Patents

Literature

197results about How to "Realize layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

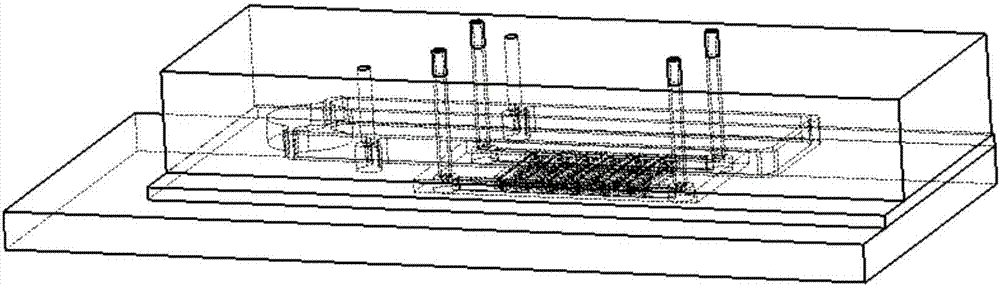

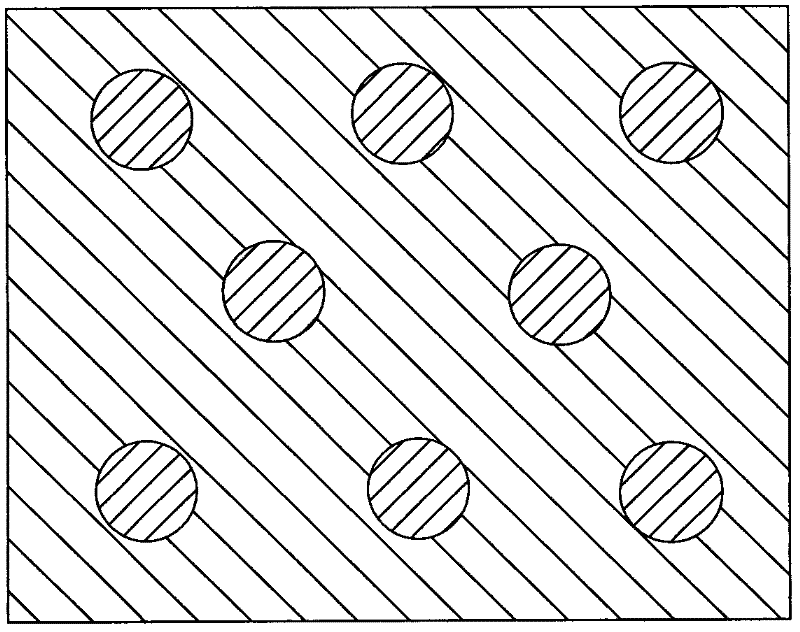

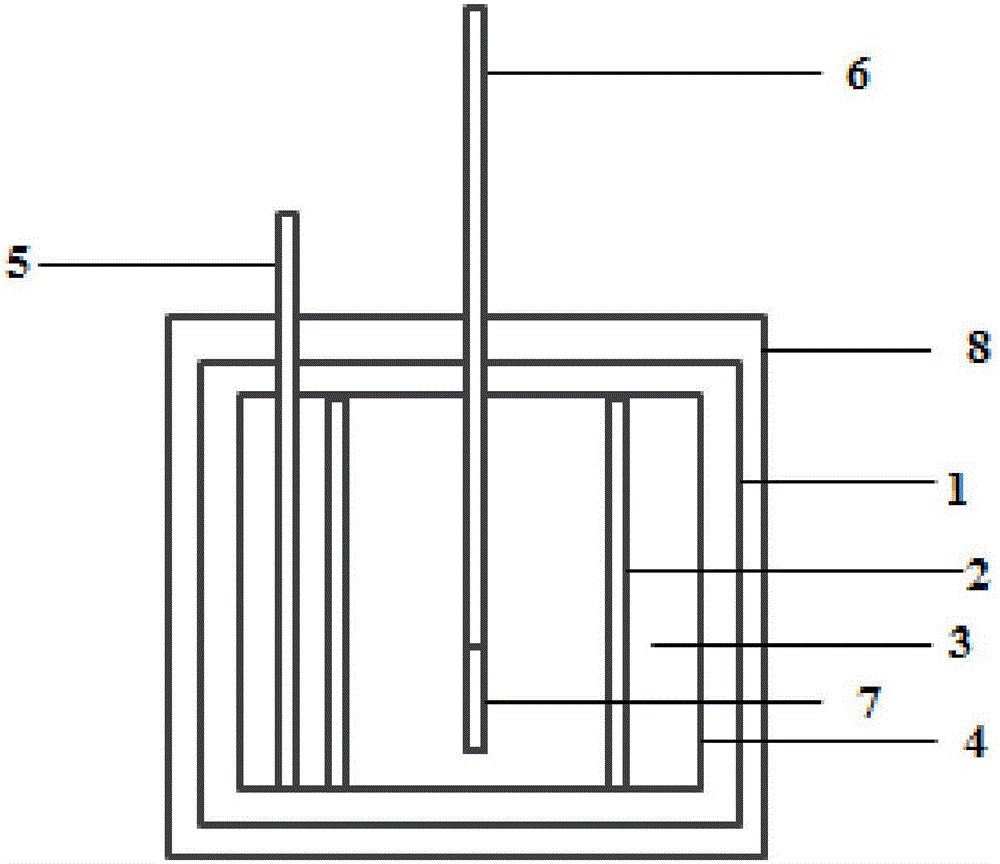

Self-circulation micro-fluidic chip as well as preparation method and usage of micro-fluidic chip

The invention discloses a self-circulation micro-fluidic chip, as well as a preparation method and a usage of the self-circulation micro-fluidic chip. The micro-fluidic chip comprises a microfluid layer, an electroosmosis driving layer and a chip base layer from top to bottom, wherein the electroosmosis driving layer defines a microfluid flow channel and a wide / narrow electrode liquid metal flow channel with the microfluid layer and the chip base layer respectively; the microfluid flow channel and the wide / narrow electrode liquid metal flow channel are independent and are filled with a to-be-driven solution and a liquid metal respectively; the electroosmosis driving layer and the wide / narrow electrode liquid metal flow channel are interdigital; the lower surface of the electroosmosis driving layer is completely covered with the wide / narrow electrode liquid metal flow channel; the upper surface of the electroosmosis driving layer is exposed in the microfluid flow channel; and the two ends of the wide / narrow electrode liquid metal flow channel are communicated with a power supply via four metal electrodes. The micro-fluidic chip has the advantages of small size, high integration level, portability, good stability and the like, is low in preparation cost and wide in application scope, and a preparation technology of the micro-fluidic chip is also very simple and practicable.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

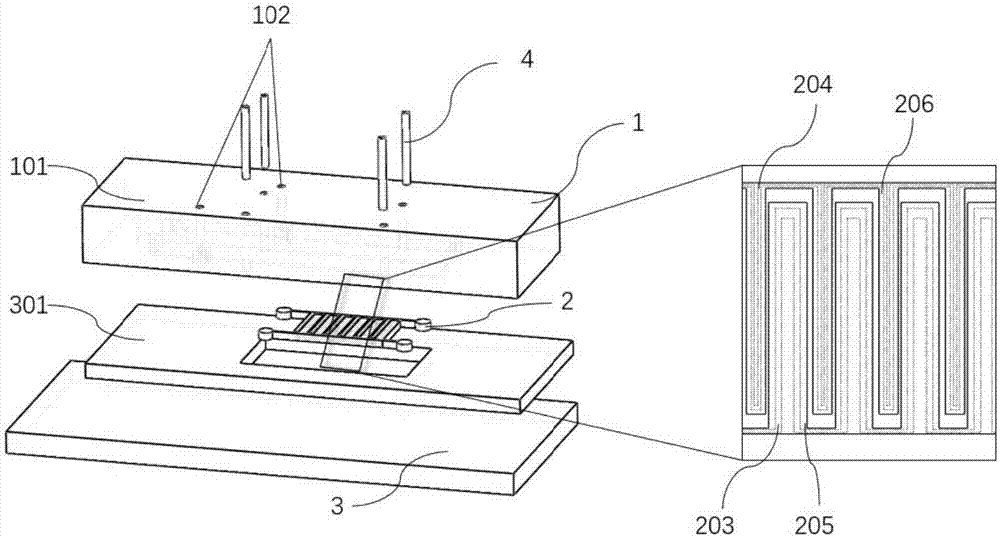

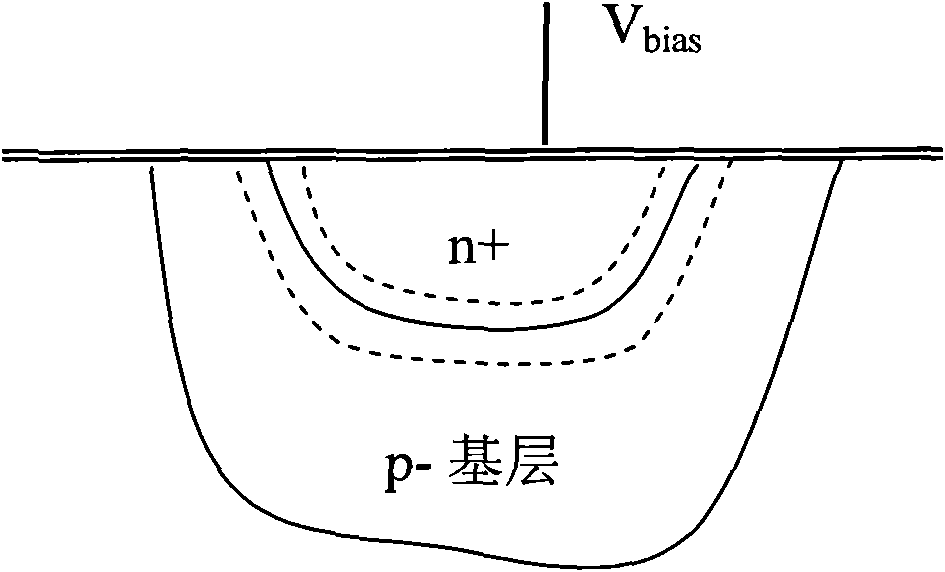

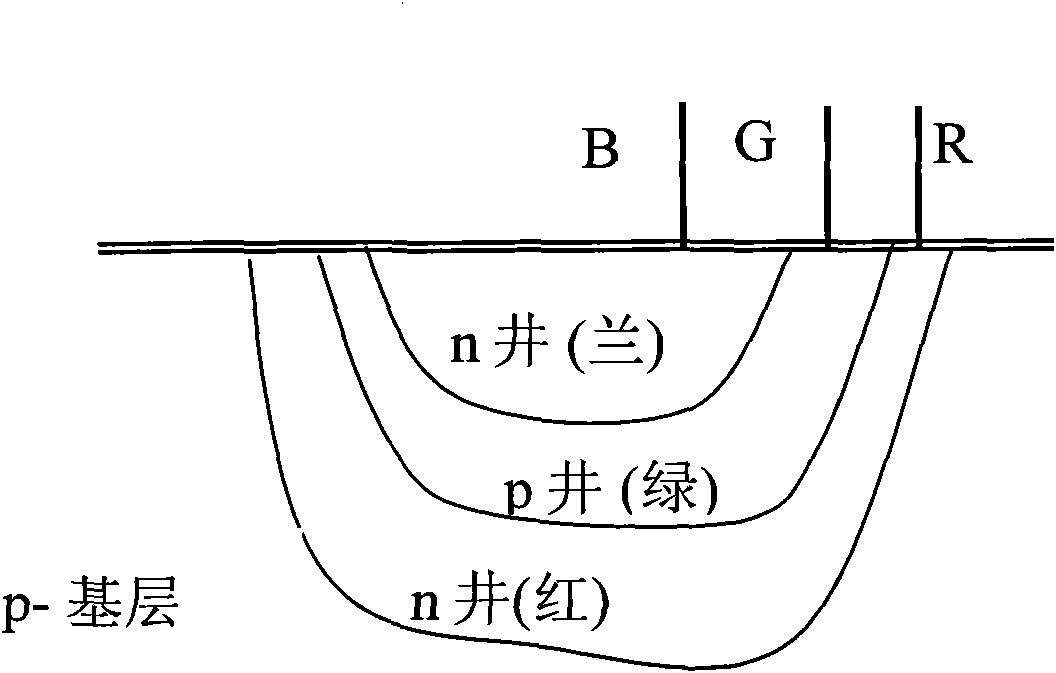

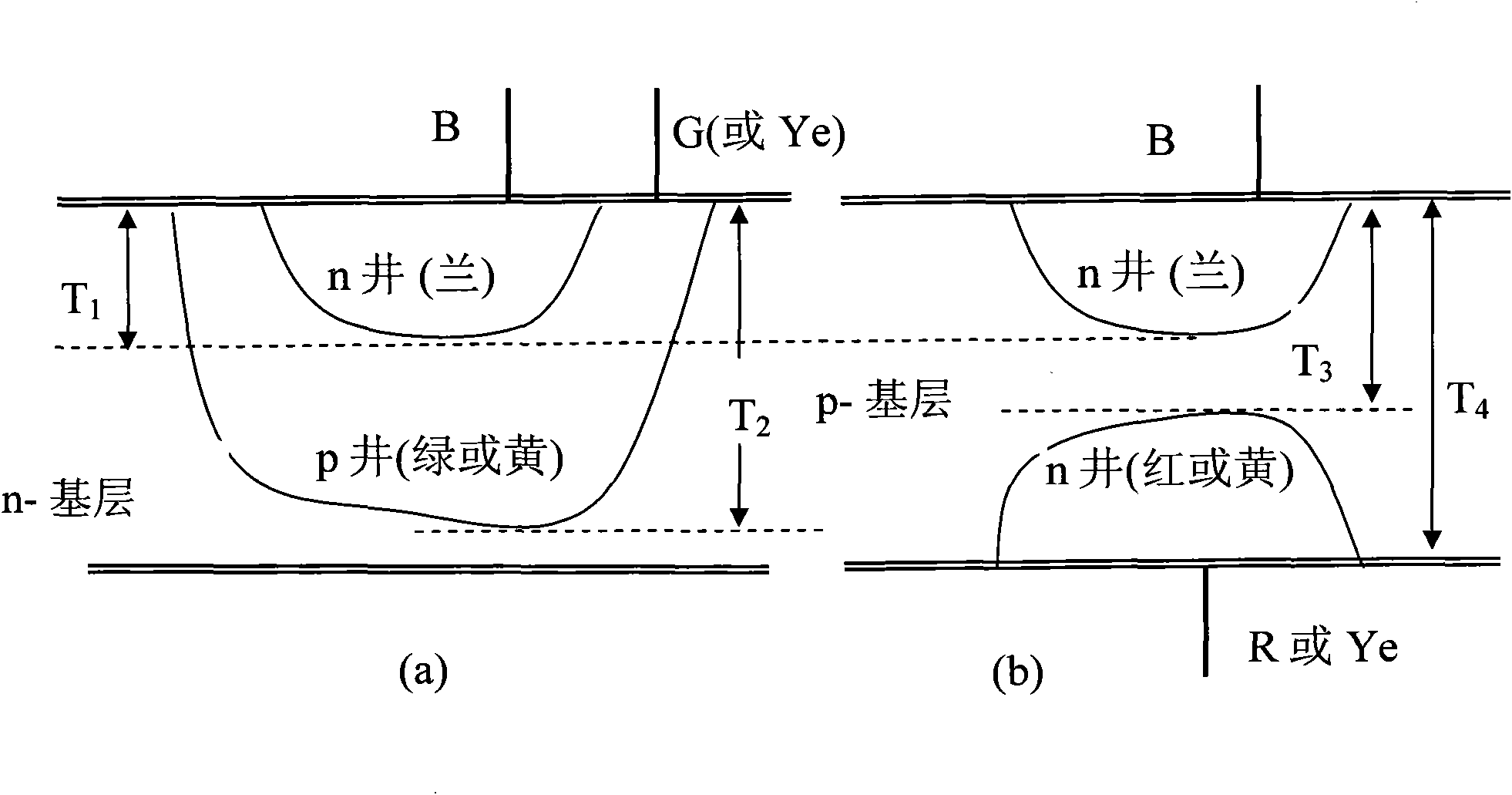

Multispectral photosensitive component

ActiveCN101807590AGood color sensitivityGood flexibilityTransistorSolid-state devicesMachining processVisible spectrum

The invention relates to a multispectral photosensitive component which comprises multilayer composite photosensitive pixels which adopt a single-face or double-face machining mode, realize up-down placement in a silicic P or N basic layer in two, three or four and respectively induct spectra which are orthogonal or complementary in visible light or visible and infrared light spectra. Basic photosensitive pixels on different levels in the composite photosensitive pixels can be designed to induct different colors or spectra, therefore, a multispectral photosensitive chip is obtained by repeatedly arranging a macro unit comprising more than one composite photosensitive pixel. The multispectral photosensitive component comprises a new design of the multilayer photosensitive pixels and examples thereof used for single-face double-layer, double-face double-layer, double-face three-layer, double-face four-layer, single-face mixed double-layer and double-face mixed double-layer or multilayermultispectral photosensitive components. The multispectral photosensitive component has more favorable colored photosensitive property and colored photosensitive and infrared photosensitive integration and simple machining process.

Owner:BOLY MEDIA COMM SHENZHEN

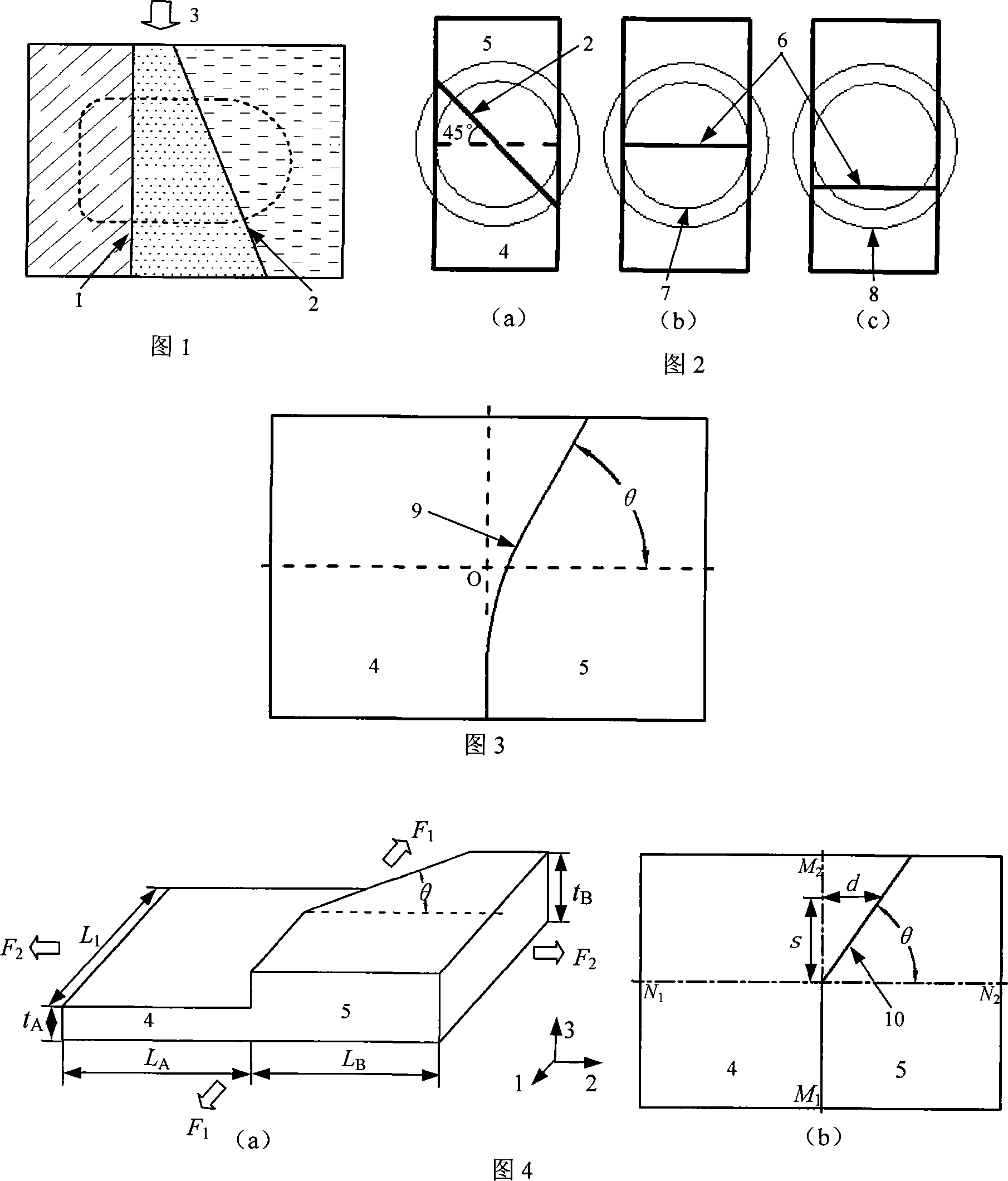

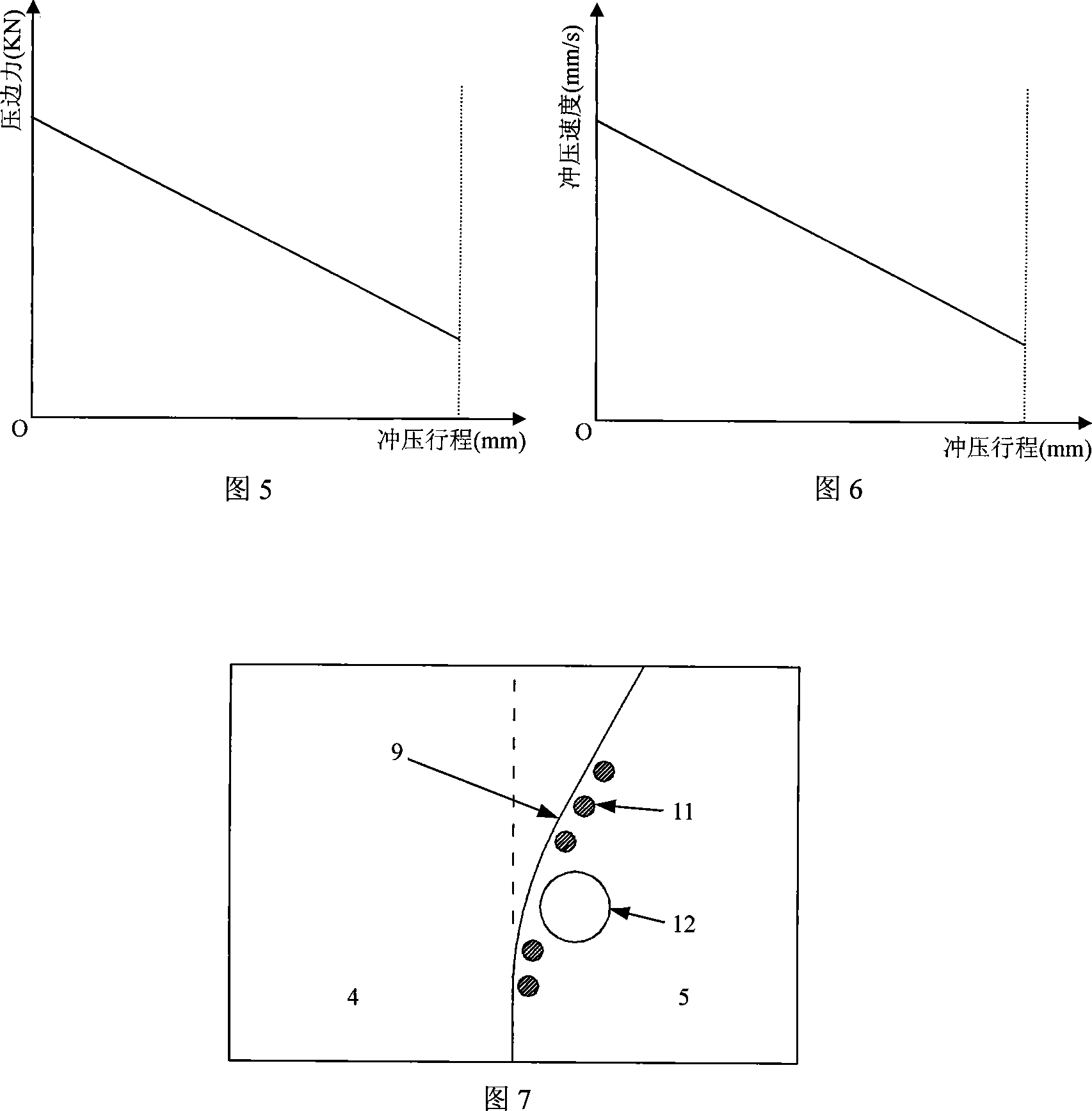

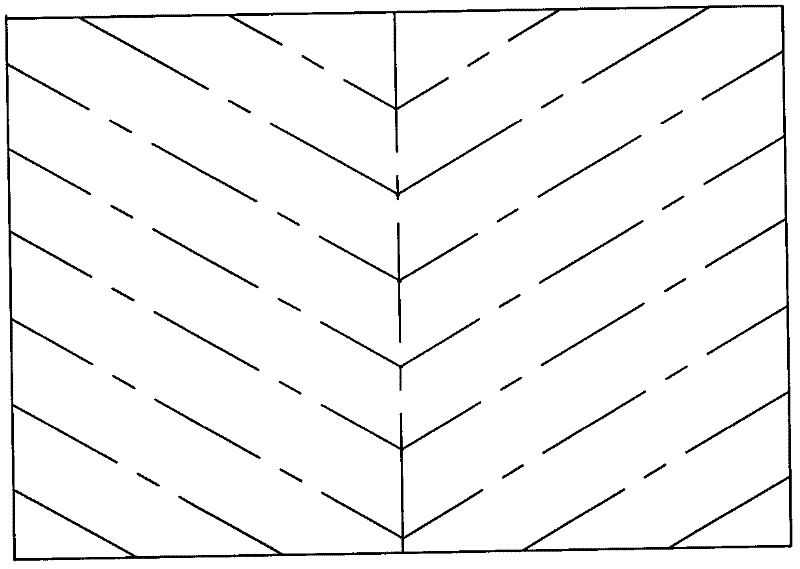

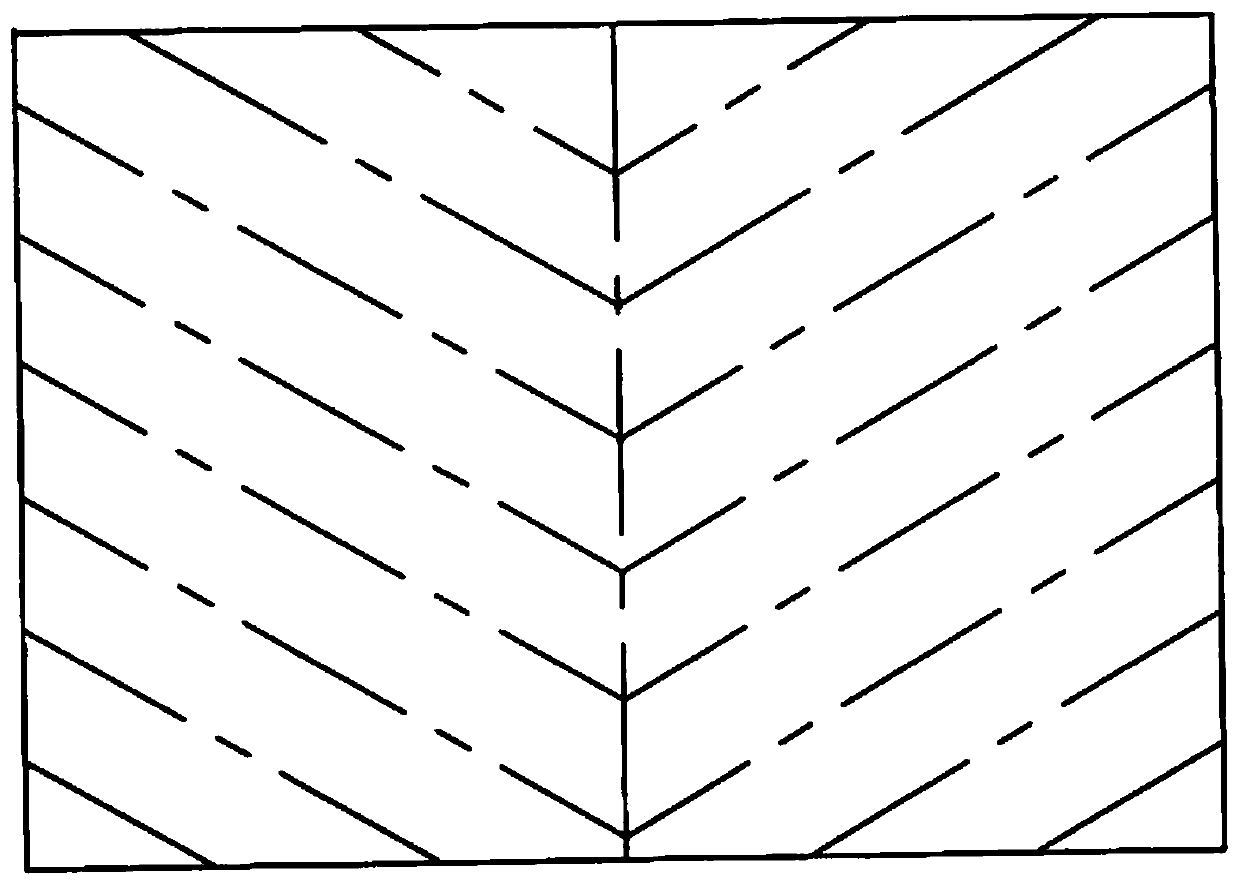

Differential thickness high intensity steel laser tailor-welded blanks curved welding line arrangement and forming method

InactiveCN101169642AImprove analysis accuracyImprove forming qualityTotal factory controlNumerical controlHigh intensityWeld seam

The invention relates to the laser welding plate forming research field, and is mainly applied to such occasion as layout and forming of different thickness high-strength steel laser welding board curved welding seams. The invention is provided with a curved welding seam which has different forms for a laser welding board, thereby getting reasonable seam layout through the welding seam moving an analytical model and the accurate modeling approach thereof, and improving the forming performance of the welding board; wherein, the flow of materials is improved and the layout and the good forming of different thickness high-strength steel plate laser welding board curved welding seam are achieved based on the variable blank-holder force, variable stamping speed, clamping in weld, designing cope hole with welding thick base metal, and other advanced forming technologies. By the method, the layout of the welding board curved welding seam is optimized, thereby increasing the forming performance of a curved welding seam welding board, and widely using.

