Ignition device for an internal combustion engine and method for its operation

一种点火装置、内燃机的技术,应用在发动机点火、电火花点火控制器、特定发动机的发电机等方向,能够解决加强气缸热负荷等问题,达到精确点火、简化机械结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

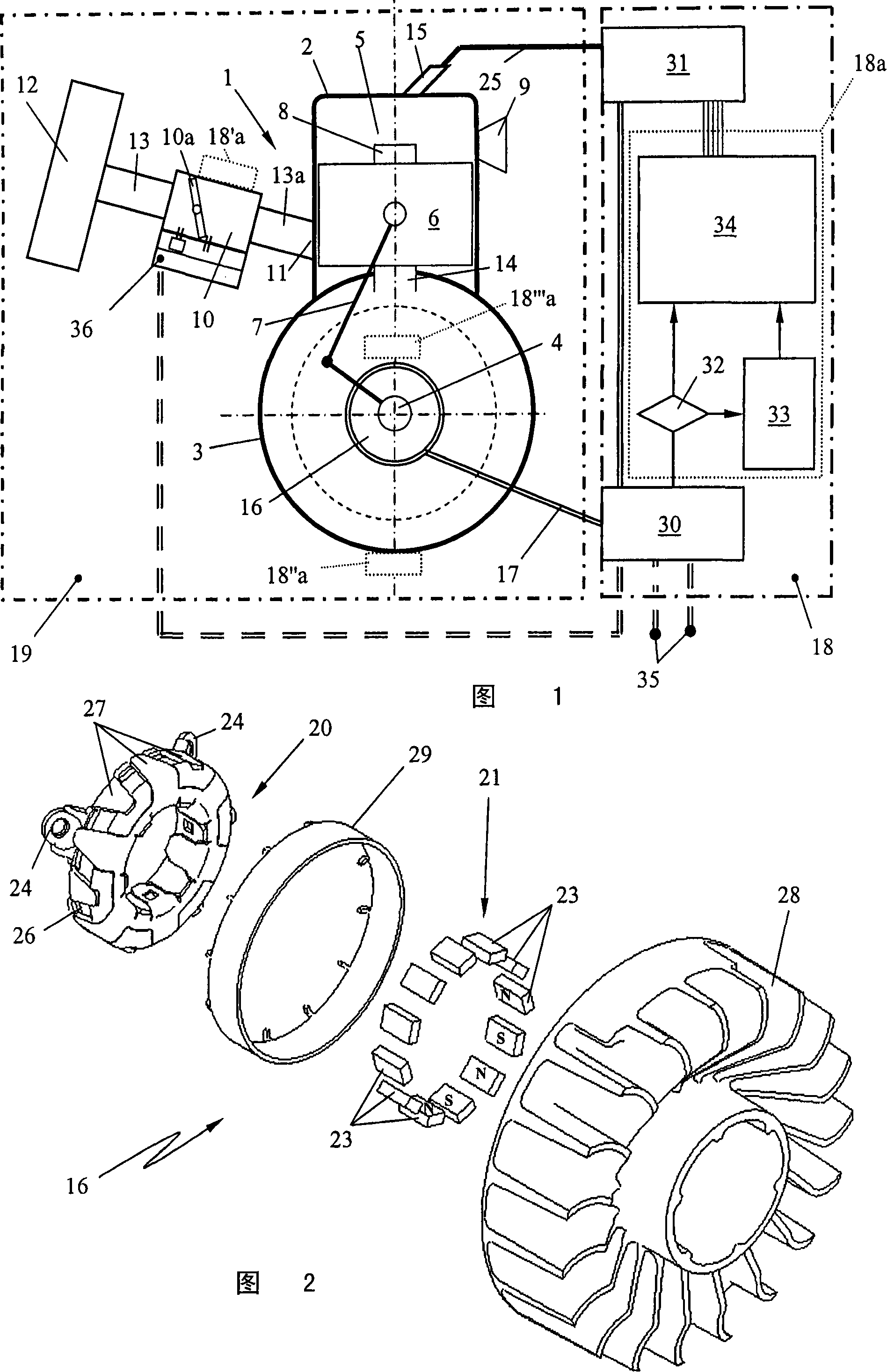

[0035] In the schematic diagram of FIG. 1 , the engine unit 19 includes an internal combustion engine 1 , which is designed in particular as a two-stroke engine. The ignition device according to the invention is not restricted to use in single-cylinder or multi-cylinder two-stroke engines, it can also be used in single-cylinder or multi-cylinder four-stroke engines or similar engines, in particular reciprocating piston engines.

[0036] The internal combustion engine 1 of the engine unit 19 encloses a cylinder 2 with a crankcase 3 in which a crankshaft 4 is rotatably mounted. A combustion chamber 5 is formed in the cylinder 2 and is delimited by a piston 6 moving up and down. The piston 6 is connected with the crankshaft 4 in the crankcase 3 through the connecting rod 7 and pushes the crankshaft 4 to rotate. In the shown embodiment, an inlet window 8 for combustion air and / or mixture opens into the combustion chamber 5, wherein the inlet window 8 is arranged at the end of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com