Prefabricated panel installation device

An installation device and a technology for prefabricated wall panels, which are applied in the construction, building structure, processing of building materials, etc., can solve the problems of difficult installation, falling incidents and hazards from high-altitude falling objects, and slow installation efficiency, so as to prevent falling incidents. and the effect of falling objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

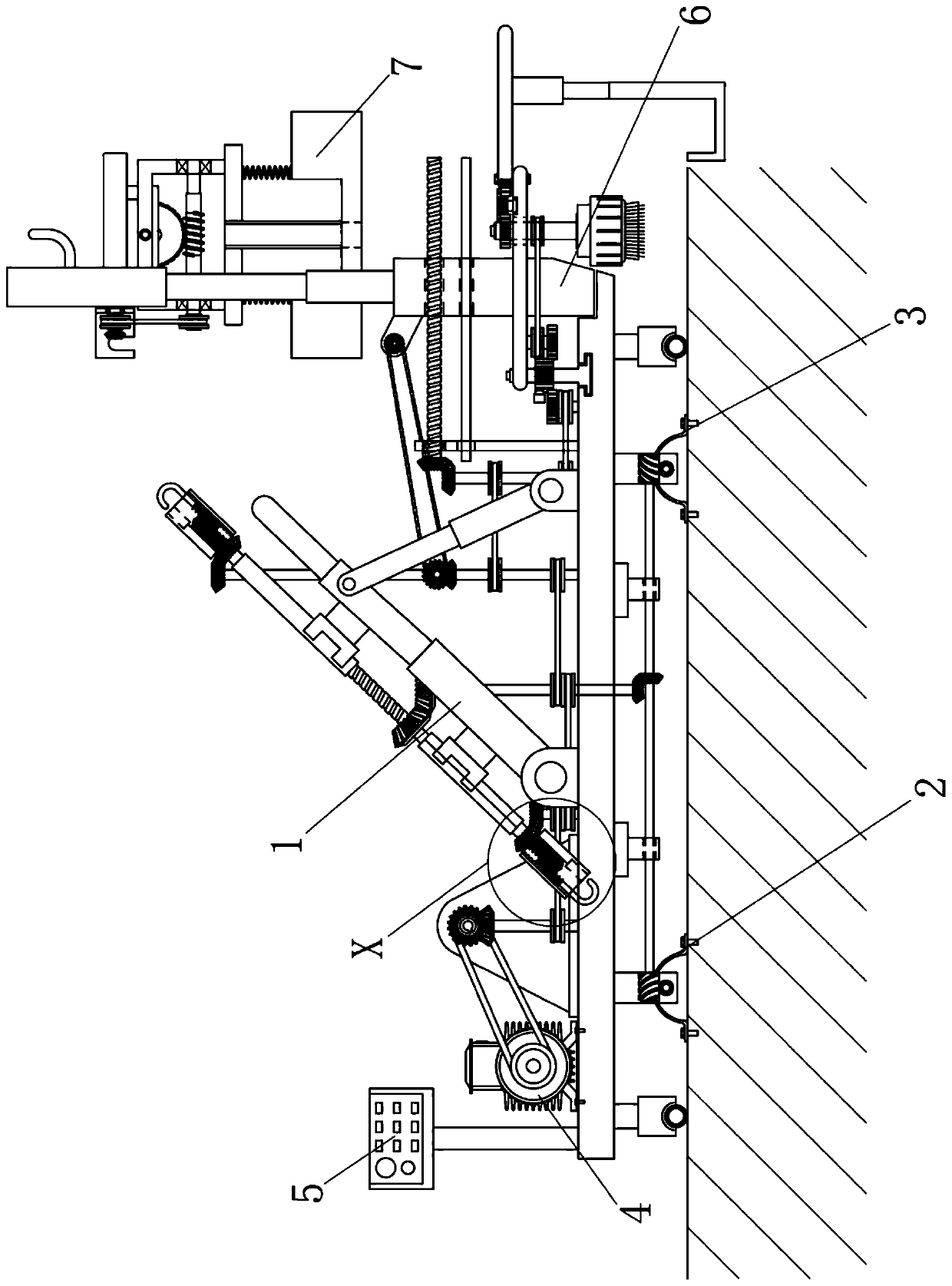

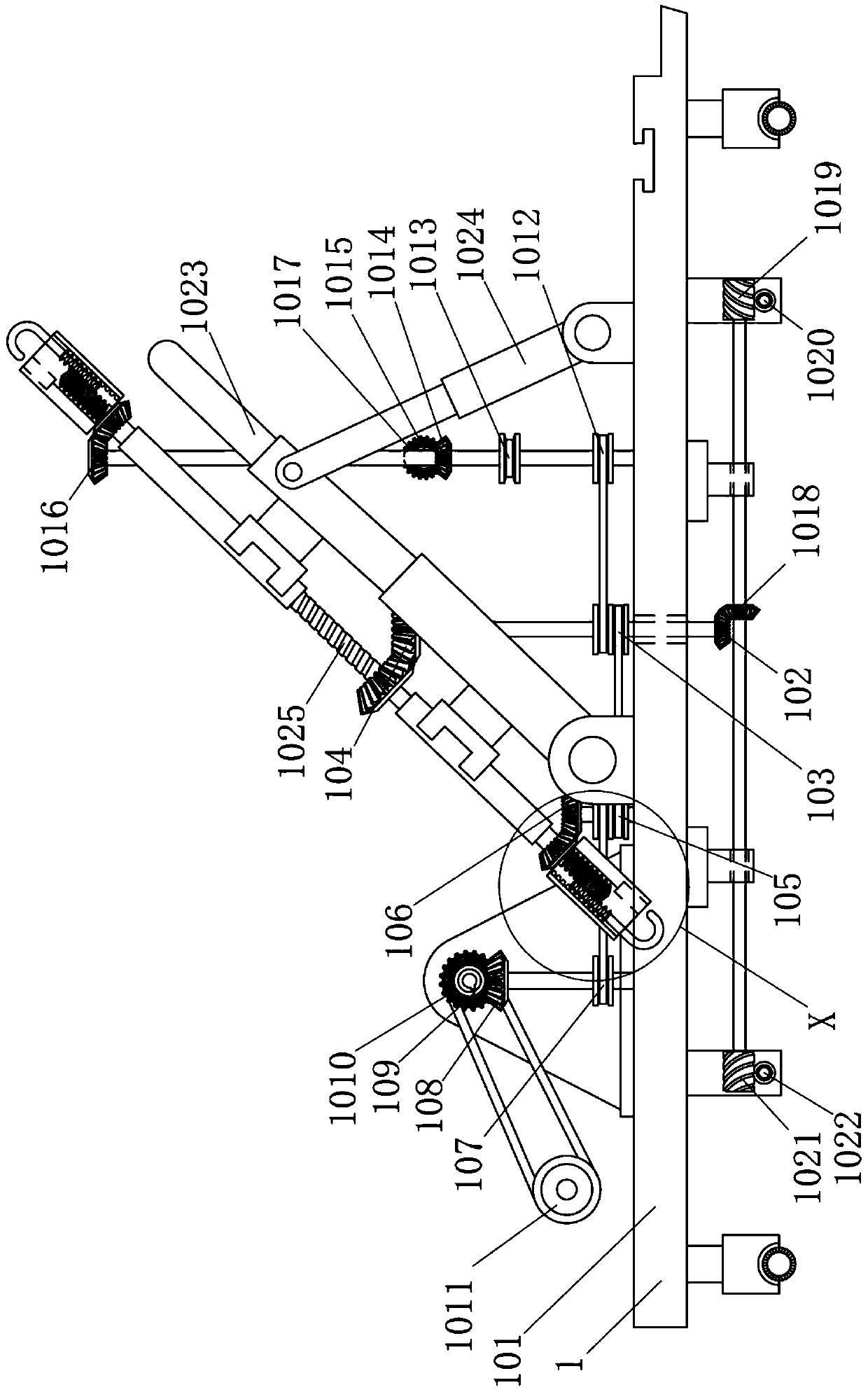

