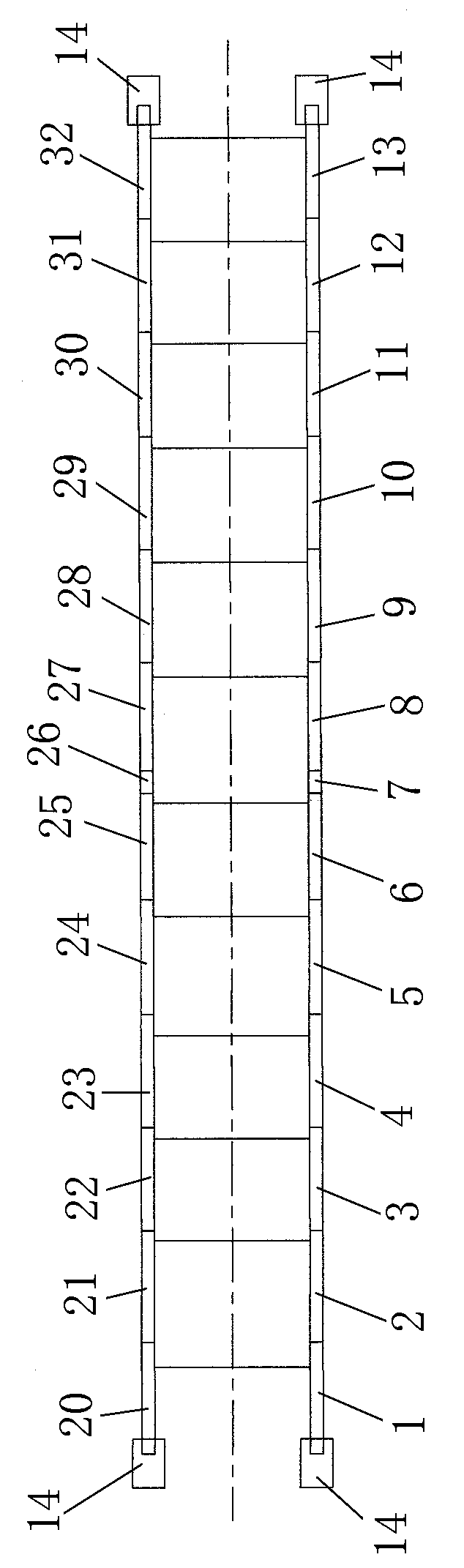

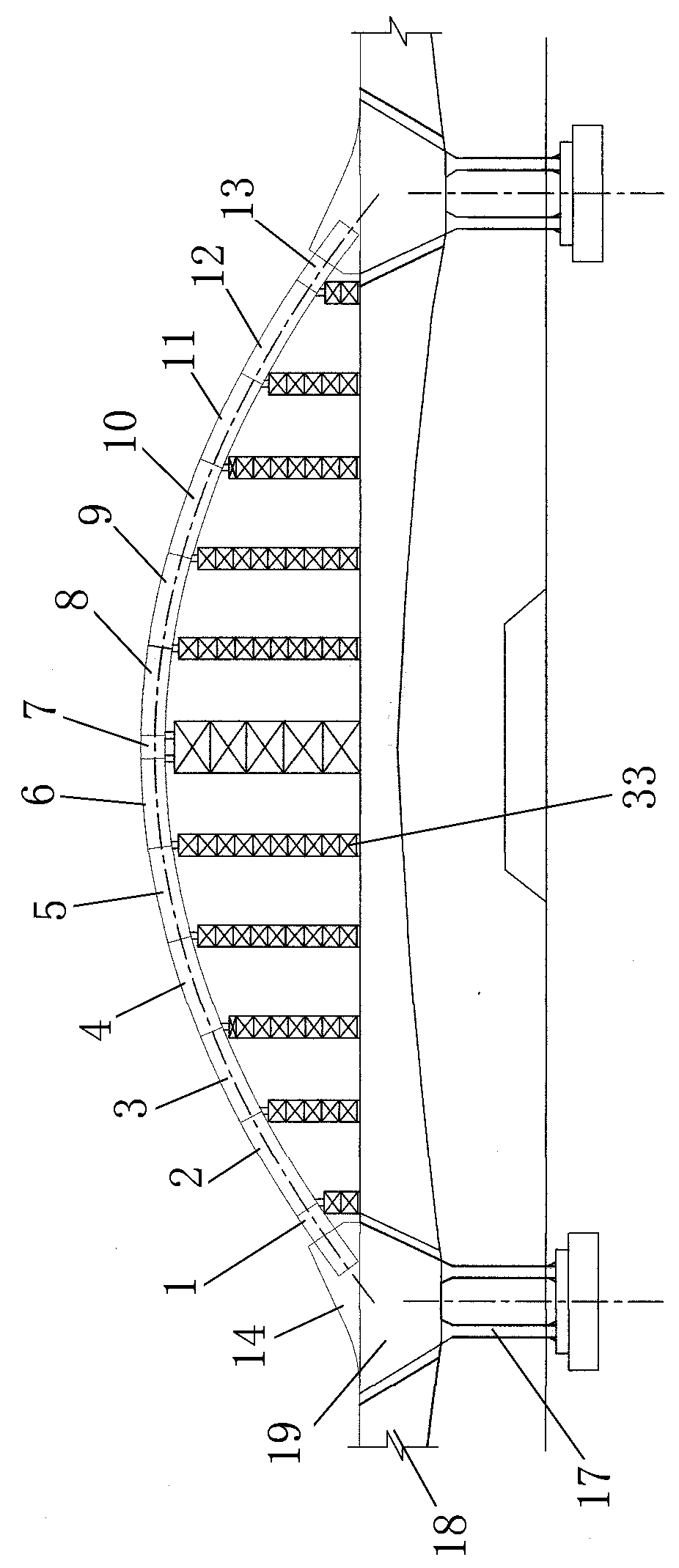

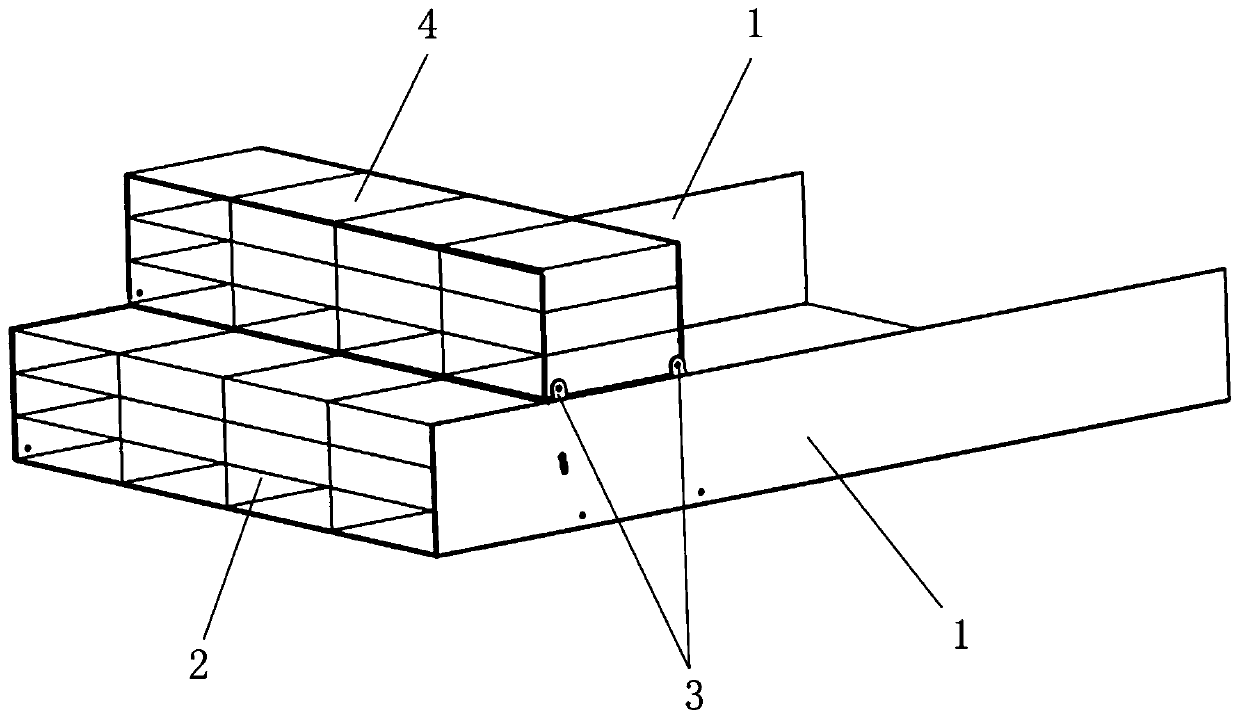

