Chain gripper mechanism

A clamping mechanism and chain-type technology, which is applied in the field of chain-type clamping mechanisms, can solve the problems of unsatisfactory automation and high packaging machinery, and achieve the effect of simple structure, accurate and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

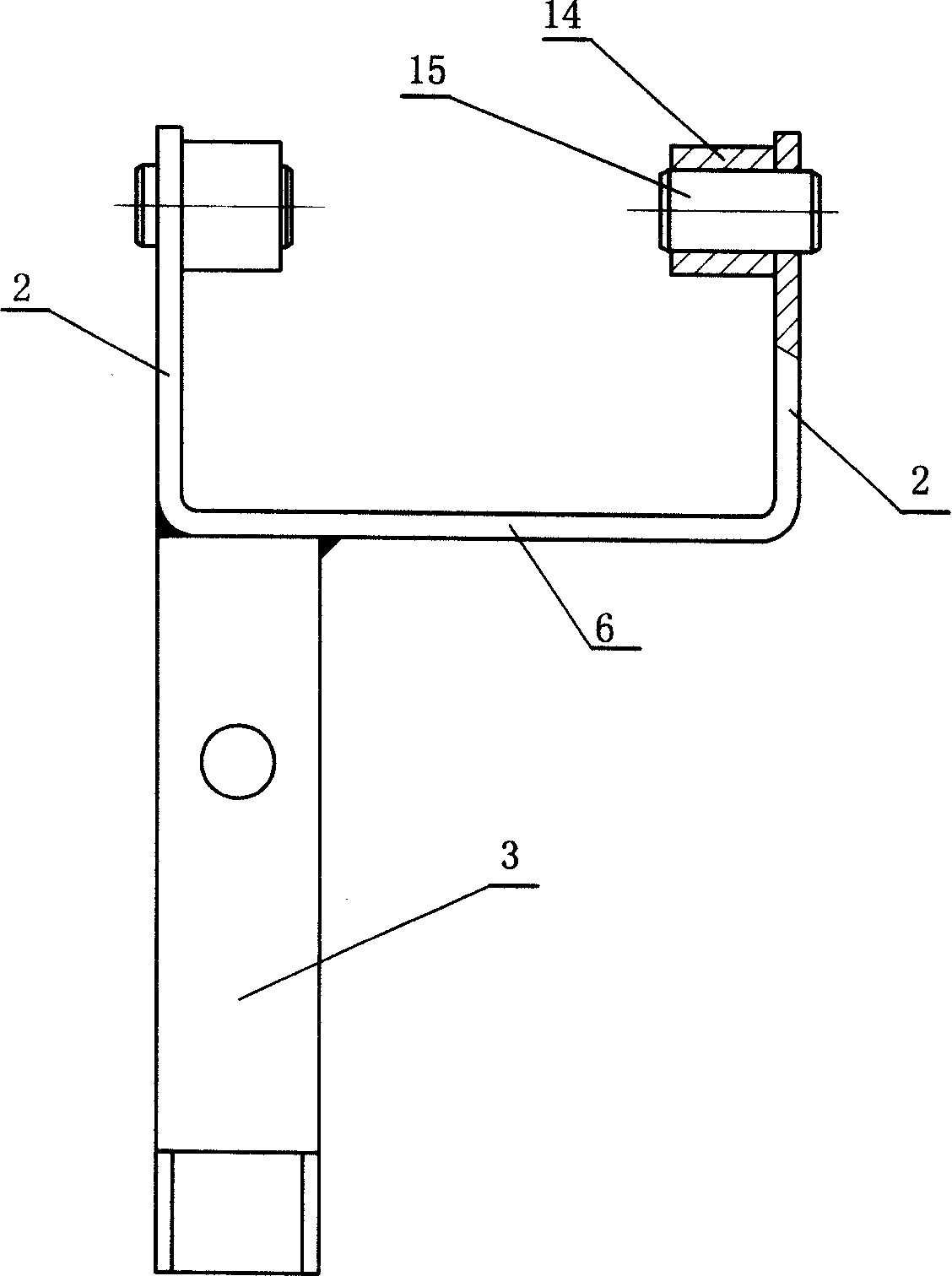

[0012] see figure 1

[0013] The clamping arm includes an arm rod 3 and two connected support plates 2, the two support plates 2 are connected through a bottom plate 6, and the two support plates 2 and the bottom plate 6 are integrated. The upper end of the arm bar 3 is affixed to the base plate 6, so that the upper end of the arm bar 3 is connected with the two support plates 2, and each of the two support plates 2 is equipped with a roller 14 through a pin shaft 15.

