Mechanical tensile experiment testing device

A testing device and experiment technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve the problems of vulnerable and experimental personnel, lack of protection mechanism, low safety factor, etc., to achieve economical The effect of experiment time, improving safety factor and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

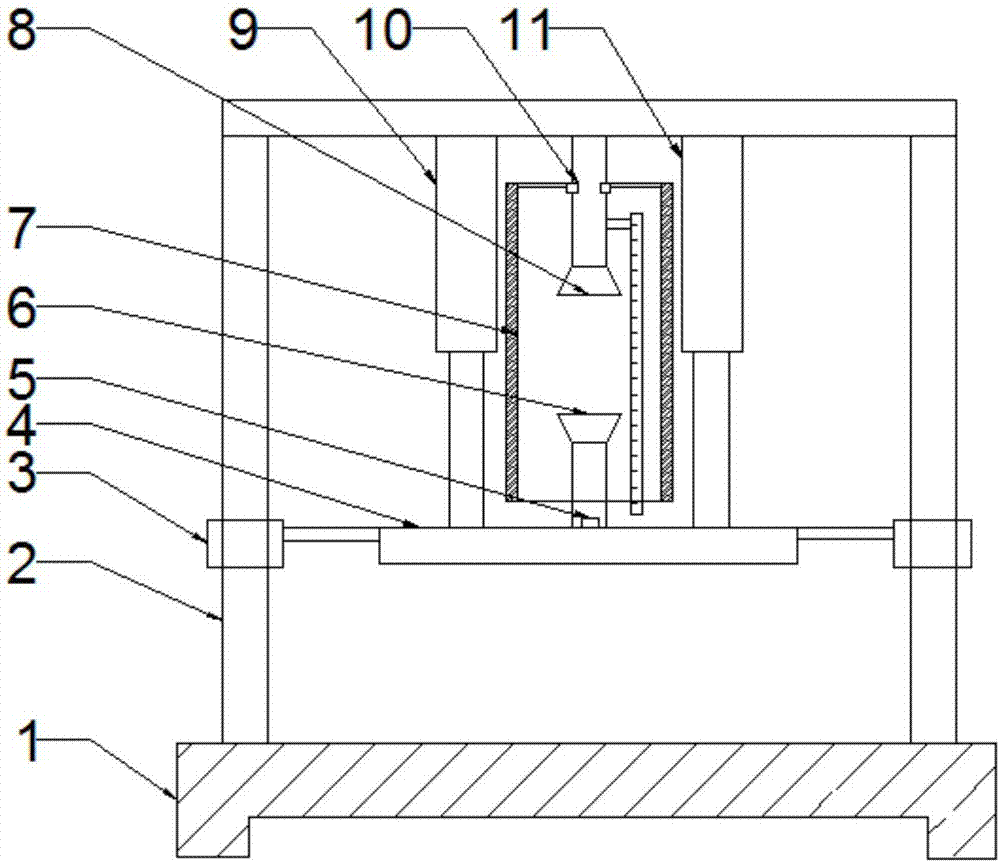

[0032] Such as figure 1 As shown, a kind of mechanical tensile experiment test device of the present invention comprises base 1, door-shaped frame 2, sliding collar 3, platform 4, load sensor 5, lower clamp 6, protective cylinder 7, upper clamp 8, the first Oil cylinder 9, second oil cylinder 11;

[0033] The top of the base 1 is fixed with a door-shaped frame 2, the column of the door-shaped frame 2 is provided with a sliding collar 3 slidingly connected with it, and the bottom end of the beam of the door-shaped frame 2 is fixedly provided with a first oil cylinder 9 and a second oil cylinder 11. , the first oil cylinder 9 and the second oil cylinder 11 are arranged vertically downward, and the left and right sides of the platform 4 are respectively fixedly arranged at the ends of the piston rods of the first oil cylinder 9 and the second oil cylinder 11;

[0034] The bottom end of the crossbeam of the portal frame 2 is fixedly provided with an upper clamp 8, the upper clamp...