Owner:JIANGSU UNIV

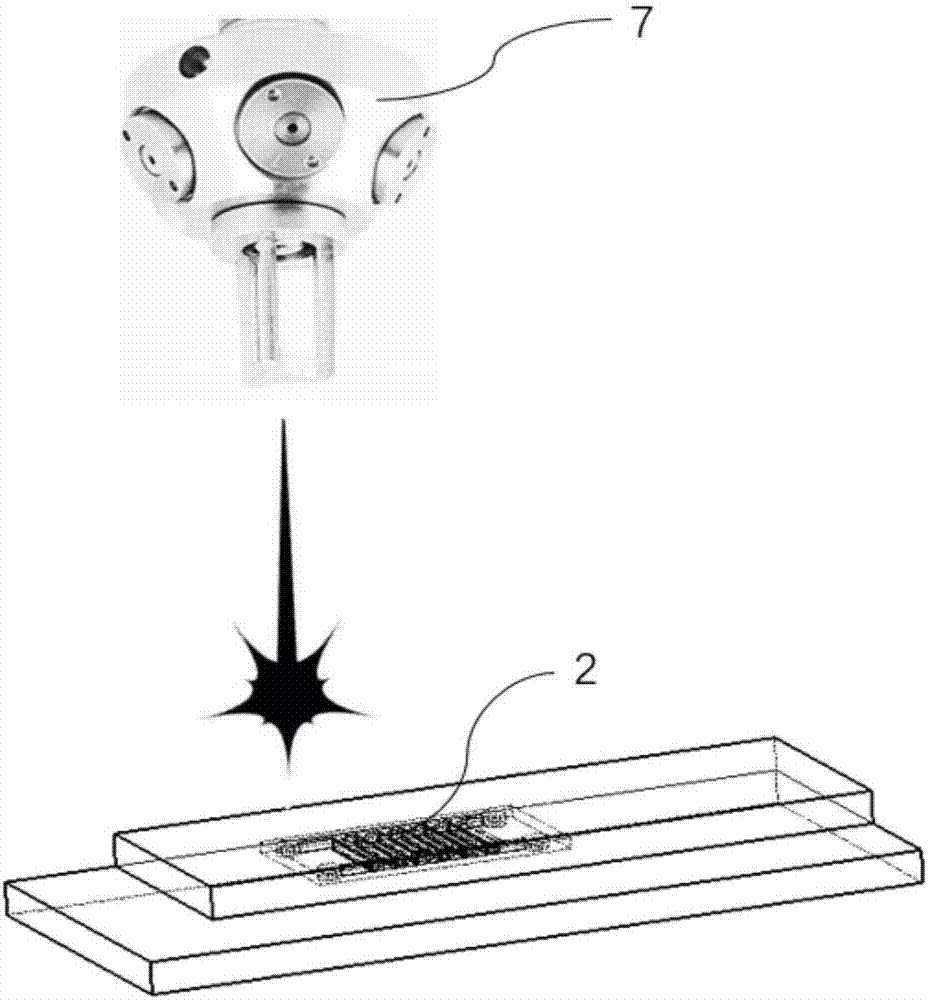

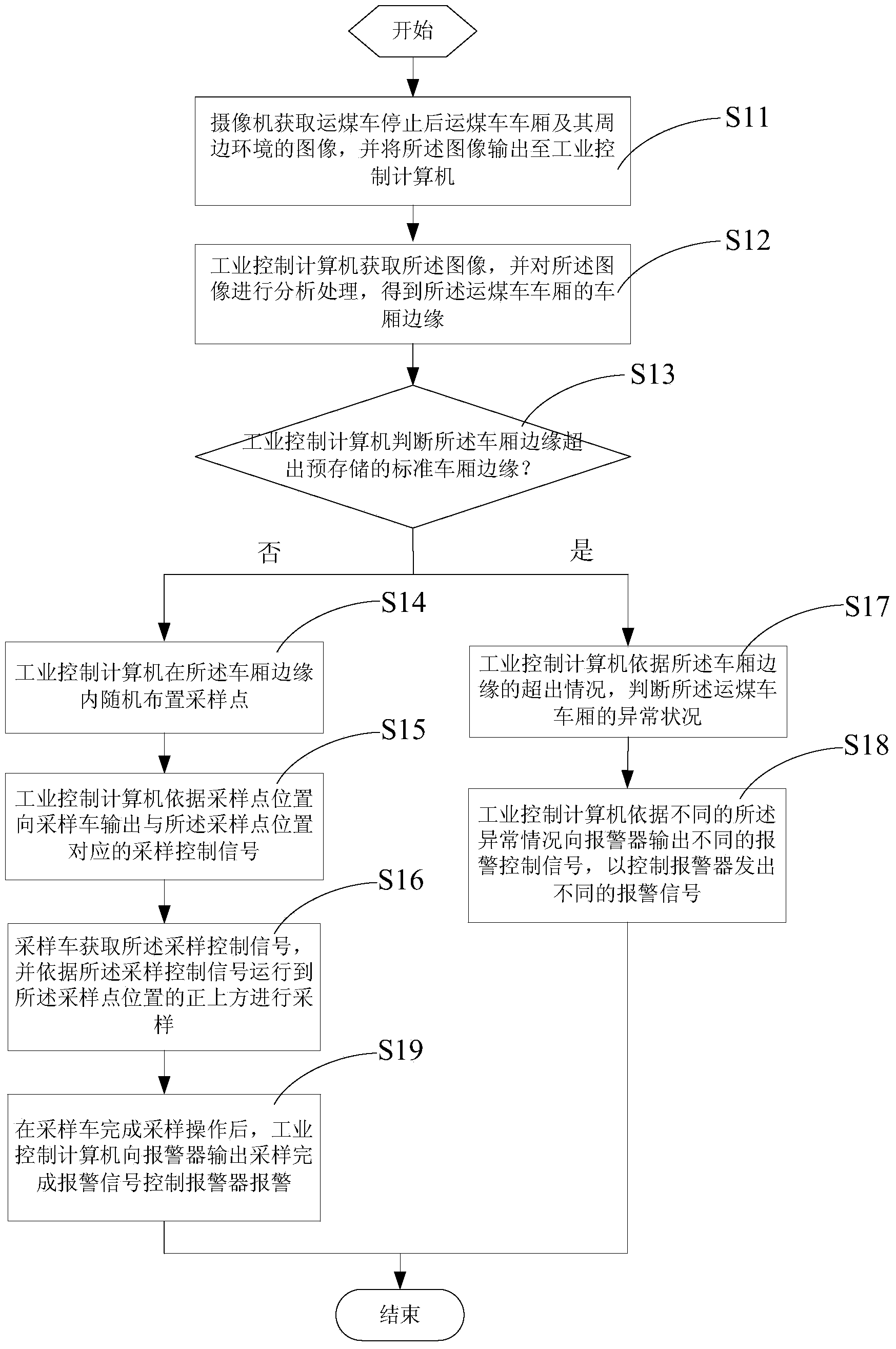

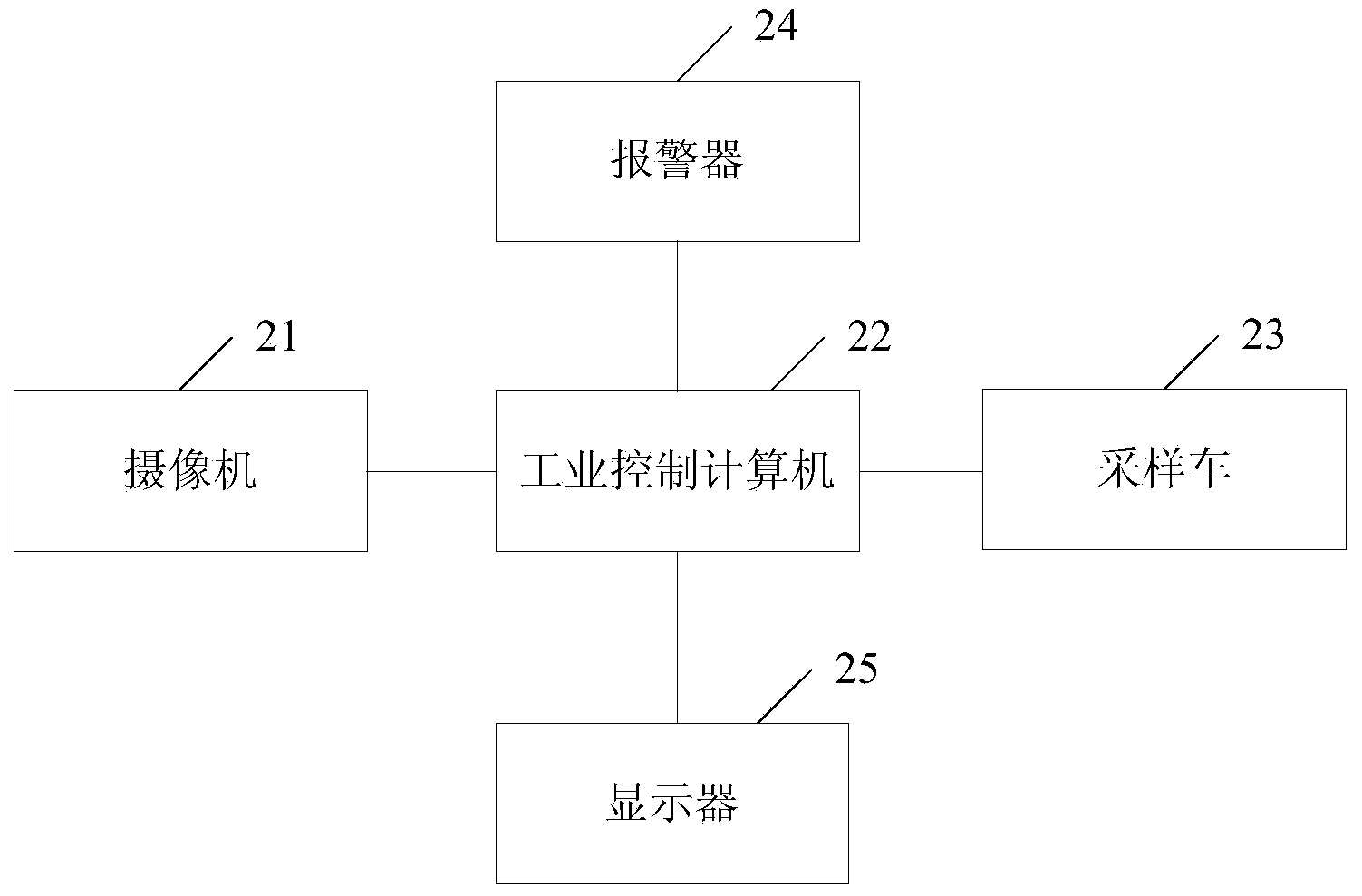

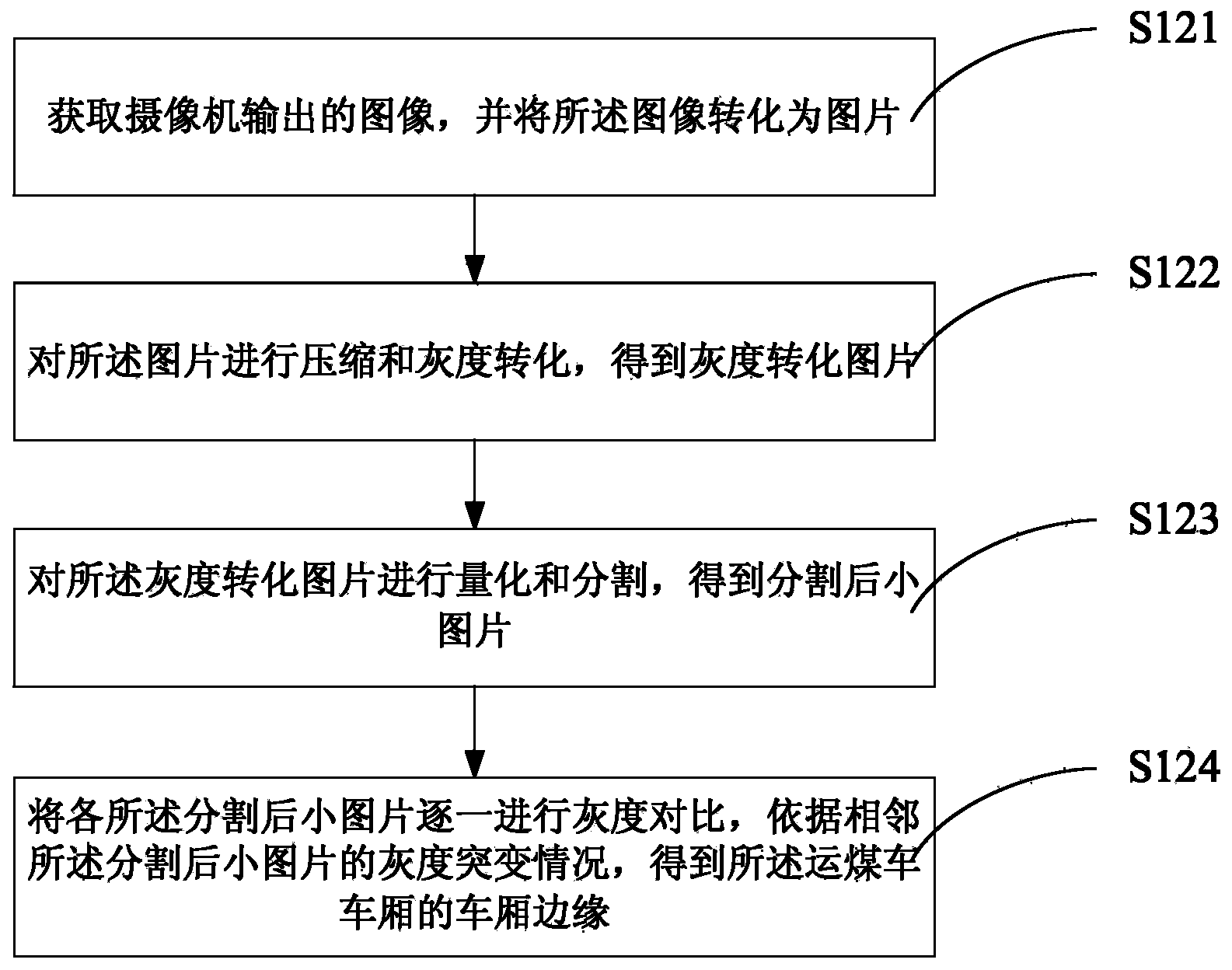

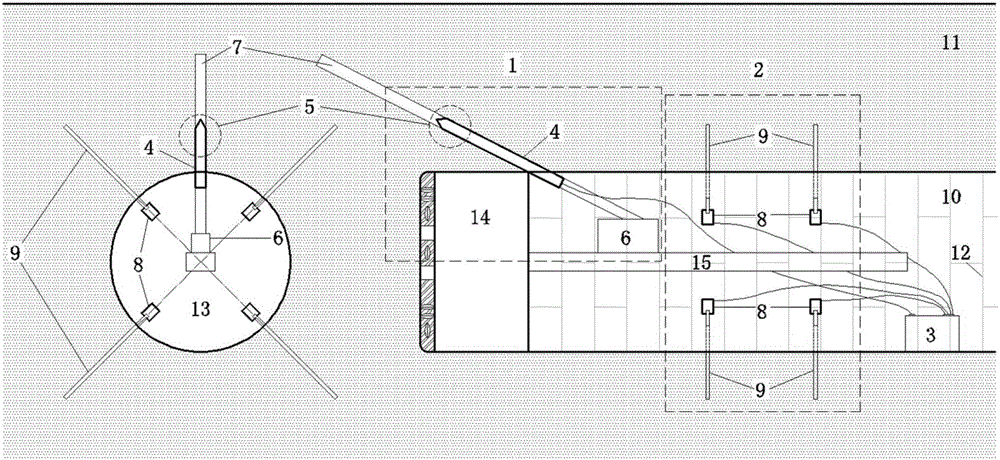

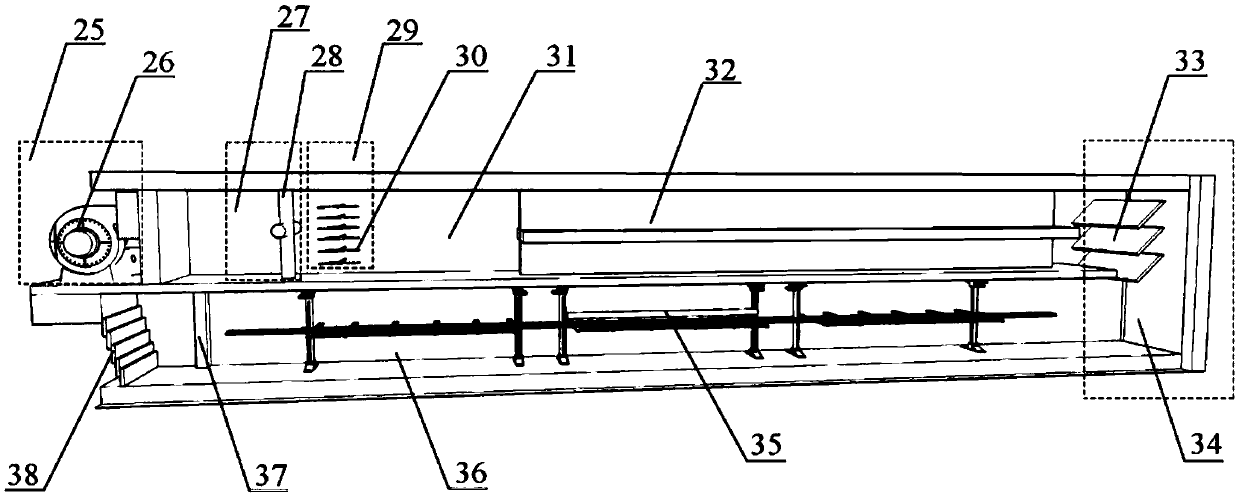

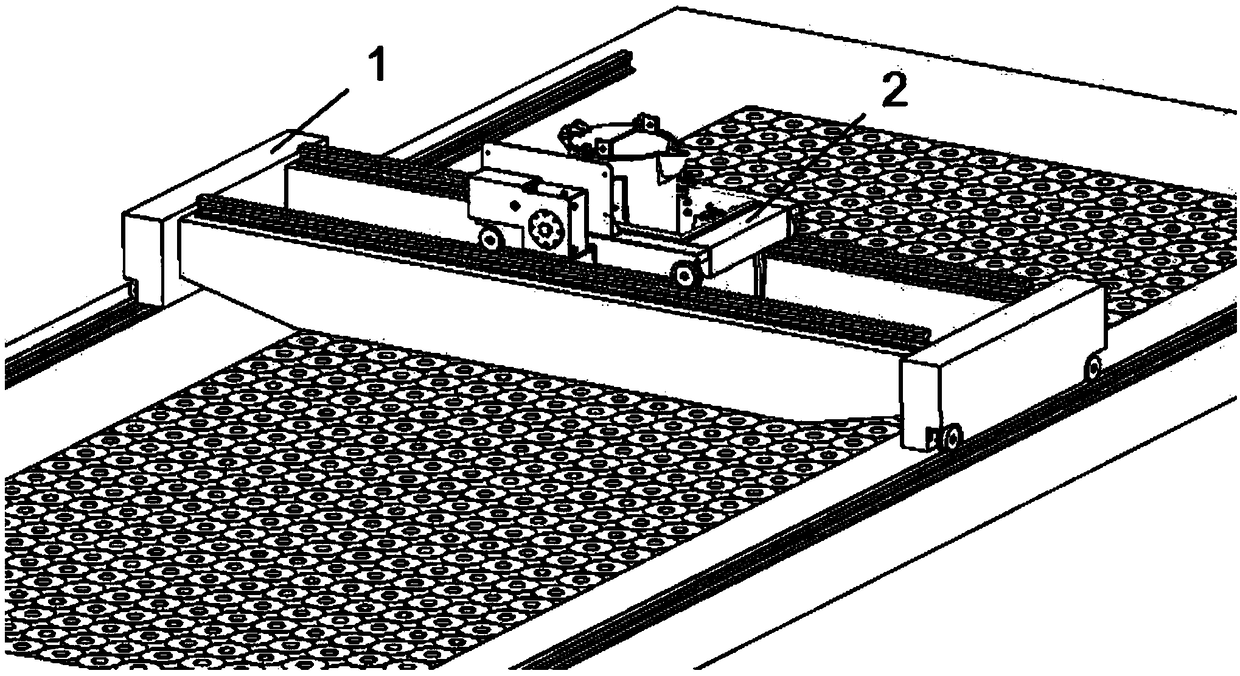

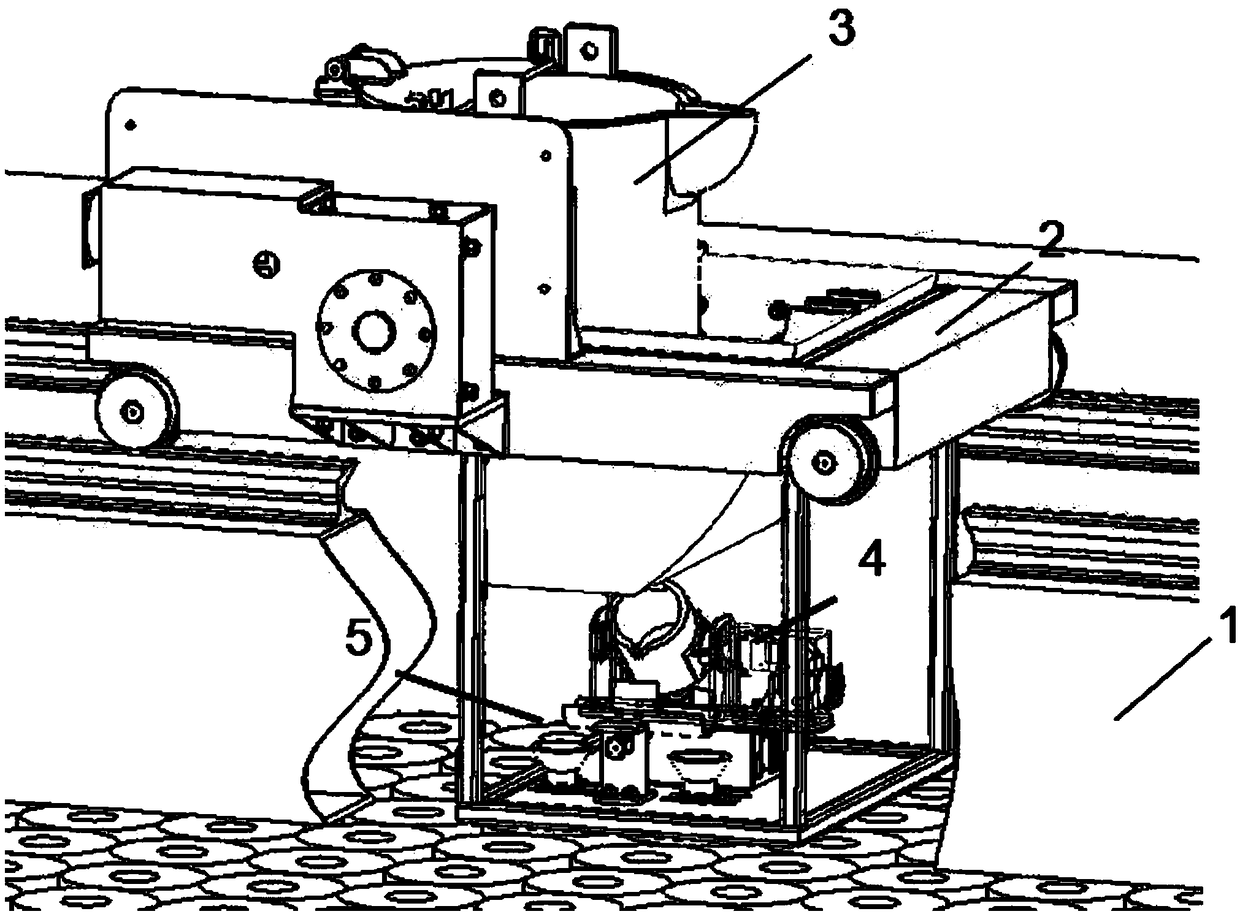

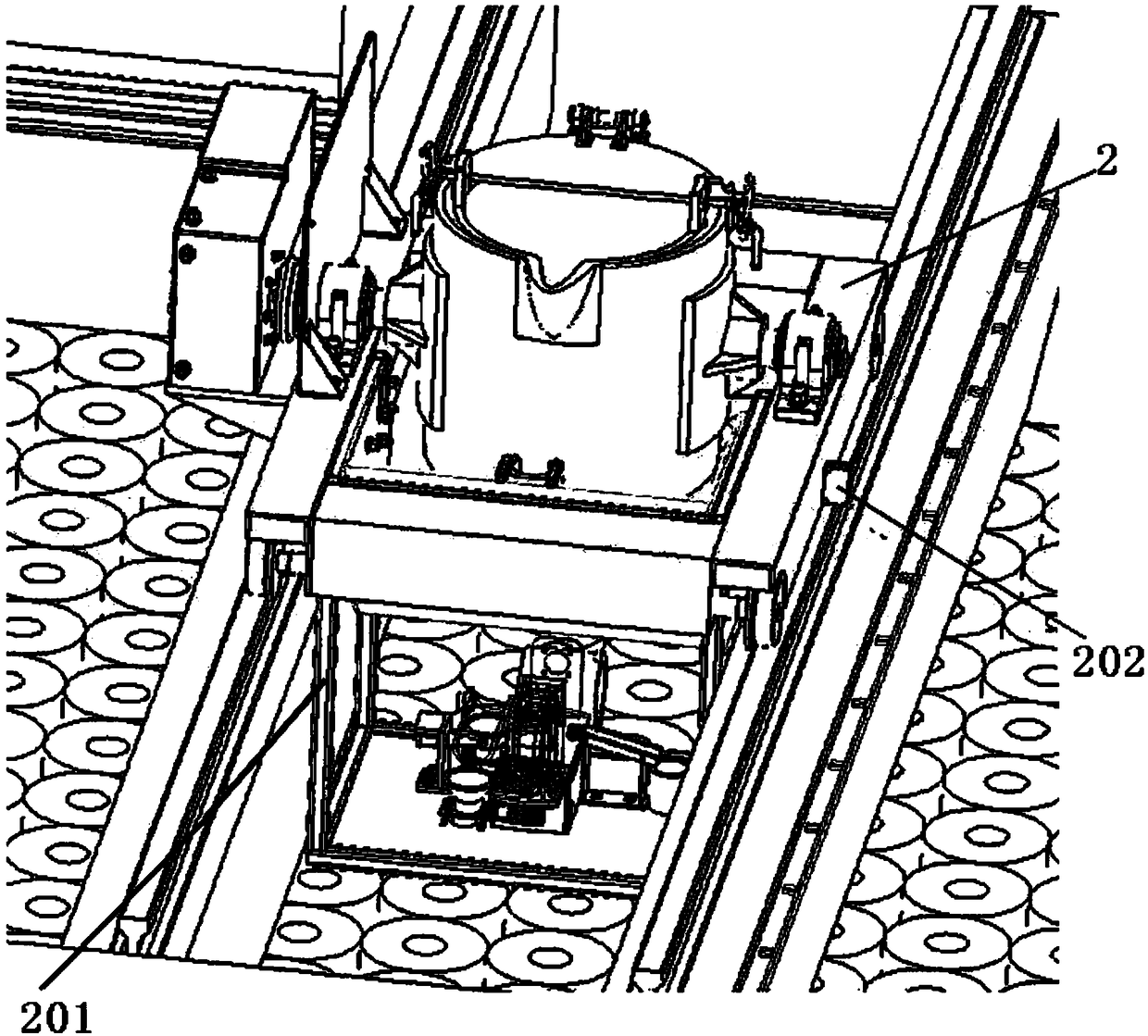

Sampling method and machine

ActiveCN103792108ARealize layoutImprove accuracyImage analysisWithdrawing sample devicesCoalIndustrial engineering

The invention provides a sampling method and machine. The sampling machine comprises a camera, an industrial control computer and a sampling trolley, wherein the camera and the sampling trolley are both connected with the industrial control computer. The method comprises the steps that the images of the compartment of a coal conveyor and the surrounding environment are acquired after the coal conveyor stops, and the compartment edge of the coal conveyor is obtained through analysis and processing of the images; comparison is conducted on the compartment edge and a pre-stored standard compartment edge to achieve the arrangement of the compartment of the coal conveyor; random arrangement of a sampling point is conducted with the whole area within the compartment edge as a sampling area, and the industrial control computer controls the sampling trolley to travel to the position over the sampling point for sampling. Due to the fact the whole compartment of the coal conveyor is taken as the sampling area, the process of selecting a sampling area in the compartment of the coal conveyor is omitted, and as a result, the influence of human factors on coal sampling is effectively avoided, and then the accuracy of estimation of the quality of coal in the whole compartment of the coal conveyor is improved.