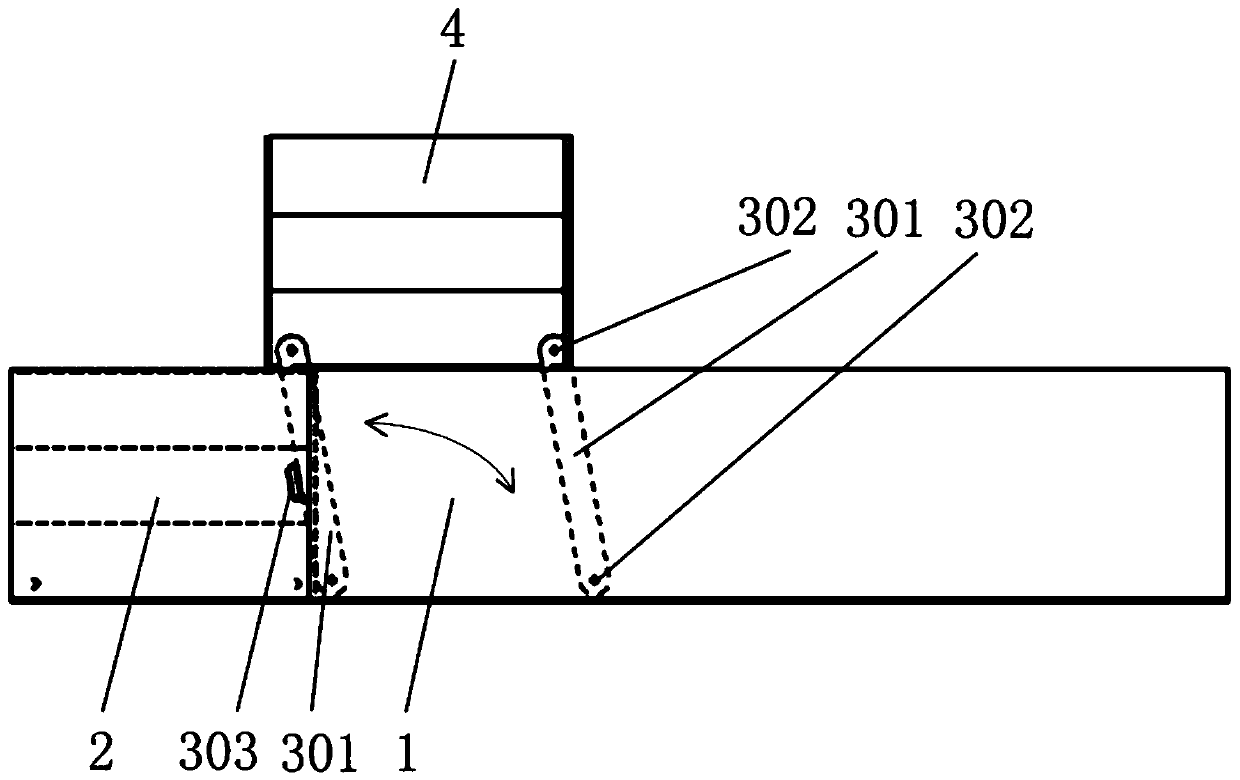

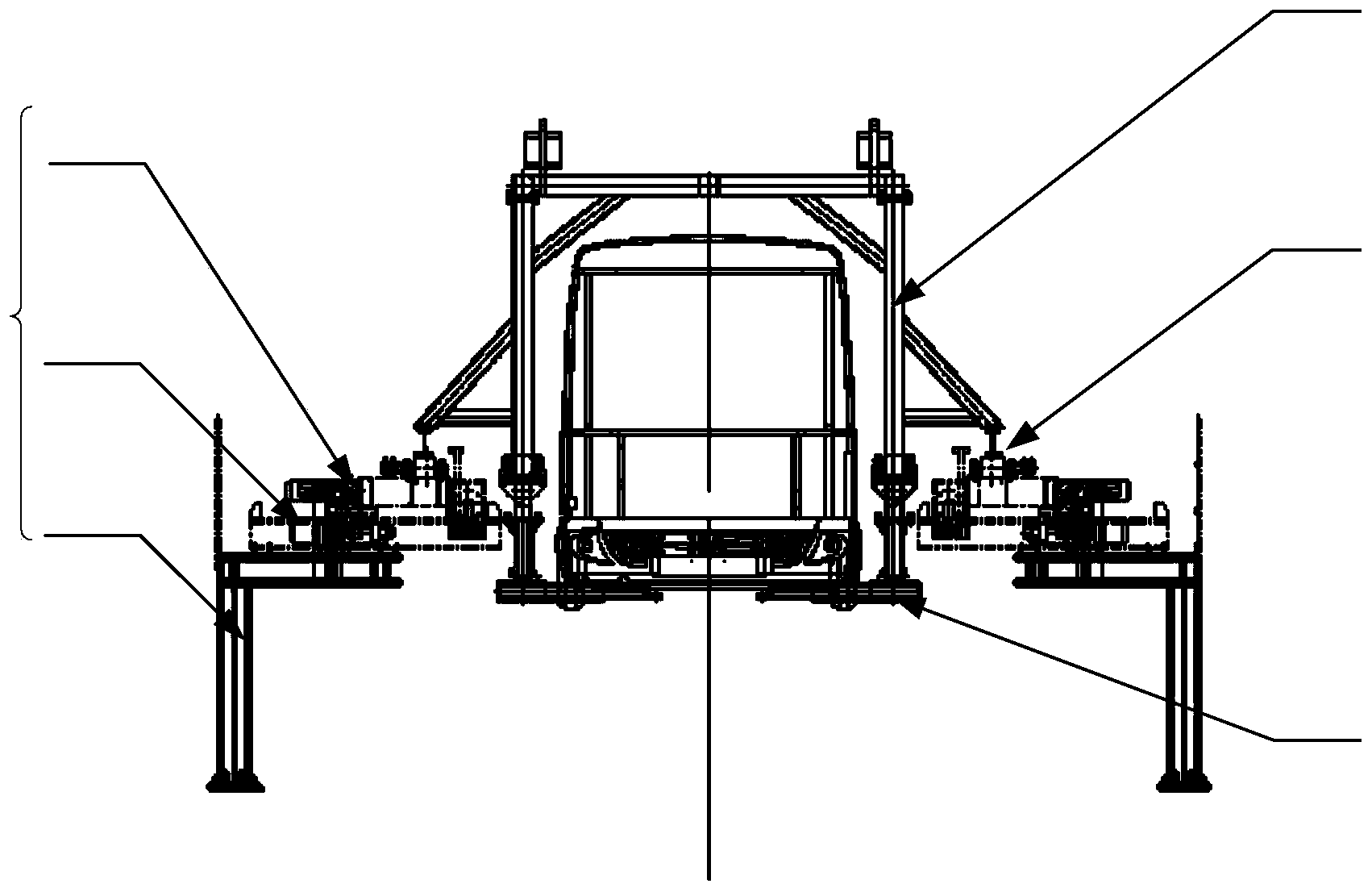

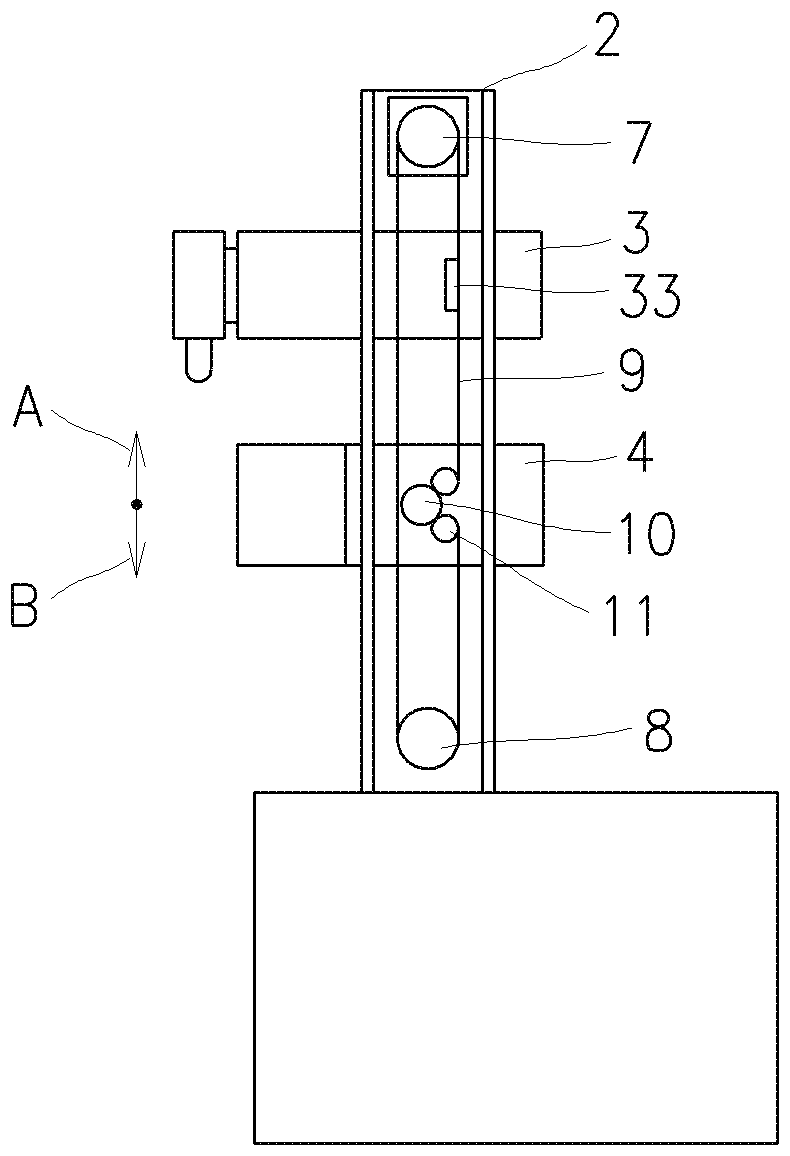

Automatic service device for an annular spinning machine, annular spinning machine, and a method for controlling groups of handling devices

