Patents

Literature

231 results about "Side lying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

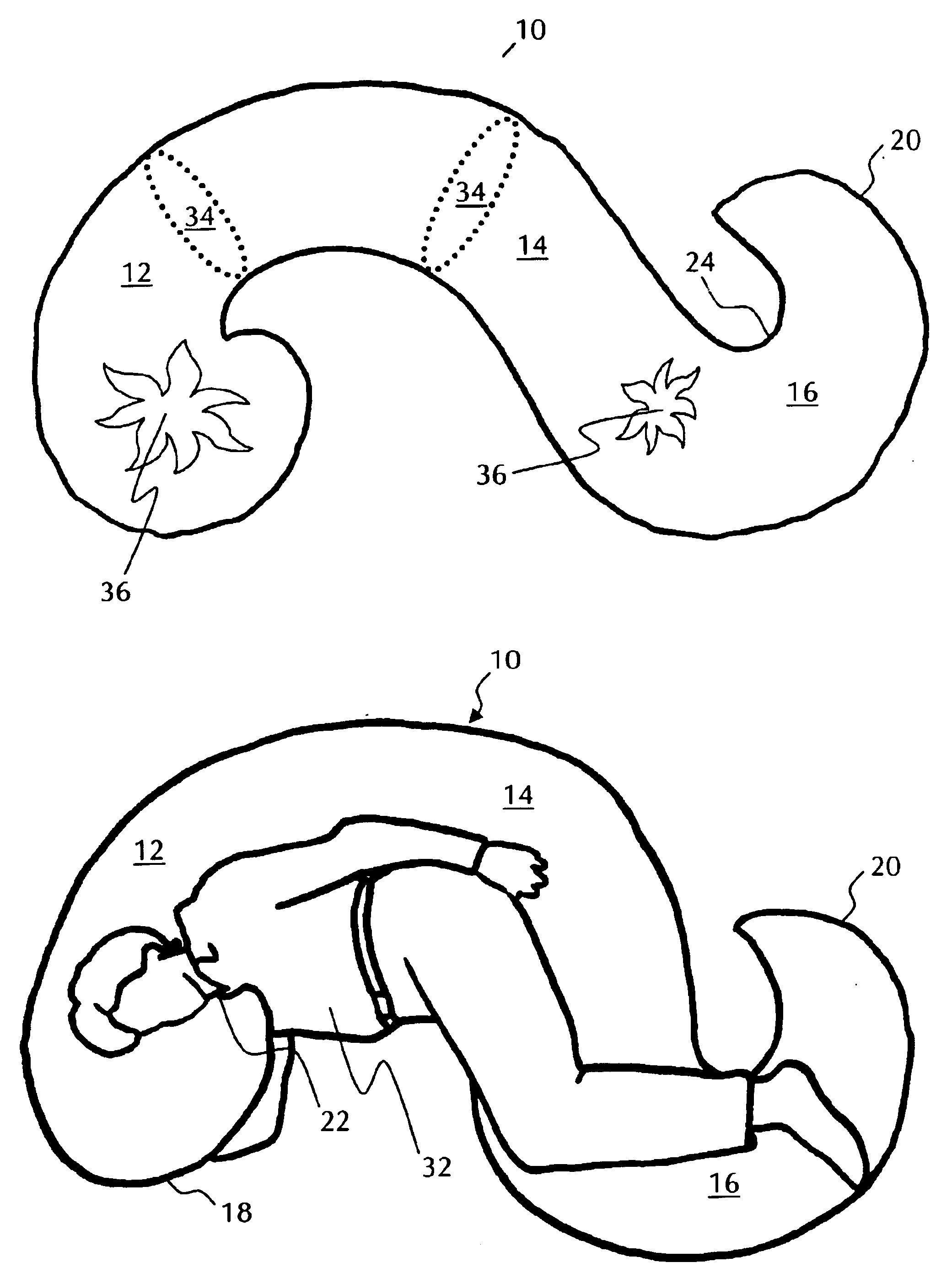

S-shaped pillow for flexible body support

InactiveUS6874183B1Improve cooling effectContributing to quality restSofasBedsRange of motionSide lying

A body support pillow having a semi-toroidal head support section (12), a substantially straight tubular back support section (14), and a semi-toroidal leg support section (16). To enhance range of motion, the head support section (12) terminates distally in a flared end (18), while the leg support section terminates distally in a tapered end (20). The proximate ends of the head support section (12) and the leg support section (16) are joined to the back support section (14) in an opposing manner to form an S-shaped pillow overall. Made of resilient and pliable material, the invention provides for direct, simultaneous, integrated, and flexible support of the head, back, legs, and feet of a side-lying individual, while allowing the ventral portion of the body to remain unobstructed. Hence the S-shaped body support pillow can be used to provide less stressful positions for anatomical members, contributing thereby to quality rest and sleep.