Owner:HUNAN WANTONG TECH

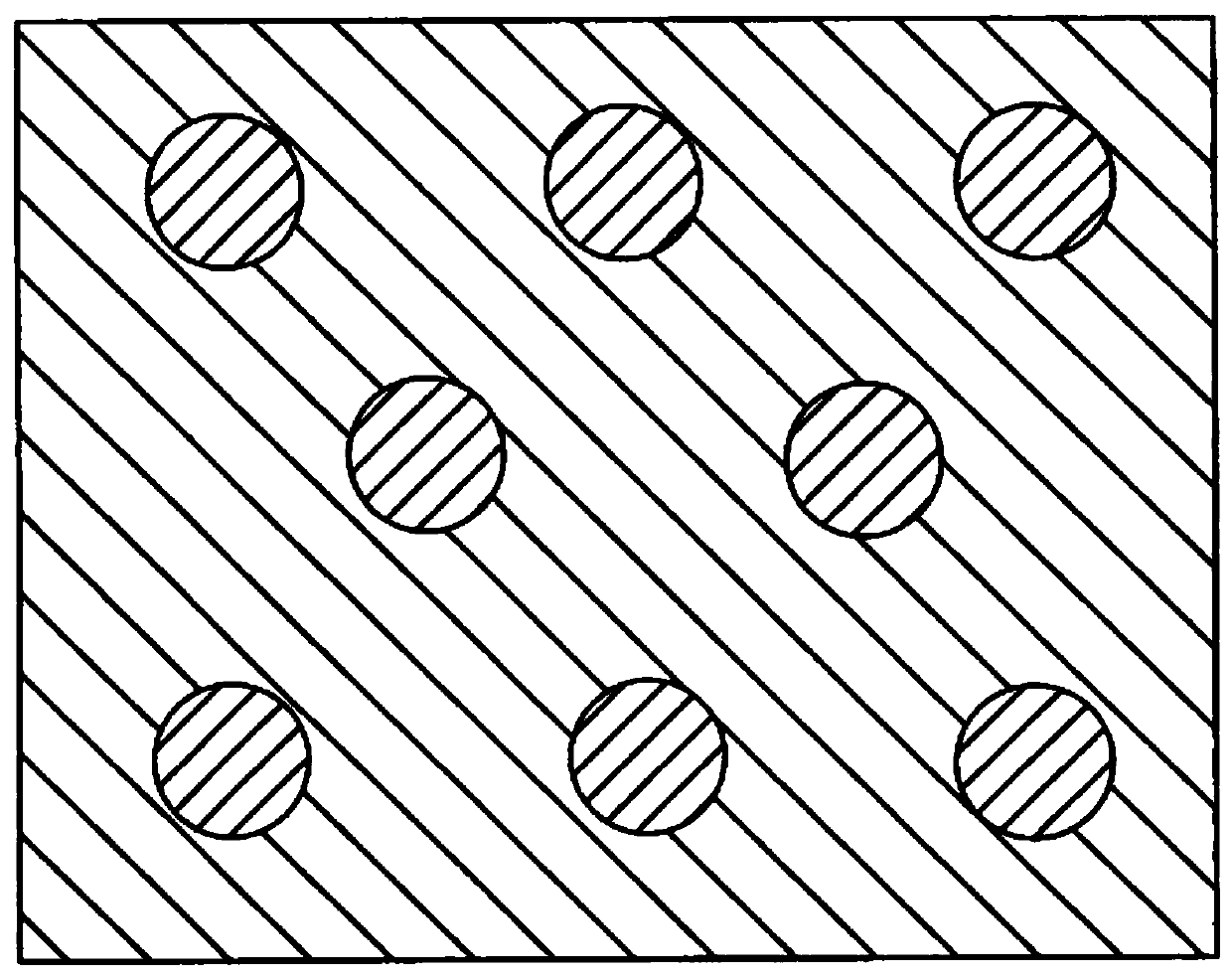

Embedded composite casting method

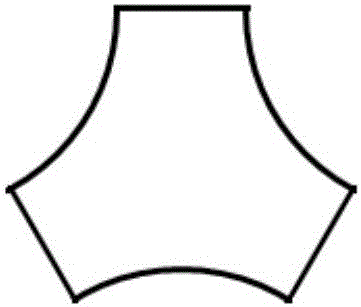

The invention discloses an embedded composite casting method, which comprises the following steps: selecting the types of reinforcing materials according to the base materials of metal castings and structures which need to be cast, and processing to form reinforcing unit bodies with certain geometric shapes; carrying out pretreatment on the surfaces of the reinforcing unit bodies; assembling the reinforcing unit bodies into a bionic reinforcing skeleton according to the position requirement of inlay casting and the solidifying contraction characters of the base materials, and then, placing the bionic reinforcing skeleton in a casting mould or directly placing the reinforcing unit bodies in the casting mould according to design position to form the bionic reinforcing skeleton; carrying out preheating on the casting mould provided with the bionic reinforcing skeleton; and injecting the base materials liquefied to be liquid into the preheated casting mould to form an embedded composite casting. By adopting the embedded composite casting method, the interface binding of the base materials and the reinforcing materials is good in the composite process. A construction member manufactured by the method is capable of achieving higher toughness, strength and abrasive resistance. Moreover, the embedded composite casting method is not only suitable for carrying out compositing by taking ferrous metals as the base materials but also is suitable for carrying out compositing by taking non-ferrous metals as the base materials.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

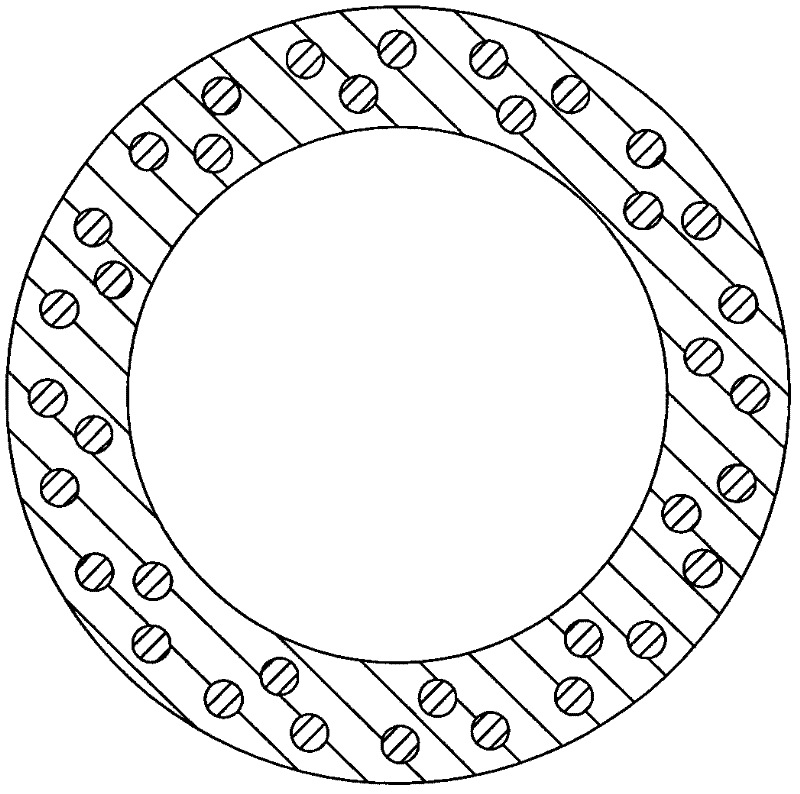

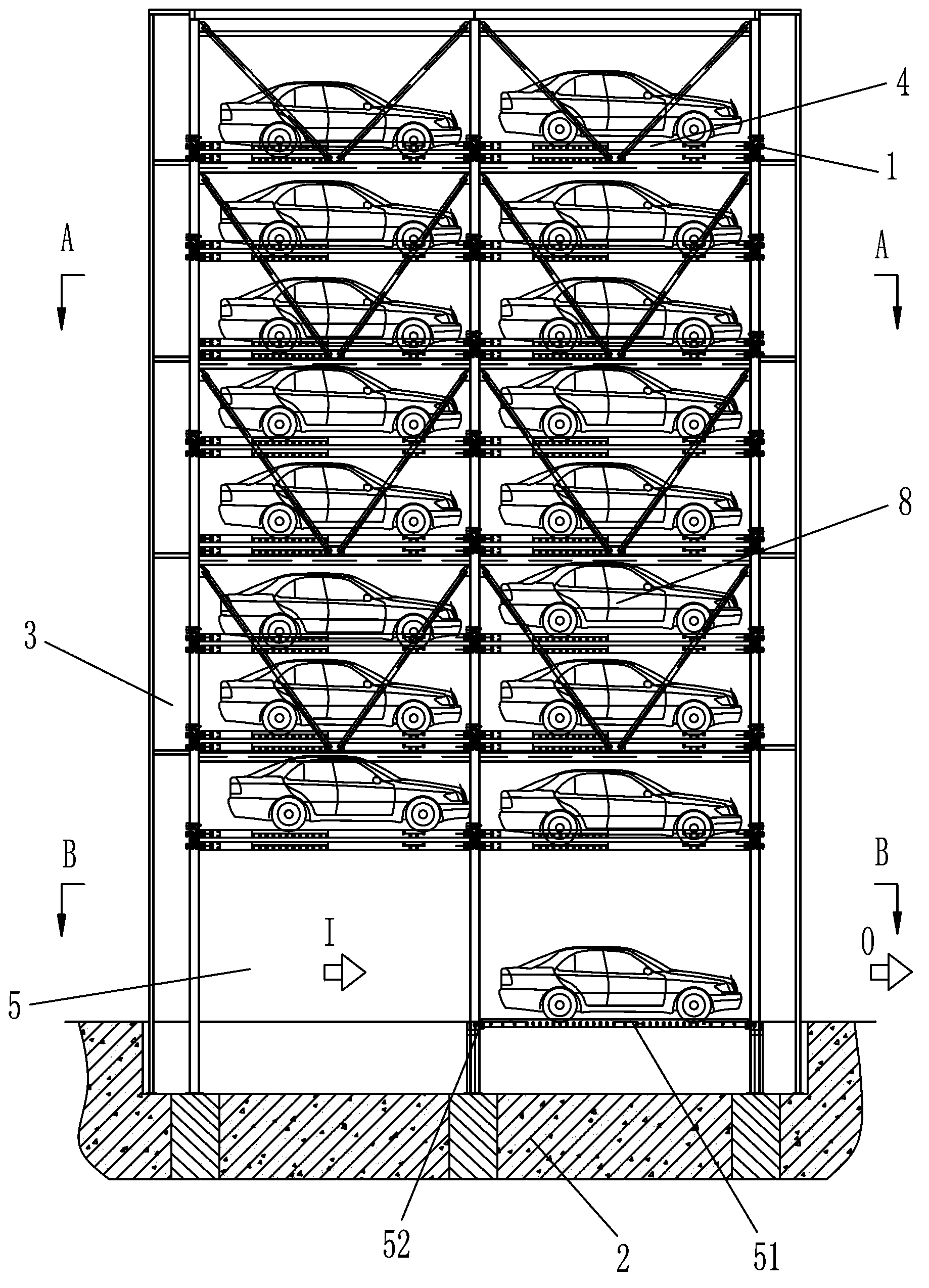

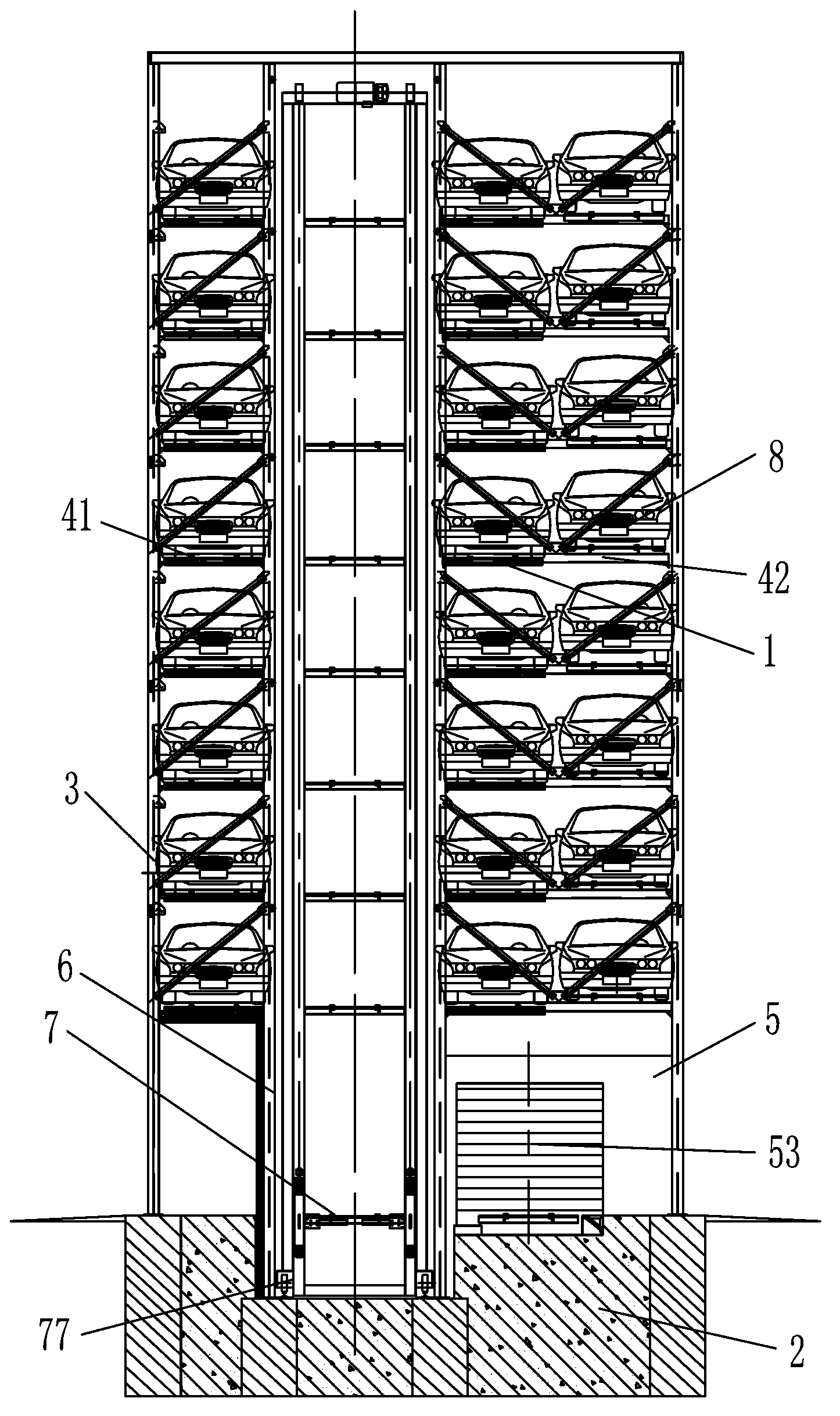

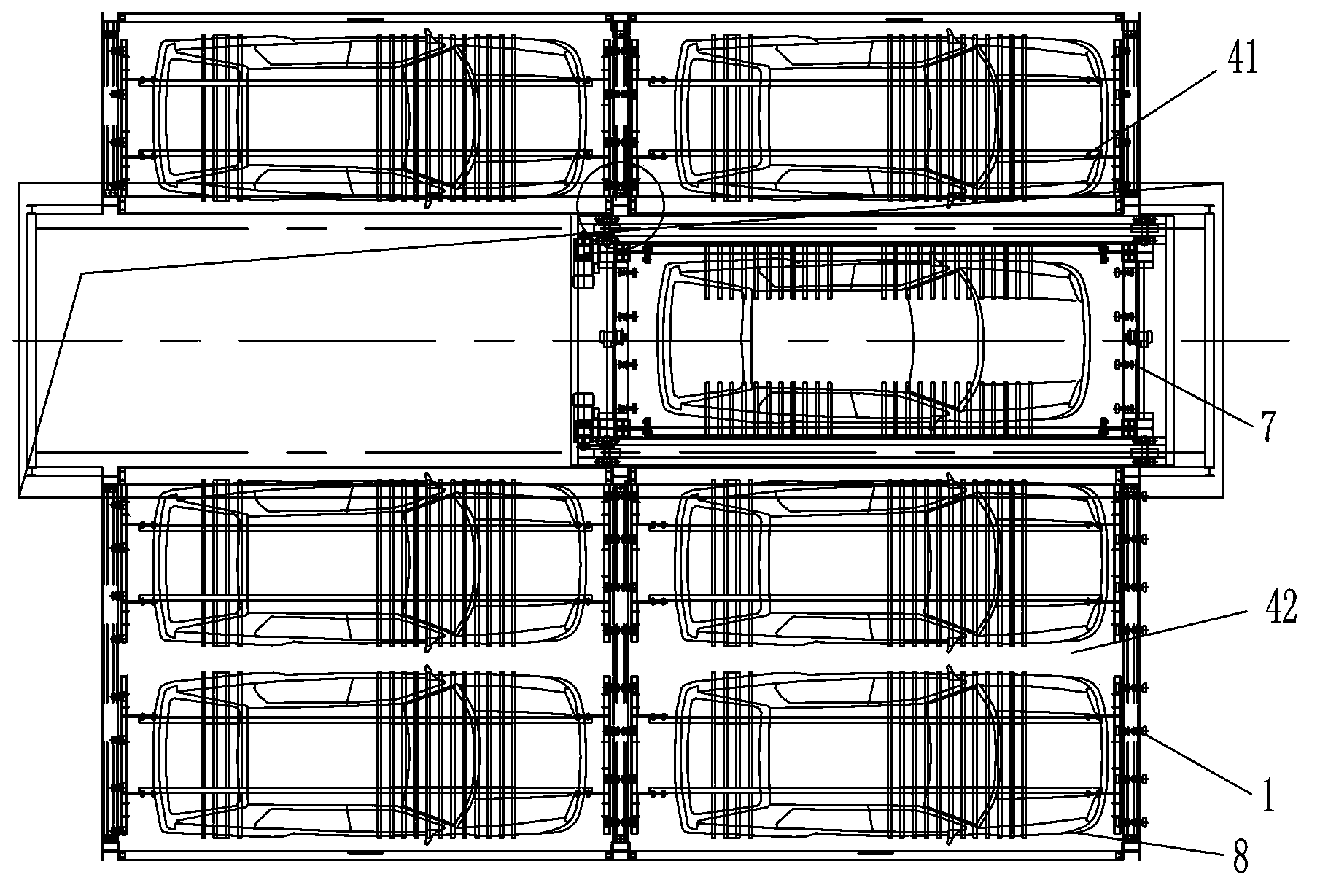

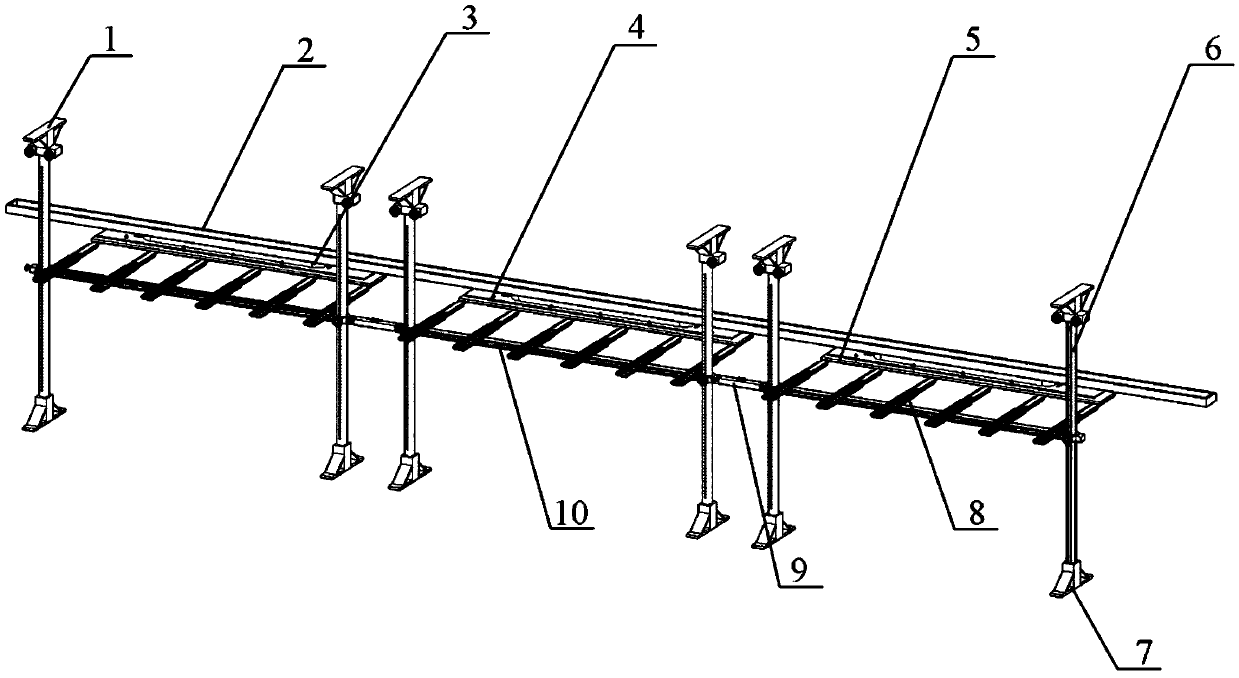

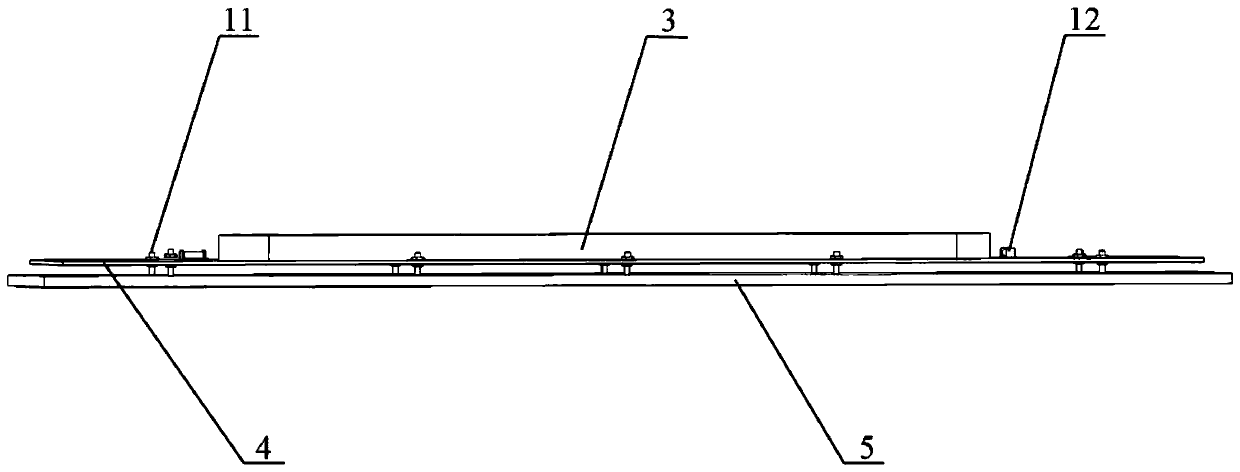

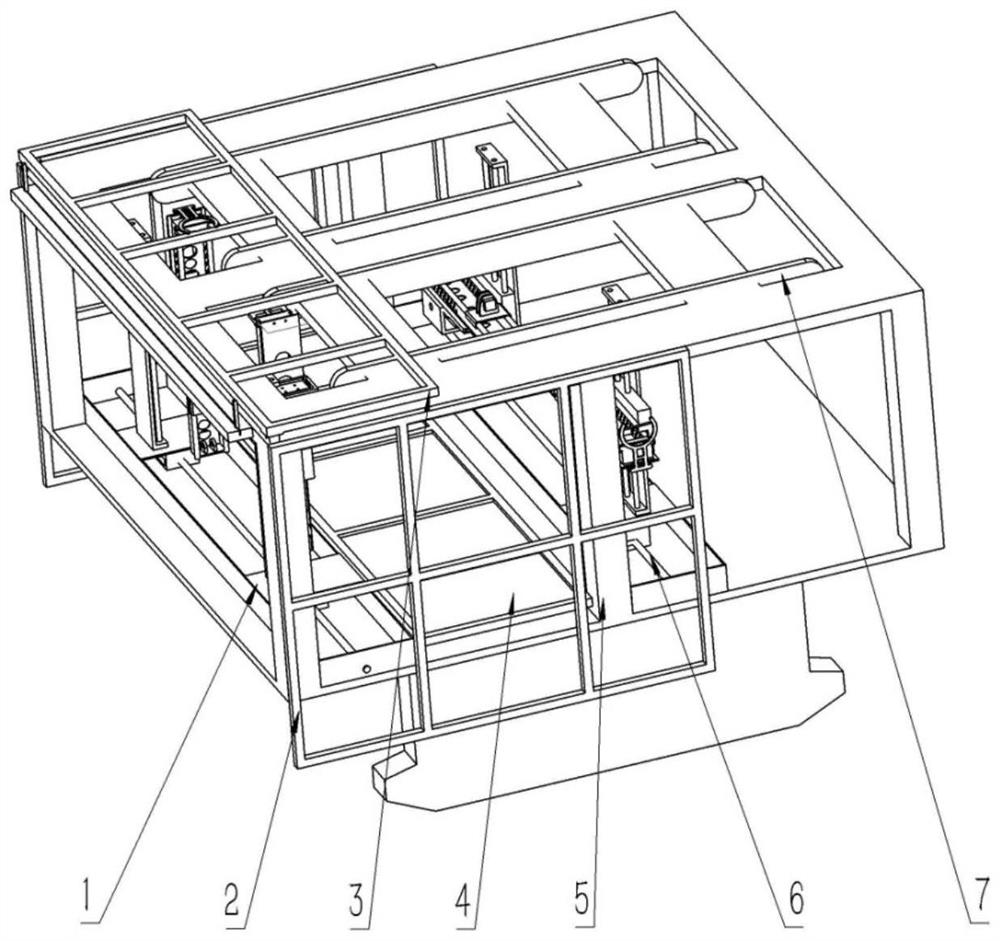

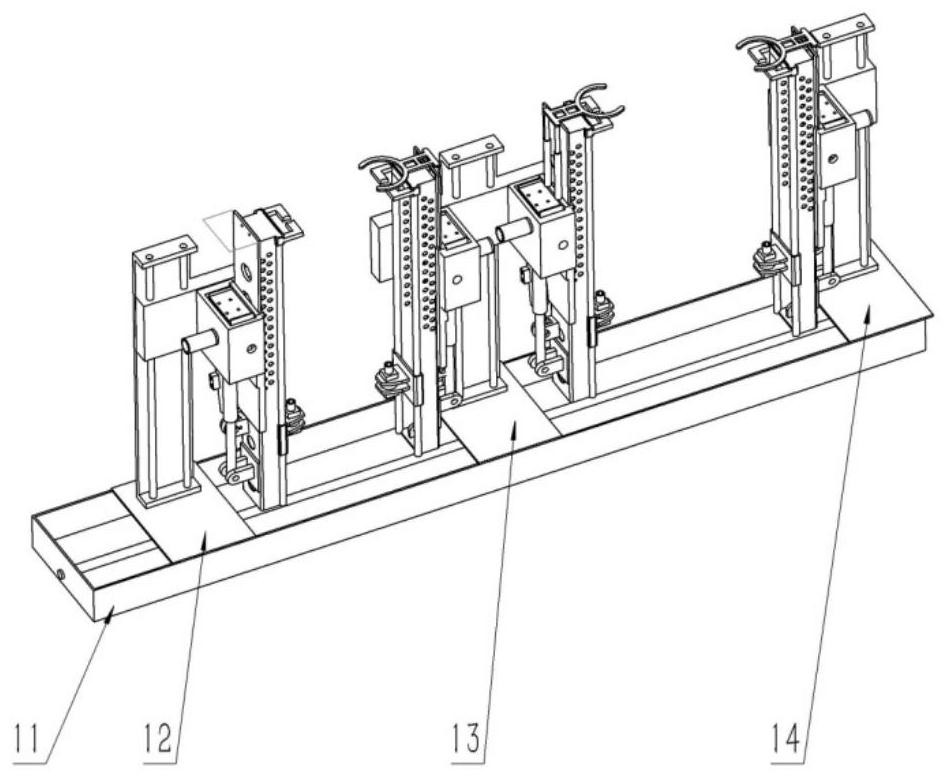

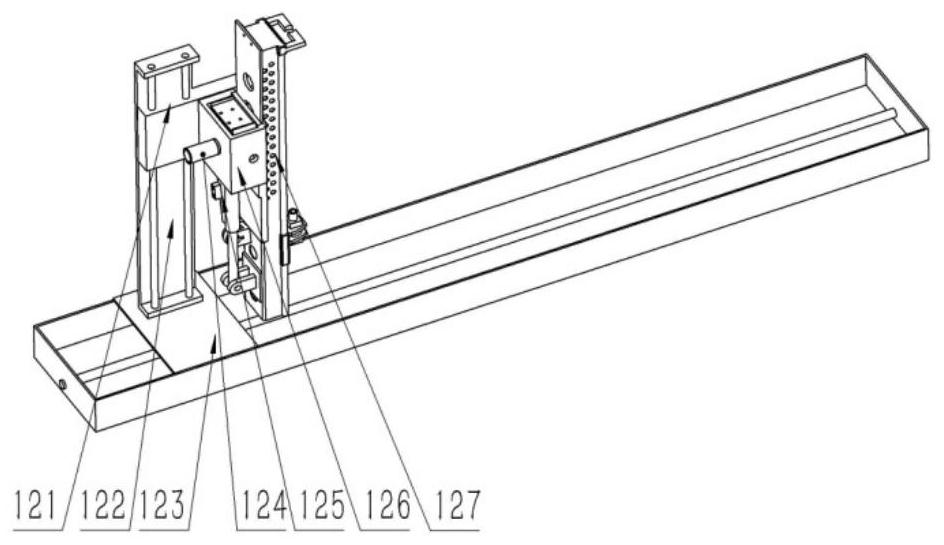

Stereo garage and vehicle storing and taking method thereof

ActiveCN103669943ASolve the problem of car accessRealize non-interference mobileParkingsParking spaceComputer science

Provided are a stereo garage and a vehicle storing and taking method of the stereo garage. The stereo garage comprises a base, a frame and parking spaces, the frame is arranged on the base, the parking spaces are fixed to the frame and are multi-column longitudinally-arranged stereo parking spaces, the multi-column longitudinally-arranged stereo parking spaces comprise a plurality of longitudinally-arranged first multi-column comb tooth parking spaces and a plurality of longitudinally-arranged single-column comb tooth parking spaces or a plurality of longitudinally-arranged second multi-column comb tooth parking spaces. A vehicle storing and taking method of the stereo garage is further provided. According to the stereo garage and the vehicle storing and taking method of the stereo garage, the single-column mode in comb tooth type longitudinally-arranged parking space roadway stacking type and vertical lifting type mechanical garages is improved, and multi-column parking space arrangement is achieved; the problem that vehicles are difficult to store and take in multi-column type longitudinal comb tooth type vehicle carrying plates is solved, and the comb tooth type vehicle carrying plates hand over the vehicles without interfering each other. Space can be effectively utilized, the stereo garage is suitable for occasions with dense vehicles, a large parking lot with the volume reduplicated can be formed, and the use ratio of the space is effectively improved.

