Mosaic compound casting method

A compound casting and mosaic technology, which is applied in the field of casting, can solve the problems of poor wettability of reinforcing materials and substrates, failure to achieve, limit the application range of mosaic compound casting methods, etc., and achieve the effect of excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is the casting of nodular cast iron wear-resistant inserts.

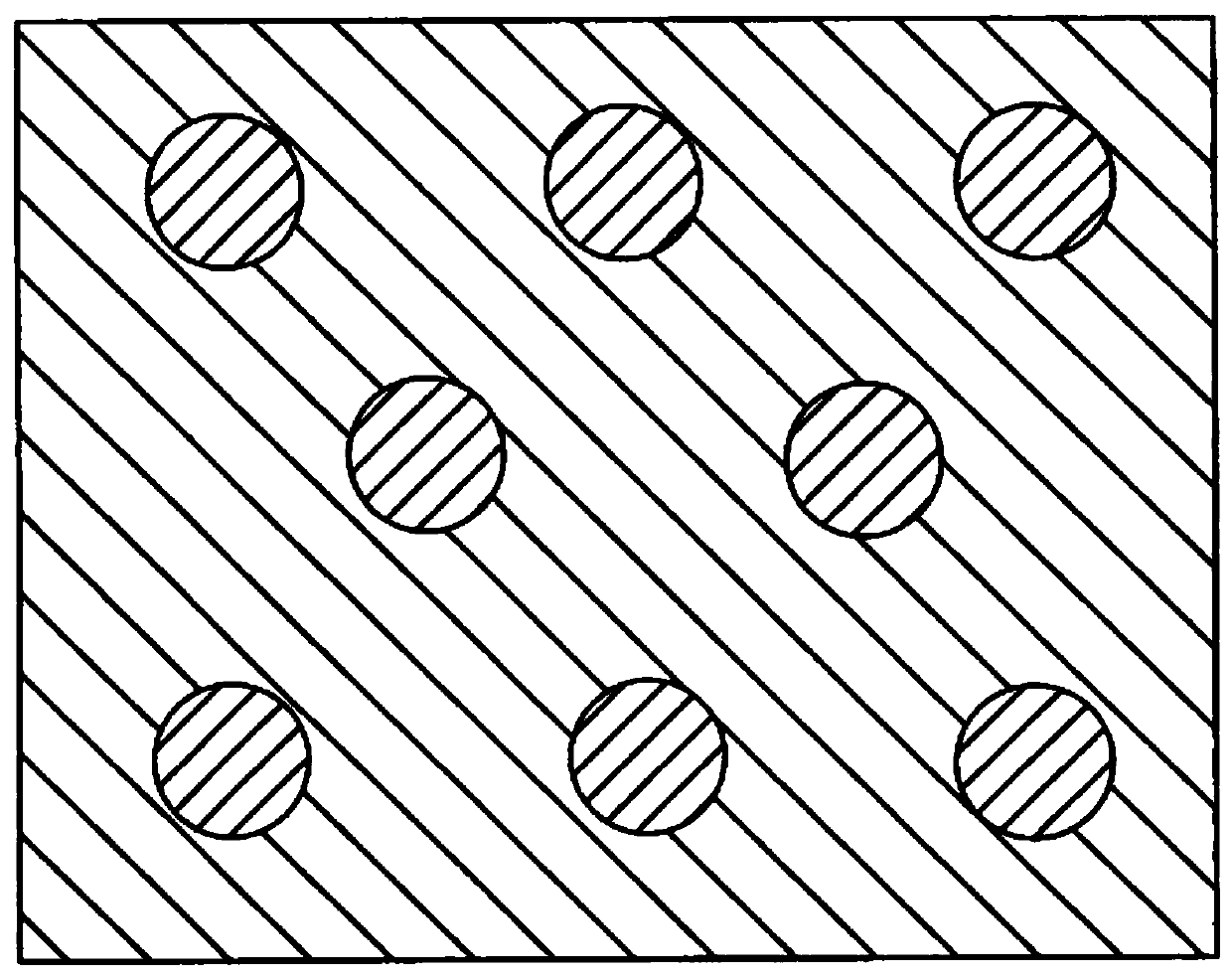

[0025] Based on the shape of the casting and the distribution of working stress, the reinforcement material is selected as cemented carbide, the specific model is YG20, and then the volume of the reinforcement unit is calculated according to the volume of the casting to be 1 / 10 of the volume of the casting to simulate the protrusion characteristics of the shellfish in the intertidal zone and further Simplified to a bionic model containing a circular unit body, processed into a round rod with a diameter of 4mm, and a boss with a height of 0.5mm on the surface of the round rod. Grind the surface of YG20 cemented carbide with sandpaper, then wash with 7% NaOH solution to remove oil, wash with hot water at 70°C, pickle with 20% H2SO4 to remove scale, hot water at 70°C, and then dry at 200°C. Attach the enhanced unit figure 1 The manner shown shows the arrangement within the mould. Dry the mold c...