Owner:TAYLOR MIRIAM LOUISE

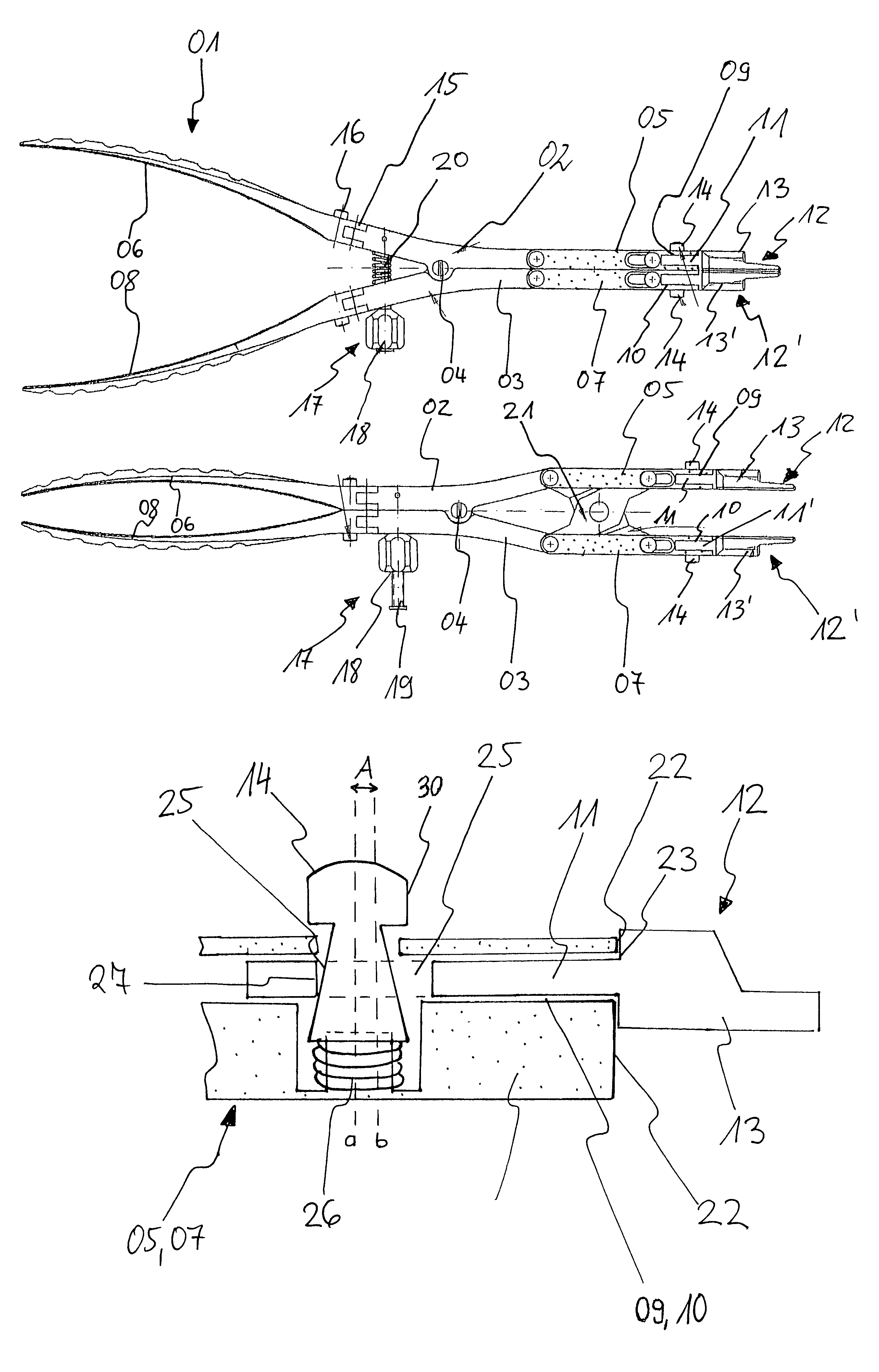

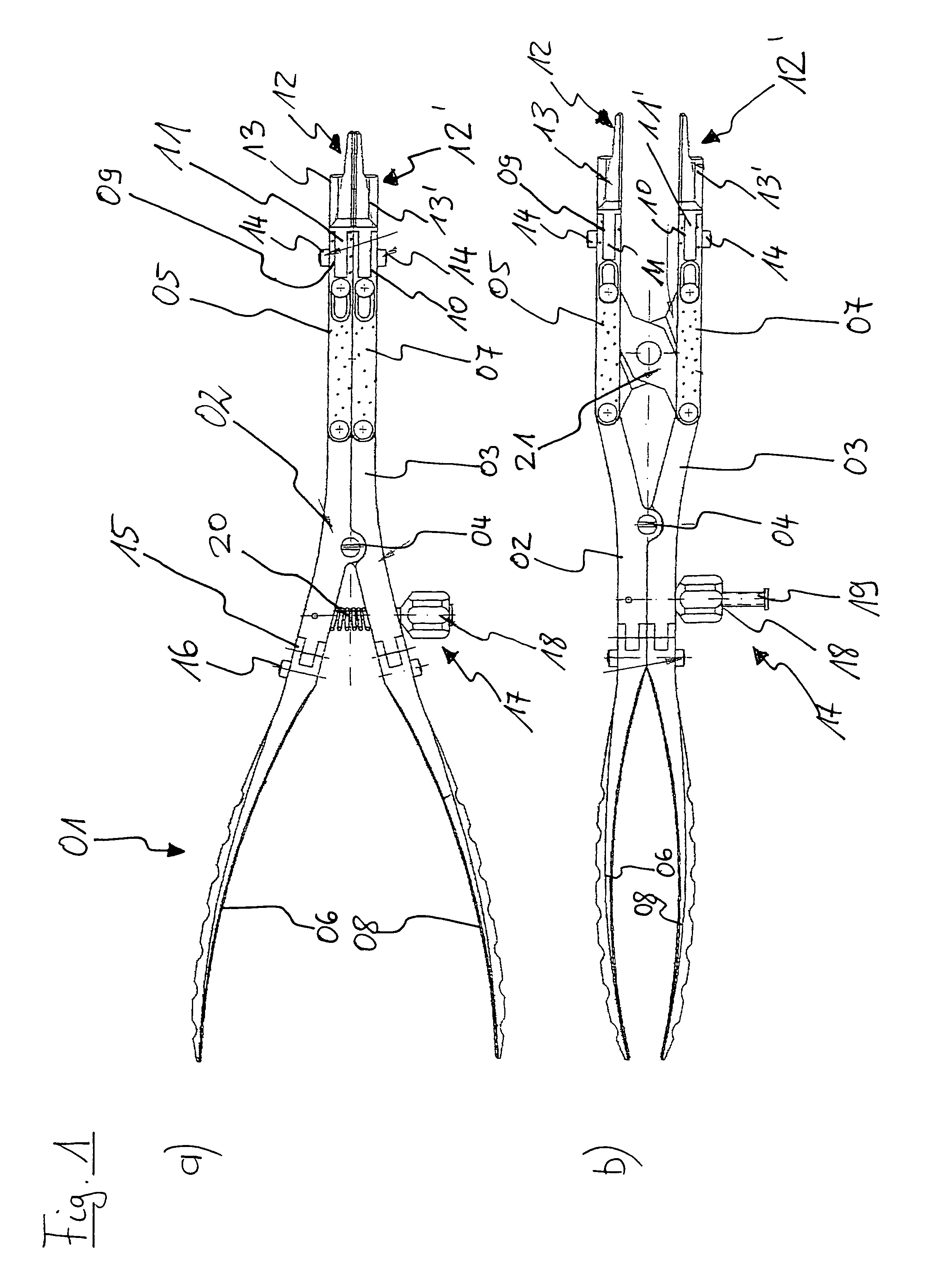

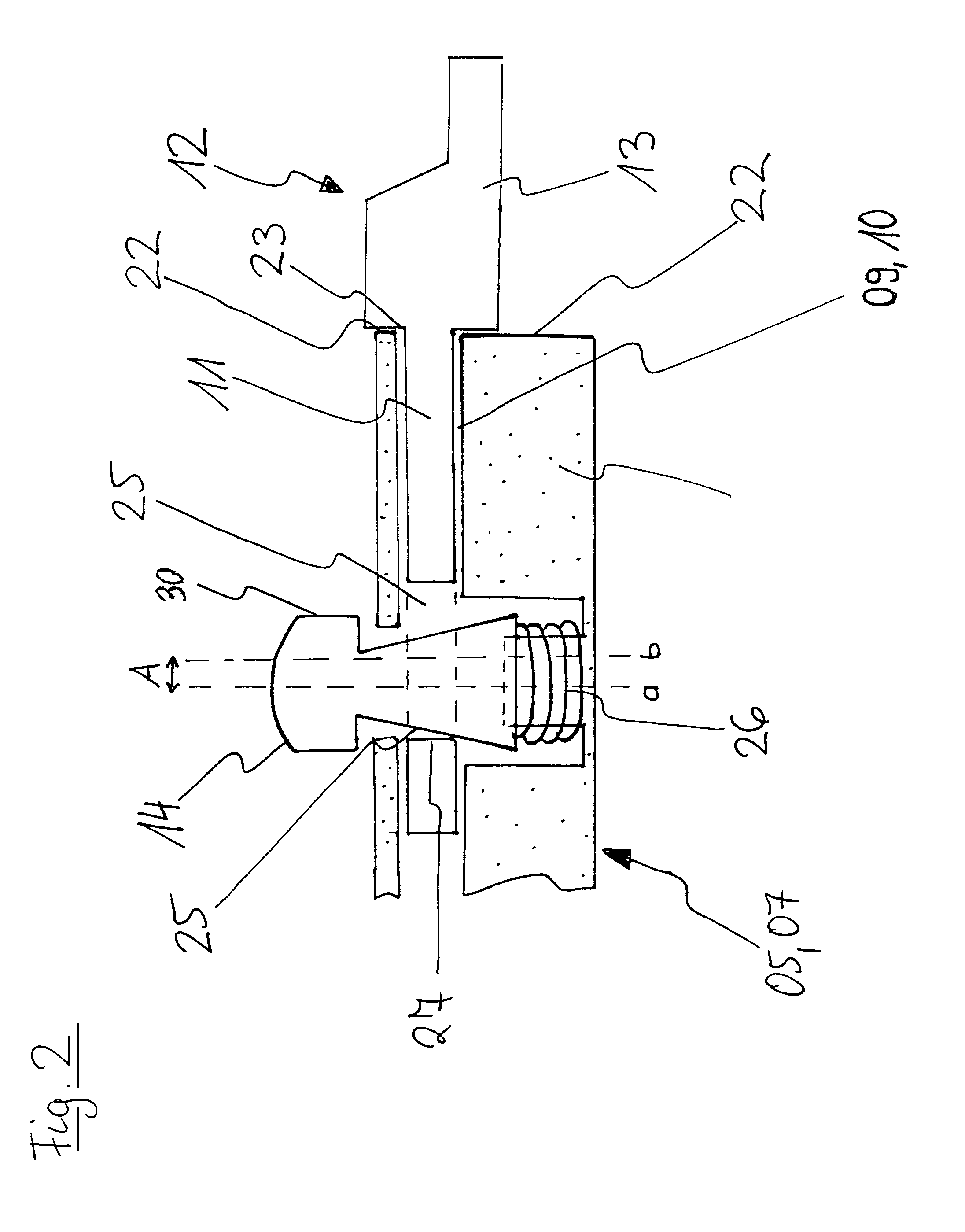

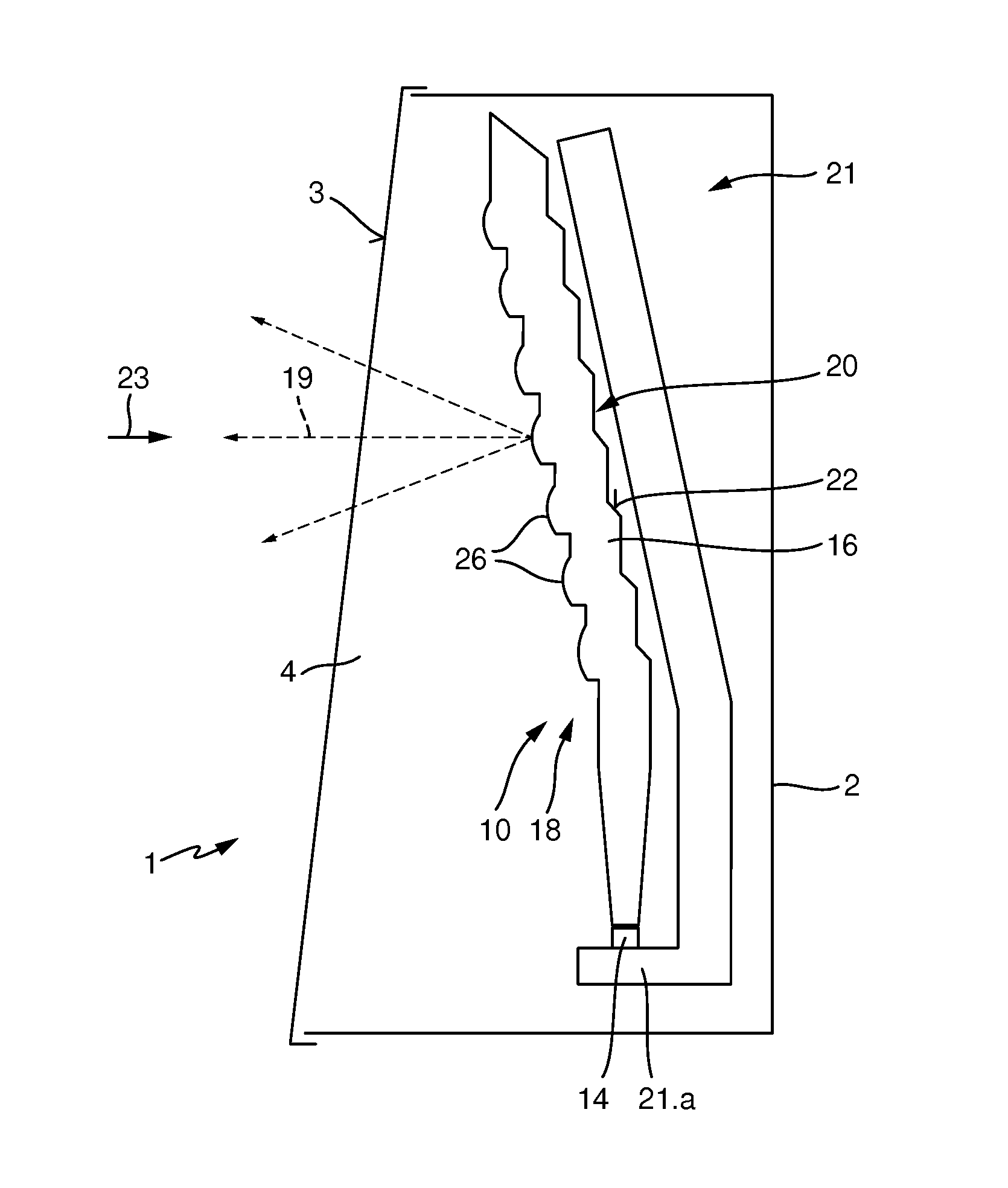

Medical tool

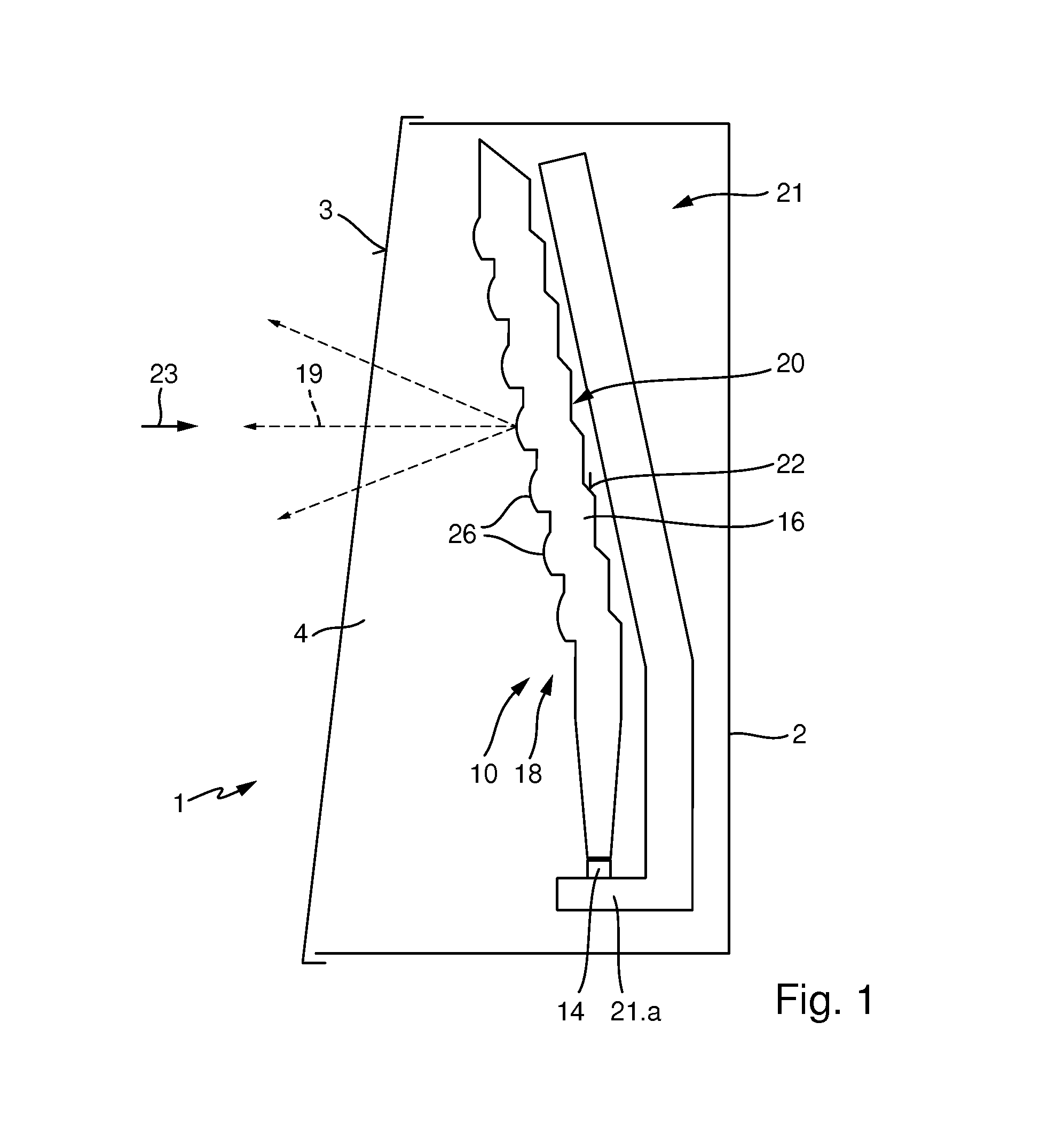

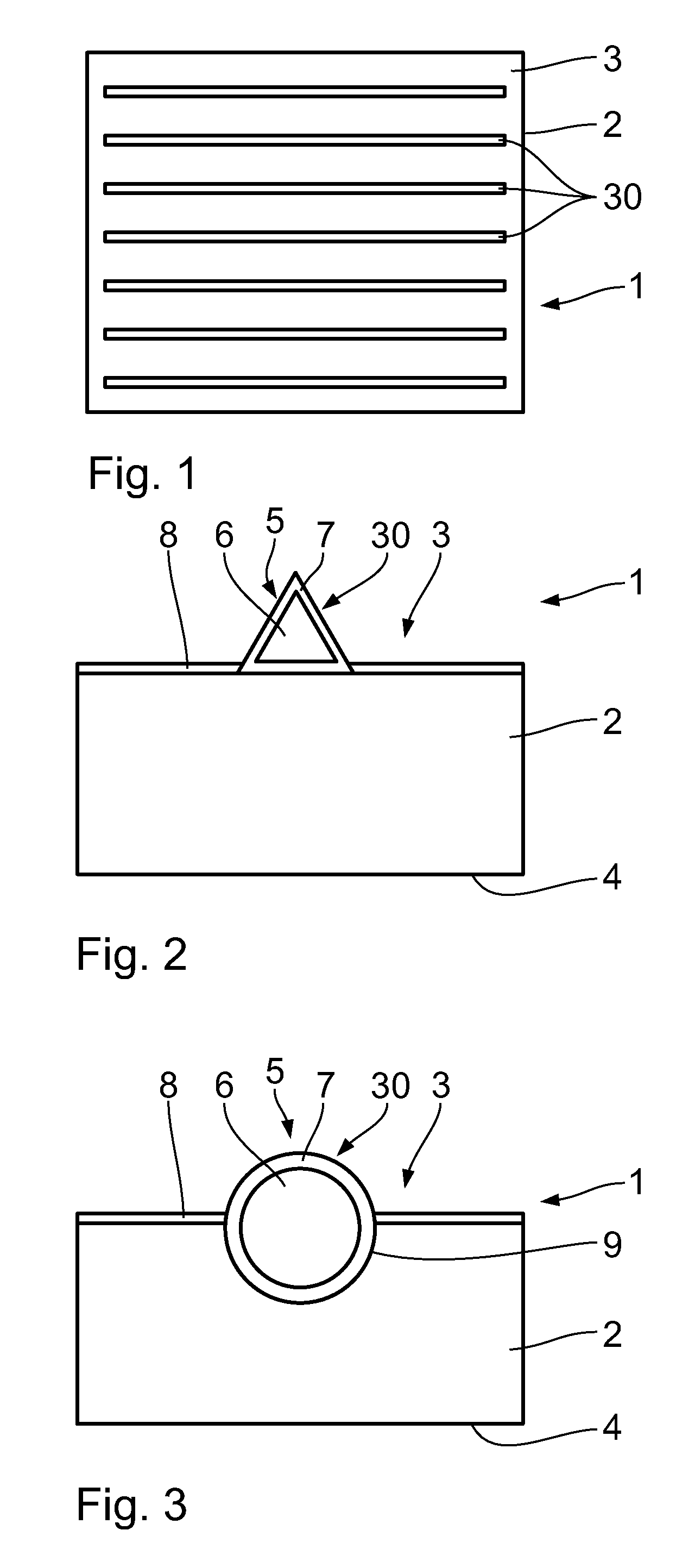

The invention concerns a medical tool, in particular a vertebral distractor (1), with a first (2) and a second link part (3), wherein the first link part (2) is connected with the second link part (3) via a rotation axis (4), and therein a grip element (6,8) and a pliers element (5,7) is provided on each link part (2,3), which are operatively associated with each other, and wherein the two grip elements (6,8) are provided on a first side relative to the rotation axis (4) and the two pliers elements (5,7) are provided on a second side lying opposite to the first side, and wherein a valve (12) is seatable in the area of the free axial ends of a pliers element (5,7) and releaseably connected by a securing mechanism of the first type, and wherein a push button of the first type (14) is provided on the securing mechanism of the first type.