Embodiment 2

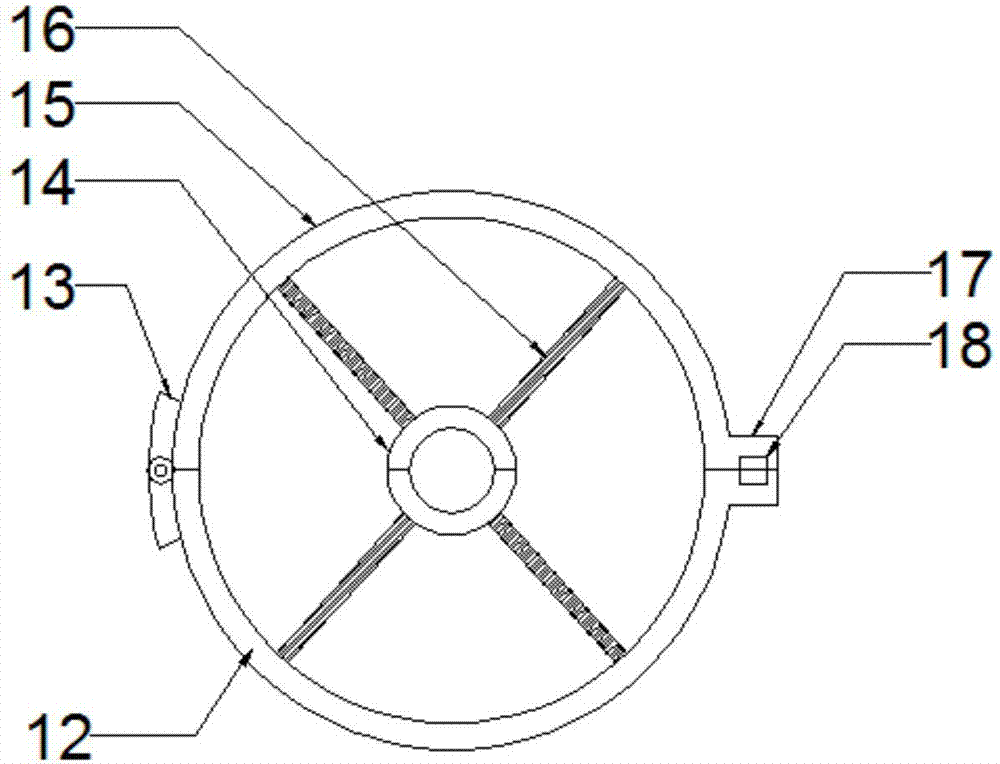

[0046] Such as figure 2 As shown, this embodiment is improved on the basis of Embodiment 1. The protective cylinder 7 includes a first half cylinder 12, a hinge 13, a locking half ring 14, a second half cylinder 15, a connecting frame 16, and a positioning protrusion. Edge 17;

[0047] One end of the first half cylinder 12 and the second half cylinder 15 is hinged together by a hinge 13, and the other end is a free end. The free ends of the first half cylinder 12 and the second half cylinder 15 are all provided with a positioning flange 17, The positioning flange 17 and the corresponding first half cylinder 12 or the second half cylinder 15 are in an integral structure, and the positioning flange 17 is provided with fixing parts, and the fixing parts fix the two positioning flanges 17 together, so that the first half The cylinder 12 and the second half cylinder 15 are fixed together;

[0048] The inner tops of the first half tube 12 and the second half tube 15 are provided ...

Embodiment 3

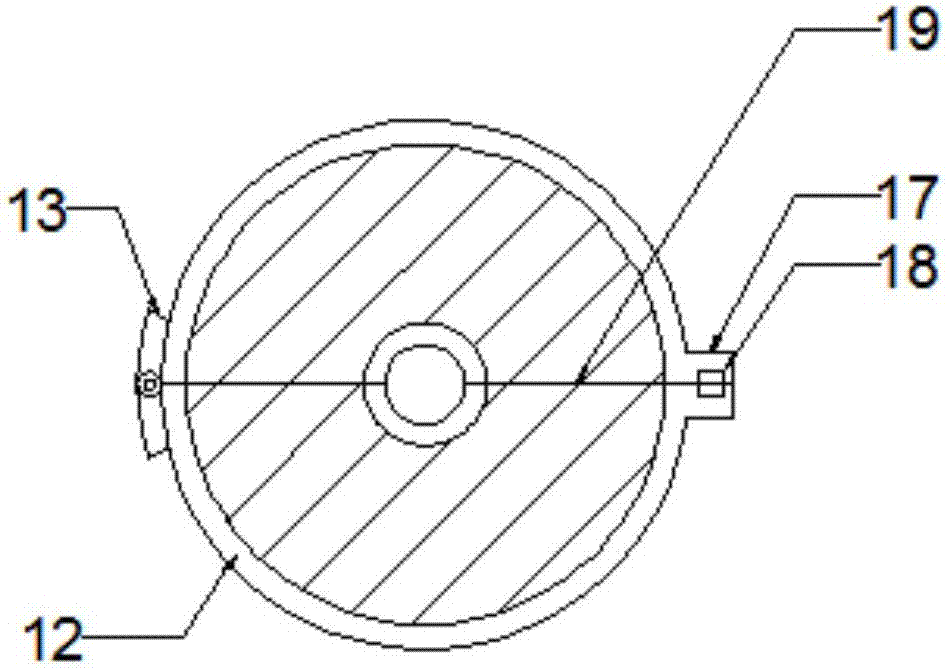

[0057] This embodiment is improved on the basis of embodiment 2, as image 3 as shown,

[0058] The tops of the first half cylinder 12 and the second half cylinder 15 are provided with a semicircular shield 19 , which is arranged between the cylinder walls of the first half cylinder 12 , the second half cylinder 15 and the locking half ring 14 .

[0059] 【Way of working】

[0060] The setting of the semicircular shield 19 can effectively prevent the material to be tested from popping up from the upper and lower ends of the protection tube 7 when it falls off or breaks, further improving the safety factor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com