Motor train unit and chassis end integration device thereof

An integrated device and EMU technology, which is applied to railway car body parts, transportation and packaging, sanitary equipment, etc., can solve the problems of poor strength in the direction of longitudinal force transmission of the vehicle chassis, and small storage space for dirt boxes, etc. Achieve the effect of increasing the storage space, improving the storage space, and avoiding the deterioration of the direction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

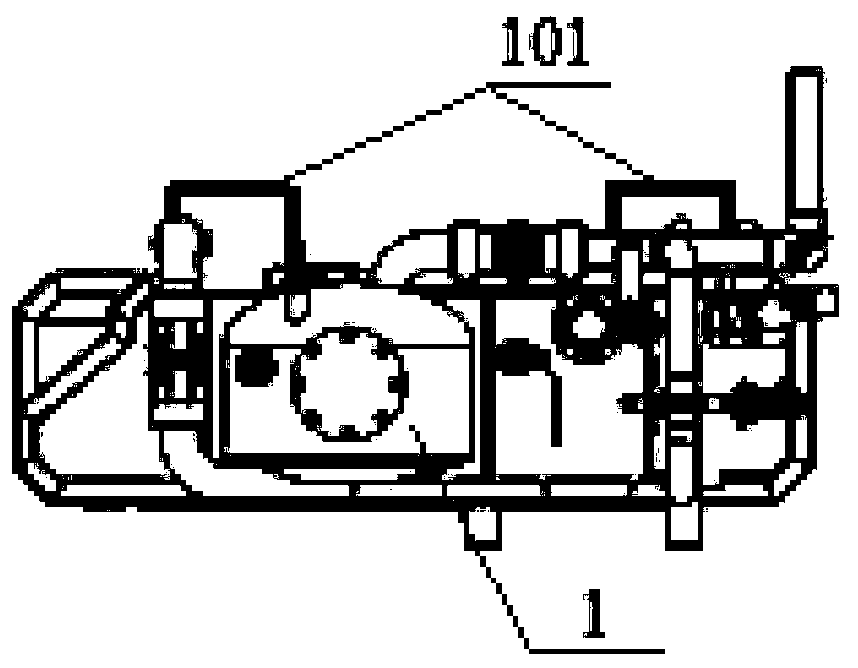

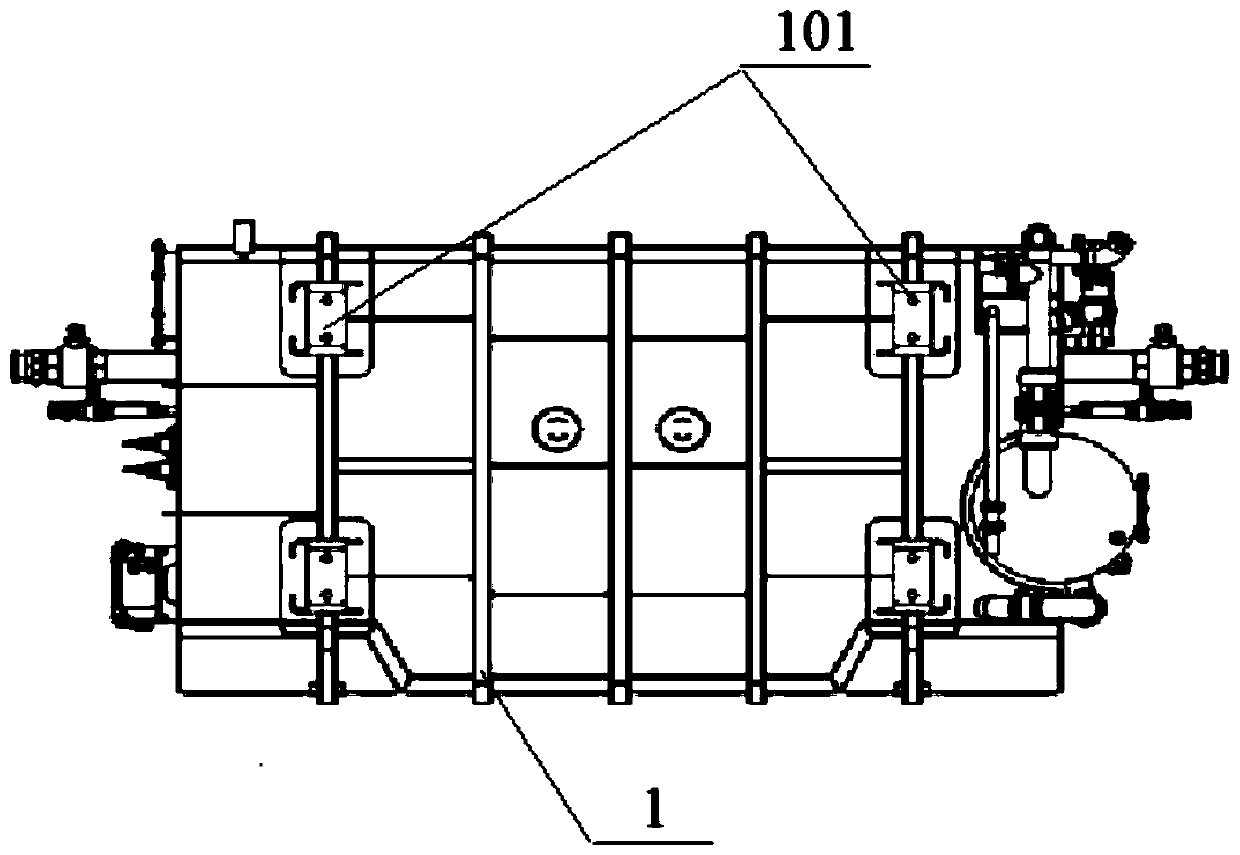

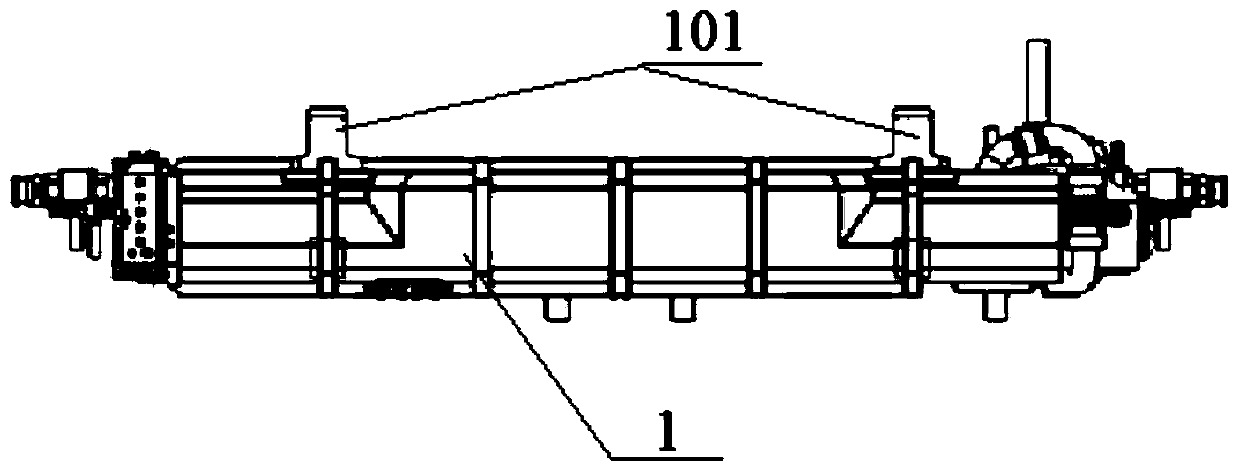

[0050] Such as Figure 1-16 As shown, the invention discloses an underframe end integration device, which can be used for various EMUs or trains. Wherein, the bottom frame end integration device includes a dirt box 1 and a dirt box lifting point 3 .

[0051] The dirt box 1 is a special-shaped dirt box, which is used to hold the dirt. Specifically, the dirt box 1 is connected with the dirt discharge pipeline on the EMU, and the dirt discharge pipeline is used for toilets, washrooms and water heaters, etc. waste discharge.

[0052] Dirt discharged from the dirt discharge pipe can enter the dirt tank 1 . The structure of the dirt box 1 is a special-shaped structure, which is located at the bottom of the vehicle underframe, and is attached to the inner wall of the space for holding the dirt box 1 formed by the end part 2 of the vehicle underframe. And when the dirt box 1 is installed on the vehicle underframe end 2, the dirt box 1 can be attached to the vehicle underframe end 2...

Embodiment 2

[0056] In the second embodiment provided by the present invention, the structure of the bottom frame end integration device in this embodiment is similar to that of the bottom frame end integration device in the first embodiment. the difference.

[0057] In this embodiment, the present invention specifically discloses that the dirt tank 1 surrounds the dirt tank lifting point 3 . Specifically, the dirt box lifting point 3 is arranged in the middle area of the dirt box 1, which has a compact structure and saves space.

[0058] Further, the present invention discloses that the integrated device at the end of the chassis further includes a buckle connector 4 and a mounting bracket 5 . The buckle-type connector 4 is used to connect the high-voltage cable 6 between the adjacent cars of the EMU and the bridge line 7 passing through from the outside of the EMU. There are several snap-in connectors 4 , which are installed on the mounting frame 5 , which is mounted on the end portion...

Embodiment 3

[0078] The present invention provides an EMU, including the bottom frame end integration device in any one of the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com