Self-circulation micro-fluidic chip as well as preparation method and usage of micro-fluidic chip

A microfluidic chip and chip technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of integrated safety, high working voltage, solution denaturation, etc., and achieve stability. Good, improve the output efficiency, the effect of the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

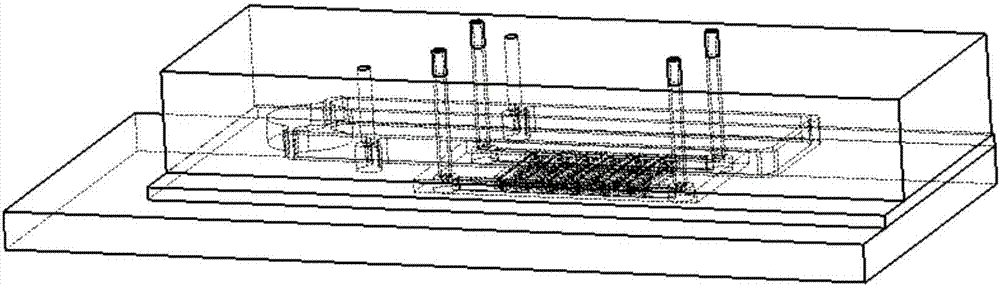

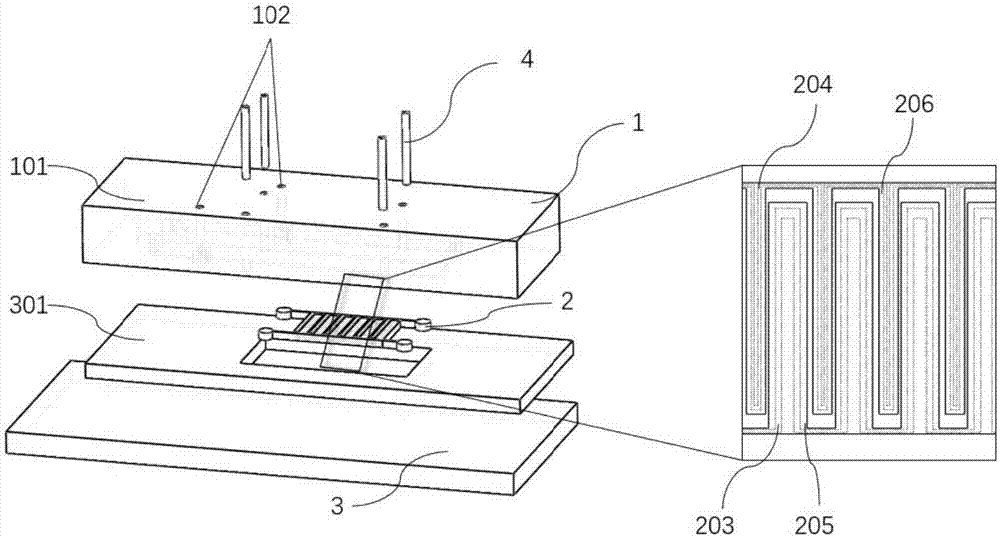

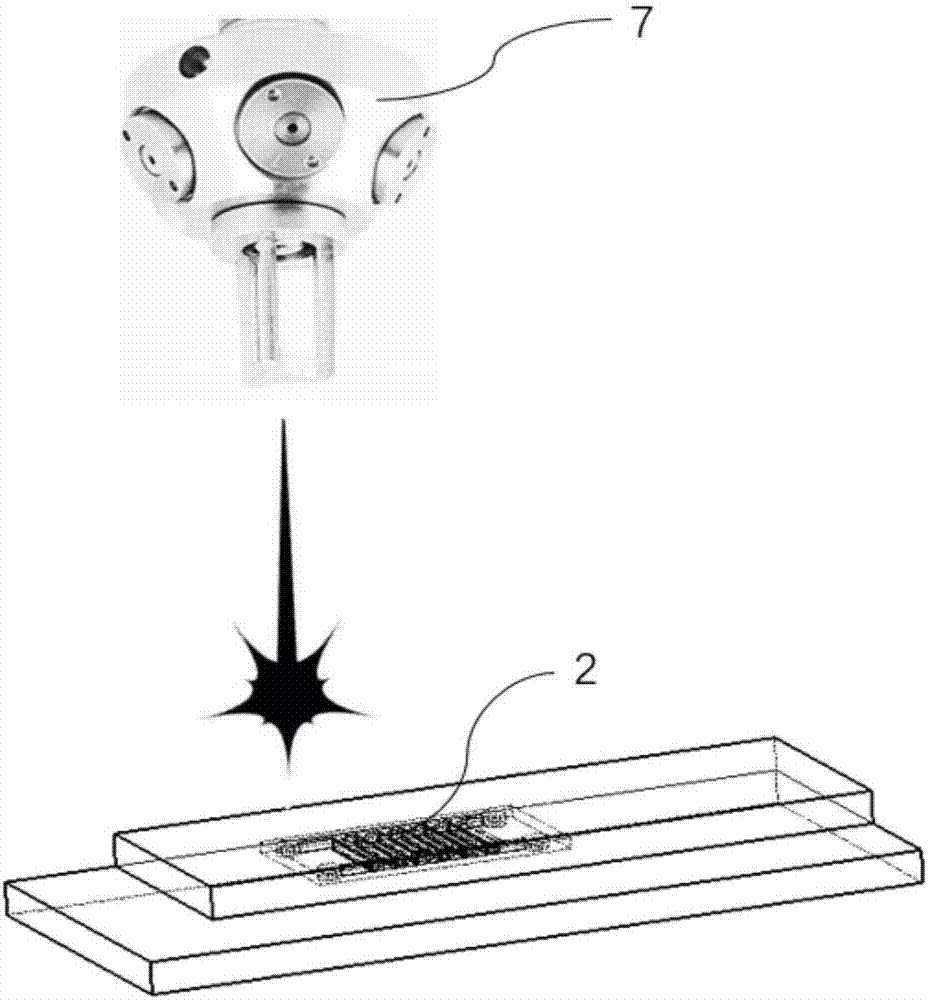

[0042] Such as figure 1 and figure 2 As shown, the self-circulating microfluidic chip of the present invention includes a top-down microfluidic layer 1 , an electroosmotic driving layer 2 and a chip substrate layer 3 . The electro-osmotic driving layer 2 and the microfluidic layer 1 and the chip base layer 3 respectively define mutually independent microfluidic flow channels and wide / narrow electrode liquid metal flow channels (203 / 204). The solution to be driven and the liquid metal are respectively perfused in the microfluid flow channel and the wide / narrow electrode liquid metal flow channel (203 / 204). Wherein the electroosmosis driving layer 2 and the wide / narrow electrode liquid metal flow channel (203 / 204) are interdigitated, and the lower surface of the electroosmotic driving layer 2 completely covers the wide / narrow electrode liquid metal flow channel ( 203 / 204), the upper surface of the electroosmotic driving layer 2 is exposed in the microfluidic channel. The two...

Embodiment 2

