Bag filter for cleaning dust-laden gases and injector nozzle for such a bag filter

A bag filter and clean gas technology, which is applied in the direction of membrane filter, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of limited use, achieve mutual parallelism, improve filtering effect, and realize the effect of arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

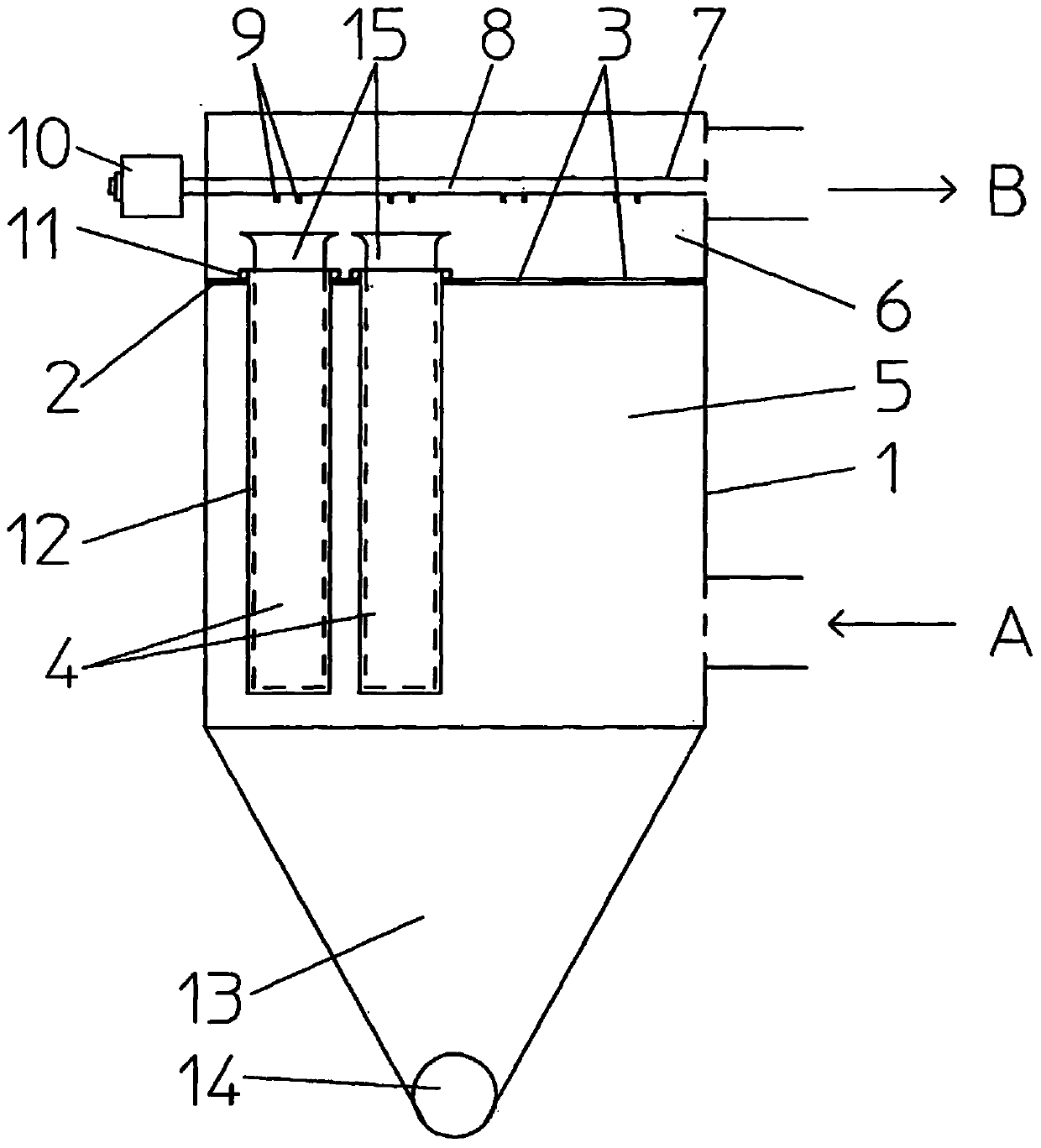

[0031] figure 1 Shows a cross section through a bag filter of known construction. There is a bag bottom 2 with openings 3 in the housing 1, and several corresponding filter bags are arranged or hung in these openings 3. The dust-containing gas A is introduced into the untreated gas side 5 of the bag filter. The filter bag 4 has an upper open end and a lower closed end. The dust-containing gas A flows through the material of the filter bag 4 and enters the clean gas side 6 of the bag filter through the opening 3 in the bottom 2 of the bag. The cleaning gas B is derived accordingly from here. A device 7 for outputting compressed air pulses into the open end of the filter bag 4 is provided in the clean gas side 6 of the bag filter in order to clean the filter bag. These devices 7 for outputting compressed air pulses can be formed, for example, by a correspondingly configured power injection pipe 8 having an opening 9 above each filter bag 4 and a compressed air source 10 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com