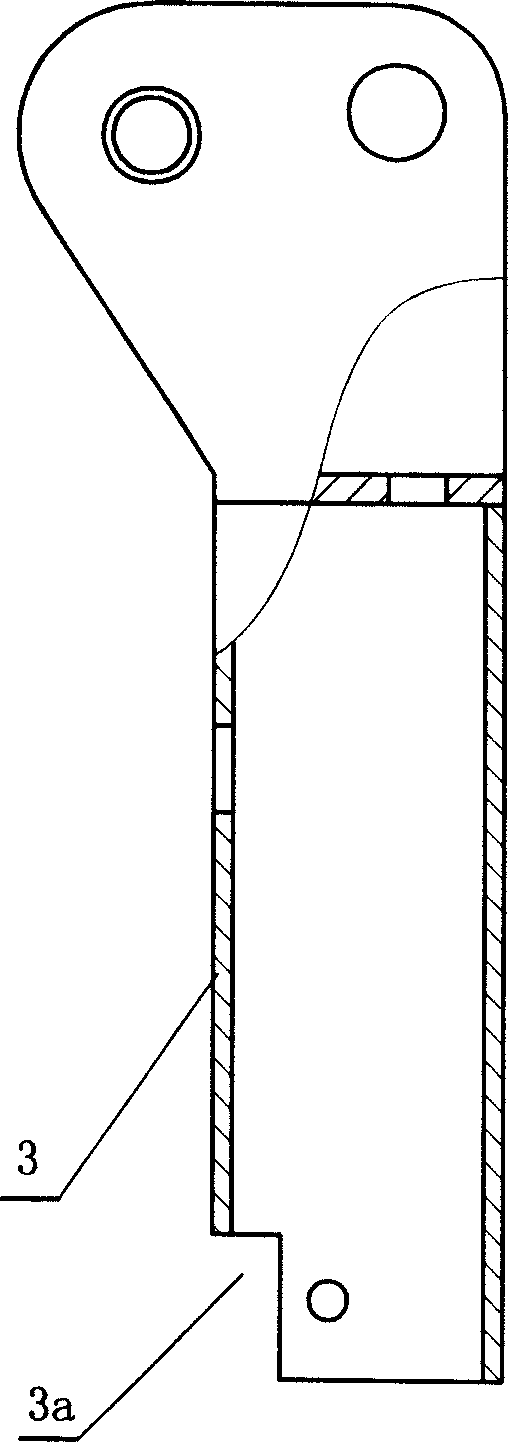

[0014] see figure 2

[0015] The inside of the arm 3 has a cavity, and the lower end of the arm 3 has a notch 3a.

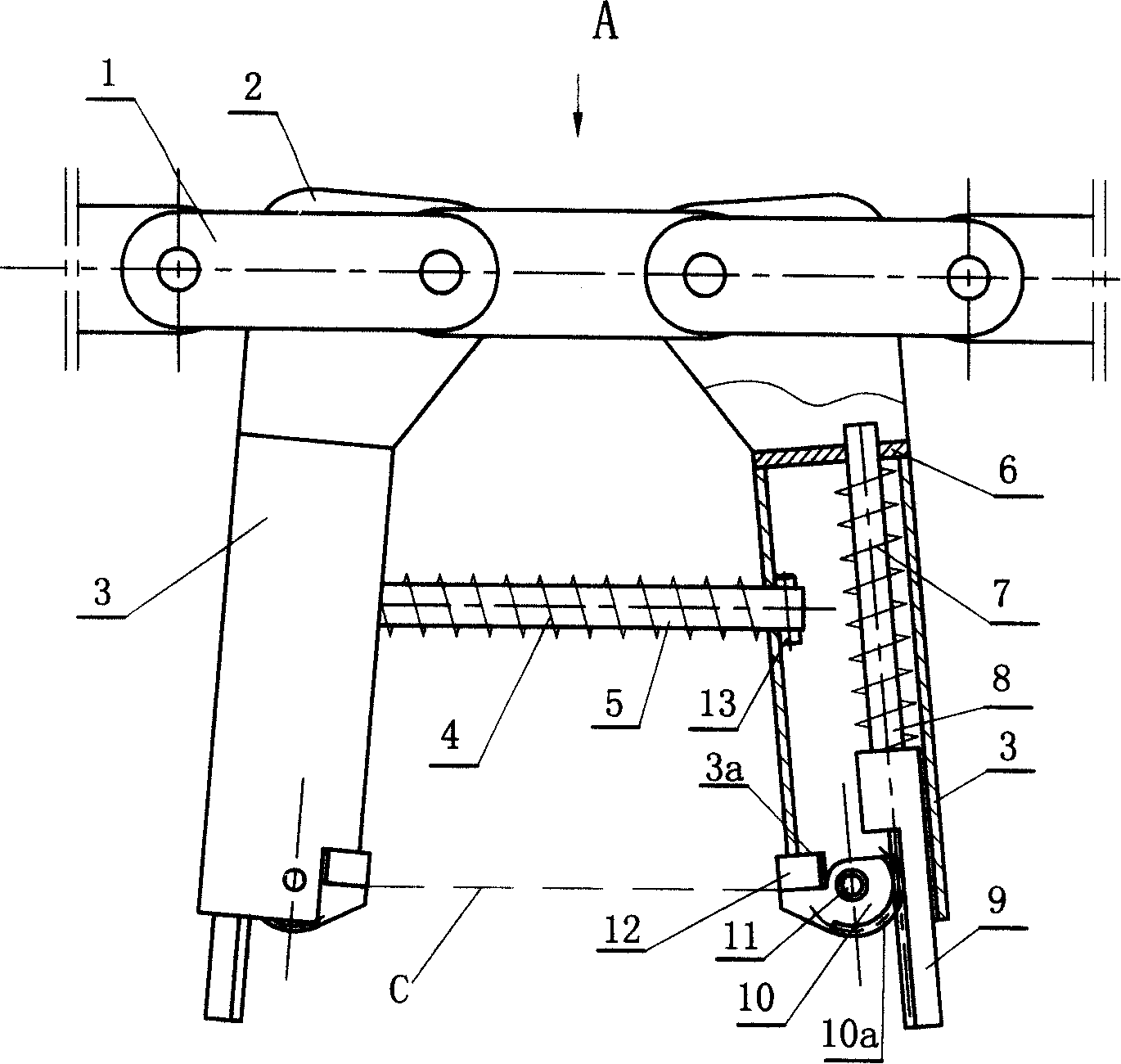

[0016] see image 3

[0017] The chain type clamping mechanism provided by the present invention includes a transmission chain 1 with double pitches and several clamping arms with support plates 2 and arm bars 3 . The clamping device provided on the arm bar 3 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com