[0046] The preparation process of the microfluidic layer 1 is as follows: mix 20g of PMDS colloid and 2g of curing agent, rotate in a planetary mixer for 1min, then put the mixed PDMS liquid glue into a vacuum drying dish for 10min to vacuumize the prepared A good patterned silicon wafer is first placed in a Petri dish covered with aluminum foil to ensure that the silicon wafer is placed horizontally. Then put it into a light-proof glass dish, add 2 drops of trimethylchlorosilane solution, and take it out after fumigation for 2 minutes. The prepared PDMS liquid colloid was poured on a patterned silicon wafer, then placed in a vacuum drying dish to vacuum for 10 minutes, taken out and baked in an oven at 85°C for 30 minutes. Take out the cured PDMS and cut it according to the edge of the pattern. The plane size of the microfluidic layer 1 is 5cm×2cm. The entry regions 102 are each pierced with through holes with a diameter of 1 mm.

[0047] The preparation process of the elec...

Embodiment 3

[0053] Embodiment 3 is basically the same as Embodiment 2, except that the preparation process of the electroosmotic driving layer 2 is as follows:

[0054] Mix 20g of PDMS colloid with 100ml of chloroform and stir for 10min. 1.8 g of carboxylated multi-walled carbon nanotube powder and 1 g of porous carbon powder were mixed, ground in a mortar for 10 min, and poured into 100 ml of chloroform. Ultrasonic stirring was carried out in a 40 kHz ultrasonic cleaner for 1 h. After taking it out, mix the solution with the previously prepared PDMS / chloroform solution, and put it into a 40kHz ultrasonic cleaner for ultrasonic stirring for 2h. After taking it out, bake it on a heating plate at 80° C. for 8 hours until the solvent forms a colloidal state. Then put the prepared solution into a vacuum oven at 60° C. and bake for 2 hours. Apply the slurry on the aluminum foil, scrape it flat with a scraper, put it into a three-roll mill for rolling, and scrape the material off the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com