Owner:WEBER HELMUT +1

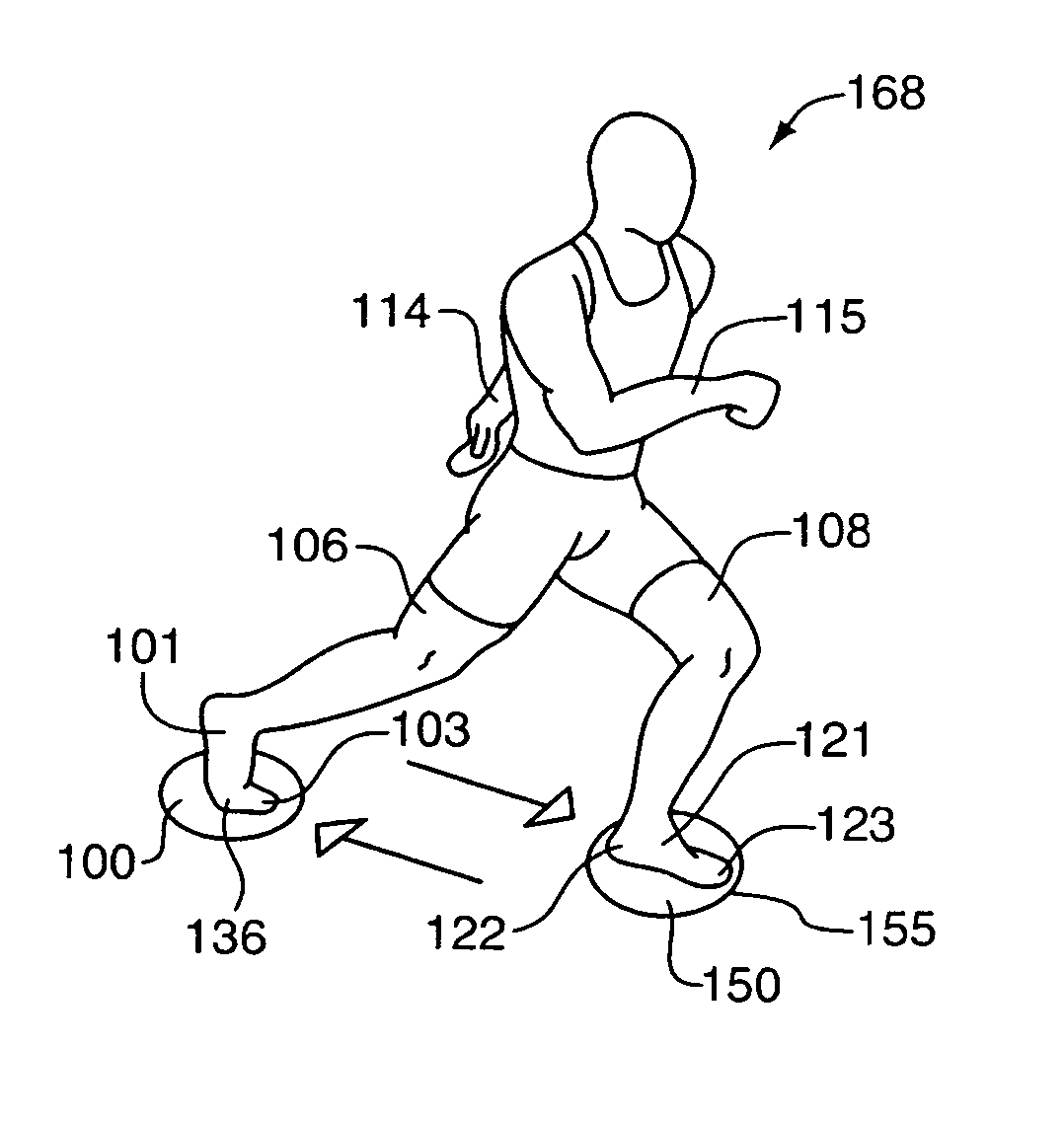

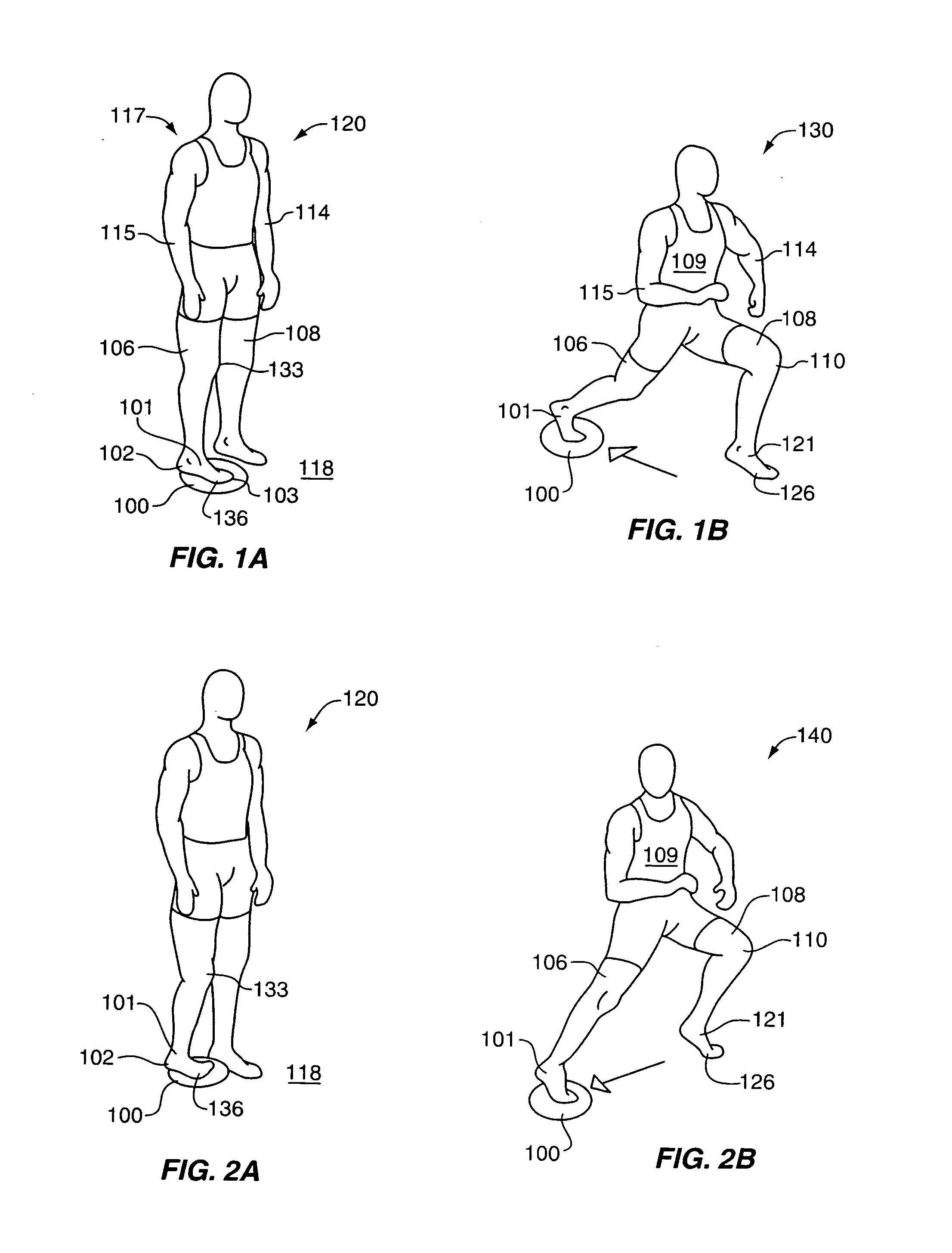

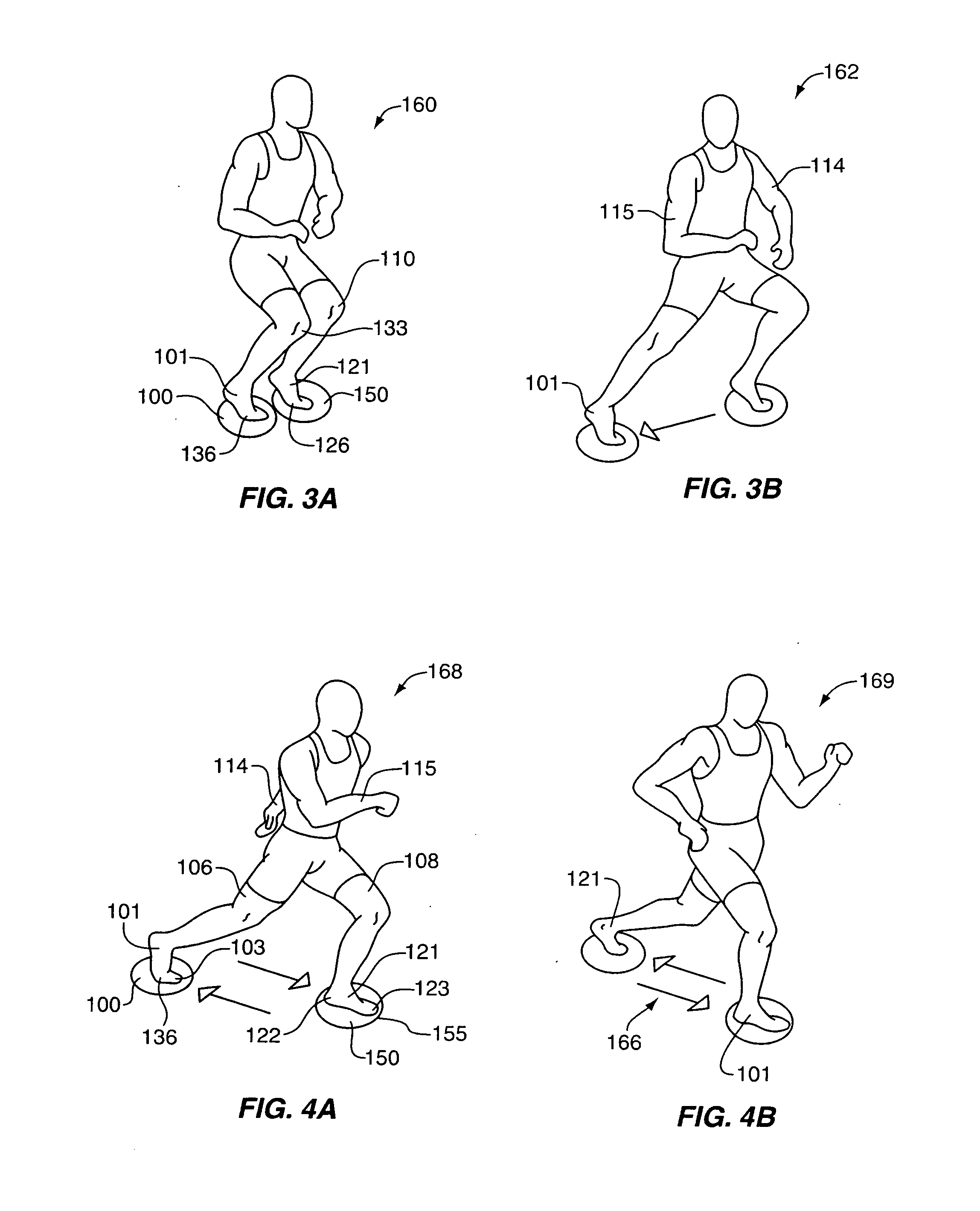

Method and apparatus for fitness exercise

A method of exercising a human body, the method comprising: providing a sliding element having a body portion adapted for receiving a limb of the human body, and a sliding surface adapted to slide on a exercise floor; placing the sliding element on an exercise floor and placing the human body limb on the body portion; and performing an exercise routine including sliding the sliding element by moving the human body limb. The exercise routine includes routines performed with the human body in a standing position; routines performed with the human body in a prone position; routines performed with the human body in a supine position; and routines performed with the human body in a side-lying position. The invention also includes an exercise device for exercising a human body, the device comprising: a sliding disc having a body portion adapted for receiving a limb of the human body; and a sliding surface adapted to slide on an exercise floor.

