Modular skid frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention may be embodied in a number of different forms. However, the specification and drawings that follow describe and disclose only some of the specific forms of the invention and are not intended to limit the scope of the invention as defined in the claims that follow herein.

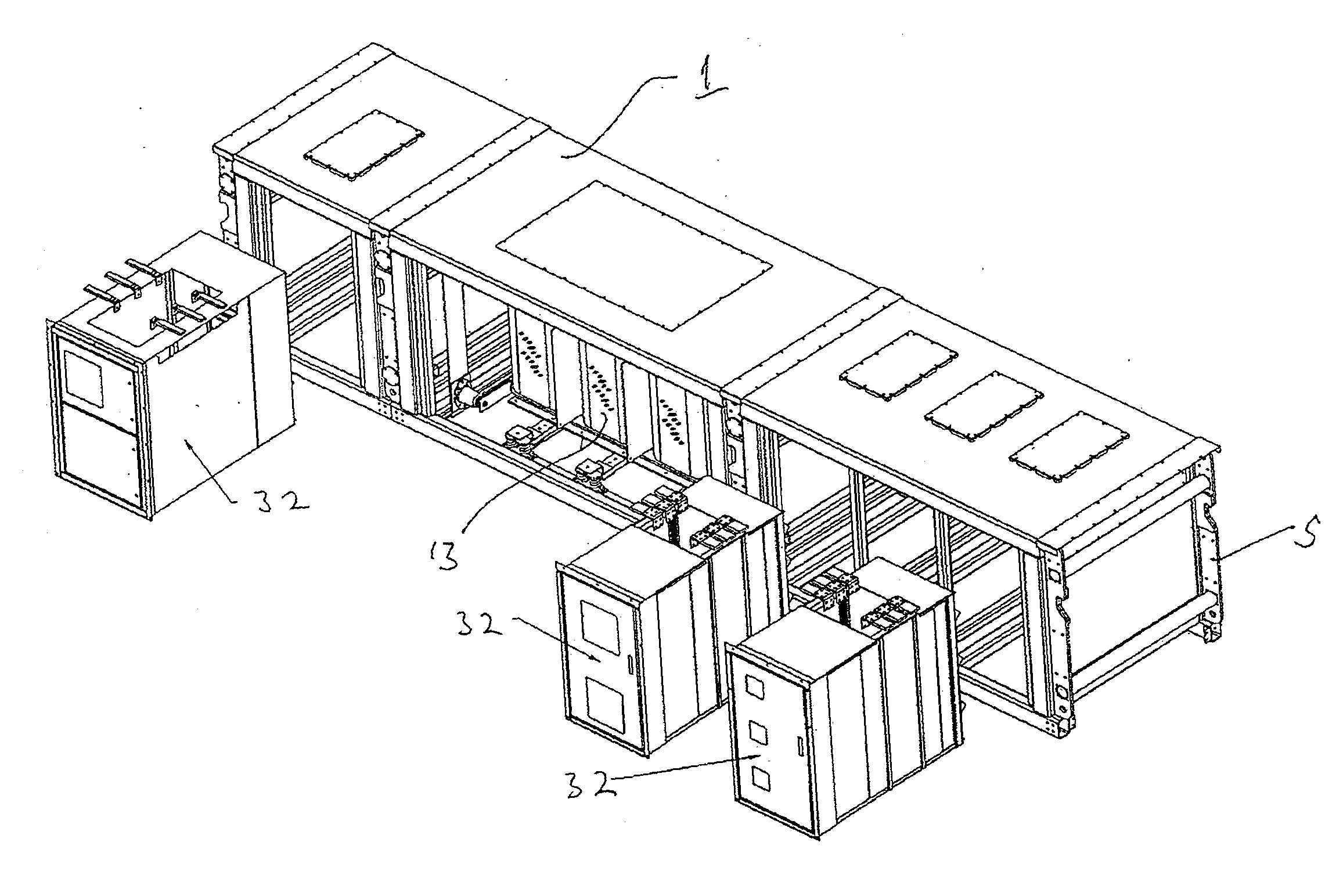