Owner:中集物联科技有限公司 +2

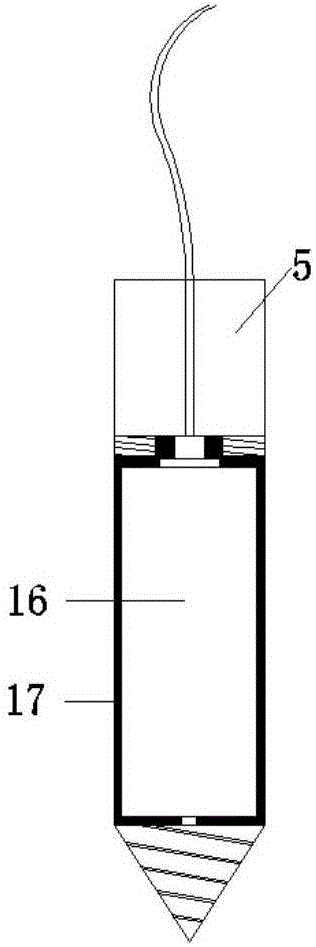

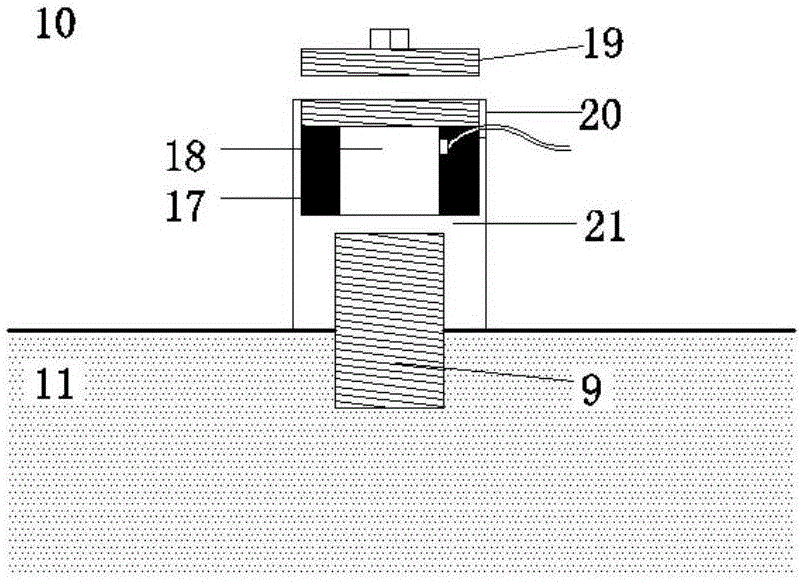

Acoustic wave device and method for metro shield tunnel front boulder detection

ActiveCN106324683ARealize layoutLow costSeismology for water-loggingUltrasound attenuationControl system

The invention discloses an acoustic wave device and a method for metro shield tunnel front boulder detection. The device comprises an acoustic wave transmitting system and an acoustic wave receiving system, wherein the acoustic wave transmitting system comprises an acoustic wave transducer arranged in a tunnel drilling hole for transmitting acoustic wave signals; the acoustic wave receiving system comprises an acoustic wave receiving sensor arranged at the end part of an anchor rod in a tunnel surrounding rock; and the acoustic wave transducer and the acoustic wave receiving sensor are respectively independently connected with a control system. The drilling hole and the anchor rod existing in the field are made full use of, layout of the acoustic wave transmitting and receiving devices is realized, the cost is low, the mounting is quick, and influences on construction are little; by using an advanced geological drilling hole already existing in the shield construction tunnel, quick layout of the acoustic wave transmitting system is carried out, an attenuation role on acoustic wave excitation by a mud area in front of a tunnel face can be effectively avoided, and the detection effects are improved; and the existing supporting anchor rod is used for mounting the receiving sensor, acoustic wave signals from the inner part of the rock can be better received, and strong reflection interference generated on a contact surface between a segment and the surrounding rock can be avoided.

Owner:山东百廿慧通工程科技有限公司

Utility tunnel fire experiment platform system and experiment method

The invention disclose a utility tunnel fire experiment platform system and an experiment method. A linear fire source experiment frame with freely-adjustable positions and a high-power fire source calorimeter system suitable for pipe gallery fire are arranged in a utility tunnel fire simulation laboratory; the flame height measuring and smoke layer thickness measuring device is arranged outside the utility tunnel fire simulation laboratory, and is used for preforming high-definition video recording on a utility tunnel combustion chamber area, and processing the recorded video to obtain a curve of flame height and smoke layer thickness changing with time; and the linear fire source experimental frame with freely-adjustable positions is arranged in the utility tunnel fire simulation laboratory, and thus the accurate movement and positioning in the horizontal direction and the vertical direction can be realized. The system and the method can realize simulation experiments of internal fires in utility tunnel under multiple spatial positions, measure data such as mass loss rate of fire source, heat release rate, flame height of fire source, thickness of smoke layer in pipe gallery andthe like in real time, and lay a foundation for scientific research of fires in the utility tunnel.

Owner:CHINA UNIV OF MINING & TECH

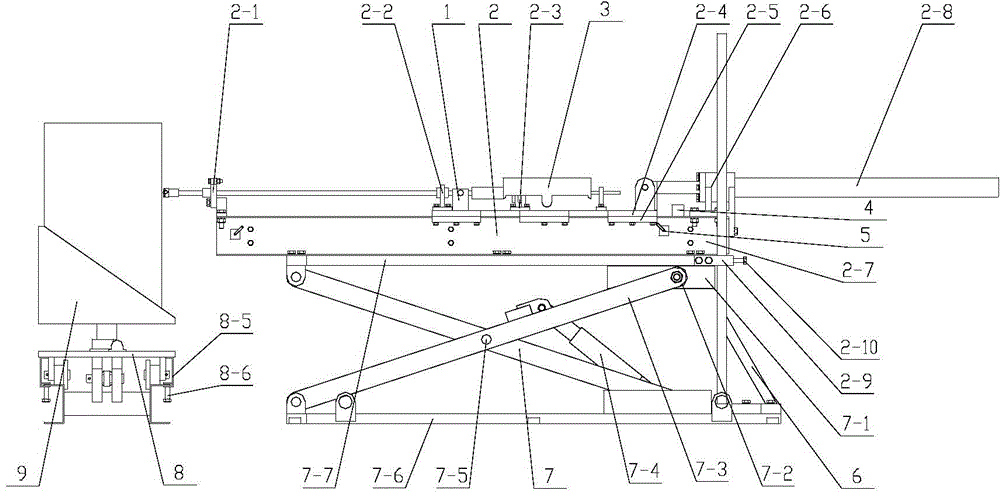

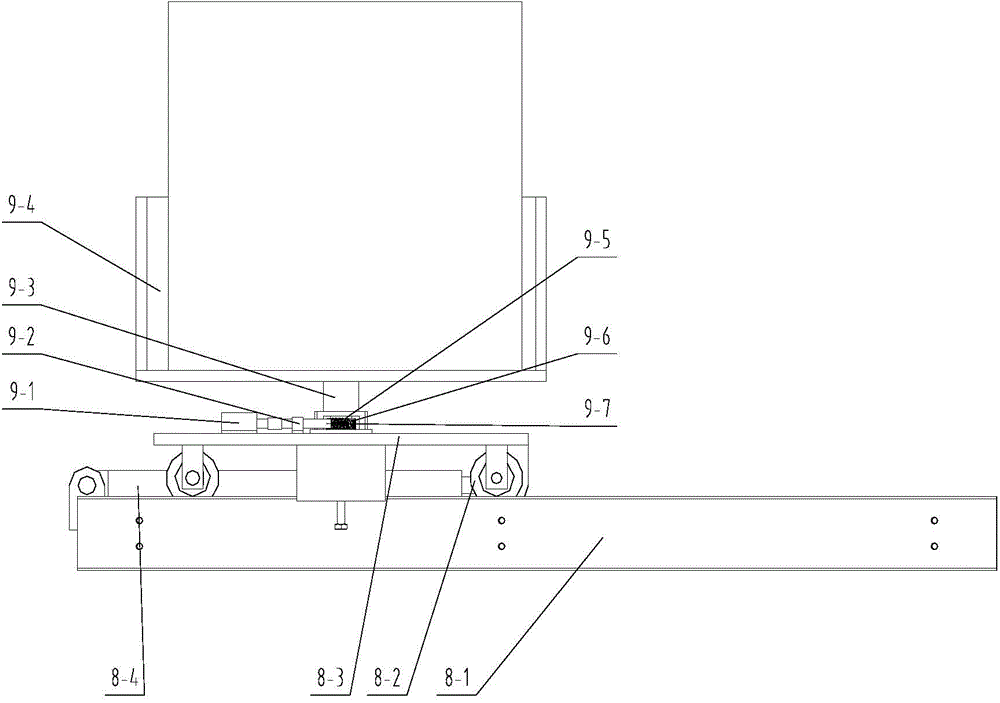

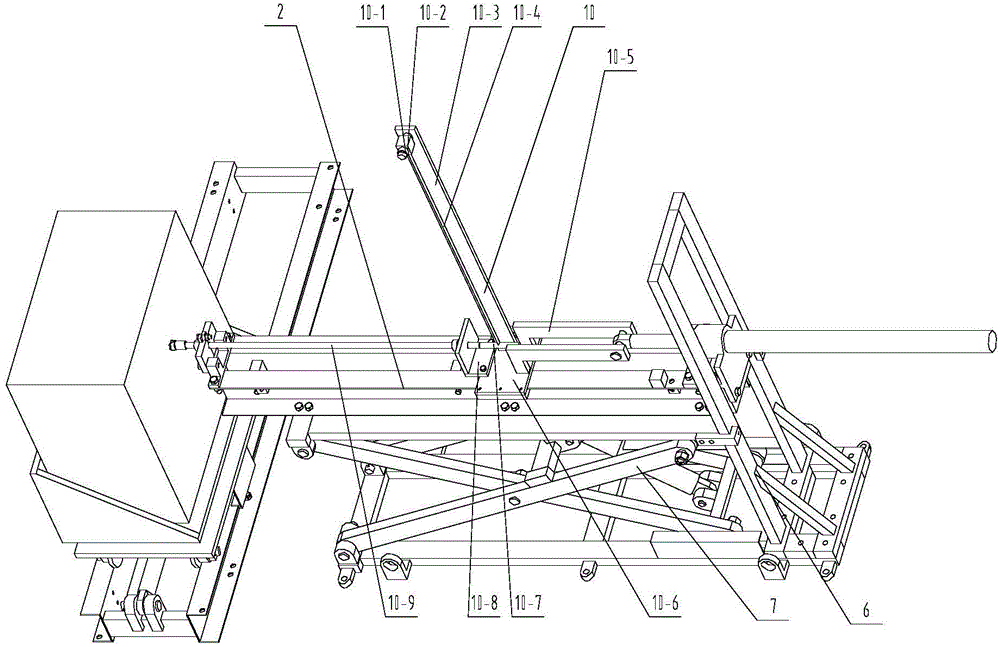

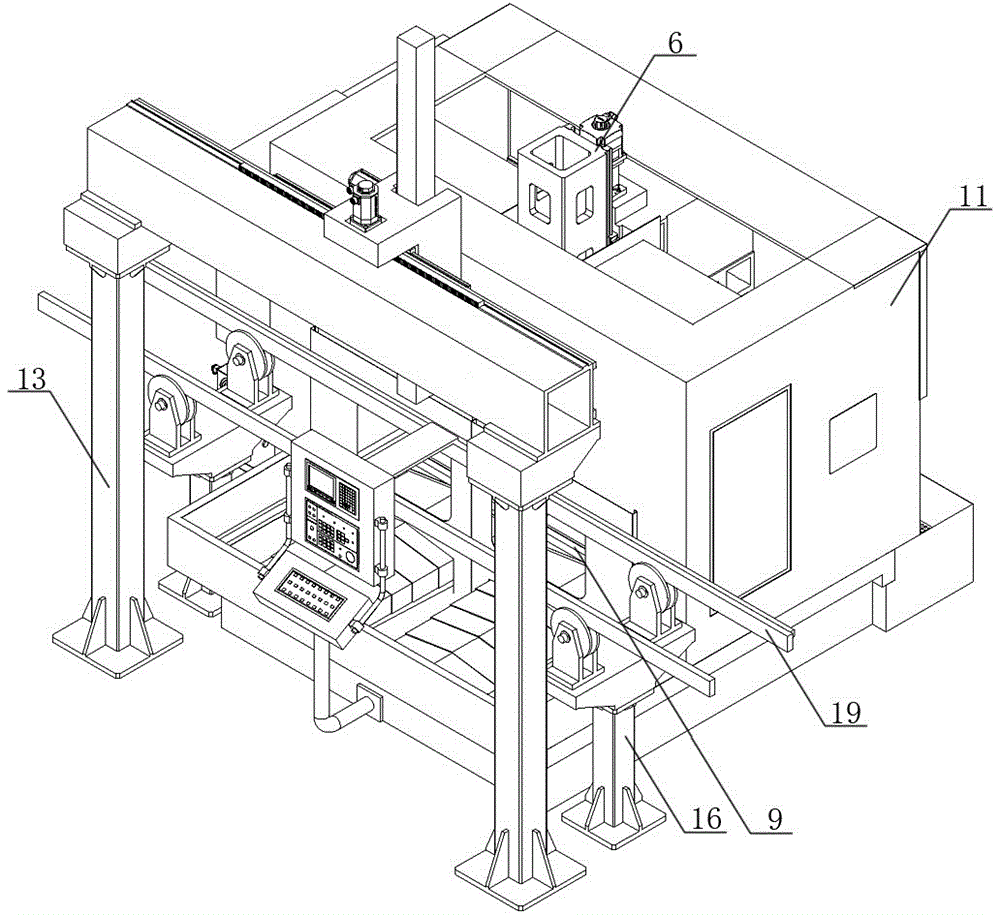

Comprehensive rock impacting breaking test stand

InactiveCN104634673AAchieve horizontal movementRealize layoutMaterial strength using single impulsive forceMaterial strength using repeated/pulsating forcesChanging equipmentSingle impact

The invention discloses a comprehensive rock impacting breaking test stand which comprises a rotating speed sensor, a propelling part, a rock drill, a displacement sensor, a travel switch, a rear support, a lifting table, a thrust rack, a rotating rack and a pendulum bob part. Optional height adjustment in the operating range, horizontal movement of rock and change of the included angle between a tool and the rock can be realized, holes in large rock at different regular positions are formed, the empty hole effect of the rock is researched, the research of rock breaking by combining impacting and rock breaking methods in other forms is realized by virtue of rapid replacement equipment, and the research of rock impacting breaking under single impact and continuous impact conditions is realized. The comprehensive rock impacting breaking test stand disclosed by the invention can serve as both research equipment in a lab and performance detection equipment in factories of rock drills, hydraulic hammers, down-the-hole drills and the like.

Owner:CHINA UNIV OF MINING & TECH

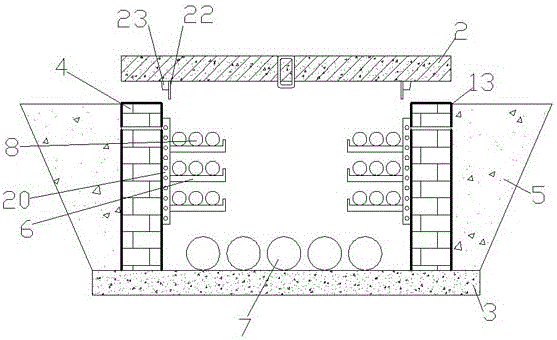

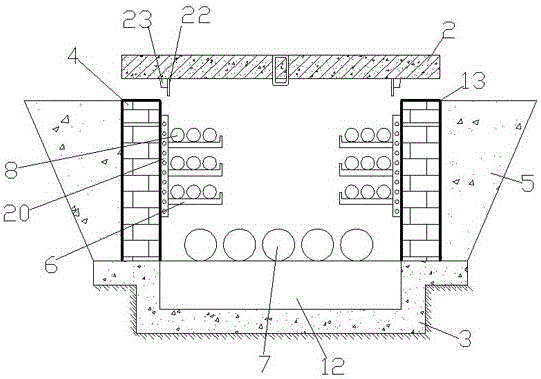

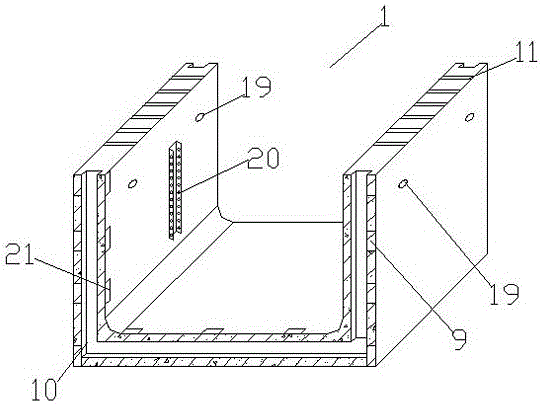

Assembly-type municipal administration integrated pipeline channel and construction method thereof

InactiveCN106759476AAvoid re-excavation and destructionLow costArtificial islandsUnderwater structuresEngineeringStructural engineering

The invention relates to a construction method of an assembly-type municipal administration integrated pipeline channel. The method includes the following steps that (1) a foundation ditch and a slope are dug out according to the design requirements; (2) the foundation ditch is well leveled, and a waterproof cement mortar bonding layer is laid; (3) a prepared assembly-type U-shaped precast pipeline is hoisted into a foundation pile, and two adjacent preset pipeline assemblies are welded and connected together after being in place; (4) grouting, pointing and finishing are carried out; (5) seven stonework at the two sides is used for backfilling and tamping, so that backfill is formed, and a layer course is poured; (6) various pipes in the pipeline are installed; and (7) a precast cover plate is hoisted and fixed. According to the construction method, a centralized-type large-specification arrangement is adopted, and the chaotic phenomena of pipelines in cities and towns can be effectively avoided.

Owner:绍兴明煌科技有限公司

Zero power physical experimental device for lead-base reactor

ActiveCN106531263ARealize layoutVerifiable Physical CharacteristicsNuclear energy generationNuclear elementsRare-earth elementTungsten

The invention provides a zero power physical experimental device for a lead-base reactor. The zero power physical experimental device comprises a reactor vessel, a fuel element, a solid lead breeder, a reflection layer, a reactivity control system, a neutron source system and a shielding system. According to the invention, the solid lead breeder is flexibly spliced with a stub of the fuel element, so that the modularized arrangement of various reactor core structures in the experimental device can be realized; the subcritical and critical double-model running of the experimental device can be realized by inserting or drawing a neutron absorbing component containing tungsten metal into or from the reactor vessel; rare earth elements are added into fissile materials in the fuel element, so that the uniformity problem of reactor core power and neutron-flux distribution under the neutron source driving condition can be solved; a novel granular neutron absorbing material is adopted, so that the flexible structure and convenient recycling of the shielding system are realized.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

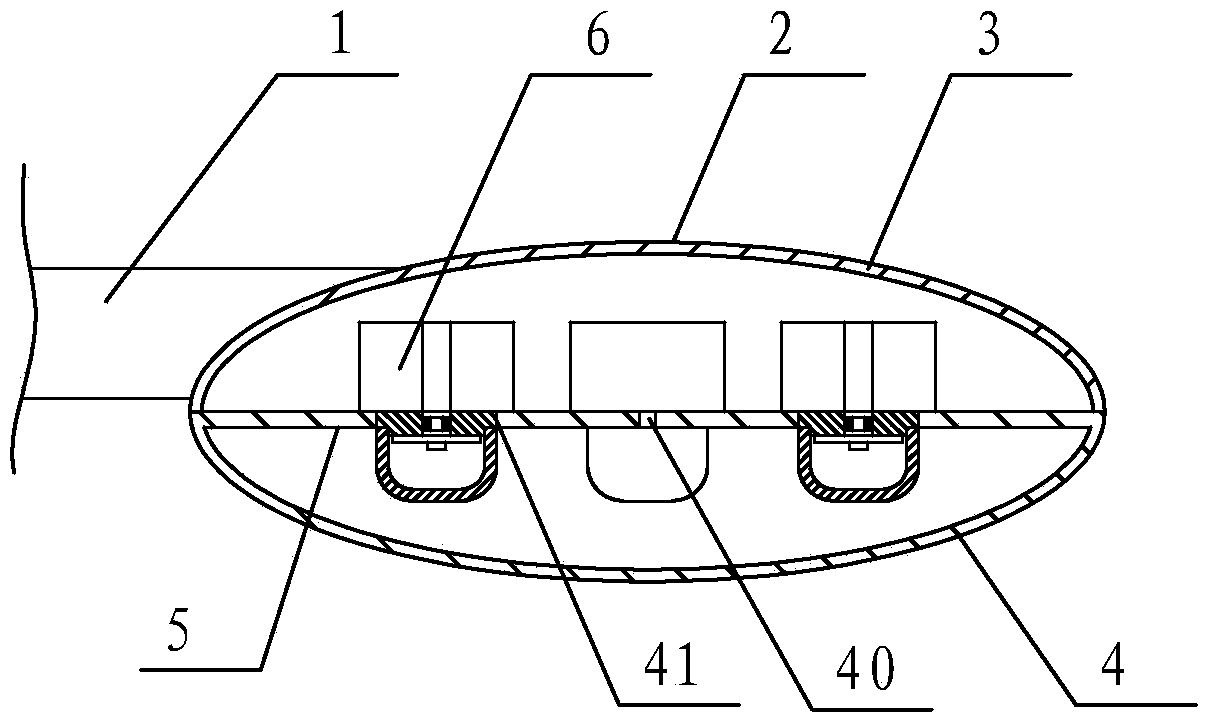

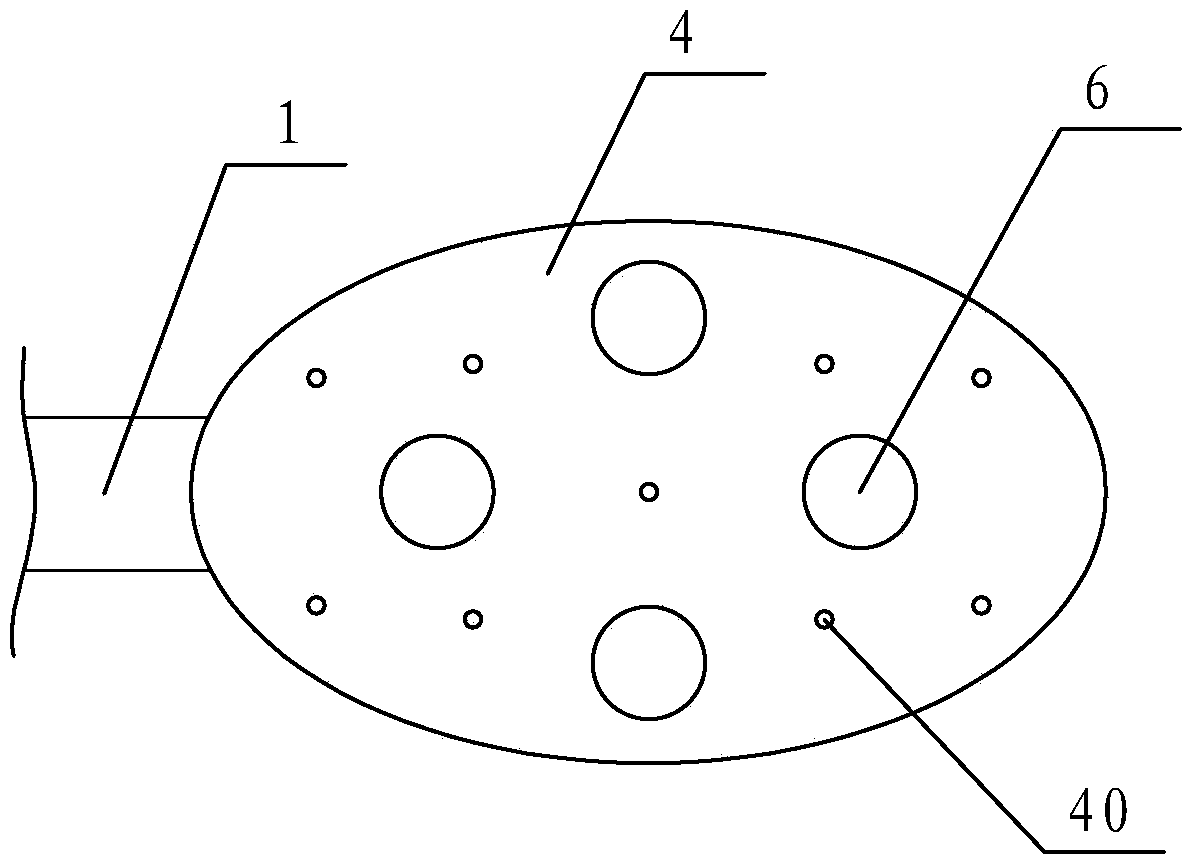

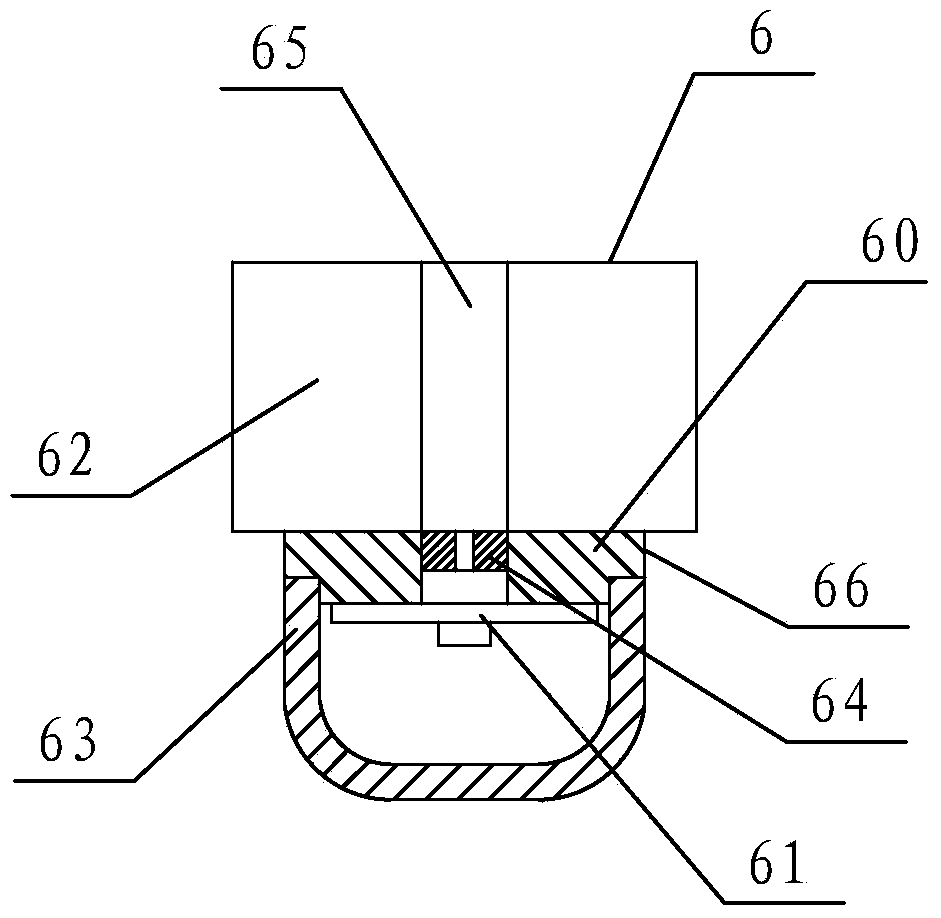

LED road lamp

ActiveCN103629610AEasy to install and fixImprove versatility and interchangeabilityPoint-like light sourceLighting heating/cooling arrangementsLight sourceEngineering

The invention discloses an LED road lamp which comprises a lampshade and an LED light source. The lampshade comprises an upper cover and a lower transparent cover. The upper portion of the lower transparent cover is provided with an installation plate for fixing the LED light source. The LED light source is composed of a plurality of independent LED modules. Each LED module comprises a radiator and an LED light-emitting assembly fixedly arranged at the bottom of the radiator. Each radiator comprises a cylindrical body and radiating fins arranged on the top of the body, wherein the whole radiating fins are in a cylinder shape, and the contour formed by the radiating fins is larger than the body in outer diameter size. Through holes matched with the bodies in outer diameter size are formed in the installation plate. A wire guide hole is formed in the center of each radiator. An elastic rubber plug is arranged inside each wire guide hole. Transparent cover lids used for sealing the LED light-emitting assemblies are arranged at the bottoms of the bodies. The LED light-emitting assemblies emit light towards the transparent cover lids. The transparent cover lids are in threaded connection with the bottoms of the bodies. The LED road lamp is good in universality and replaceability and low in maintenance cost.

