Tube shields having a thermal protective layer

a technology of thermal protective layer and tube shield, which is applied in the direction of corrosion prevention, steam boiler components, metal-working apparatuses, etc., can solve the problems of high corrosive environment, high corrosive environment, and high temperature exposure of boiler tubes employed in combustion chambers, so as to reduce maintenance costs, prolong effective repair and replacement cycles, and reduce overall cost of utility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

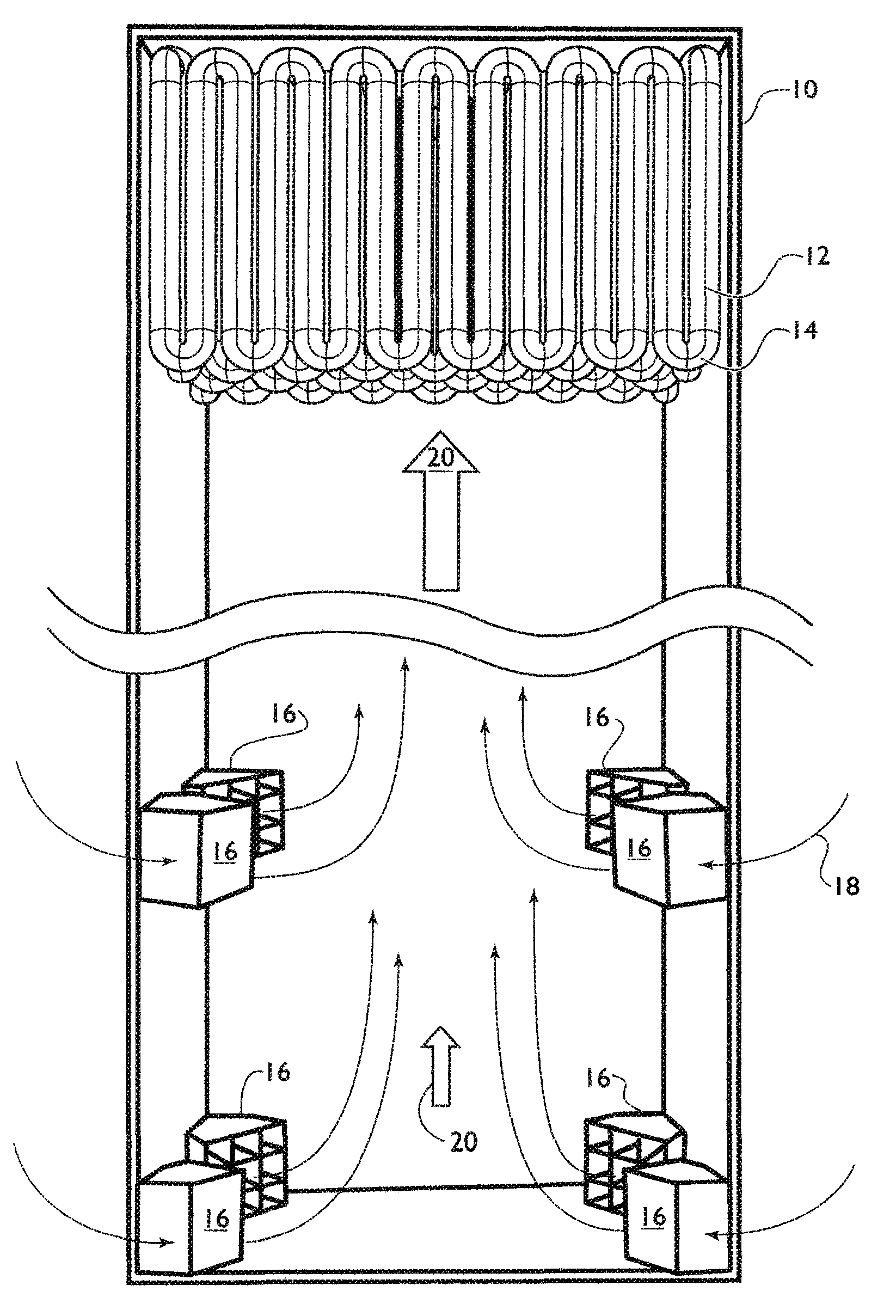