Owner:SAVVIER FITNESS LLC

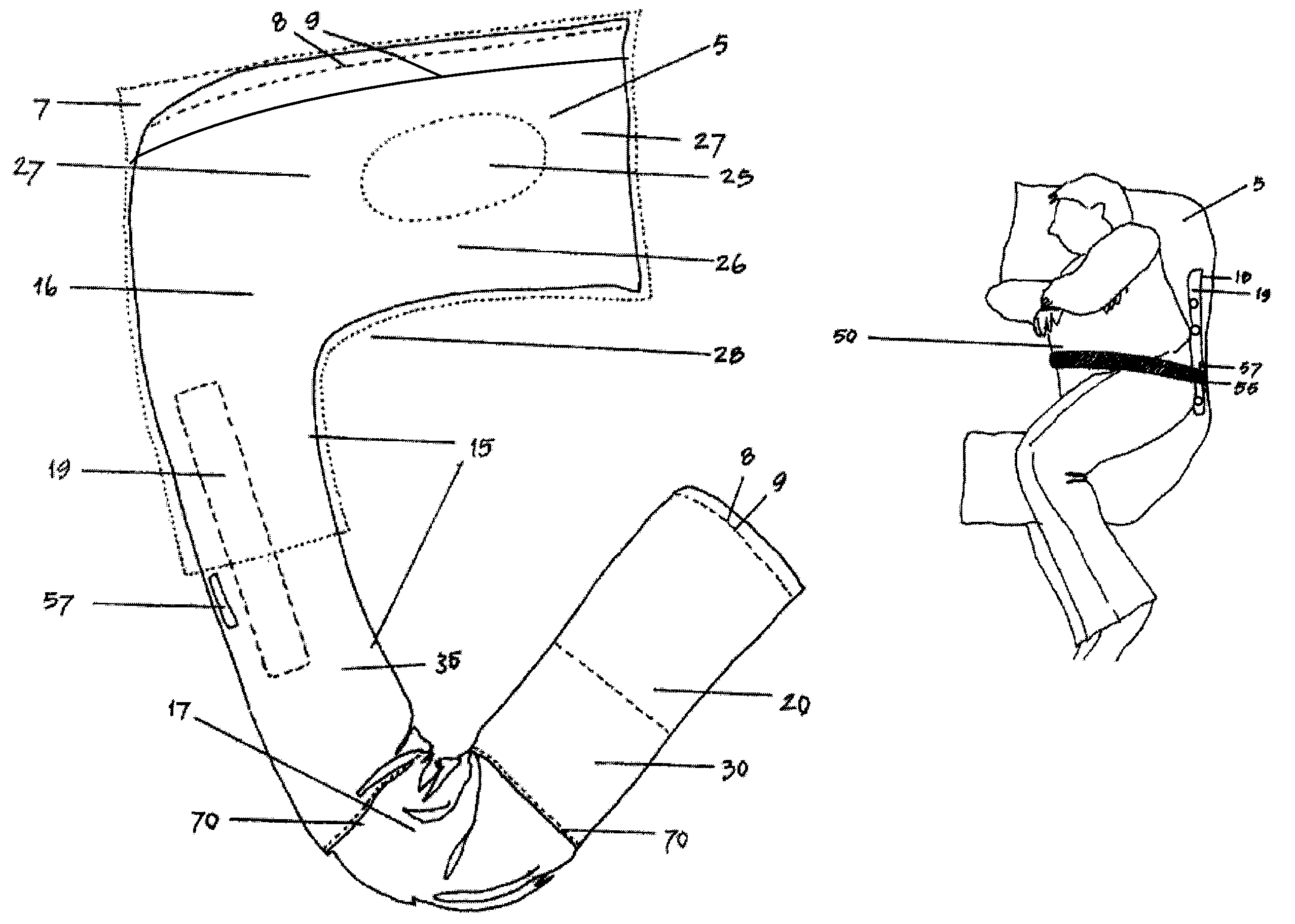

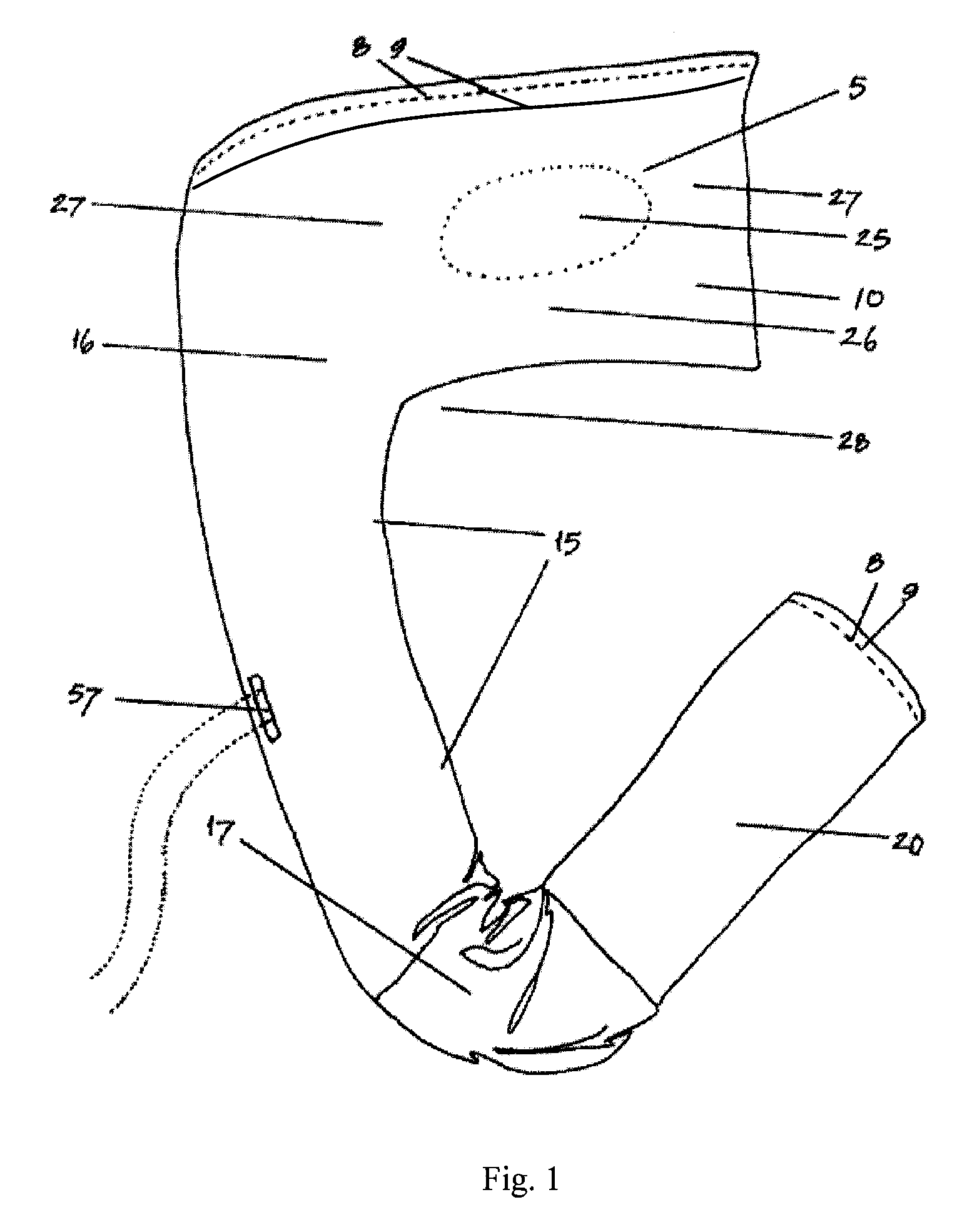

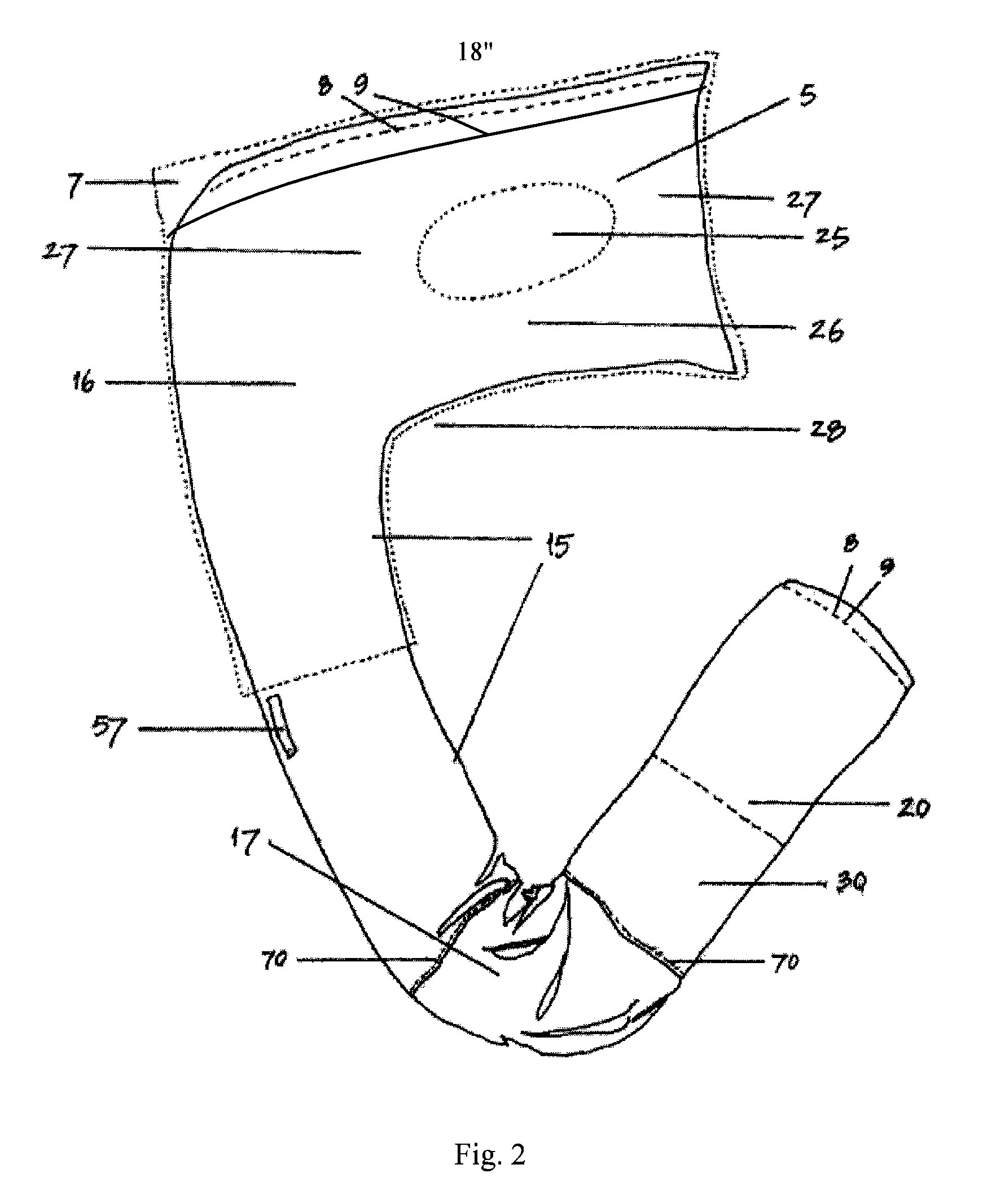

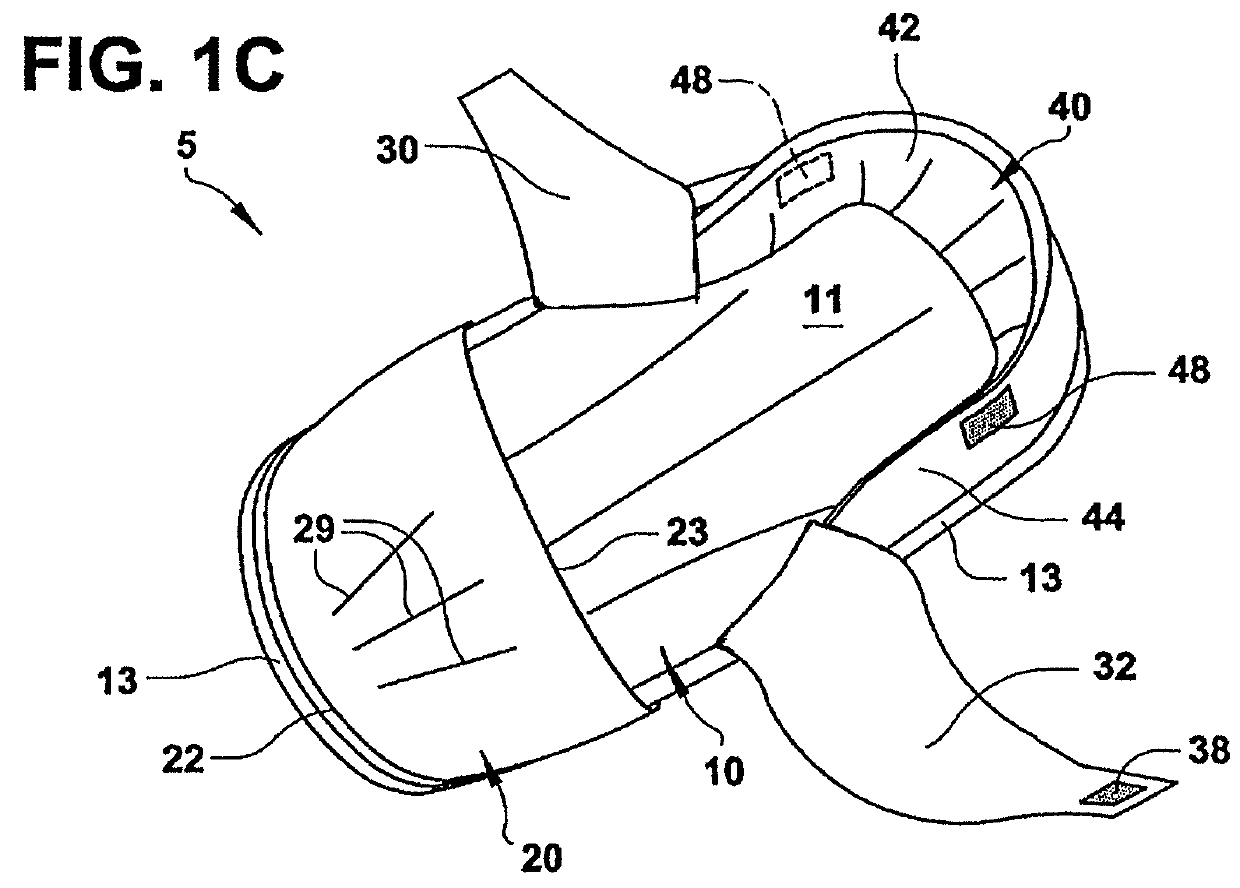

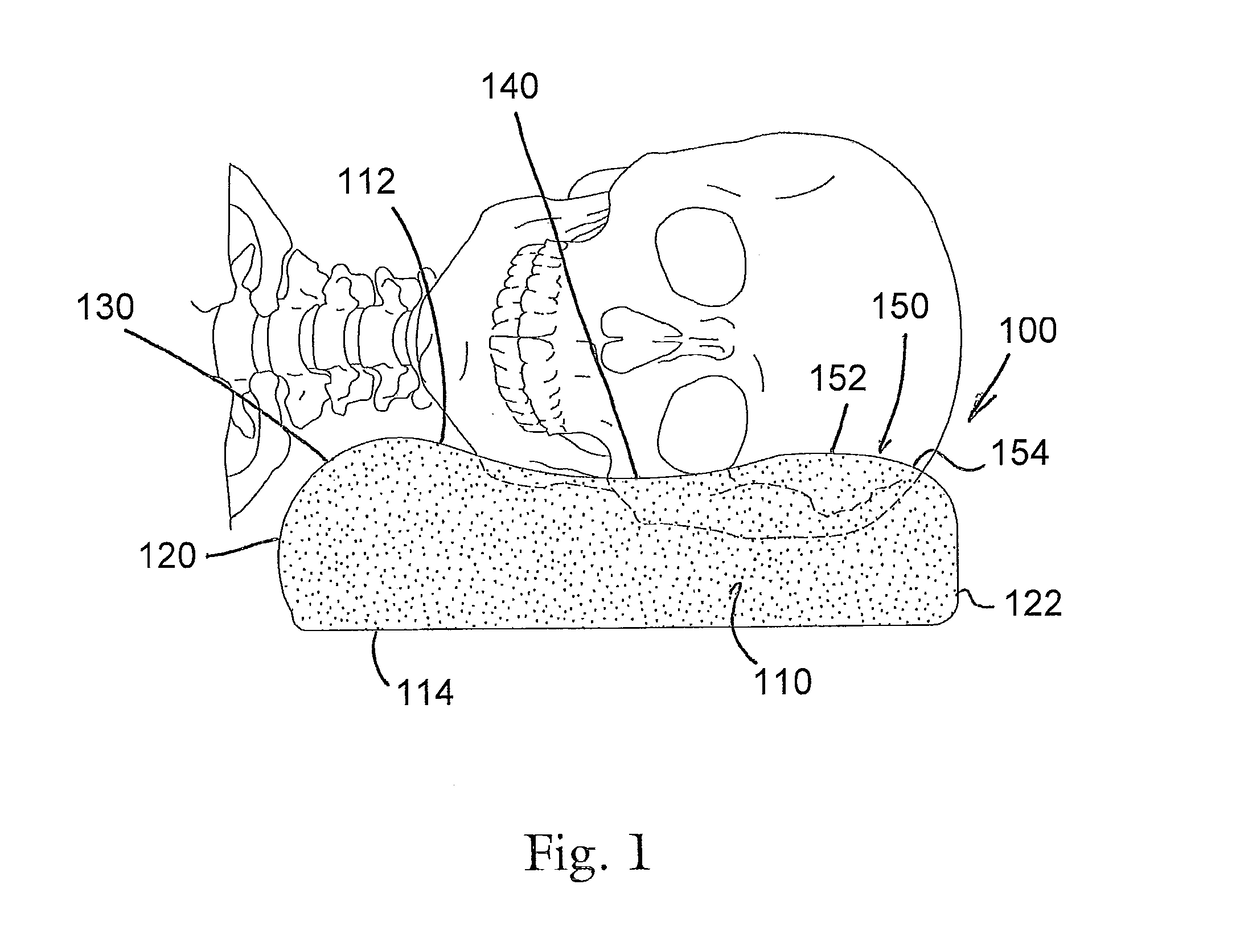

Therapeutic positioning device

InactiveUS7578013B2Relieve painReduce riskElectric signal transmission systemsSofasSide lyingSurgery

The present invention relates to a body support pillow made and contoured to promote side lying to reduce snoring and negate the consequences of sleep apnea and symptoms. It consists of a body support pillow with integrated, semi-rigid yet flexible support for a person's head, back, and legs while lying on their side thereby encouraging either left or right side position sleeping.

