Patents

Literature

473results about How to "Extend effective life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

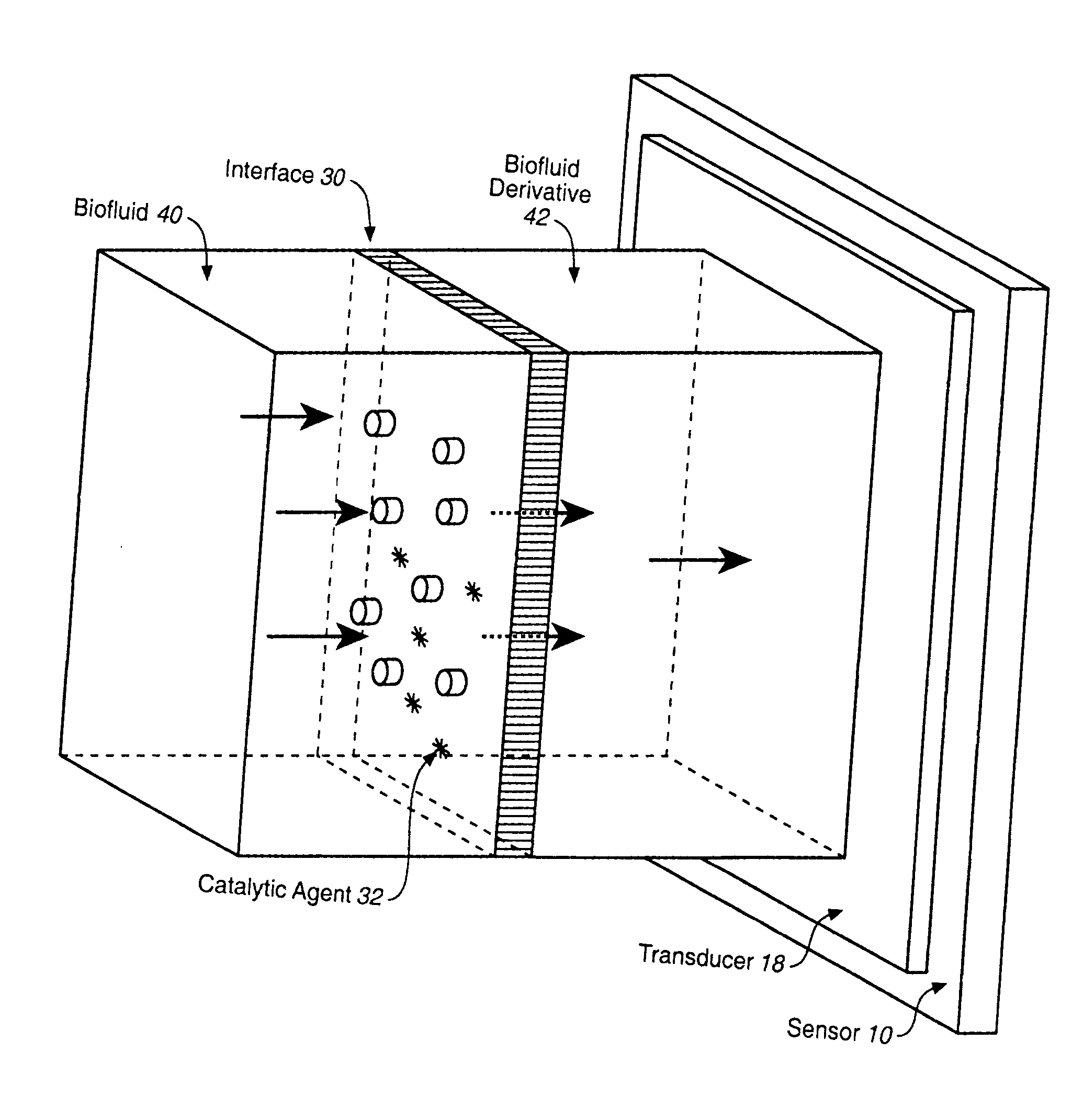

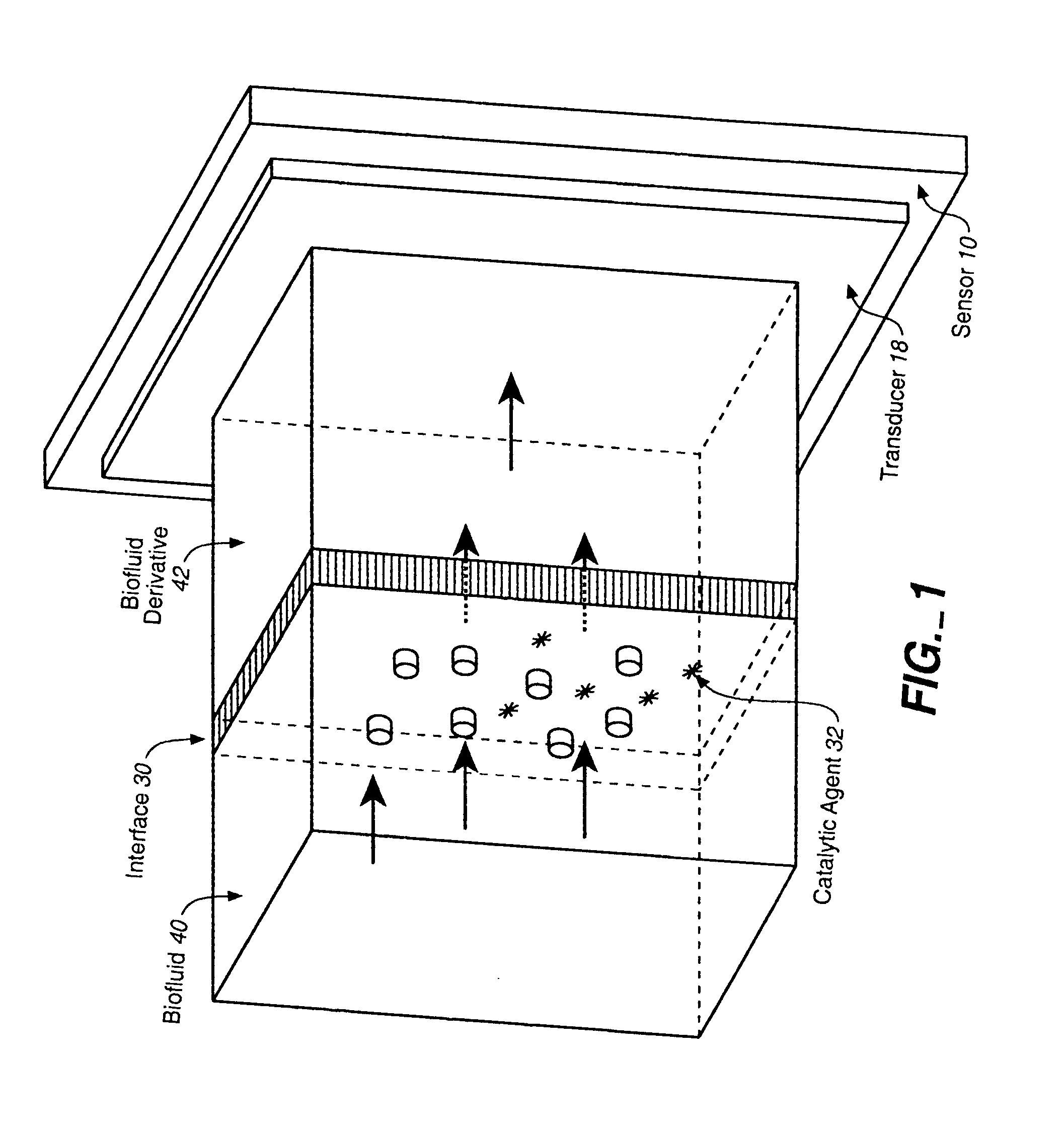

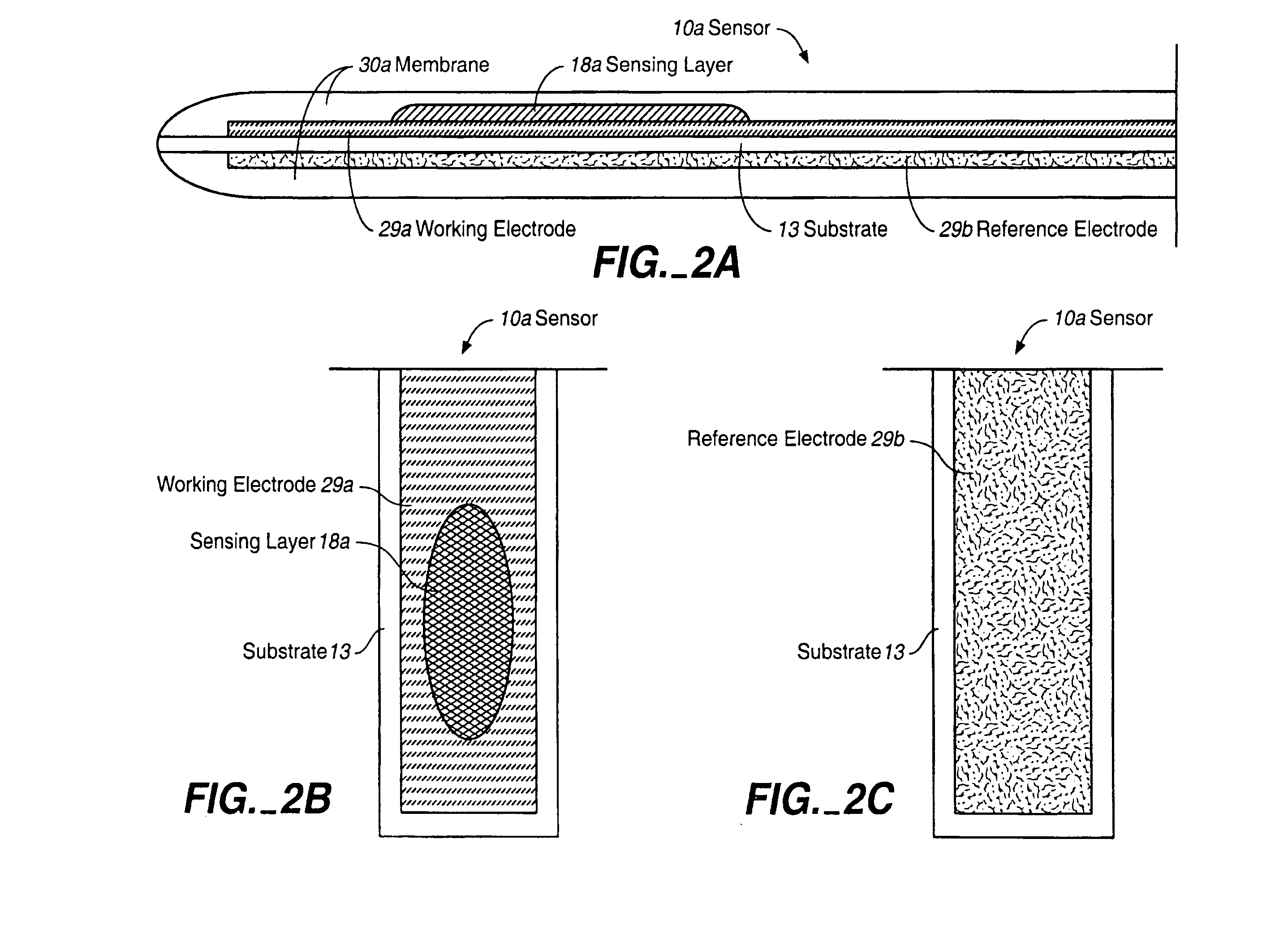

Analyte Sensor, and Associated System and Method Employing a Catalytic Agent

InactiveUS20070191701A1Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteTransducer

An analyte sensor for use in connection with a biofluid is described. The analyte sensor may comprise any suitable interface between the biofluid and a derivative of the biofluid and any suitable transducer of information concerning an analyte. At least one catalytic agent is provided in a locale or vicinity of the interface. The catalytic agent, such as a proteinaceous agent or a non-proteinaceous, organic-metal agent, is sufficient to catalyze the degradation of reactive oxygen and / or nitrogen species that may be present in the vicinity of the interface. An analyte-sensing kit and a method of sensing an analyte are also described.

Owner:ABBOTT DIABETES CARE INC

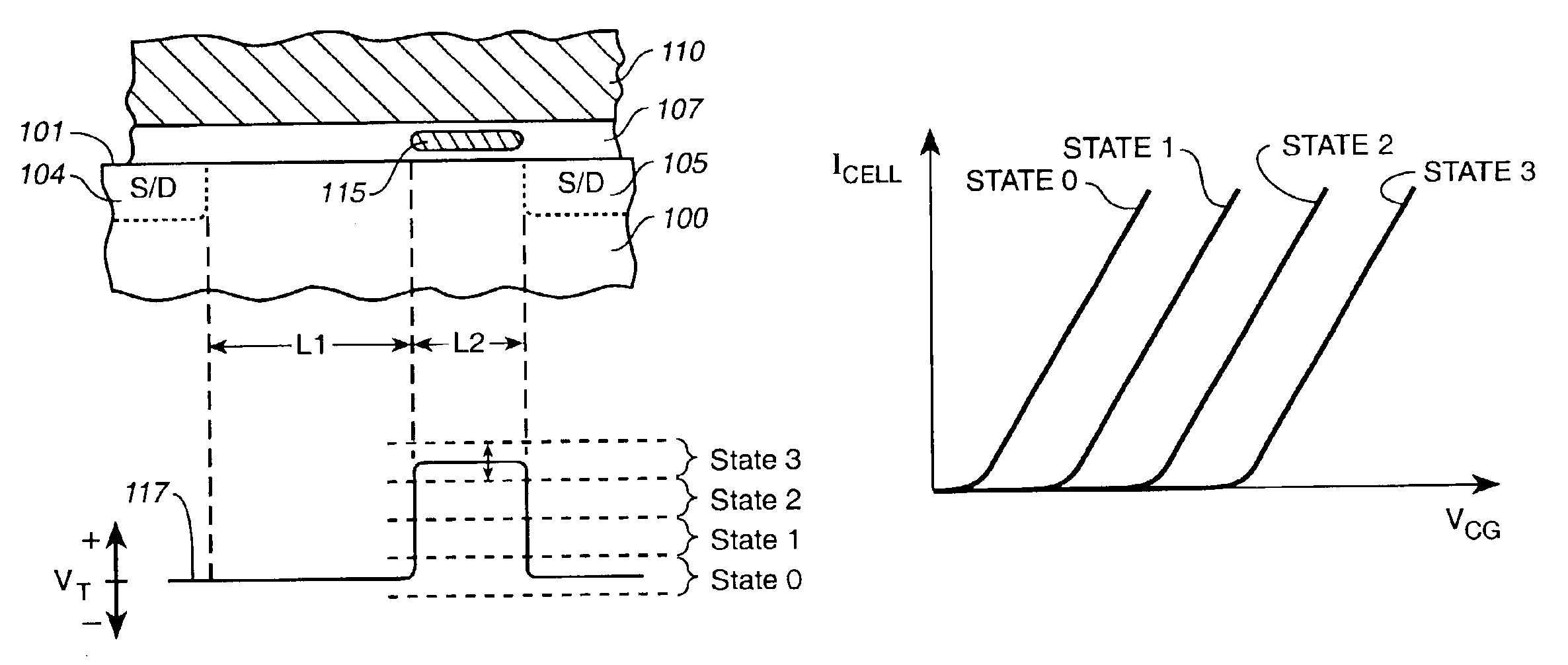

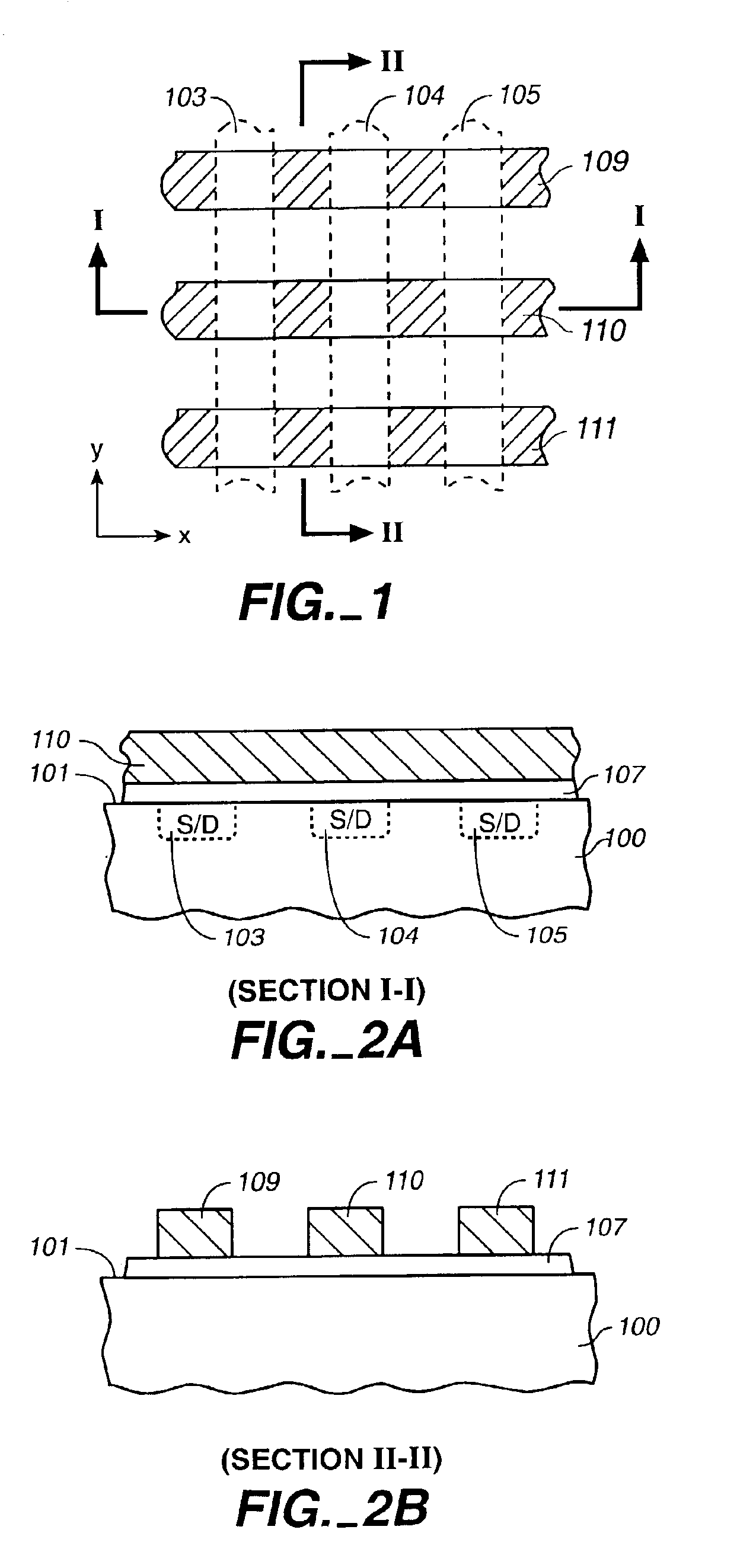

Multi-state non-volatile integrated circuit memory systems that employ dielectric storage elements

InactiveUS6925007B2Increase the number ofExtend effective lifeTransistorNanoinformaticsEngineeringDielectric layer

Non-volatile memory cells store a level of charge corresponding to the data being stored in a dielectric material storage element that is sandwiched between a control gate and the semiconductor substrate surface over channel regions of the memory cells. More than two memory states are provided by one of more than two levels of charge being stored in a common region of the dielectric material. More than one such common region may be included in each cell. In one form, two such regions are provided adjacent source and drain diffusions in a cell that also includes a select transistor positioned between them. In another form, NAND arrays of strings of memory cells store charge in regions of a dielectric layer sandwiched between word lines and the semiconductor substrate.