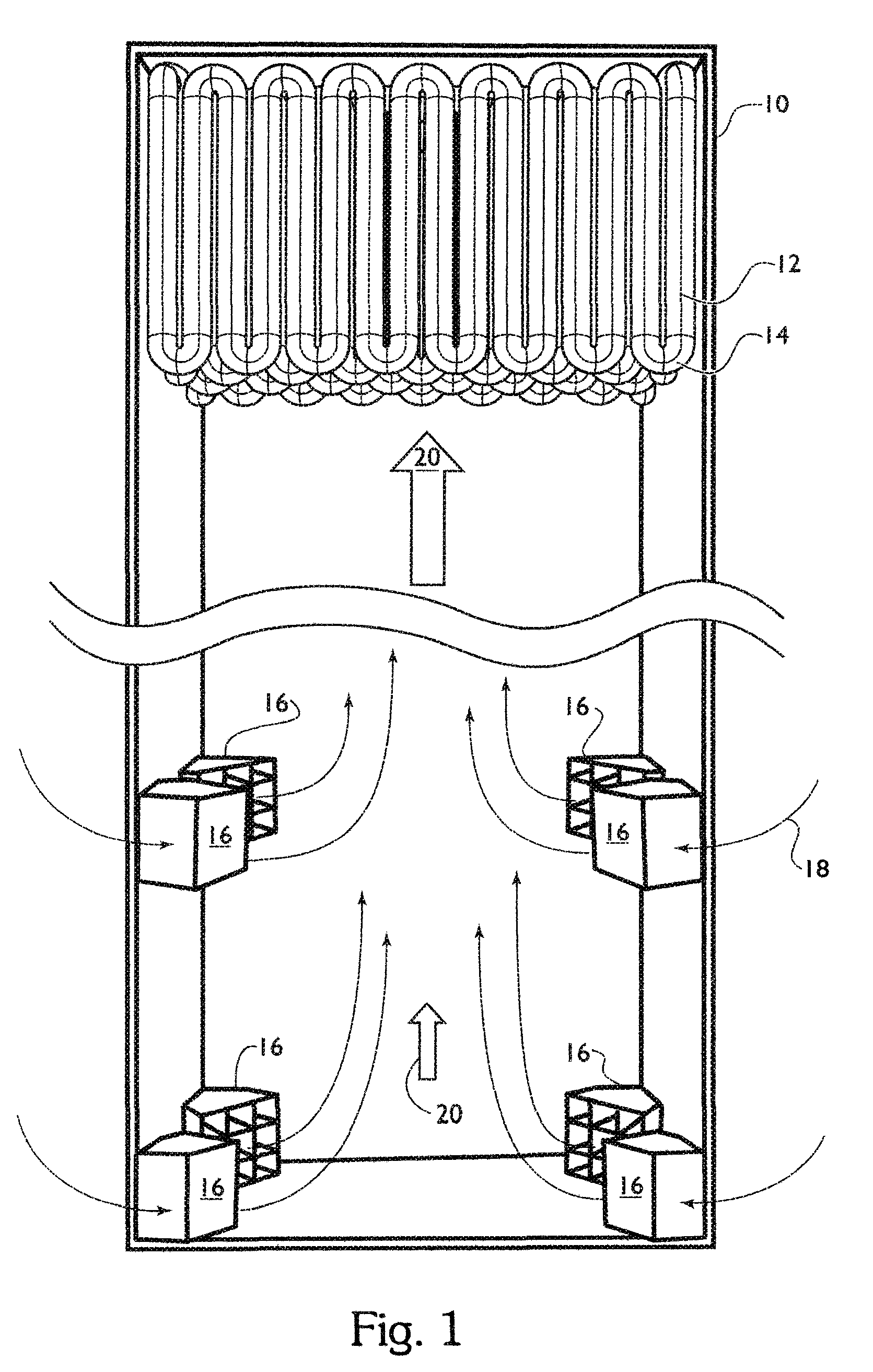

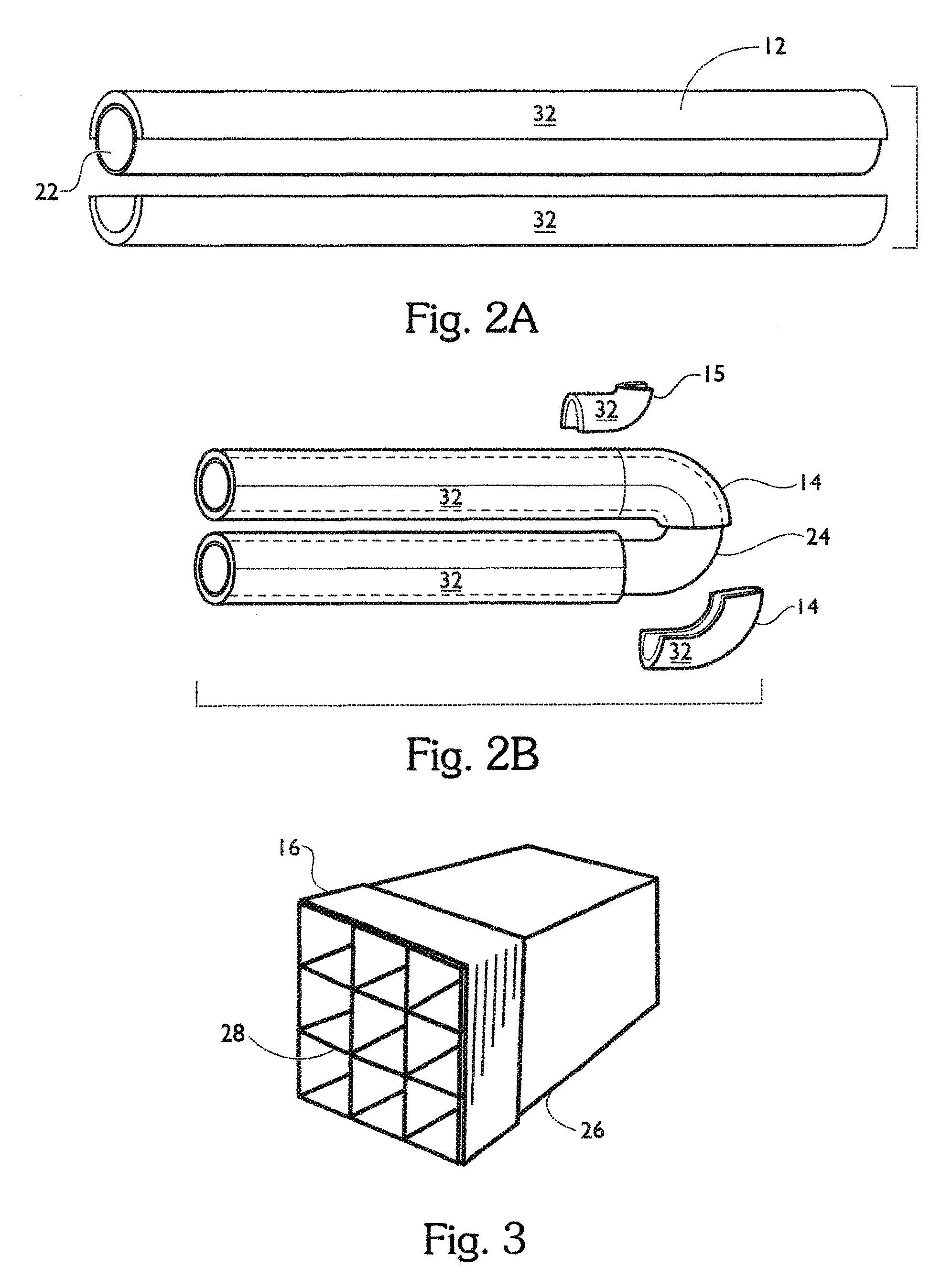

[0041]The present invention is described herein in light of a tangentially fired coal-burning furnace utilizing half shell tube shields 12, graphically represented in FIGS. 1, 2A, 2B, 4A, 4B, 5A, 5B, 5C, and 7 by example only, and is not limited to such a furnace and tube shield 12 designs, or applications. In a tangentially fired furnace, burner tips 16, shown in FIG. 3, may be located at each corner of a combustion chamber 10 having a square-shaped floor / ceiling. The axis of each burner tip 16 may be offset with respect to a central axis of the combustion chamber 10 and extend generally tangent to an imaginary cylinder, which defines a combustion zone 20, as shown in FIG. 1, where a fireball is generated during operation of the burner tips 16. Burner tips 16 are also customarily referred to simply as “burners”. Tangentially fired furnaces are used to heat many utility boilers, especially for the generation of energy from fossil fuel sources such as coal, propane, oil, petroleum, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com