Owner:SOMNAFORM CORP

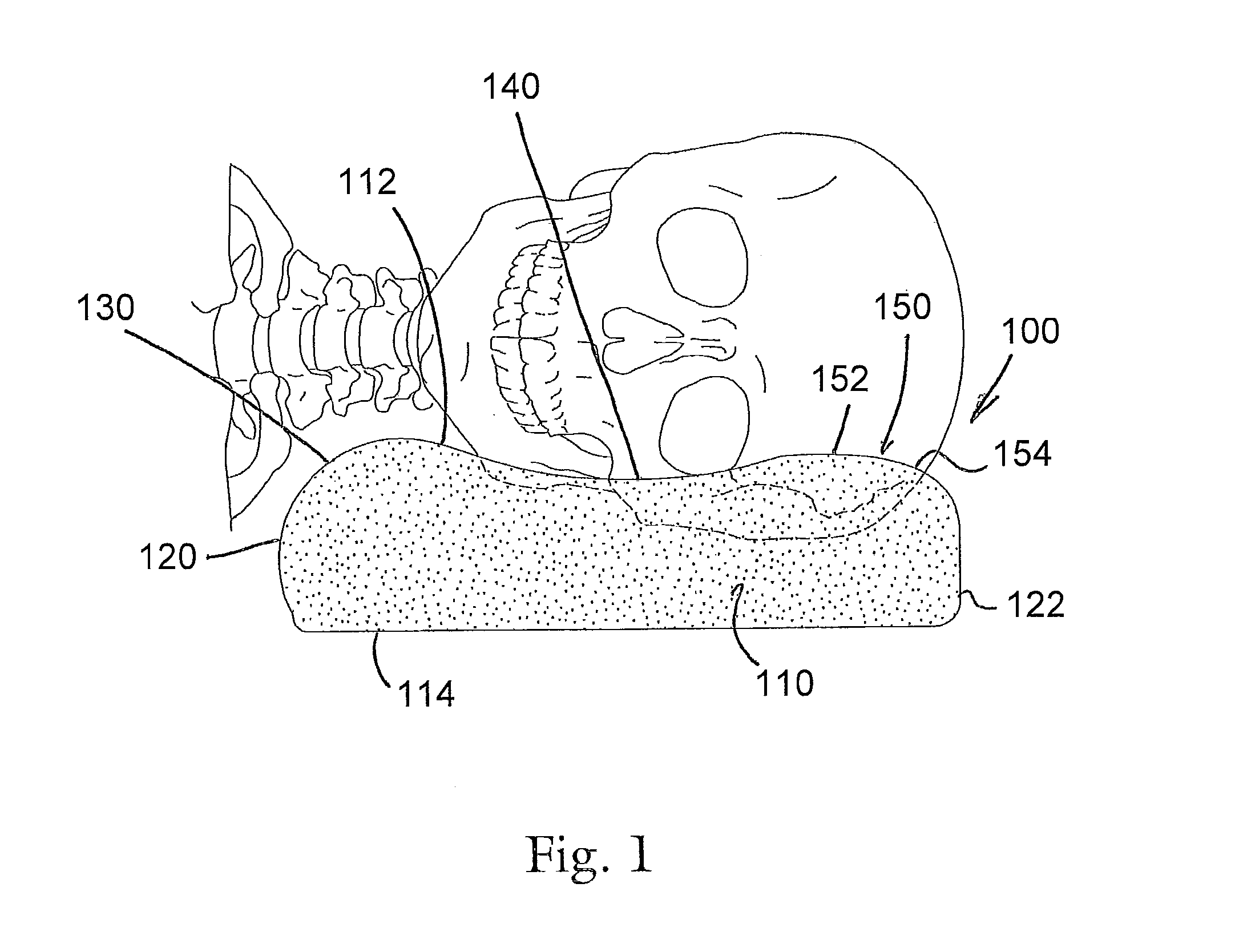

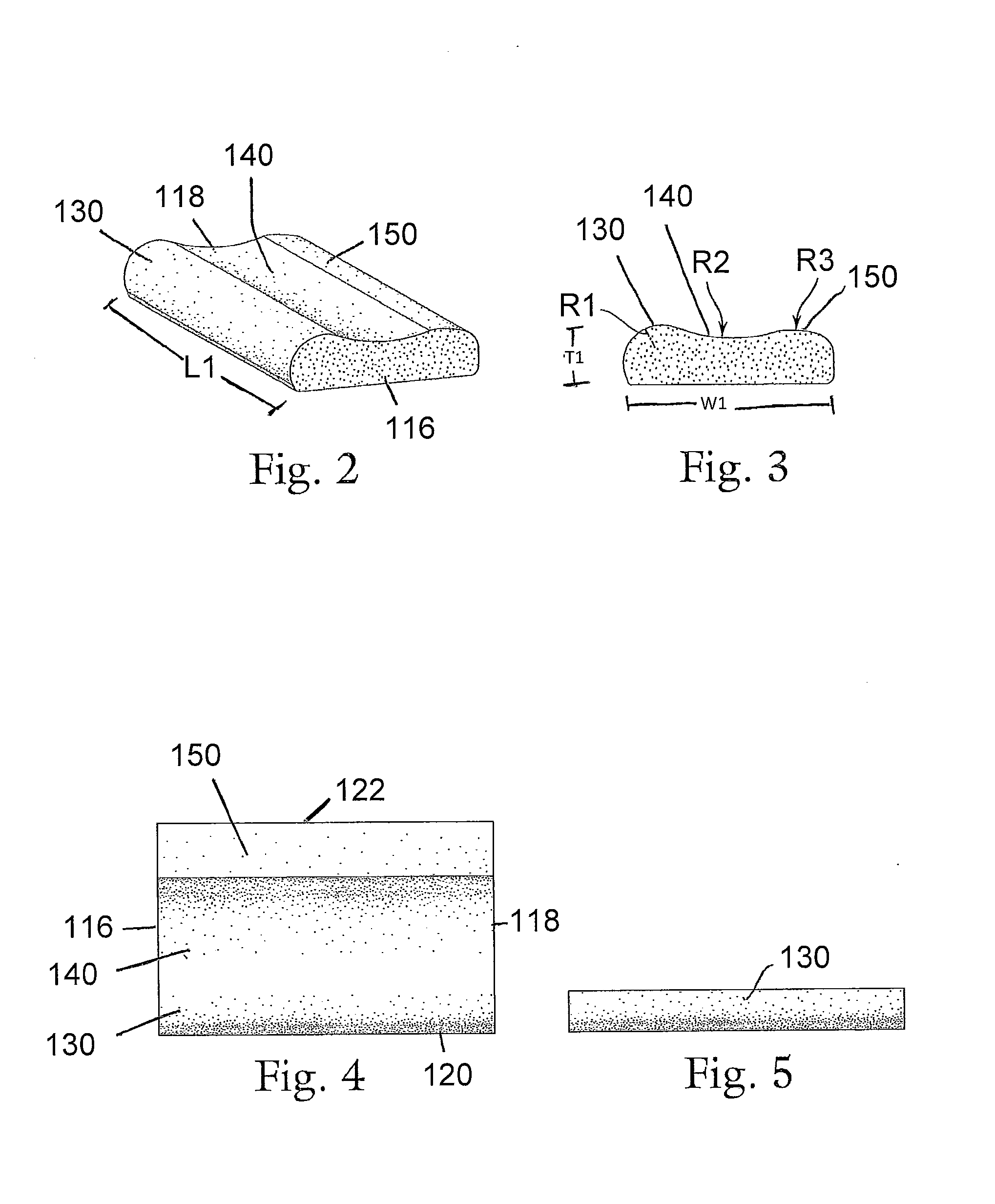

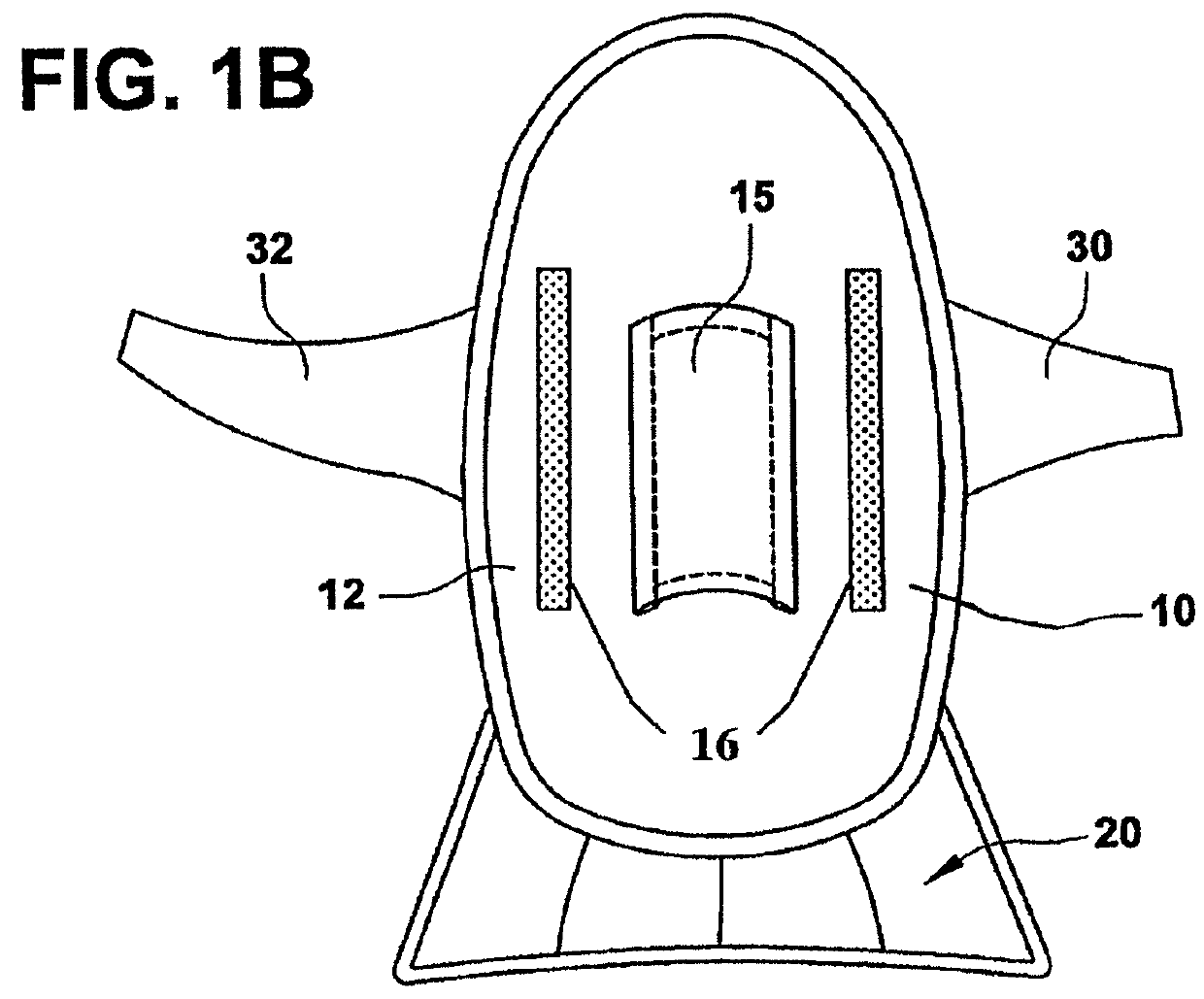

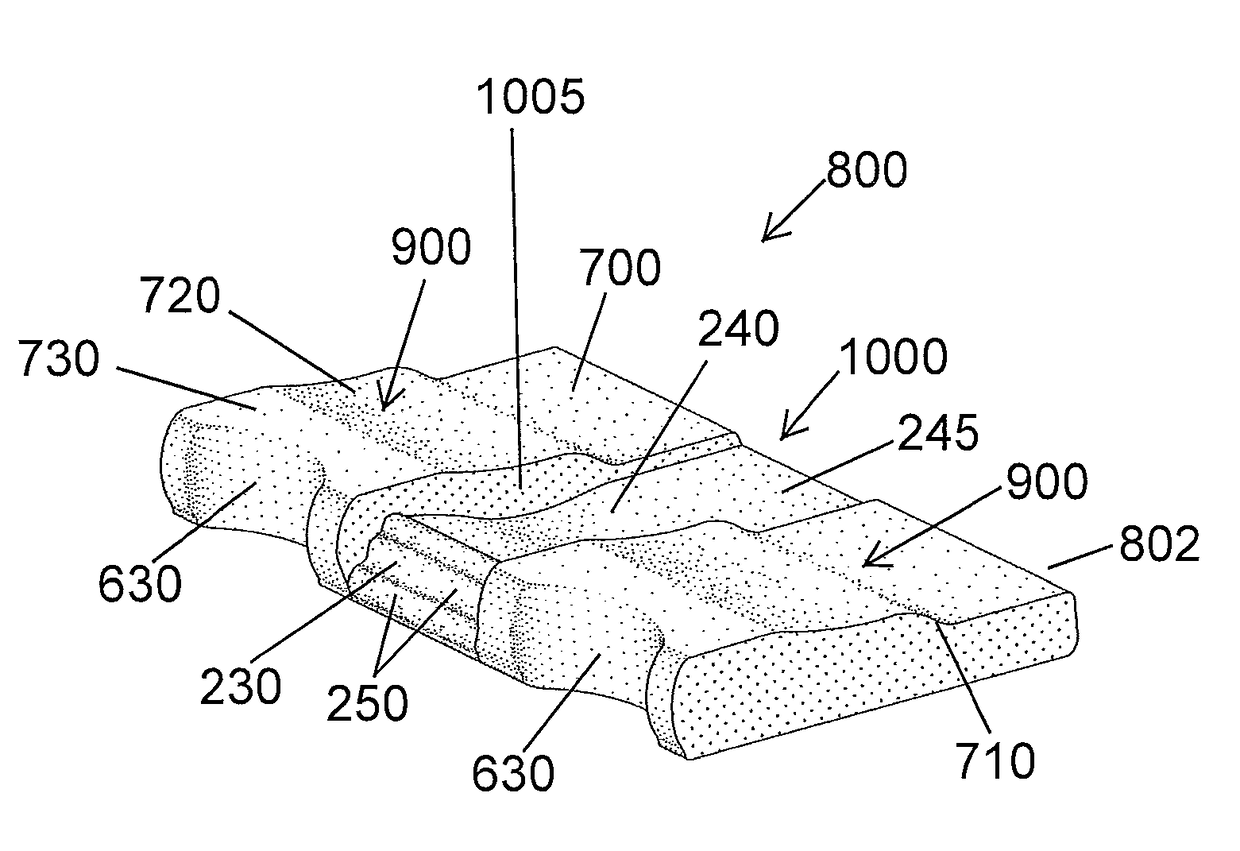

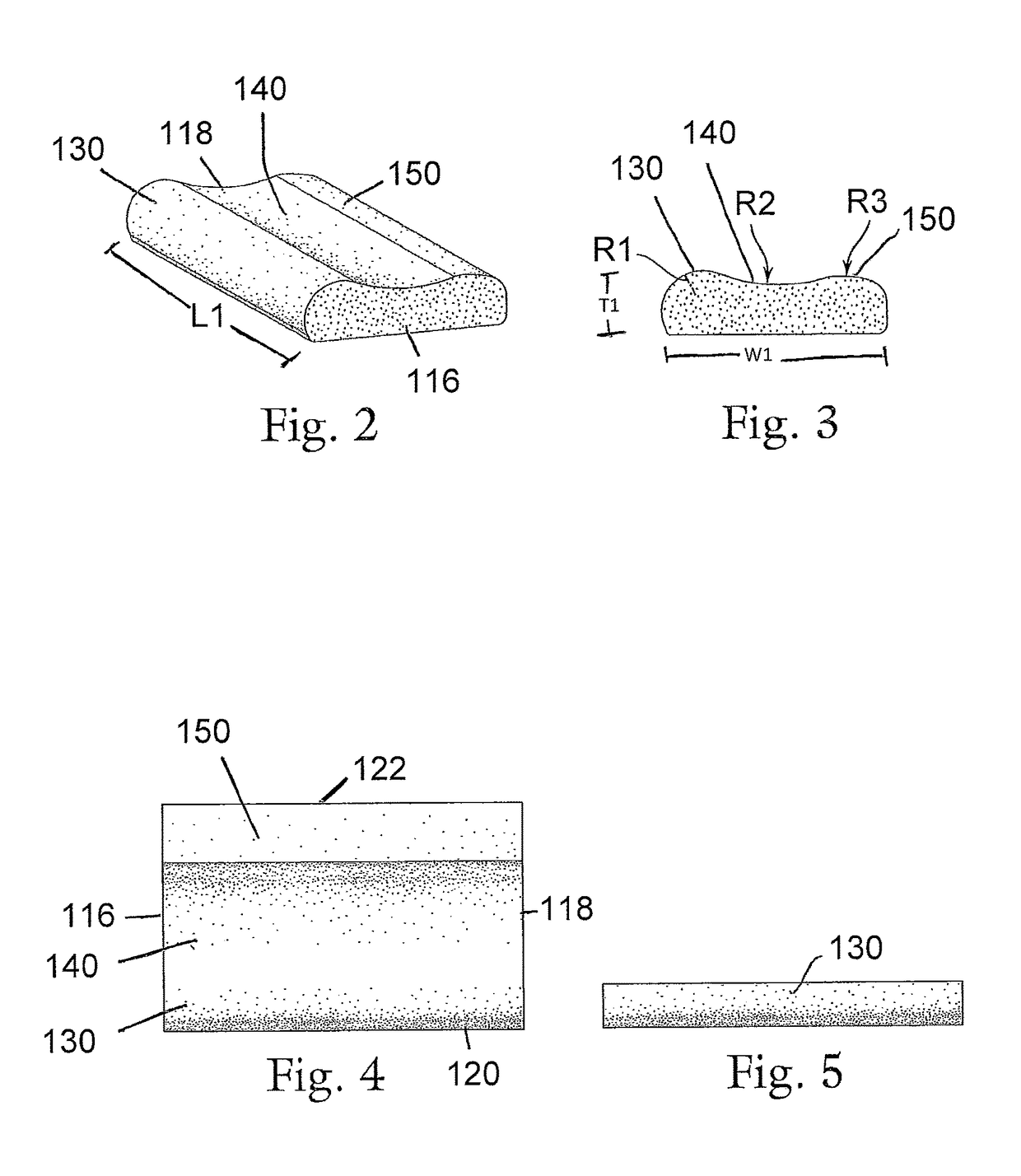

Therapeutic pillow

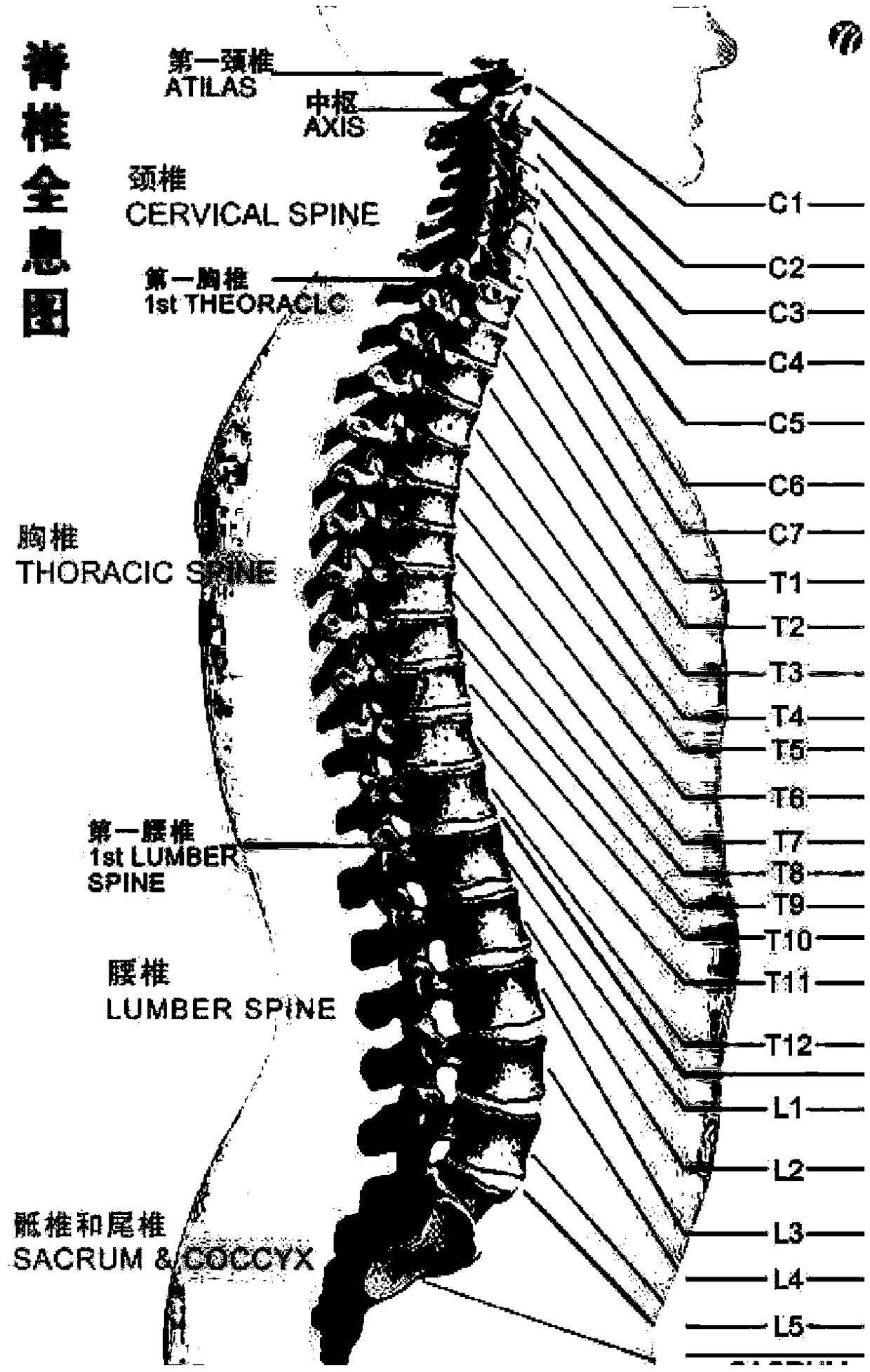

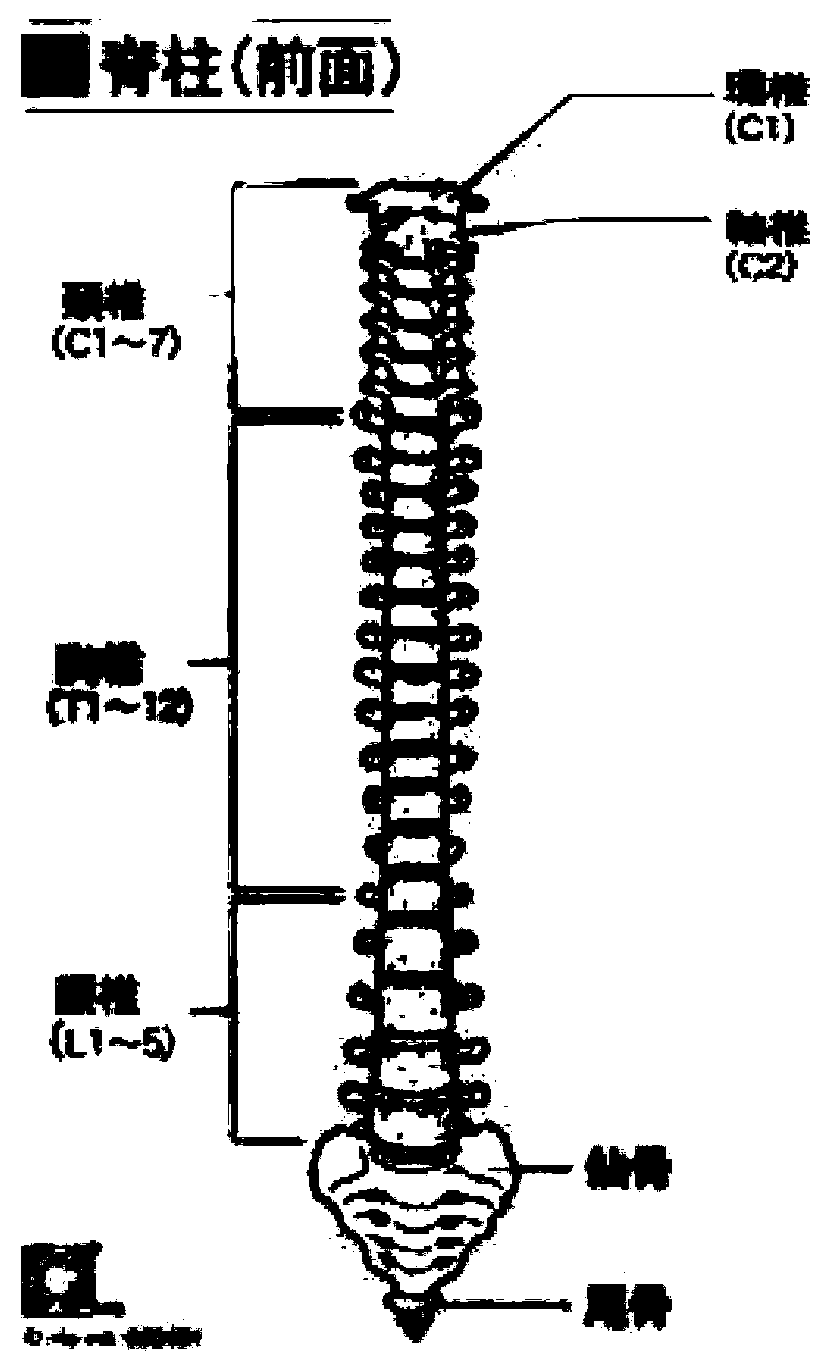

ActiveUS20150047646A1Many of adverse symptomEasy alignmentPillowsOperating chairsSide lyingSpinal Curvatures

The present invention provides devices for neck support and correction, for example, pillows, headrests, or cushions, designed to be placed under the head and neck of a person lying in a supine or side-lying position. Such devices are useful for maintaining or improving cervical and / or thoracic spinal curvature and / or alignment and for reducing pain associated with ailments of the neck or cervical vertebrae. Also provided are methods of improving cervical spinal alignment and for treating or ameliorating ailments of the neck or cervical vertebrae.

Owner:MARINKOVIC JOHN

Motor vehicle light with a light conductor and a shield that is visible through the light conductor

InactiveUS20140140084A1High signal effectLow costOptical signallingRoad vehiclesElectrical conductorSide lying

Presented is a motor vehicle light with a light source, a light conductor, which comprises a bordering decoupling volume opposite of a first side and a second side lying opposite the second side, wherein the second side comprises decoupling elements, which decouple light distributed about a principal propagation direction, and wherein the motor vehicle light comprises a colored shield which is positioned behind the second side in a direction opposite to the principal propagation direction. The shield is a black shield.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

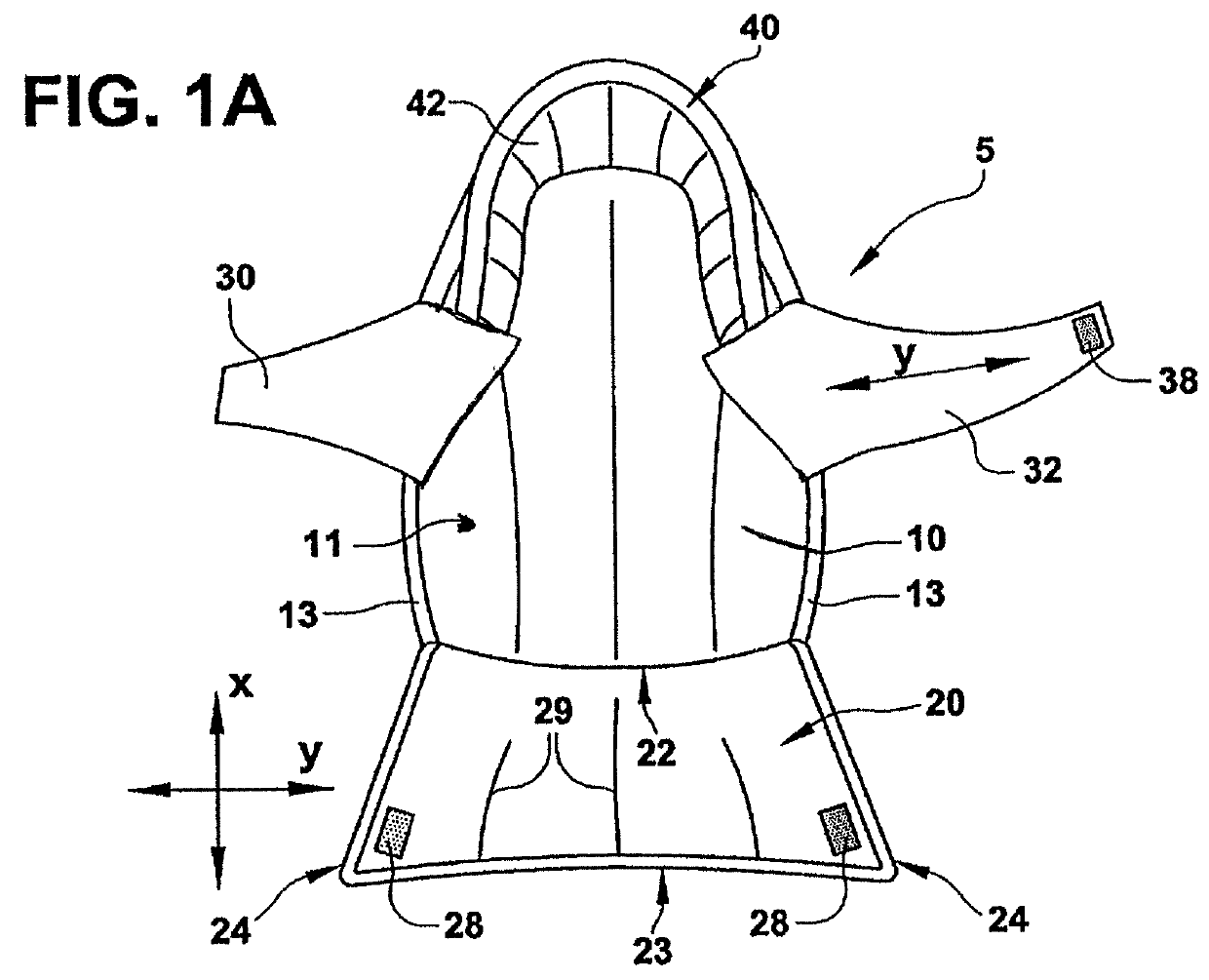

Multipurpose positioning device for infants

ActiveUS9332791B1Flexible positioningImprove comfortDressing tableBaby-incubatorsSide lyingEngineering

A multipurpose infant positioning device that includes a lower pad with front and back surfaces, wings attached to lateral sides of the lower pad and a bottom flap attached to the bottom portion of the lower pad. At least one of the wings and bottom flap have fastening segments attached thereto for adjustably attaching these components to portions of the lower pad. The fastened wing and bottom flap are made of a material having sufficient resiliency to maintain and bring an infant back to flexed midline position within the infant positioning device. These infant positioning devices may further include a headpiece, brim, pocket at the back surface of the lower pad and a detachable readjustable multipurpose pillow for positioning the infant from and between supine, prone and side-lying positions, all while maintaining and reinforcing the flexed midline position of the infant for normal development.