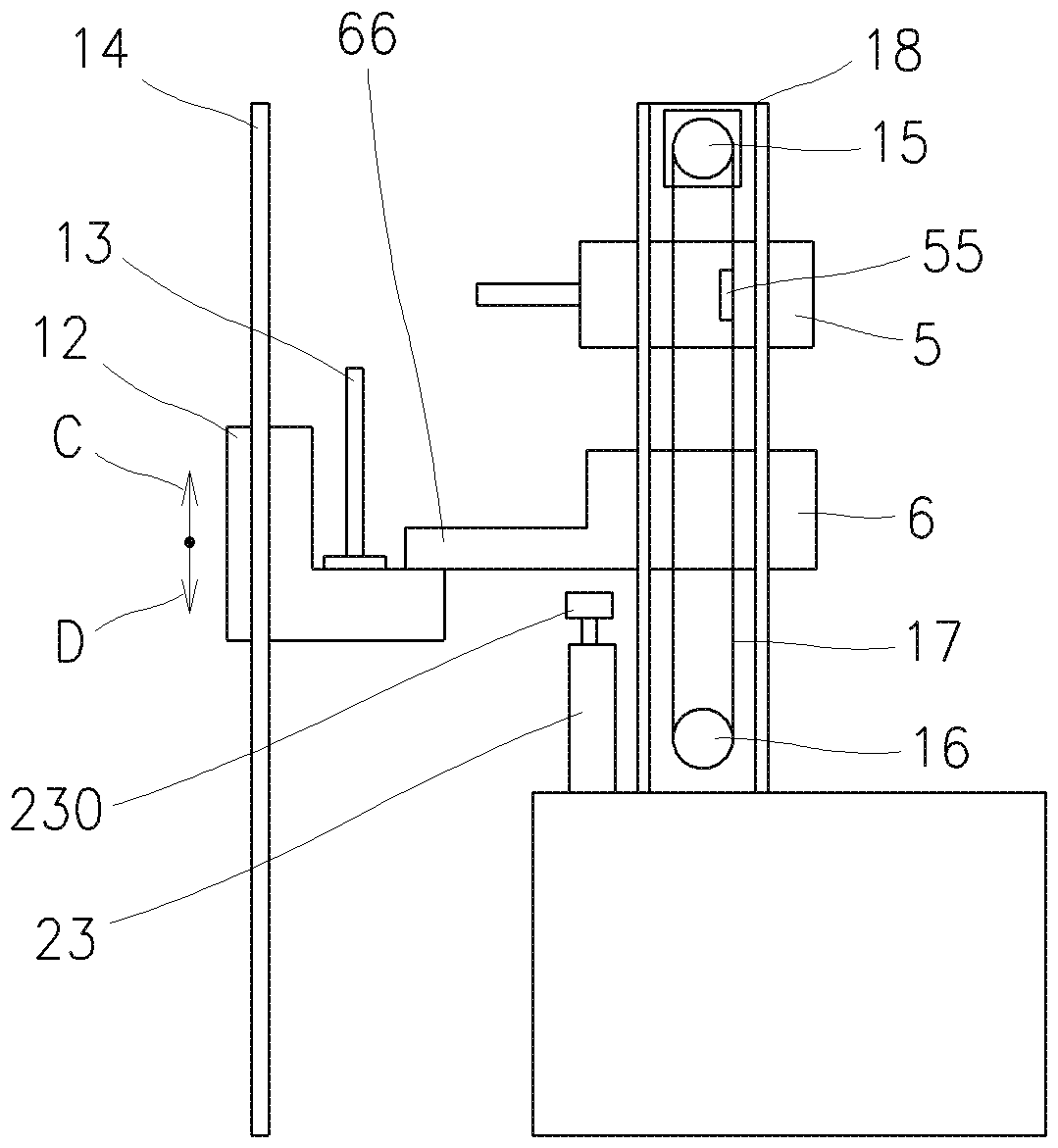

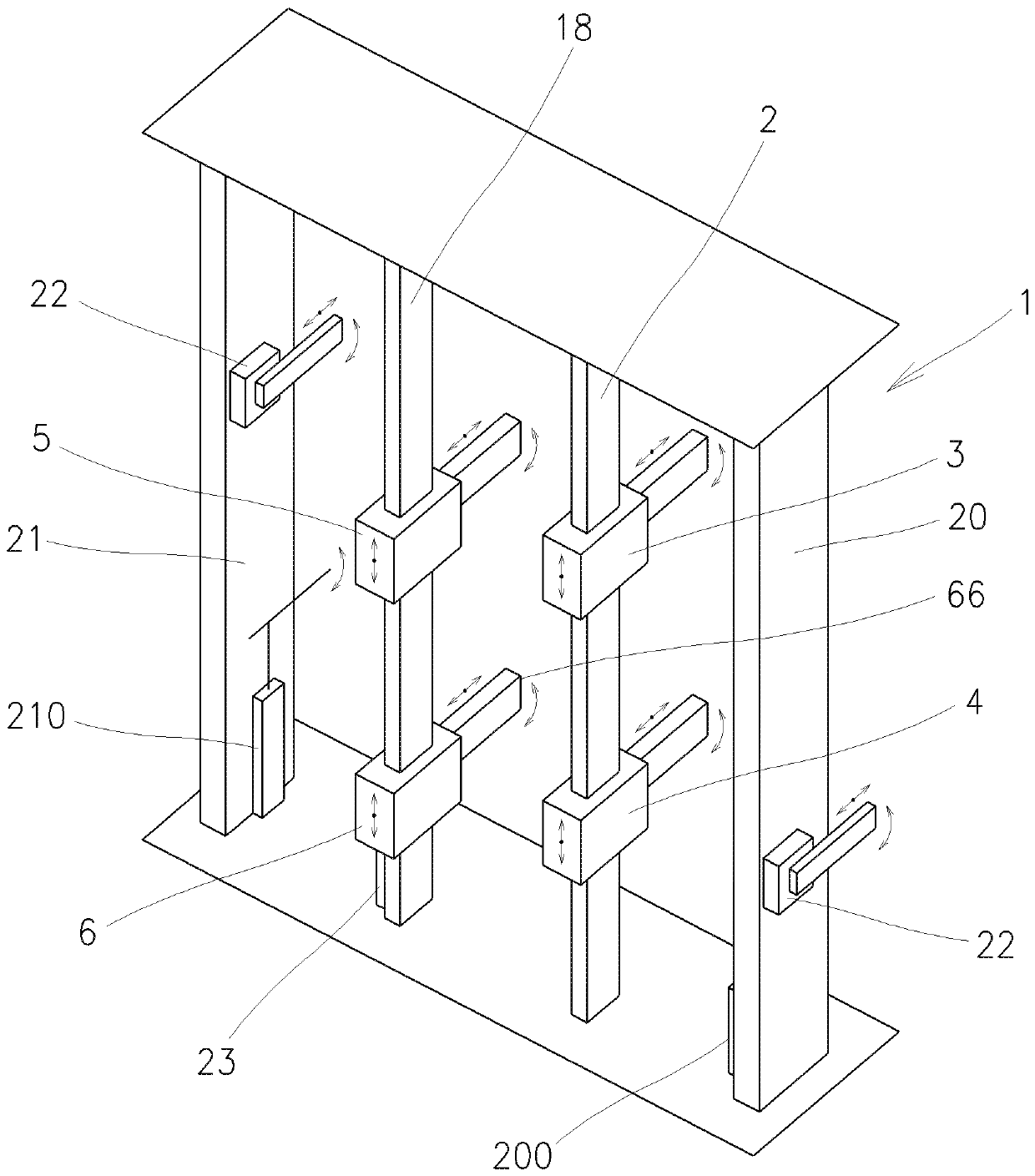

ActiveCN110067055AReduce manufacturing costShorten the timePiercing arrangementsContinuous wound-up machinesEngineeringService robot

The invention relates to a service robot of a ring spinning machine, arranged displaceably along a row of spinning stations with an option of stopping at a selected spinning station requiring a service operation, whereby the service robot is provided with groups of handling means (3, 4, 5, 6) coupled to drives. The service robot (1) is arranged as a vertical frame, which is provided with at leasttwo vertical linear guides (2, 18, 20, 21), whereby at least one of them is associated with at least two movable groups (3, 4, 5, 6) of handling means to perform service operations at the spinning station. The invention also relates to a ring spinning machine with a service robot, which is arranged displaceably along a row of spinning stations with an option to stop at a selected spinning stationrequiring a service operation. In addition, the invention relates to a method for controlling a service robot or its spinning means.