Owner:江门市佳颂贸易有限公司

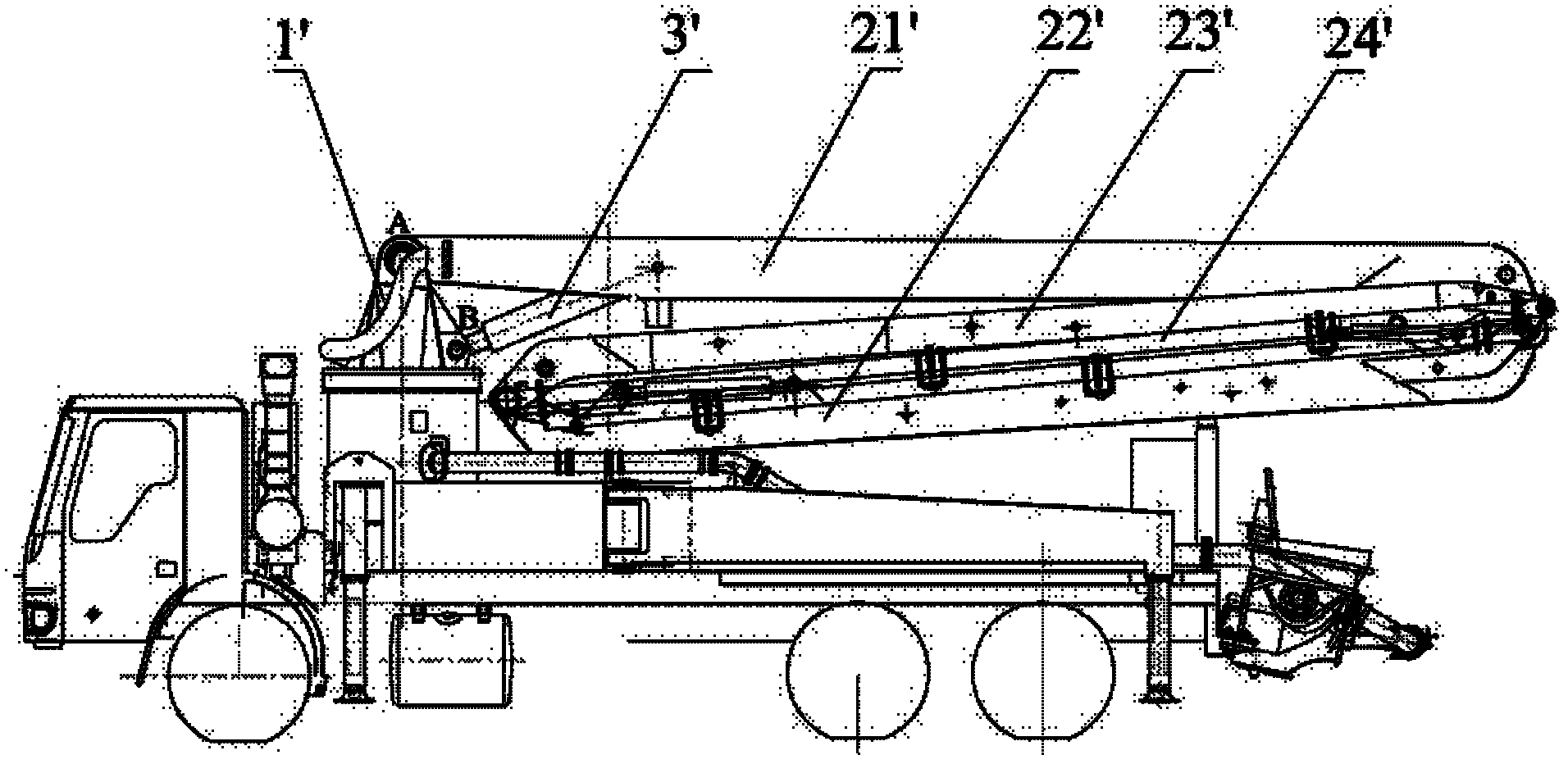

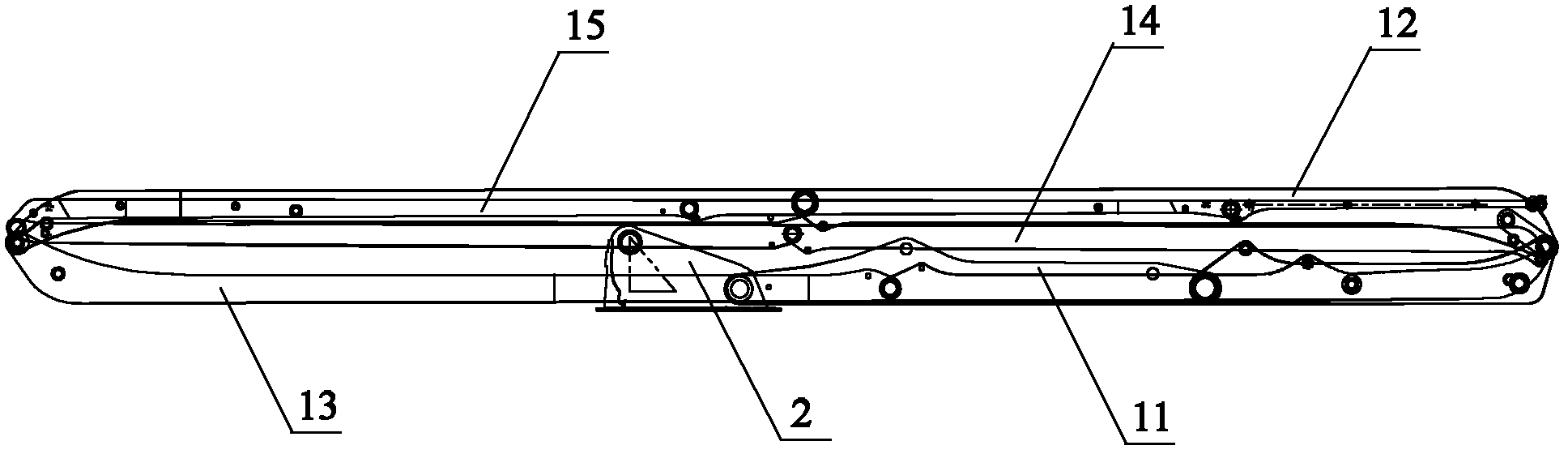

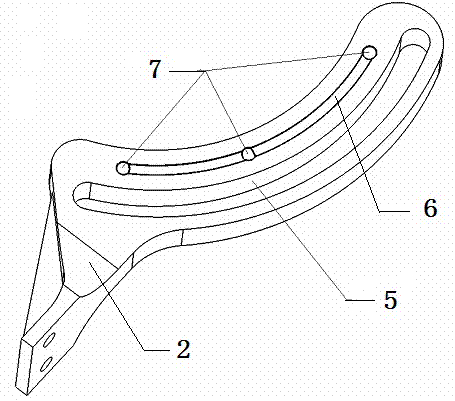

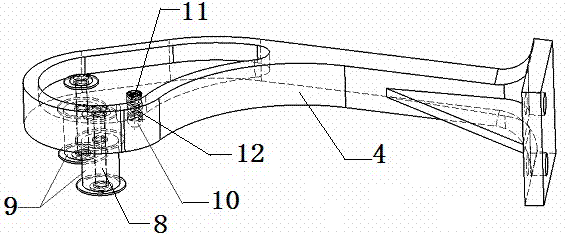

Boom device and concrete pump truck

ActiveCN102561703AExpand the cloth rangeRealize layoutBuilding material handlingHoisting equipmentsEngineeringMechanical engineering

The invention discloses a boom device, which comprises a plurality of boom segments hinged in sequence. The first boom segment is hinged to a rotary table of an engineering machine, the rotary table is disposed in the middle of the engineering machine, the first boom segment is disposed upside down, the second boom segment is hinged to the first boom segment and folded above the first boom segment, and all of from the second boom segment to the final boom segment penetrates through a body of the engineering machine. The rotary table is disposed in the middle of the engineering machine, the first boom segment is disposed upside down and extends towards the tail of the engineering machine or towards a cab of the engineering machine, all of from the second boom segment to the final boom segment can penetrate through the body of the whole engineering machine, namely penetrating from the cab of the engineering machine to the tail thereof lengthwise along the engineering machine, and accordingly, arrangement of an ultra-long boom can be achieved, extension height of the whole boom device is further increased so as to extend the distribution range of the boom device. The invention further provides a concrete pump truck.

Owner:SANY HEAVY IND CO LTD (CN)

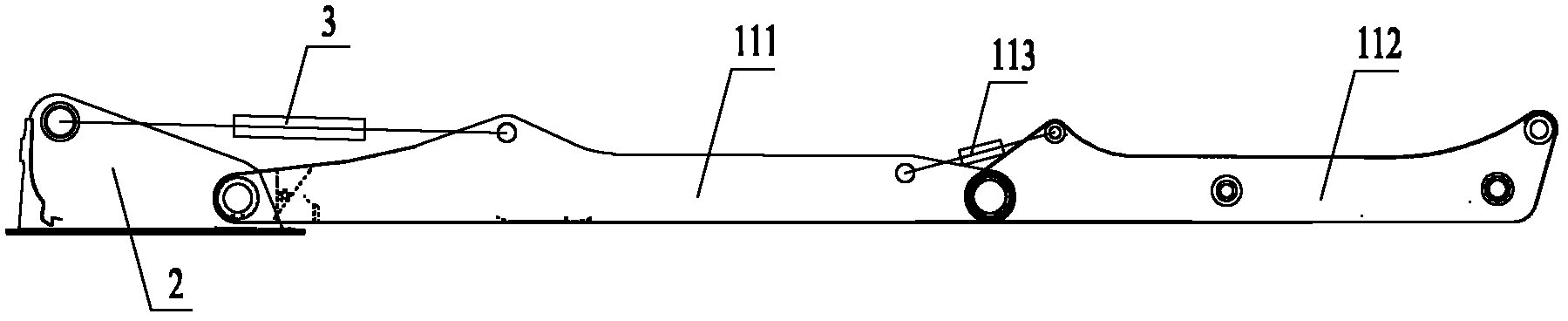

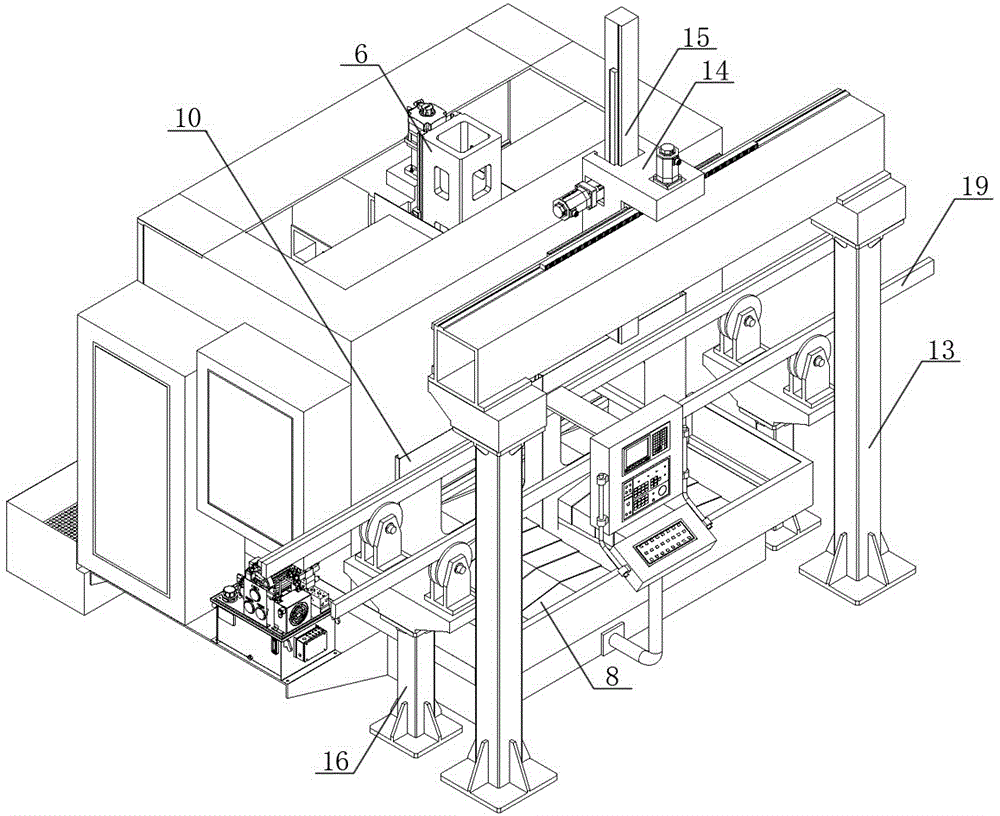

Flexible automatic production line and method used for machining car engine cylinder cover

ActiveCN105750927AOvercome unreasonable designImprove work efficiencyOther manufacturing equipments/toolsMetal working apparatusManipulatorMachine tool

The invention discloses a flexible automatic production line and method used for machining a car engine cylinder cover. The automatic production line comprises a row of machine tools arranged at intervals, and further comprises truss manipulators and a material transportation system; the truss manipulators are in one-to-one correspondence with the machine tools, and are arranged in front of the machine tools; a transportation belt of the material transportation system is across the front end of the row of the machine tools, and continuously extends to the final machine tool from the first machine tool; and horizontal tool plates are uniformly connected to the transportation belt at intervals. According to the automatic production line, a machining center is adopted for line assembly, so that 100% flexibility of the automatic production line is realized, the machining demands of different products can be completely met, and the labor intensity of workers is reduced; each machine tool is configured with two worktables, and the two worktables alternately work, so that the precision of the machine tool can be kept for a long term and the response speed of the machine tool is increased; and in addition, the loading and unloading time is guaranteed to be overlapped with the machining time by 100%, so that the loading and unloading time is saved and the production efficiency is improved. The automatic production line can be widely applied to the machining and production of car engine cylinder covers.

Owner:CHONGQING WNC INTELLIGENT EQUIP

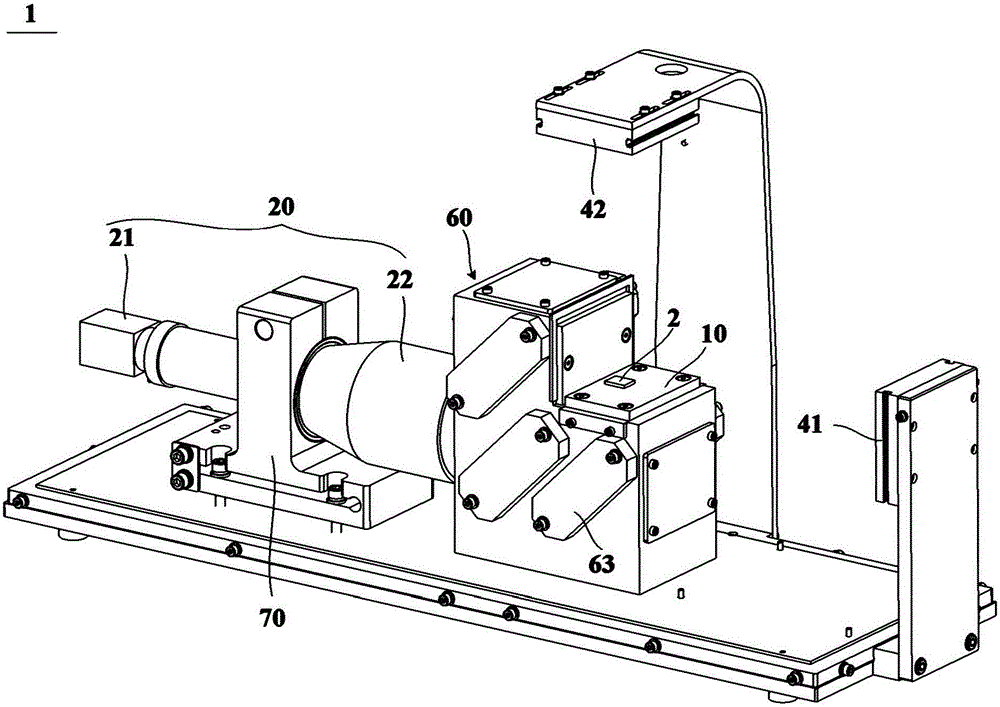

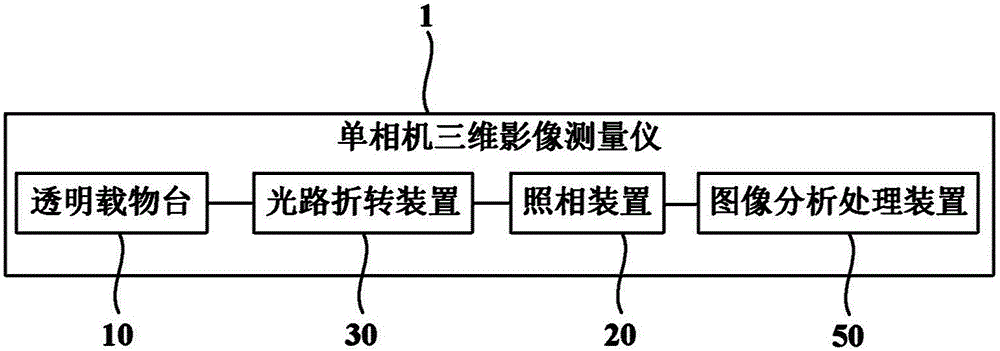

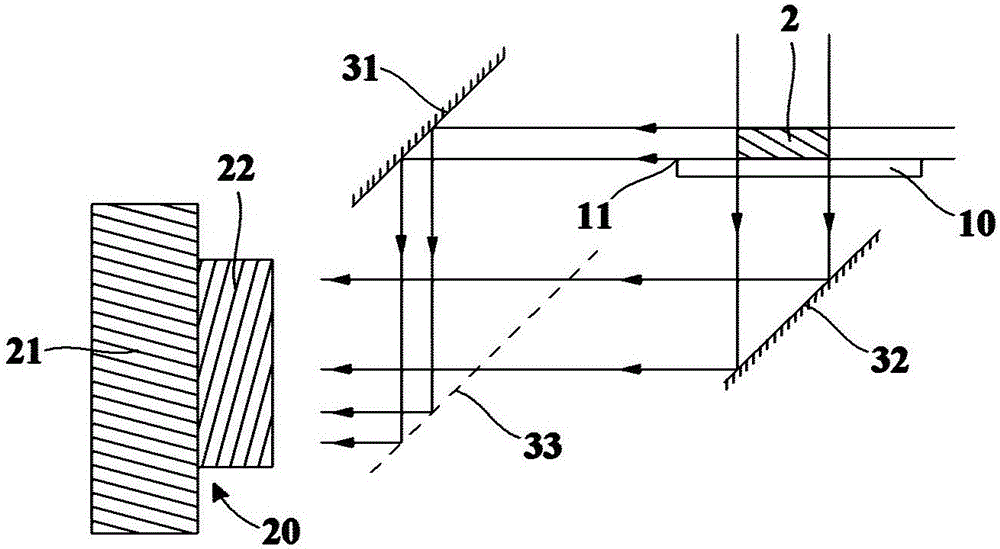

Single-camera three-dimensional image measuring instrument

ActiveCN105973165ASimple structureImprove image acquisition efficiencyUsing optical meansMeasuring instrumentComputer science

Owner:BEIJING LEADERTECH INTELLIGENT EQUIP CORP

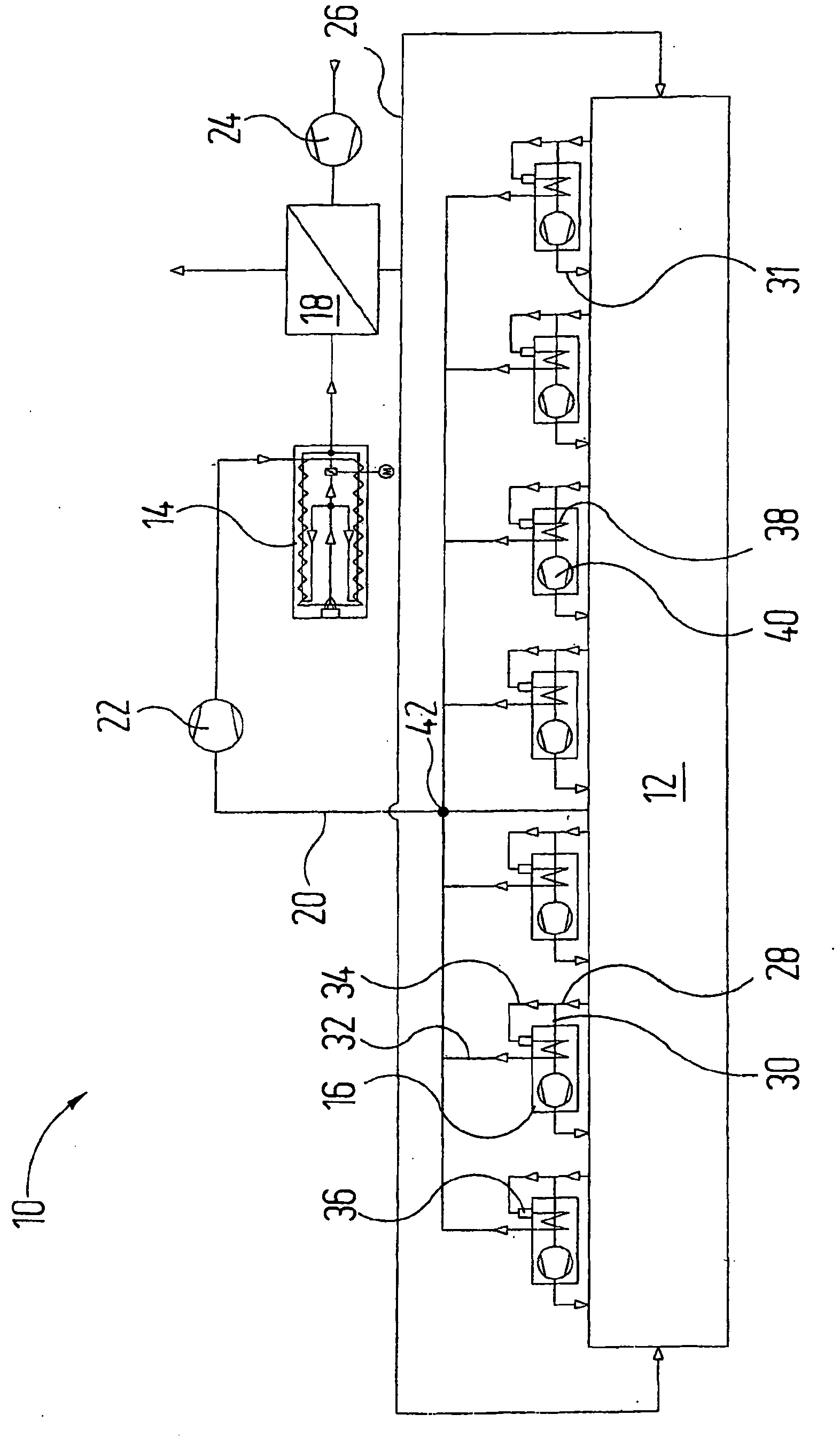

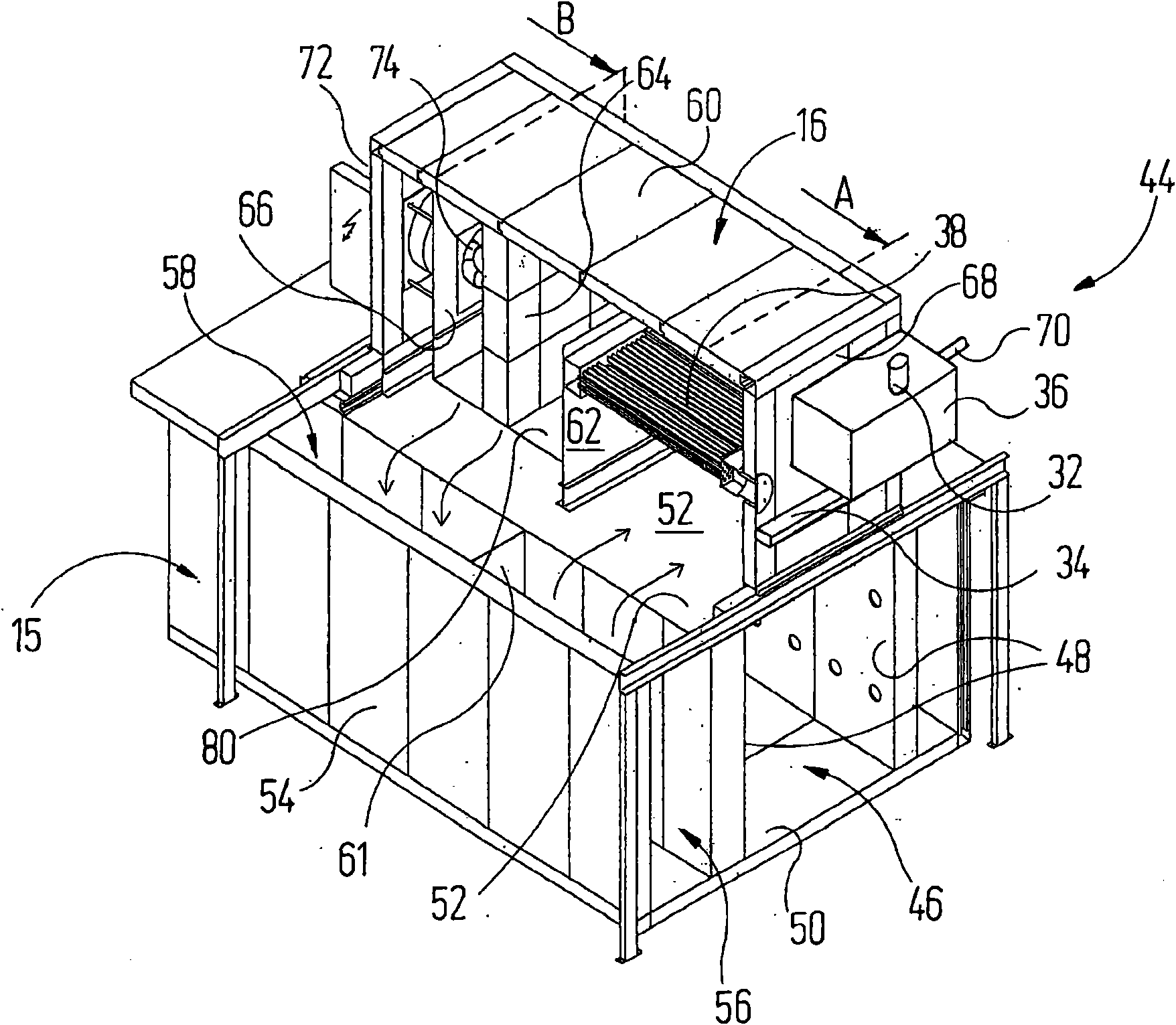

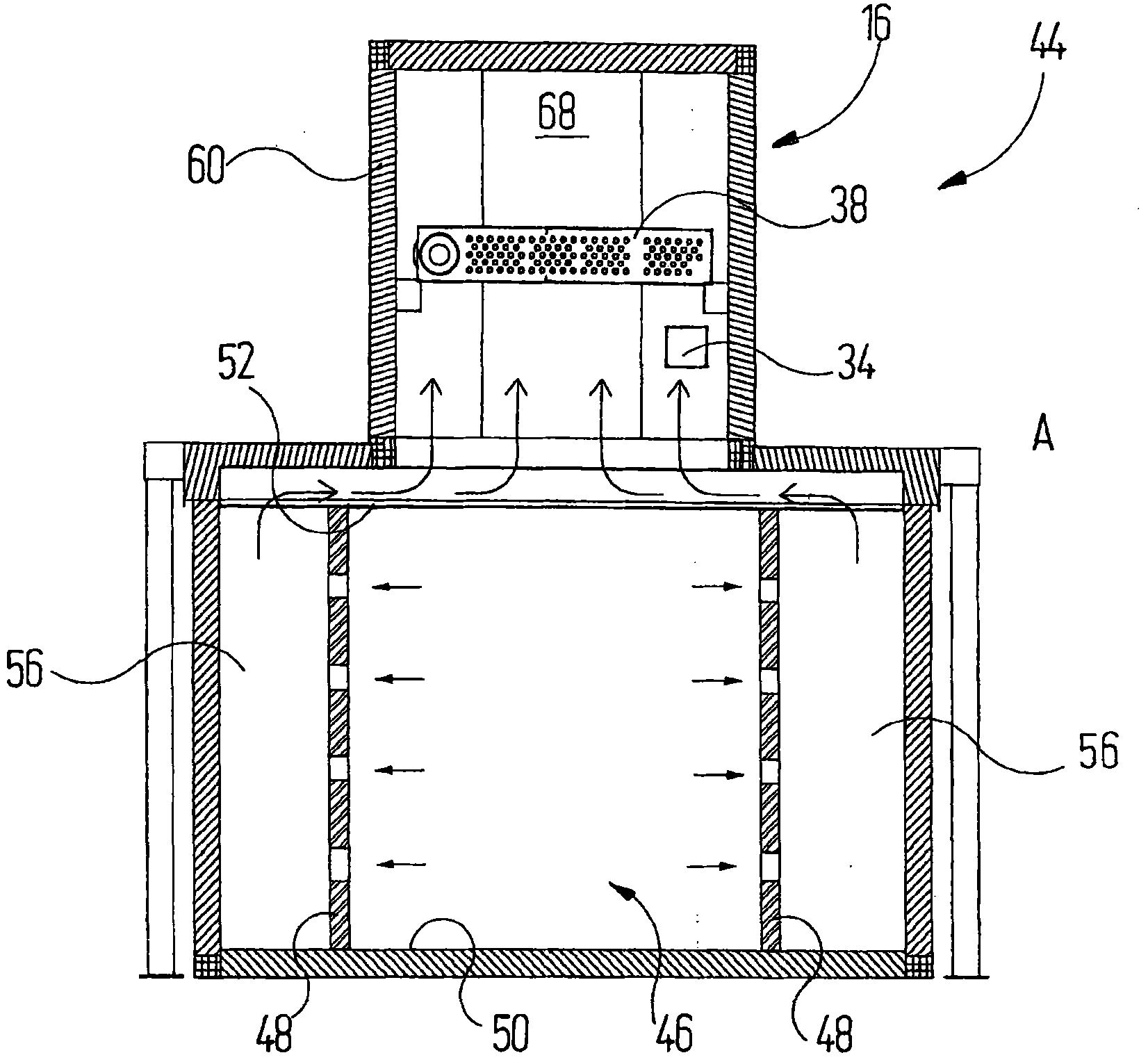

Dryer for lacquering facility

The invention relates to a dryer for a lacquering facility: a) having a dryer housing (12), in which heated air is circulated, b) having an exhaust air line (20) for a exhausting exhaust air from the dryer housing (12); c) having a combustion unit (14), which is connected to the exhaust air line (20), and which is used for thermal post-treatment of the exhaust air from the dryer housing (12) and for providing hot air to a heat exchanger (18); d) wherein said heat exchanger (18) is set up to supply said dryer housing (12) with heated fresh air; and wherein e) at least one heating unit (16) for heating the air circulated in said dryer housing (12) is associated with said dryer housing (12). It is provided according to the invention that a combustion air supply (34) of the heating unit (16) is connected so it communicates with the dryer housing (12).

