A preparation method of a printing thimble template and a printing thimble template

A production method and technology of thimbles, which are applied in the fields of printed circuit manufacturing, printed circuits, printed circuits assembled with electric components, etc., can solve the problems of inaccurate layout position, low efficiency of thimbles, and low product reliability, and solve the problem of easy concentration of stress , Improve work efficiency and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for making a printing thimble template in the present invention, which specifically includes:

[0057] S1. Confirm that the first layout position on the PCB is consistent with the distribution of ejector pins;

[0058] S2. Perform stress simulation on the first arrangement position, select a second arrangement position, and arrange several thimbles under the second arrangement position.

[0059] In step S1, the process of determining the first arrangement position is as follows:

[0060] First determine the thickness of the PCB board, set the thickness of the PCB board as b, and the connection distance between two adjacent and nearest thimbles as c, and then the thimble layout needs to meet:

[0061] When 0mm

[0062] When 1mm

[0063] When 1.6mm

[0064] If there are many electrical components on the PCB, the value of the thimble spacing c in the actual layout is relatively large, wh...

Embodiment approach

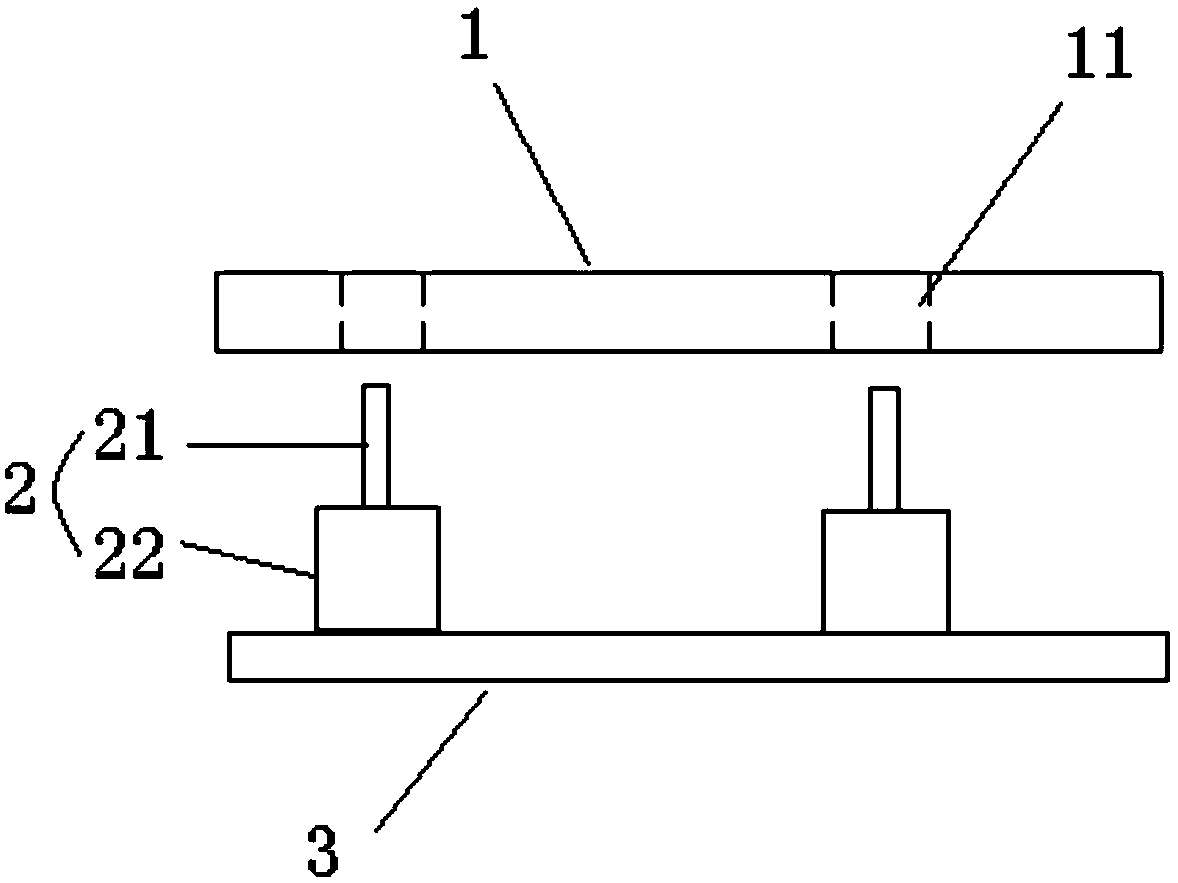

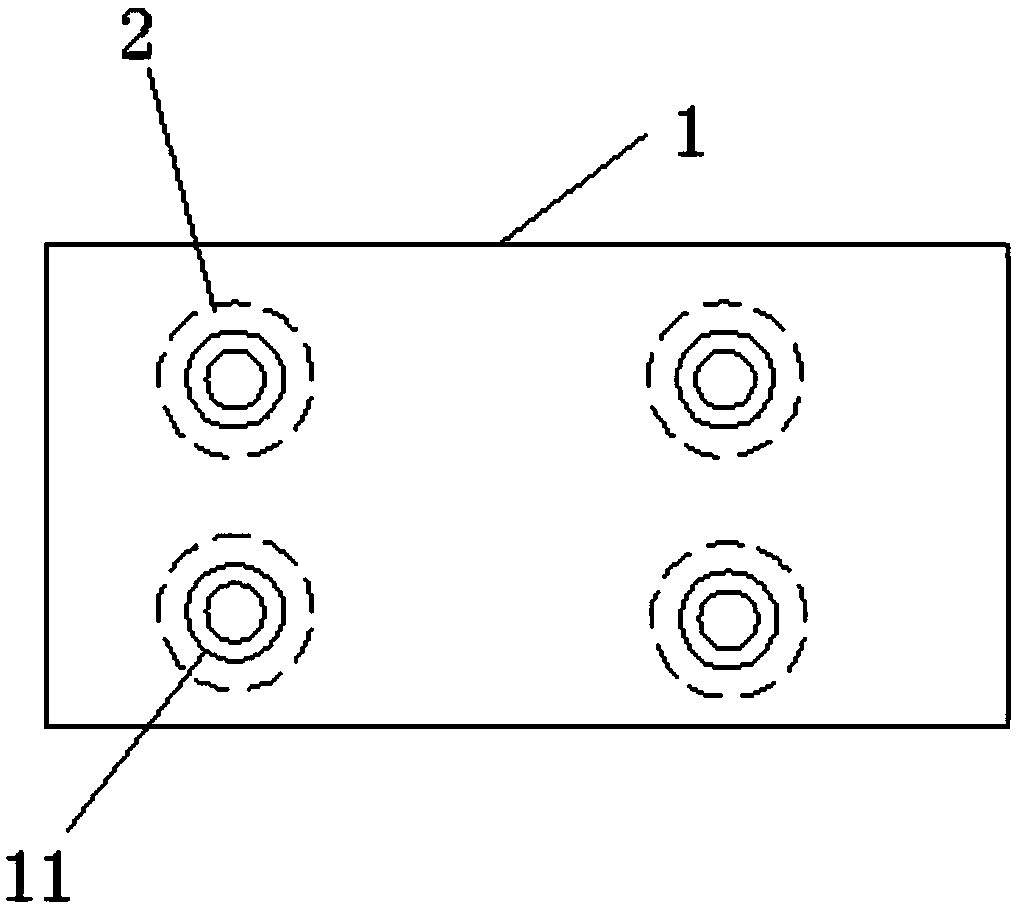

[0077] like figure 2 and 3 As shown, the present embodiment provides an implementation of the printing ejector pin template described in the present invention, including:

[0078] The SMT printing thimble template 1 made by the printing thimble template manufacturing method in Embodiment 1 is specifically provided with a thimble arrangement hole 11 on the PCB, and a thimble 2 is arranged directly below the thimble arrangement hole 11.