Owner:MASCHINENFABRIK RIETER AG

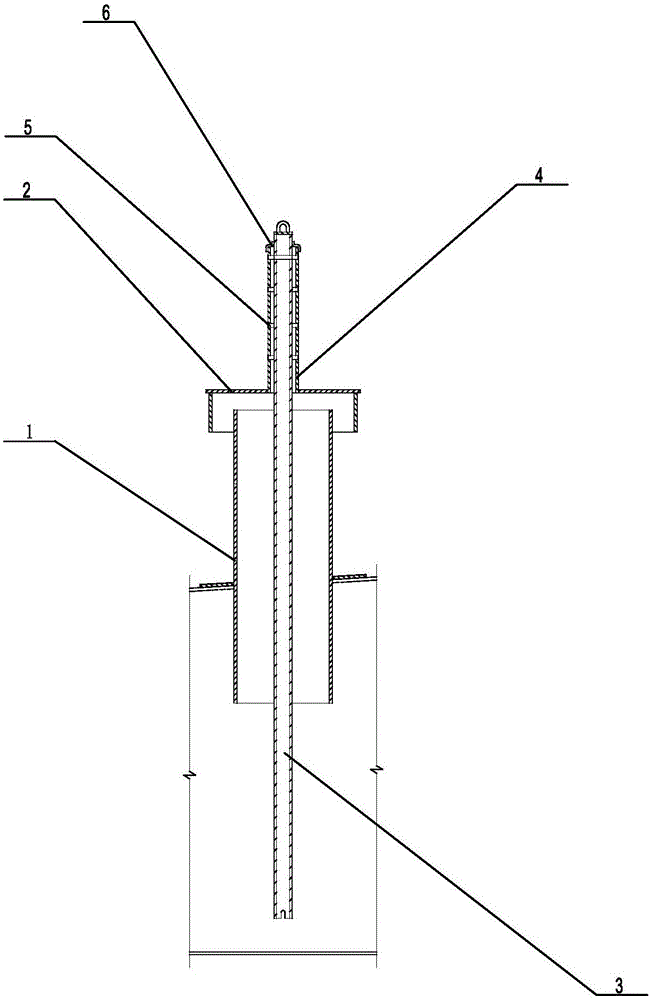

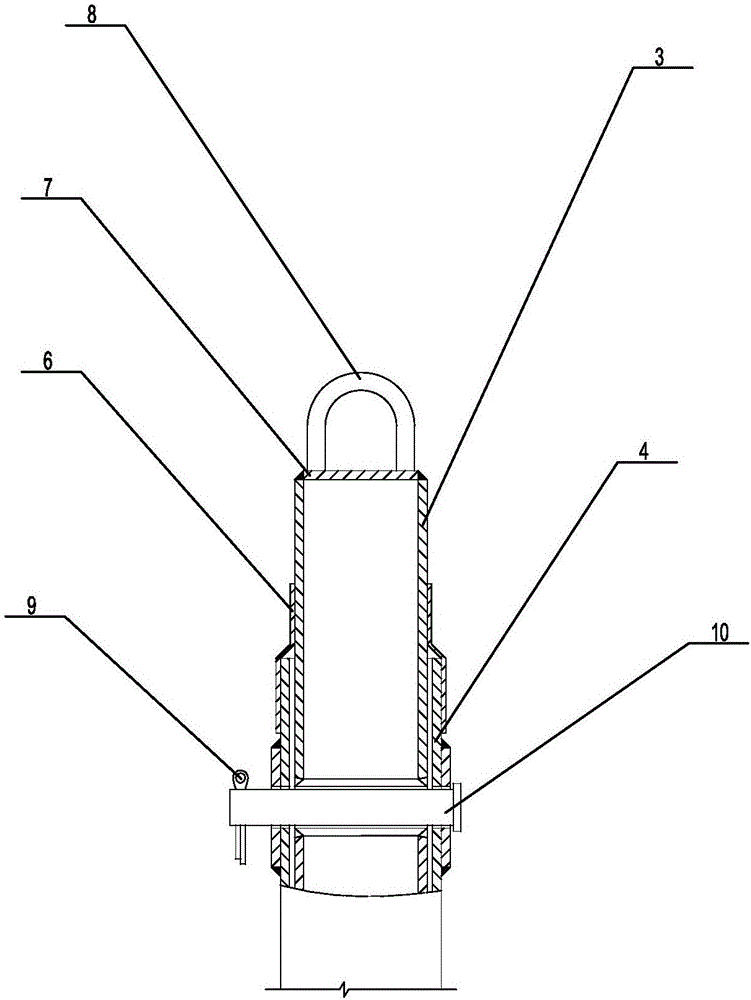

Height adjustable automatic vent valve

ActiveCN106809541AReduce evaporation lossAvoid wastingLarge containersEvaporationMechanical engineering

The invention discloses a height adjustable automatic vent valve. The height adjustable automatic vent valve comprises a valve body, a valve deck on the top of the valve body, and a valve rod sleeved inside the valve body. A casing pipe is disposed in the upper portion of the valve deck. A plurality of location holes is disposed in the casing pipe along the vertical direction. The valve rodthrough the back of the valve deckextends to the outside of the casing pipe. The valve rod is connected with the upper end of the casing pipe in sealing mode through a seal cartridge. Apin hole capable of matched connecting with all the location holes is disposed on the valve rod. Asleeve with location holes is disposed in the automatic vent valve. By adjusting the height of the valve rod to change the distance between the automatic vent valve and the baseplate of the storage tank, on one hand the loss of oils evaporation is reduced effectively and on the other hand the check and maintenance is not hampered. The height adjustable automatic vent valve with good practicability is worth to popularize widely.

Owner:QINZHOU UNIV