Owner:艾森曼机械设备上海有限公司

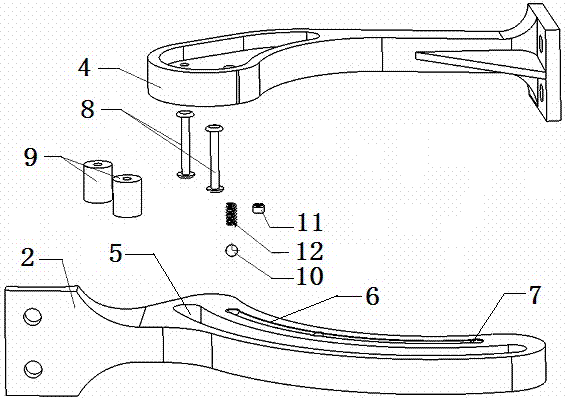

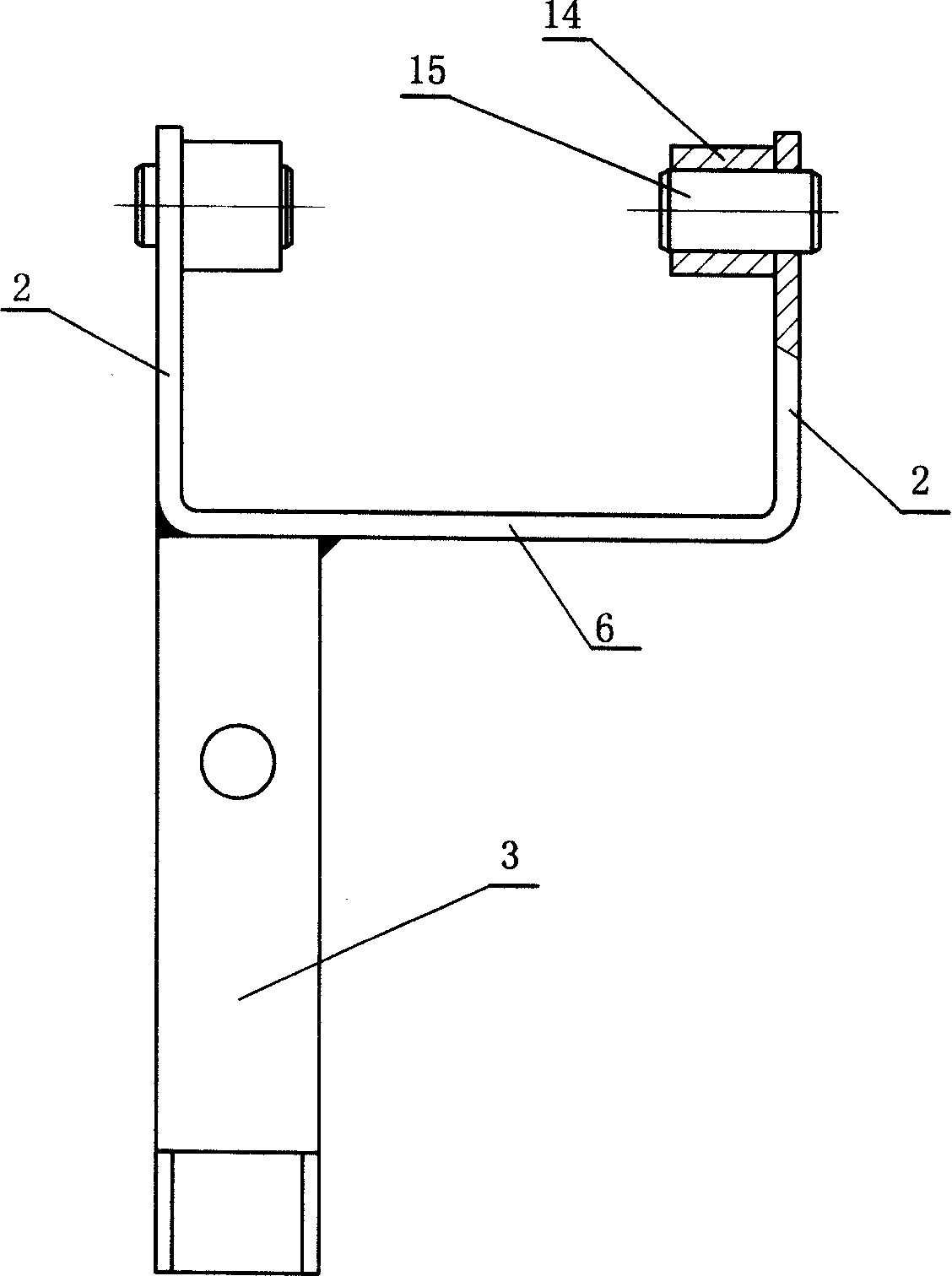

Automobile rotating door hinge

The invention discloses an automobile rotating door hinge, which comprises a fixed arm and a rotating arm, wherein the fixed arm is fixedly connected onto a door post of an automobile body; the rotating arm is fixedly connected onto the automobile body; the fixed arm is respectively provided with an arc-shaped roller guide slot and an arc-shaped limit chute; and at least two limit pits are arranged in the limit chute. The rotating arm is provided with a roller mechanism and a limit ball mechanism, wherein the roller mechanism corresponds to the roller guide slot, and the limit ball mechanism corresponds to the limit chute. The roller mechanism and the limit ball mechanism respectively do relative slip in the roller guide slot and the limit chute, and thus, the fixed arm and the rotating arm can be rotatablely and glidingly connected. According to the automobile rotating door hinge, the opening angle of the automobile door is increased to the maximum degree; the opening and closing and limit function of the automobile door is realized; the arrangement of the hinge is realized by using a smaller space, therefore, the weakening to the door post is reduced, and the strength of the door post is ensured. Castings are respectively adopted to serve as the fixed arm and the rotating arm, therefore, the cost is reduced.

Owner:SUZHOU AUTO TECH

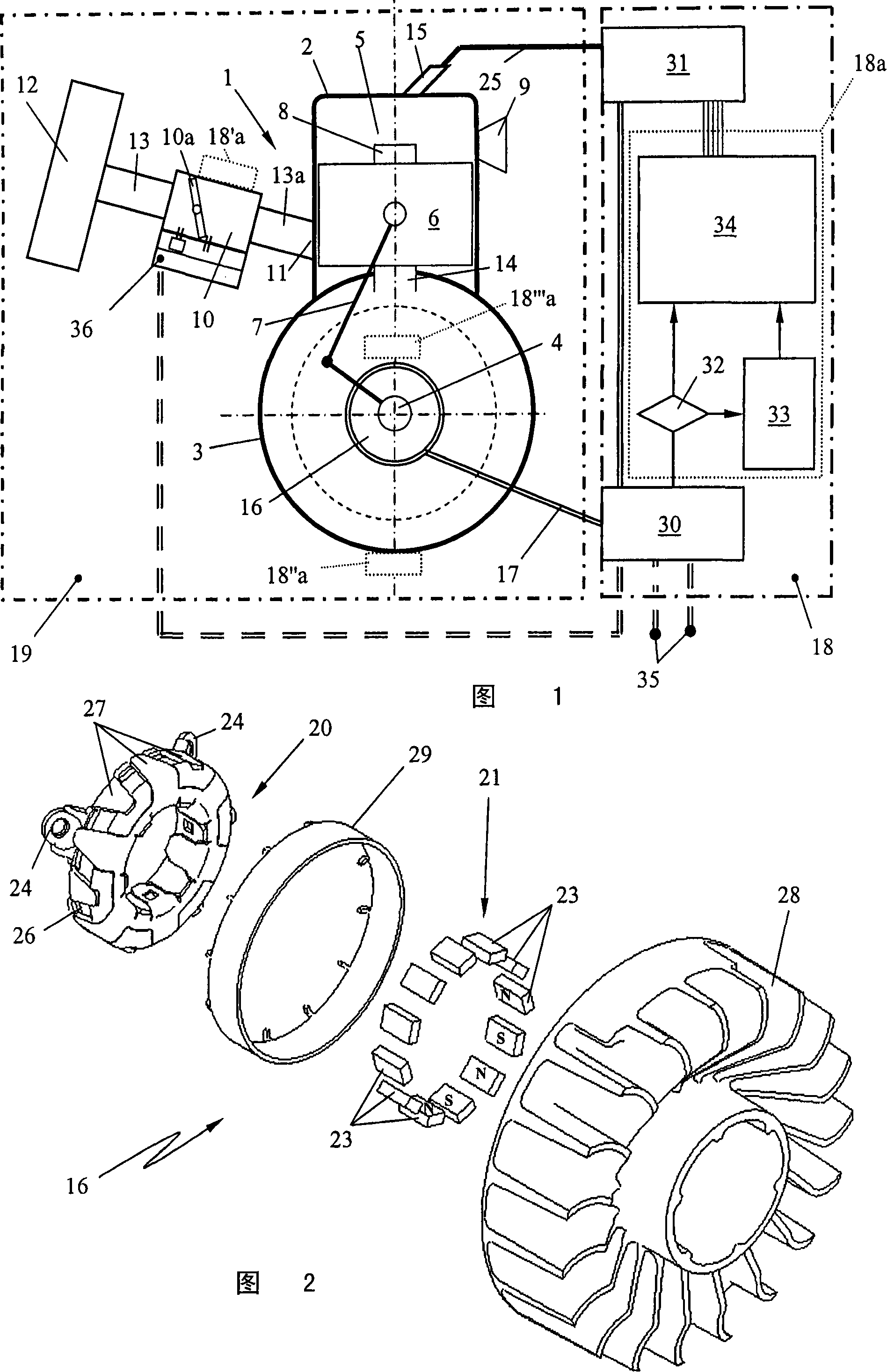

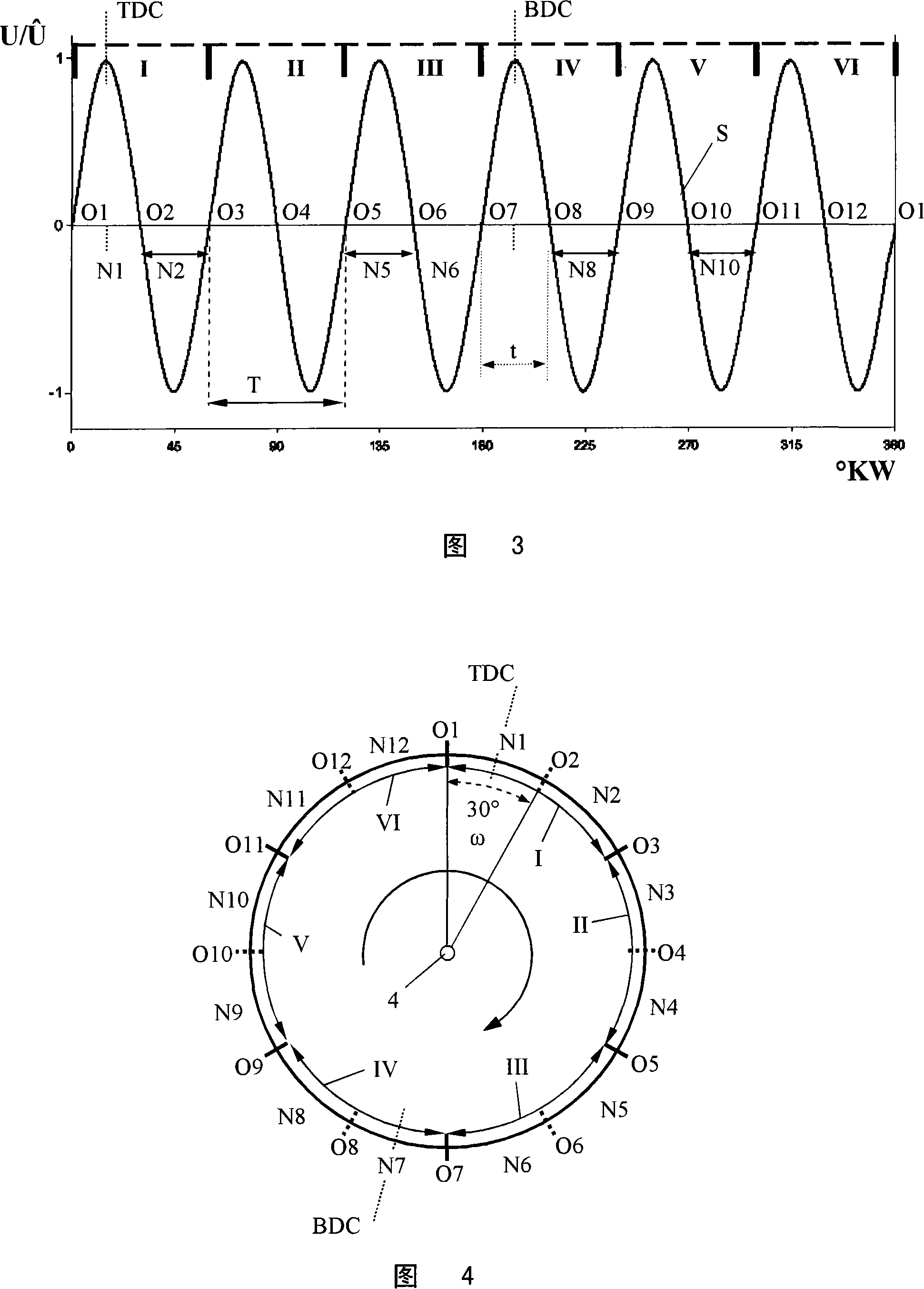

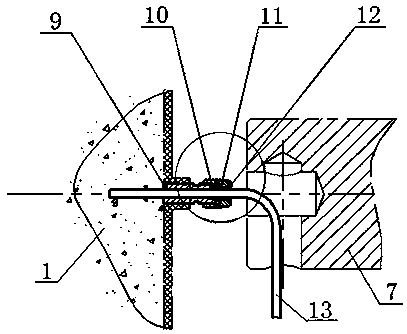

Ignition device for an internal combustion engine and method for its operation

ActiveCN101126363ARealize layoutSimple mechanical structureGenerator for specific enginesMachines/enginesCombustion chamberHand held

Owner:ANDREAS STIHL AG & CO KG

Rail changing device and method for straddle-type monorail rails and rail

InactiveCN106740994AImprove traffic efficiencyLarge Passenger Carrying CapacityVisible signalsMonorailsEngineeringMechanical engineering

The invention discloses a rail changing device for straddle-type monorail rails and the rail. The rail changing device comprises a walking rail beam, a crossing rail beam block, a rail changing beam block part, a rail changing execution part, a rail changing locking part, a signal lamp, support columns and an installation platform fixed to the tops of the support columns. The position of the rail changing beam block part is changed through the rail changing execution part installed on the installation platform, and therefore different trains can go through different straddle-type monorail rails. The invention further provides a rail changing method for the straddle-type monorail rails. The rail changing device has the advantages of being simple in structure, stable, reliable and efficient.

Owner:王国伟

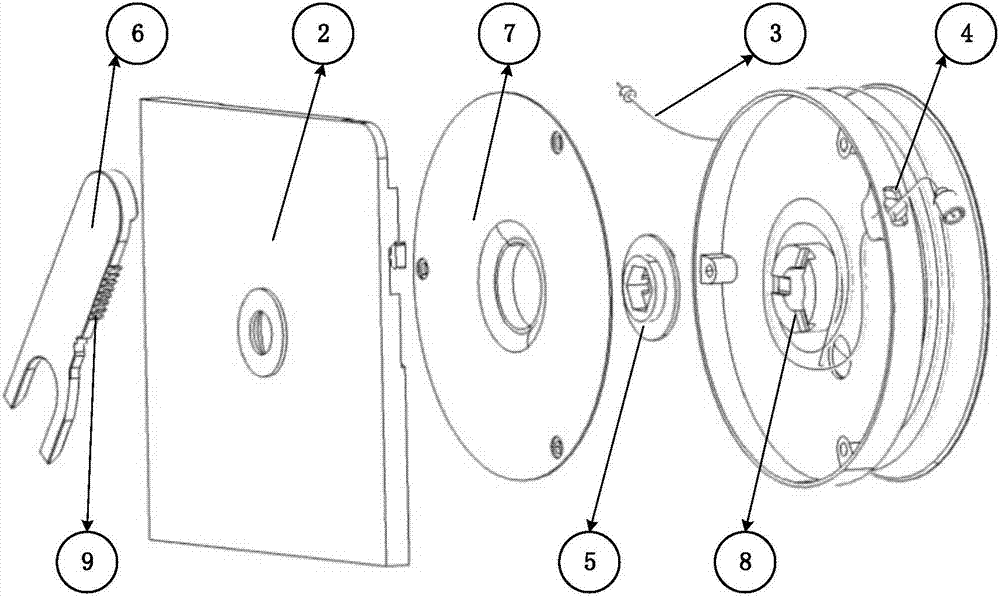

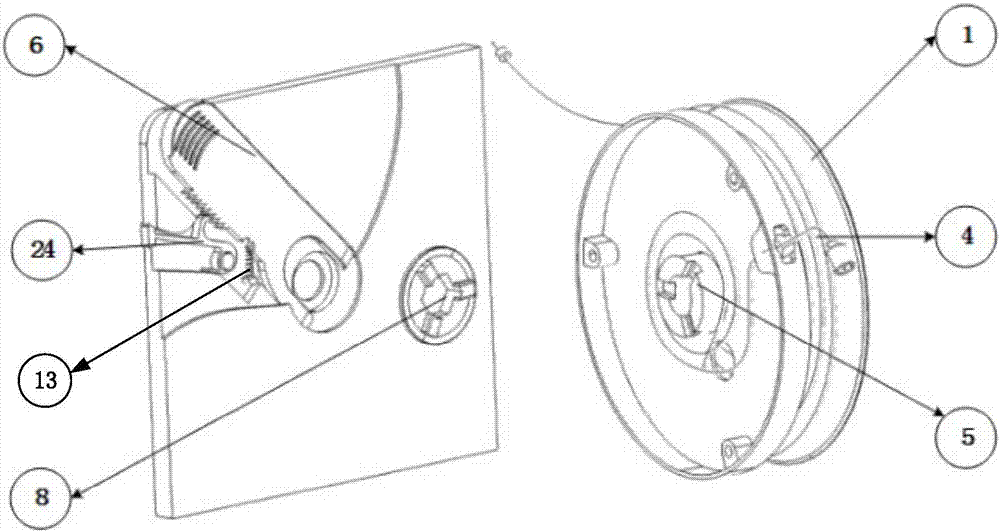

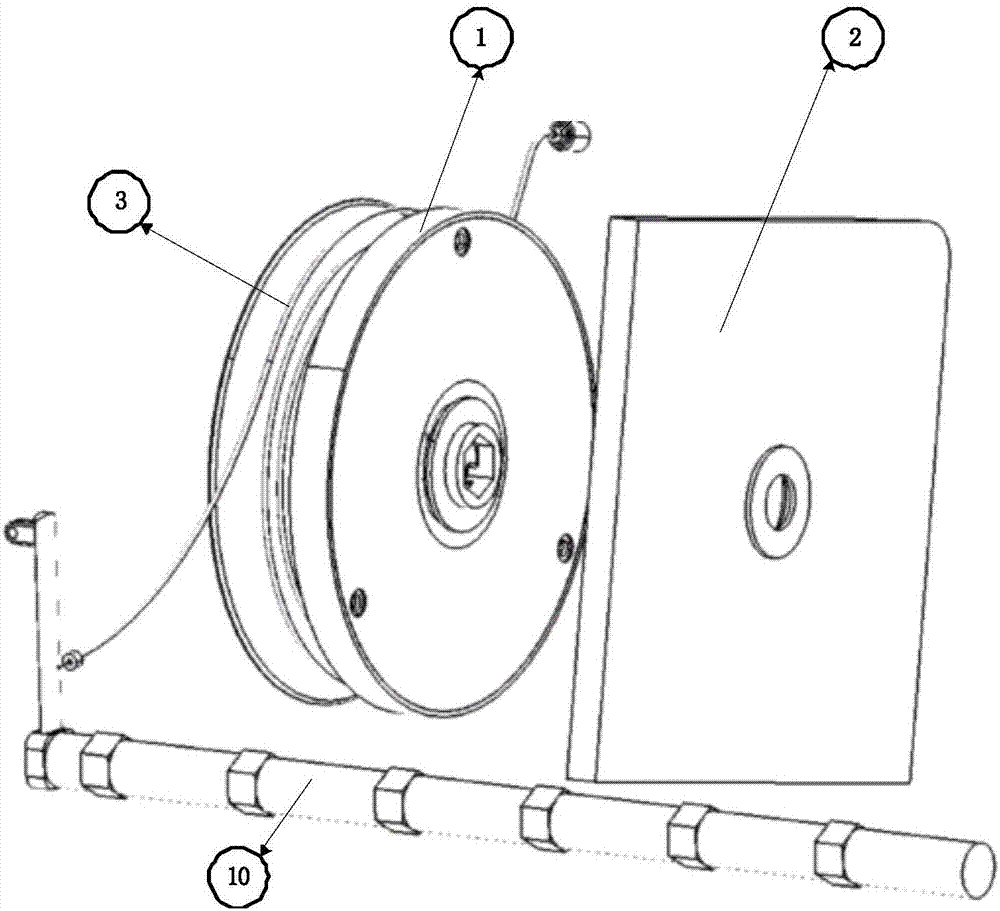

Instrument for ship vibration impact site test and cable integration device

The invention provides an instrument for a ship vibration impact site test and a cable integration device. The instrument is composed of a tool box, cable winding discs, a cable disc control mechanism, an L-shaped instrument transposition structure and the like. Multiple partition bins and a cable disc mounting control structure bracket are arranged on the tool box, multiple sets of cable holes and movable rolling wheels are arranged at the bottom, and the cable winding discs are mounted on the partition bin at the bottom of a tool box framework structure; the cable winding discs are connected coaxially and are controlled by the cable disc control mechanism; the L-shaped instrument transposition structure is mounted in the partition bin on the upper portion of the tool box, and an instrument fixing structure is arranged at the bottom of the L-shaped instrument transposition structure. According to the instrument for the ship vibration impact site test and the cable integration device, through the integrated tool box device, storage of multiple experimental devices is achieved, quick take-up and pay-off of multiple sets of experimental signal lines can be achieved, the trouble brought by traditional manual cable arrangement is saved, and the structure is convenient and fast to use and practical.

Owner:HARBIN ENG UNIV

Piling technology for building workshop

The invention discloses a piling technology for a building workshop. The piling technology comprises the following steps that 1, a pile position is determined, construction layout is carried out through a total station or a theodolite, the pile position is determined, the angle of a setting-out point is determined at first through the setting-out principle of the theodolite, and then the design distance is pulled through a steel rule or a tape measurer; and 2, precast piles are manufactured, hoisted, conveyed and stacked, it is ensured that the precast piles are stably stacked and kept a proper distance away from the piling position. Compared with a traditional piling method, the technology is easy to operate, has various ways, can adapt to piling on various geological conditions, can effectively achieve pile preembedding operation, is reasonable in design, easy to operate, simple in steps, wide in application range and beneficial to being popularized, and operation time is saved.