Owner:SANDISK TECH LLC

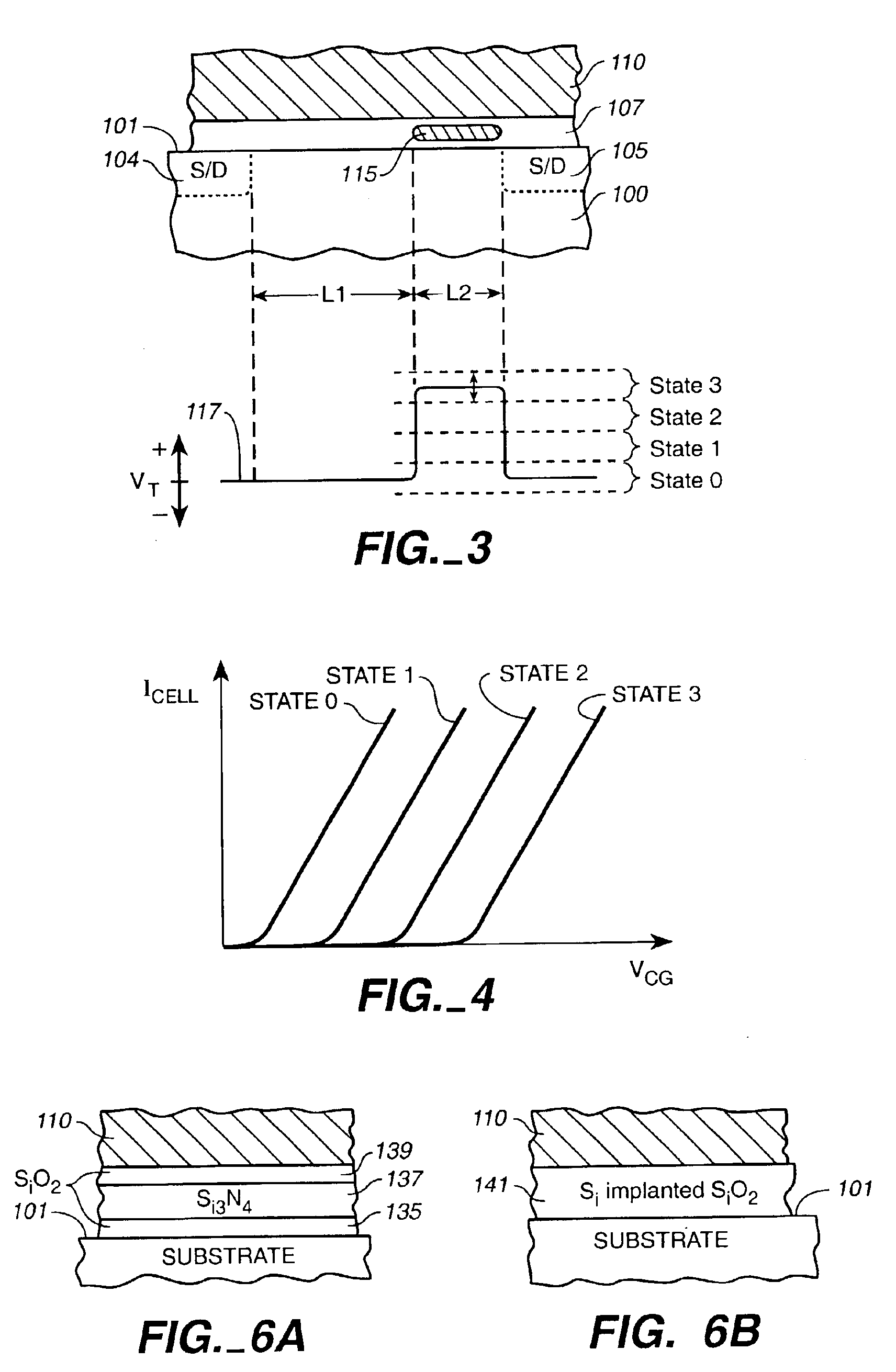

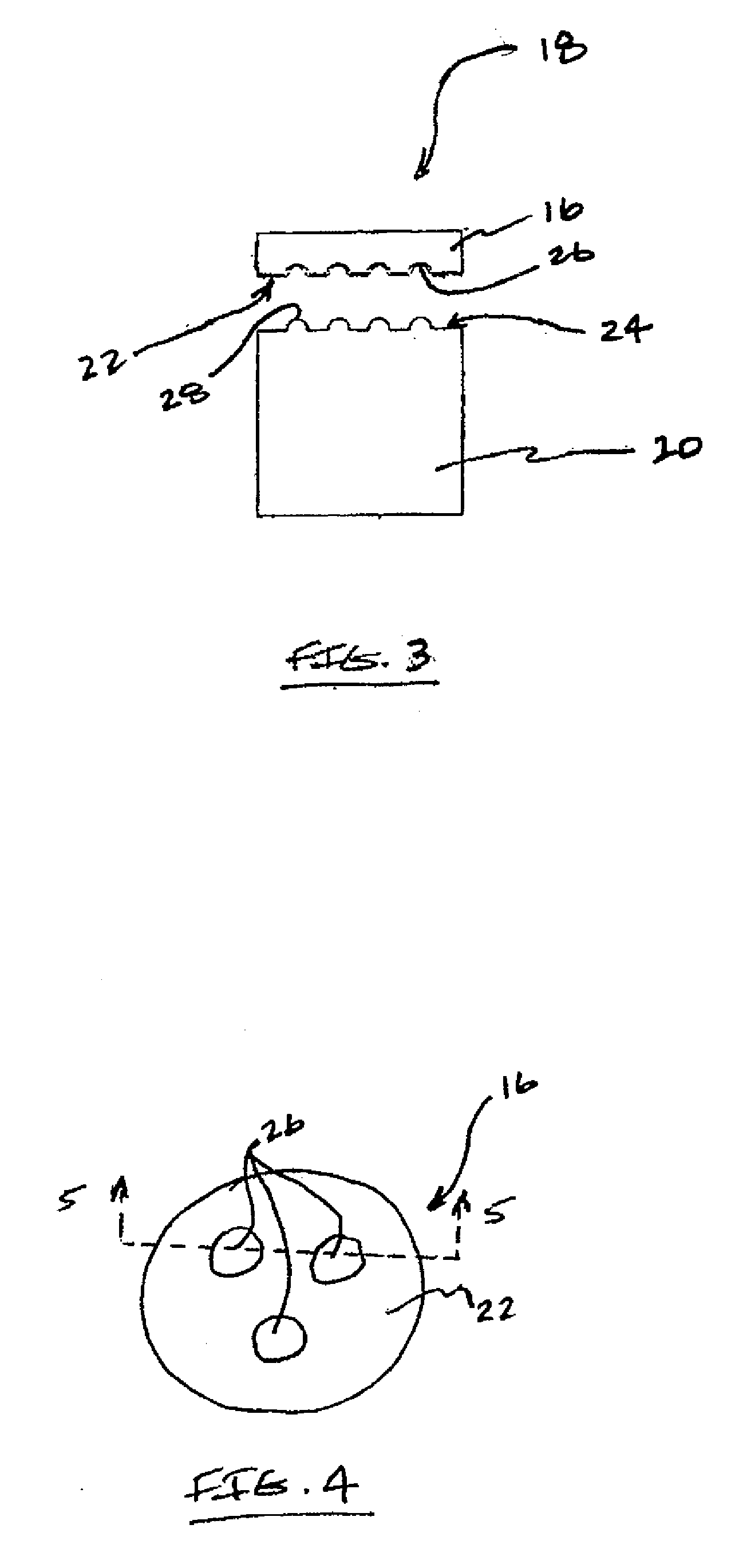

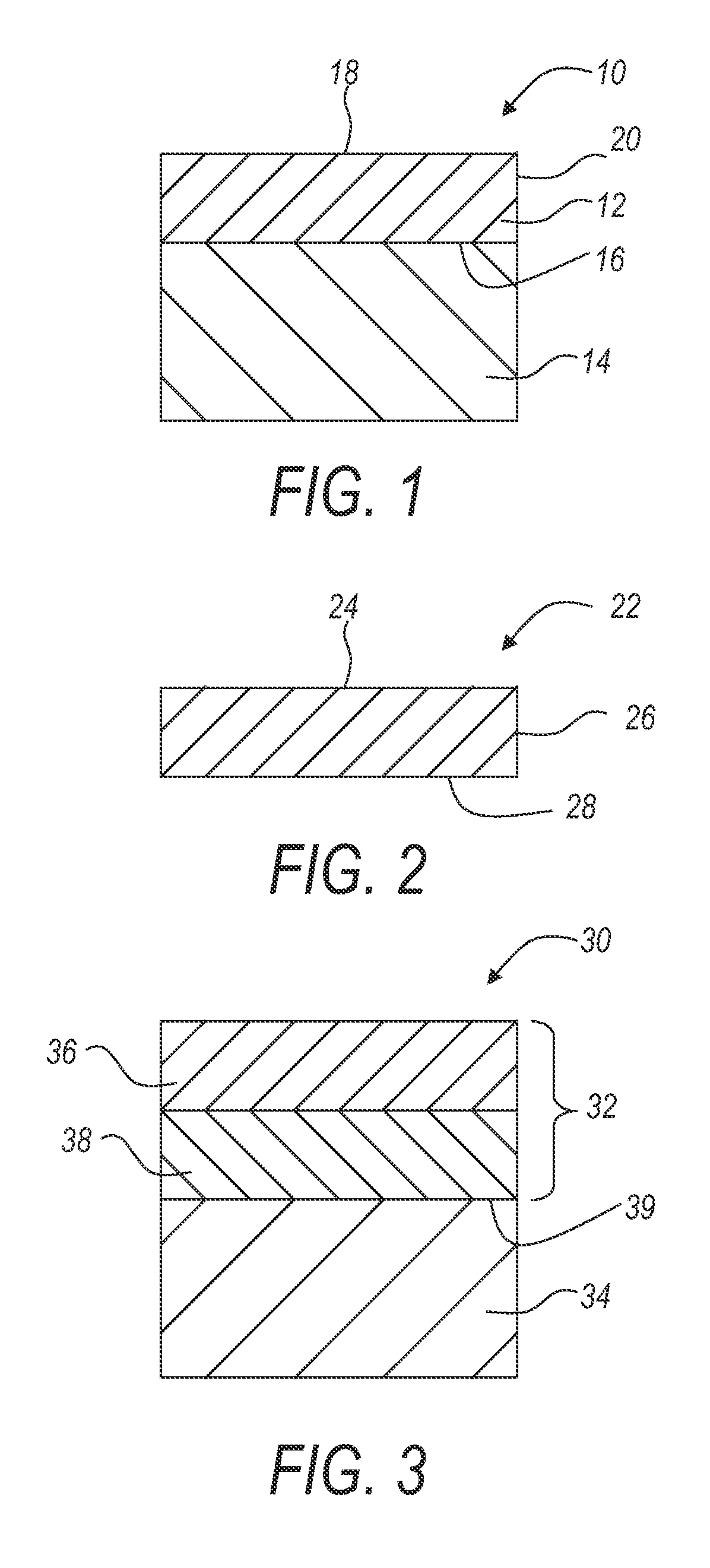

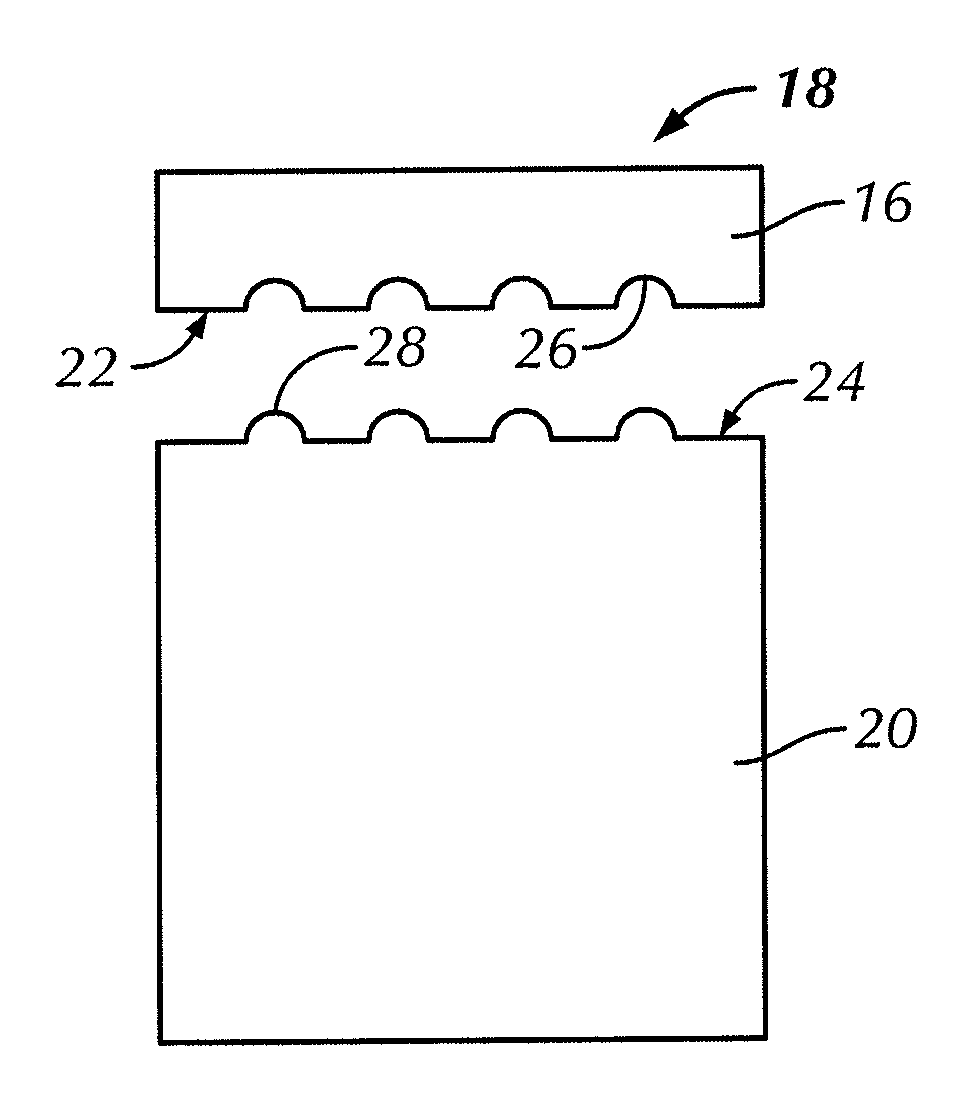

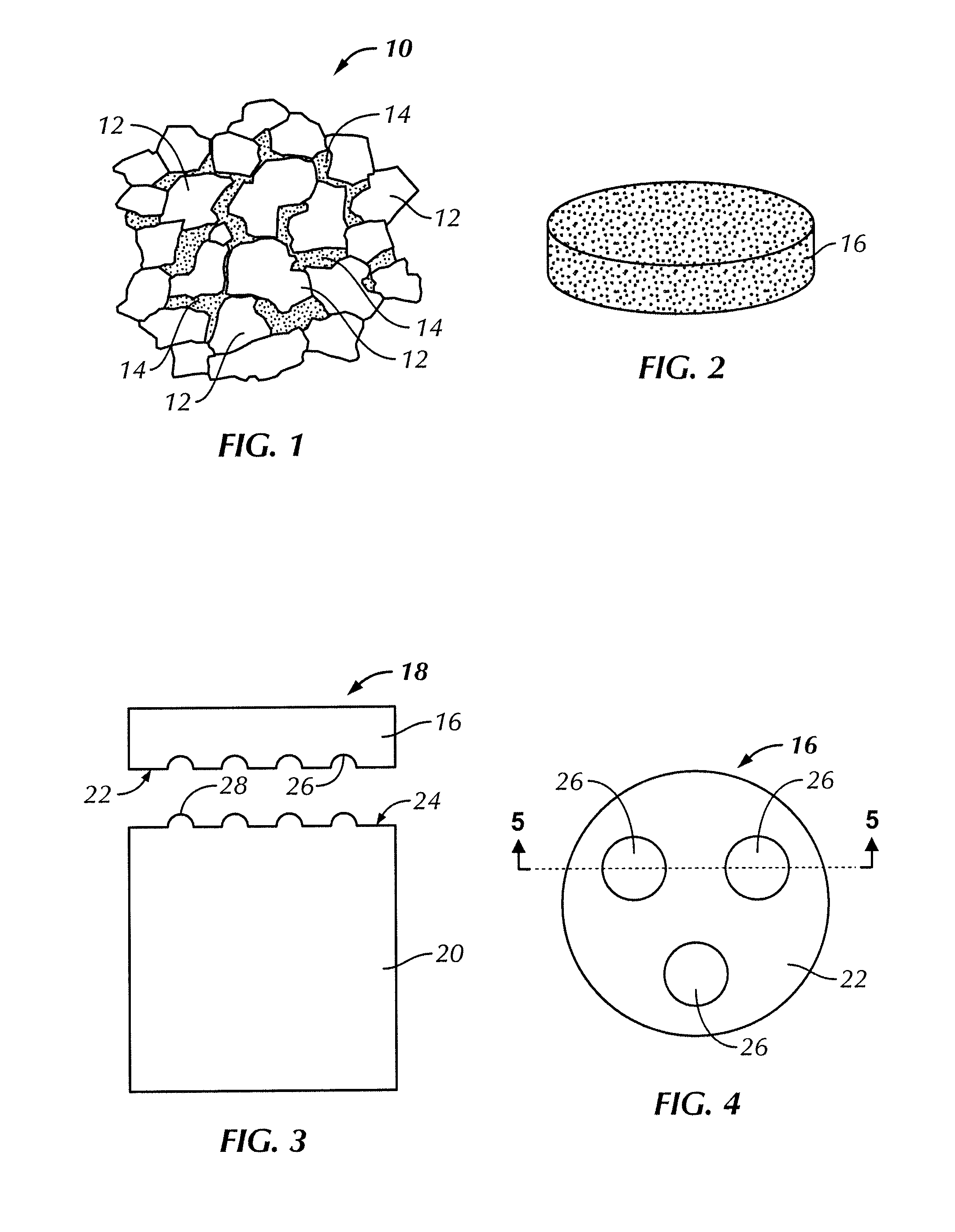

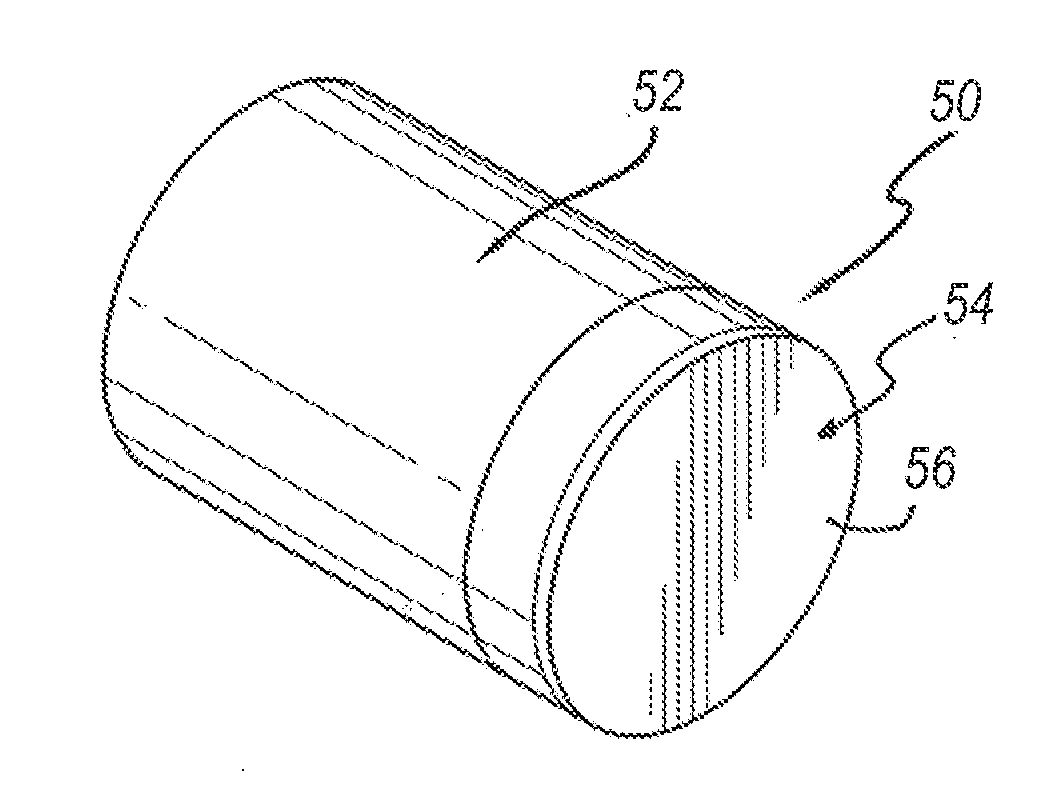

Thermally stable ultra-hard material compact constructions

InactiveUS20080142276A1Extend effective lifePigmenting treatmentDrill bitsSuperhard materialPolycrystalline diamond

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

Memory system

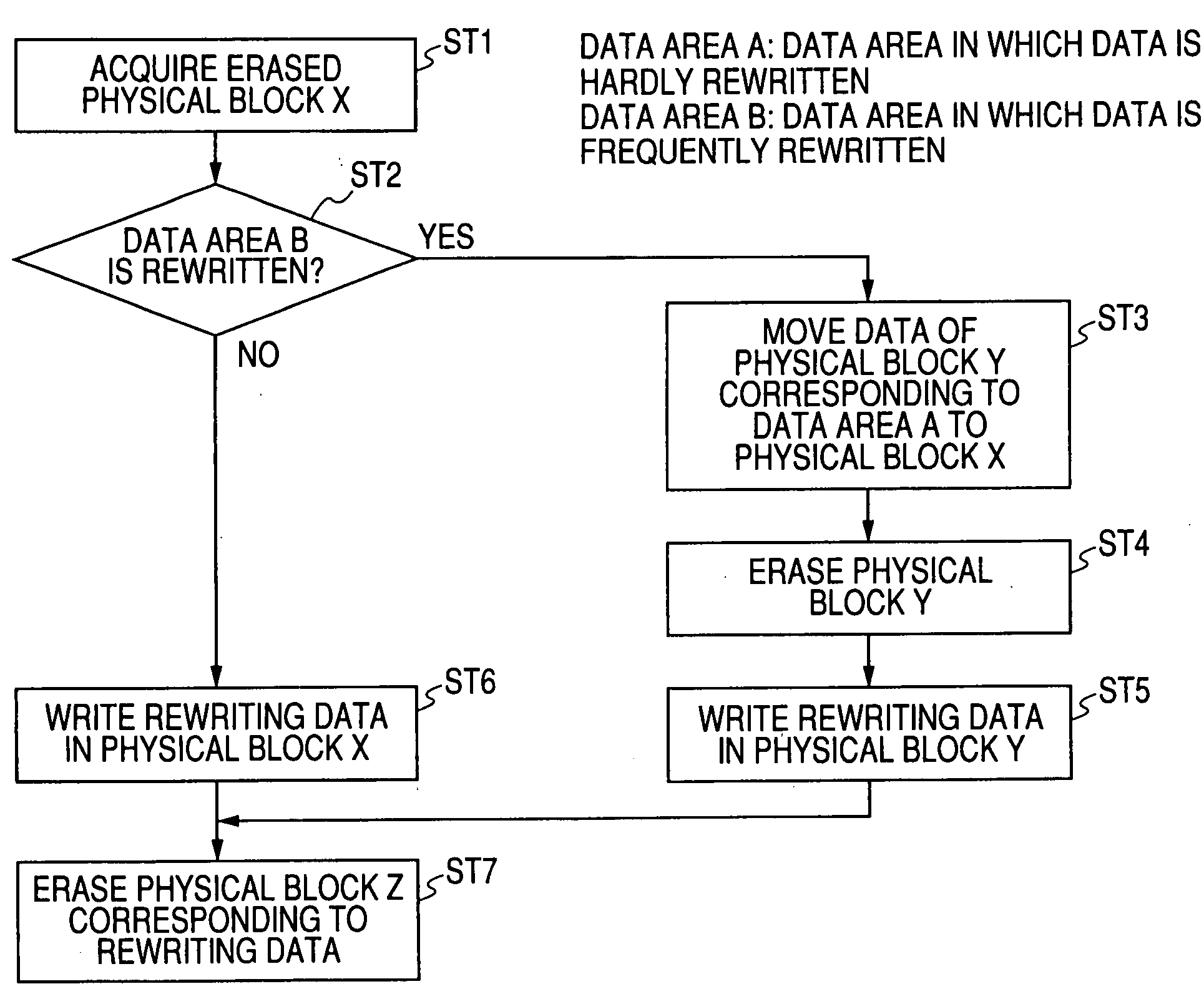

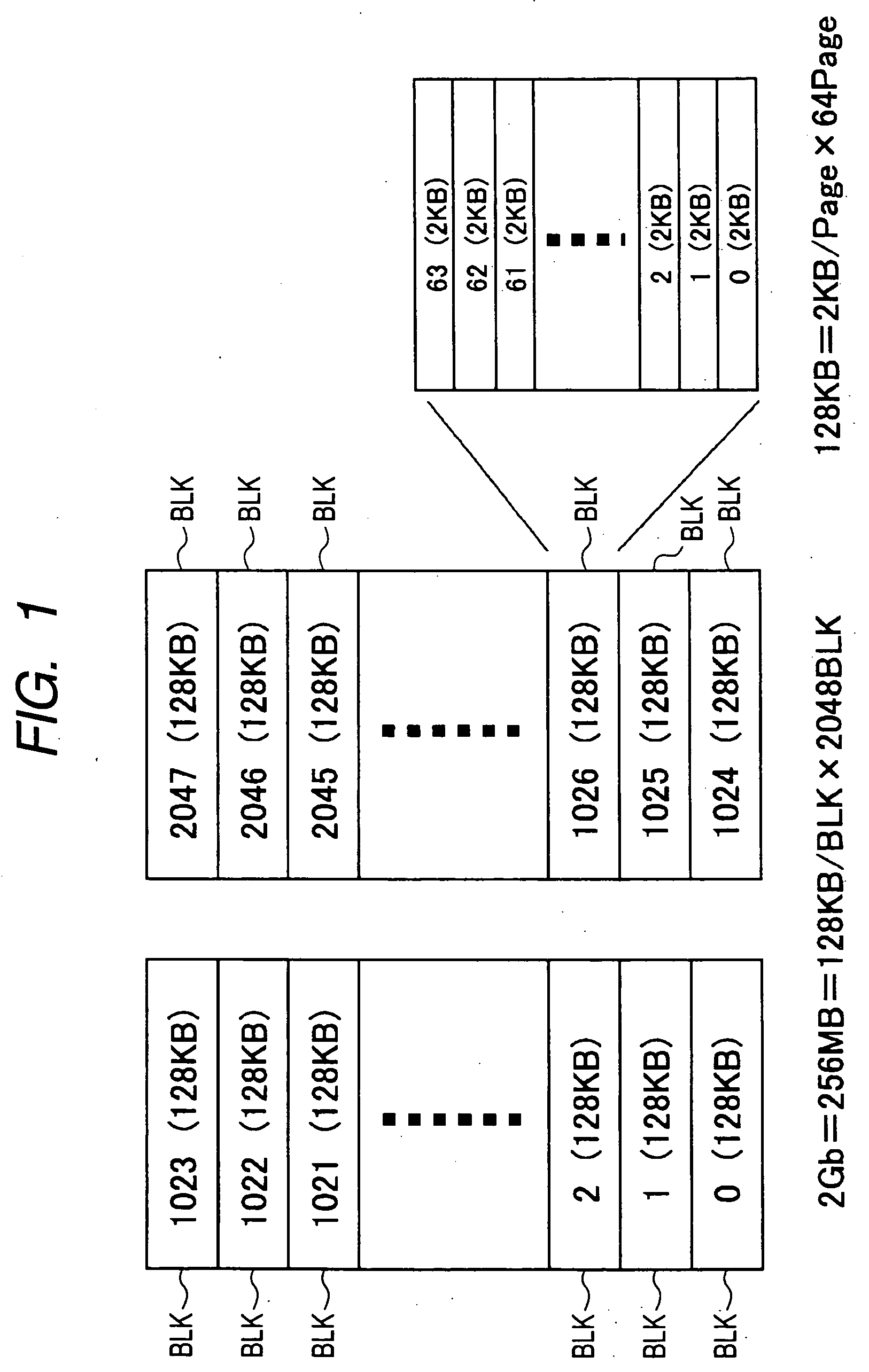

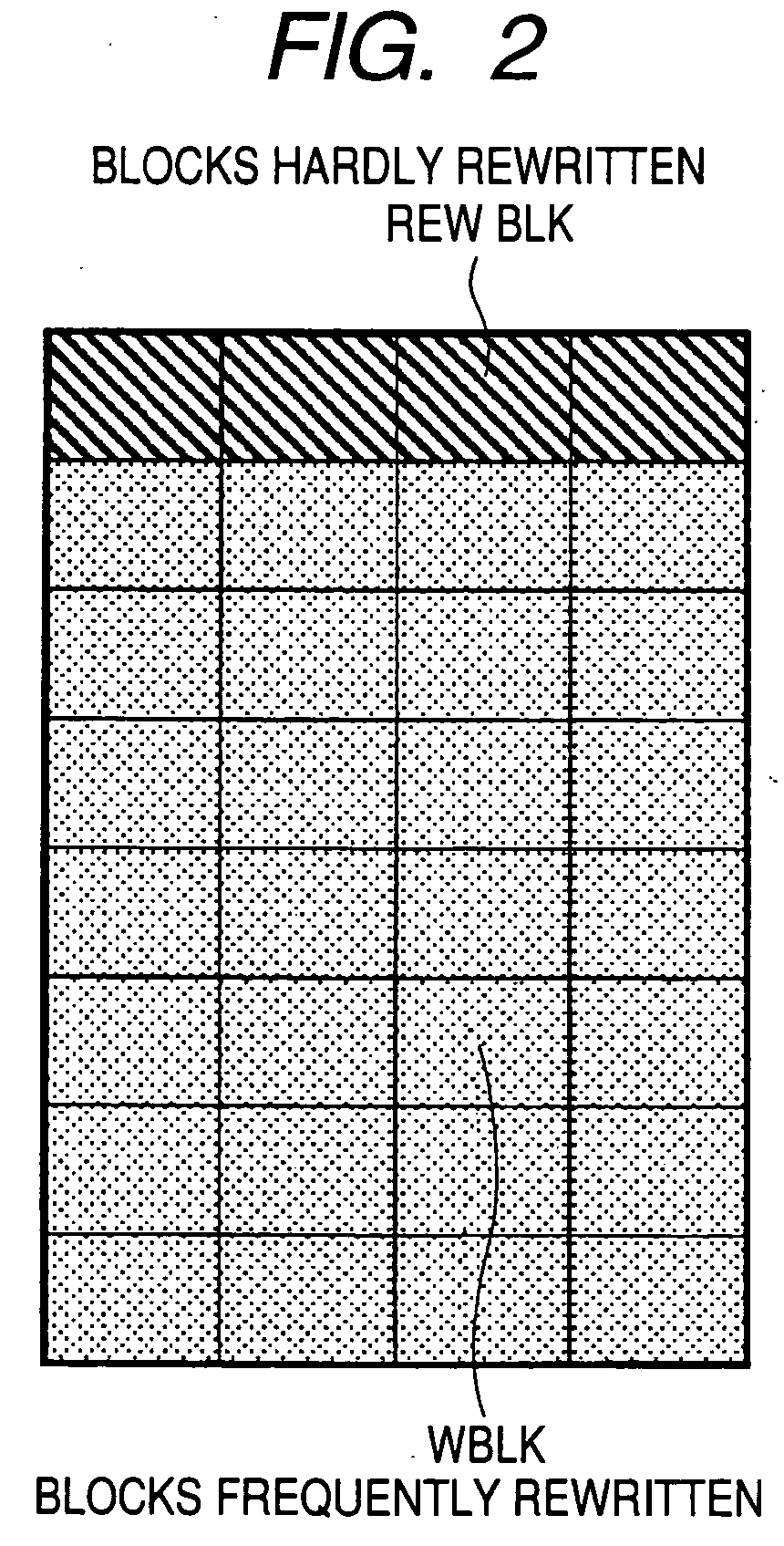

ActiveUS20070103992A1Extend effective lifeEasy to controlMemory architecture accessing/allocationRead-only memoriesLogical block addressingSemiconductor storage devices

A memory system including a nonvolatile semiconductor storage device includes: a nonvolatile memory unit that includes a first data area in which data is frequently rewritten and a second data area in which data is hardly rewritten; and a control unit. The control unit sequentially selects logical block addresses in the second data area in which data is hardly rewritten and updates physical block addresses at new rewriting destinations in the first data area in which data is frequently rewritten to physical block addresses corresponding to the logical block addresses selected.

Owner:SONY CORP

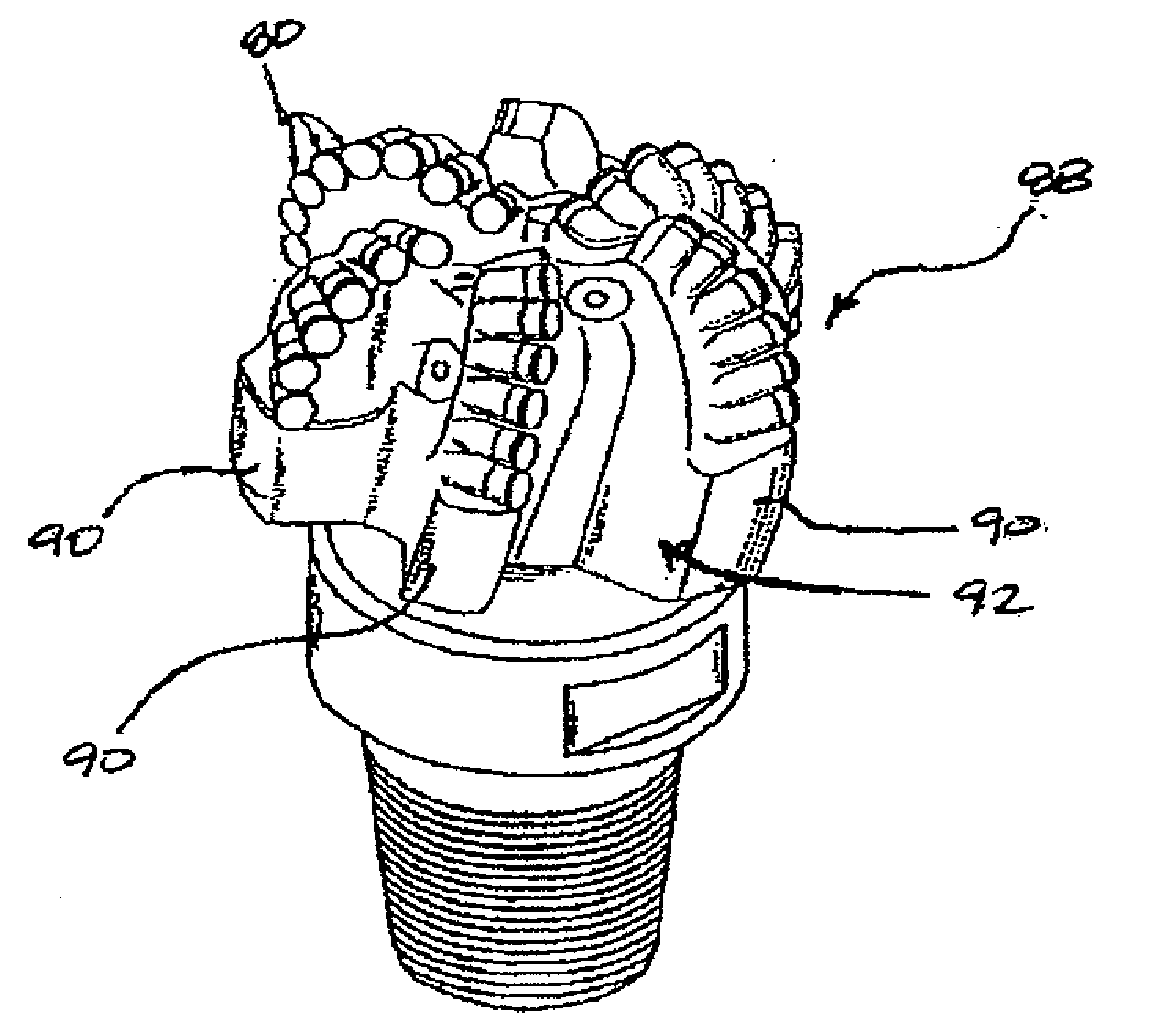

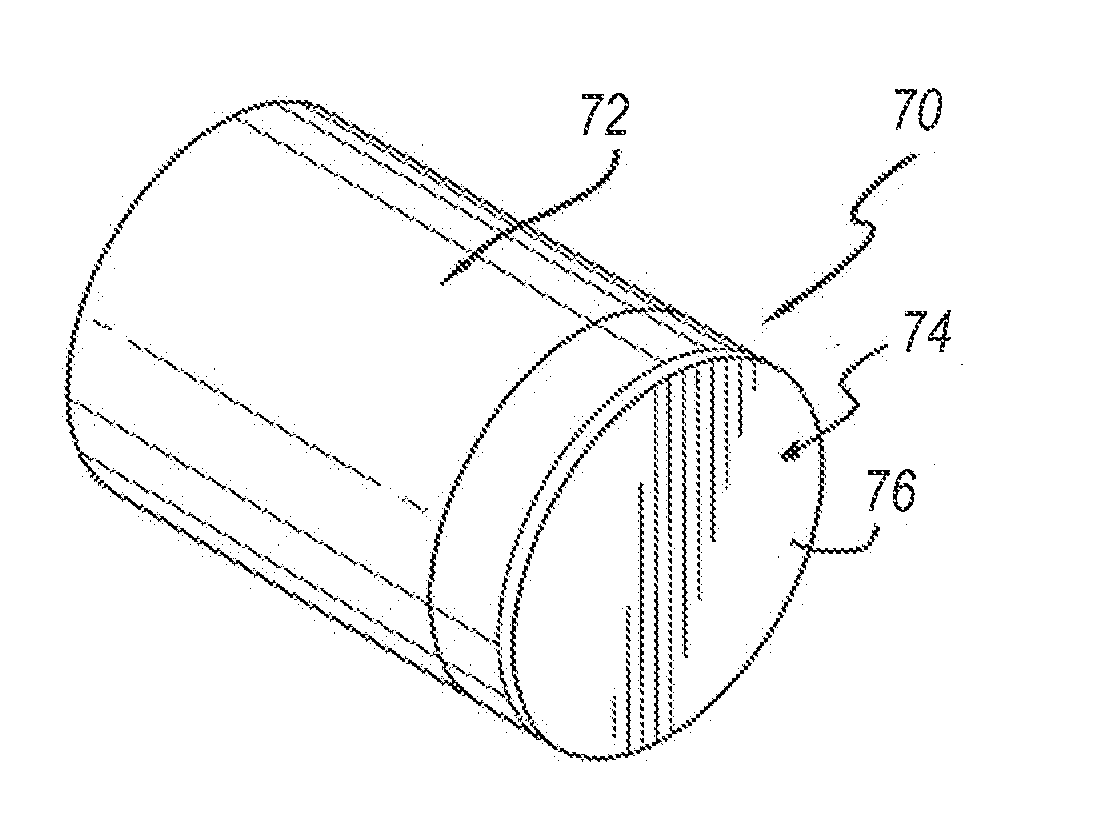

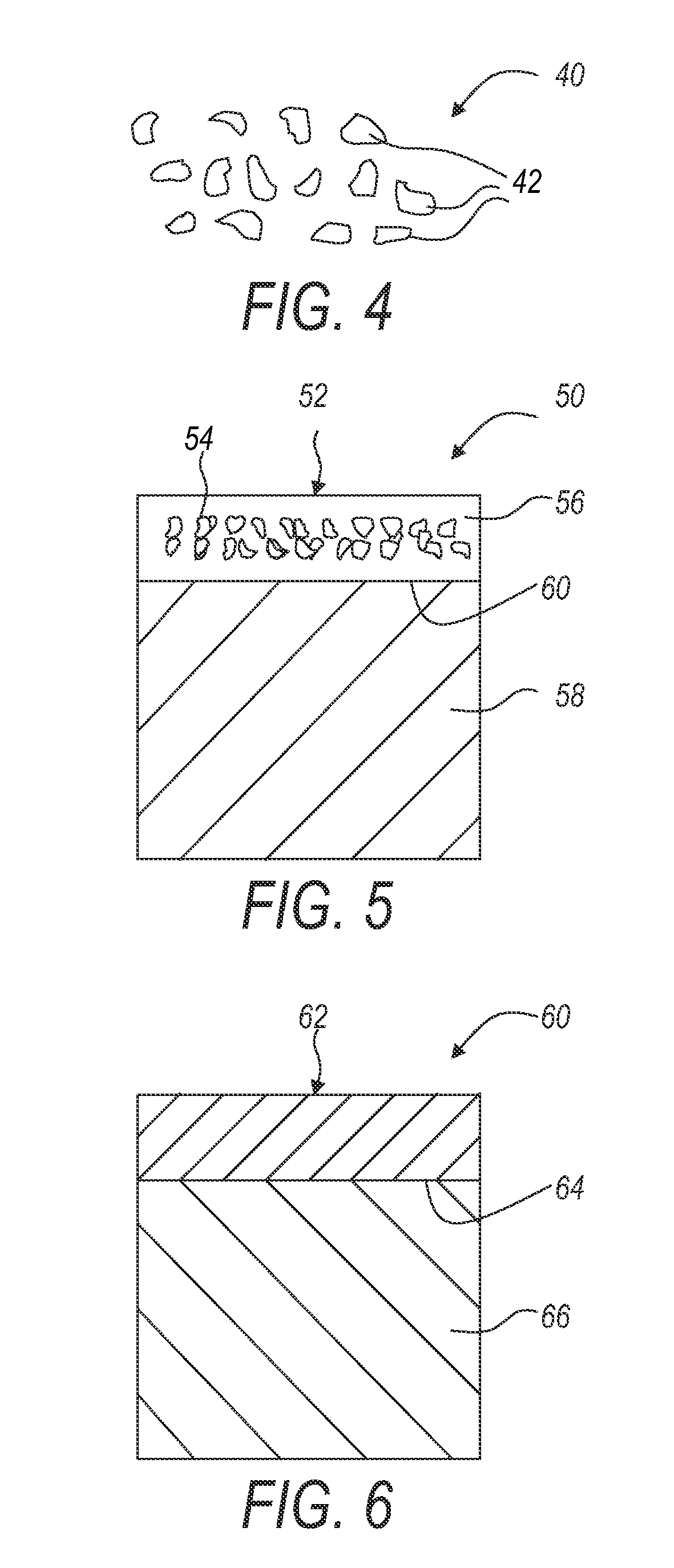

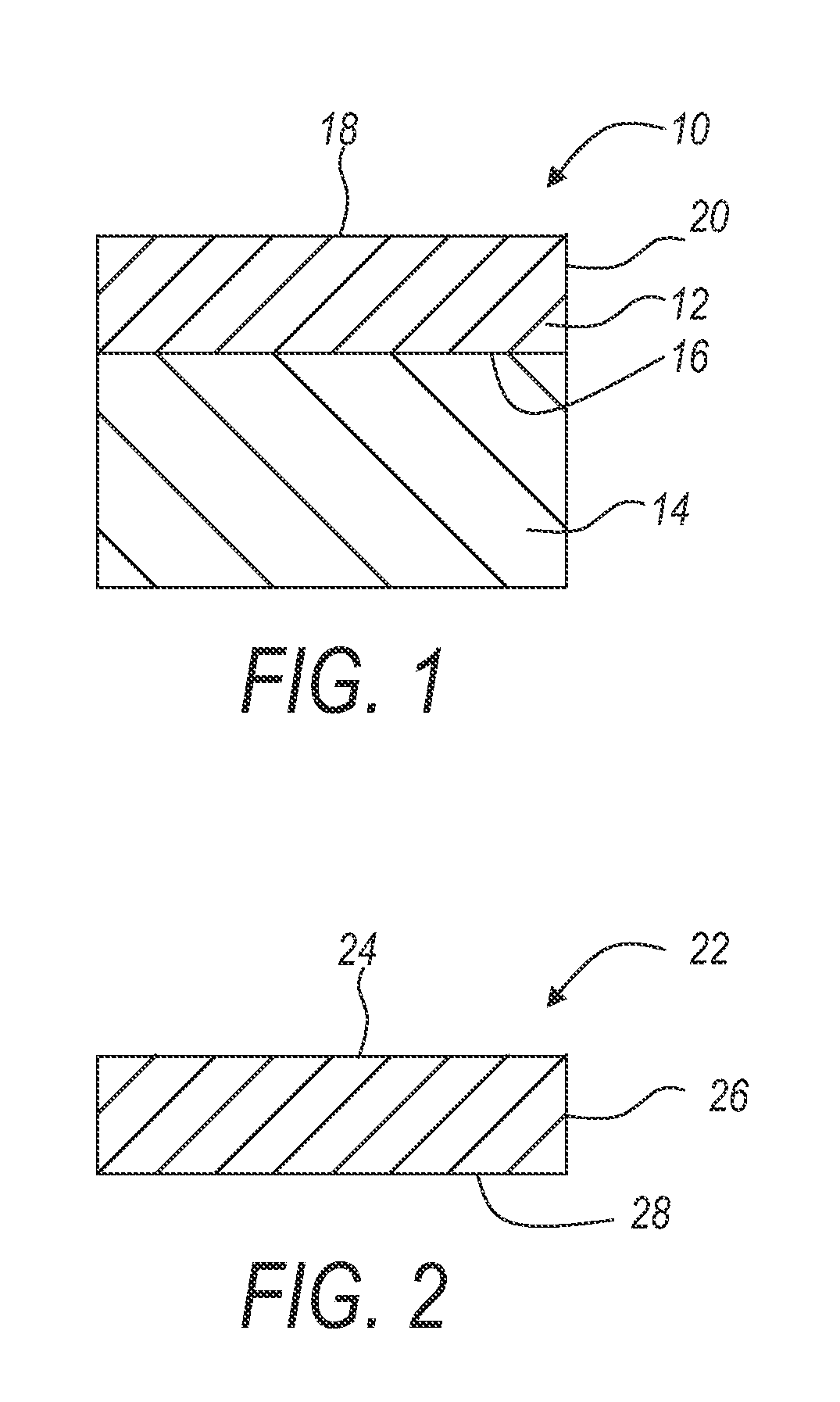

Diamond Bonded Construction Comprising Multi-Sintered Polycrystalline Diamond

InactiveUS20110083908A1Lower Level RequirementsImprove sintering performancePigmenting treatmentDrill bitsPolycrystalline diamondVolume content

Diamond bonded constructions comprise a diamond body attached to a substrate, wherein the body includes a first diamond bonded volume, and a second diamond bonded volume attached thereto. The second volume may be provided in the form of a powder or a presintered mass prior to attachment, and the first volume may be provided in the form of presintered pieces when combined with the second volume. The first volume diamond volume content is greater than about 94 percent, and is the same or greater than that of the second volume. The first volume is sintered during a first HPHT process, and the second volume is sintered and / or attached to the first volume during a second HPHT process. The first HPHT pressure is greater than the second HPHT pressure. The substrate is not an infiltration substrate used to form the first diamond volume. The diamond body may be thermally stable.