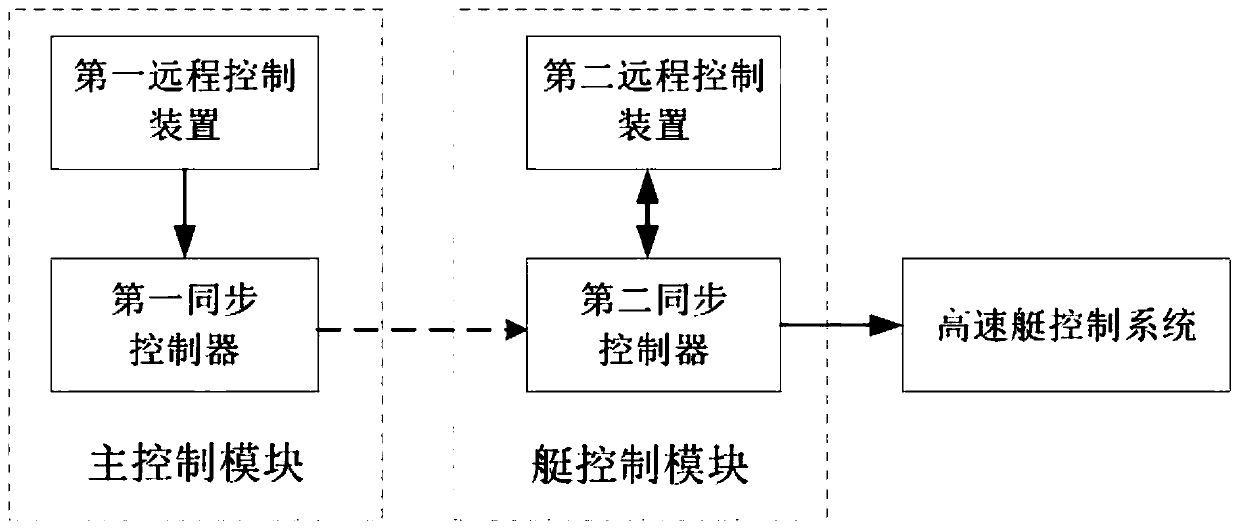

High-speed boat multi-place remote control method and system based on follow-up synchronization

PendingCN111522272AAchieve regulationEasy to observeProgramme controlComputer controlDriver/operatorRemote control

The invention relates to the technical field of remote control, and particularly discloses a high-speed boat multi-place remote control method and system based on follow-up synchronization, and the method comprises the steps: S1, collecting a set rotation angle theta s of a first boat speed assembly and a set rotation angle theta s of a first heading assembly; S2, converting the set rotation angleinto a set ship speed vs, and converting the set rotation angle theta s into a set heading angle omega s; S3, sending the set ship speed vs, the set heading angle omega s, the set rotation angle andthe set rotation angle theta s to a ship control module; S4, detecting the actual rotating angle of the second ship speed assembly and the actual rotating angle theta r of the second heading assembly;S5, controlling the second ship speed assembly to rotate, making the set rotating angle to be equal to the actual rotating angle S6, controlling the second heading assembly to rotate, and making theset rotating angle theta s to be equal to the actual rotating angle theta r. By adopting the technical scheme, a local driver can conveniently observe a remote operation result.