Owner:广东广强基础工程有限公司

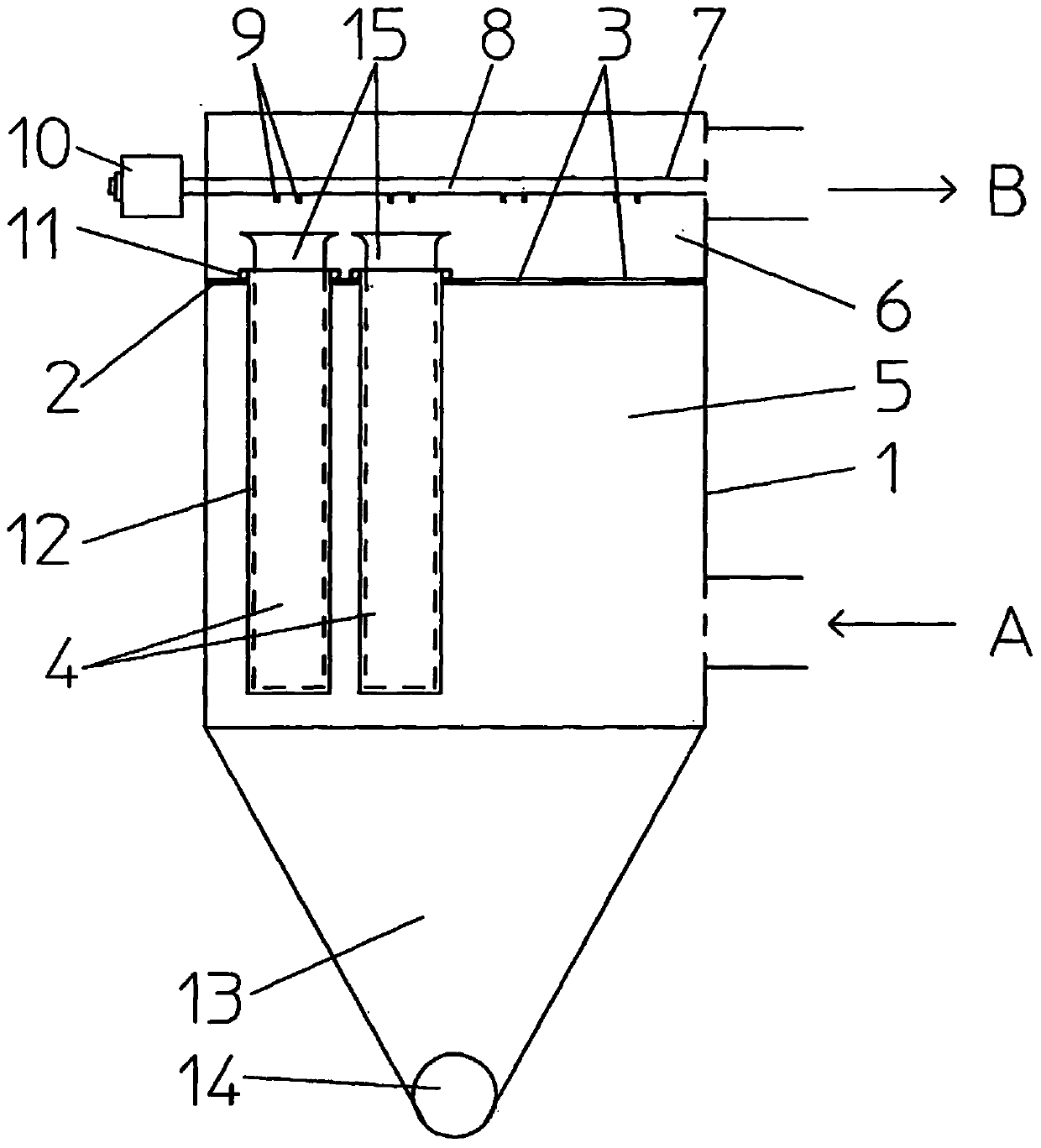

Bag filter for cleaning dust-laden gases and injector nozzle for such a bag filter

InactiveCN103635244AImprove filtering effectEasy to cleanDispersed particle filtrationTransportation and packagingSpray nozzleInjector nozzle

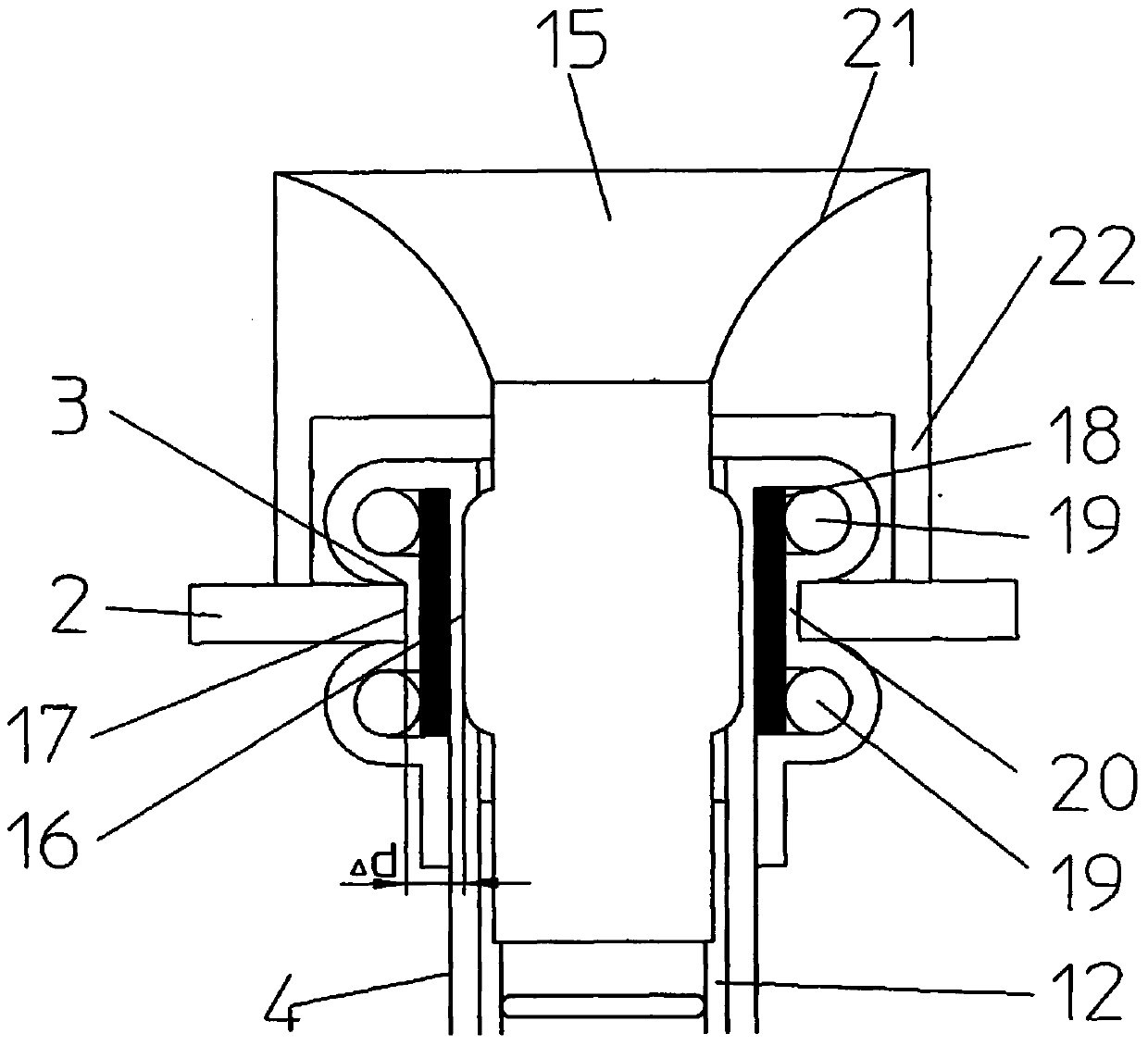

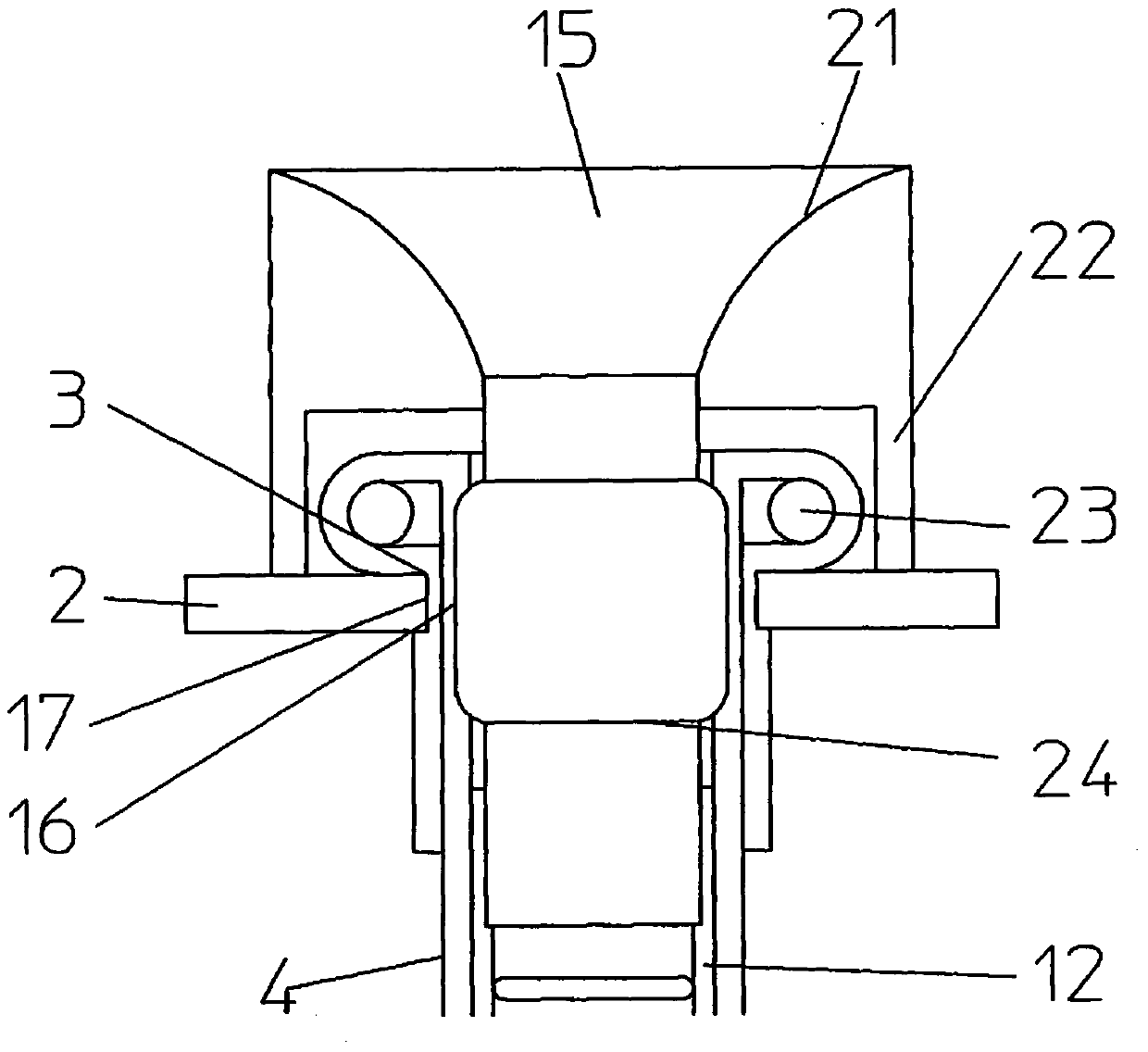

The invention relates to a bag filter for cleaning dust-laden gases A, comprising a housing (1), which is divided into a filtered-gas side (6) and a unfiltered-gas side (5) by a bag bottom (2) having openings (3), in which housing (1) several filter bags (4) having a flat cross-section are arranged in the openings (3) of the bag bottom (2). According to the invention, each support basket (12) is connected at the end associated with the open end of the respective filter bag (4) to an injector nozzle (15) for conducting and accelerating the dedusting compressed-air pulses, which injector nozzle (15) protrudes at least partially into the openings (3) of the bag bottom (2), and sealing elements (16) are arranged on the outside of the injector nozzle (15) at the height of the bag bottom (3) in order to form a defined gap ([delta]d) for a defined compression of the filter bag (4) between the sealing elements (16) and the jacket surface (17) of the opening (3) in the bag bottom (2) and thus to independently seal the filter bag (4) with respect to the opening (3) of the bag bottom (2).

Owner:SCHEUCH GMBH

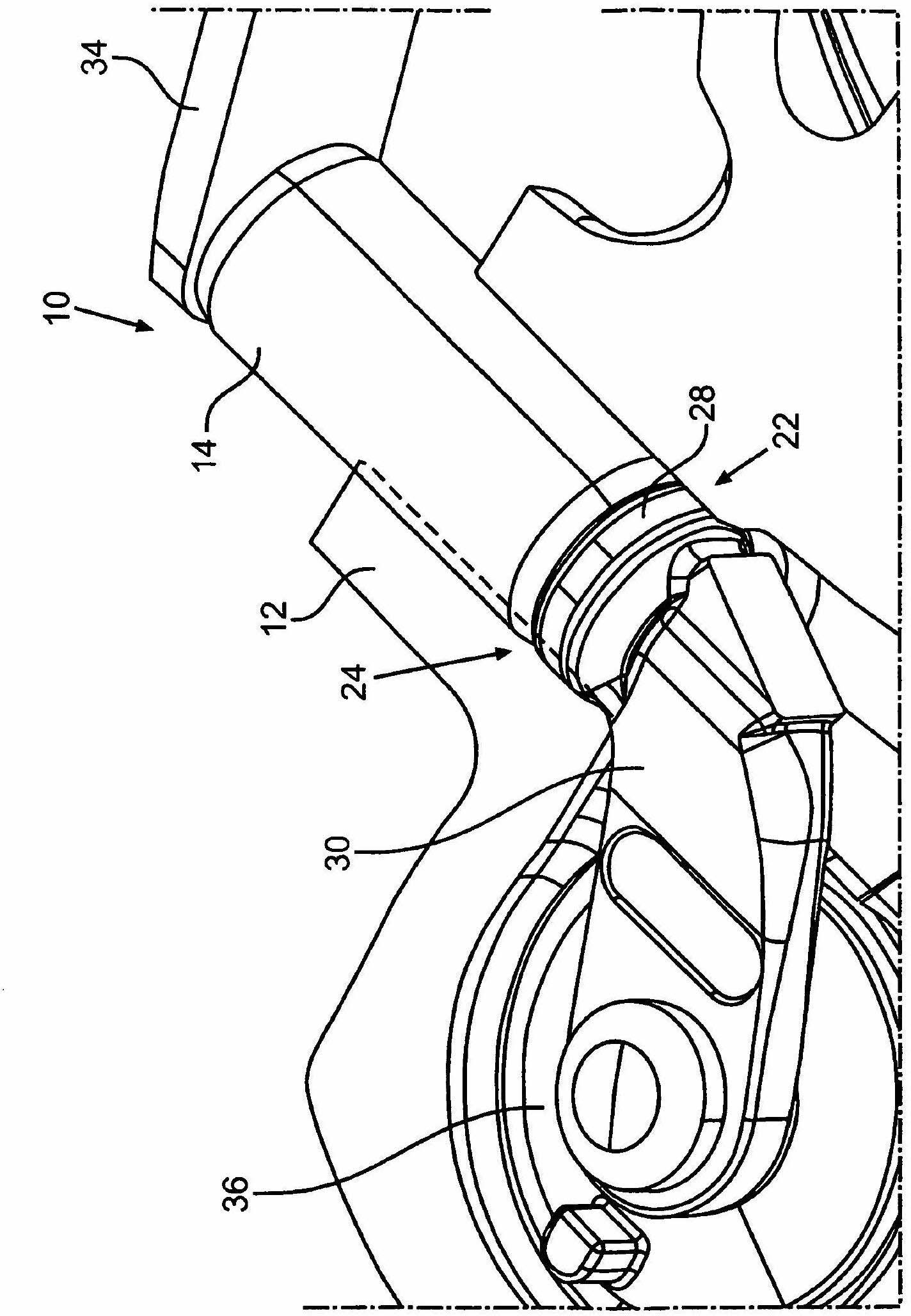

Seal for an adjustment device for a supercharging device

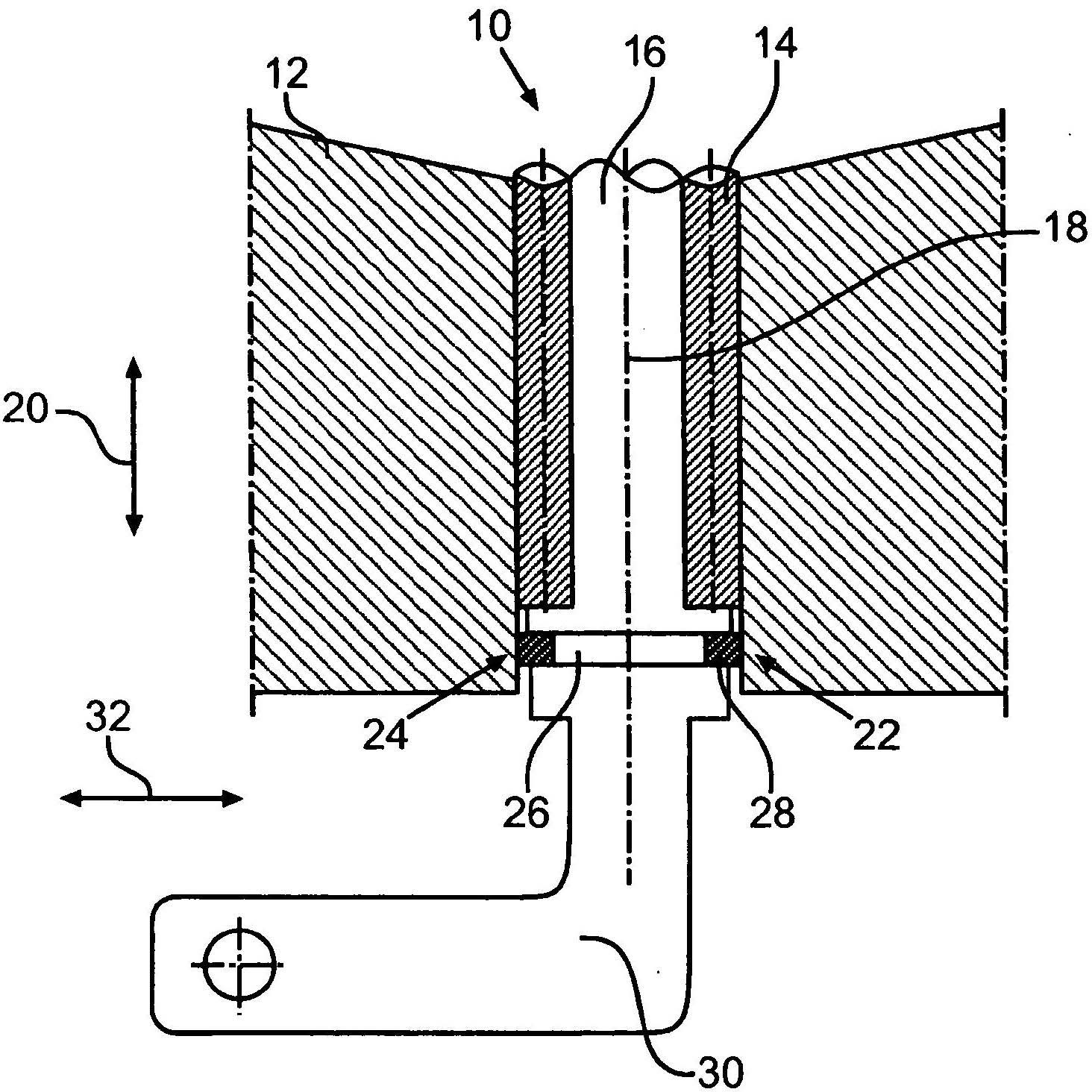

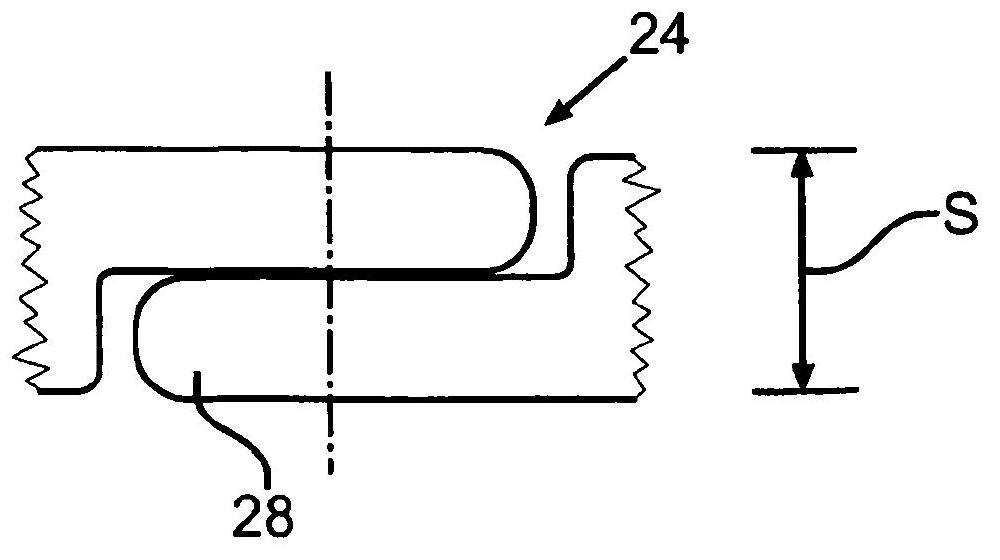

InactiveCN102656351APrevent leakageAchieving sealed contactGas turbine plantsEngine componentsTurbochargerEngineering

The invention relates to an adjustment device (10) for a supercharging device, in particular an exhaust gas turbocharger, comprising a bearing element (14), in particular a bushing (14), in which an adjustment shaft (16) is accommodated at least in some sections and by means of which the adjustment shaft (16) can be supported in a housing (12) of the supercharging device, wherein at least one sealing element (28) is arranged on the adjustment shaft (16) in a section (22) of the adjustment shaft (16) that protrudes beyond the bearing element (14) in the axial direction (20).

Owner:IHI CHARGING SYST INT

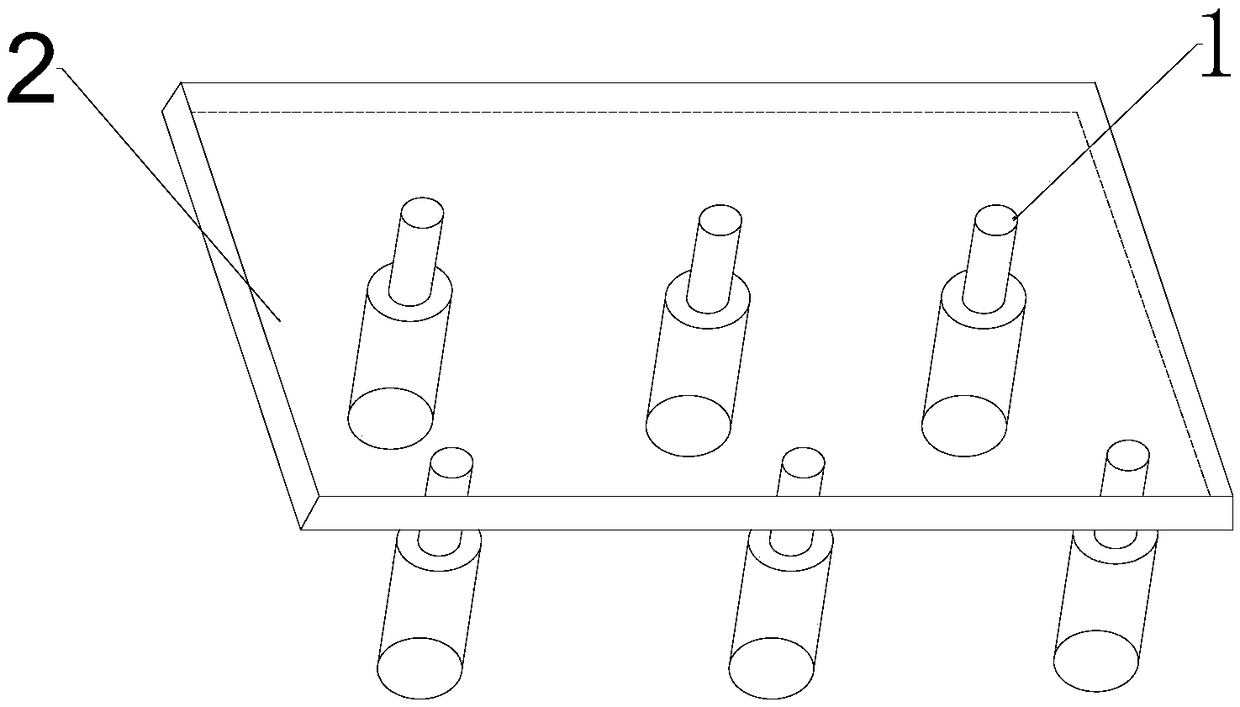

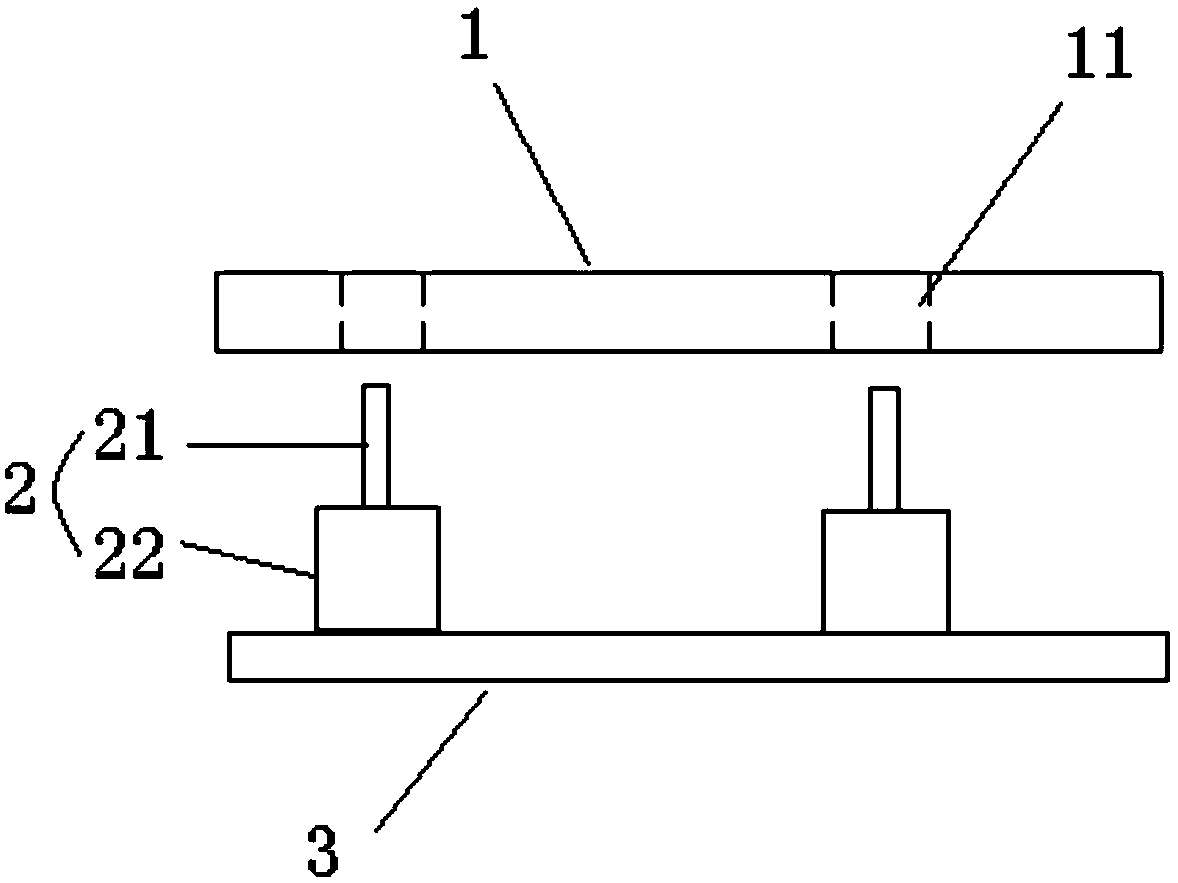

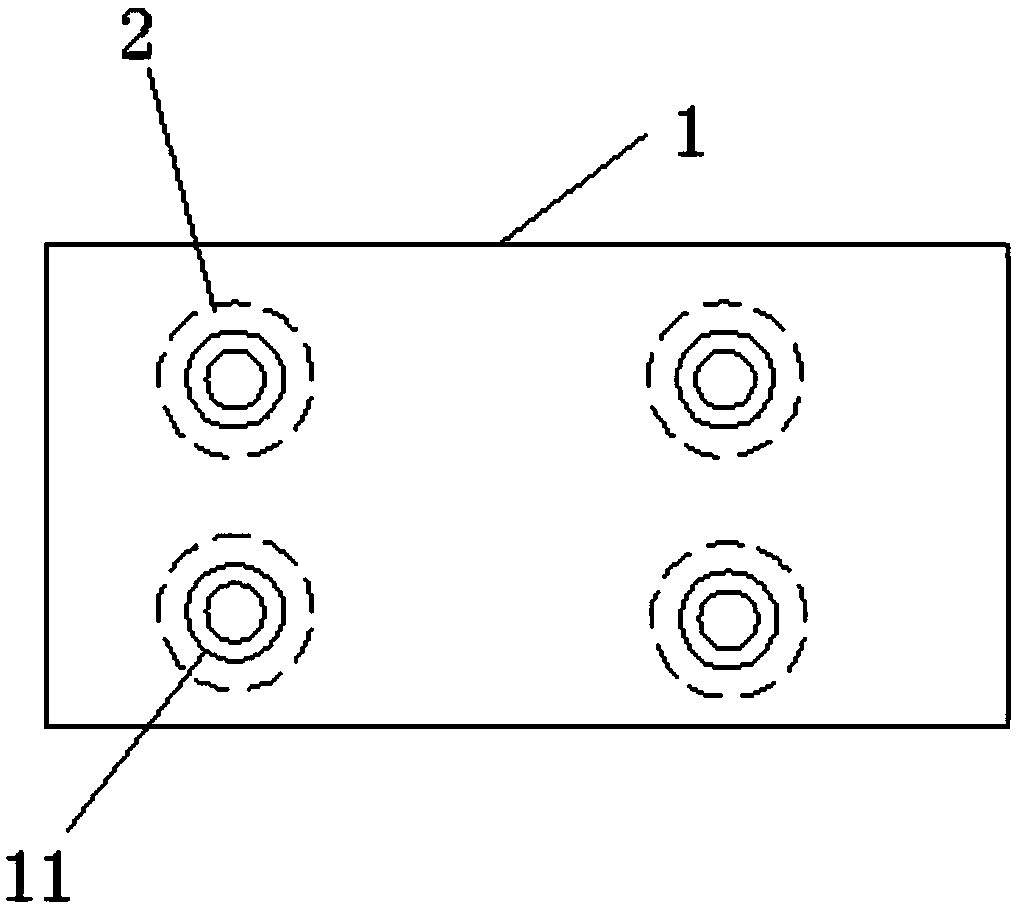

A preparation method of a printing thimble template and a printing thimble template

ActiveCN108990307AImprove work efficiencyAvoid damagePrinted circuit assemblingCircuit board tools positioningComputer engineeringMechanical engineering

The invention provides a manufacturing method of a printed thimble template, comprising the following steps: S1. confirming a first arrangement position on a PCB board consistent with the thimble distribution; S2. Stress simulation is performed on the first arrangement position, a second arrangement position is selected, a plurality of thimbles are arranged below the second arrangement position, and a printing thimble template produced according to the printing thimble template method is provided. The invention relates to a printing thimble stencil making method, the pre-fabricated printed thimble template is one-to-one matched with the PCB board to be printed, In addition, the position of the thimble arrangement on the PCB in the invention has accurately measured the stress and strain amount thereof, effectively preventing the damage of components or solder joints on the PCB caused by the printing process, and improving the reliability of the product.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