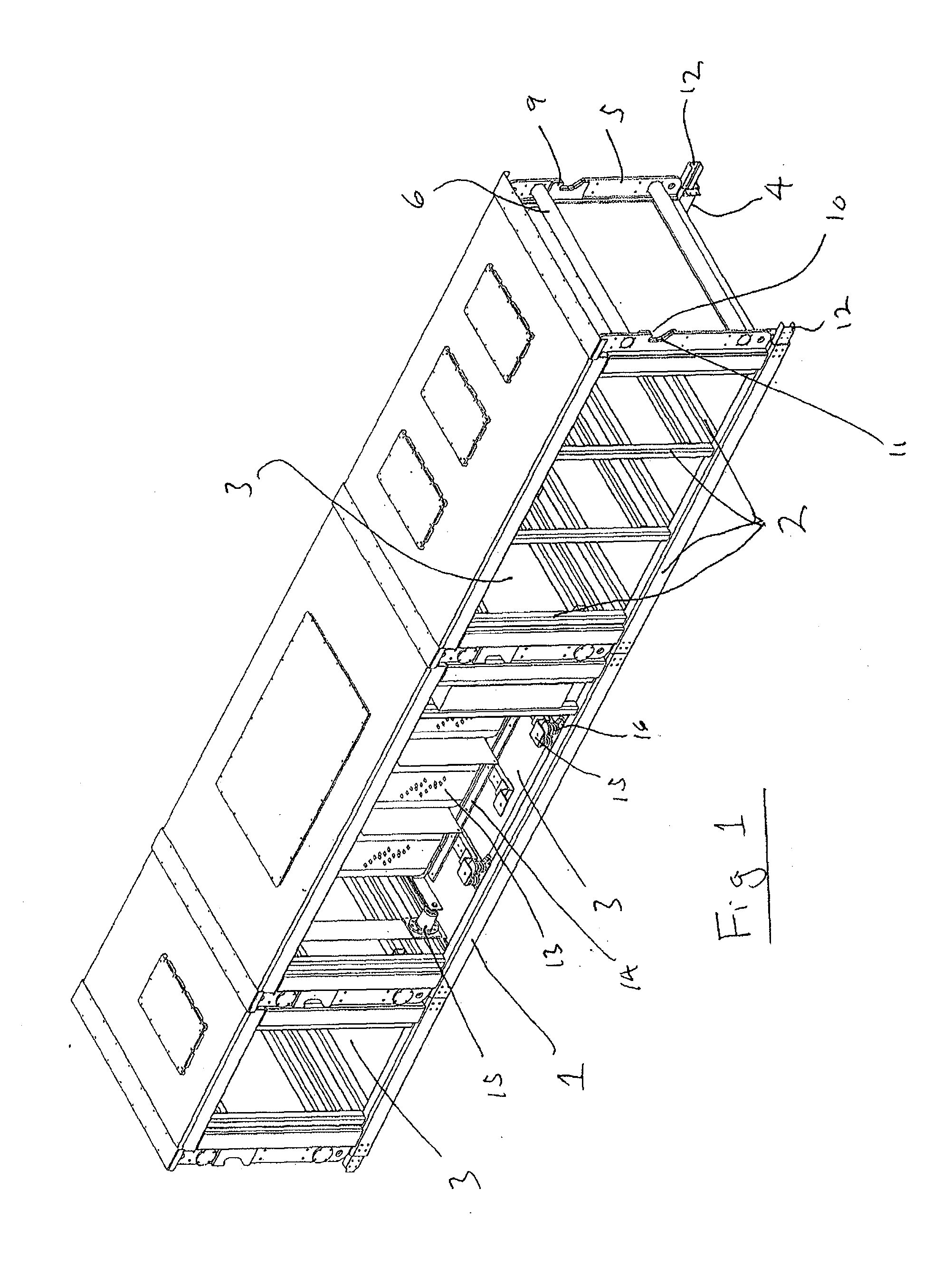

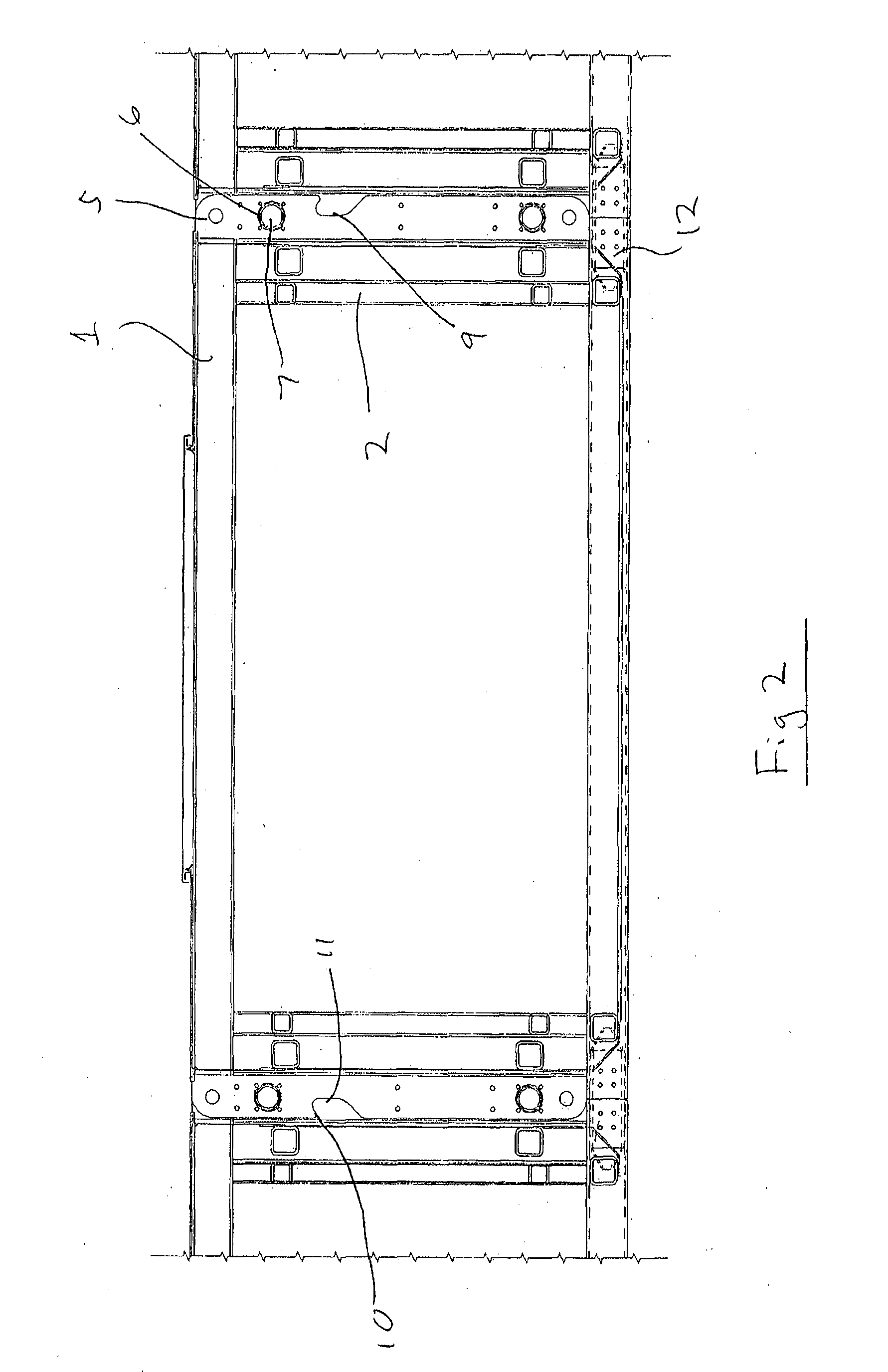

[0033]With reference to FIG. 1, a modular skid frame constructed in accordance with one of the preferred embodiments of the present invention is noted generally by reference number 1. Skid frame 1 is comprised generally of a plurality of frame members 2 which would in most cases be constructed of a high strength material, such a as steel, a steel alloy or a composite. Depending up the particular application, the frame members may be subjected to hardening or heat treating processes, may be painted, coated for corrosion resistance, or have any one of a wide variety of other treatments applied to them. Typically the frame members would be assembled in a fashion to form one or more semi-encl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com