Owner:TARRY MEDICAL PROD

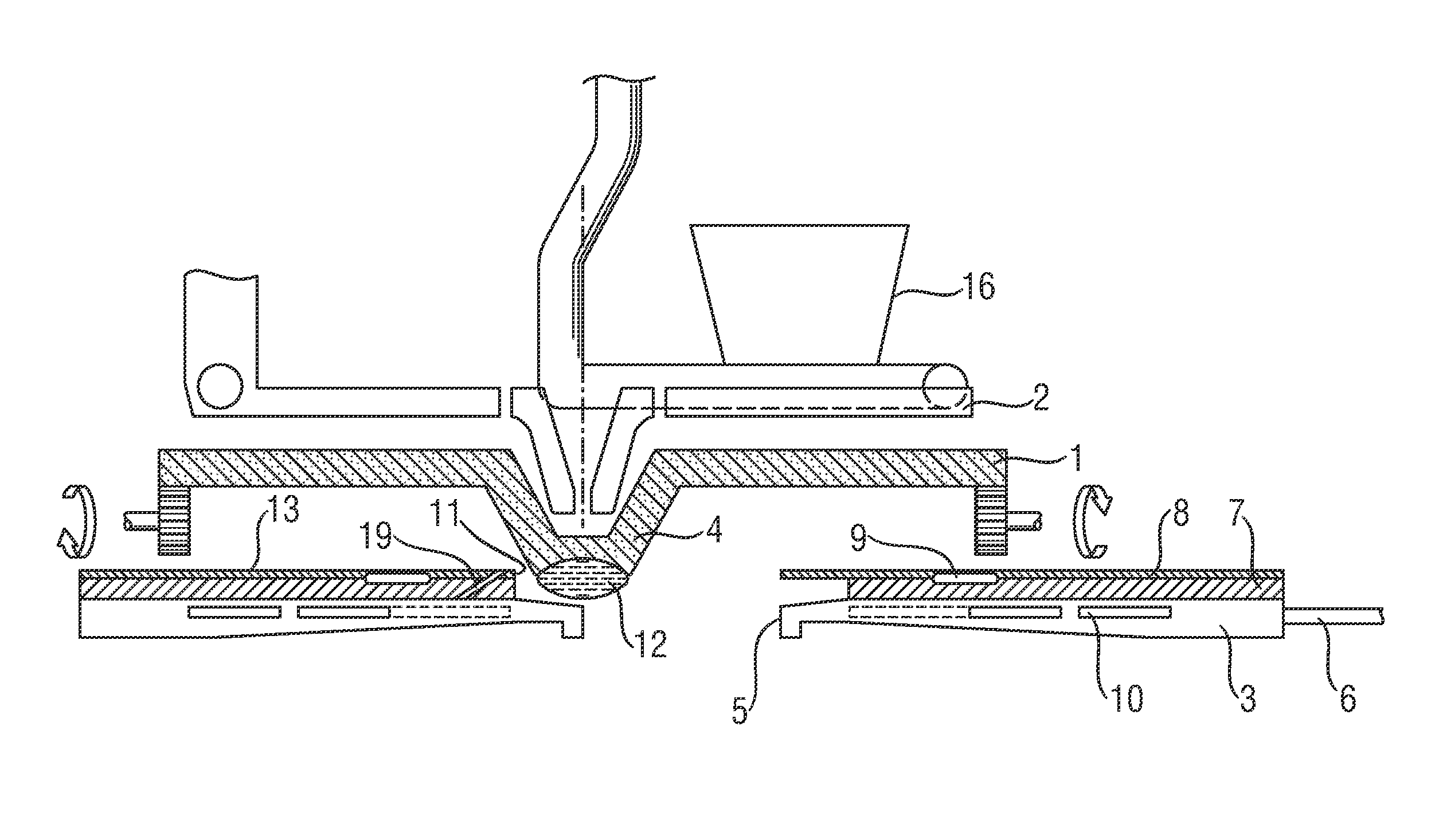

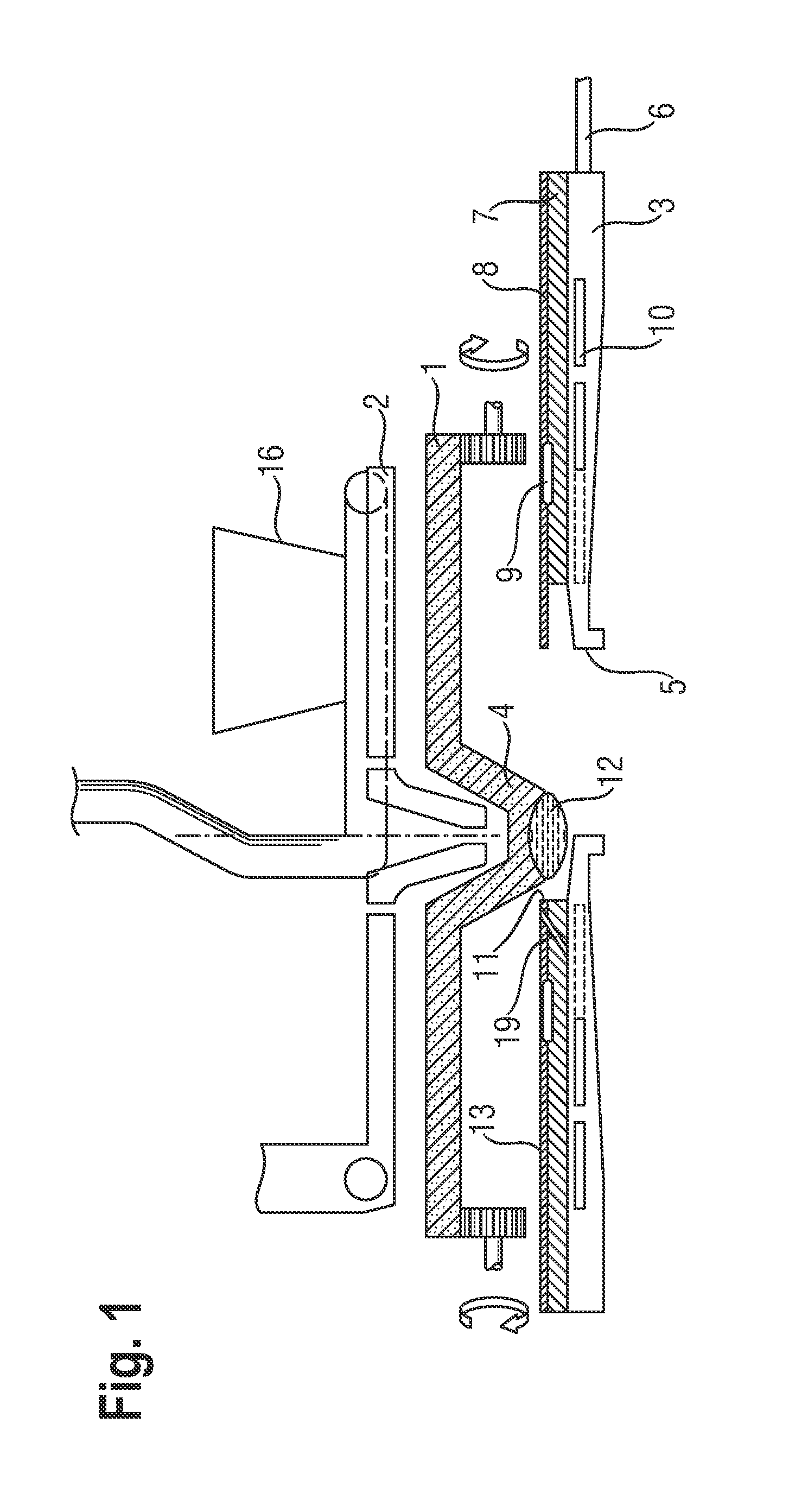

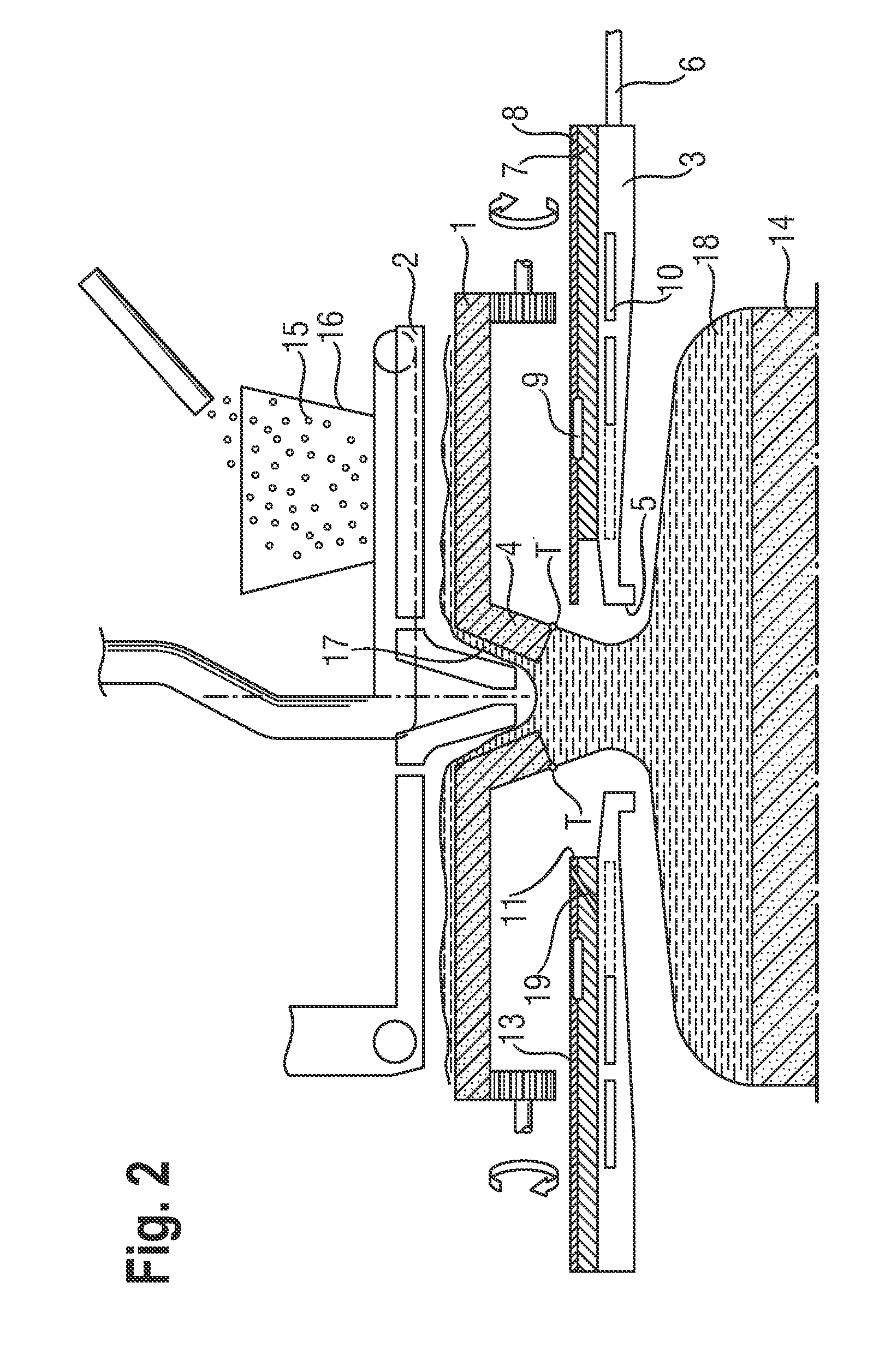

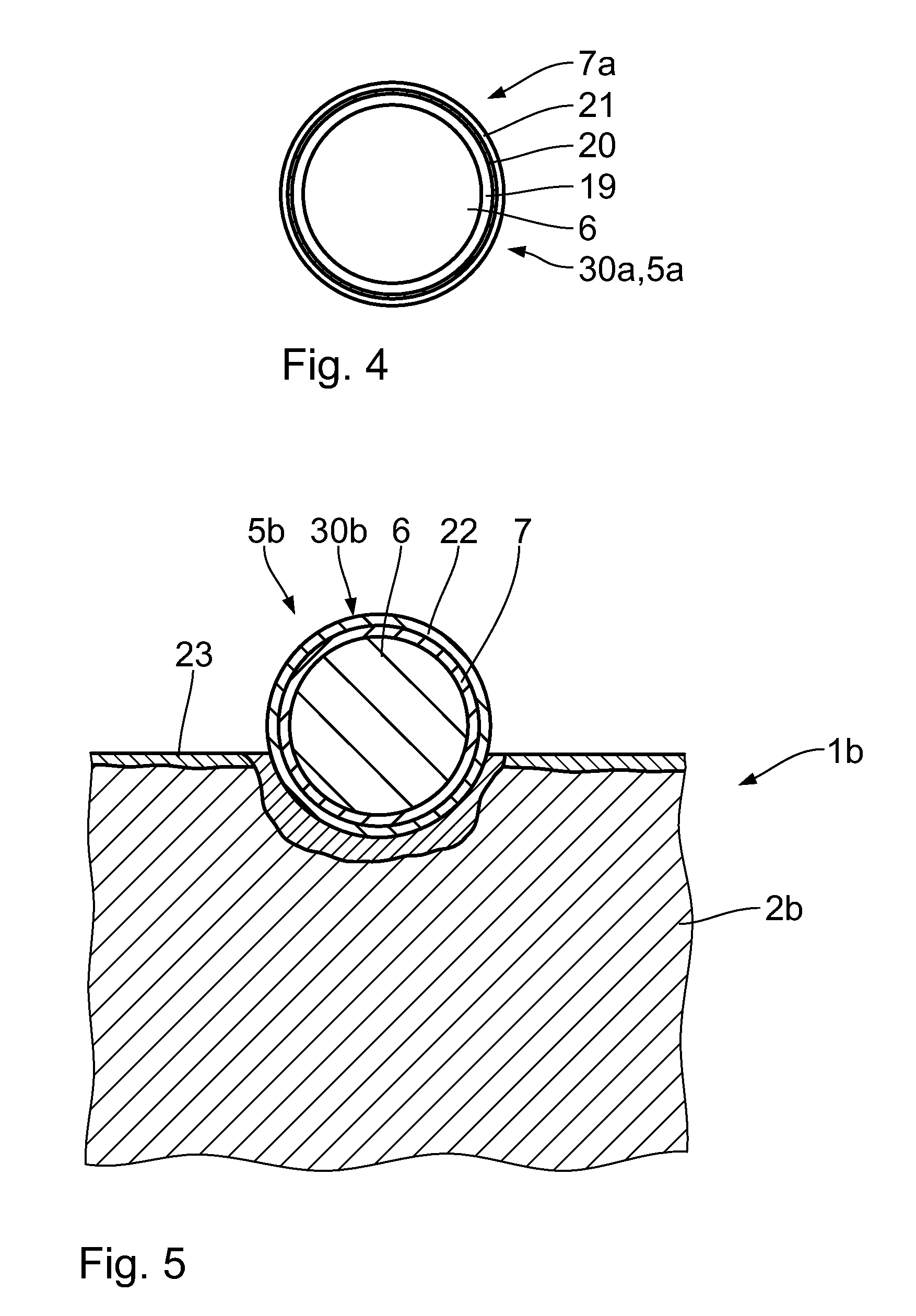

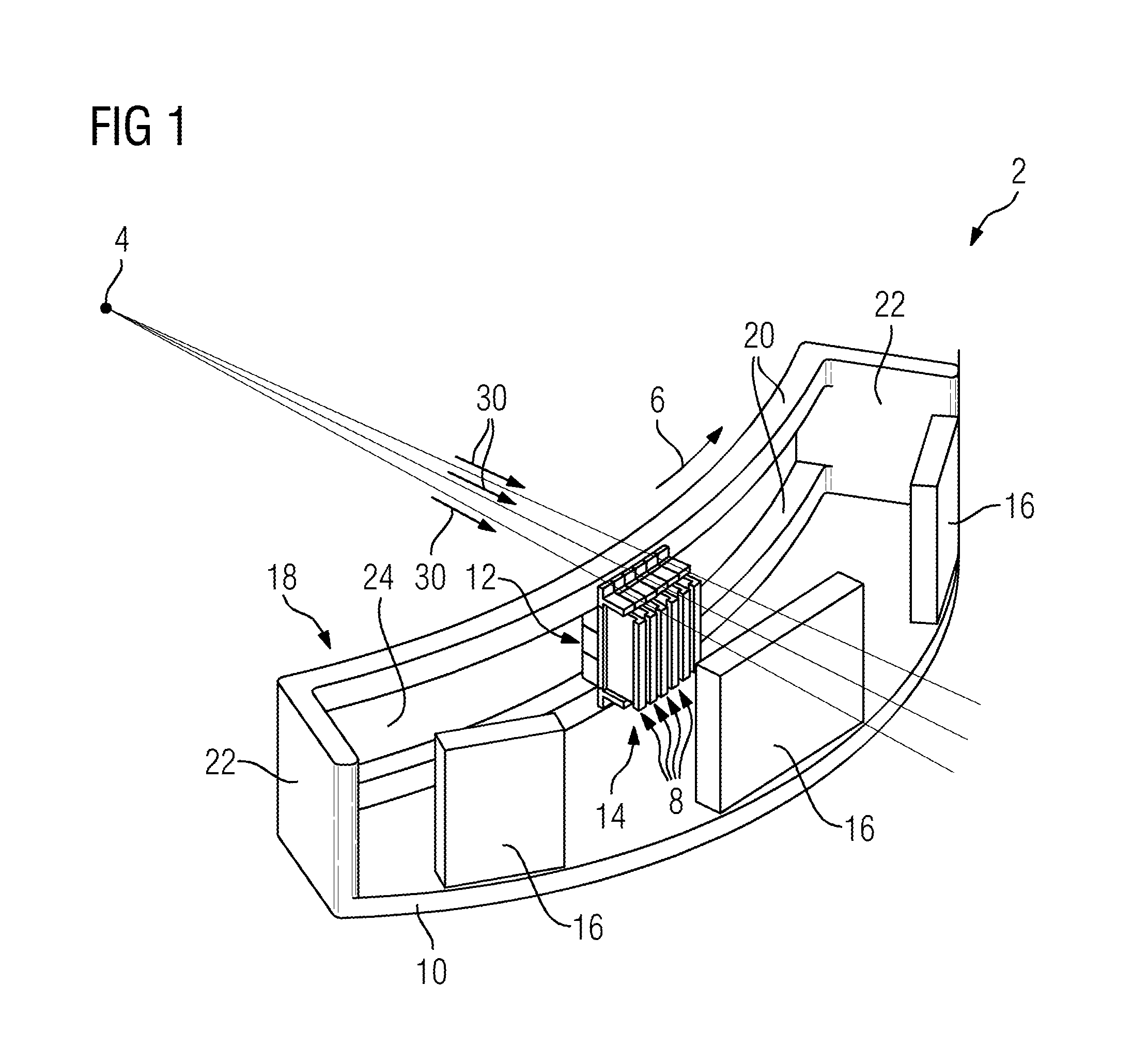

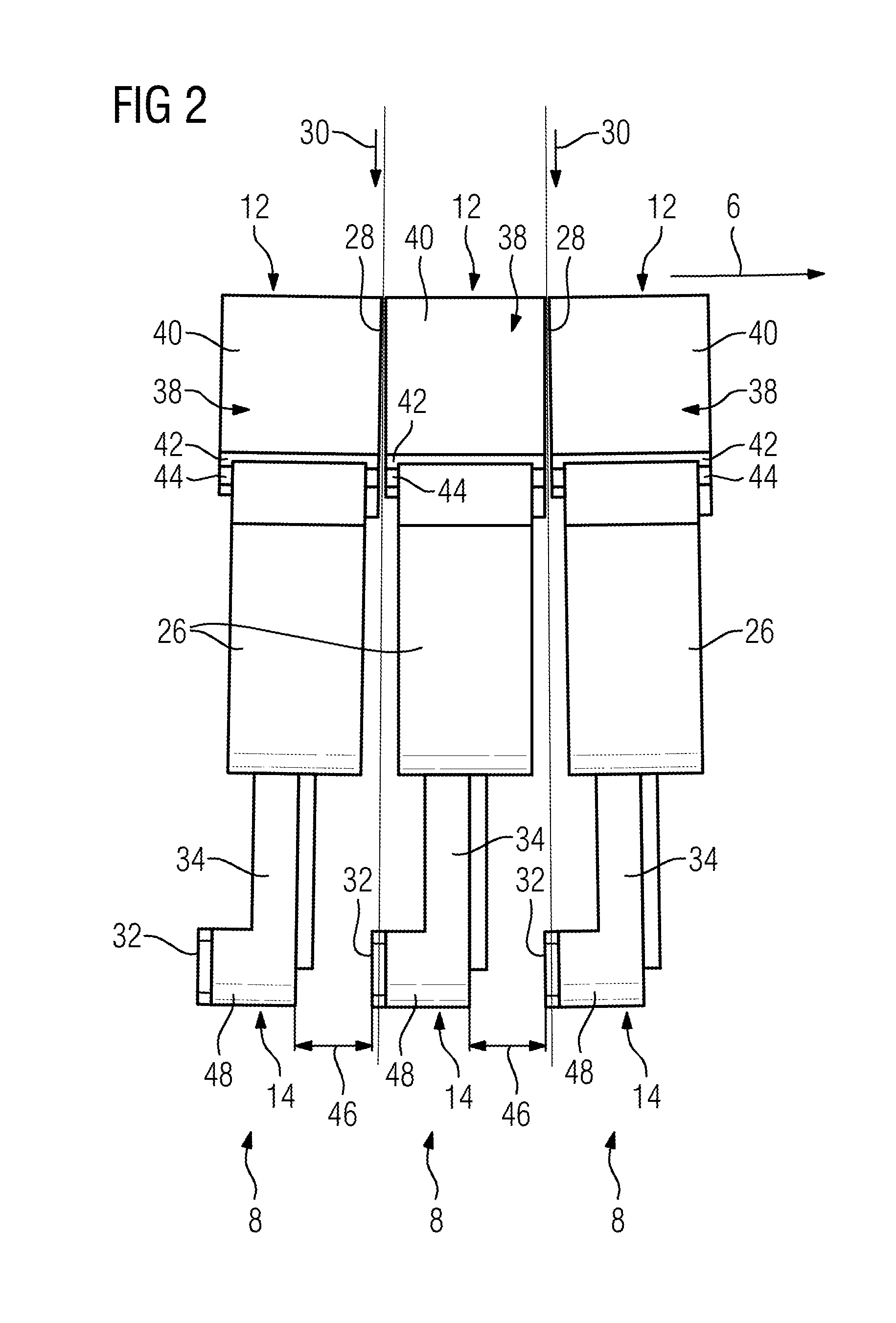

Device For Producing A Single Crystal Composed Of Silicon By Remelting Granules

InactiveUS20110095018A1Polycrystalline material growthBy zone-melting liquidsSide lyingConduction cooling

A device for producing a silicon single crystal by remelting granules has a rotating plate of silicon having a central opening and having a silicon tubular extension which encloses the opening and extends below the plate; a first induction heating coil above the plate for melting granules; and a second induction heating coil below the plate for crystallizing the molten granules, wherein the second induction heating coil has, on its side lying opposite the silicon plate, a lower layer composed of a magnetically permeable material and an upper layer in which there is at least one cooling channel for conducting a coolant.