Owner:SMITH INT INC

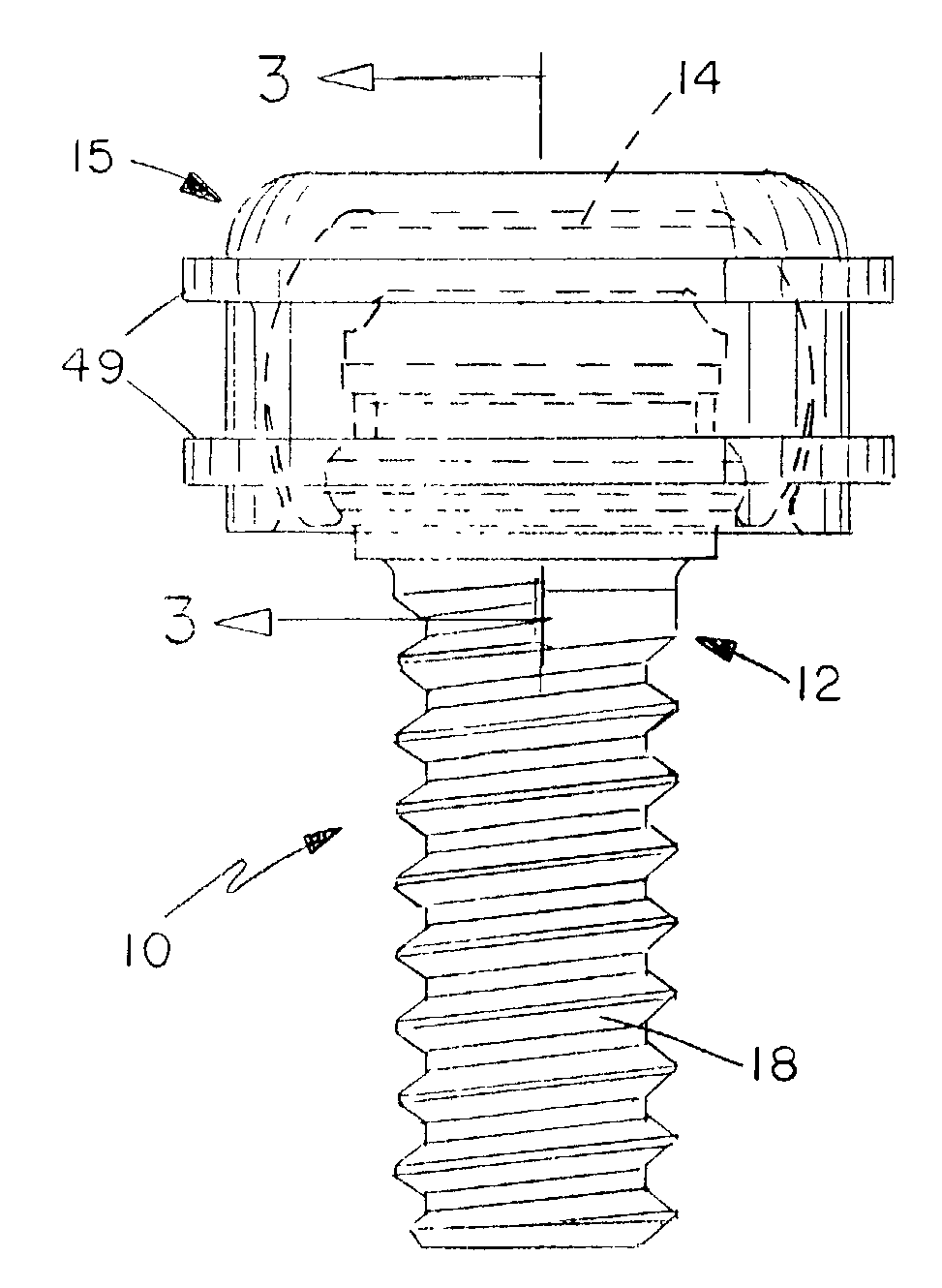

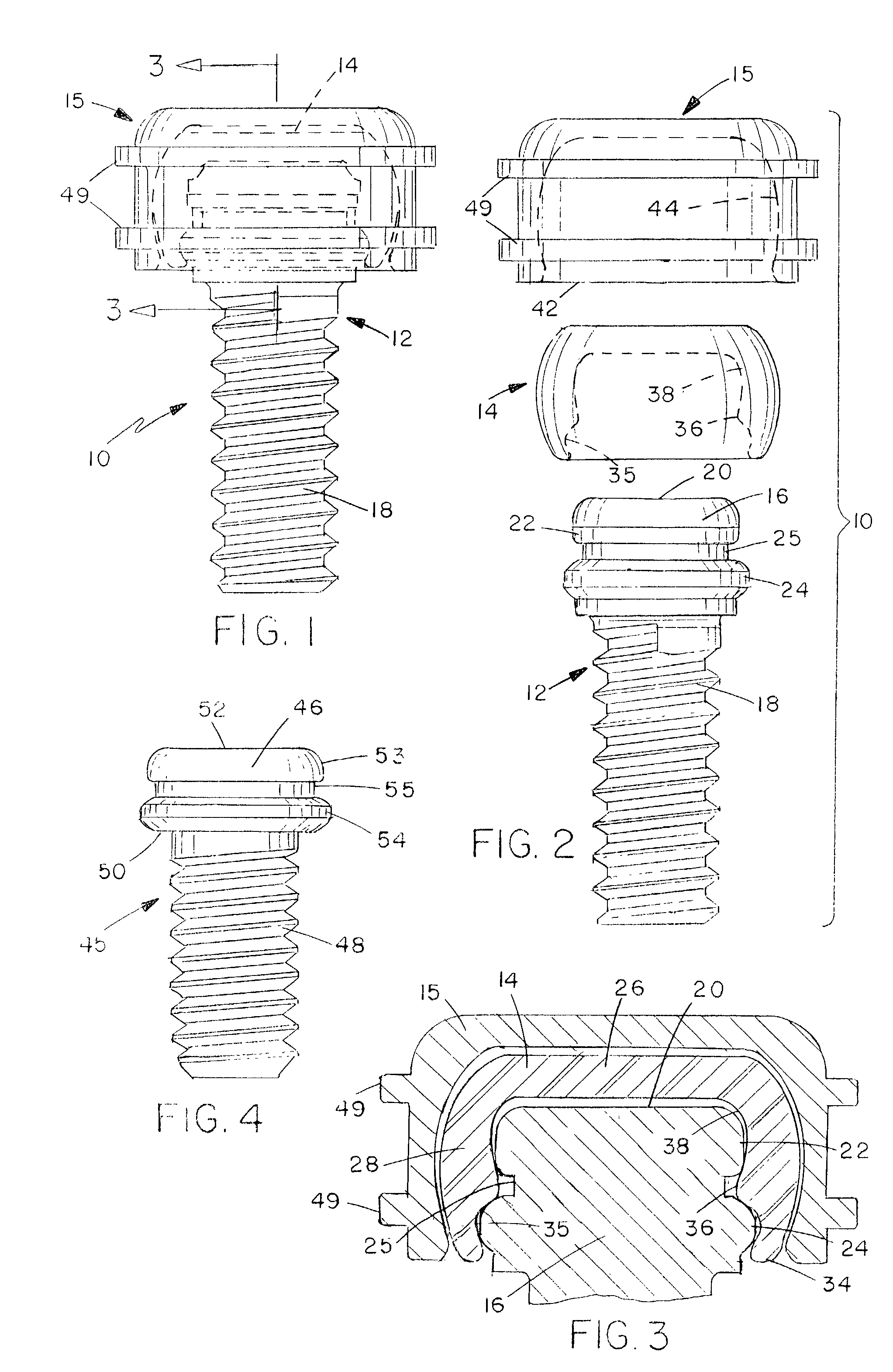

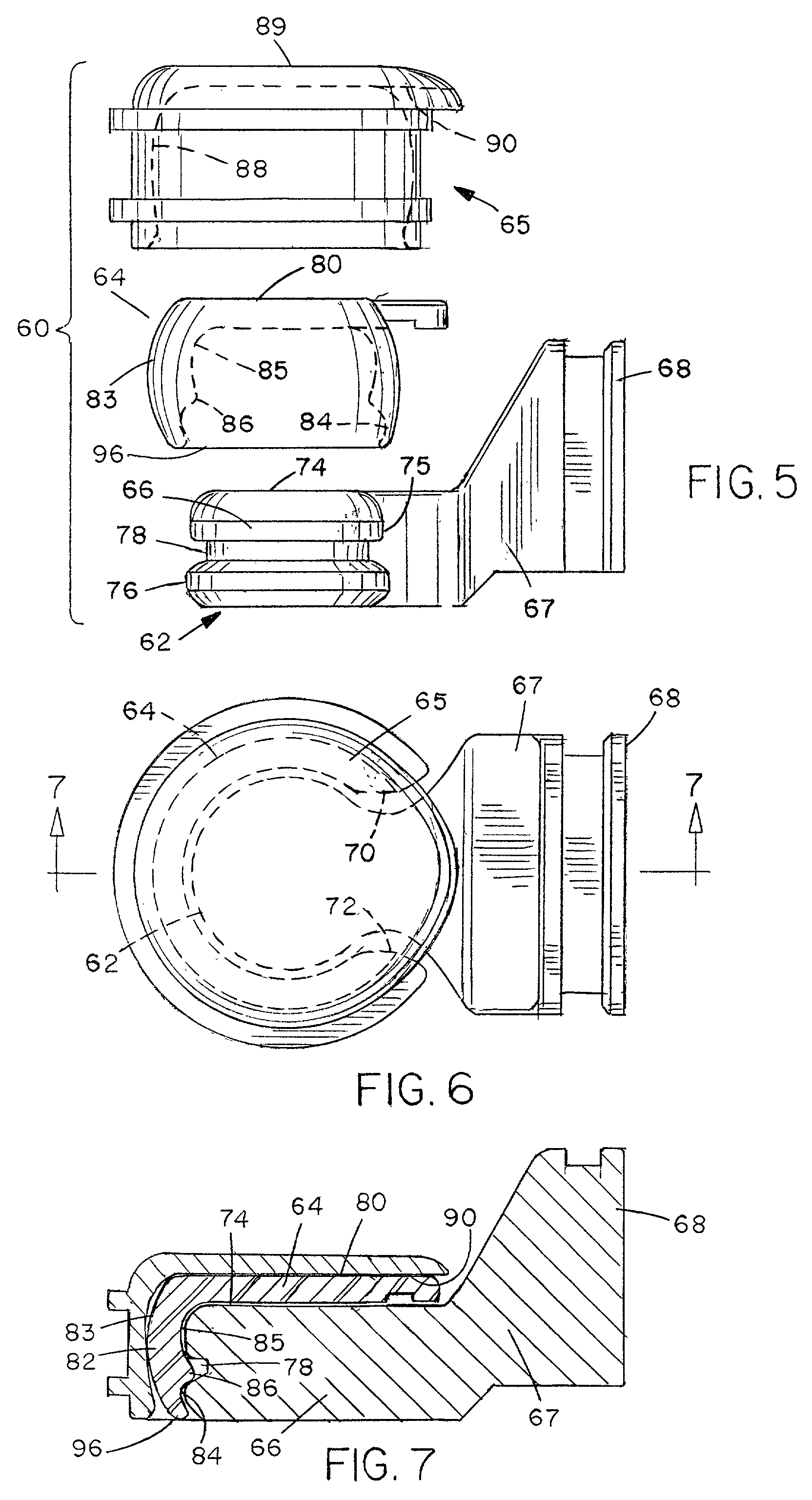

Dental attachment assembly and method

Owner:ZEST IP HLDG

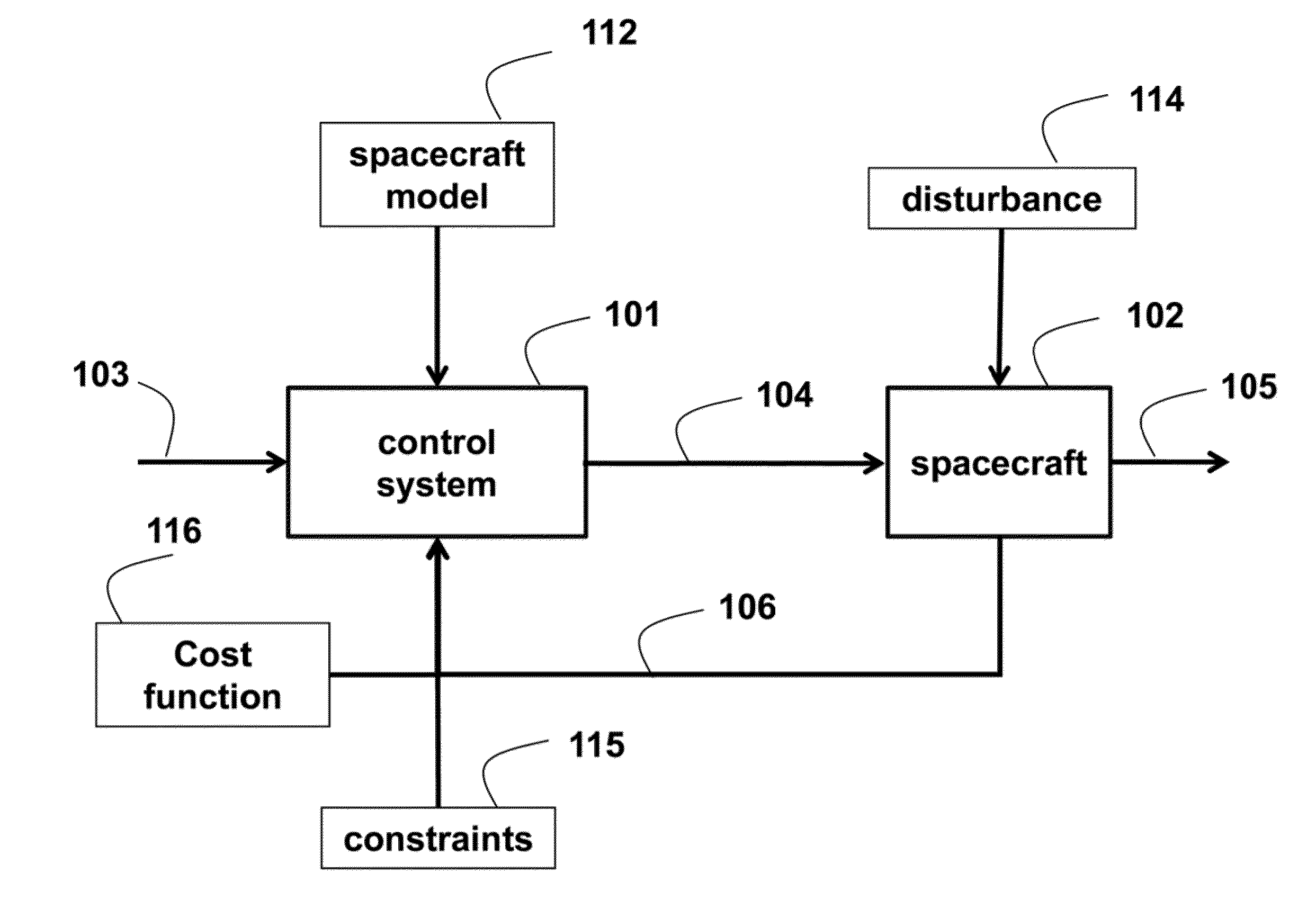

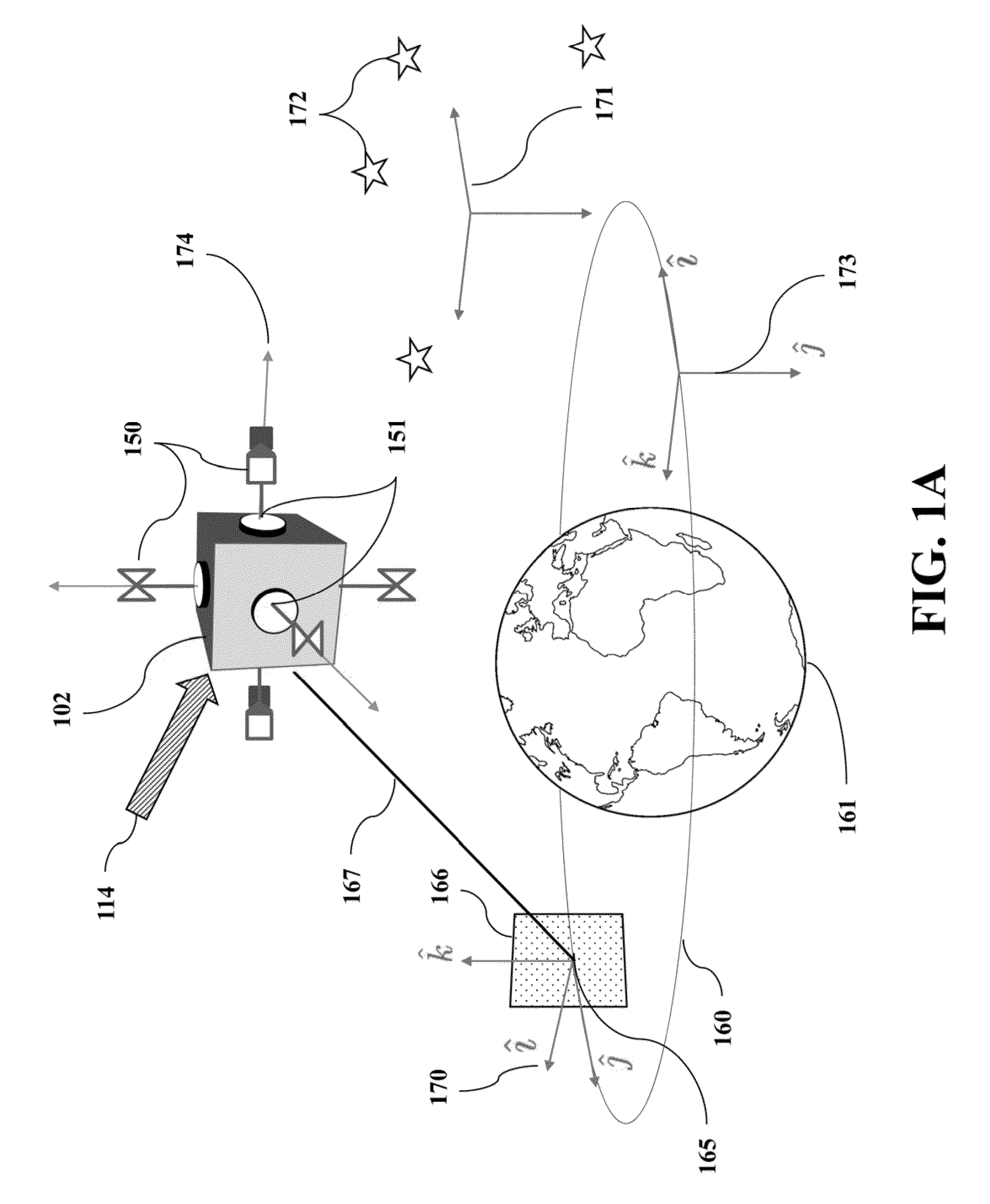

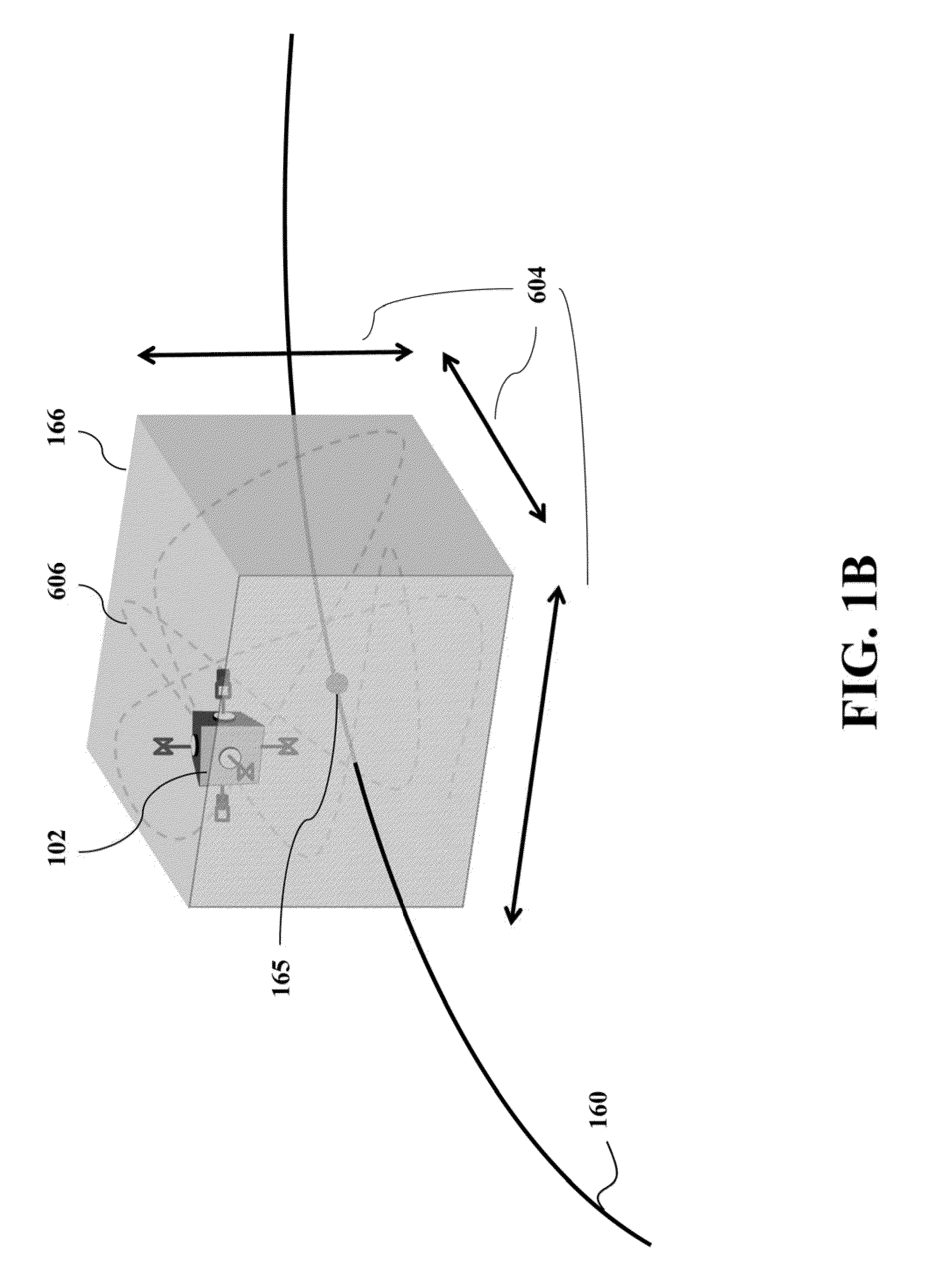

Model Predictive Control of Spacecraft

ActiveUS20160194095A1Tighter and accurate station keepingTighter and accurate and momentum unloadingCosmonautic vehiclesDigital data processing detailsHorizonMomentum

A method controls an operation of a spacecraft according to a model of the spacecraft. The method determines control inputs for controlling concurrently thrusters of the spacecraft and momentum exchange devices of the spacecraft using an optimization of a cost function over a receding horizon subject to constraints on a pose of the spacecraft and constraints on inputs to the thrusters. The cost function includes components for controlling the pose of the spacecraft and a momentum stored by the momentum exchange devices. The method generates a command to control concurrently the thrusters and the momentum exchange devices according to at least a portion of the control inputs.

Owner:MITSUBISHI ELECTRIC RES LAB INC

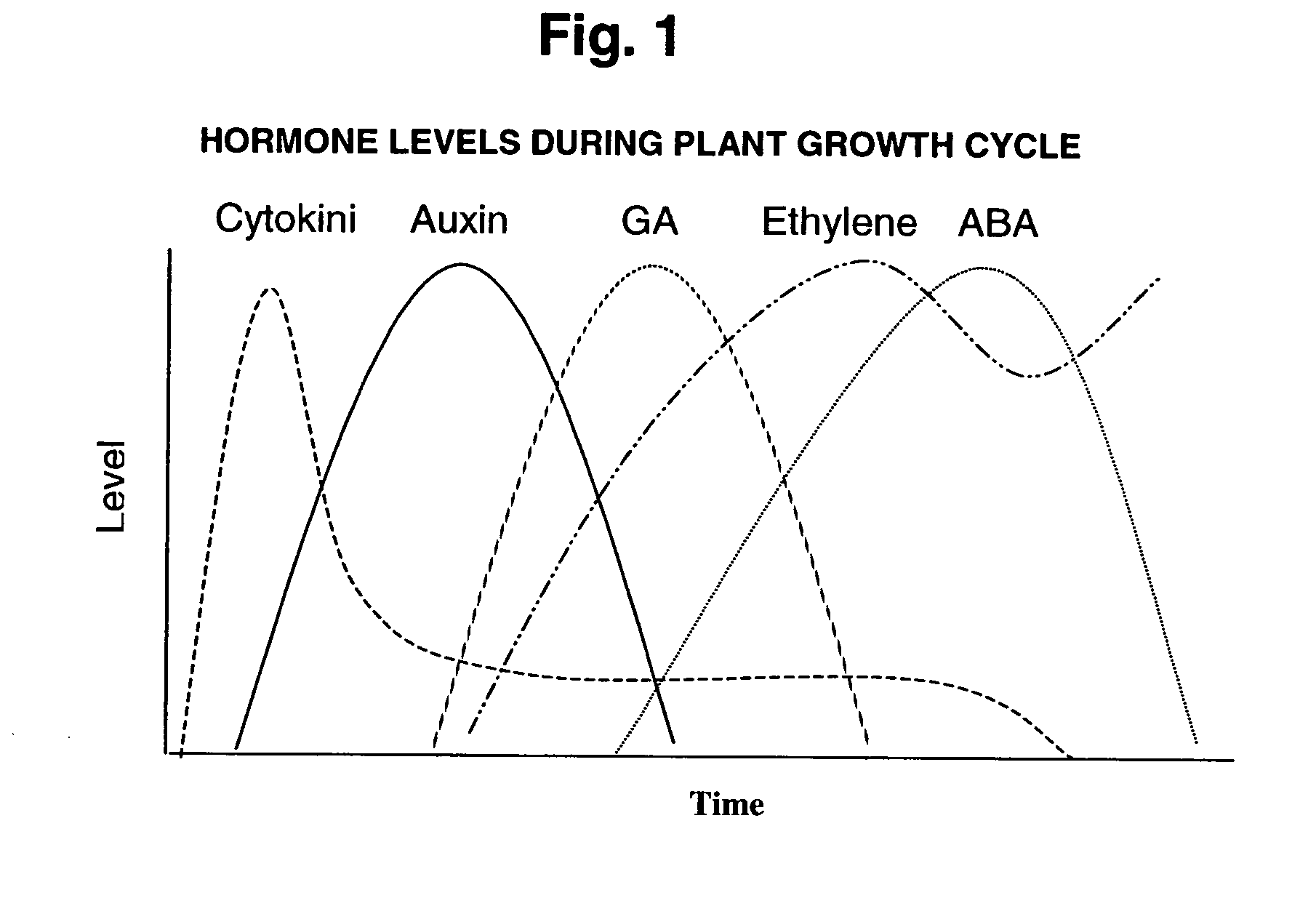

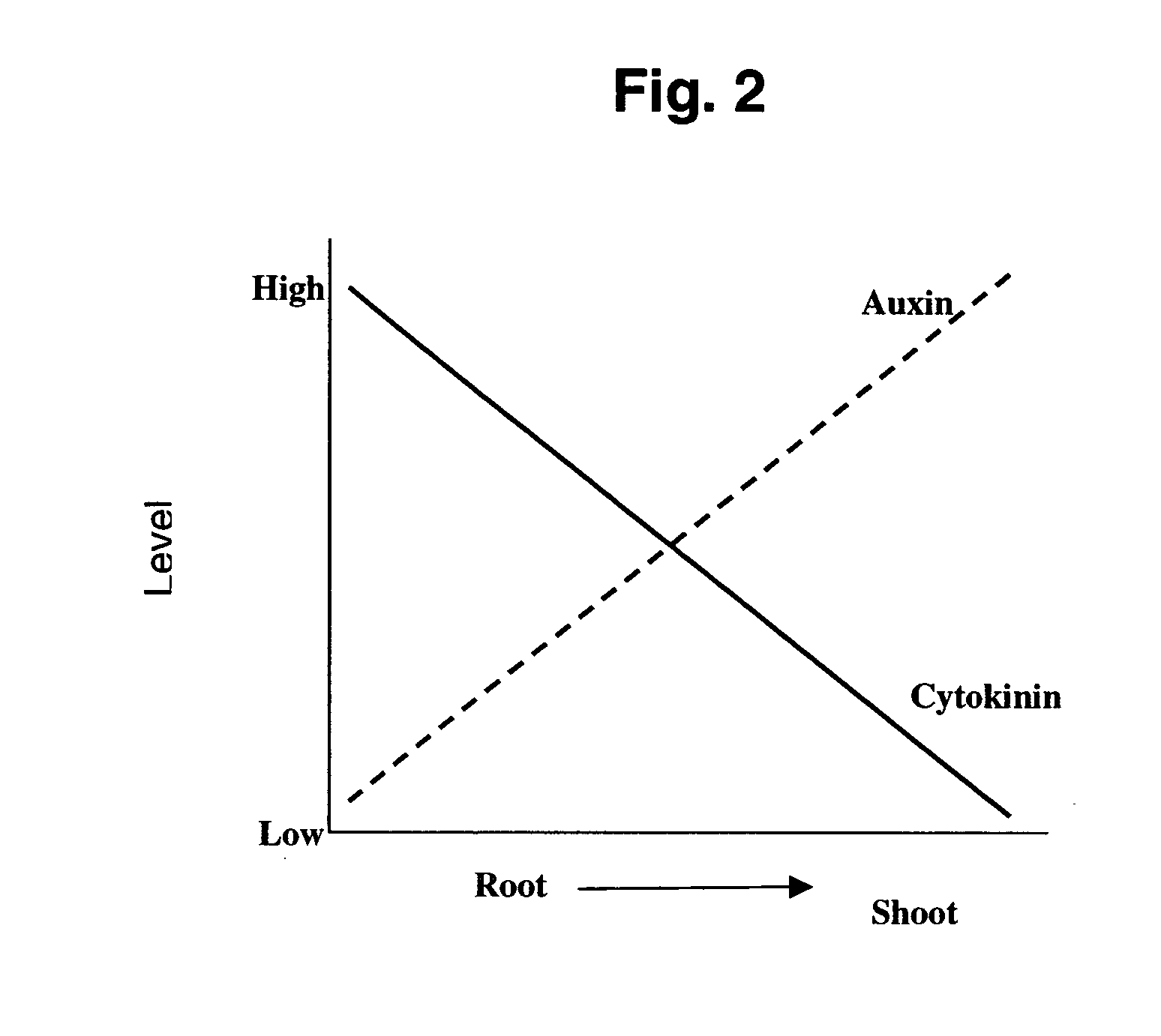

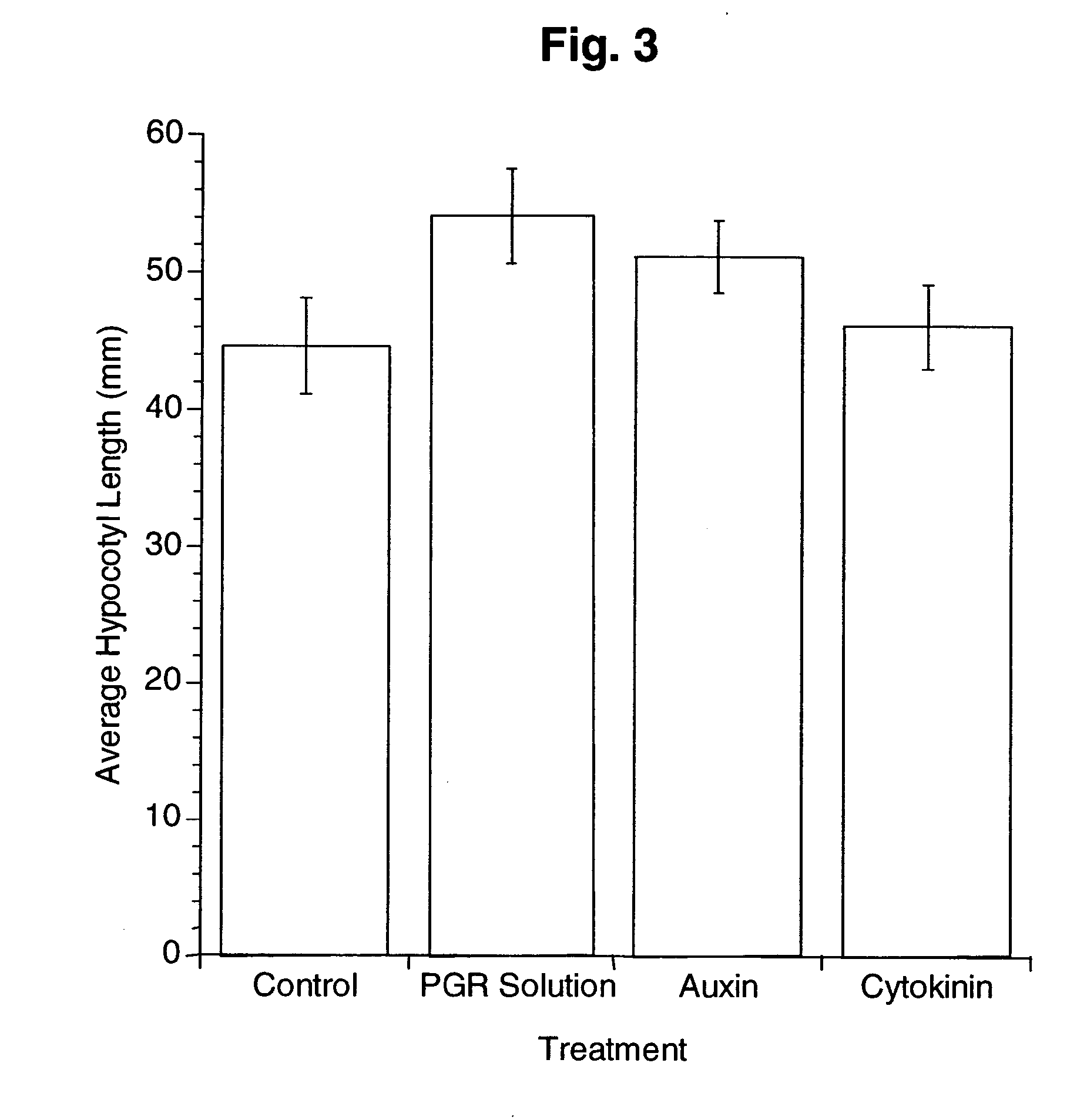

Methods for improving growth and crop productivity of plants by adjusting plant hormone levels, ratios and/or co-factors

ActiveUS20050197253A1Improve architectureIncrease crop yieldBiocideAnimal repellantsCytokininDisease

In agriculture when temperature and moisture deviate from the norm two things happen, plant growth suffers and disease flourishes. The Stoller model for plant growth states that proper hormone balance is necessary for optimum growth and performance. When growth conditions deviate from the norm, hormone balance is altered and plant growth suffers. This invention presents evidence to support this model and explain the relationship between hormone levels and plant growth. A clear understanding of this relationship will facilitate crop treatments aimed to eliminate these problems. Although we cannot control the climate, we can control the damage caused by environmental stresses by manipulating the levels and / or ratio of plant hormones in the different plant tissues. By adjusting the levels and / or ratios of hormones, particularly auxin and cytokinins in the root tissue, we can assist the plant in overcoming or compensating for this environmental stress.