[0079] The thimble 2 in the present embodiment is formed with the supporting portion 21 of small diameter and the fixed portion 22 of large diameter, and magnetite is installed on the fixed portion 22, and the diameter of described thimble arrangement hole 11 gets final product larger than the diameter of supporting portion 21, guarantees that the worker When the thimble 2 is moved, the position of the thimble 2 can be seen through the thimble arrangement hole 11 .

[0080] During specific implementation, when switching lines in the PCB boar...

Embodiment 3

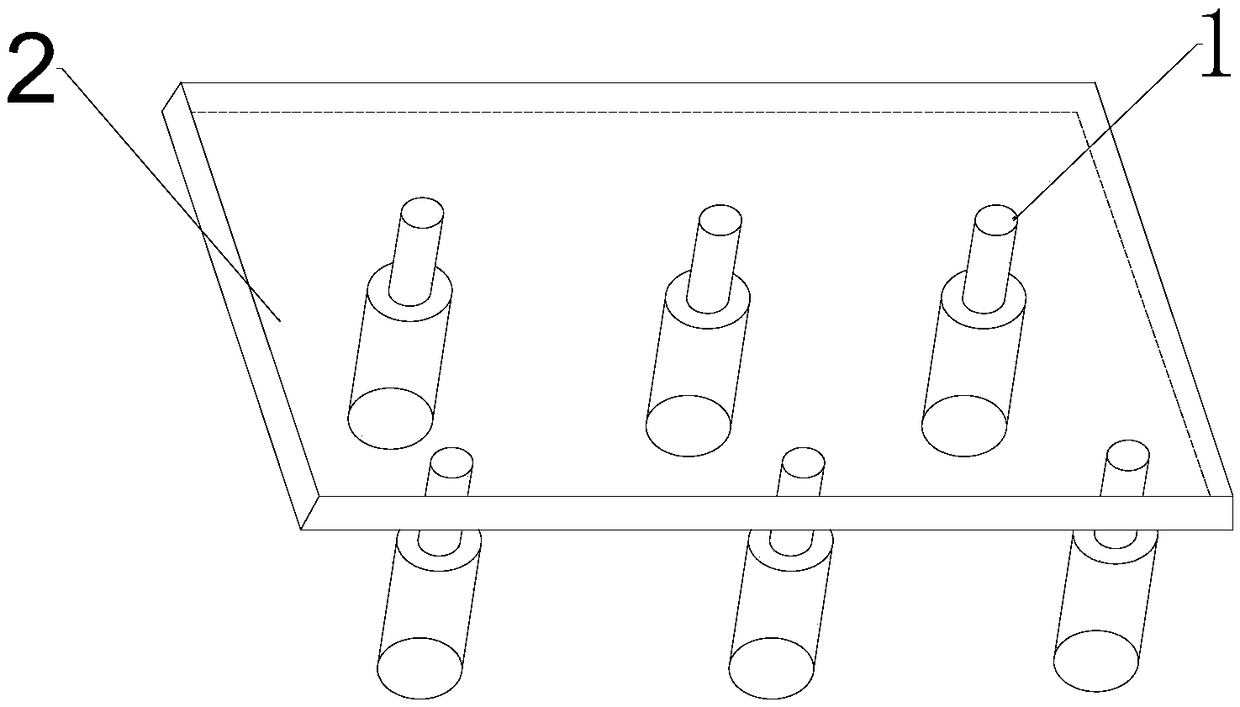

[0082] like Figure 4 and 5 As shown, this embodiment provides the second implementation of the printing thimble template in the present invention.

[0083] Compared with Embodiment 2, this embodiment is applicable to another structure of the thimble 2, and the thimble 2 is a cylinder with a certain length.

[0084] SMT printing thimble template 1, on which according to the manufacturing method of printing thimble template in the present invention, a thimble arrangement hole 11 is opened, and a thimble 2 is arranged directly under the thimble arrangement hole 11, and the diameter of the thimble arrangement hole 11 is larger than the above-mentioned The diameter of thimble 2.

[0085] During specific implementation, when switching lines in the PCB board printing solder paste process, first install the SMT printing thimble template 1 on the position of the PCB board to be printed, according to the position of the thimble hole 11 on the SMT printing thimble template 1 , holdin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com