Owner:SILTRONIC AG

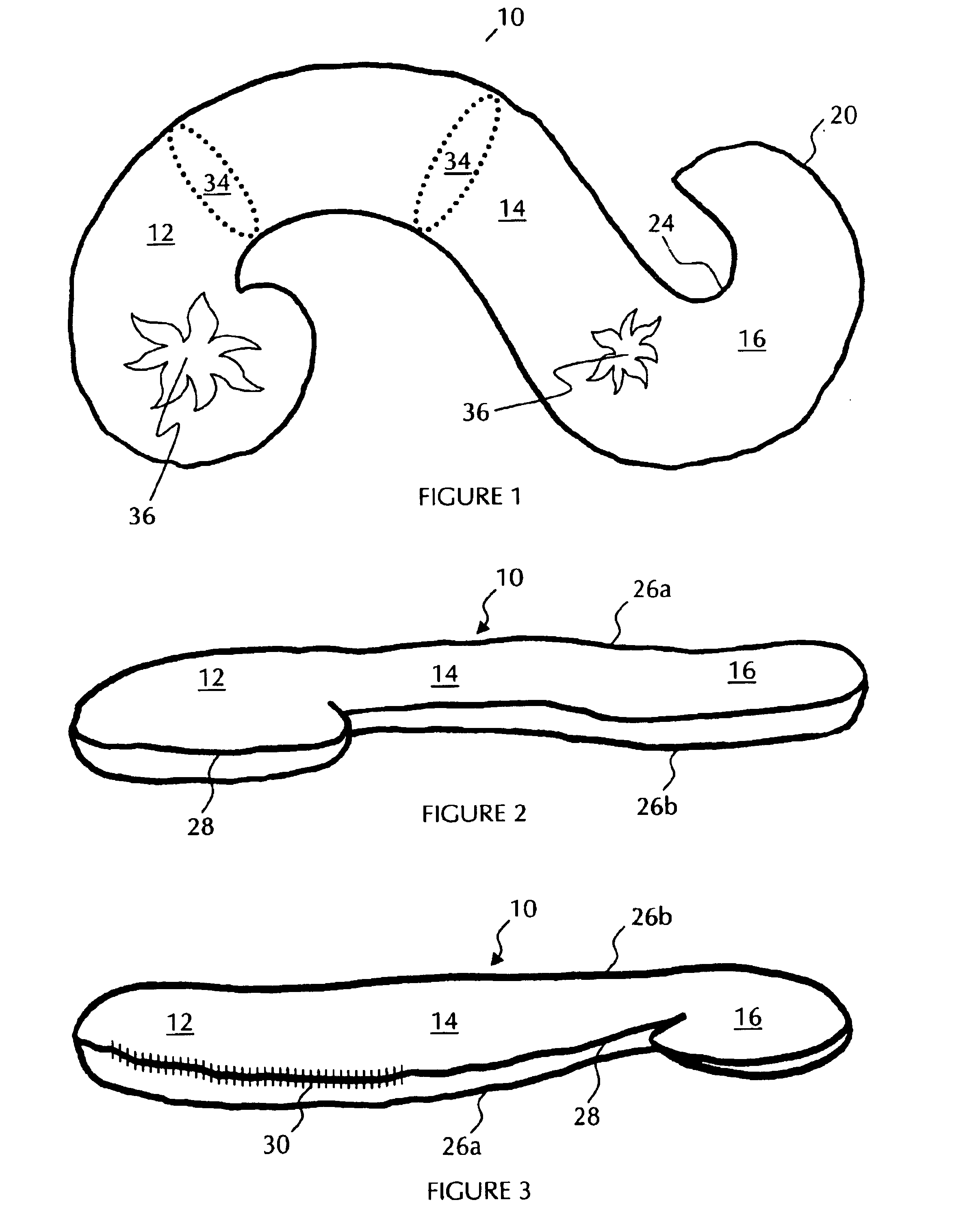

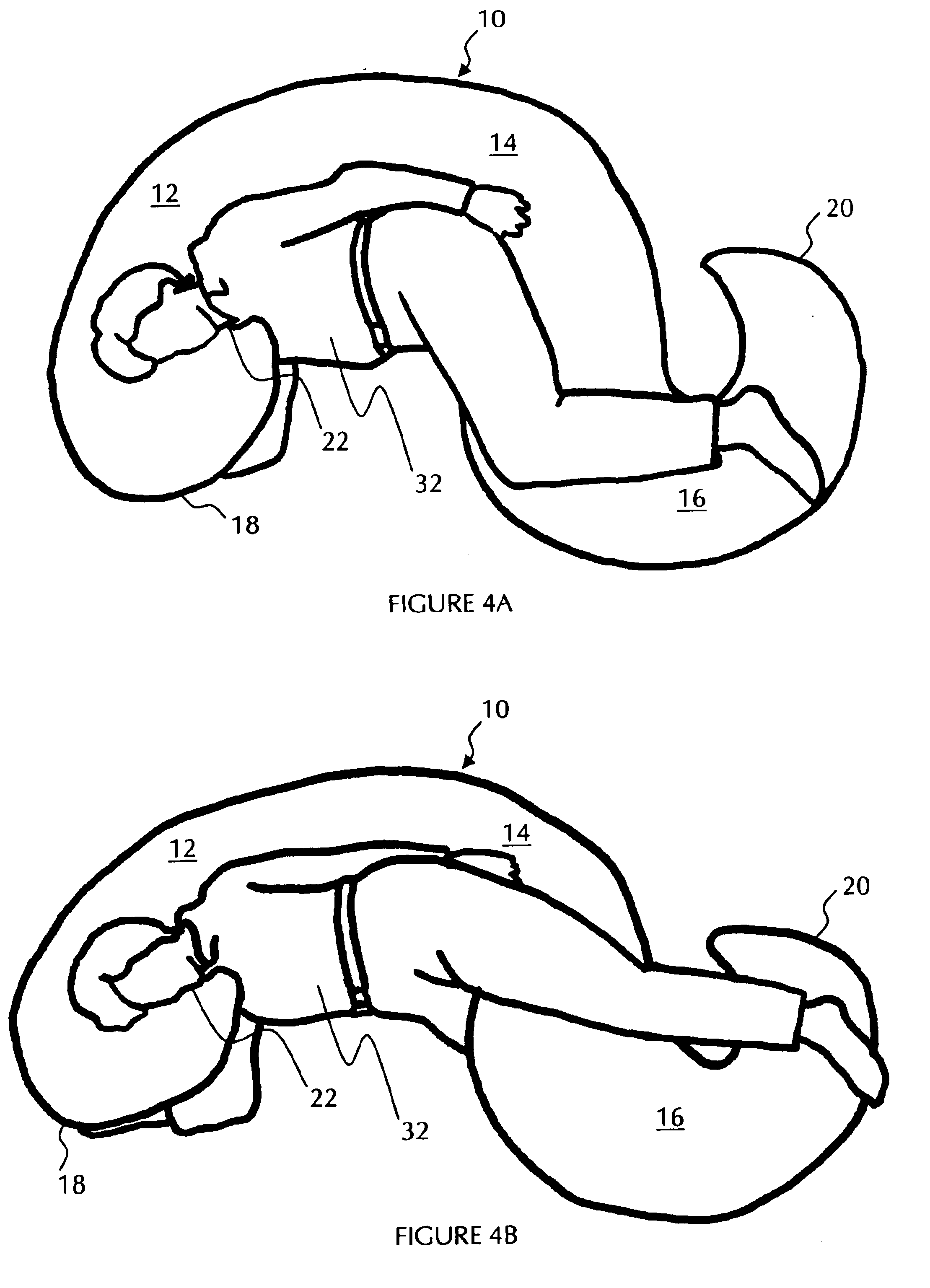

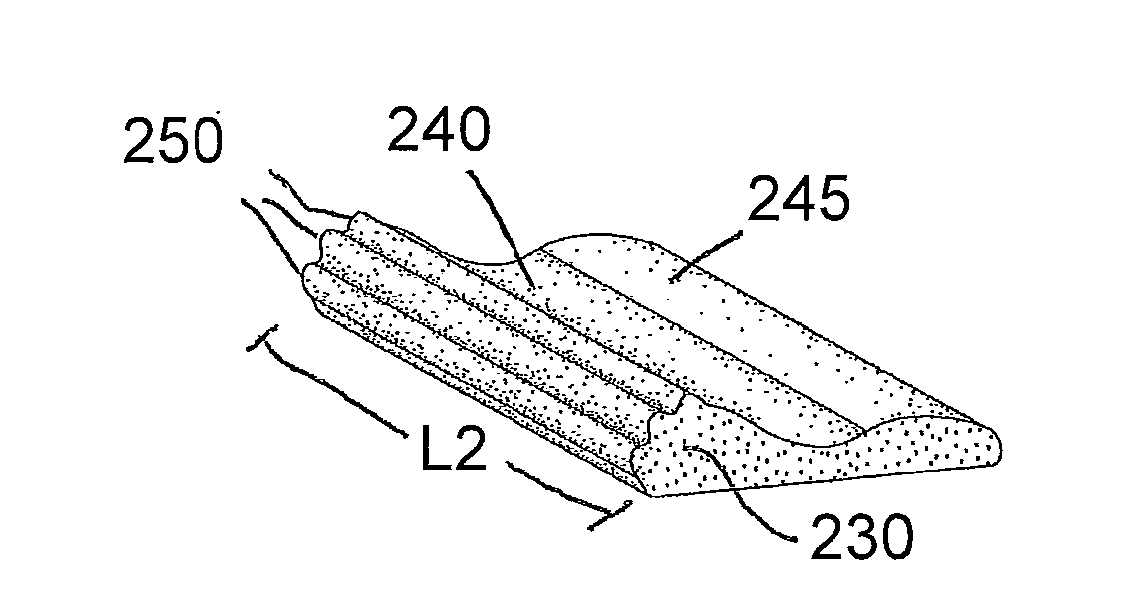

Therapeutic Positioning Device

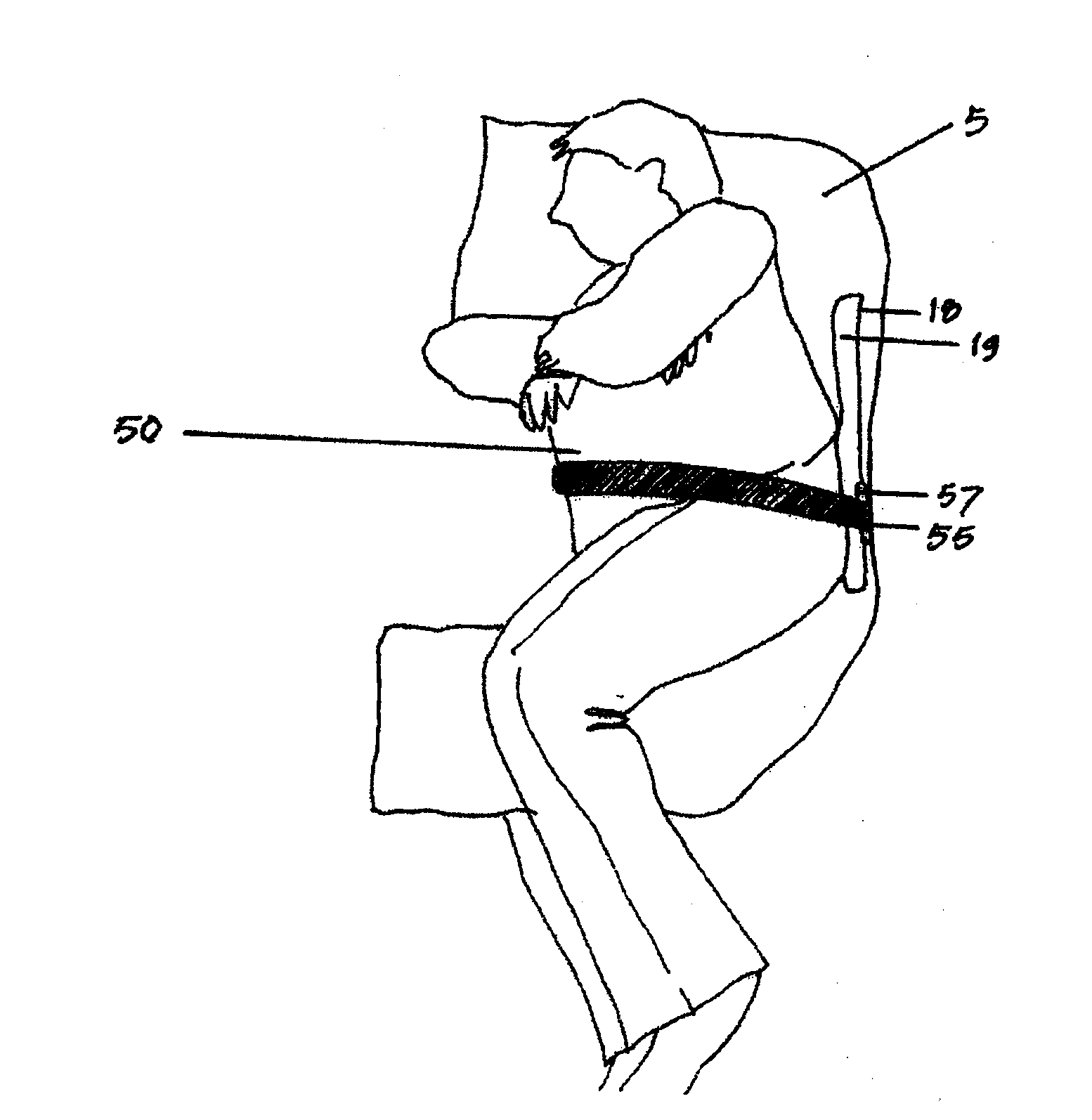

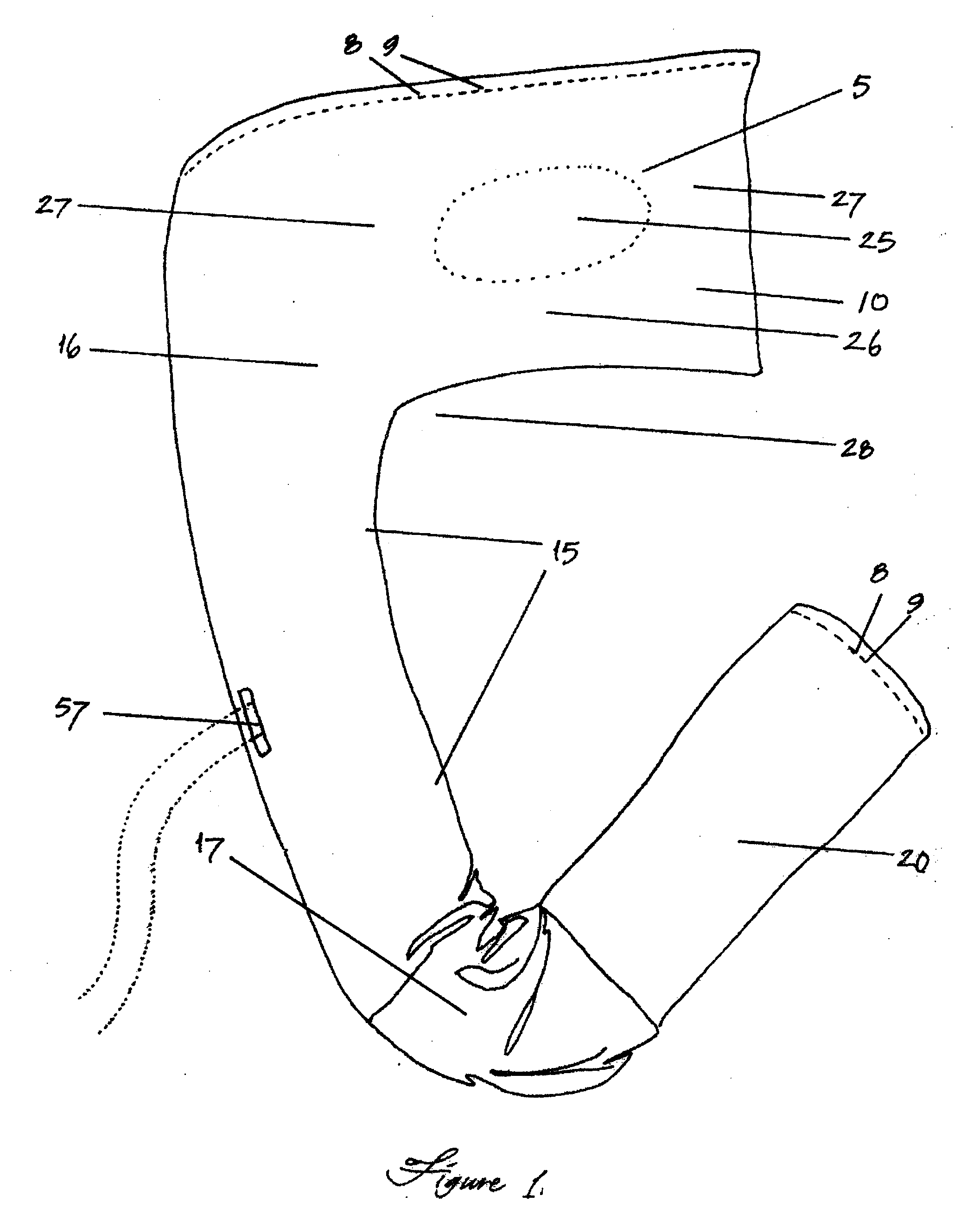

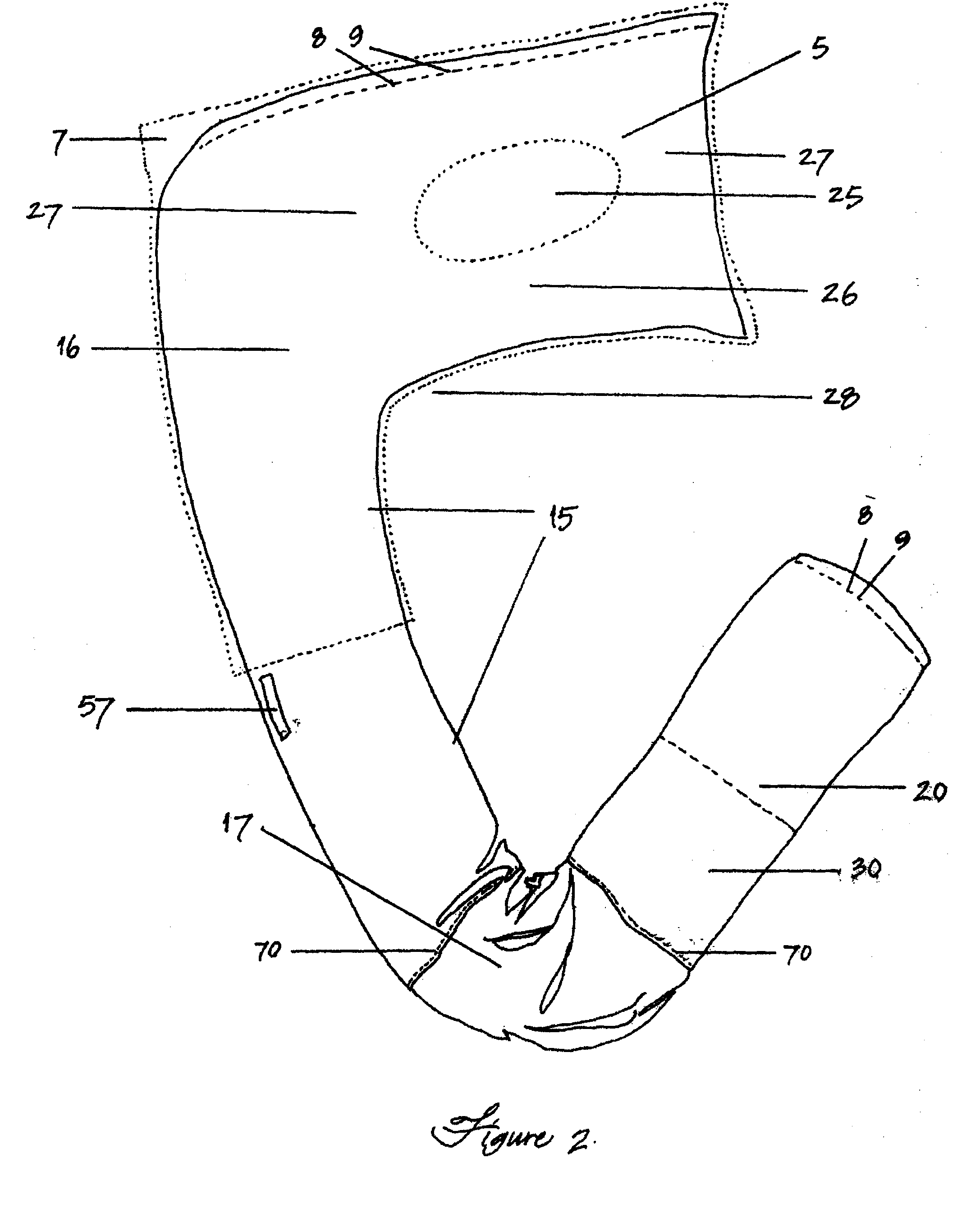

InactiveUS20080222813A1Reduces restless leg syndromeRelieve painPillowsElectric signal transmission systemsSide lyingSurgery

The present invention relates to a body support pillow made and contoured to promote side lying to reduce snoring and negate the consequences of sleep apnea and symptoms. It consists of a body support pillow with integrated, semi-rigid yet flexible support for a person's head, back, and legs while lying on their side thereby encouraging either left or right side position sleeping.