Owner:STOLLER ENTERPRISES INC

Thermally stable ultra-hard material compact constructions

InactiveUS8066087B2Extend effective lifePigmenting treatmentDrill bitsPolycrystalline diamondHigh pressure

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

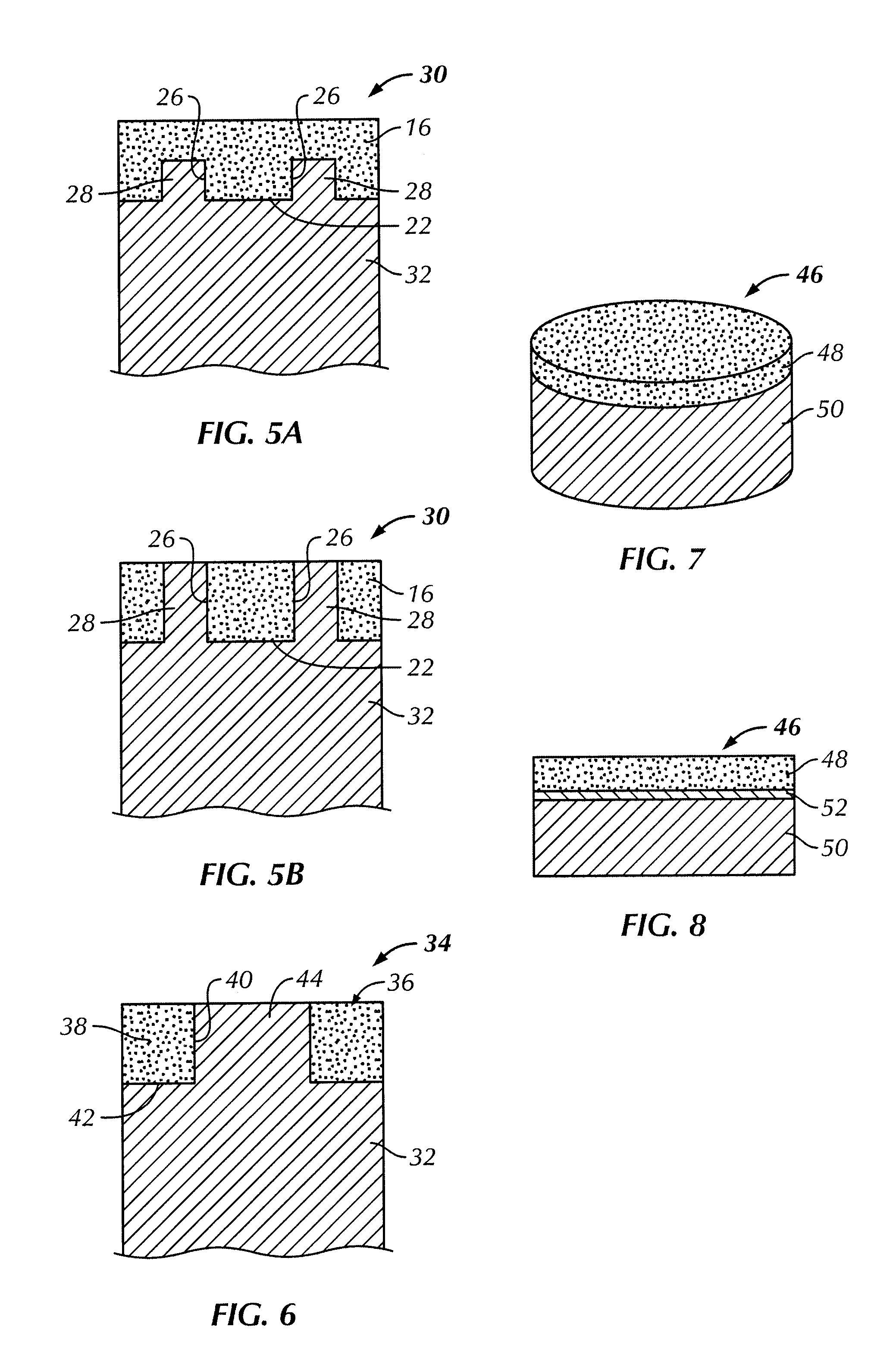

Enzymatic antioxidant of allene oxide for lipid peroxidation in biological systems

InactiveUS6132711ABeneficial antioxidativeExtend effective lifeSugar derivativesPeptide/protein ingredientsLipid formationFatty acid

The present invention relates to the isolation and use of an allene oxide synthase enzyme as an antioxidant of lipid peroxides in biological systems. It is based, at least in part, on the discovery that antioxidation is accomplished enzymatically by RPP, a species of allene oxide synthase, in guayule, and on the discovery that the allene oxide synthase RPP disrupts the chain reaction and propagation steps of lipid peroxidation. The present further invention relates to the use of an allene oxide synthase to result in a time-dependent disappearance of conjugated dienes (i.e. lipid hydroperoxides). The allene oxide synthase rapidly converts free or esterified fatty acid peroxides or hydroperoxides into their corresponding epoxides, which, in turn are converted to ketols. The lipid peroxide and hydroperoxide substrates for this enzyme are known to be toxic to biological organisms and can generate additional peroxides by chain propagation reactions. In the presence of an allene oxide synthase these compounds are rapidly and effectively converted to allene oxides (the epoxide), thus breaking the chain reaction.

Owner:ARIZONA STATE UNIVERSITY

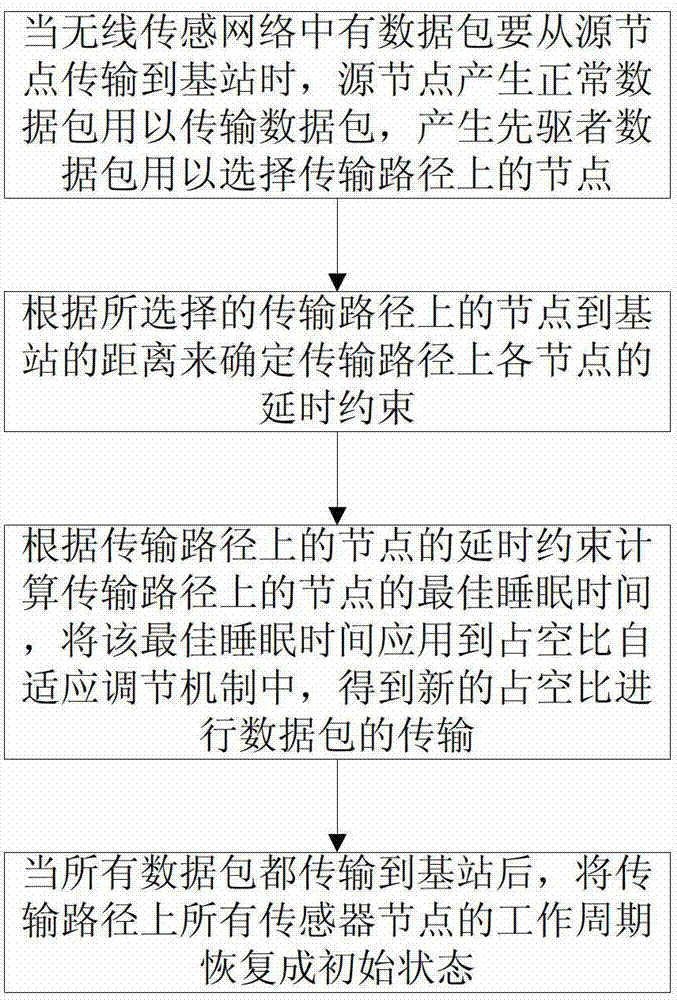

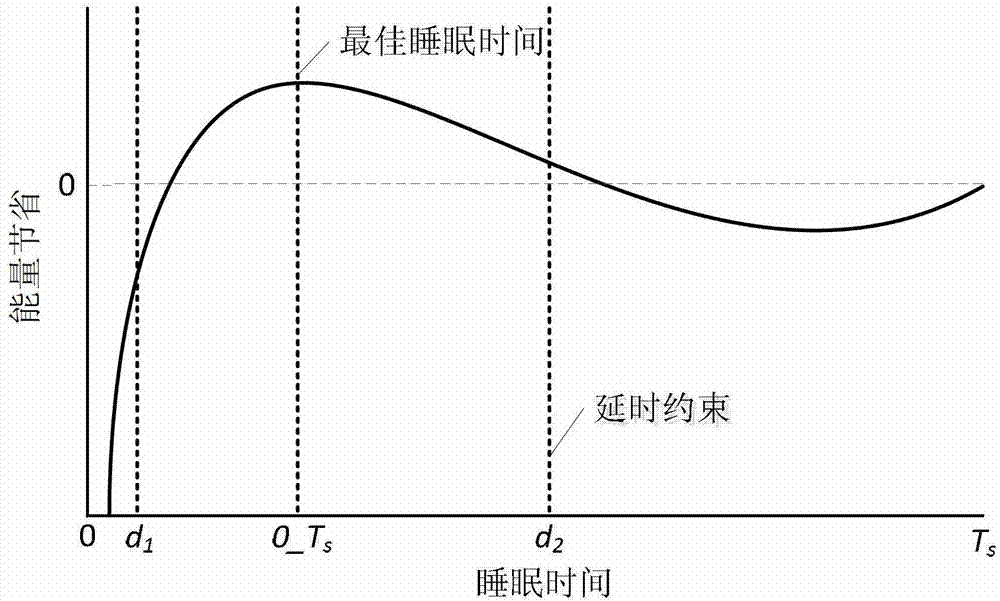

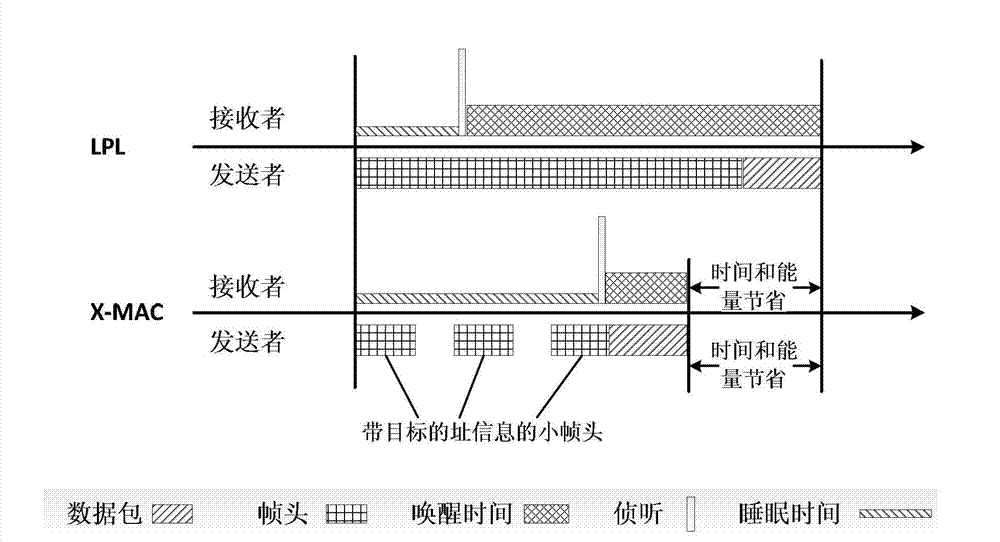

Energy consumption control method under delay constraint in wireless sensor network

InactiveCN103052131AReduce energy consumptionExtend effective lifePower managementHigh level techniquesWireless mesh networkWork cycle

The invention relates to the field of wireless self-organizing networks and sensor networks, in particular to an energy consumption control method under delay constraint in a wireless sensor network. The energy consumption control method comprises the following steps of: generating a normal data packet and a pioneer data packet by a source node when data packets in the wireless sensor network need to be transmitted to a base station from the source node, wherein the normal data packet is used for transmitting the data packets, and the pioneer data packet is used for selecting nodes on a transmission path; determining the delay constraint of the nodes on the transmission path; computing the best sleep time of the nodes on the transmission path; applying the best sleep time to a duty ratio self-adaptive adjustment mechanism to obtain new duty ratio to transmit the data packets; and respectively recovering work cycles of all the nodes on the transmission path into an original state after all the data packets are transmitted to the base station. According to the energy consumption control method under the delay constraint in the wireless sensor network, on the premise that the constraint condition of the wireless sensor network on transmission delay is met, the energy consumption of the wireless sensor network is reduced to the maximum limit, and the service life of the wireless sensor network is prolonged.

Owner:RUN TECH CO LTD

Latent coating for metal surface repair

A corrosion protective coating composition, applied over a metal surface, contains frangible microcapsules which rupture and release fluid upon impact or other stress likely to damage the coating. The fluid, from the microcapsules, contains a film forming component to cover the damaged area of the coating and a corrosion inhibitor for the metal surface.

Owner:3M CO

Acid lining material of medium-frequency induction furnace and furnace building method thereof

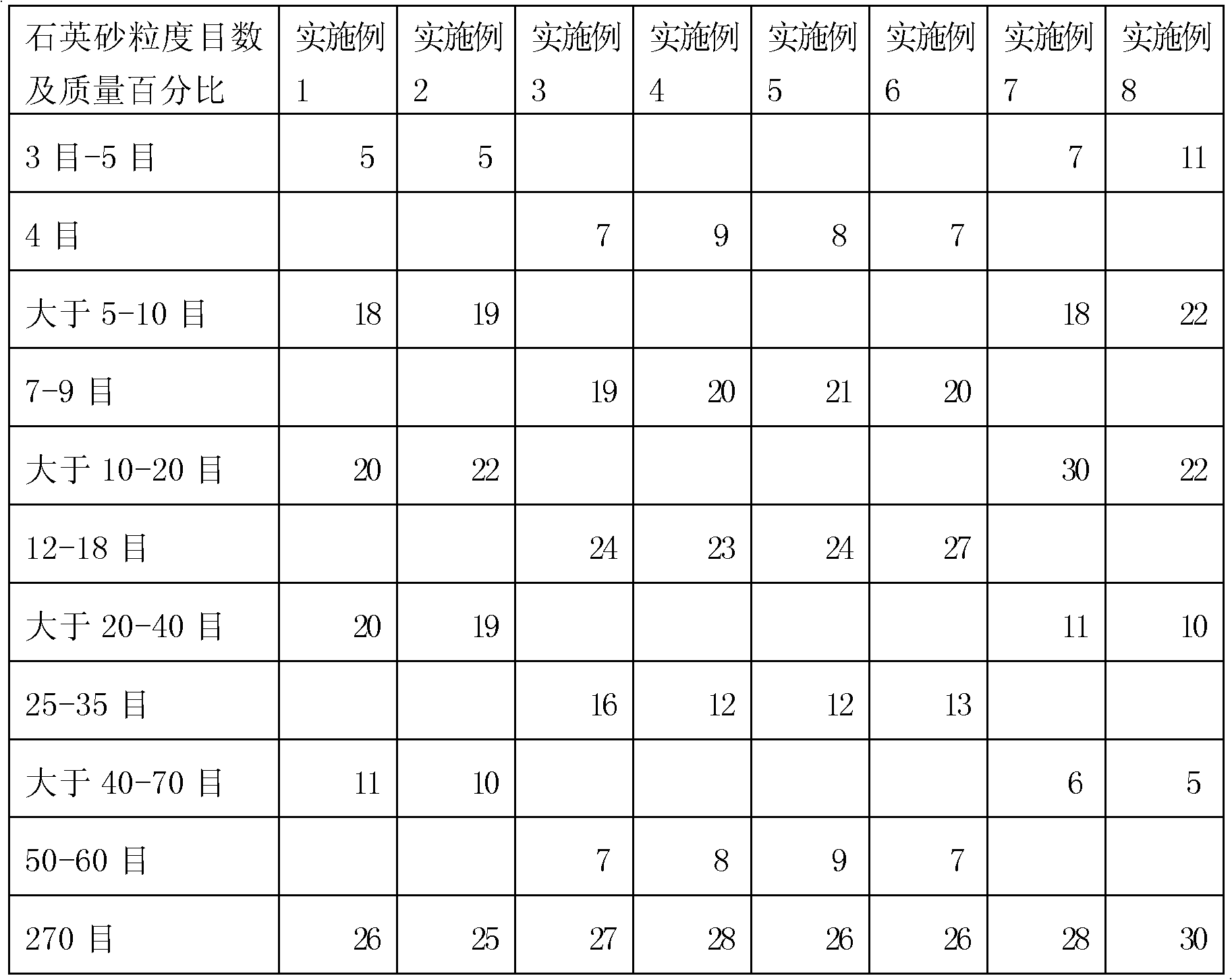

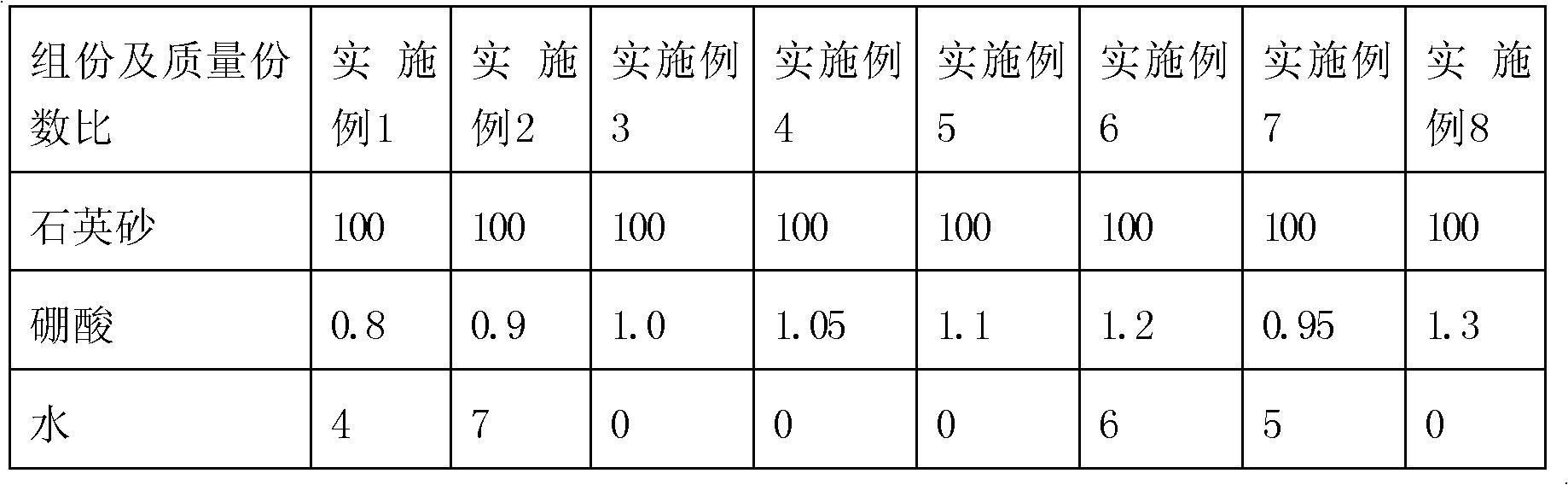

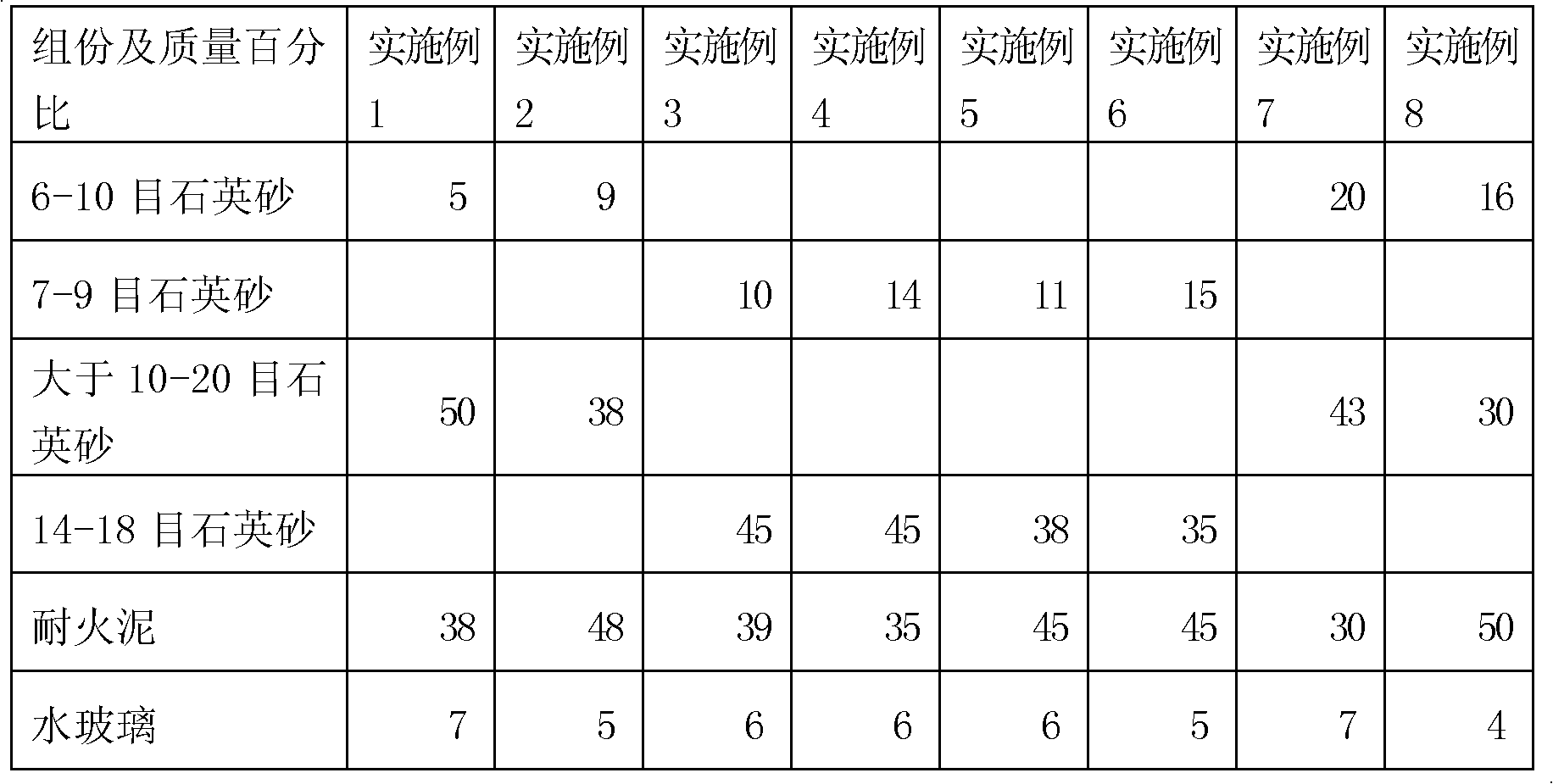

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

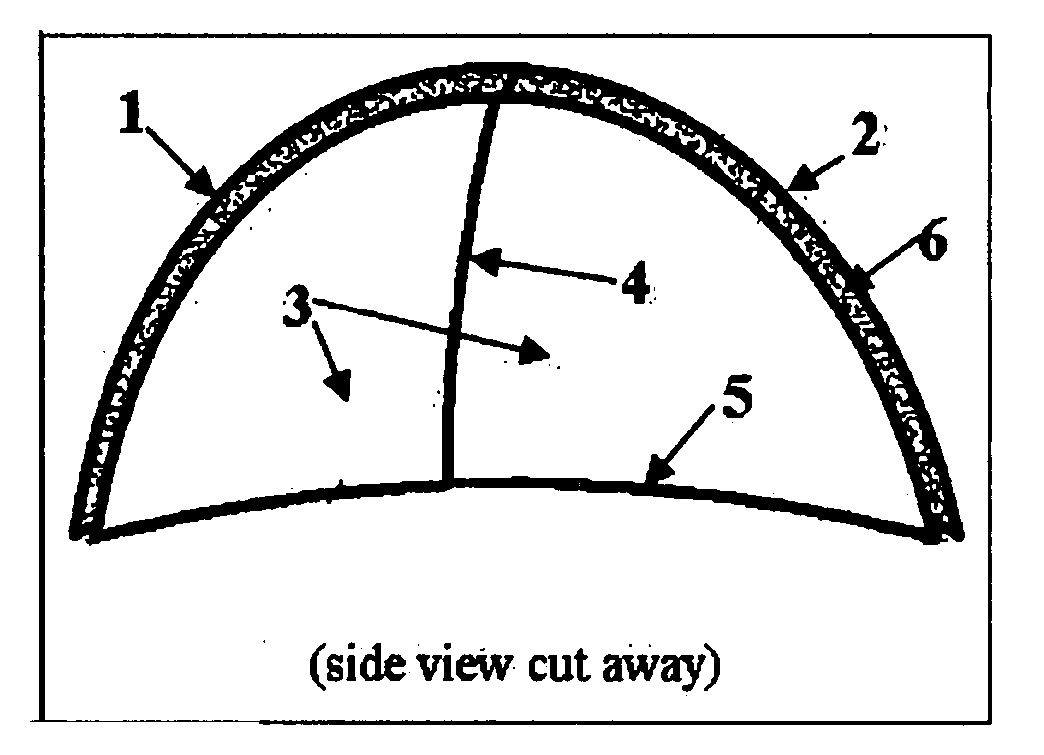

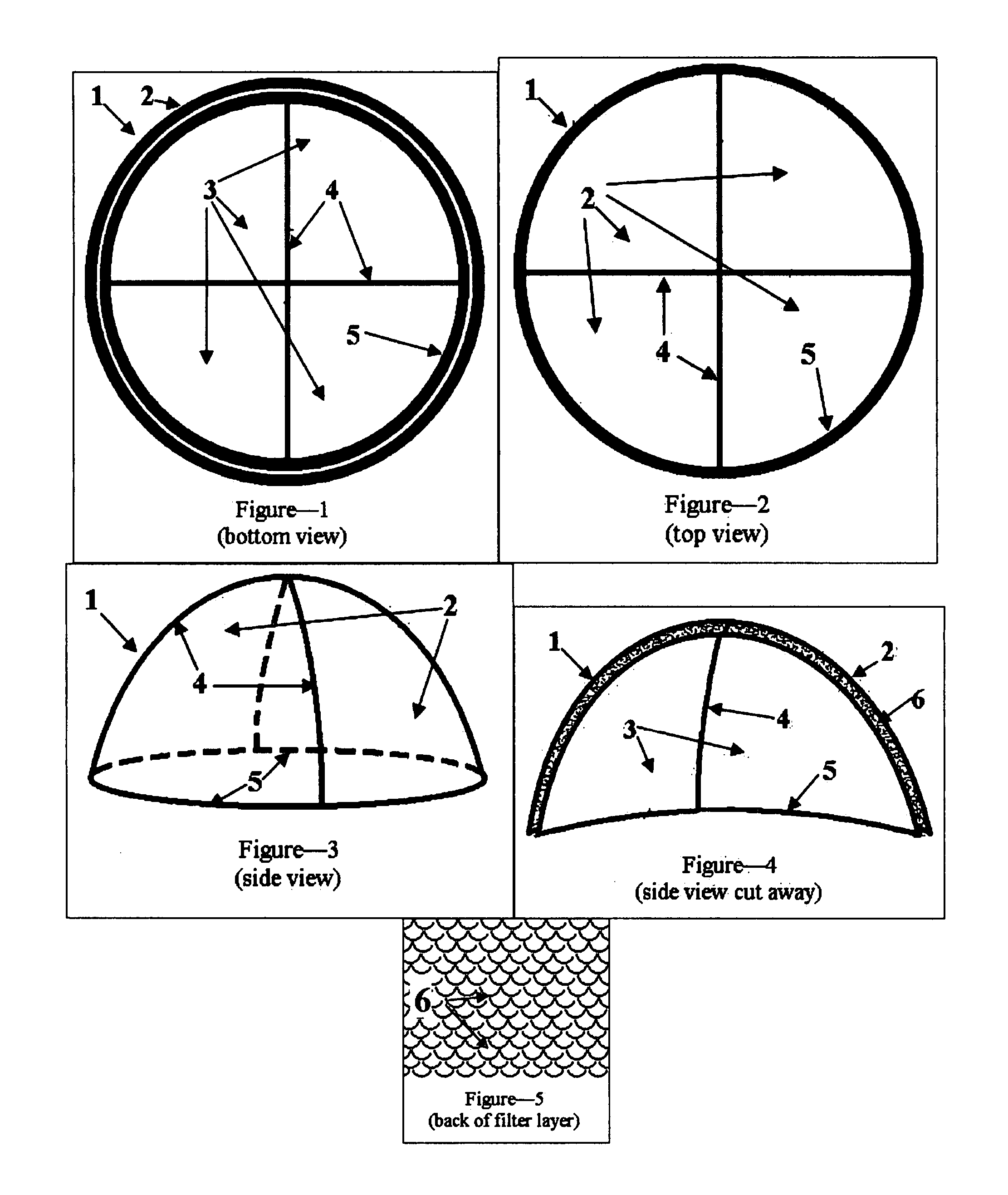

Removable, reusable, washable liner for use with various types of head gear

A lining for use under head gear—such as baseball hats, top hats, helmets, cowboy hats, hard hats, beanies, stocking caps, etc.—comprised of two layers, one specifically for comfort, in both softness and breathability, and a second specifically for the filtering of salt, dirt, oils, particulate matter and other undesirable constituents contained in the sweat of the wearer. The two layers are each comprised of four roughly equal pieces of an isosceles triangular shape that are stitched together to form a half-dome. The two layers are then stitched together along the bottom circumference of said dome two form a single half-dome comprised of two individual layers. The two layers employ their relative absorbency to transport moisture from the head of the wearer and into the lining. The outer layer employs its maximal surface area to filter and store the sweat of the wearer, while maintaining breathability. Together the two layers form a lining that both protects the head gear from stains, discoloration, premature wear and odors, maximizing the effective lifespan of the head gear, while also maximizing for the wearer comfort both in terms of fit and breathability, maximizing the effective value of the head gear for the wearer.

