Large electromechanical pointer clock

A pointer-type, large-scale technology, which is applied to electric mechanical clocks, mechanically driven clocks, and electrical indication of time. It can solve problems such as oil stagnation, large friction coefficient, and unevenness of the plane, and achieve accurate travel time. No oil stagnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

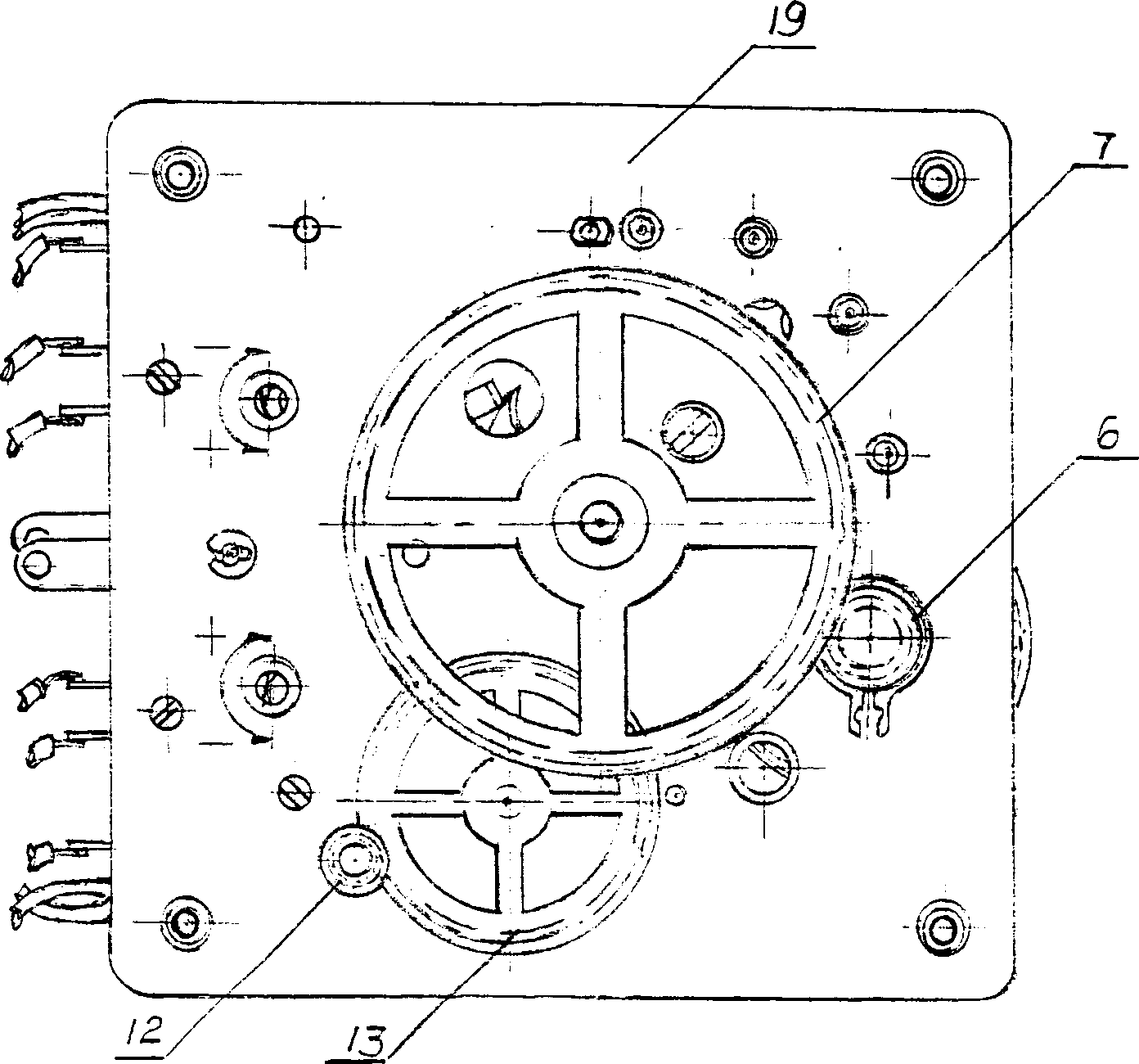

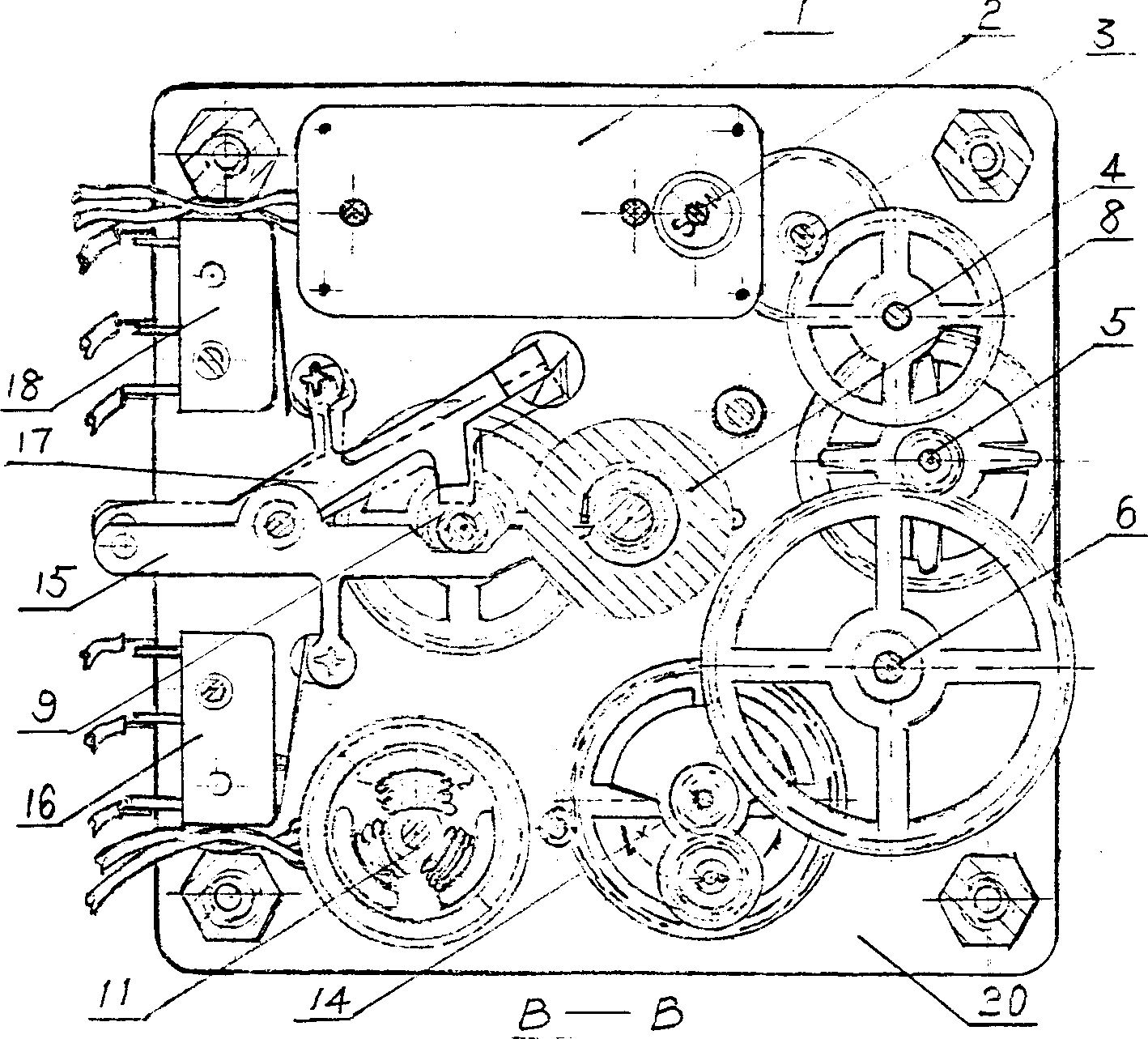

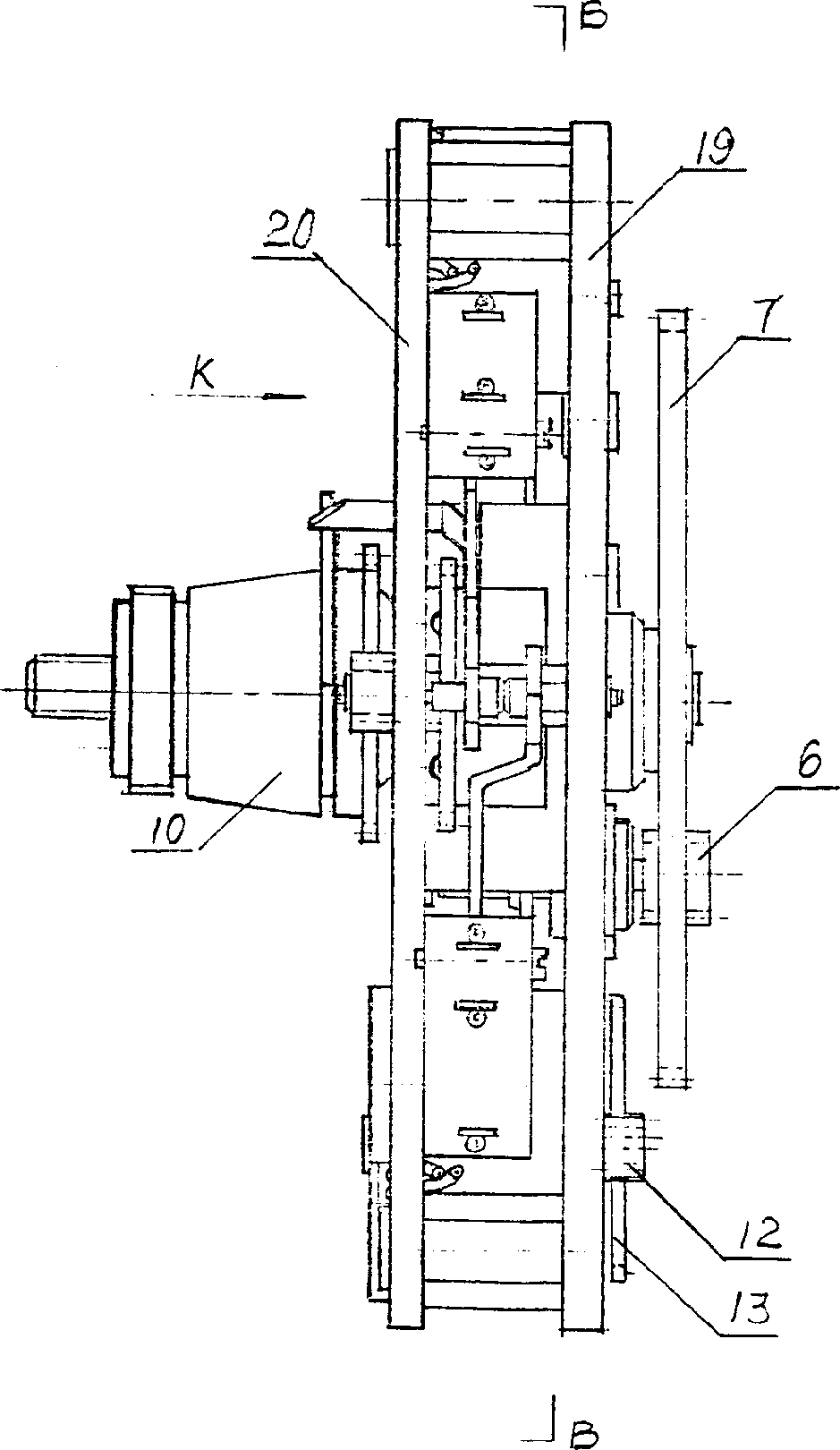

[0031]A large quasi-square electromechanical pointer clock. The clock face installation adopts the floating installation of tension spring and compression spring. The shaft structure adopts polytetrafluoroethylene bushing and stainless steel shaft, which has passed the oil-free operation of the shaft hole for eleven years, providing a structural guarantee for the long-term operation of the movement without oil and maintenance. The transmission wheel train of the needle movement can choose to use the transmission wheel train with two speed ratios of 8HZ / S or 0.5HZ / S. The assembly precision of the minute wheel shaft of the needle movement movement is high, the shaft diameter runout is about 0.008mm, the radial load test is greater than 60 kg, and the minute hand with a circumference radius of 0.5 meters can be carried in a balanced linear motion under general closed conditions, and the power consumption of the needle movement is : 0.5HZ / S series DC4.8v, power consumption is les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com