Embodiment 2

[0027] This embodiment is the casting of magnesium alloy airtight casting.

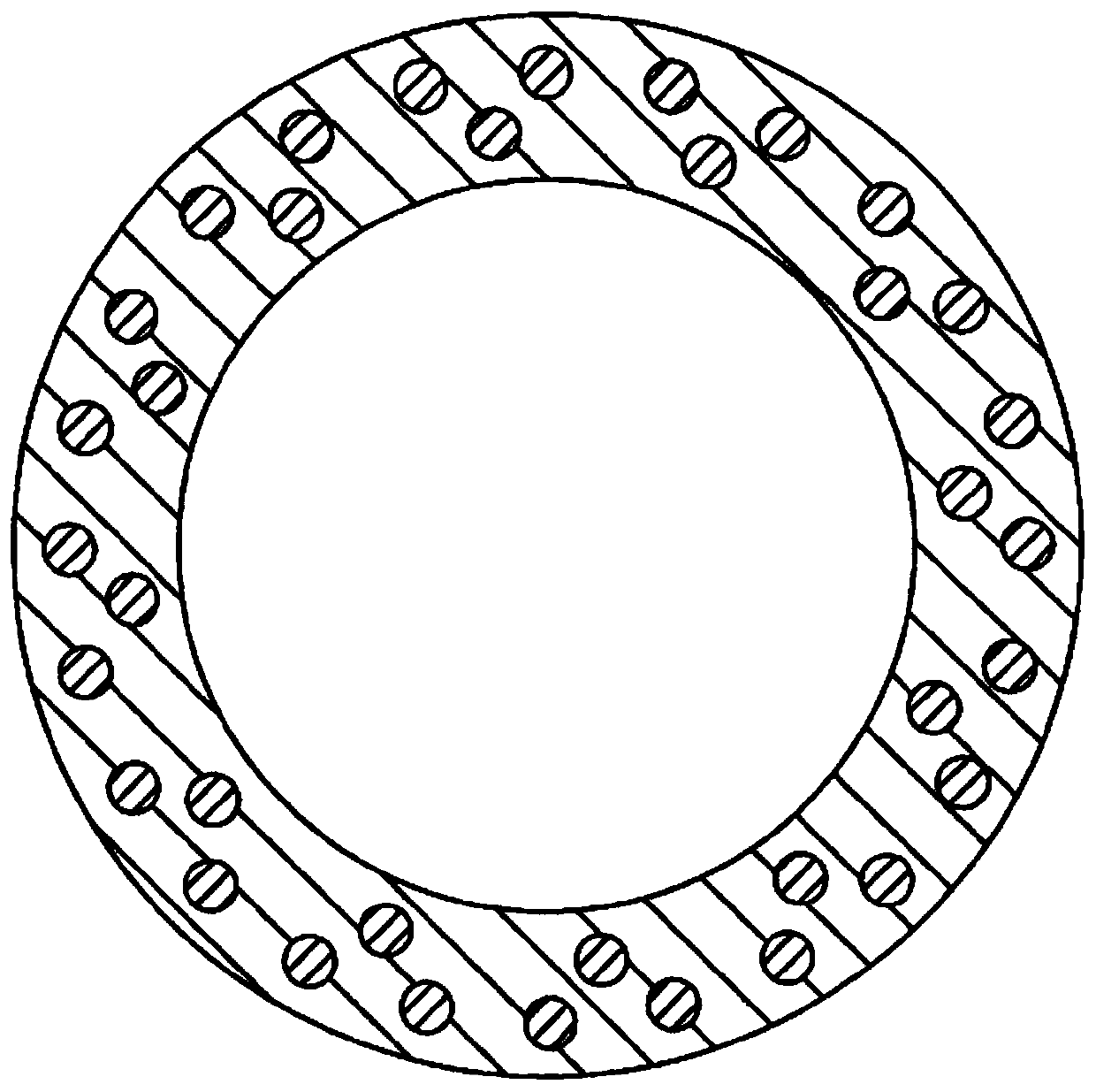

[0028] According to the shape of the casting and the distribution of working stress, the reinforcement material is selected as carbon steel, the specific model is Q235 steel, and it is processed into a round bar with a diameter of 2mm. Polish the surface with sandpaper, and after cleaning, silver-plate the surface of the reinforcement with an electroless plating method, and the thickness of the silver-plated layer is about 30 nanometers. According to the volume of the casting, the volume of the reinforcement unit is calculated as 1 / 8 of the volume of the casting, and the bamboo fiber is simulated along the radial distribution of the bamboo stem wall. figure 2 The manner shown shows the arrangement within the mold to form a biomimetic reinforced skeleton. Then place the dried cavity in a medium-frequency induction device to preheat to 450°C, then slowly pour the refined AZ91D magnesium alloy melt (at...