Owner:CAMPBELL DOUGLAS A +1

Environmentally safe insect repellent composition

InactiveUS7201926B2Effectively repelsHigh strengthOrganic active ingredientsBiocideAdditive ingredientPeppermints

An insect repellent composition containing citronella oil, D-limonene, 2 or more synergists, and 3 or more essential oils as the active ingredients. The preferred essential oils are geranium oil, rosemary oil and peppermint oil, but other essential oils may be used. In the preferred embodiment the synergists are aldehyde C-14 and aldehyde C-18. As desired, vanillin may be used as a stabilizer, and fragrances, fragrance enhancers and surfactants may be utilized.

Owner:BUGAWAY BRANDS +1

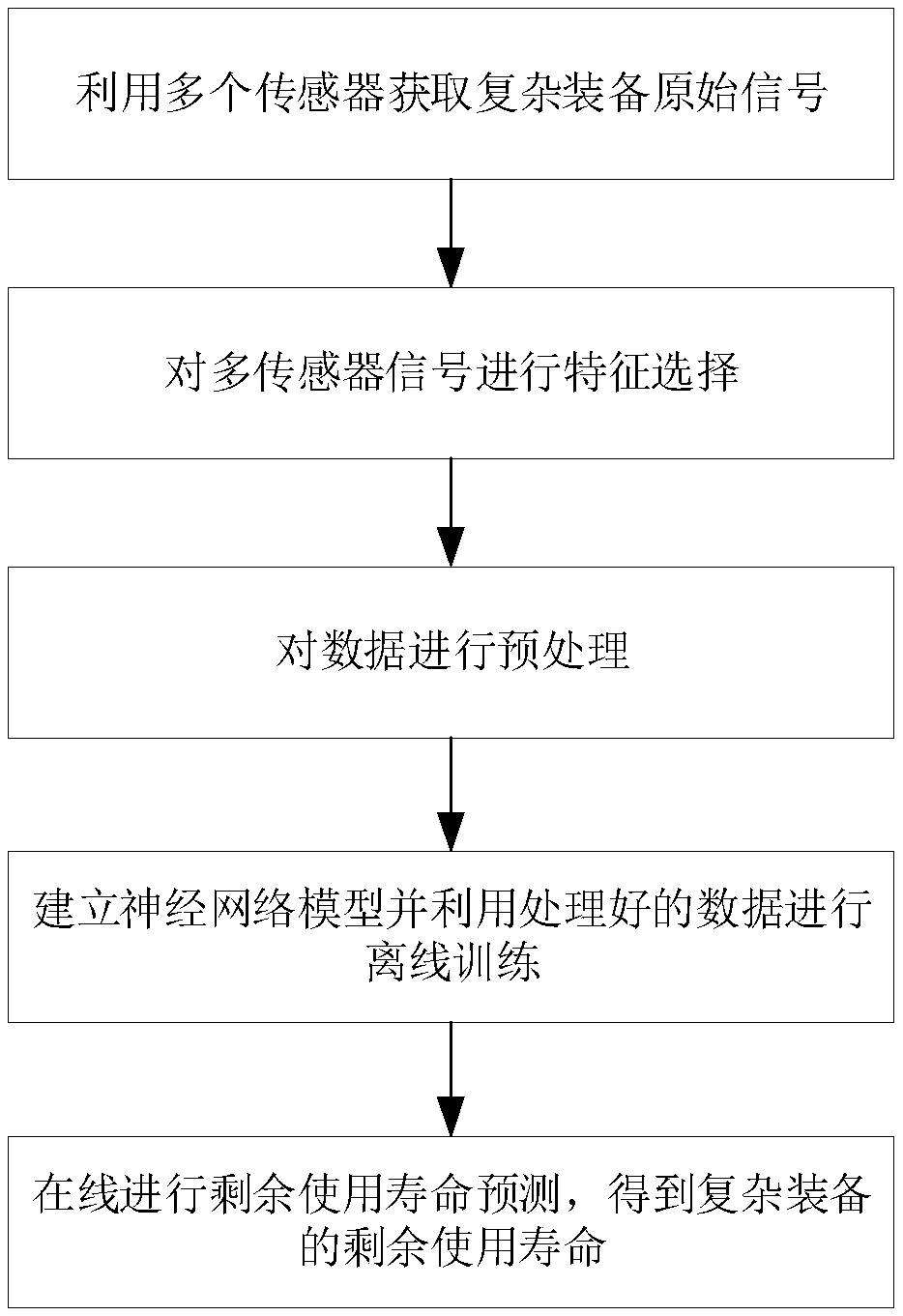

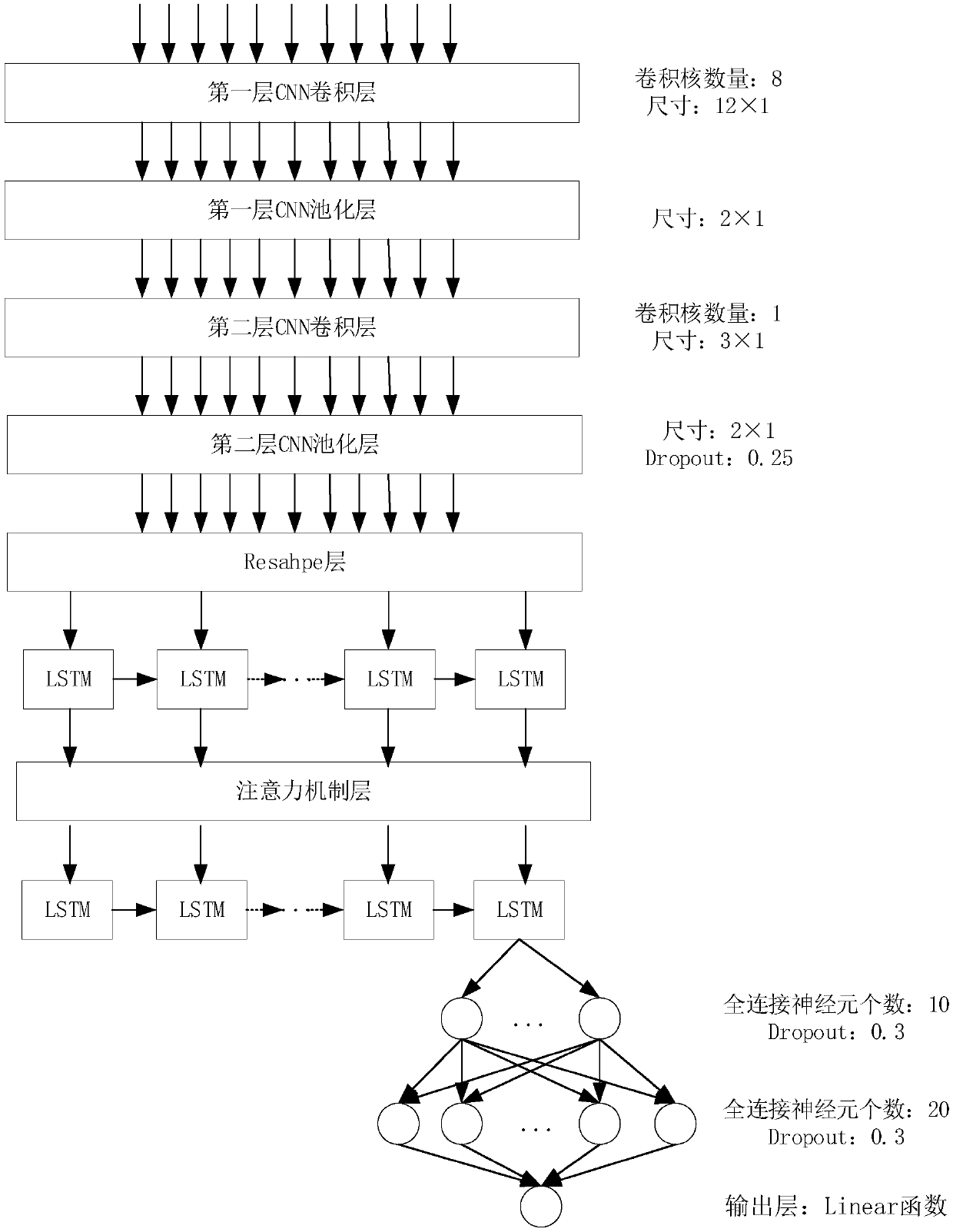

Residual service life prediction method of complex equipment based on combined depth neural network

ActiveCN109522600AStrong feature extraction abilitySimple structureGeometric CADCharacter and pattern recognitionFeature selectionSlice sampling

The invention discloses a method for predicting the remaining service life of complex equipment based on a combined depth neural network. The main steps are as follows: acquiring multi-sensor data ofcomplex equipment; Obtaining effective measurement data by feature selection; obtaining A plurality of slice samples by preprocessing; Establishing the neural network regression model which combines the attention mechanism and depth neural network; The slice samples and their corresponding labels are inputted into the neural network regression model to train the neural network regression model offline. inputting The slice samples of multi-sensor data to be predicted into the trained neural network regression model, and the remaining service life of complex equipment is obtained. Considering the data characteristics of the multi-sensor signal, the invention fully excavates the local characteristics and the time sequence information in the data, has high prediction accuracy and wide applicability, and can be widely applied to various pieces of complex equipment.

Owner:ZHEJIANG UNIV

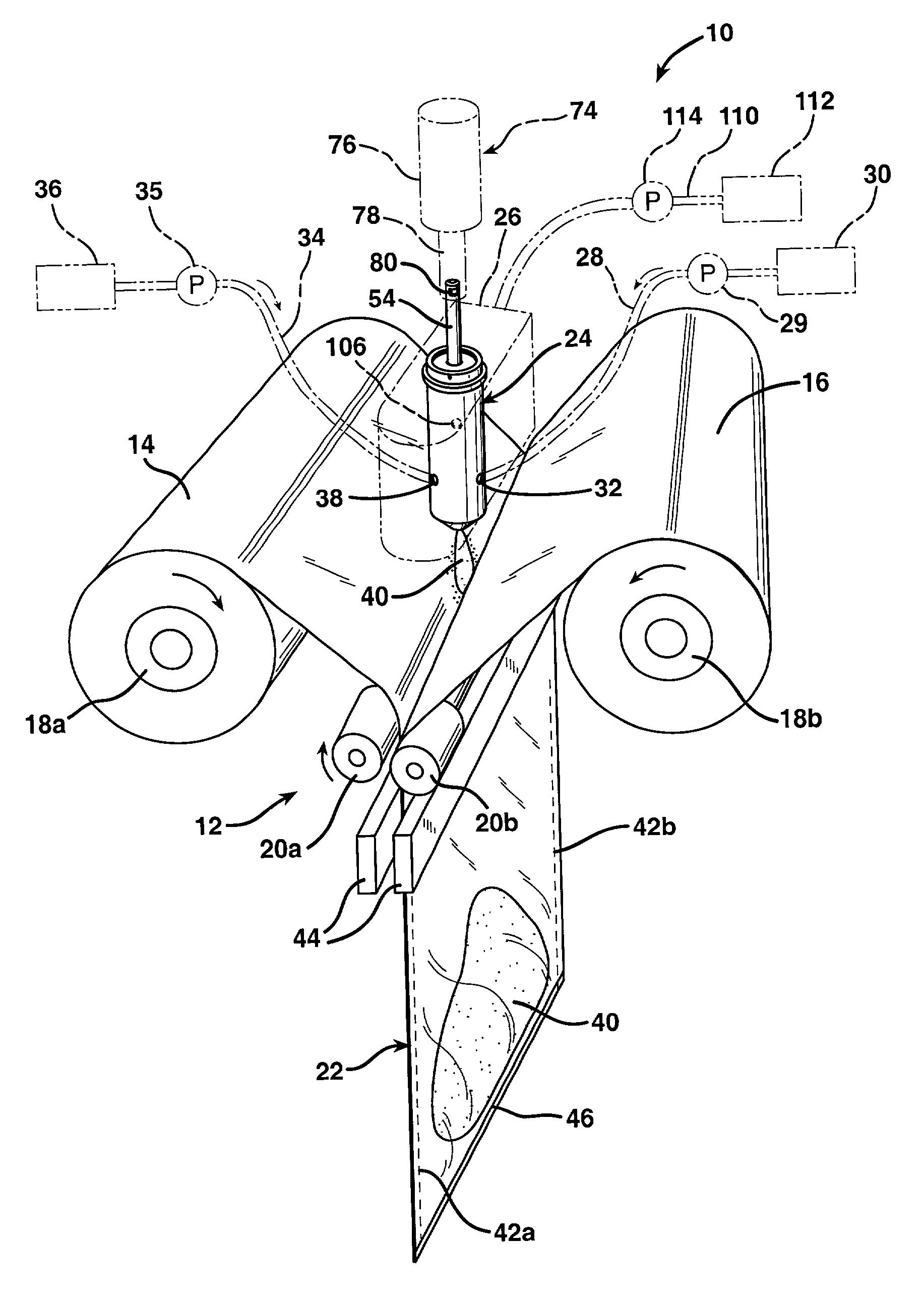

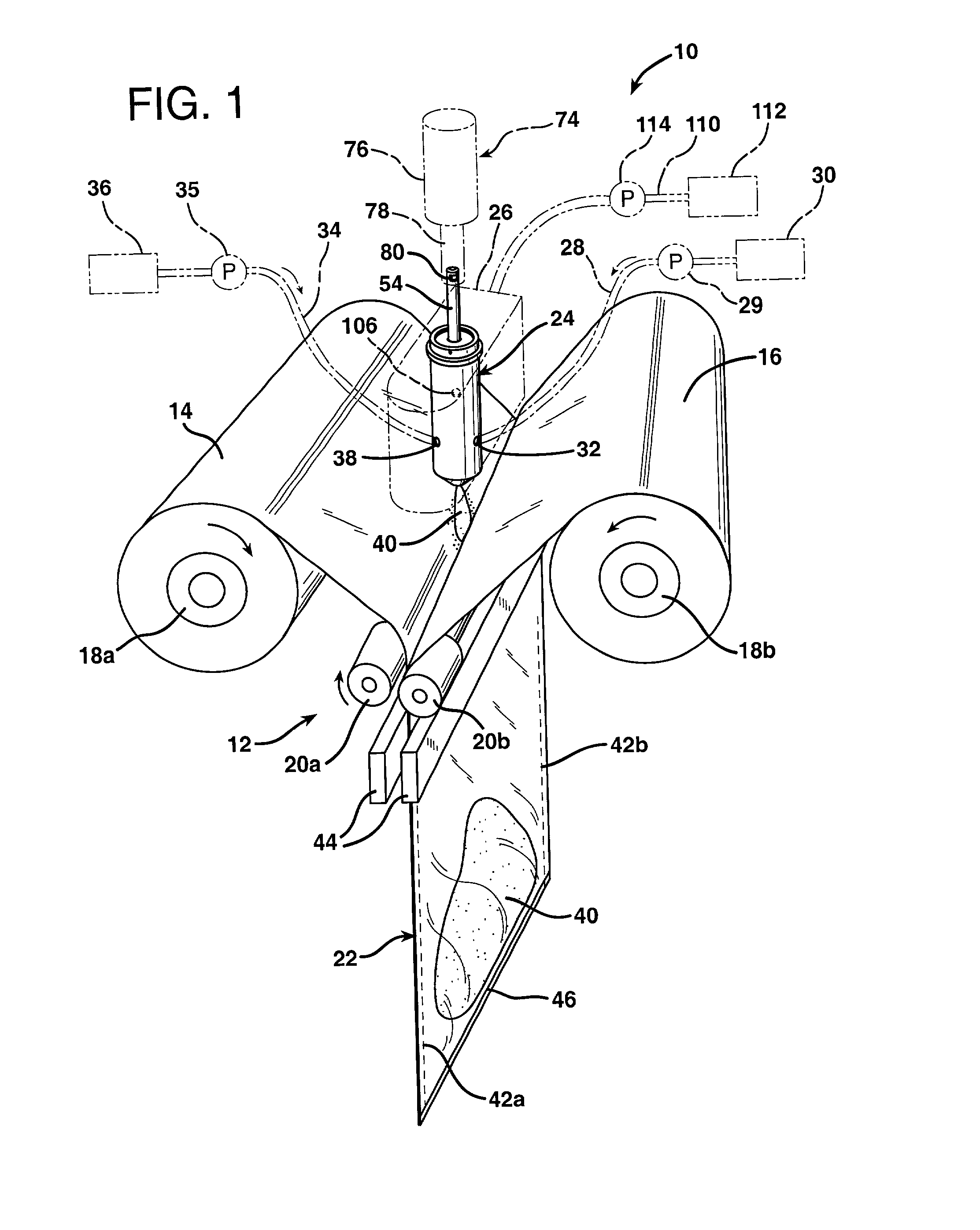

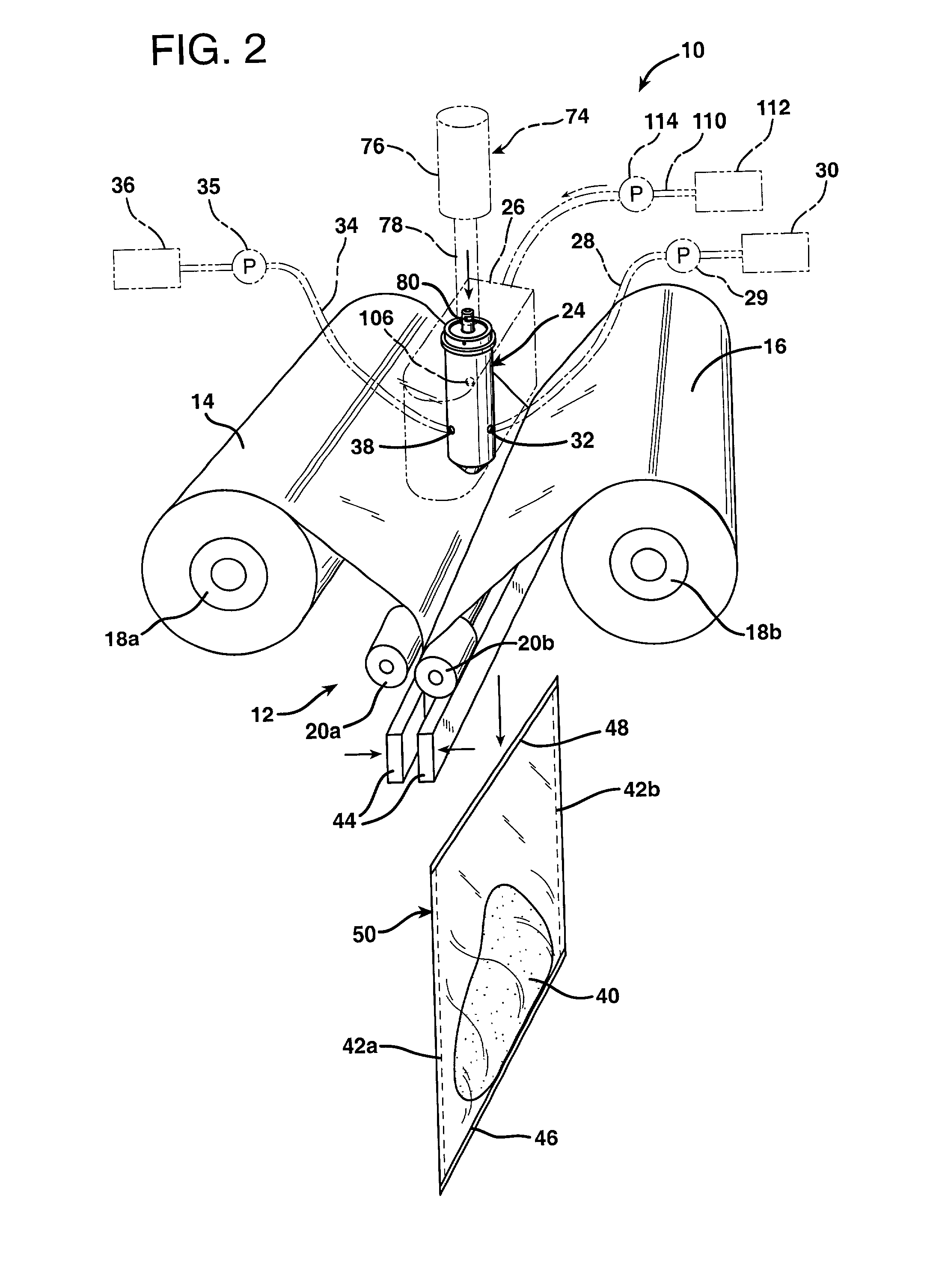

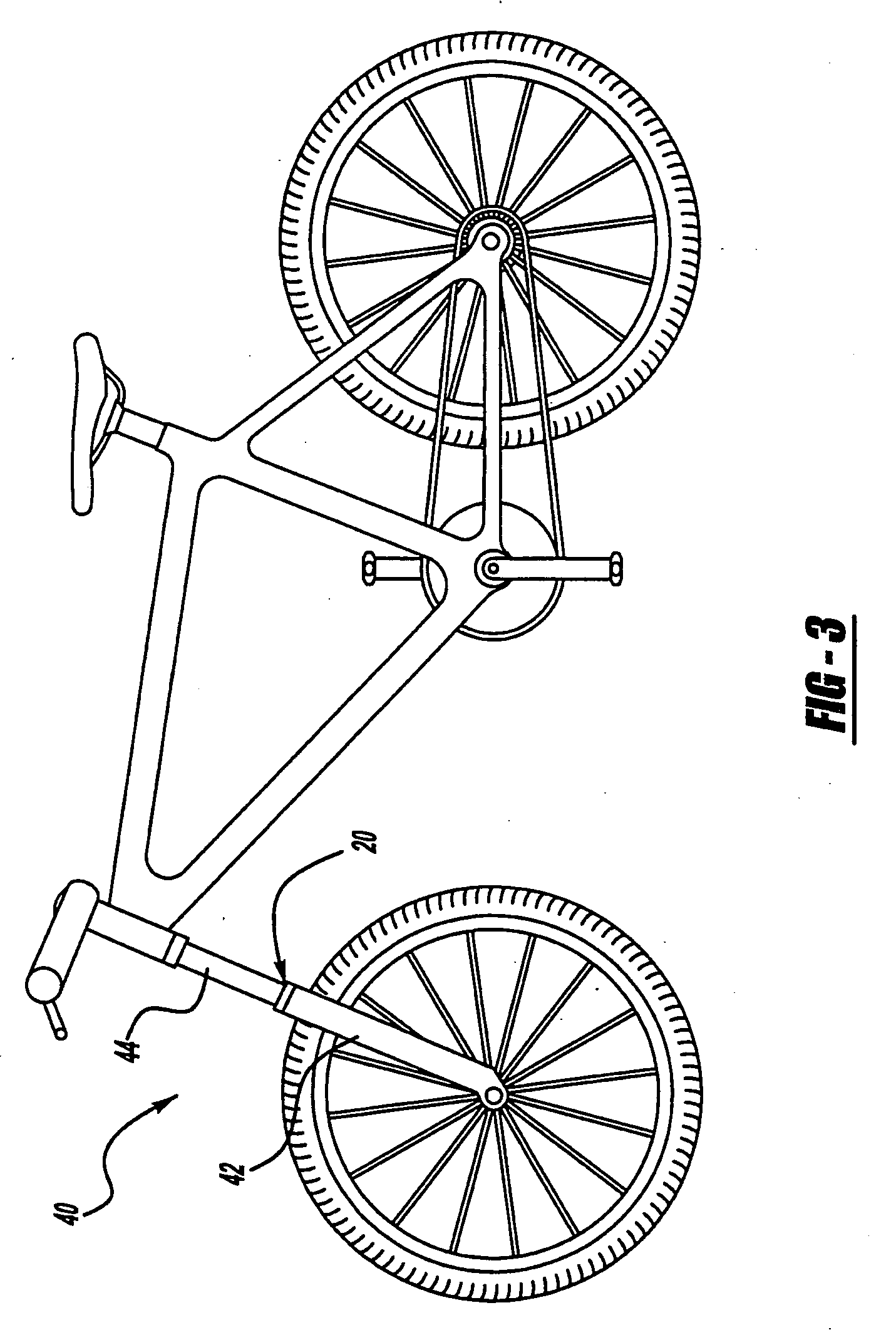

Fluid dispenser having improved cleaning solvent delivery system

InactiveUS6996956B2Easy to disassembleEffective service lifeLiquid fillingPaper/cardboard articlesSolventMechanical engineering

A fluid dispenser generally includes a housing and a valving rod disposed in and movable within the housing, the valving rod including a central bore, at least one inlet for receiving a cleaning solvent, and one or more outlet ports in fluid communication with the bore, wherein the outlet ports are capable of directing cleaning solvent radially outwards from the bore and against an interior surface of the dispenser to facilitate the removal of at least a portion of any fluid product or derivatives thereof that may be in adherence with such interior surface.

Owner:SEALED AIR U S

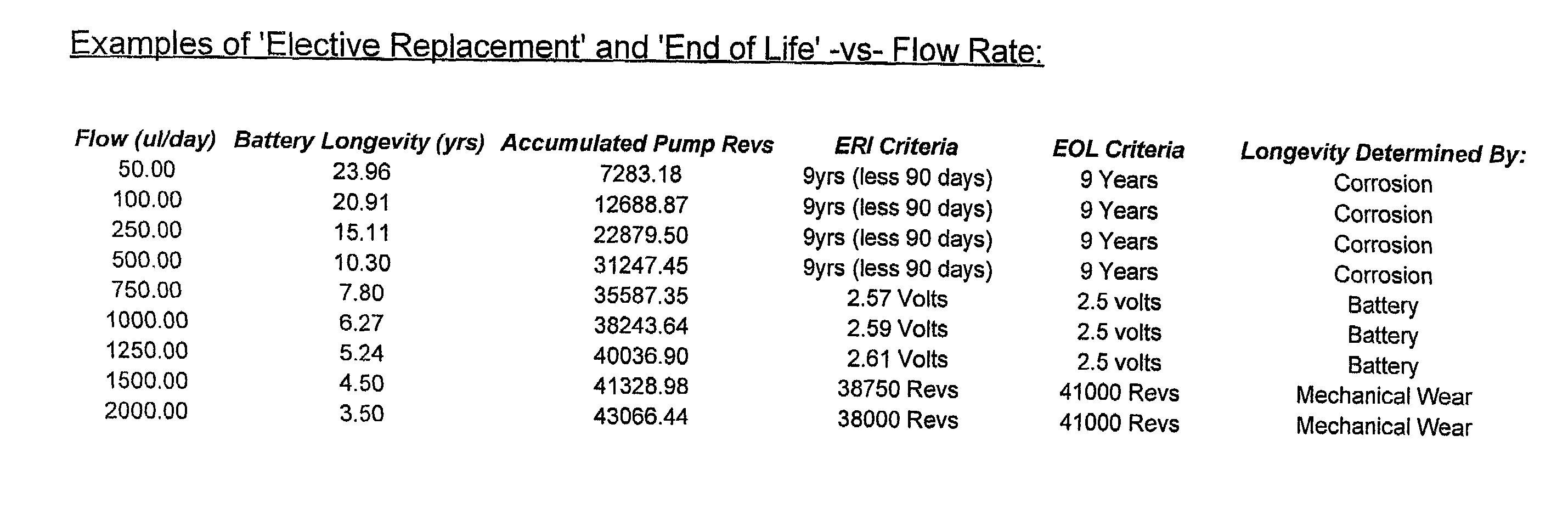

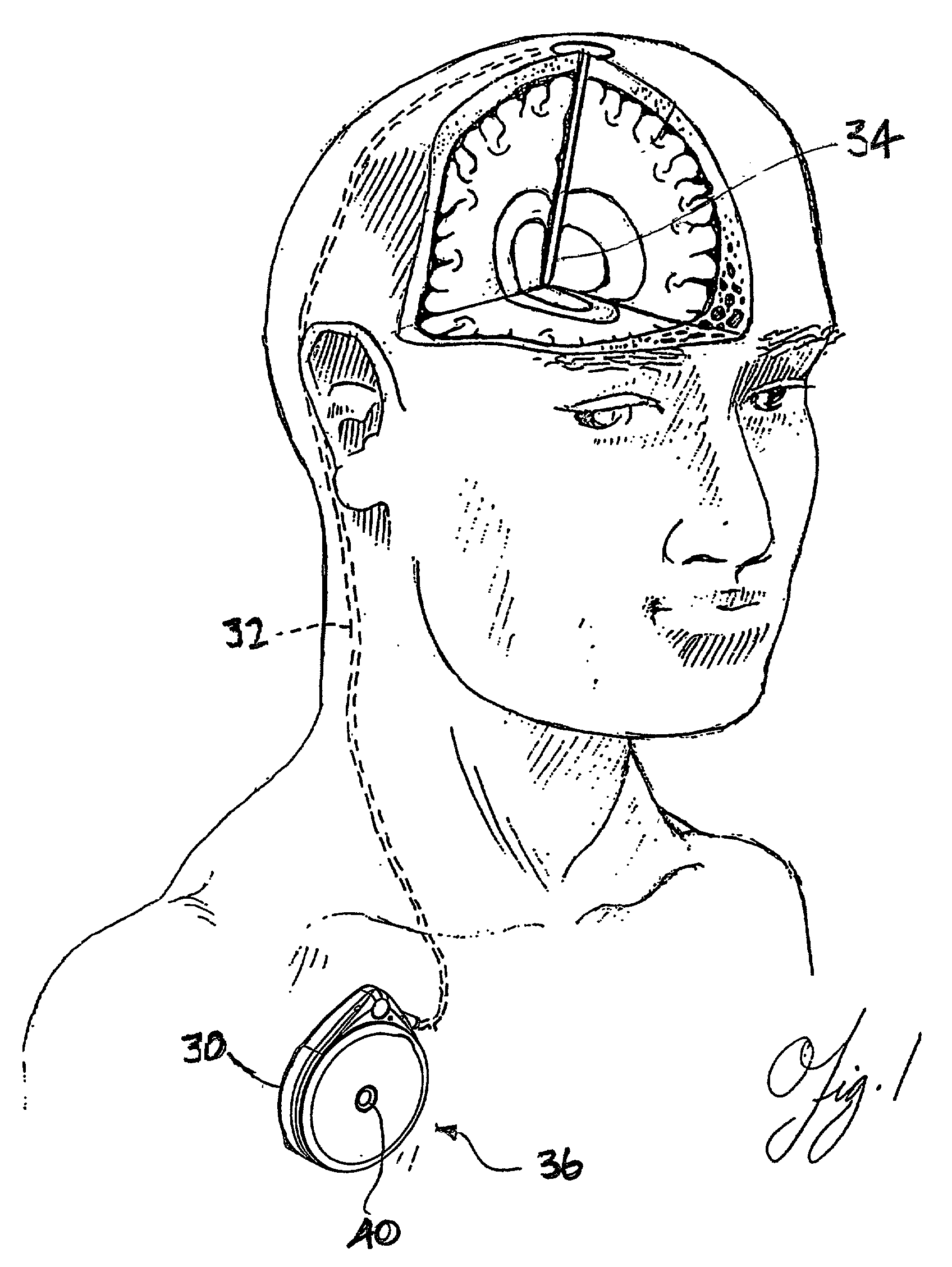

Implantable therapeutic substance infusion device with active longevity projection

InactiveUS7001359B2Extend effective lifeFacilitate elective replacement schedulingLocal control/monitoringDrug and medicationsDiseaseGenetic Materials

A medical device known as an implantable therapeutic substance delivery device is configured for implanting in humans to deliver a therapeutic substance such as pharmaceutical compositions, genetic materials, and biologics to treat a variety of medical conditions such as pain, spastisity, cancer, and many other conditions. The infusion device embodiment has active longevity projection that more accurately predicts an elective replacement period for the infusion device to increase the infusion device's effective life, reduce the need for a clinician to perform static longevity forecasts for therapy changes, facilitate elective replacement scheduling for the convenience of the patient and clinician, and many other improvements. The infusion device has a housing, a power source, a therapeutic substance reservoir, a therapeutic substance pump, and electronics. Many embodiments of the therapeutic substance delivery device with active longevity projection and its methods of operation are possible.

