90-DEG bent connector

A connector and curved technology, which is applied in the field of new energy high-voltage connectors, can solve the problems of low terminal connection accuracy and limited use space, and achieve the effects of novel operating space, simple structure and reliable shielding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

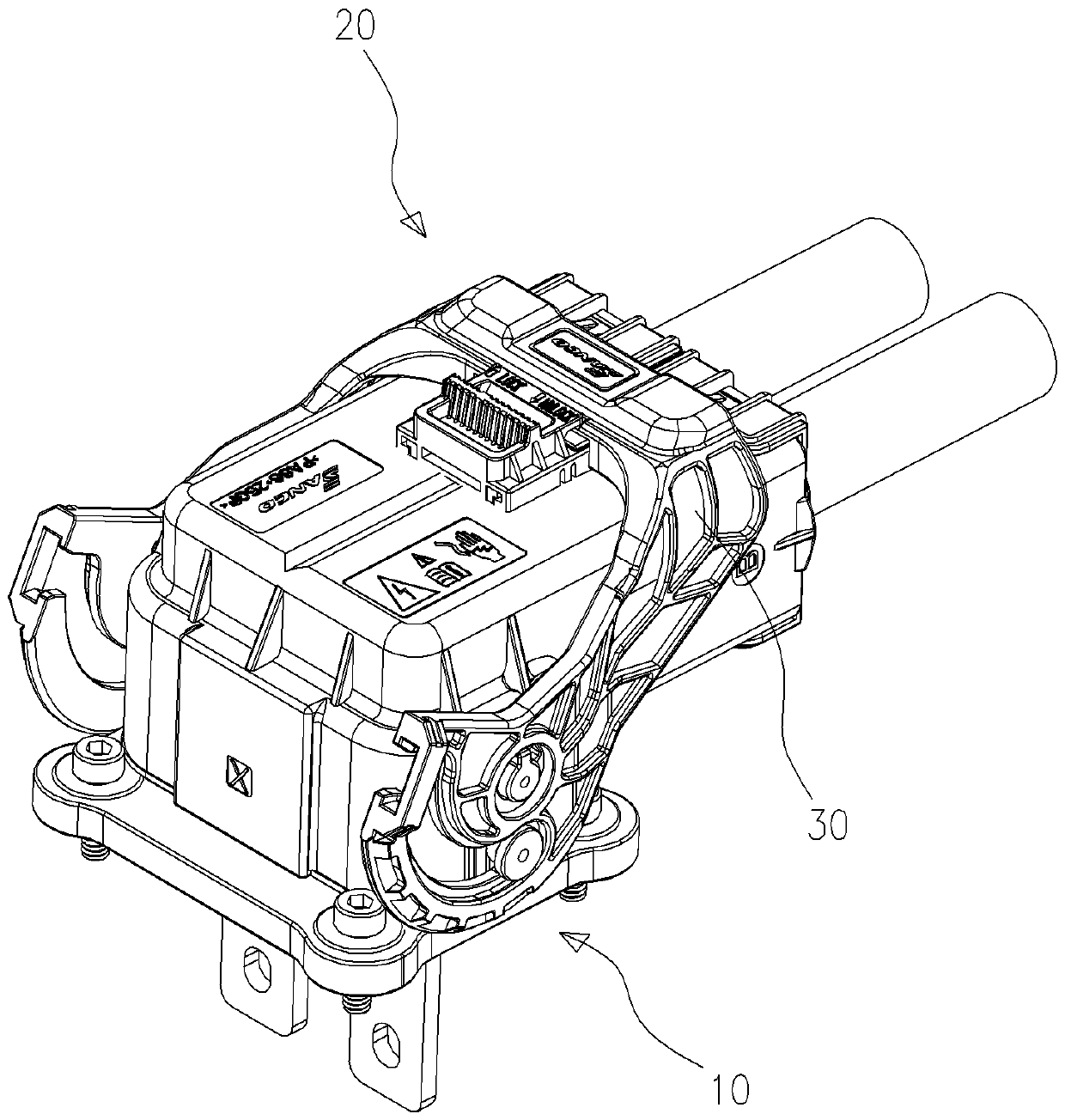

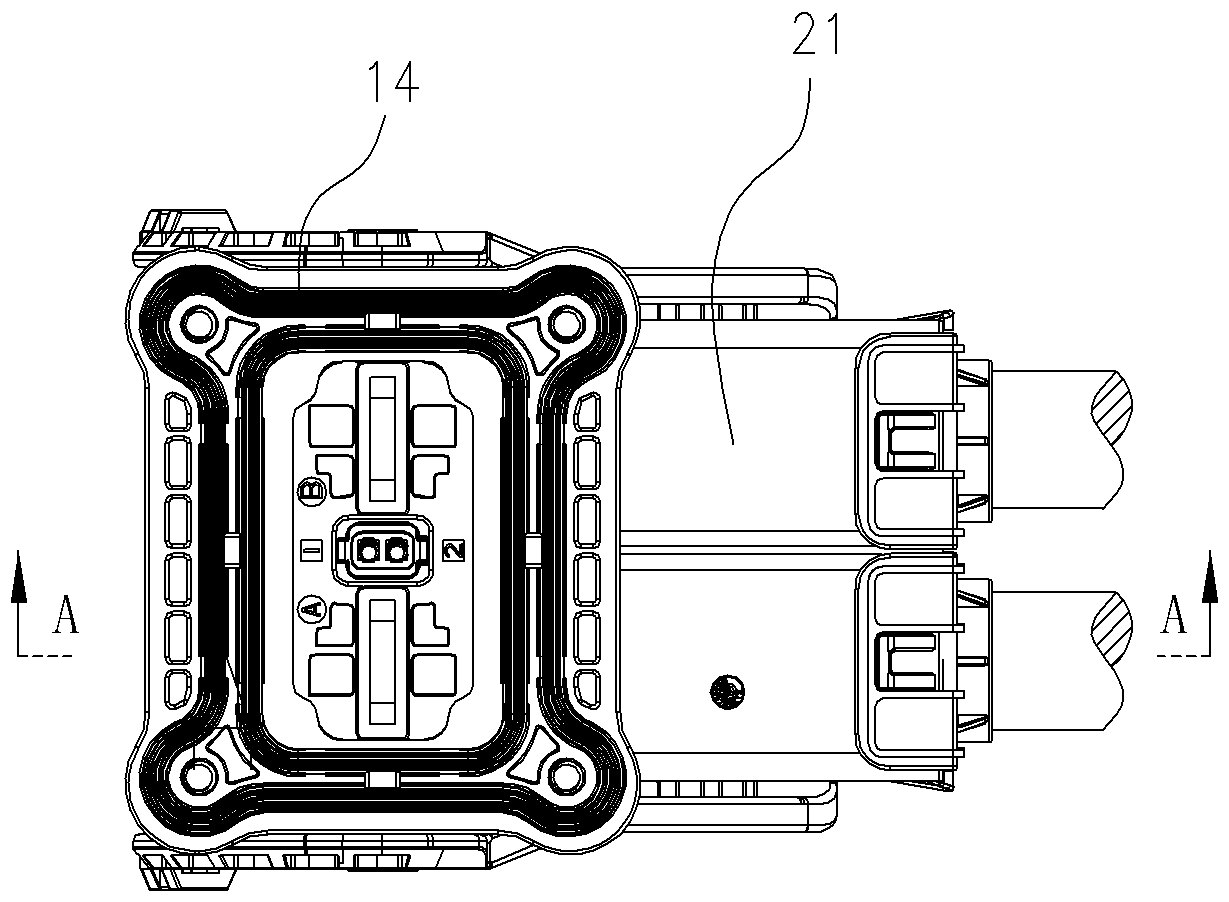

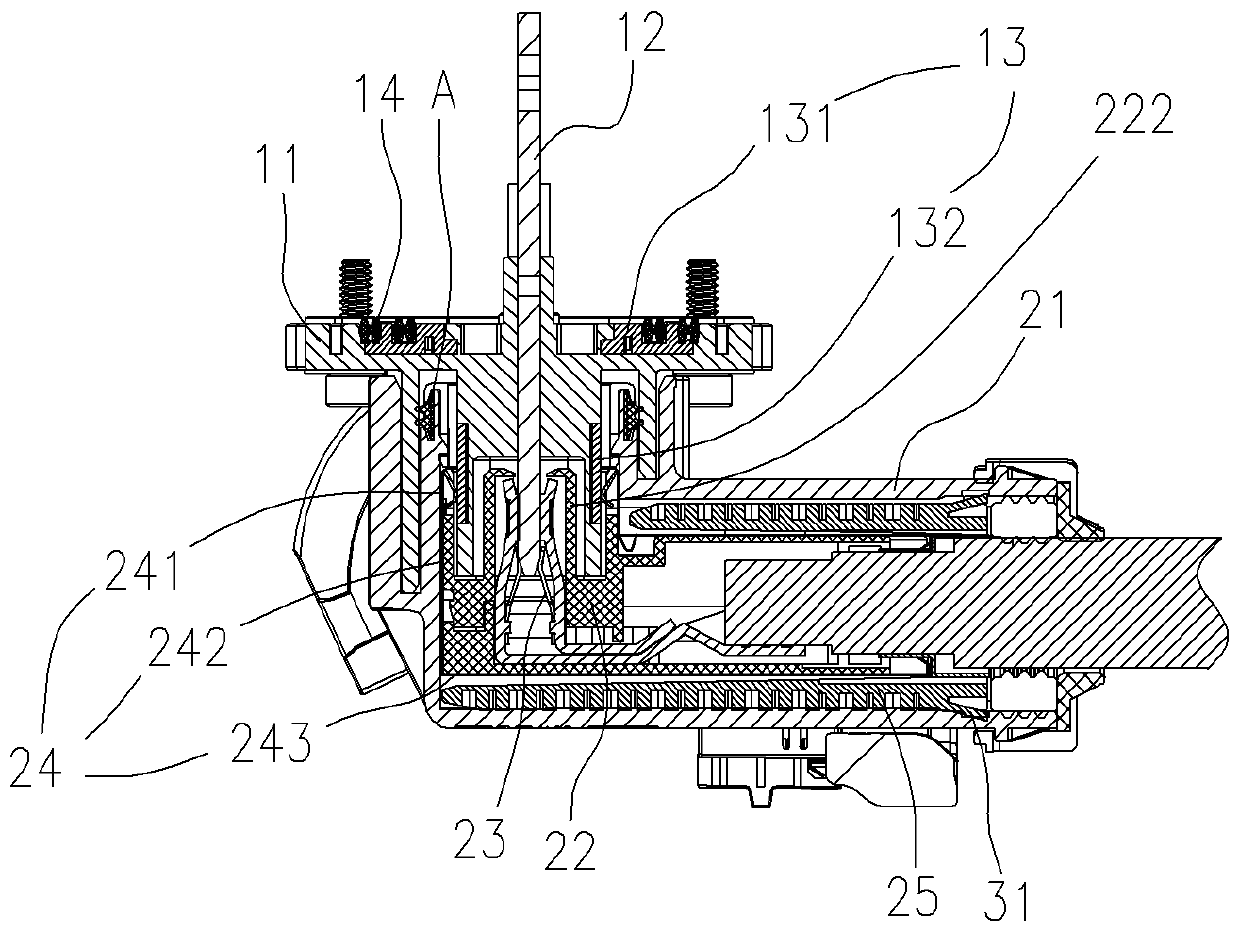

[0023] Such as Figure 1 to Figure 9 Shown is a preferred specific implementation example of the present invention, a 90º bent connector, such as figure 1 As shown, including the socket 10 and the plug 20, wherein, as image 3 , Figure 5 As shown, the socket 10 includes a socket insulator 11, a copper brand male terminal 12 inserted in the socket insulator 11, and a socket shield 13 inserted in the socket insulator 11, as Figure 6 As shown, the socket shielding seat 13 includes a shielding plate body 131 and a shielding cover 132 vertically arranged on the shielding plate body 131, and the shielding plate body 131 is embedded in the end face of the socket insulator 11, as figure 2 As shown, the shielding plate body 13 is provided with a conjoined double sealing ring 14, and the outer sealing ring 141 of the conjoining double sealing ring 14 is located between the outer edge of the shielding plate body 13 and the socket insulator 11. The inner sealing ring of the ring 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com