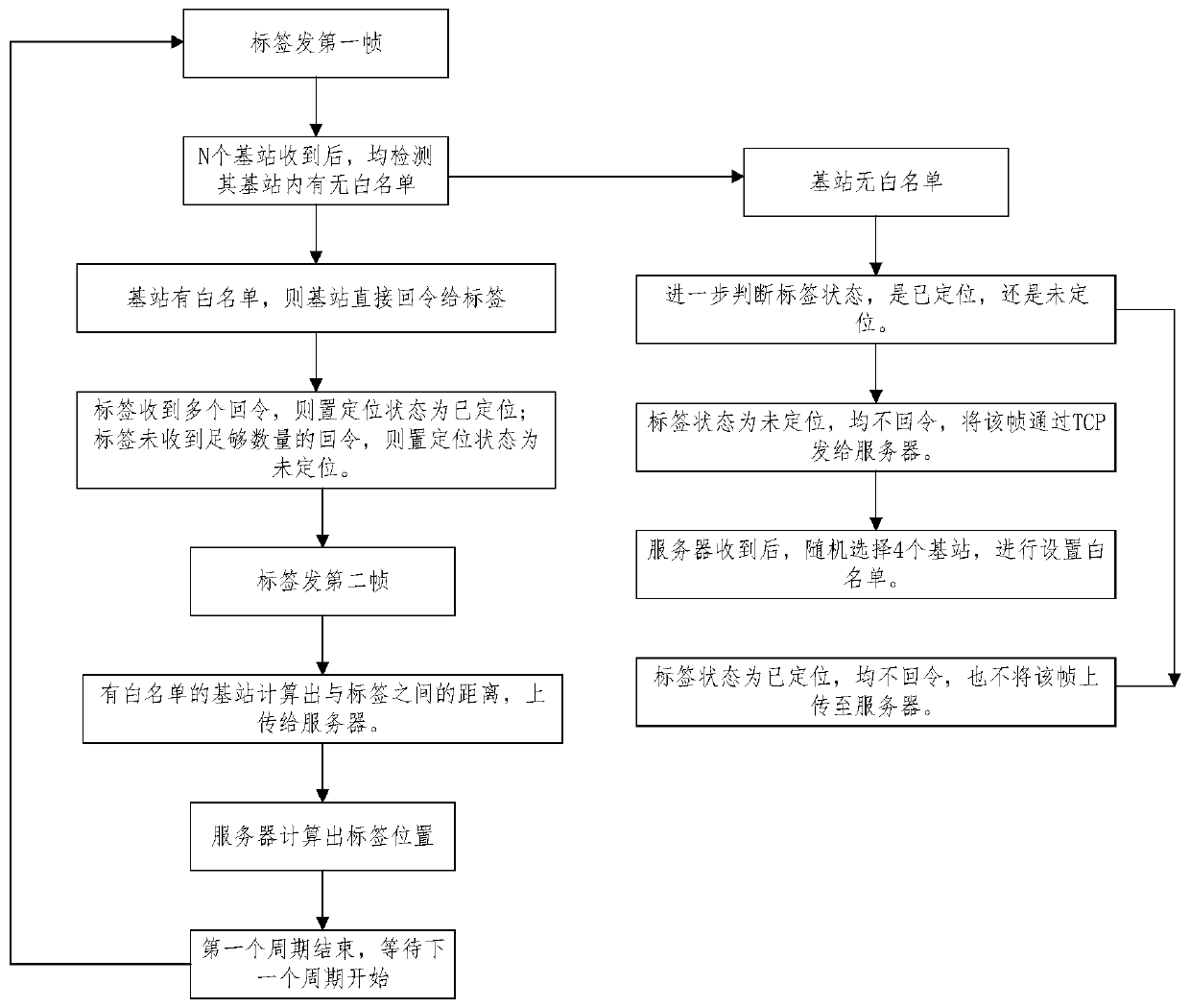

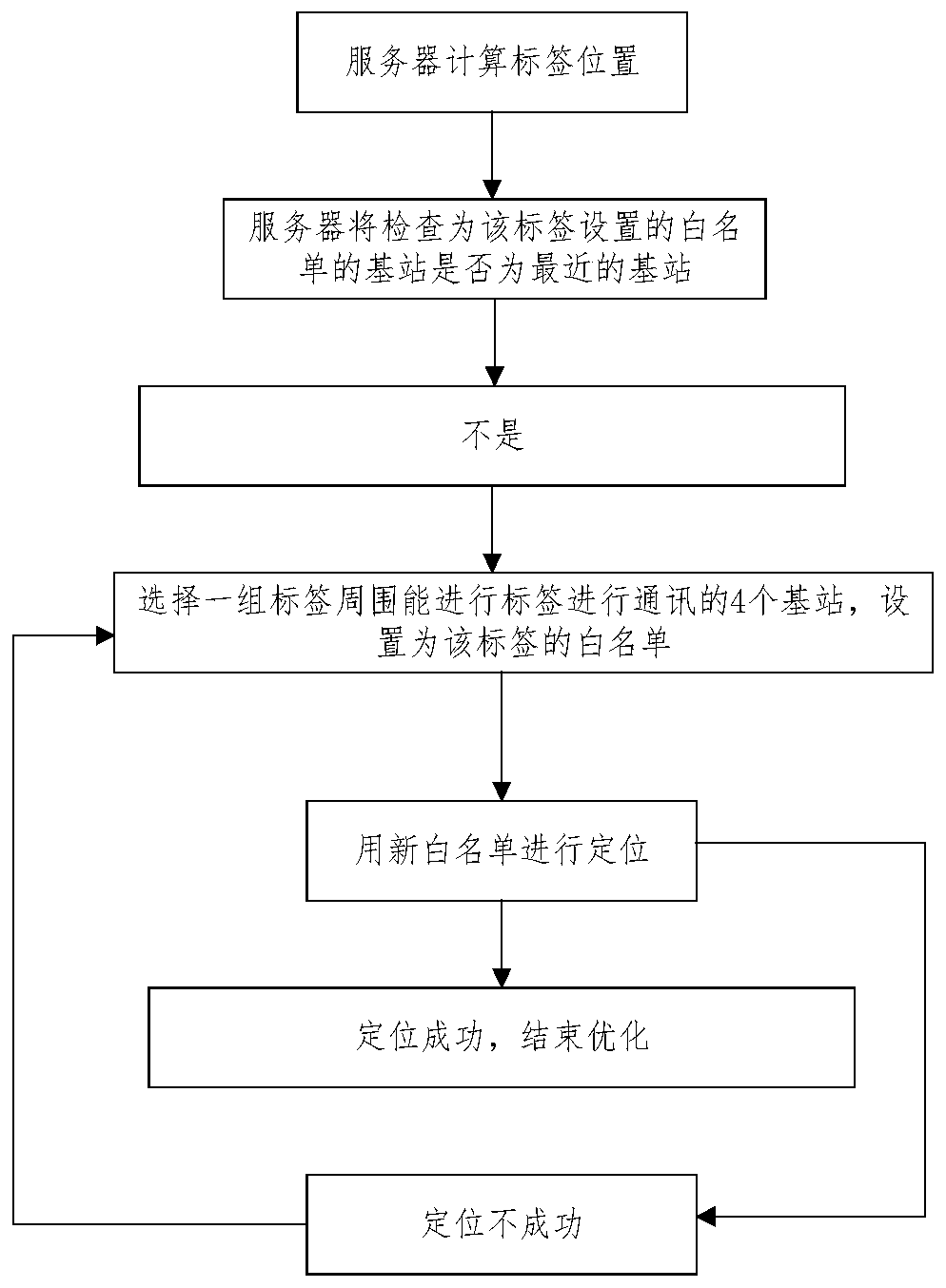

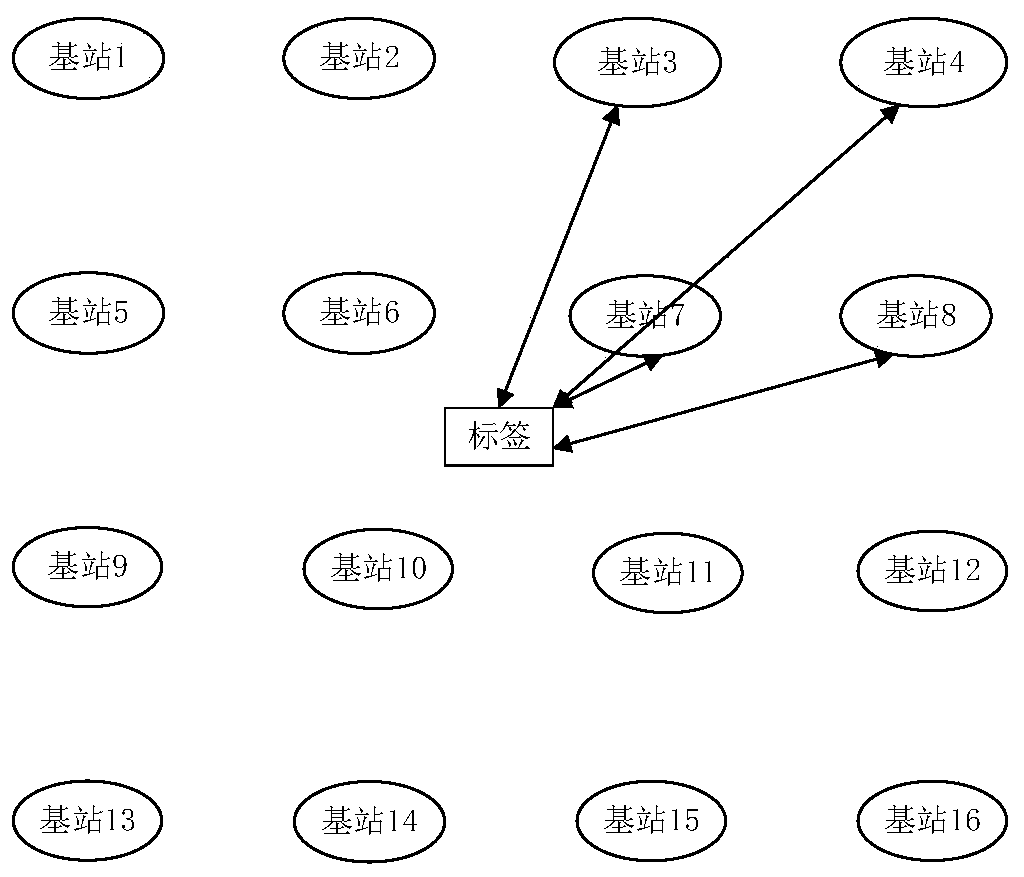

Indoor positioning method and system based on UWB

ActiveCN110958576AAchieve positioningRealize layoutParticular environment based servicesTransmissionWhitelistRemote sensing

The invention provides an indoor positioning method and system based on UWB, and the method comprises the steps: employing a TWR positioning method, a positioning server calculating the position of alabel according to the distance between a base station and the label, and achieving the positioning of the label. According to the technical scheme provided by the invention, the white list base station is arranged for the label, so that the label can be positioned within the shortest time, and meanwhile, the mutual conflict between UWB signals is effectively avoided. Moreover, according to the technical scheme of the invention, the white list base station is adjusted according to the distance between the base station with the white list and the label, the positioning network is optimized, andthe positioning precision is ensured. According to the technical scheme, no complex requirement is needed for arrangement of the base station, the construction difficulty is low, the positioning precision is high, and good application value and popularization value are achieved.

Owner:GUODIAN LONGYUAN ELECTRICAL +1

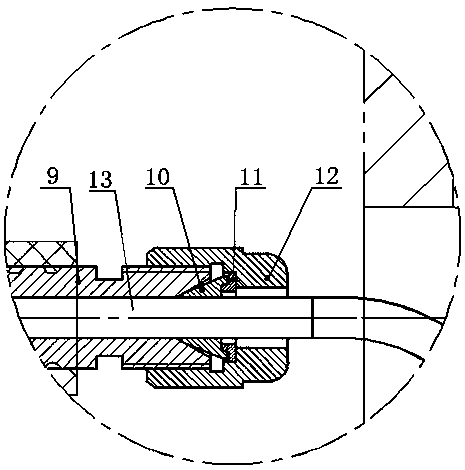

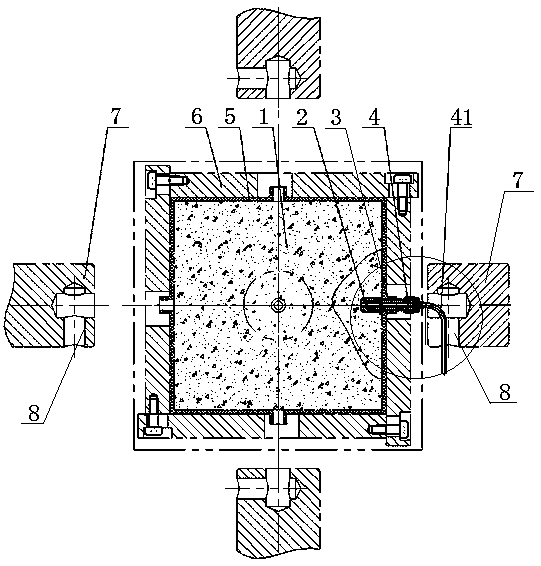

True triaxial fracturing test device

InactiveCN110082221AReduced operating requirementsEasy to installMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a true triaxial fracturing test device, which comprises a loading assembly, a fracturing pipe and an injection pump. The fracturing pipe comprises a first connector, an adapterpipe and a second connector, which are communicated. The first connector is embedded in a fracturing hole in a test sample, one end close to the test sample is fixedly connected with a first fracturing pipeline, and the other end is detachably connected with the end portion of the adapter pipe; the other end of the adapter pipe is detachably connected with the second connector; the end portion ofthe second connector is fixedly connected with a second fracturing pipeline; and the other end of the second fracturing pipeline is communicated with the injection pump. The test device is fast and convenient to assemble and disassemble, can be reused and meets the requirement of arranging fracturing shafts on different side surfaces of the test sample simultaneously.

Owner:中国平煤神马控股集团有限公司 +2

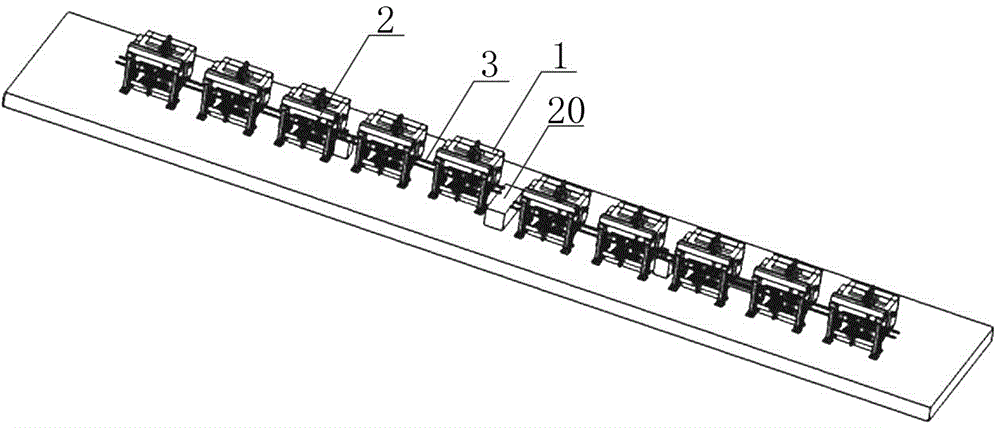

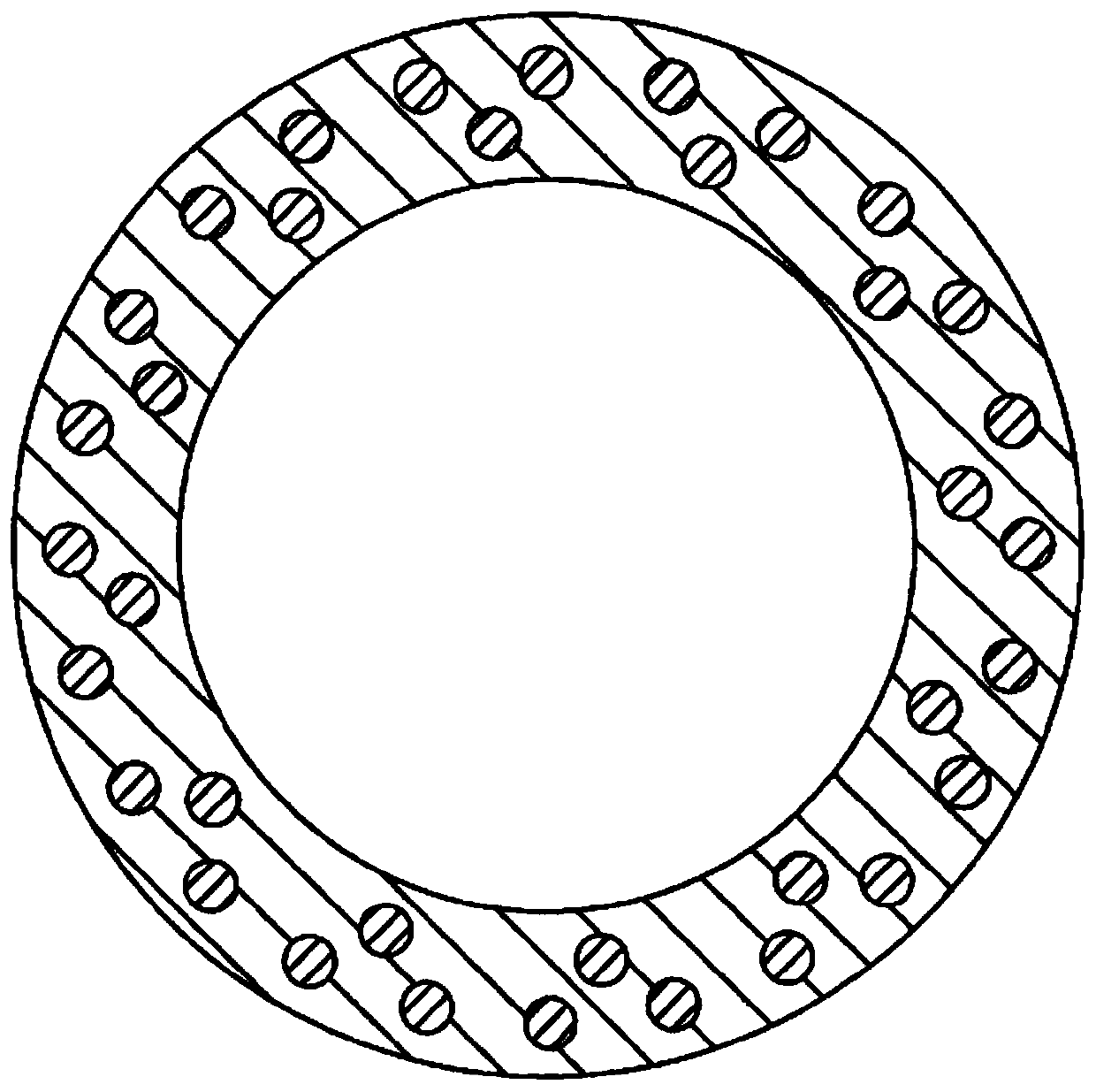

Numerically controlled quantitative weighing type multi-station continuous casting machine

ActiveCN109482850ARealize layoutEnable mobilityMolten metal supplying equipmentsNumerical controlEngineering

The invention discloses a numerically controlled quantitative weighing type multi-station continuous casting machine. A cross-beam operation module is arranged on a foundation rail, a trolley operation module is arranged on the cross-beam operation module, a numerical control ladle pouring mechanism, an automatic quantitative weighing mechanism and a multi-station runner system are arranged on thetrolley operation module, and the numerical control ladle pouring mechanism is used for bearing molten metal and pouring the molten metal into the automatic quantitative weighing mechanism. The automatic quantitative weighing mechanism is used for bearing the molten metal of the numerical control ladle pouring mechanism, weighing the born molten metal and pouring the molten metal into the multi-station runner system. The multi-station runner system is used for guiding the molten metal, so that the trolley operation module can pour workpieces of multiple stations at the same position. The trolley operation module is further provided with a pouring positioning device for positioning the operation position of the trolley operation module. The numerically controlled quantitative weighing typemulti-station continuous casting machine realizes the functions of continuous operation, quantitative weighing, multi-station pouring and positioning of a pouring trolley with high space utilizationrate.

Owner:XI AN JIAOTONG UNIV

Mosaic compound casting method

The invention provides a mosaic compound casting method. The mosaic compound casting method comprises the steps that a type of a reinforcing material is selected according to a base material and a to-be-casted structure of a metal casting part, and a reinforcing unit body in a certain geometric shape is machined and molded; the surface of the reinforcing unit body is pretreated; according to position requirements of mosaic casting and the solidification contraction characteristic of the base material, the reinforcing unit body is assembled into a bionic reinforcing skeleton and then placed ina mold, or the reinforcing unit body is directly placed in the mold according to a designed position to form a bionic reinforcing skeleton; the mold with the bionic reinforcing skeleton is preheated;and the base material liquidized into a liquid state is injected into the preheated mold to form a mosaic composite casting part. According to the mosaic compound casting method, the interface betweenthe base material and the reinforcing material is well combined in the compounding process, and a member manufactured by the method mosaic compound casting method can achieve high toughness, strength, and wear resistance; and the mosaic compound casting method is suitable for compounding with ferrous metal as the base material and compounding with non-ferrous metal as the base material.

Owner:合肥四维铸造有限公司

Frame-type drilling and anchoring robot

The invention discloses a frame-type drilling and anchoring robot. The frame-type drilling and anchoring robot comprises a first gang drill mechanism, side wall shield mechanisms, a front net feedingmechanism, a lifting working platform mechanism, a frame-type machine body, a second gang drill mechanism and an anchor net conveying mechanism. When the drilling and anchoring robot reaches the drilling and anchoring position, a supporting anchor net is conveyed to the front net feeding mechanism through the anchor net conveying mechanism; after the side wall shield mechanisms unfold and supportthe net to side wall coal walls and loosen the net, the front net feeding mechanism unfolds the anchor net towards the left side and the right side and then jacks the net to make the net attached to aroof, side wall net pieces and side walls are attached by shields, all drilling machines enter a standby state before the anchor net reaches the position in front of the to-be-supported position, andafter the anchor net reaches the to-be-supported position, drilling and anchoring operation is conducted according to a drilling and anchoring process. The drilling and anchoring robot integrates netconveying, net laying, net jacking, wall protecting, drilling and anchor rod feeding, mechanical efficient and reliable supporting of a roadway is achieved, the labor intensity of workers is reduced,the safety of the workers is guaranteed, and support is provided for further improving the tunneling efficiency.

Owner:XIAN COAL MINING MACHINERY

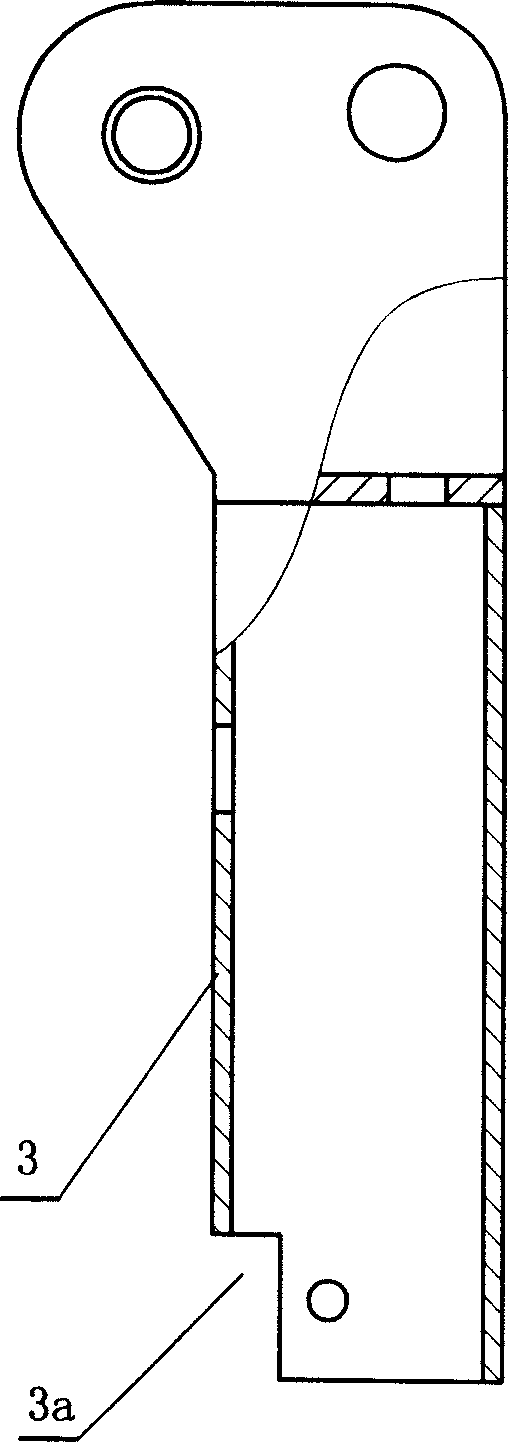

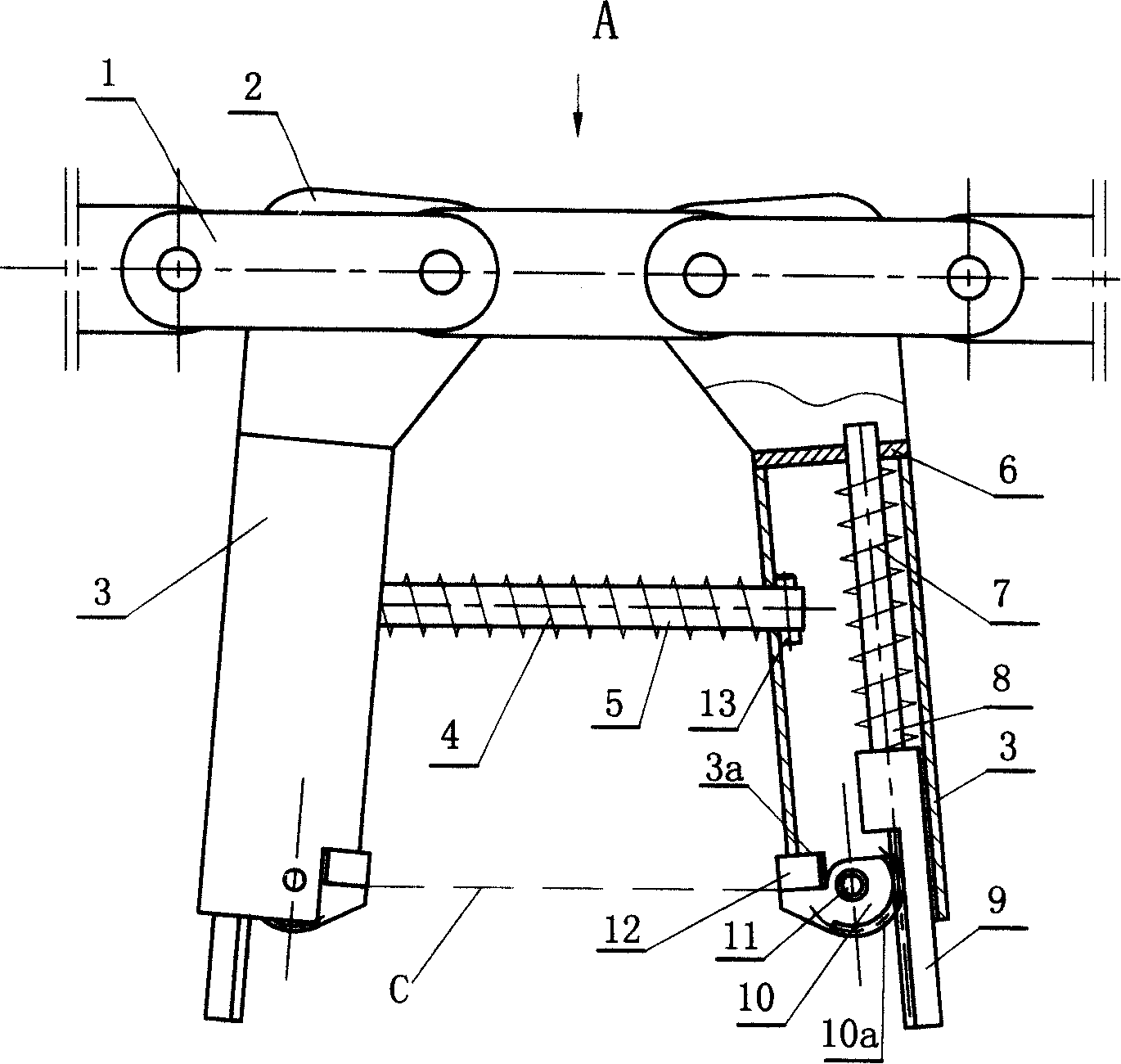

Chain gripper mechanism

The invention relates to a chain clamping mechanism comprising two parallelly arranged double pitch gearing chains and a plurality of clamping arms, wherein, the clamping arm comprises an arm rod and two support plates connected with the arm rod, the two support plates of every clamping arm are respectively hinged to the pin spindle of one chain joint of one gearing chain, a roller provided on the support plate is positioned between two rollers on the chain joint, the clamping arms on the two gearing chains are symmetrically arranged in pairs, and the clamping devices provided on each pair of the arm rods are opposed to each other, a spring is arranged between each pair of the arm rods. In the operation that gearing chains are transmitted by chain wheels, each pair of the clamping arms has the changes of closing up and opening, through the changes, packing bags clamped by each pair of the clamping arms are able to be filled with materials, or be vacuum-pumping, be filled with nitrogen, and be sealed. The chain clamping mechanism provided by the invention has simple structure, and accurate and reliable actions, the chain clamping mechanism is arranged on a packing machine and has variety of running orbits under the transmission of the chain wheels, thereby being able to achieve the arrangement of every process that the packing machine accomplishes the operation similar to the assembly line.

Owner:魏徽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com