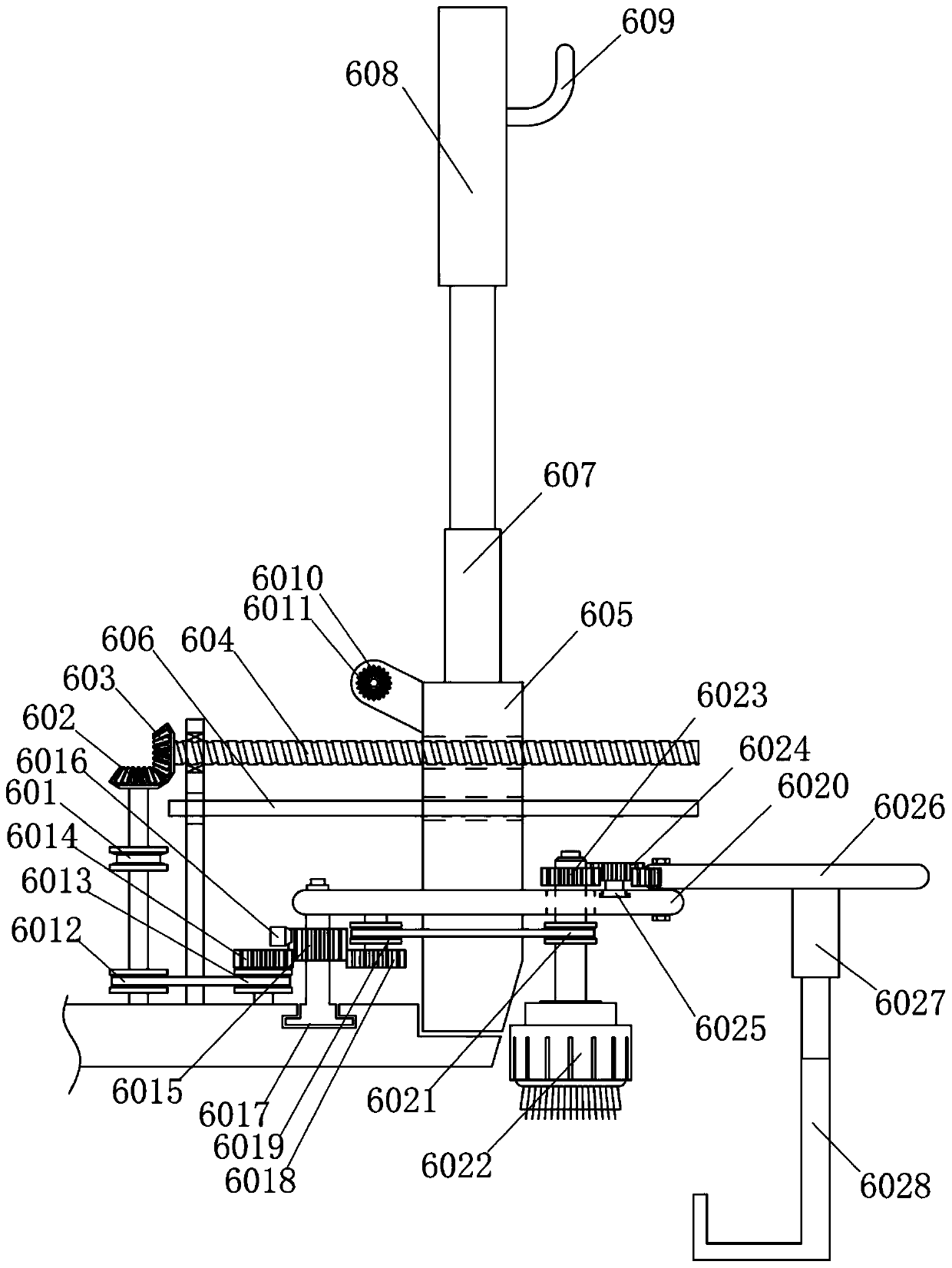

[0029] A prefabricated wall panel installation such as Figure 1-8 As shown, it includes a diagonal brace locking mechanism 1, a first bottom suspension ring 2, a second bottom suspension ring 3, a stepping motor 4, a control display 5, an installation attitude adjustment mechanism 6 and a steel bar straightening mechanism 7; the diagonal brace locking mechanism 1 The left part of the bottom end is provided with a first bottom suspension ring 2; the bottom right part of the diagonal brace locking mechanism 1 is provided with a second bottom suspension ring 3; the top left part of the diagonal brace locking mechanism 1 is bolted to the stepper motor 4; the control display 5 is located on the left side of the stepper motor 4; the top right part of the diagonal brace locking mechanism 1 is connected with the installation posture adjustment mechanism 6; the top right part of the diagonal brace locking mechanism 1 is connected with the steel bar straightening mechanism 7, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com