All-terrain hybrid power chassis

A hybrid and all-terrain technology, applied in the field of agricultural machinery, can solve the problems of being unsuitable for long-distance, long-time and heavy-duty operations, limited power and battery life, and large driving resistance, so as to simplify the chassis drive device and improve The effect of energy utilization rate and obstacle surmounting ability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

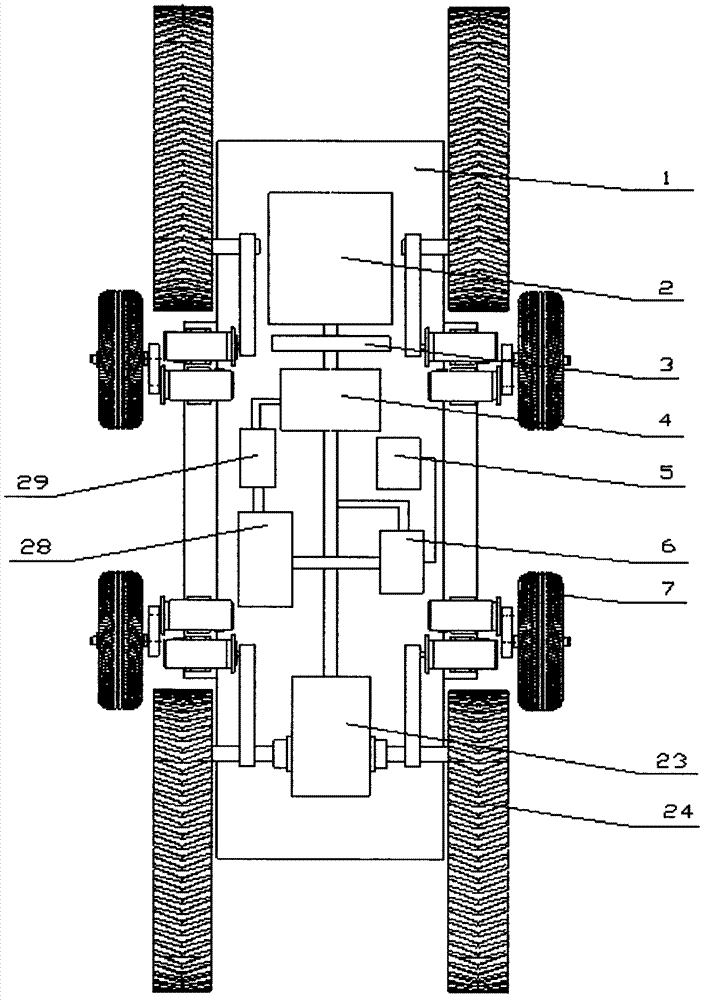

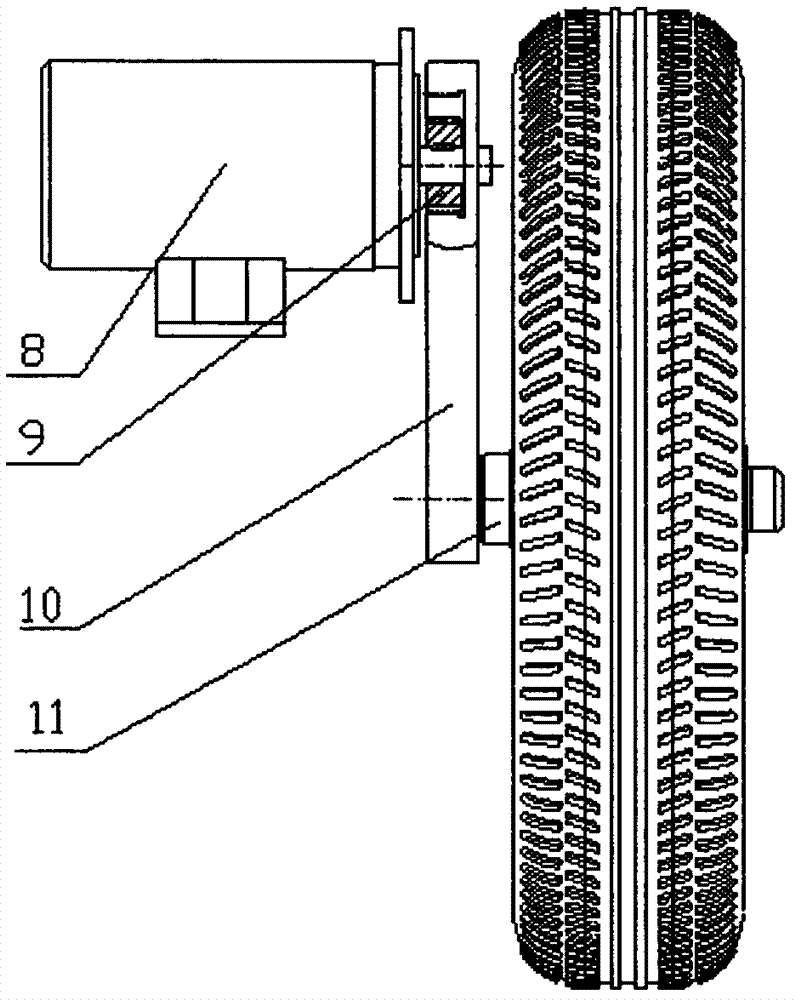

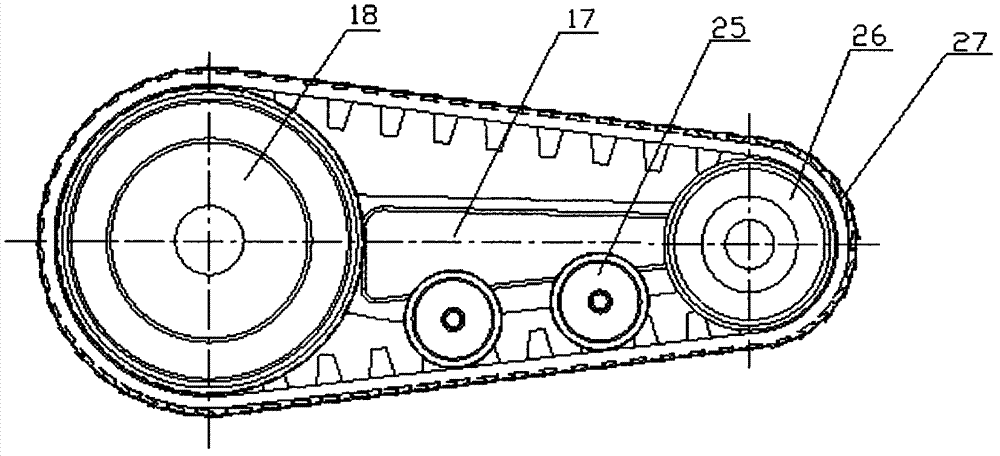

[0022] Such as figure 1 As shown, the present invention can lift the drive wheel mechanism (7), crawler belt swing arm mechanism (24) and hybrid power device. Four groups of liftable driving wheel mechanisms (7) and two sets of crawler track swing arm mechanisms (24) are respectively placed on both sides of the vehicle frame (1), and the hybrid power device is then arranged on the vehicle frame (1).

[0023] Described hybrid device comprises diesel engine (2), clutch (3), alternator (4), rectifier (29), storage battery (28), electric motor (6) and control unit (5), diesel engine (2 ) is connected with the alternator (4) via the clutch (3), drives the alternator (4) to generate electricity, and the current is stored in the battery (28) through the rectifier (29), and the battery (28) drives the motor (6), and the clutch (3 ) is turned on, the battery (28) dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com