Gettering method for prolonging effective service life of crystalline silicon substrate

A technology of effective life and crystalline silicon, which is applied in the field of solar cells, can solve problems such as the inability to use solar cells to produce, and achieve the effects of improving photoelectric conversion performance, increasing life, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

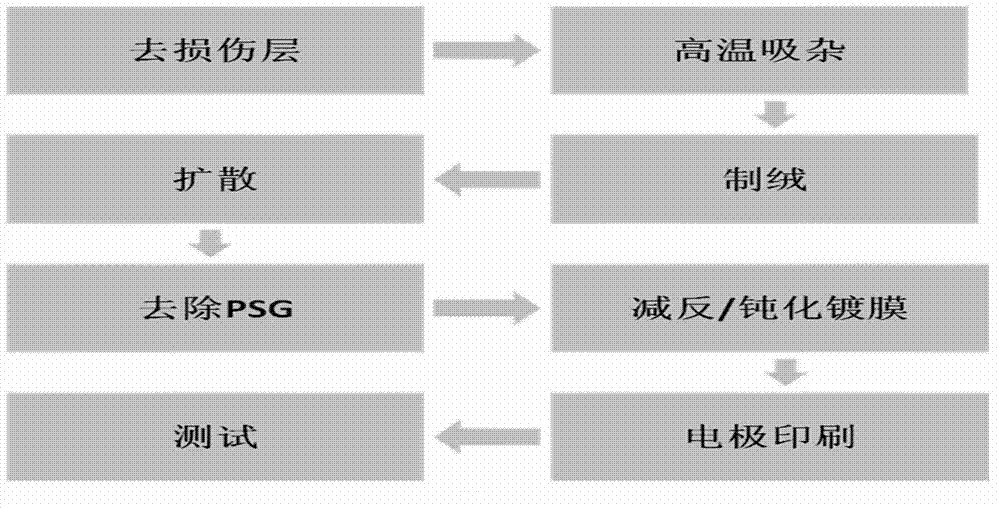

[0020] figure 1 Is the preparation flowchart of the solar cell in embodiment 1-3;

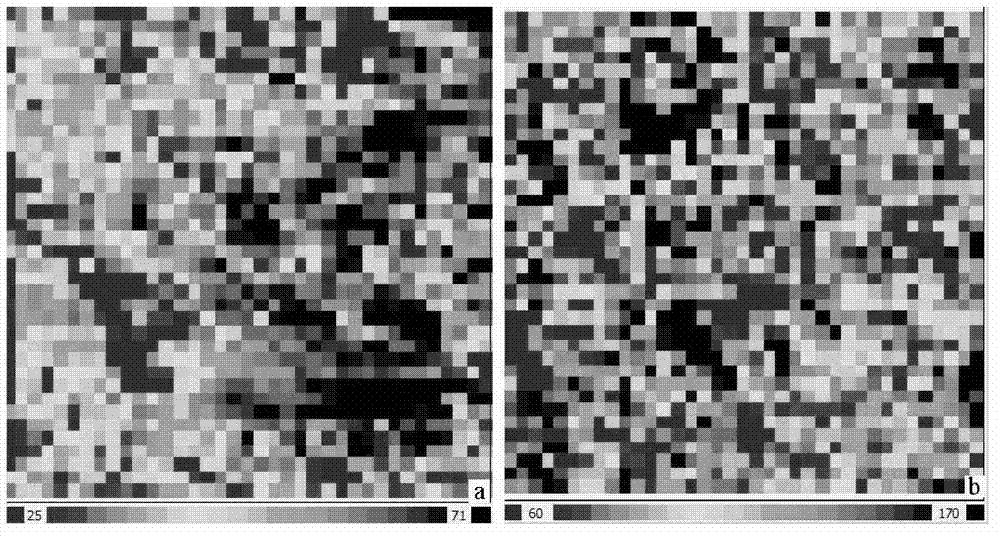

[0021] figure 2 It is the test data comparison of the high-temperature gettering in embodiment 1 applied to the minority carrier lifetime of p-type polysilicon wafer;

Embodiment 1

[0024] (1) Select a p-type polycrystalline silicon wafer with a resistivity of 0.5~5Ω·cm, and use a chemical solution to pre-clean the silicon wafer to remove the damaged layer on the surface of the silicon wafer before gettering. The chemical solution is hydrofluoric acid, hydrofluoric acid The mass percentage content of the silicon wafer is 10%, the cleaning time is 0.5-60 minutes, the temperature is 5-90°C, and the weight loss range of the silicon wafer after removal is: 0.1g-0.5g.

[0025] (2) Diffusion gettering of heavy phosphorus

[0026] Phosphorus oxychloride liquid source is used to carry out heavy phosphorus diffusion and gettering in an industrial tubular diffusion furnace, which is divided into two processes, one is the constant temperature process of phosphorus diffusion, and the other is the variable temperature process of phosphorus gettering; The temperature in the constant temperature zone is 850°C, the diffusion time is 50 minutes, and the diffusion square r...

Embodiment 2

[0042] (1) Select a p-type single crystal silicon wafer with a resistivity of 0.5~5Ω·cm, and use a chemical solution to pre-clean the silicon wafer before gettering to remove the damaged layer on the surface of the silicon wafer. The chemical solution is hydrofluoric acid, hydrogen The mass percentage of hydrofluoric acid is 40%, the cleaning time is 0.5-60 minutes, the temperature is 5-90°C, and the weight loss range of the silicon wafer after removal is: 0.1g-0.5g.

[0043] (2) Diffusion gettering of heavy phosphorus

[0044] Phosphorus oxychloride liquid source is used to carry out heavy phosphorus diffusion and gettering in an industrial tubular diffusion furnace, which is divided into two processes, one is the constant temperature process of phosphorus diffusion, and the other is the variable temperature process of phosphorus gettering. In the constant temperature process of phosphorus diffusion, the temperature in the constant temperature zone is 900°C, the diffusion tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com