Owner:MEDTRONIC INC

Oil-based additive for corrosion inhibitors

InactiveUS7014694B1Extend effective lifeLow costOther chemical processesAdditivesFatty acidViscosity

An oil-based corrosion inhibitor composition for use in lubricating and / or hydraulic oils includes an oil-soluble sulfonate salt, an imidazoline salt of a fatty acid or a poly acid, and a polymerized ester, with the corrosion inhibitor composition being diluted with a polyalphaolefin to a suitable viscosity for subsequent use as an additive to such oils. In preferred embodiments, the corrosion inhibiting additive composition is mixed with the lubricating and / or hydraulic oils at a concentration of between about 2–5% by weight of the combination.

Owner:CORTEC

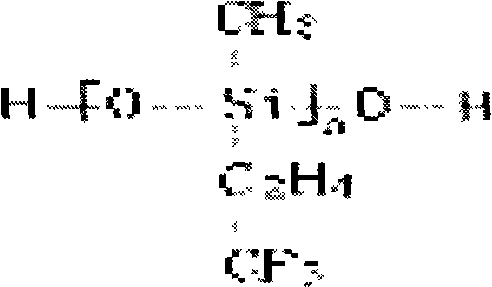

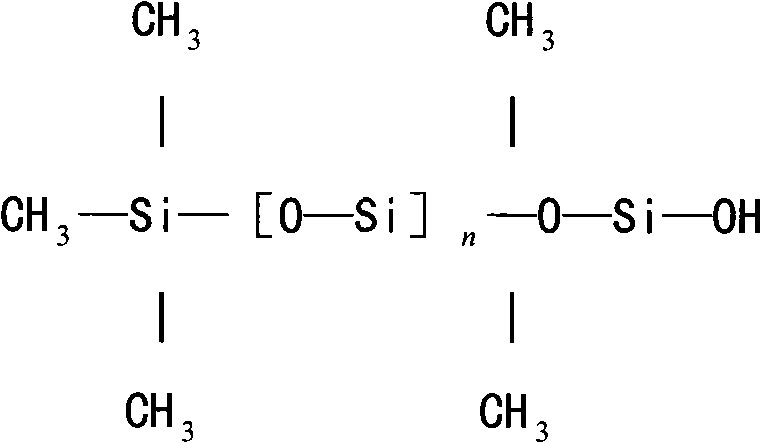

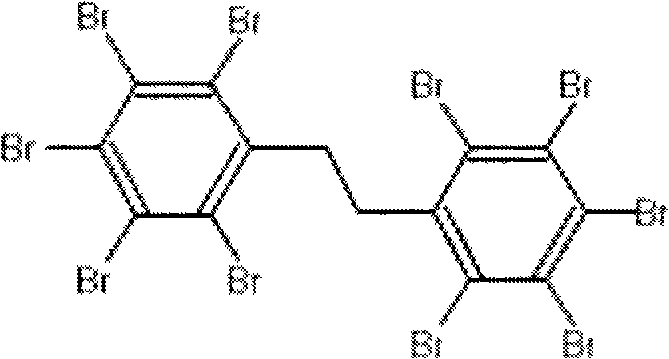

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

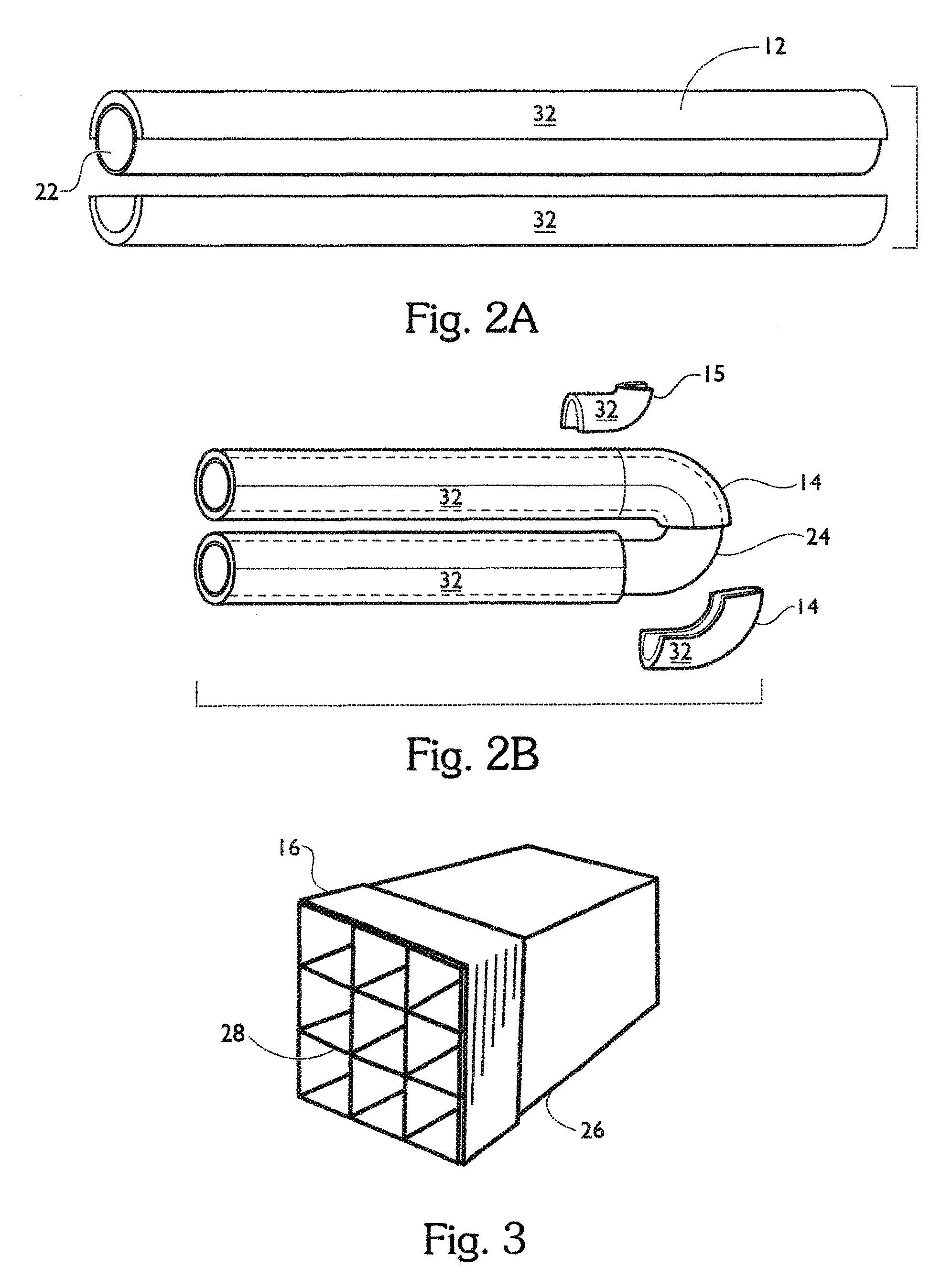

Tube shields having a thermal protective layer

InactiveUS20100038061A1Extend effective repair and replacement cycleReduce use costMetal-working apparatusCorrosion preventionColloidal silicaEmissivity

A tube shield, and method of manufacturing the tube shield, having a support structure with an external surface, an internal surface, and an edge, and a thermal protective layer on at least one surface of the shield support structure. The thermal protective layer is composed of a filler, one or more emissivity agent, and either an inorganic adhesive or a binder that is colloidal silica, colloidal alumina, or combinations thereof. A colorant, a surfactant, and / or a stabilizer may be incorporated into the thermal protective layer.

Owner:WESSEX

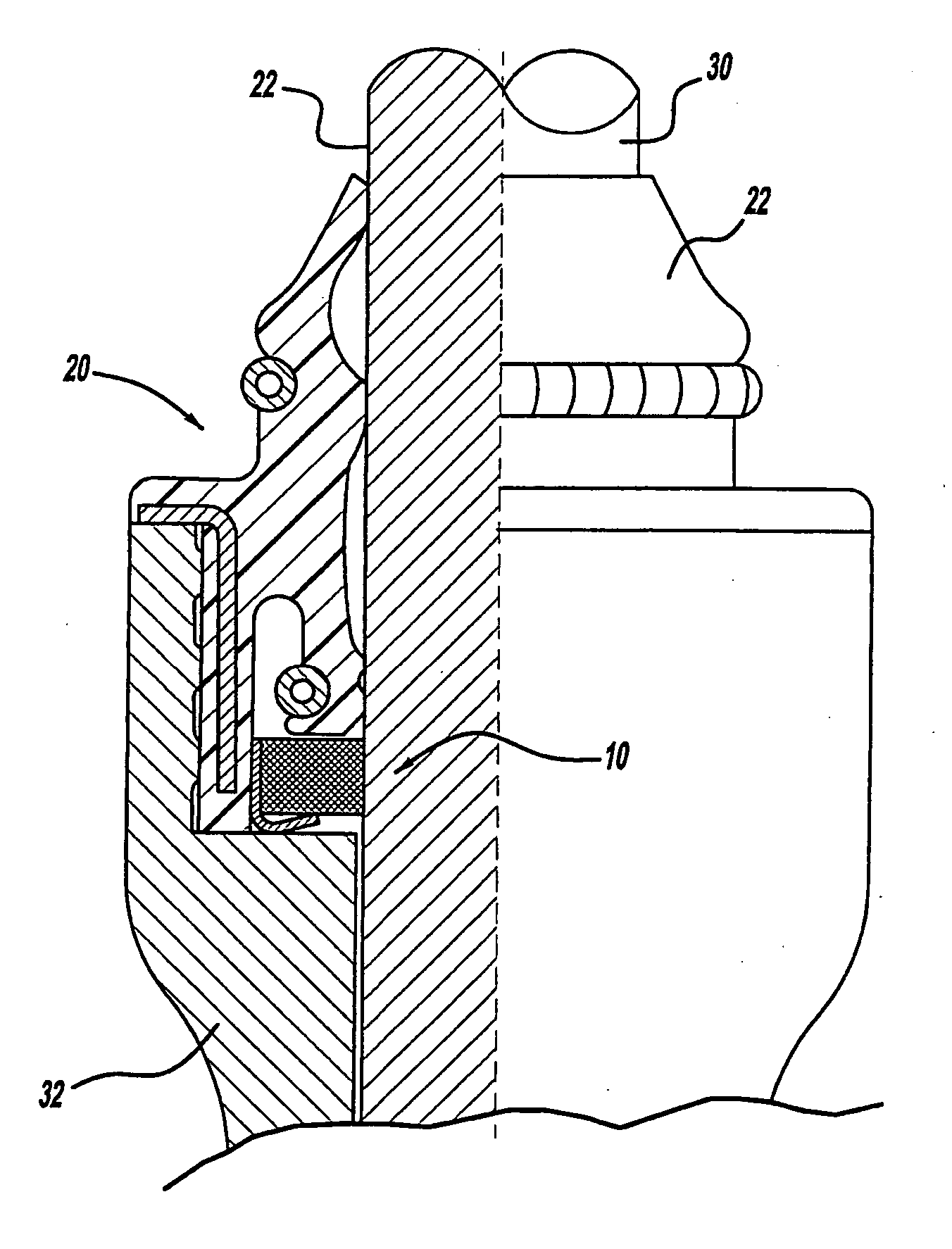

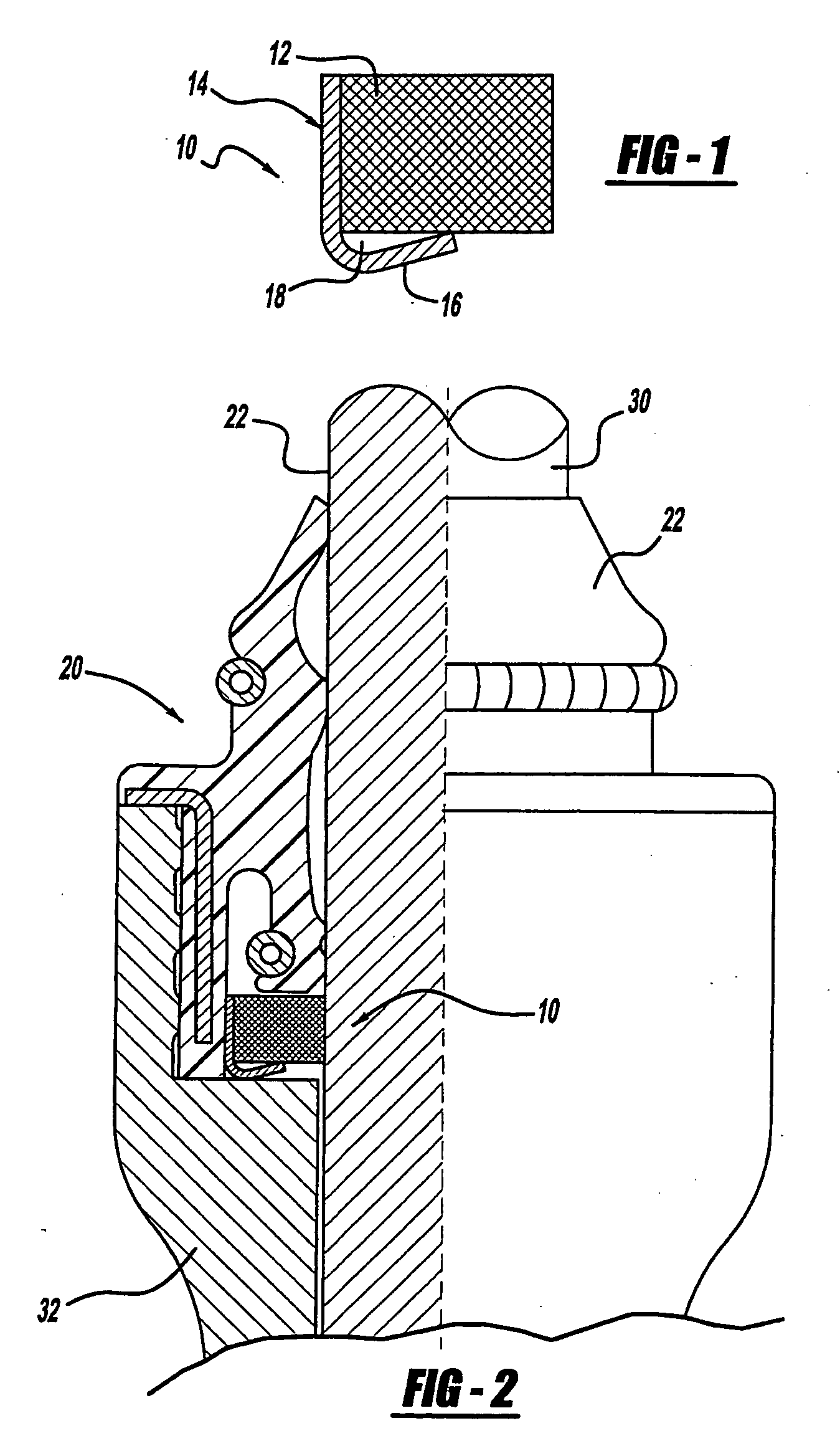

Shaft seal with lubrication device

InactiveUS20060071430A1Extend effective lifeAvoid accumulationEngine sealsSpringsAxial displacementWorking fluid

A shaft seal assembly for use with a reciprocating or rotating shaft includes a shaft seal, a lubricant-storing ring, and a retainer. The retainer and ring can be formed as a subassembly and then combined with a shaft seal. The seal includes an annular body portion, a first sealing lip portion, and a first pocket portion. The first sealing lip portion has a substantially uniform axial dimension and is adapted to sealingly engage a shaft. The first pocket portion includes a plurality of pockets, each having an opening toward the first sealing lip portion. The plurality of pockets are each adapted to collect a working fluid when the shaft axially displaces in a first direction and to dispense the working fluid when the shaft axially displaces in a second direction. The assembly provides a lubricated shaft and seal that improves the effective life of the shaft seal.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

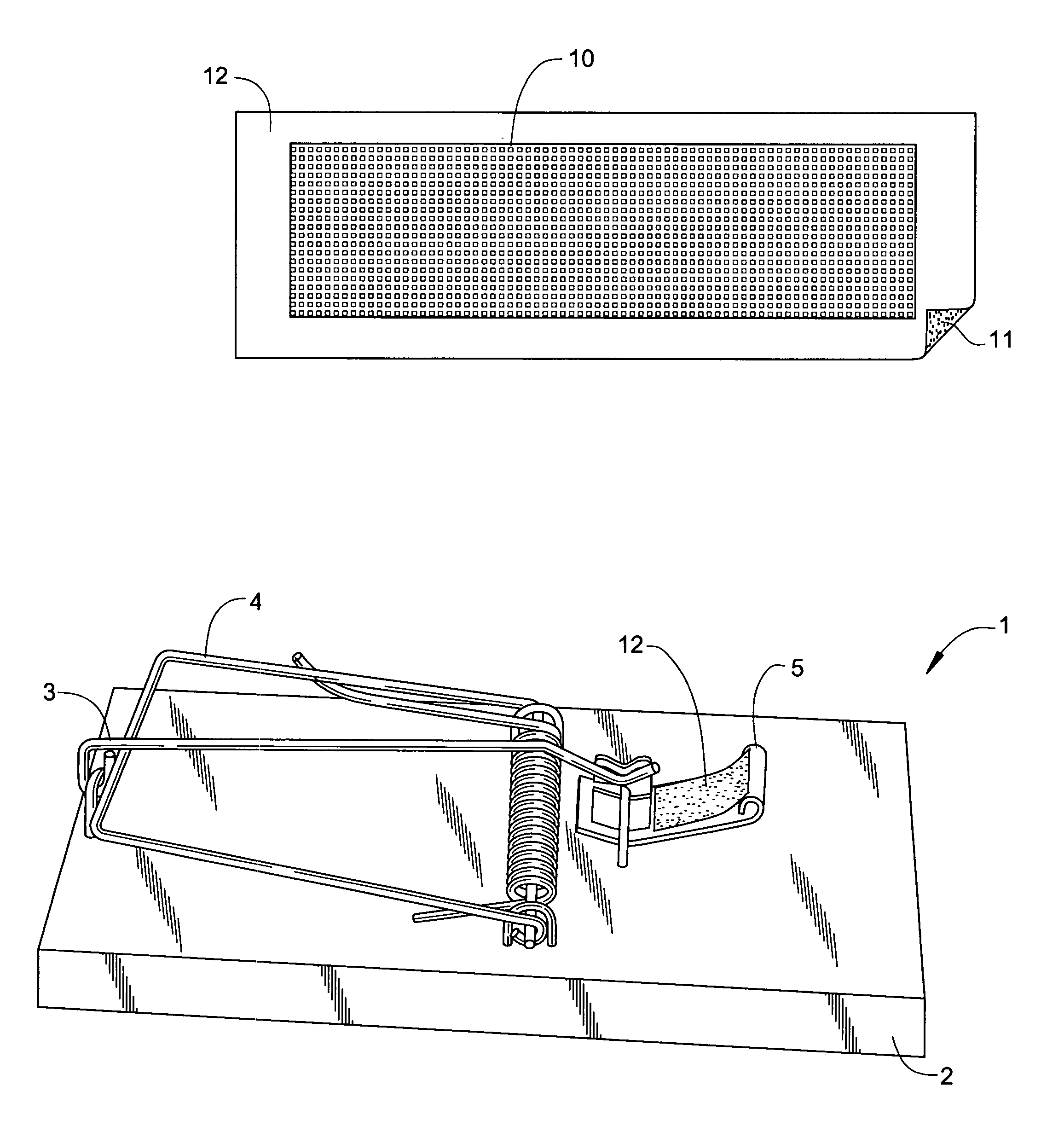

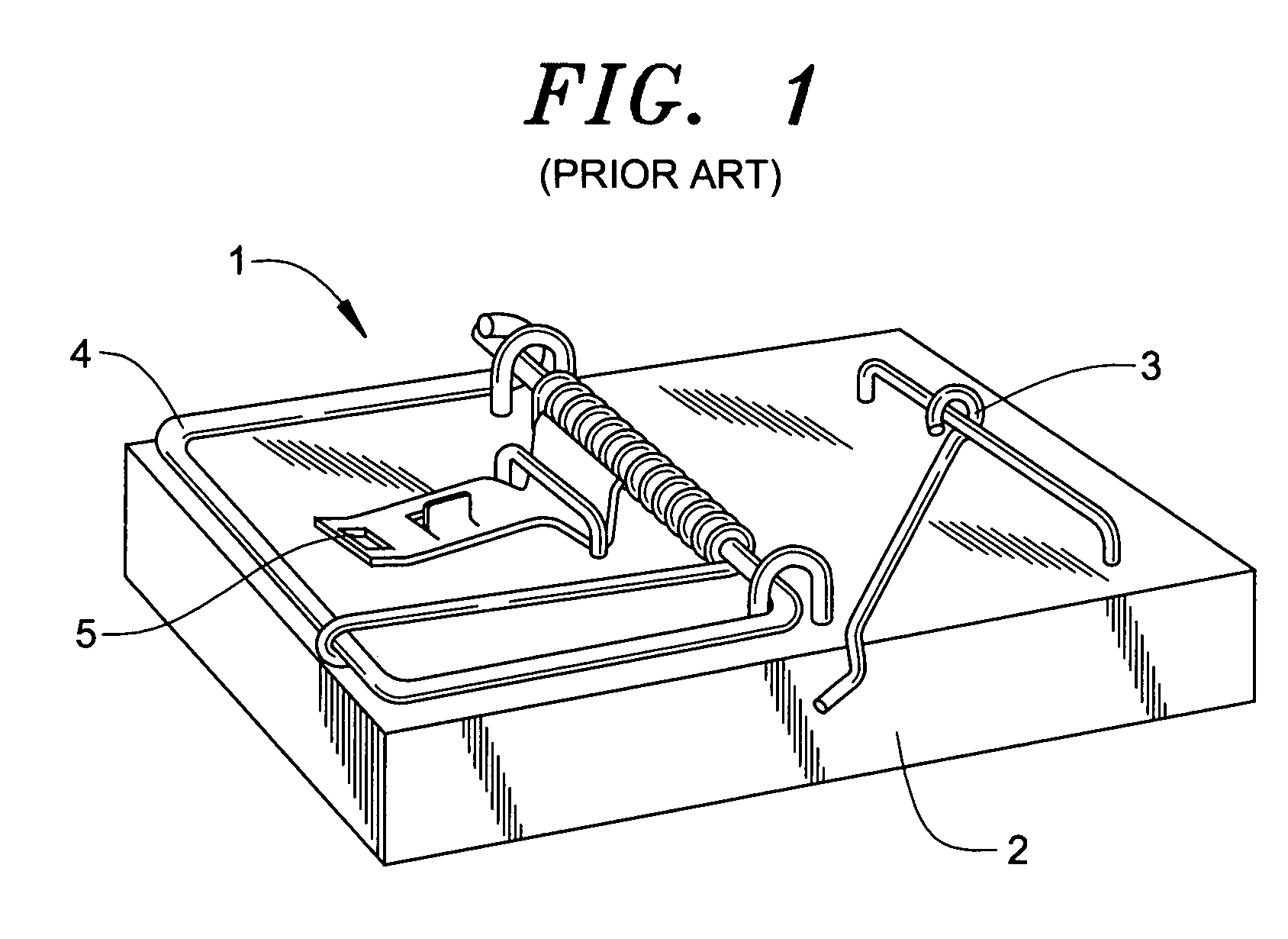

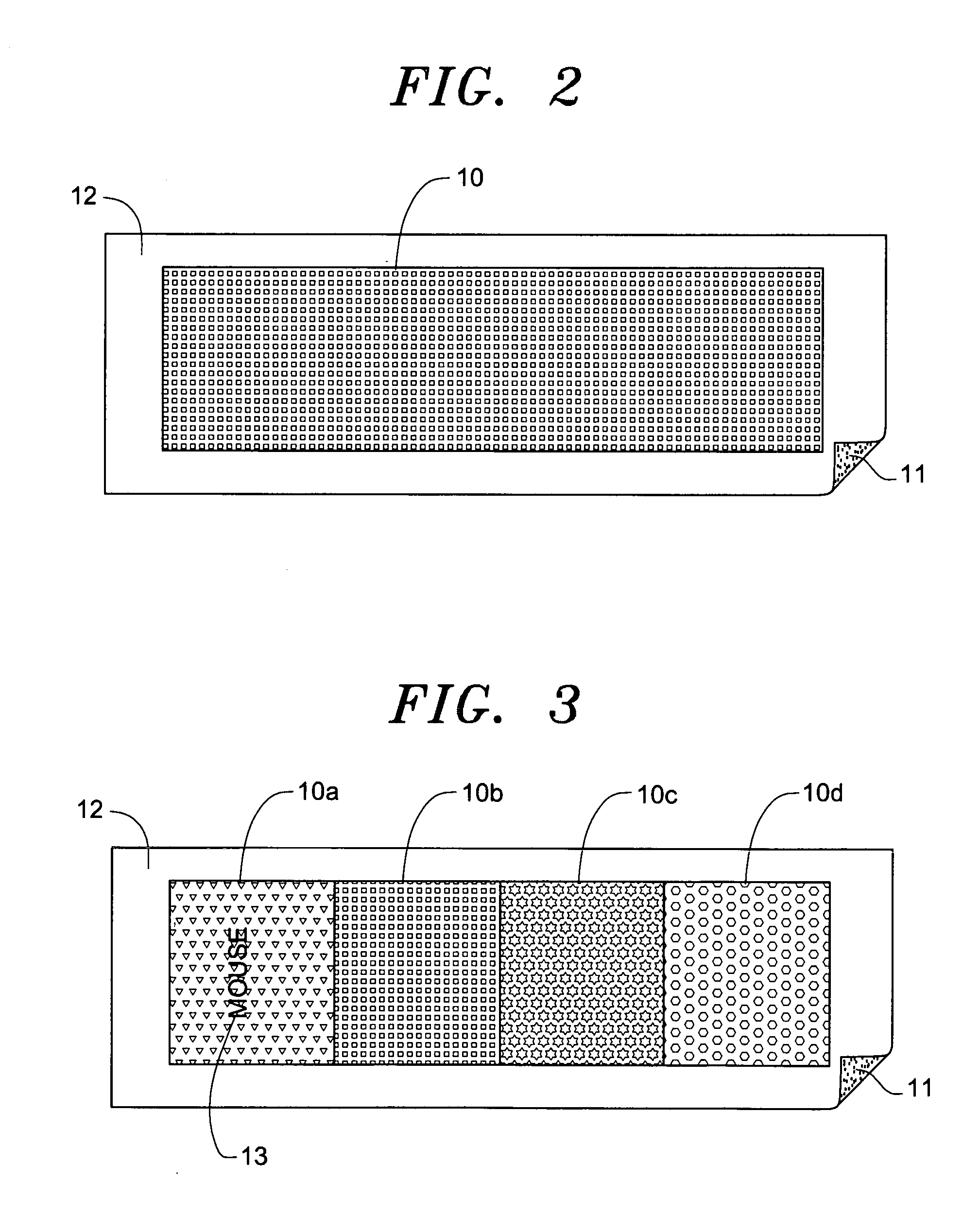

Microencapsulated animal trap bait and method of luring animals to traps with microencapsulated bait

The present invention is directed towards an animal trap kit and method for luring animals to trap. The kit preferably includes a any well known animal trap in combination with a microencapsulated bait that can be applied during manufacturing of new traps or existing traps alike. The microencapsulated scent may be applied to the trap via brush, spray or adhesive backed tape. The bait can be activated by merely scratching the scented portion of the trap. Alternatively the microcapsules may be constructed and arranged for timed release of the scents, flavors or phermones contained in the bait.