Embodiment 3

[0030] This embodiment is the casting of aluminum alloy sliding guide rail.

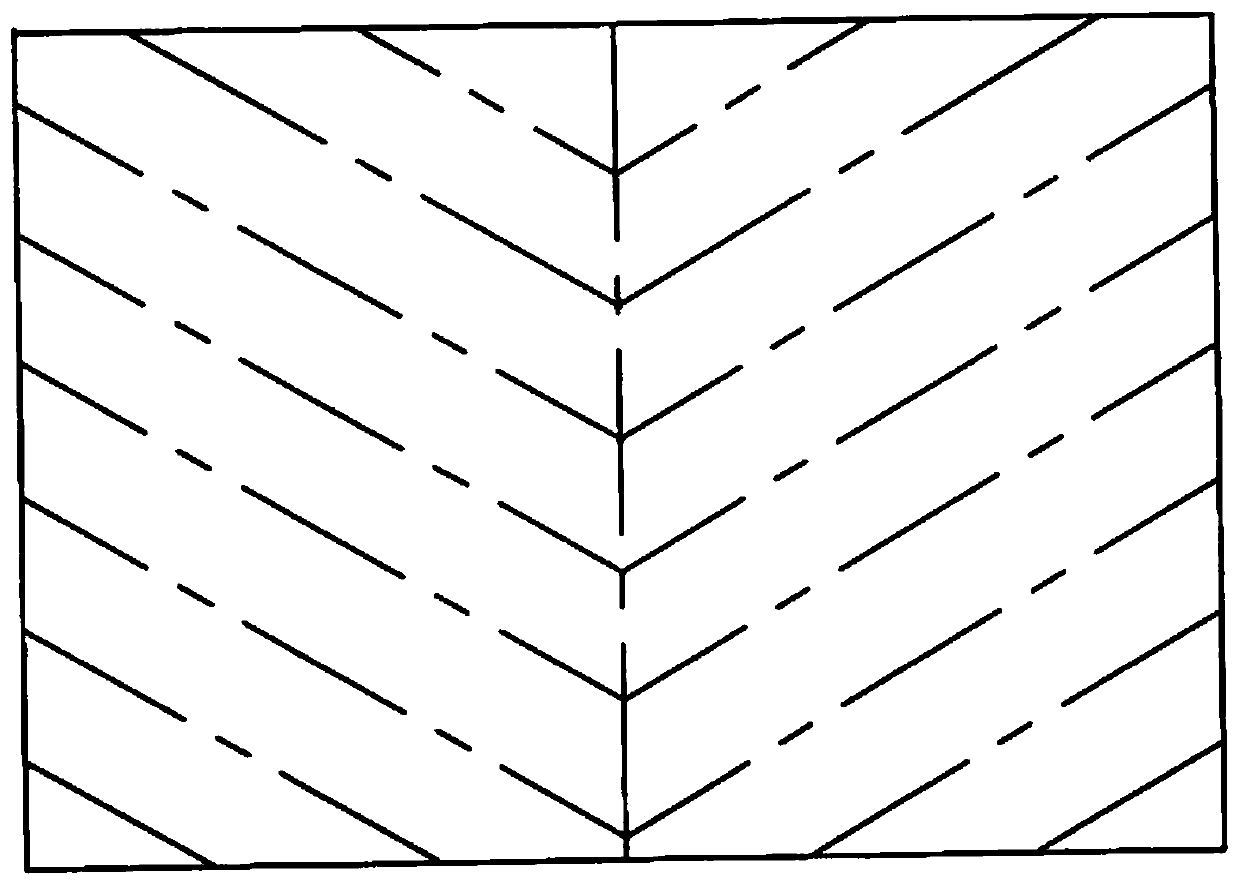

[0031] According to the shape of the casting and the distribution of working stress, the embedded reinforcement material is selected as alloy steel, the specific model is H13 steel, and it is processed into a sheet of 40mm×20mm×1.5mm as the reinforcement unit. After quenching and tempering, the reinforcement unit simulates the plant blade. Or dragonflies, butterflies and other insect wing features are combined into a image 3 The biomimetic reinforced skeleton shown, and then polished the surface with sandpaper, followed by alkaline washing with 7% NaOH solution to degrease, rinsing with hot water at 70°C, pickling with 20% H2SO4 to remove scale, cleaning with absolute ethanol, and then aluminum plating on the surface, The aluminum layer is about 60 nanometers thick. According to the volume of the casting, the volume of the reinforced skeleton is calculated as 1 / 6 of the volume of the casting, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com