Differential thickness high intensity steel laser tailor-welded blanks curved welding line arrangement and forming method

A high-strength steel, laser tailored welding technology, applied in the direction of comprehensive factory control, digital control, electrical program control, etc., can solve problems such as curve weld layout and forming research, and achieve the effect of improving forming quality and improving analysis accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

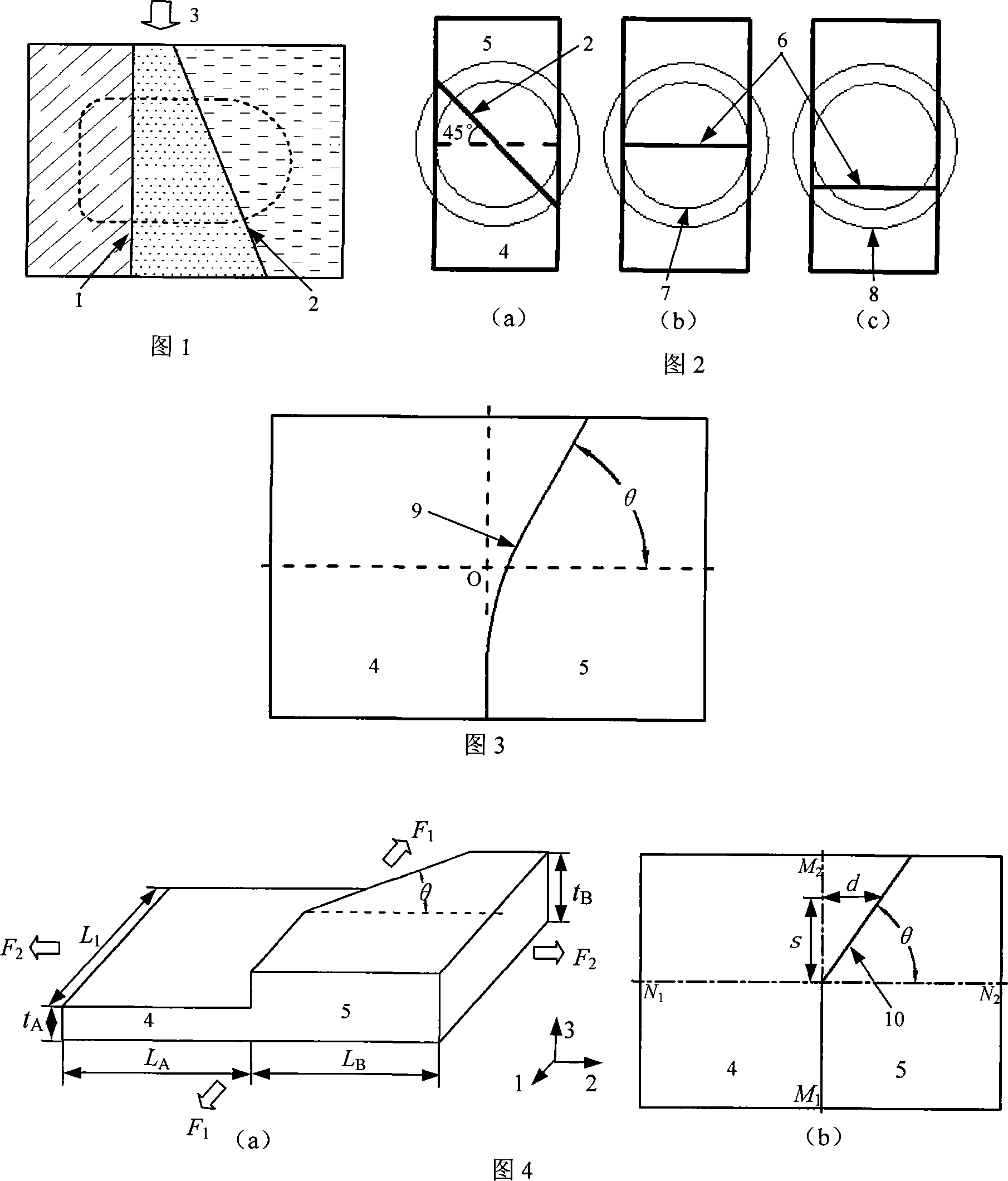

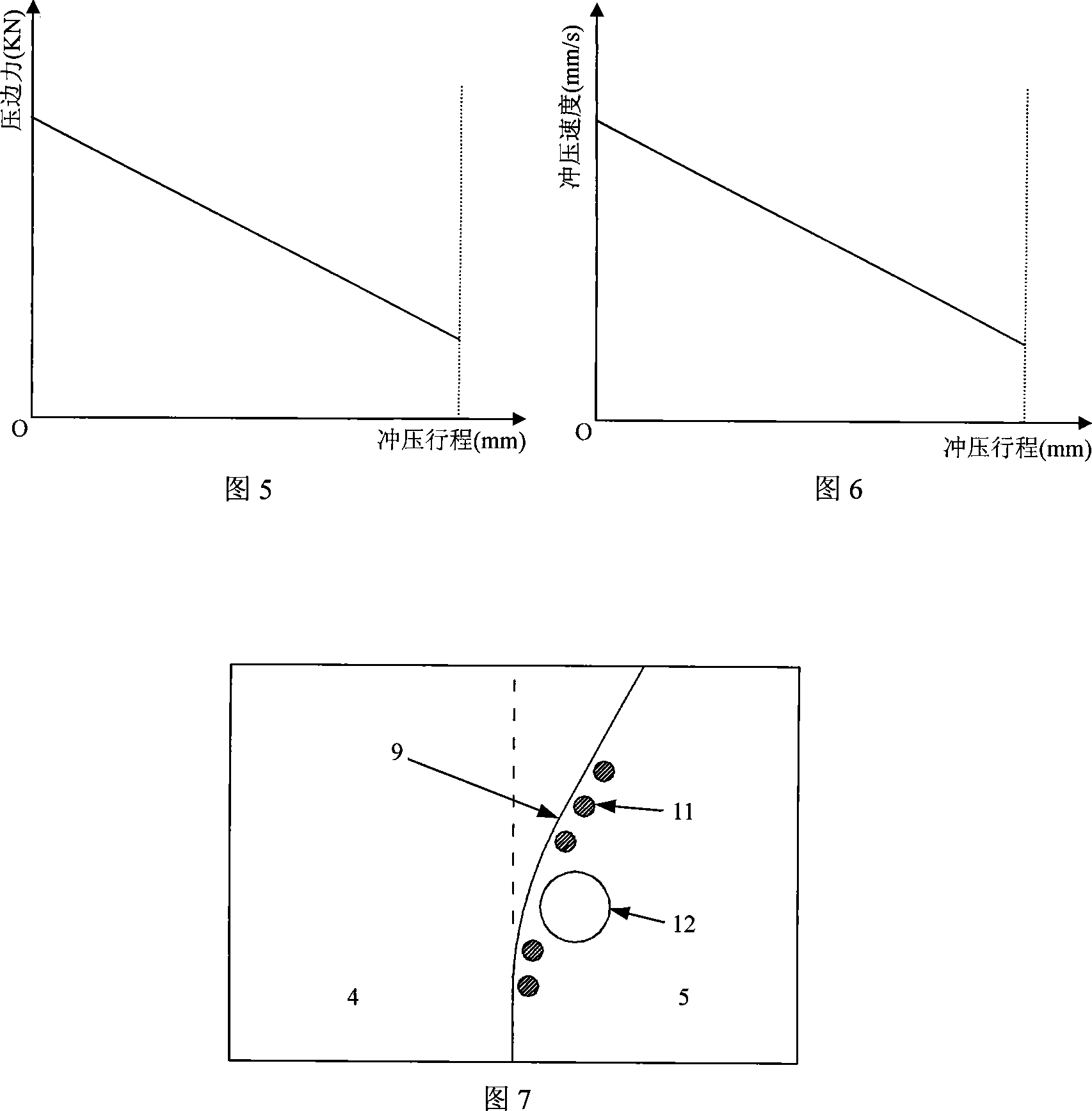

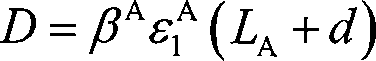

[0044] Example 1: In the stamping process of high-strength tailor-welded blanks with differential thickness of curved weld seams, step blankholders are used to load variable blankholder forces that decrease linearly with the stroke of the punch (see Figure 5), or linearly decreasing blankholders are used. The variable punching speed technology (Figure 6) can control the direction and size of the sheet metal flow, and ensure that the curved weld seam difference thickness high-strength steel laser tailor-welded blank obtains better formability.

Embodiment 2

[0045] Example 2: Simultaneously adopt linearly decreasing variable blank holder force and linearly decreasing variable stamping speed technologies, and coordinate and optimize these two technologies to improve the formability of curved weld seam differential thickness high-strength steel laser welded blanks .

Embodiment 3

[0046] Embodiment 3: Design 5 clamping columns to control the movement of the weld seam near the thick-side base metal near the weld, and design a circular radius of 100mm process hole (Fig. 7) near the weld near the thick-side base metal to increase The flow of thick-side material makes the thick-side sheet metal deform more fully, and achieves better forming performance of laser-welded blanks of high-strength steel with different thickness.

[0047] The curve welds of different shapes differ in thickness and high-strength steel laser welded blanks, and the weld arrangement in the range of 120° to 150° can obtain better formability. If the arranged curvilinear welds are poor in thickness and high-strength steel tailor-welded blanks have poor formability or cannot be formed, advanced forming technologies such as variable blank holder force, variable stamping speed, welding seam clamping columns, and forming process holes can be used. Achieve shaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com