Owner:MICRO BAIT TECH

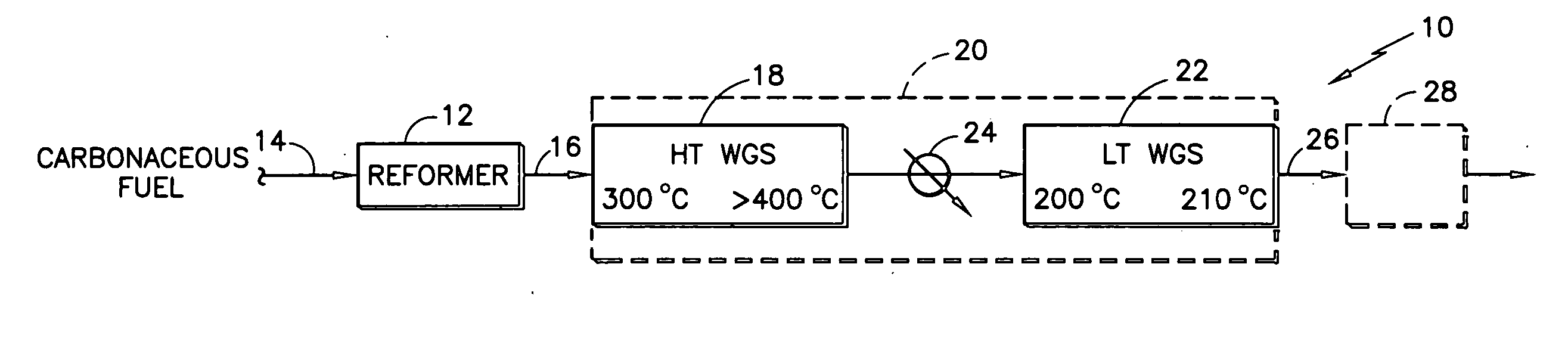

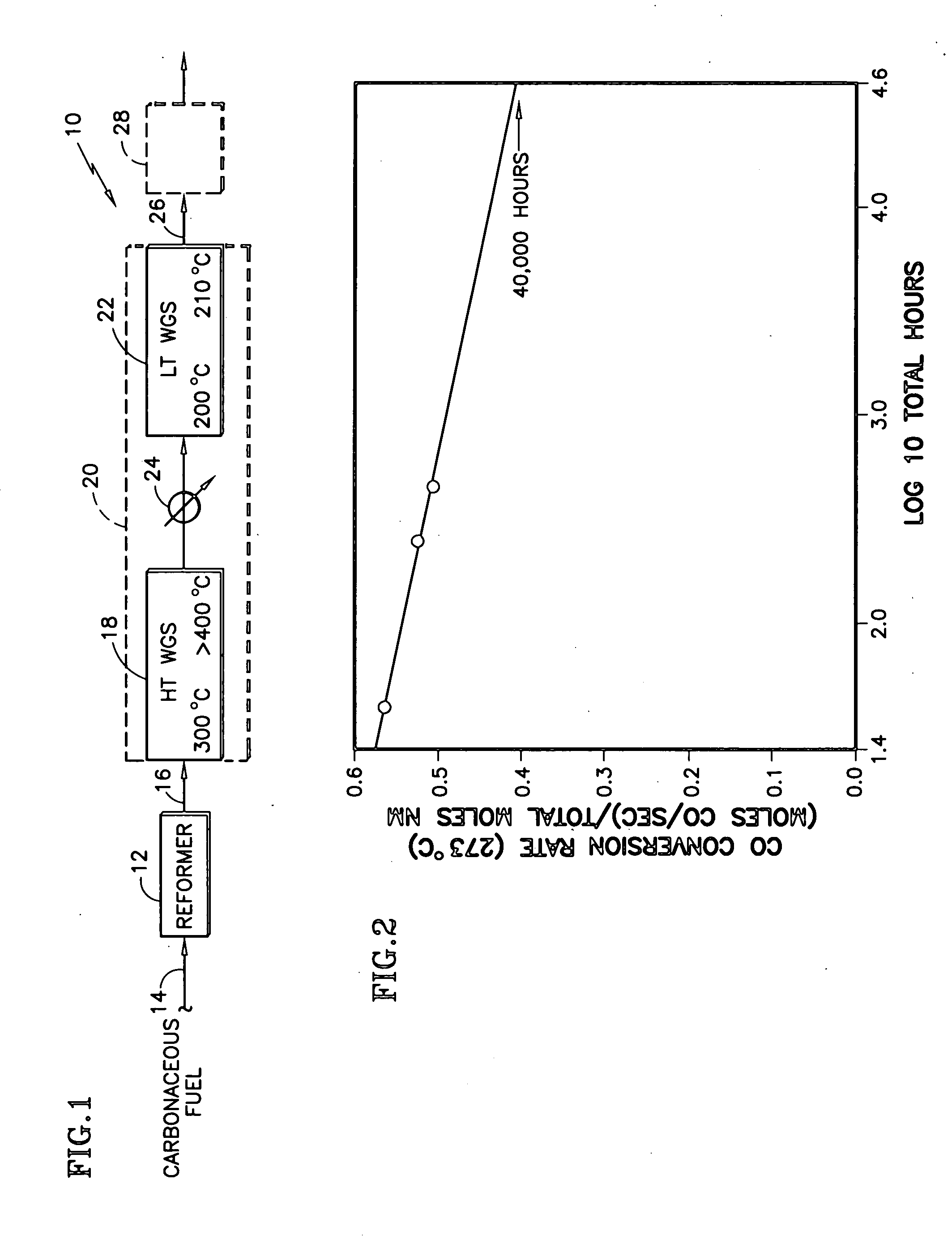

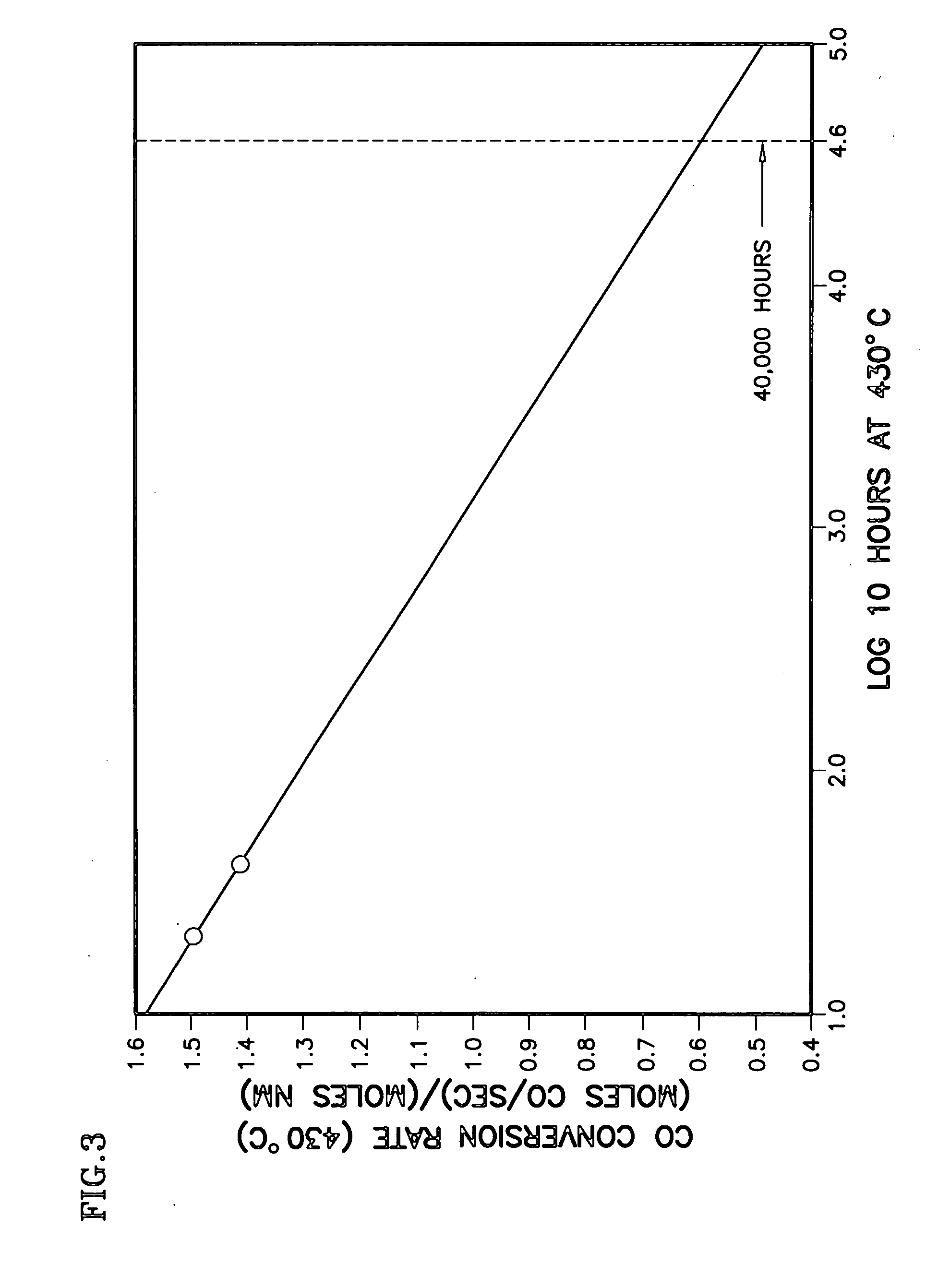

Durable catalyst for processing carbonaceous fuel, and the method of making

InactiveUS20060233691A1Simple structureAvoid turbidityTantalum compoundsHydrogen/synthetic gas productionBoiling pointWater-gas shift reaction

A doped, nanocrystalline, ceria-containing, mixed metal oxide supports a noble metal to provide a thermally-durable catalyst for processing carbonaceous fuels, particularly for the water gas shift reactions. The mixed metal oxide includes Zr and / or Hf and is normally susceptible to oxide ion vacancy ordering at elevated temperature reducing conditions. A dopant is selected to inhibit such oxide ion vacancy ordering. The dopant is preferably selected from the group consisting of W, Mo, Ta, and Nb, most preferably W, for providing a thermally-durable catalyst at operating temperatures exceeding 400° C. The noble metal is preferably Pt and / or Re. The doped ceria-containing mixed metal oxide is prepared from 2 or 3 aqueous solutions variously containing ceria, Zr and / or Hf, the dopant, and urea. The solutions are heated to below boiling, combined in a particular sequence and manner, and brought to boiling to crystallize and precipitate the doped ceria-containing mixed metal oxide.

Owner:INT FUEL CELLS

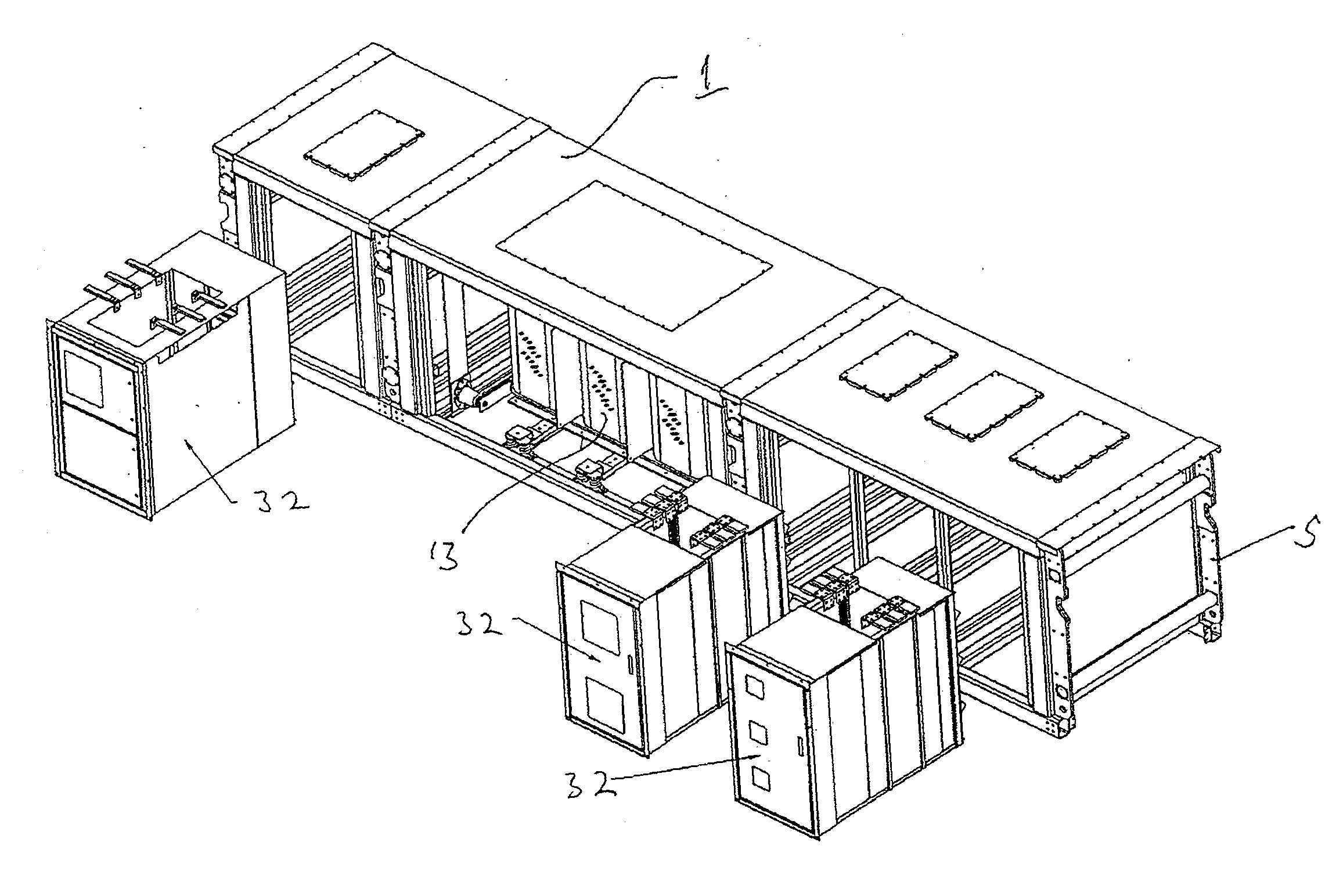

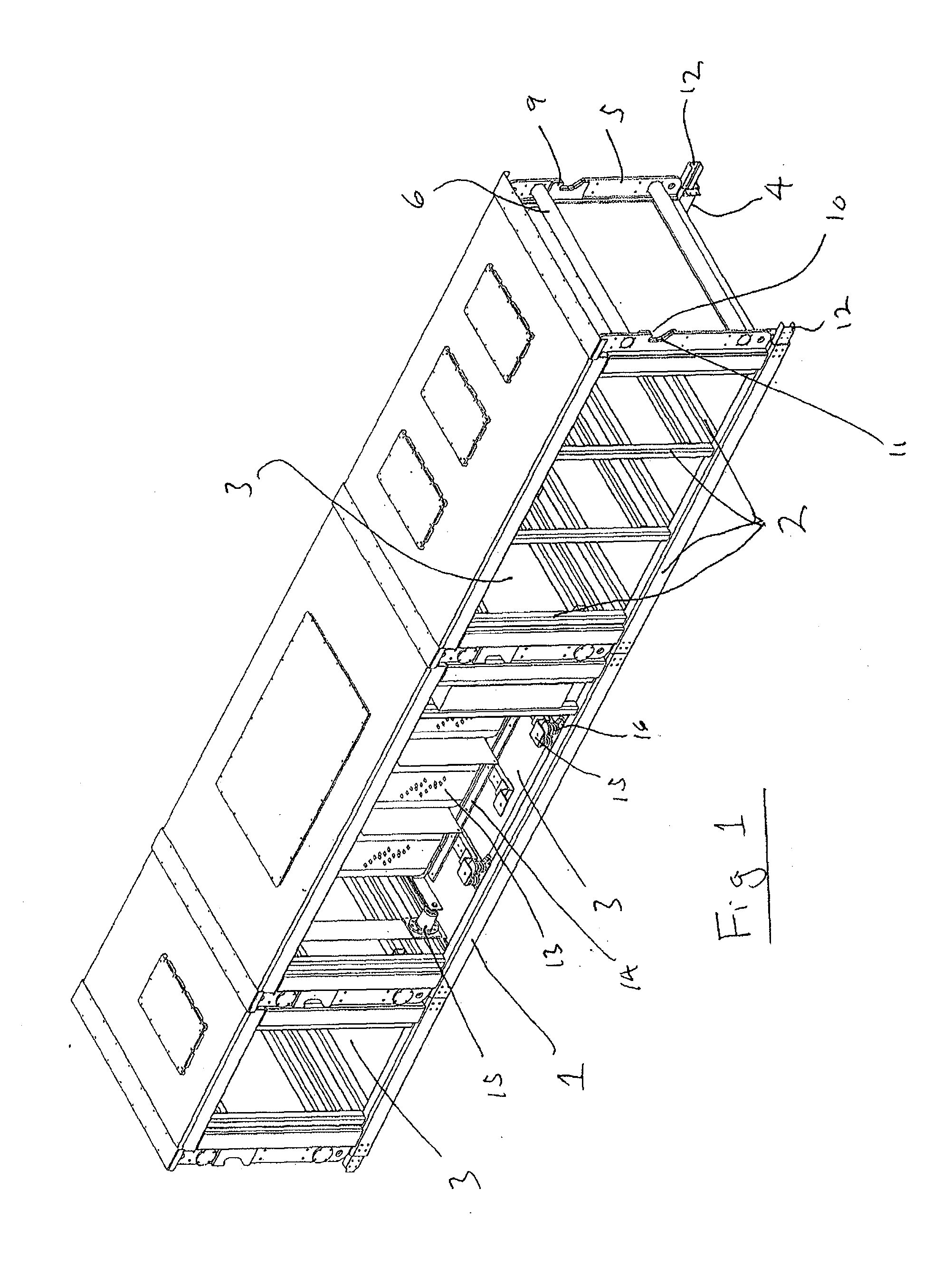

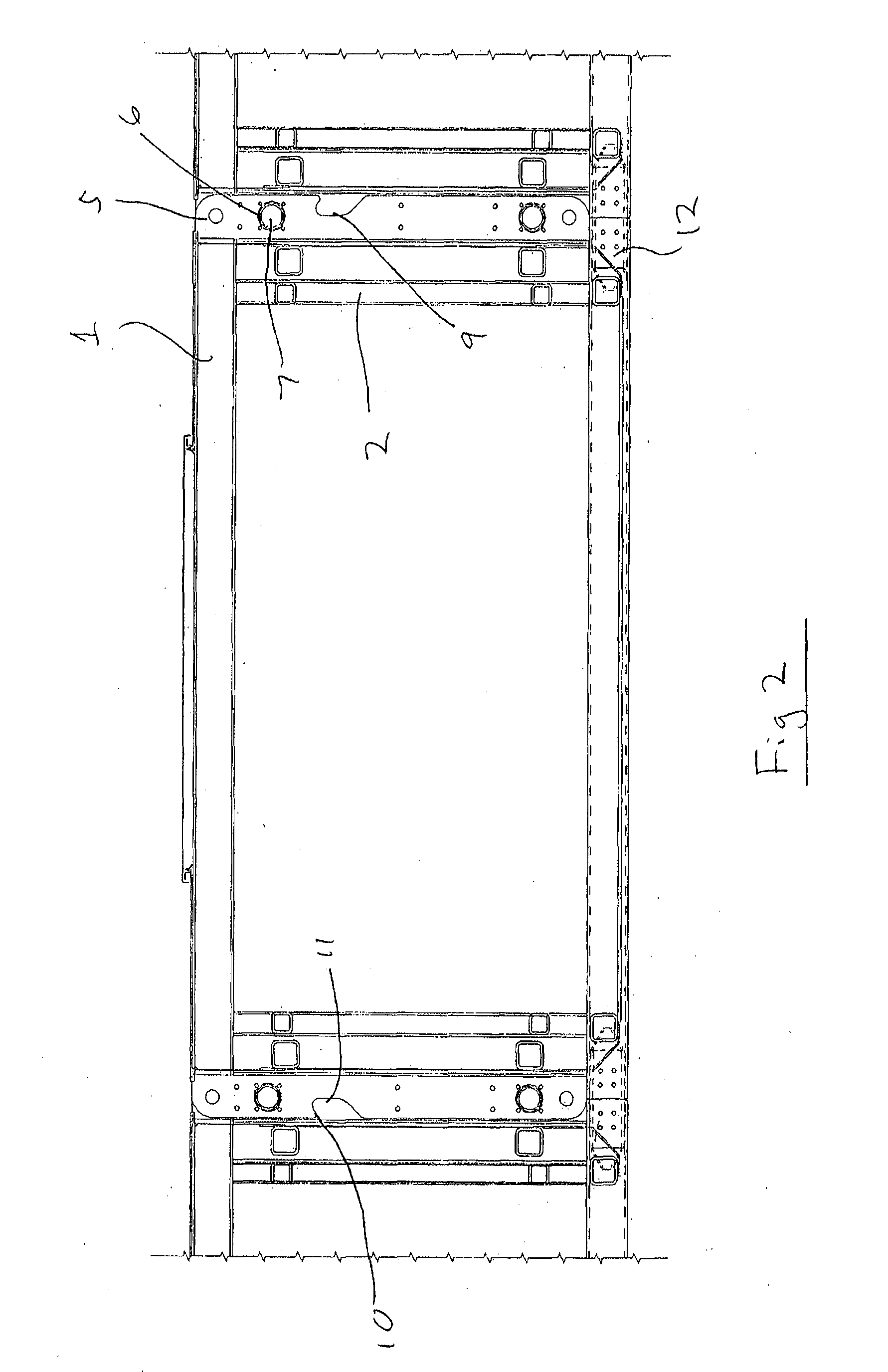

Modular skid frame

InactiveUS20130194059A1Increased effective operating lifeReduce potential for injury and deathTransformers/reacts mounting/support/suspensionSubstation/switching arrangement detailsModularityArc flash

A modular skid frame and device to reduce the potential for harm and injury from arc flashes. The modular skid frame comprises a plurality of frame members secured together to form the skid frame, and one or more hook members formed on one or more of the frame members to permit the receipt of a bucket or blade from a loader, scoop tram or other construction or mining equipment into the bowl portion and behind the bill portion of the hook member to facilitate the lifting and moving of the skid frame. Also disclosed is a device for racking a circuit breaker into and out of a circuit breaker cradle. The device comprises an actuator operatively connected to the circuit breaker cradle to permit the circuit breaker to be racked into and out of the cradle without direct or indirect contact on the part of an operator.