Owner:宁波扇贝科技有限公司

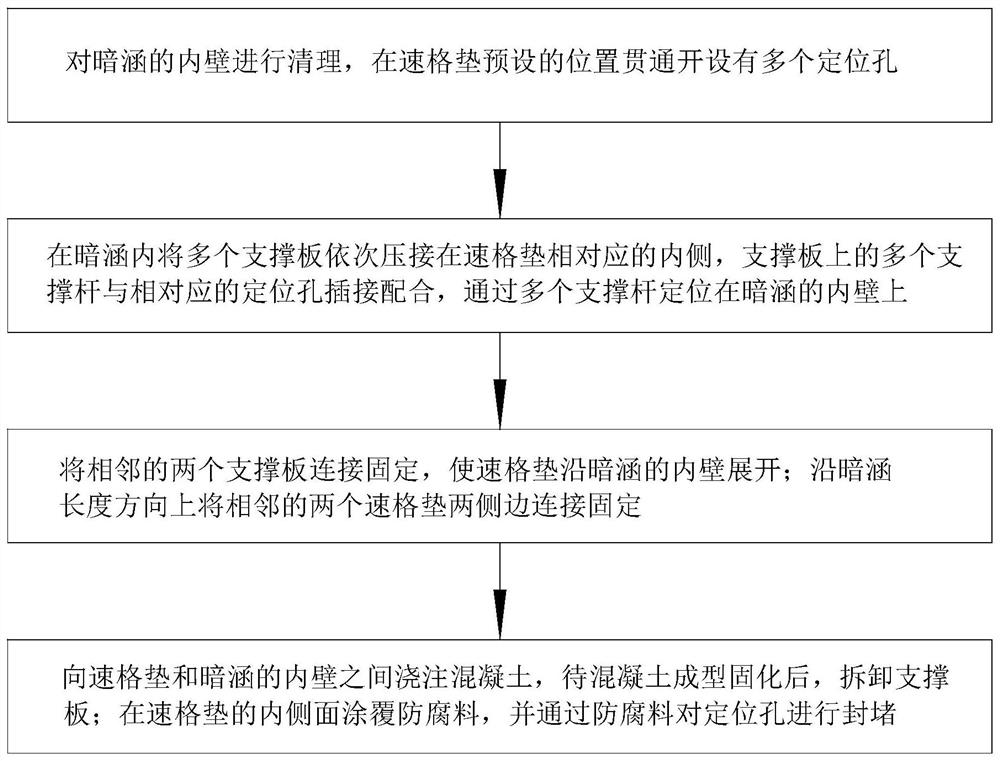

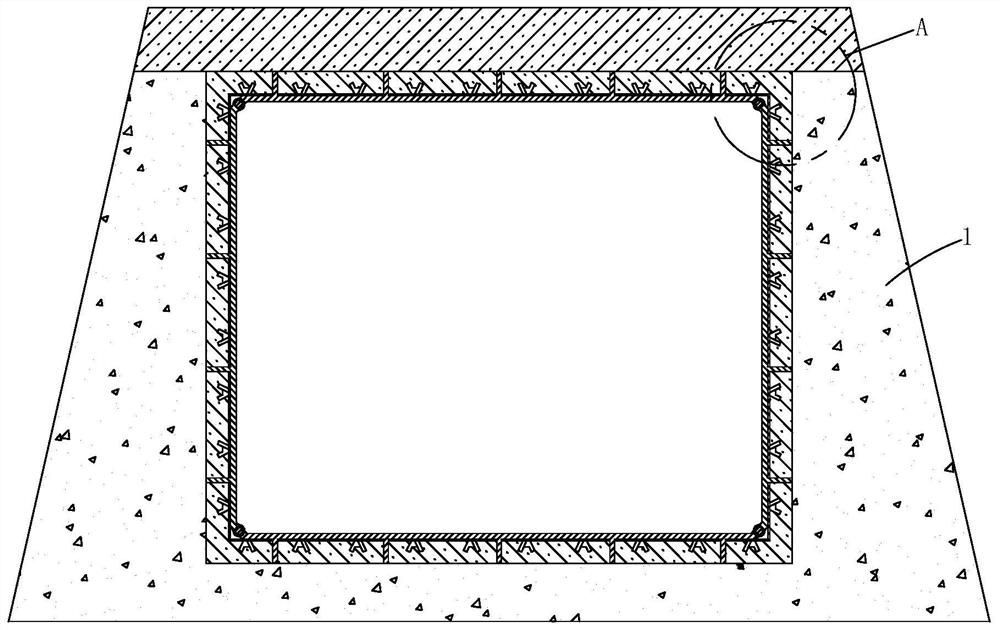

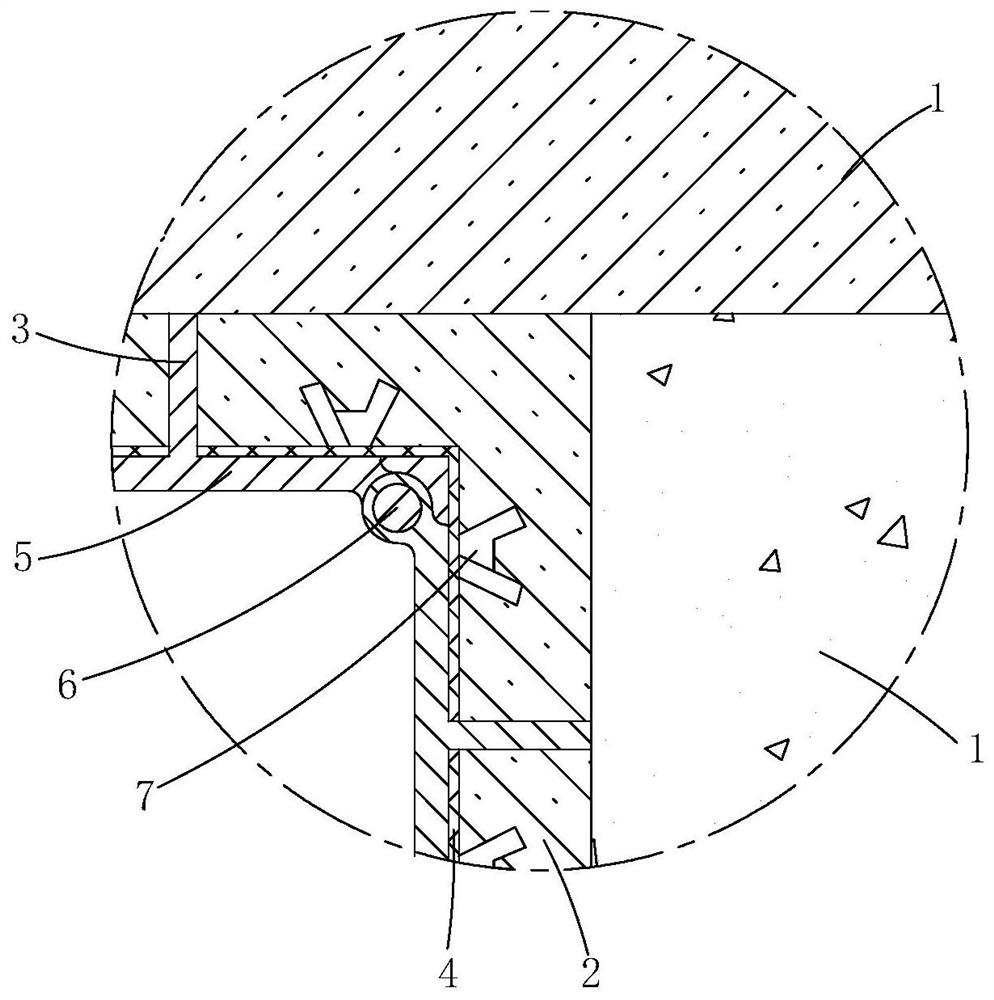

Large-section concealed culvert repairing method

PendingCN112112086ASufficient operating spaceAvoid stampedeGround-workProtective foundationArchitectural engineeringCulvert

The invention provides a large-section concealed culvert repairing method, and belongs to the technical field of concealed culvert repairing. The large-section concealed culvert repairing method comprises the following steps that the inner wall of a concealed culvert is cleaned, and a plurality of positioning holes are formed in the preset positions of each anchored plastic sheet in a penetratingway; a plurality of supporting plates are sequentially connected with the corresponding inner sides of the anchored plastic sheets in a pressed mode in the concealed culvert, a plurality of supportingrods on the supporting plates are matched with the corresponding positioning holes in an inserted mode, and the plurality of supporting rods abut against the inner wall of the concealed culvert; twoadjacent supporting plates are connected and fixed, so that the corresponding anchored plastic sheet is unfolded along the inner wall of the concealed culvert; the two side edges of every two adjacentanchored plastic sheets are connected and fixed in the length direction of the concealed culvert; concrete is poured between the anchored plastic sheets and the inner wall of the concealed culvert, and after the concrete is formed and solidified, the supporting plates are disassembled; and the inner side surfaces of the anchored plastic sheets are coated with anti-corrosive material, and the positioning holes are plugged through the anti-corrosive material. According to the large-section concealed culvert repairing method, the formed supporting platform can provide sufficient operation space,and the whole construction efficiency is improved.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

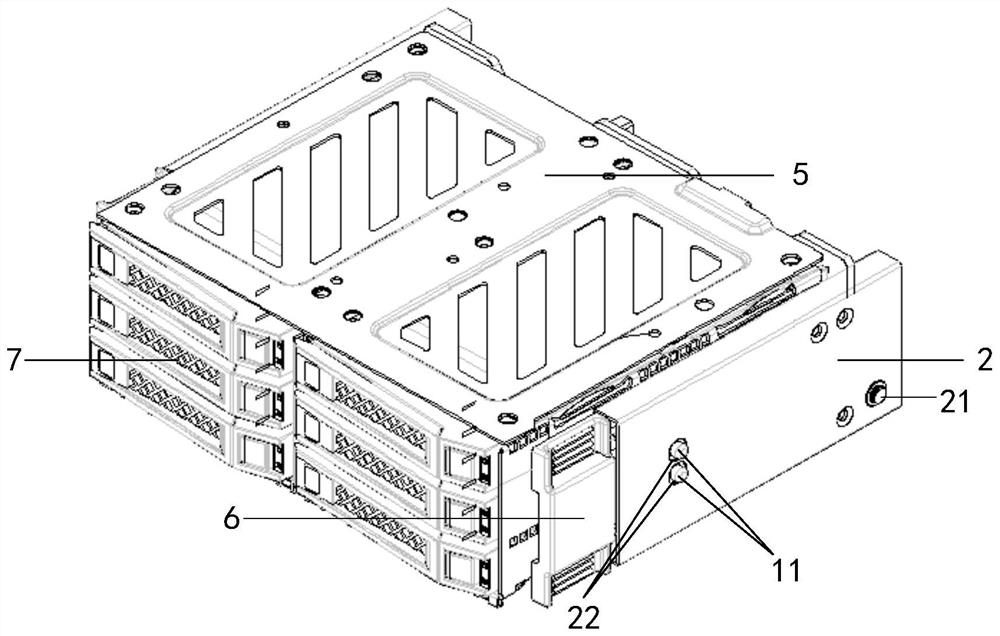

Hard disk rack device and electronic equipment

ActiveCN112181071ASufficient operating spaceShorten working timeDigital processing power distributionEngineeringComputer hardware