Owner:PARR WILLIAM R

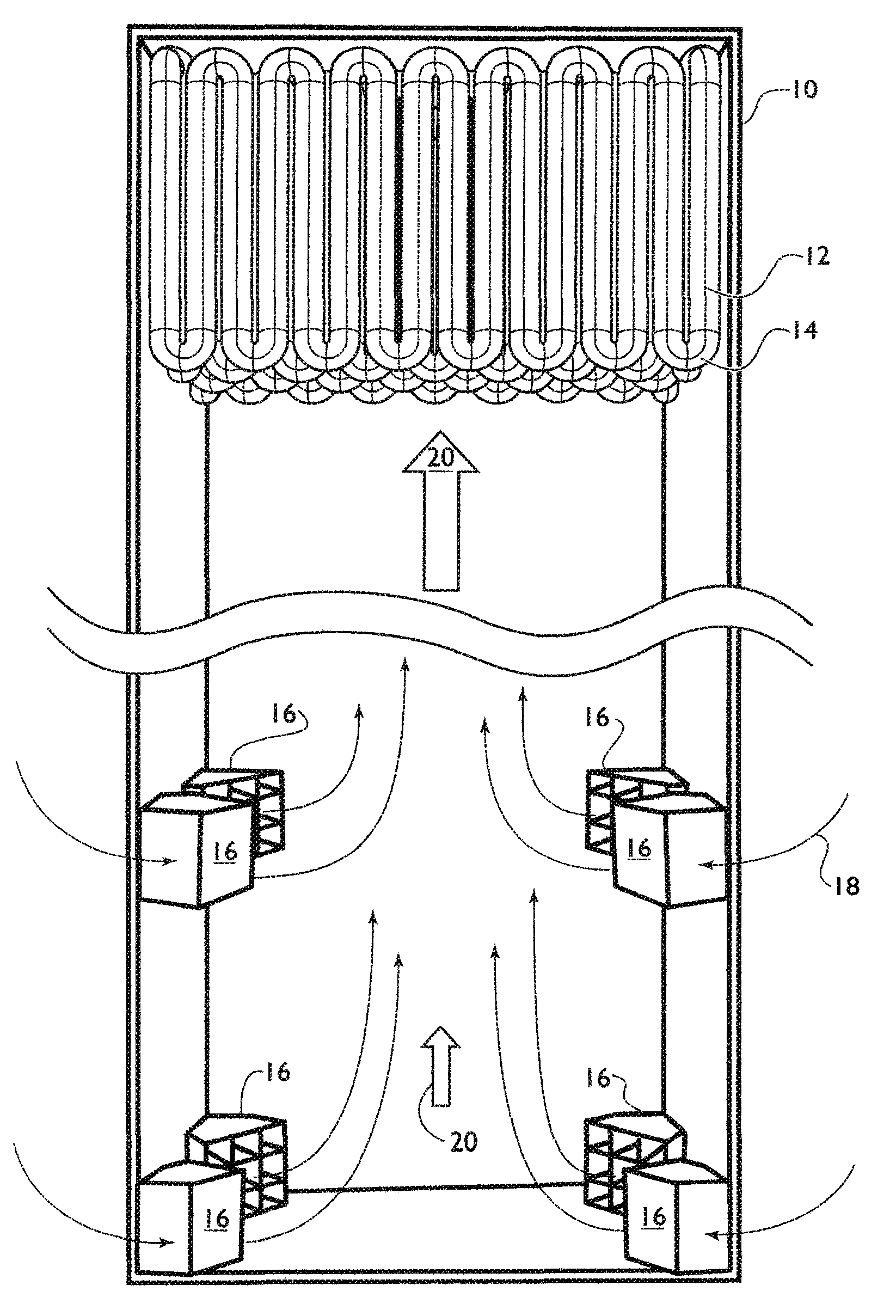

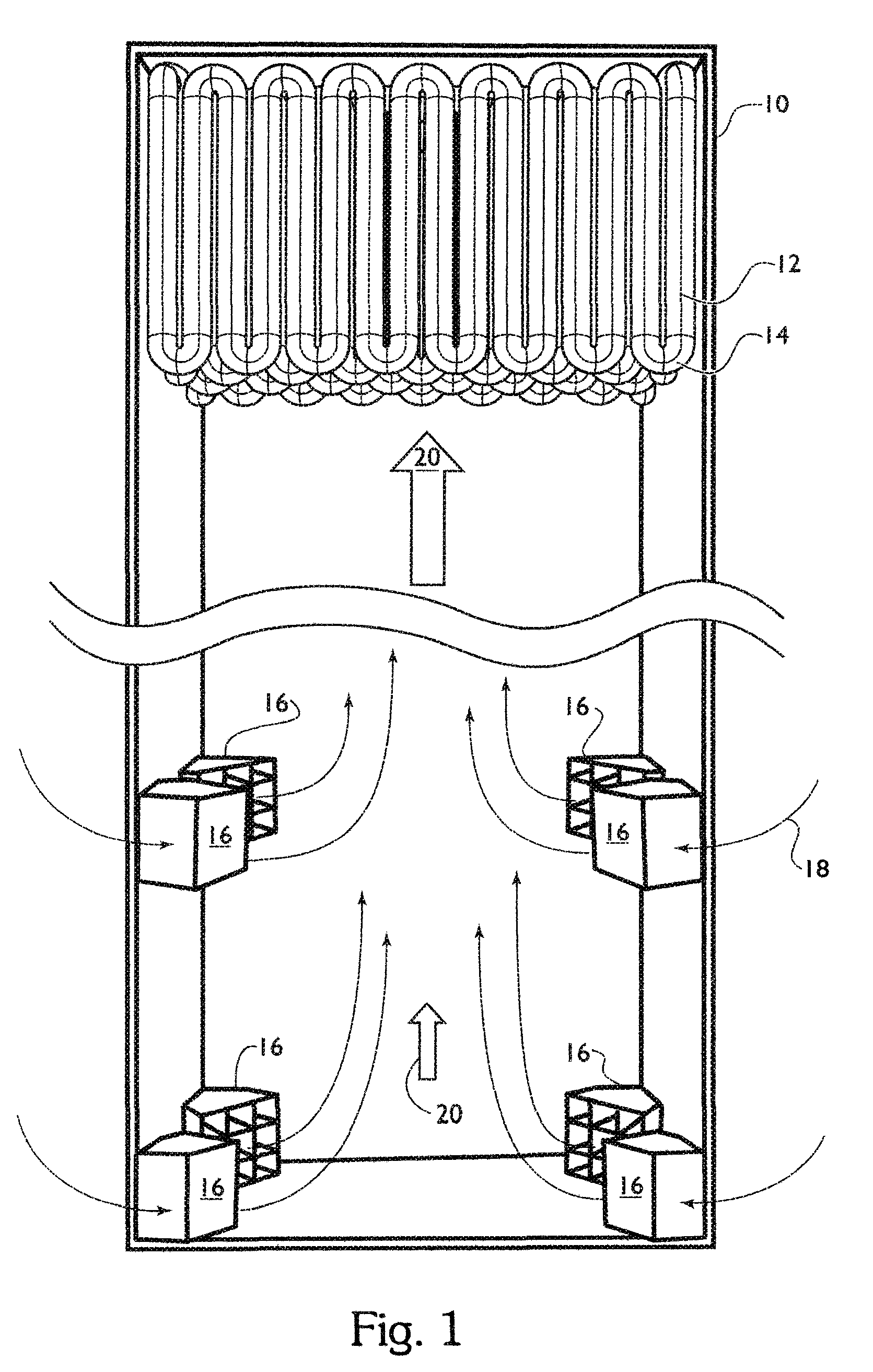

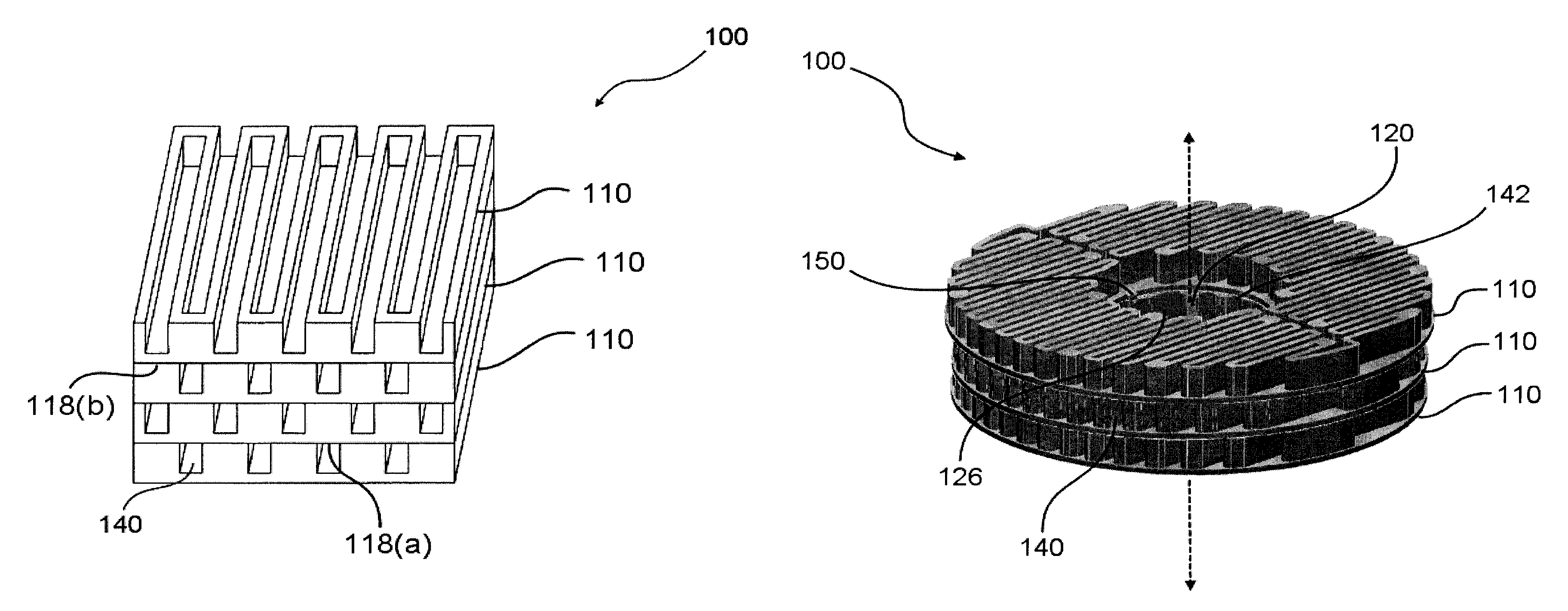

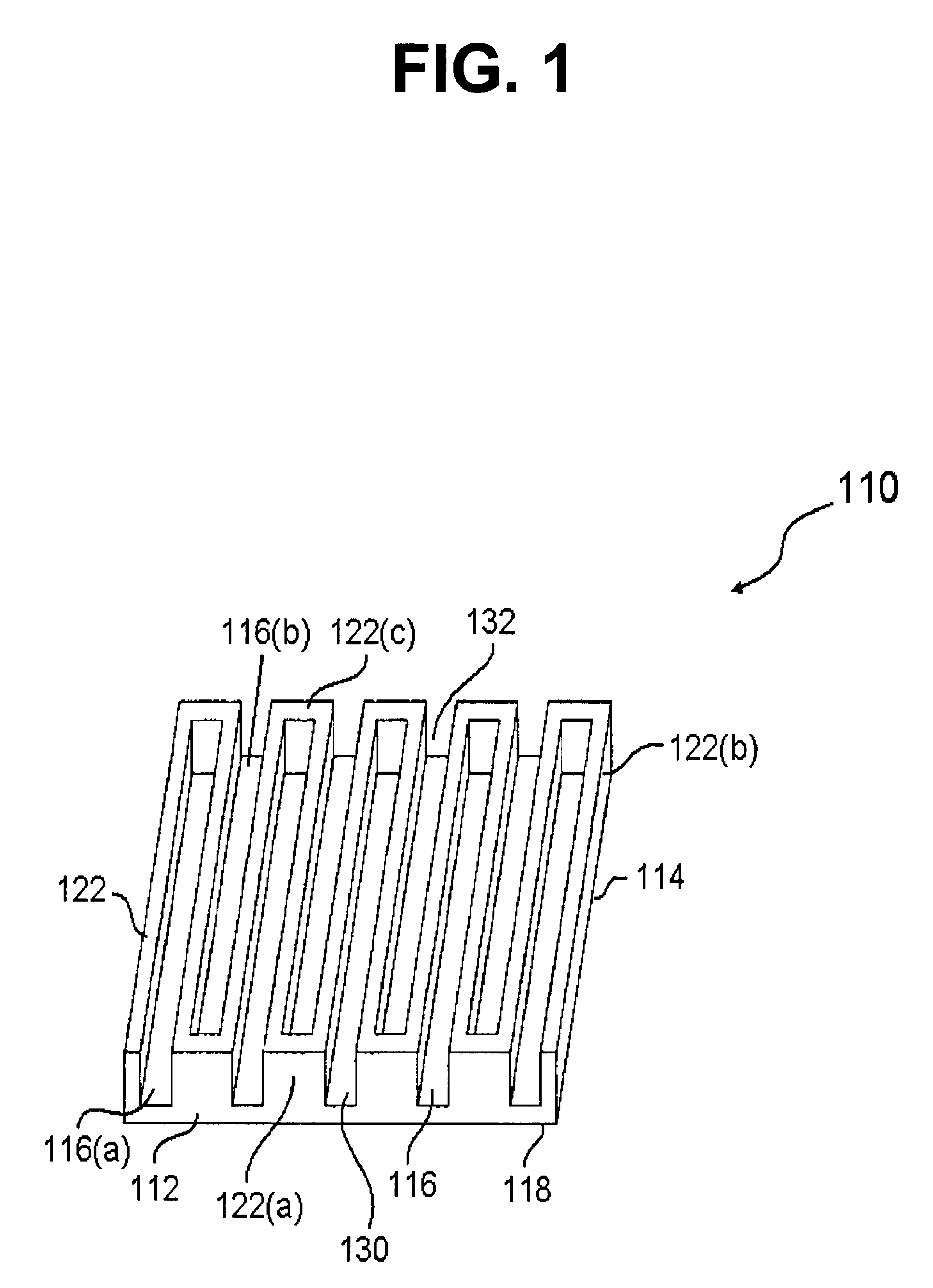

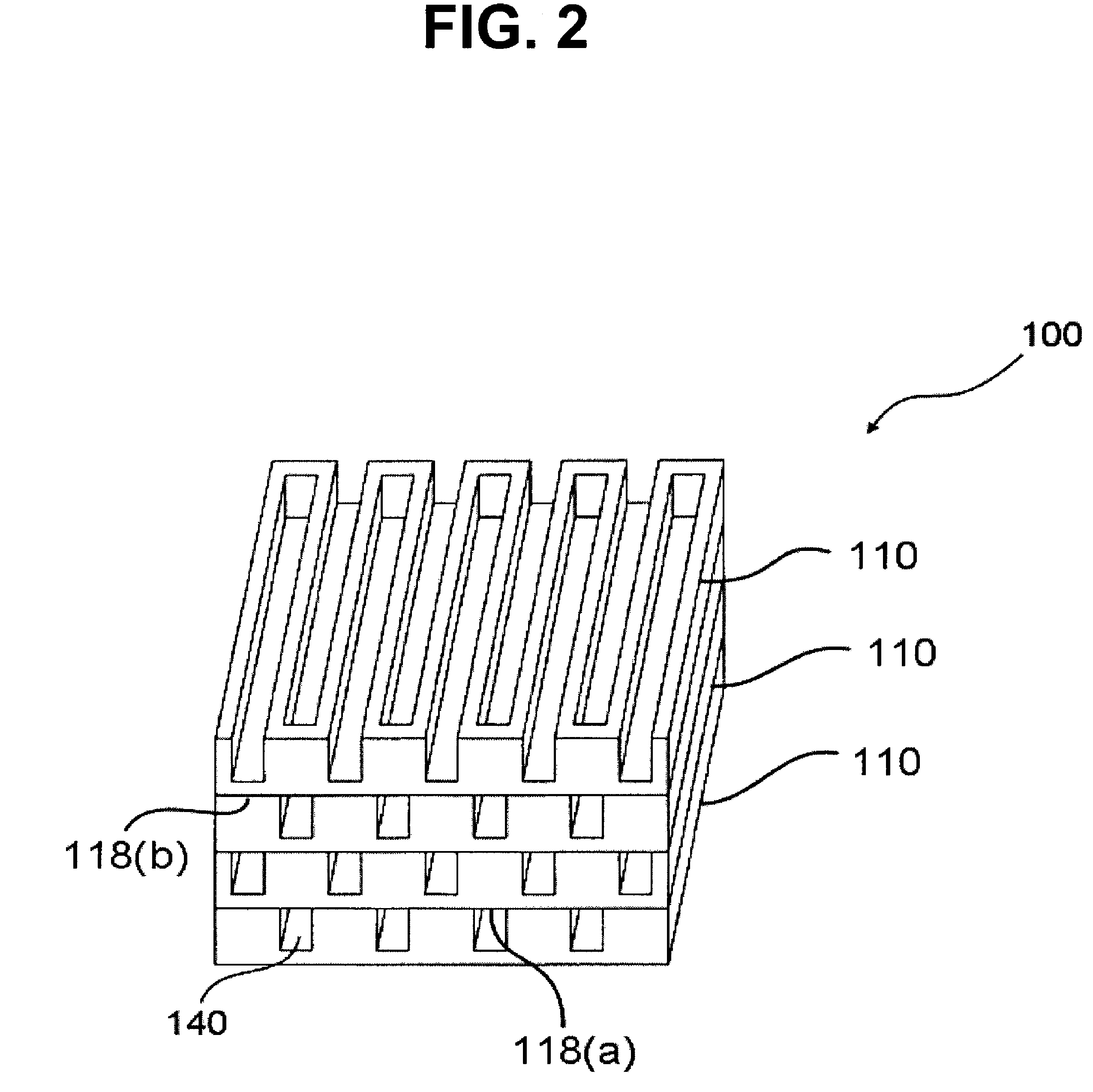

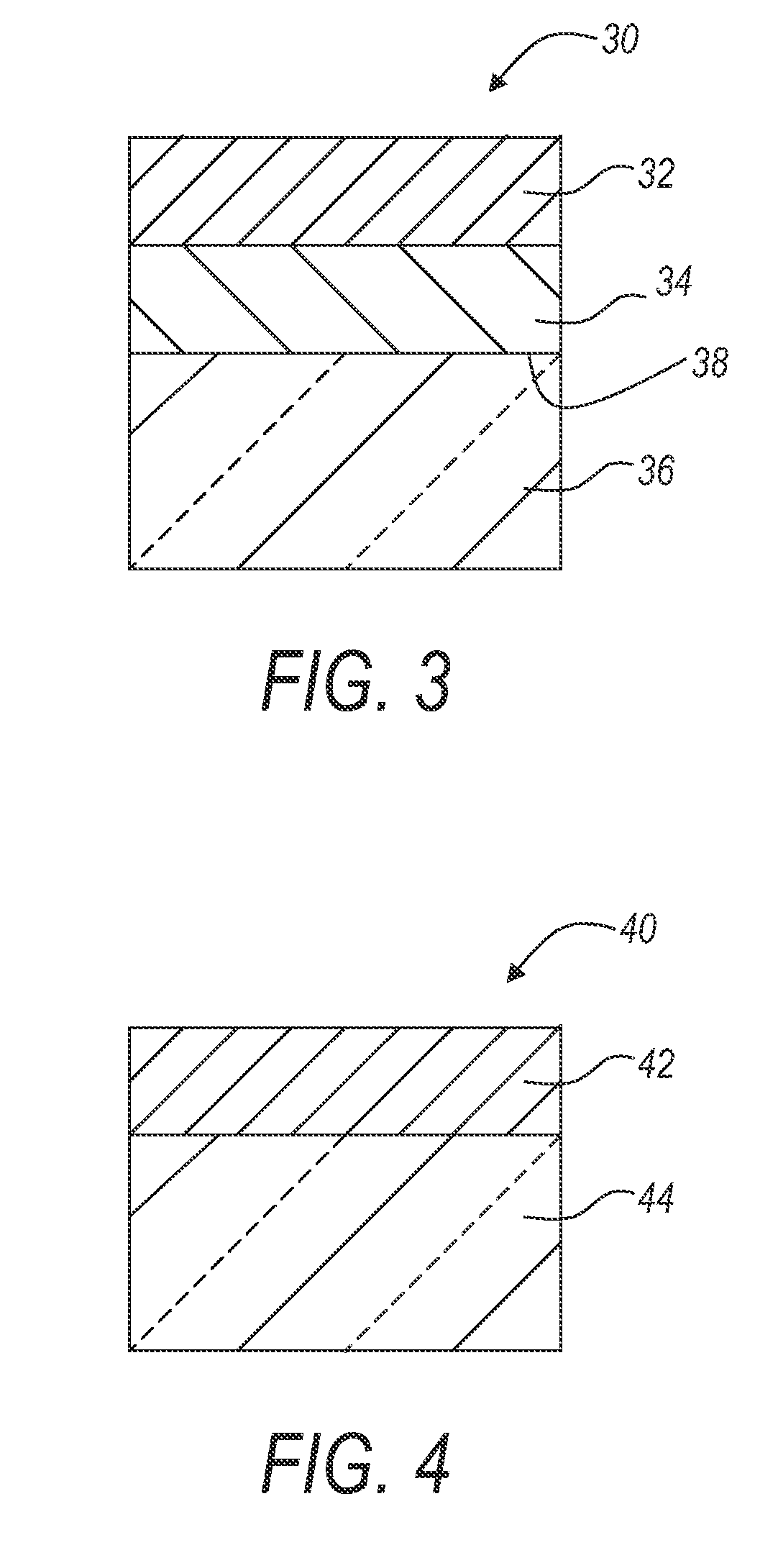

Modular filter assembly

InactiveUS7985343B2Improve filtering effectImprove the immunityCombination devicesWater/sewage treatment by centrifugal separationModularityMechanical engineering

Disclosed herein are modular filter assemblies having a plurality of stacked filter plates formed from a porous material. The filter plate can comprise a planar base portion from which a convoluted ridge wall, having a ridge outer side surface, a ridge inner surface, and a top ridge surface extends. A plurality of fluid inlet troughs and a plurality if fluid outlet troughs are defined by the ridge wall. Adjoining filter plates form a plurality of fluid inlet cavities defined by the fluid inlet trough of one filter plate and a portion of the bottom surface of the adjoining filter plate; and a plurality of fluid outlet cavities defined by the fluid outlet trough of the one filter plate and a portion of the bottom surface of the adjoining filter plate. In use, the plurality of fluid inlet cavities are in filtered communication with the plurality of fluid outlet cavities.

Owner:POREX CORP

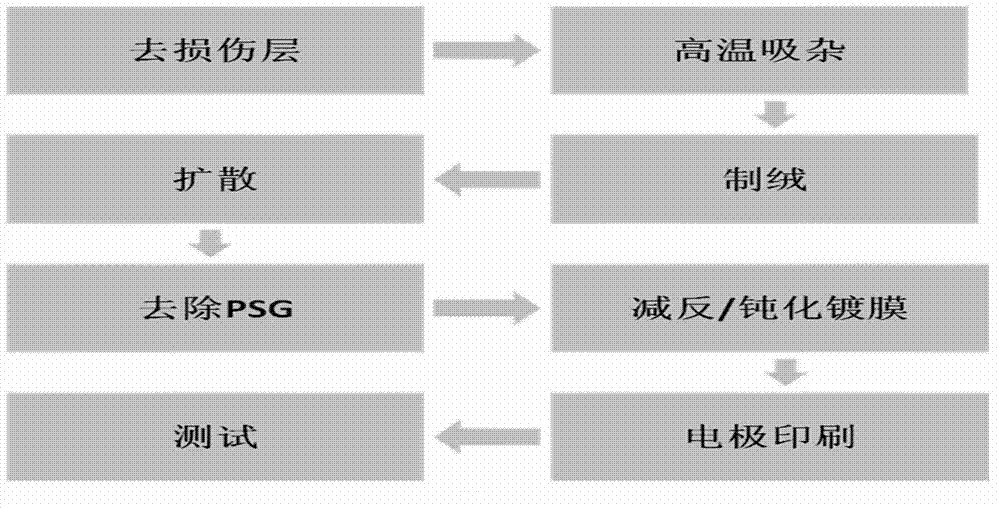

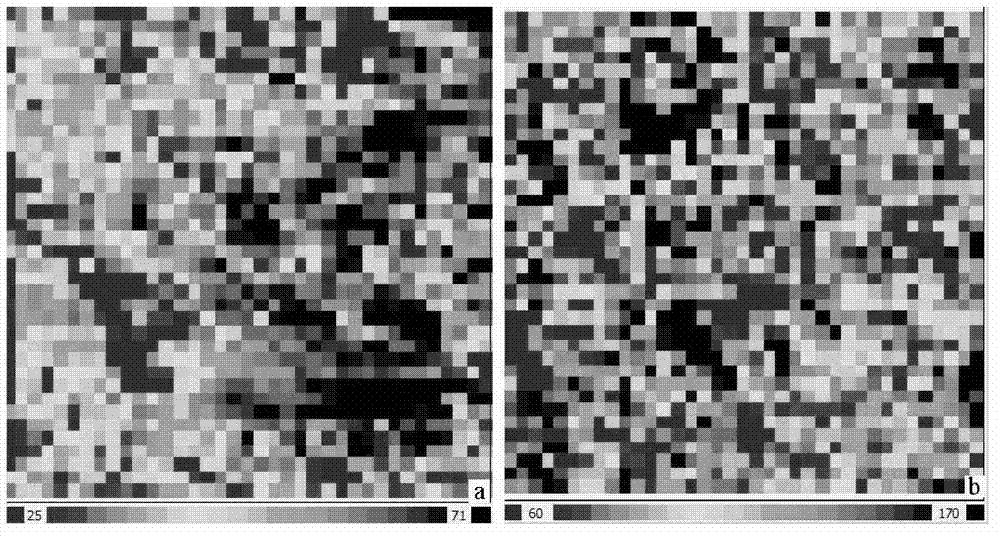

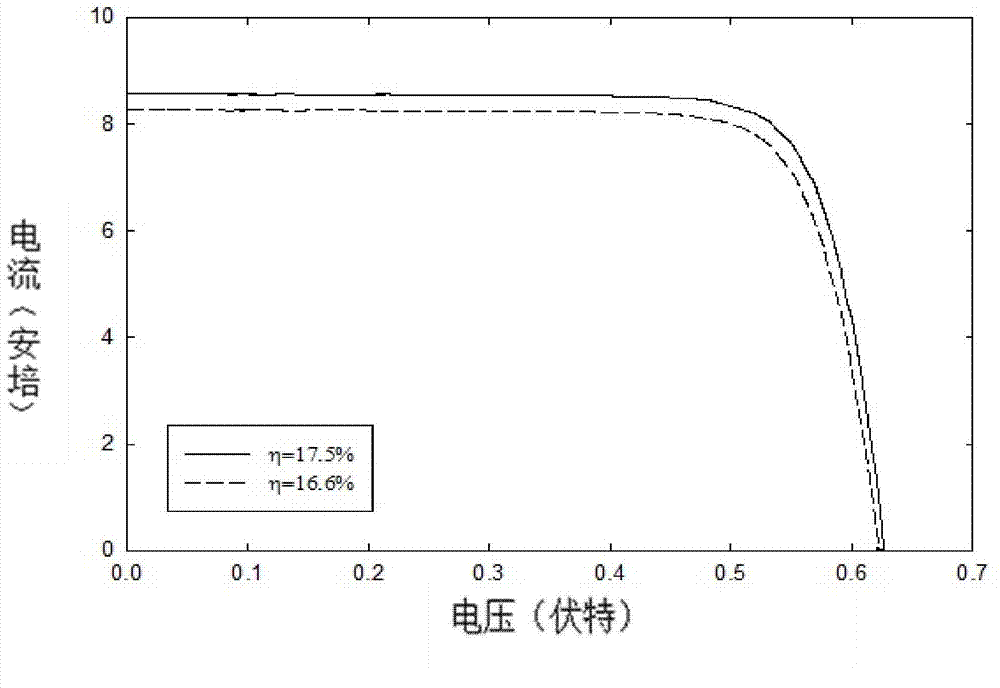

Gettering method for prolonging effective service life of crystalline silicon substrate

ActiveCN102820378AExtend effective lifeImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSolar batteryCrystalline silicon

The invention provides a gettering method for prolonging the effective service life of a crystalline silicon substrate. The method comprises the following steps: carrying out a heavy phosphorous diffusion gettering on the crystalline silicon substrate without a surface damage layer by using a phosphorus source, and removing a phosphorous diffusion layer from the crystalline silicon substrate after phosphorous gettering and then carrying out the following processes. The heavy phosphorous diffusion gettering step comprises a phosphorous diffusion constant temperature process and a two-section cooling process for phosphorous gettering; the temperature of a constant temperature region in the phosphorous diffusion constant-temperature process is 800-950 DEG C, and the time of the phosphorous diffusion constant-temperature process is 30-50min; in the two-section cooling process for the phosphorous gettering, the temperature range of the first section is 980-800 DEG C and the treatment time of the temperature range of the first section is 5-30min, the temperature range of the second section is 800-700 DEG C and the treatment time of the temperature range of the second section is 30-90min, and a cooling rate is 2-10 DEG C / min. With the adoption of the method provided by the invention, the effective service life of a photo-production carrier can be prolonged; the photo-electric conversion efficiency of a solar battery is increased; the gettering method can be completely compatible with the conventional solar battery production process; and the gettering method can be directly applied to the mass production of the solar battery.

Owner:JA SOLAR TECH YANGZHOU

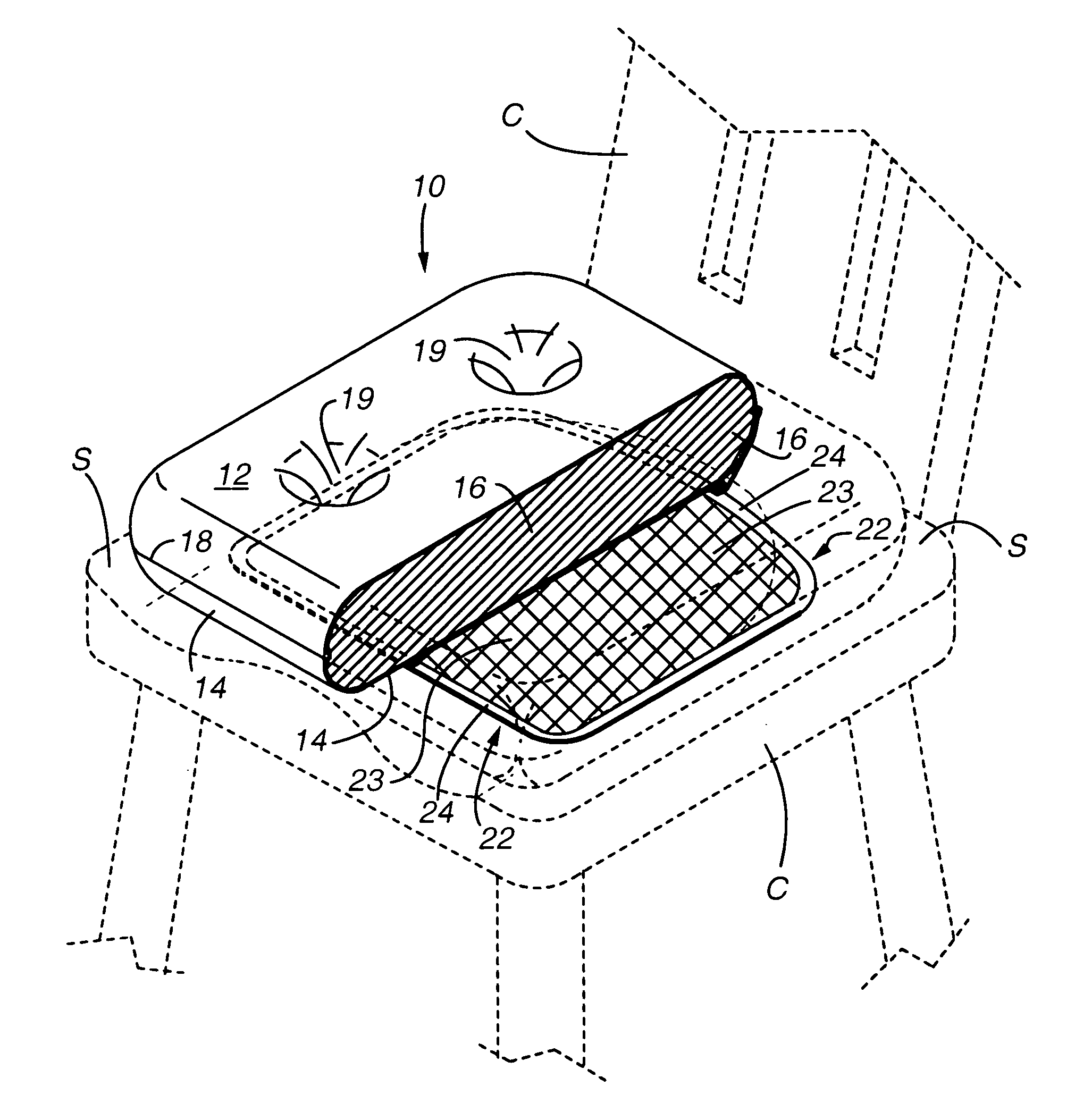

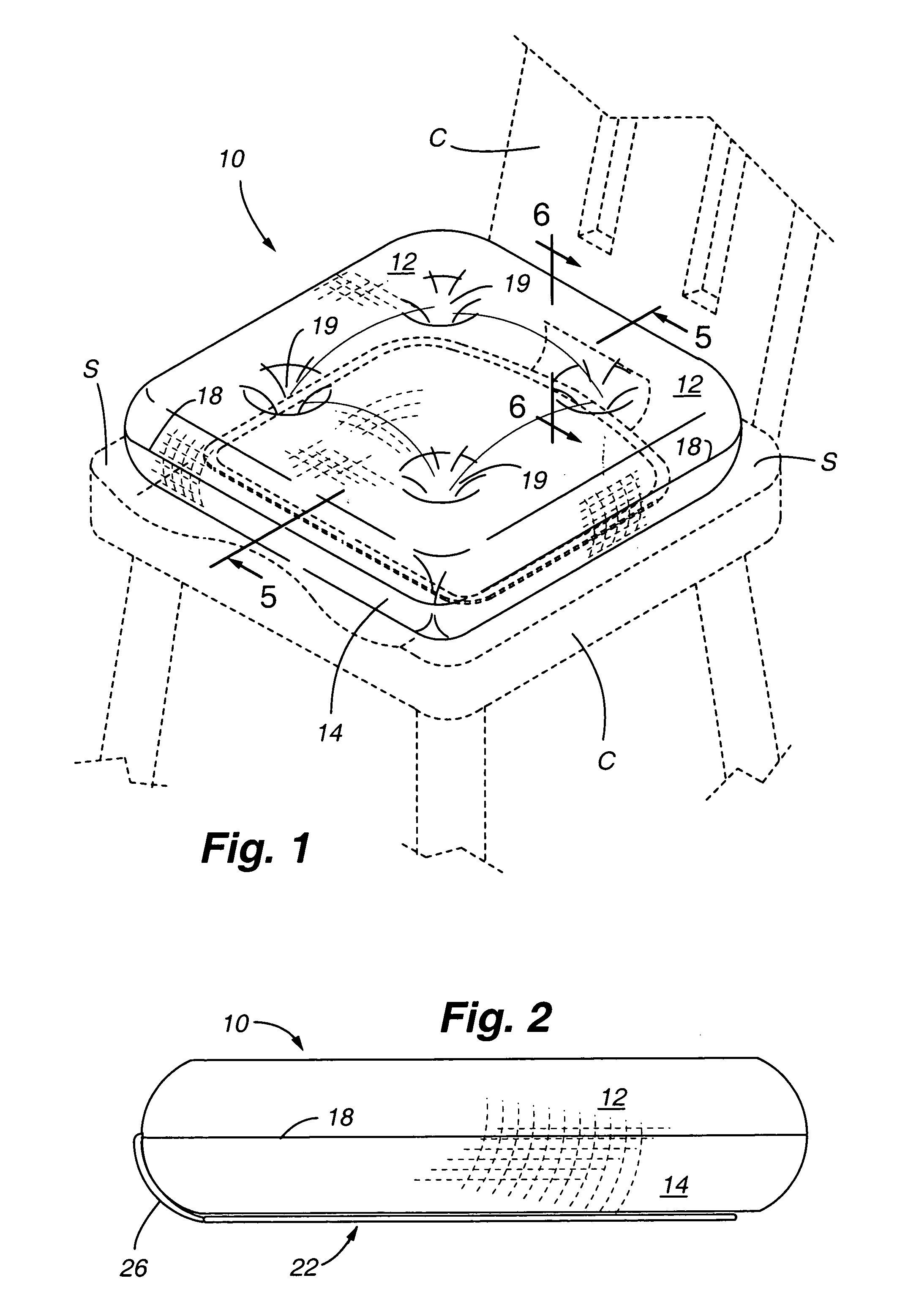

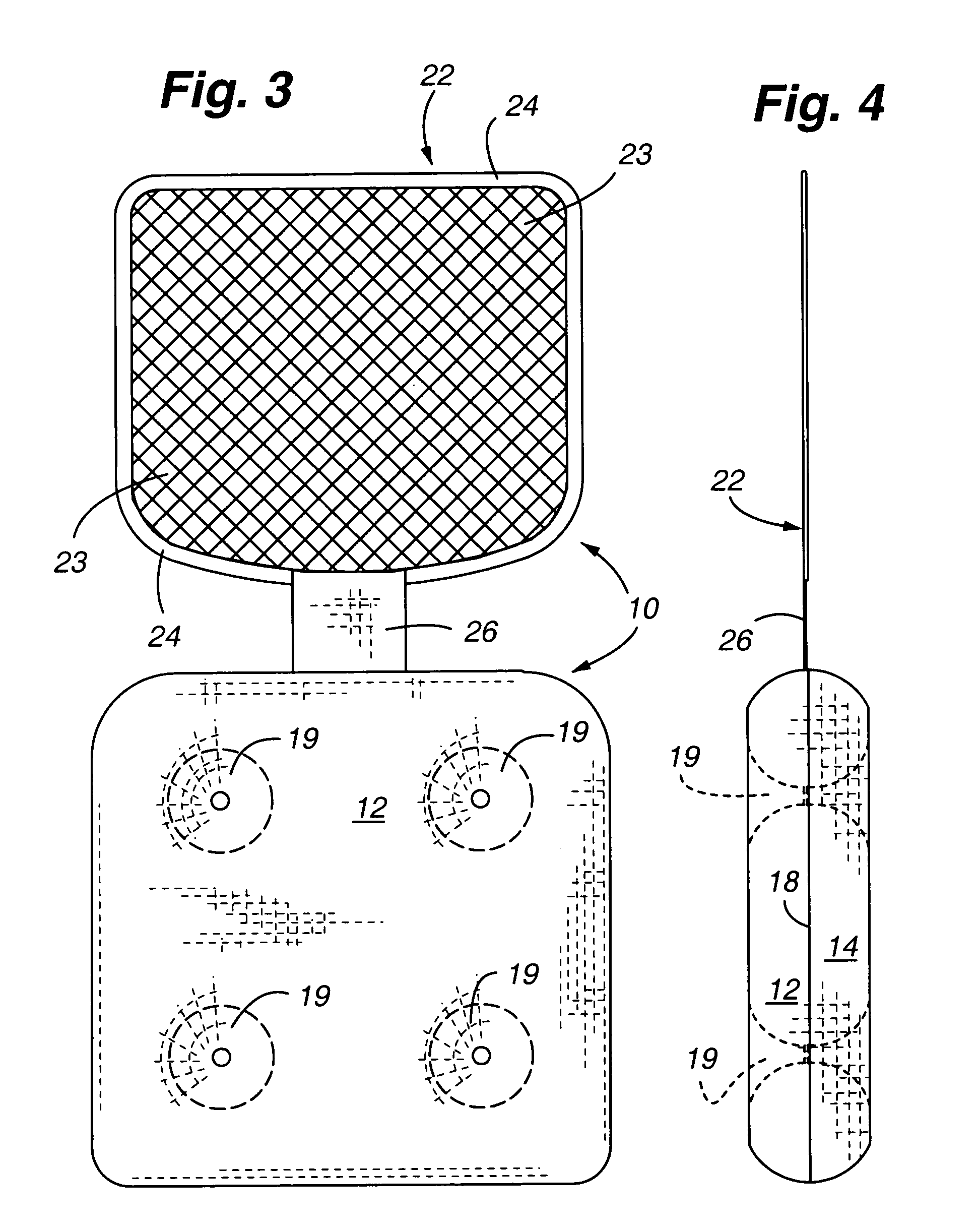

Seat cushion with gripping member

InactiveUS7207627B2Prevent slippingIncrease coefficient of frictionVehicle seatsSeating furnitureEngineeringCushion

A seat cushion is provided including an integral gripping member that prevents the cushion from sliding during use. The gripping member attaches to the cushion by a connecting strap which therefore allows the gripping member to be selectively placed in contact with either panel of the cushion. Accordingly, either one of the panels may be exposed during use which allows the seat cushion to be constructed of differing materials, colors or patterns for the respective panels. Additionally, damage to one of the panels still allows the gripping member to be used because the cushion can be reversed to expose the non-damaged panel.

Owner:NEW HARBOR

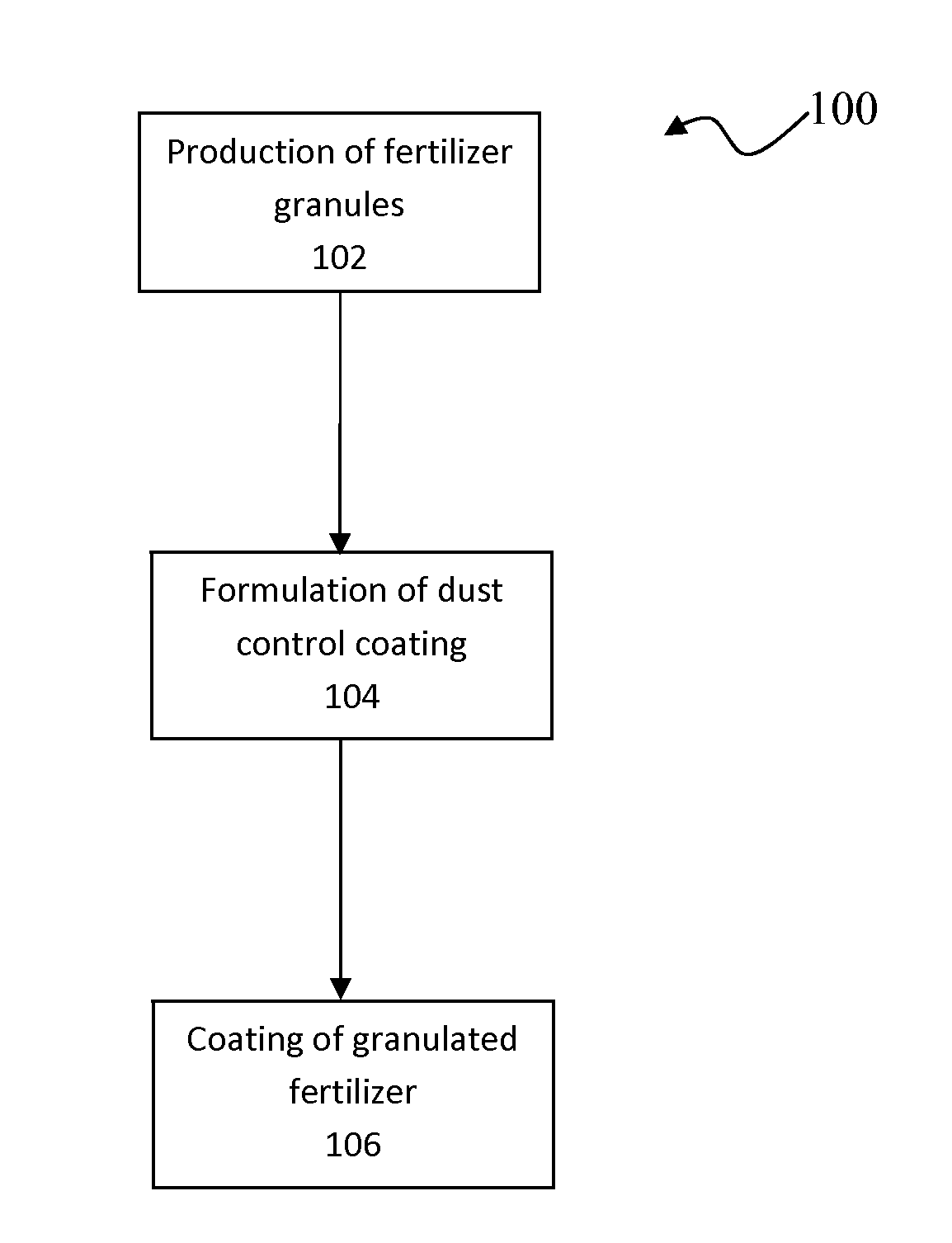

Granular fertilizers having improved dust control

InactiveUS20140137616A1Adequate dust controlHigh viscositySewage/sludge fertilisersUrea compound fertilisersParticulatesPolymer science

An oil-based coating for fertilizer granules impregnated with a polymer additive and related methods of applying the oil-based coating. The polymer additive can comprise homopolymers, copolymers, or combinations thereof, including polyethylene homopolymers. The polymer additive increases the viscosity of the oil-based coating, thereby increasing the duration for which the coating is capable of controlling or inhibiting the formation of dust particulates from the fertilizer granules.

Owner:THE MOSAIC COMPANY

Diamond Bonded Construction with Reattached Diamond Body

InactiveUS20110083909A1Reduce residual amountEnhance operate lifePigmenting treatmentDrill bitsMaterial structureMaterials science

Diamond bonded construction comprise a diamond body attached to a support. In one embodiment, an initial substrate used to sinter the body is interposed between the body and support, and is thinned to less than 5 times the body thickness, or to less than the body thickness, prior to attachment to the support to relieve stress in the body. In another embodiment, the substrate is removed after sintering, and the body is attached to the support. The support has a material construction different from that of the initial substrate, wherein the initial substrate is selected for infiltration and the support for end use properties. The substrate and support include a hard material with a volume content that may be the same or different. Interfaces between the body, substrate, and / or support may be nonplanar. The body may be thermally stable, and may include a replacement material disposed therein.

Owner:SMITH INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com