The invention provides a hard disk frame device and electronic equipment, belongs to the technical field of electronic equipment, and solves the problem of low efficiency when a hard disk of an existing hard disk frame is replaced. The hard disk frame device comprises a hard disk frame, an inner side support and a partition plate support. The hard disk frame is fixed with the inner side bracket; the inner side bracket is provided with an elastic sheet convex point and a fixed supporting point; the partition plate support is provided with a positioning hole and a fixing hole. The fixing fulcrumis matched with the fixing hole, and the elastic sheet convex point is matched with the positioning hole; the inner side support can move to a plurality of positions around the fixing fulcrum, and each position is correspondingly provided with one positioning hole.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Secondary air supplementing device and engine

PendingCN111997720APromote oxidation reactionIncrease Qi effectExhaust apparatusSilencing apparatusCombustion chamberExhaust valve

The invention relates to a secondary air supplementing device and an engine. The secondary air supplementing device utilizes the time nonuniformity of the pollutant content in waste gas to timely supplement secondary air into an exhaust passage through an air supplementing pipe so as to improve the air supplementing effect; meanwhile, when an exhaust valve is opened or closed, the valve lift is small, so that the flow of waste gas in a combustion chamber entering the exhaust passage is small, the flow speed is low, the flow speed gradient of the waste gas on all cross sections in the exhaust passage is large, and more waste gas flows along the inner surface, farther away from the combustion chamber, of the exhaust passage. Therefore, according to the air supplementing device, an air outletis formed in the first pipe surface, so that the secondary air supplemented from the air supplementing pipe can be rapidly captured by more waste gas, the oxidation reaction of pollutants in the waste gas is accelerated, and the emission of the pollutants is effectively reduced, so that the secondary air can be supplemented in time and space through the air supplementing device, and the emissionof the pollutants in the waste gas is reduced.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com