Owner:SOMNAFORM CORP

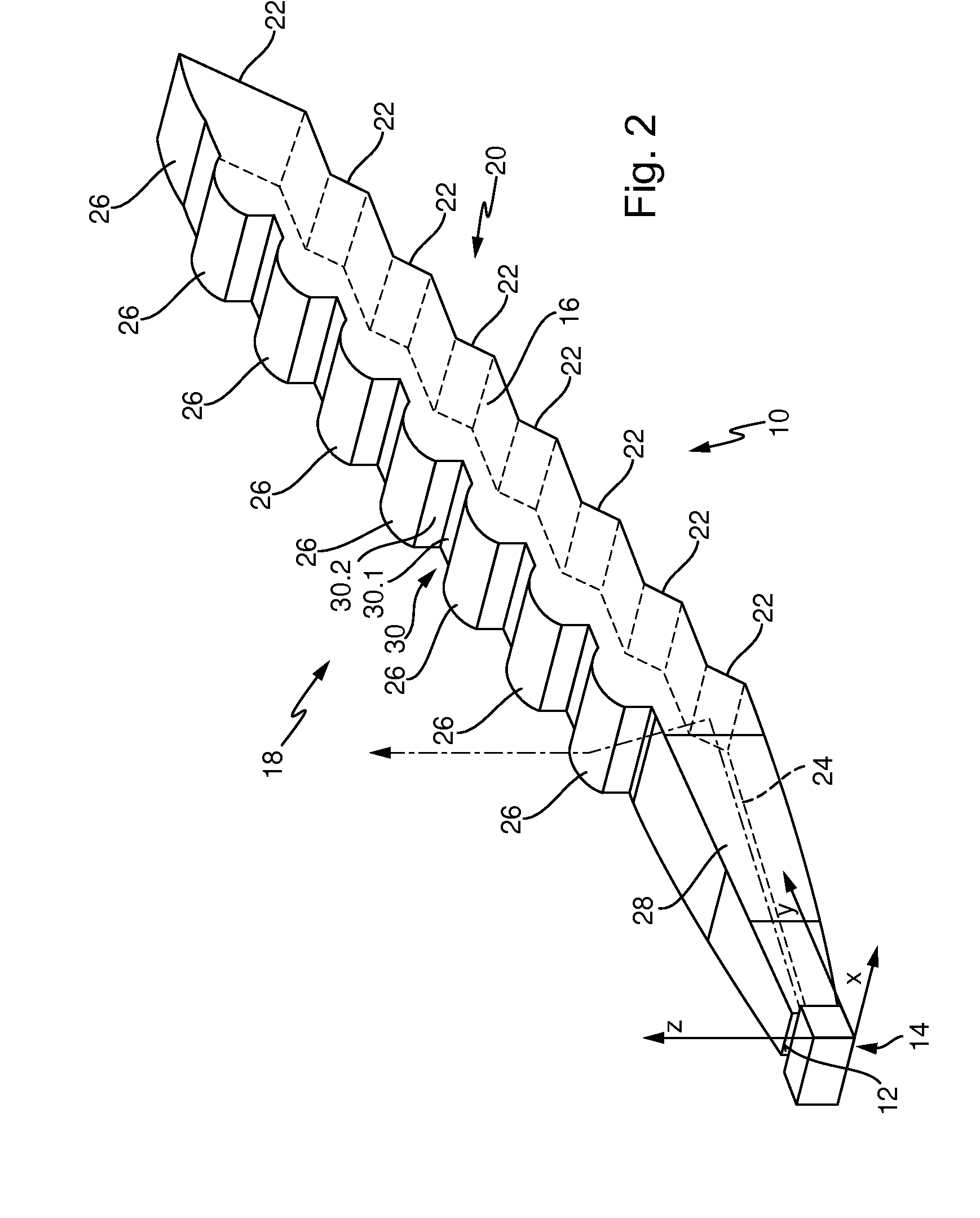

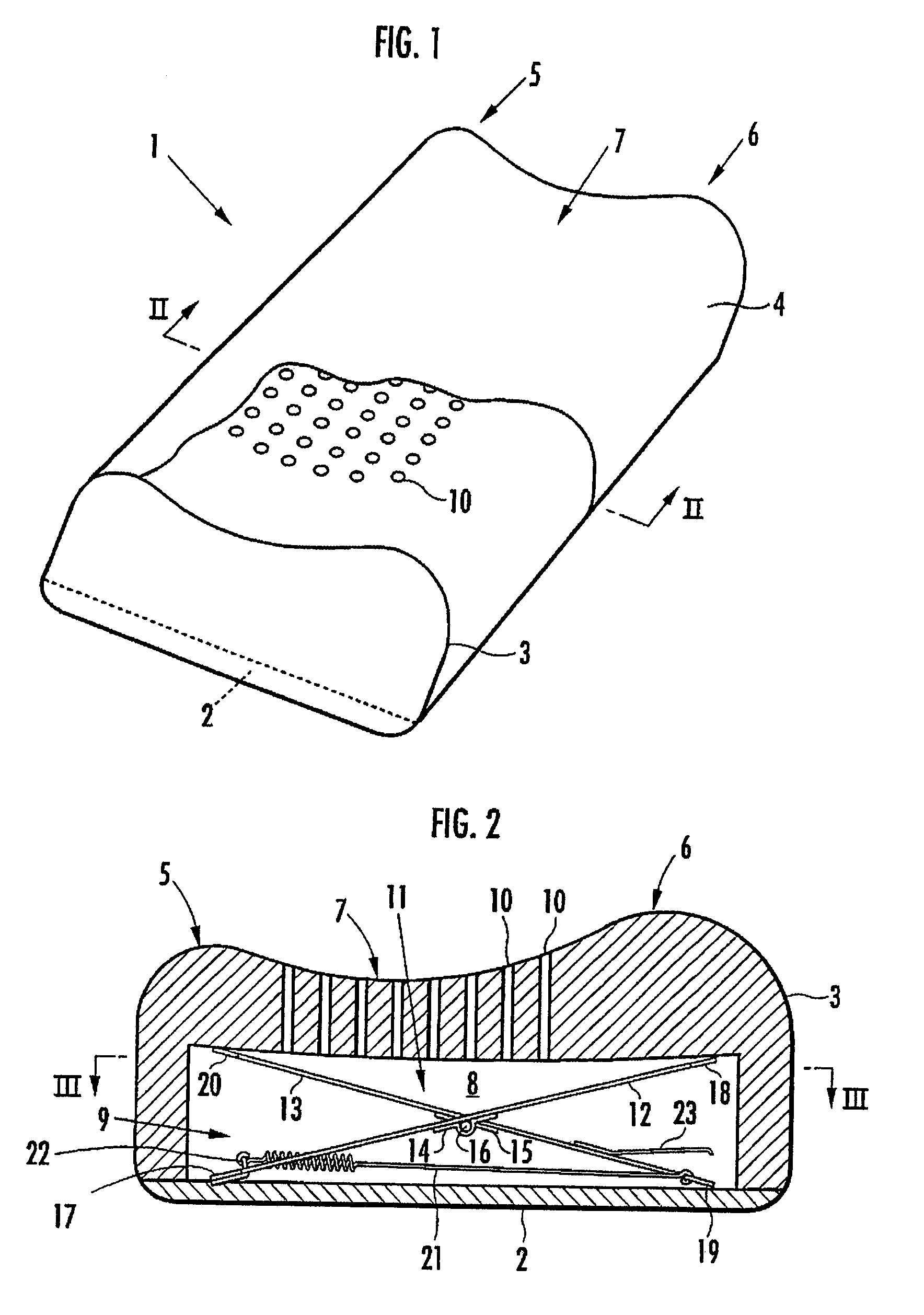

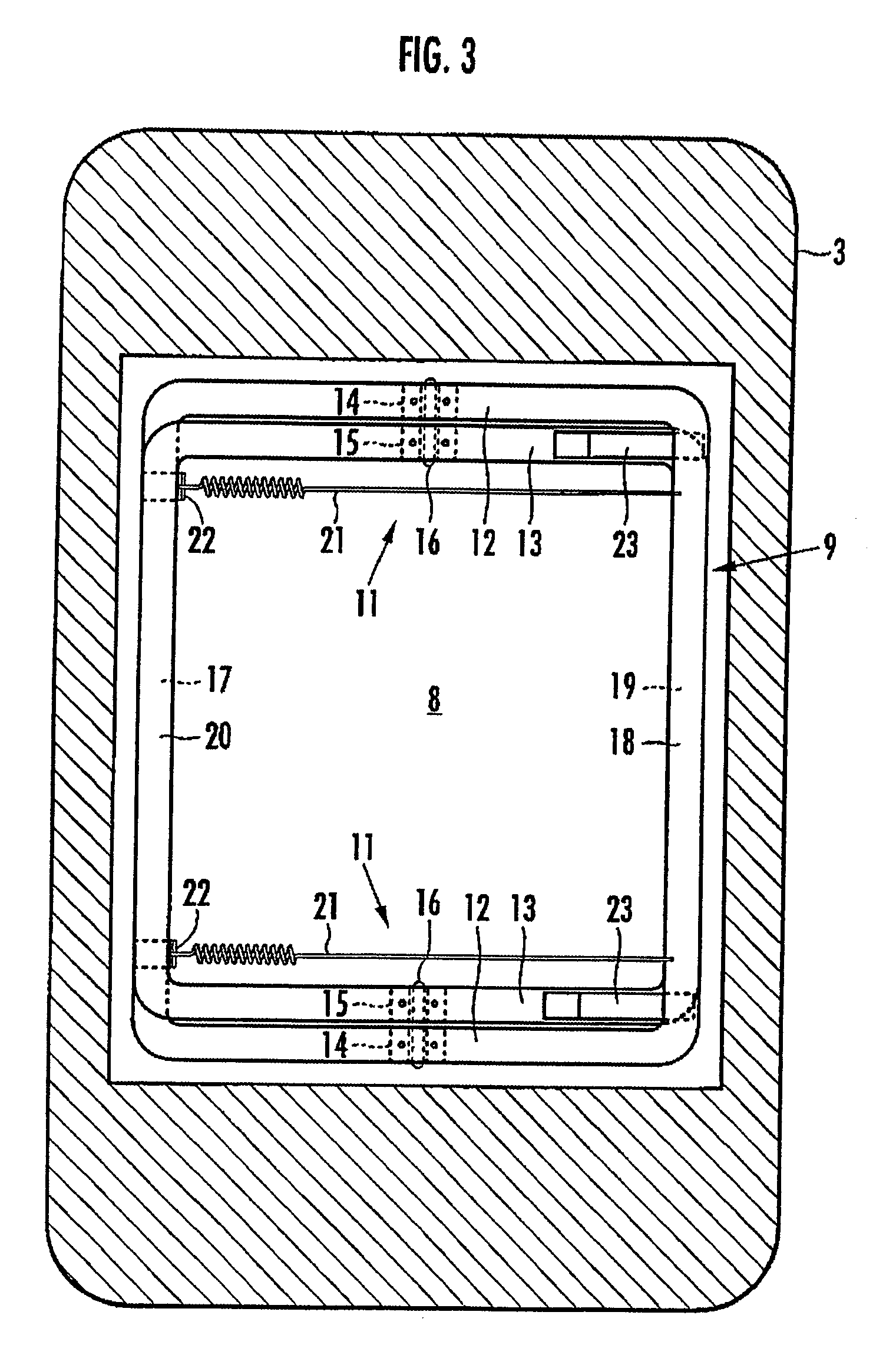

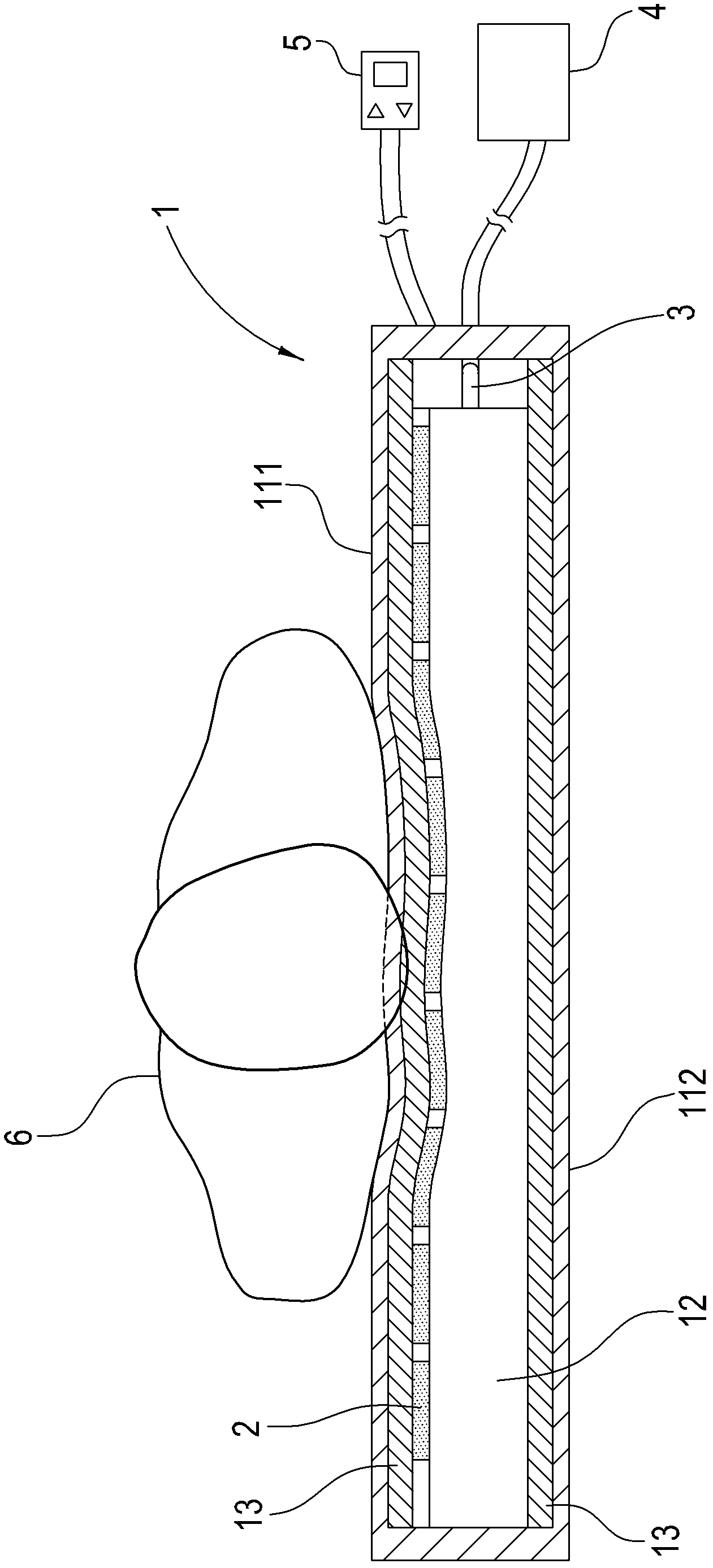

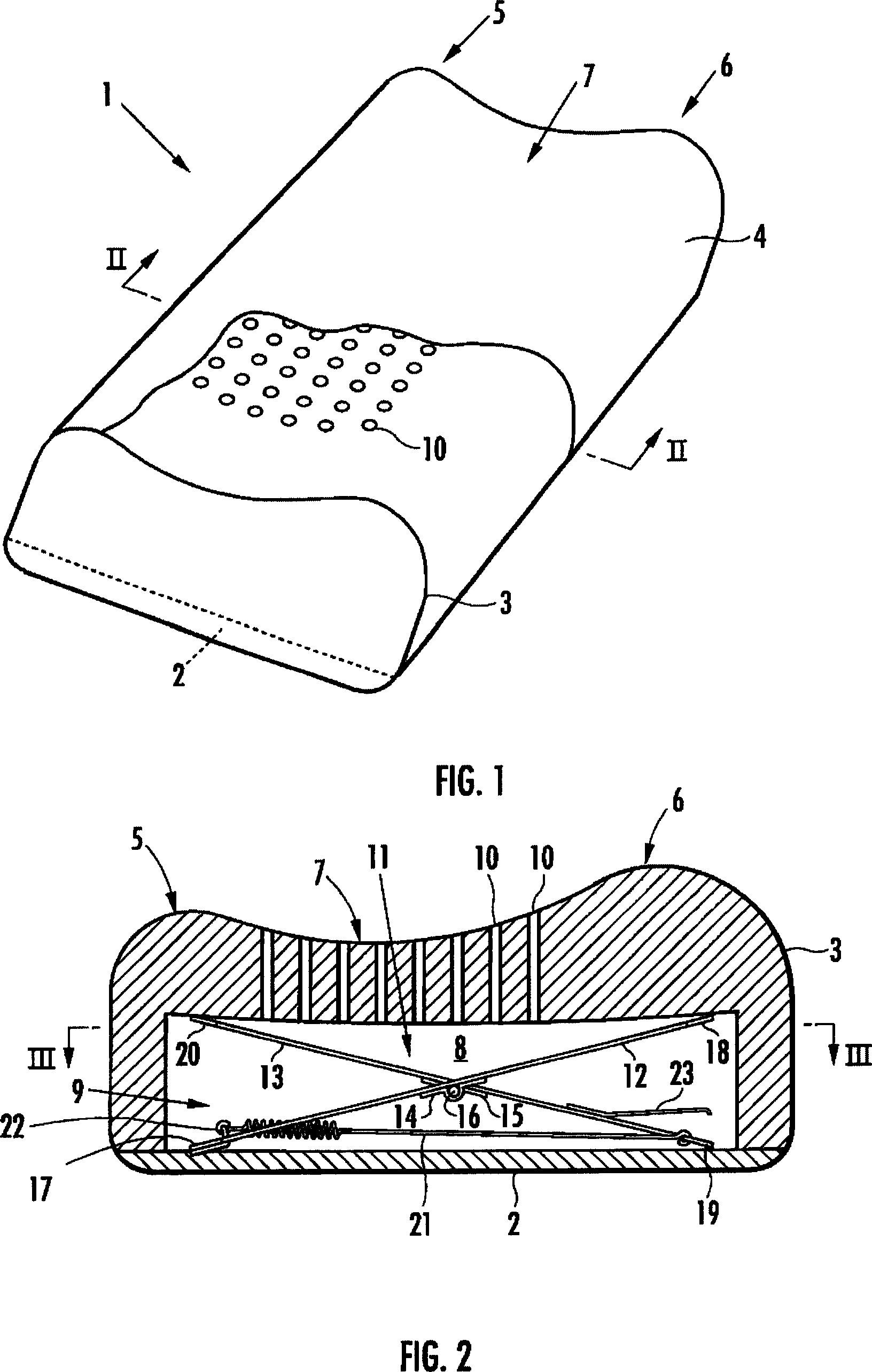

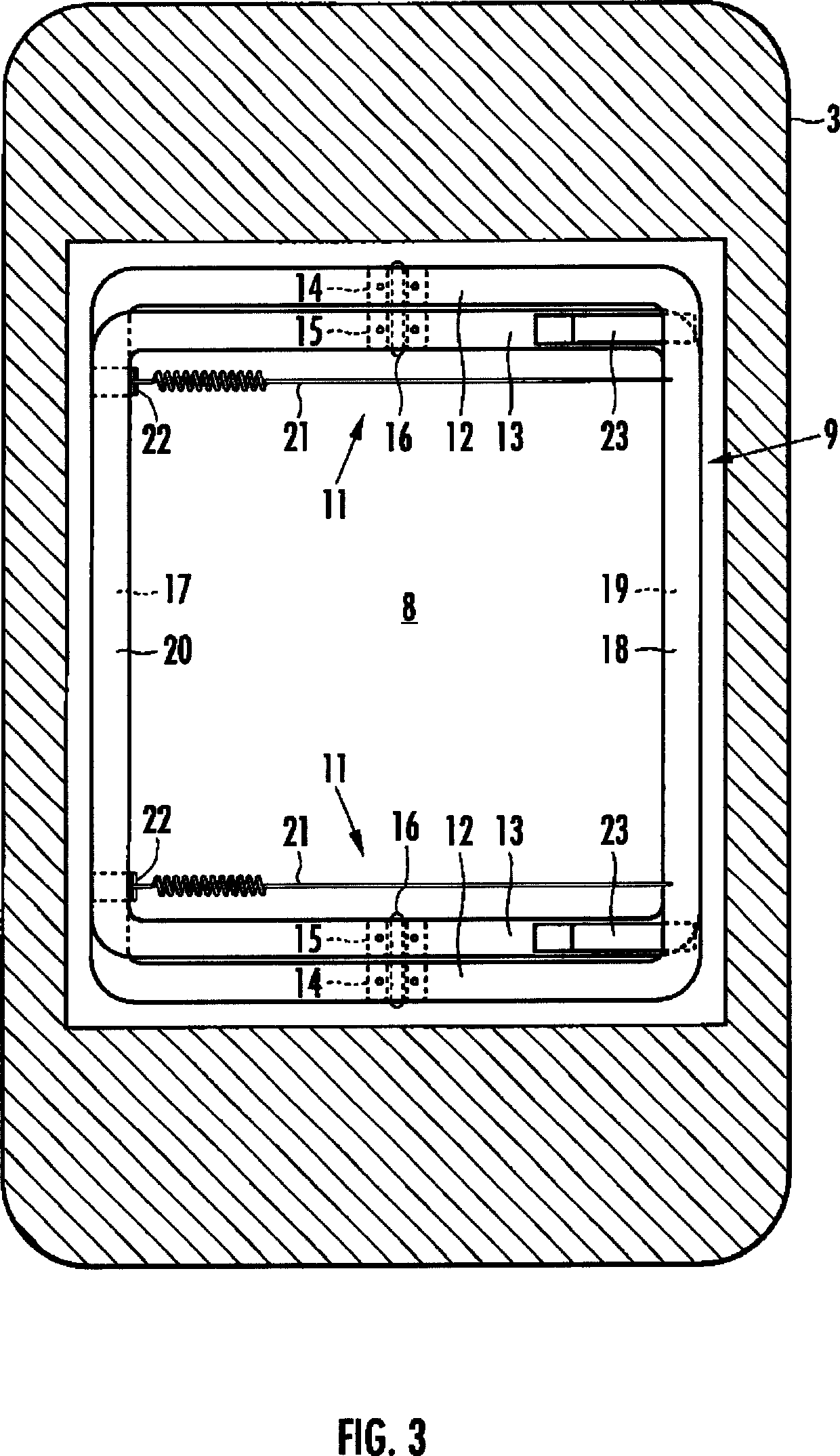

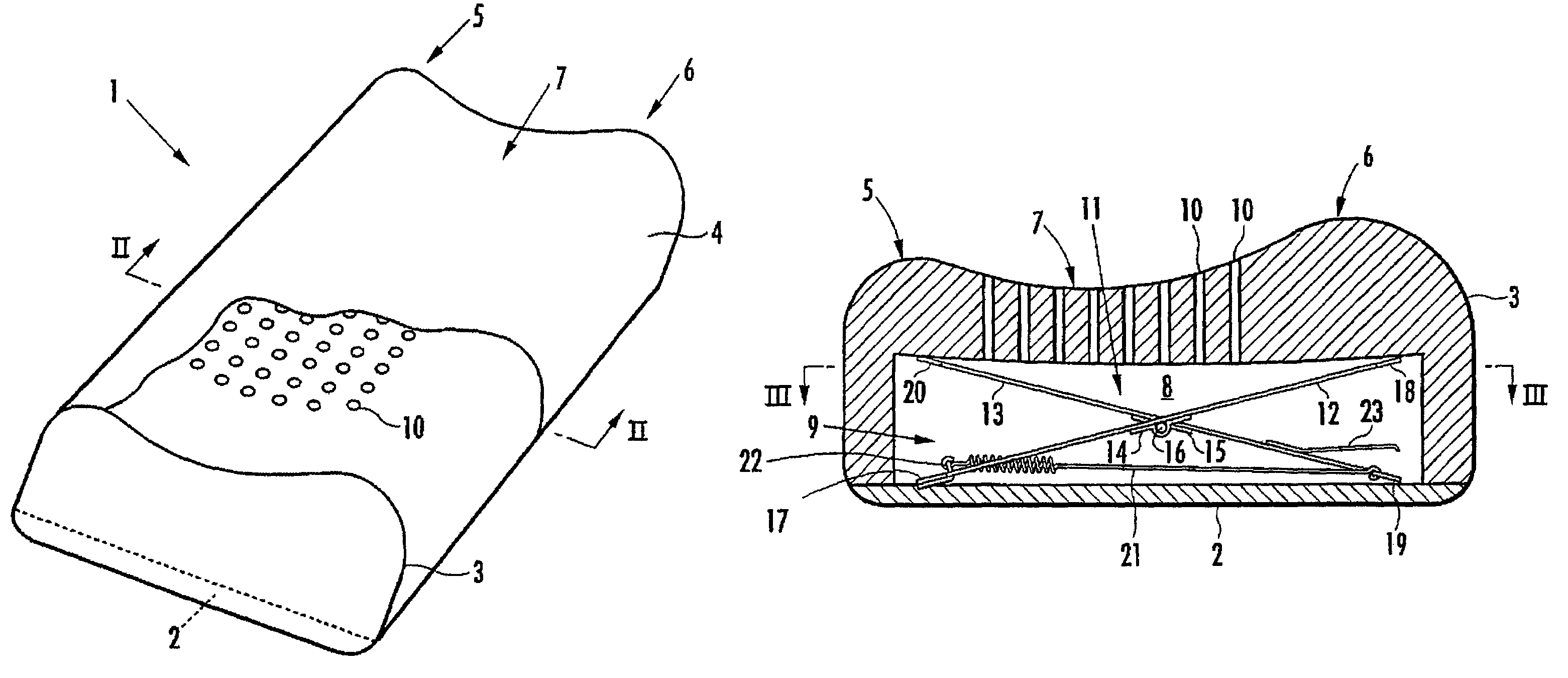

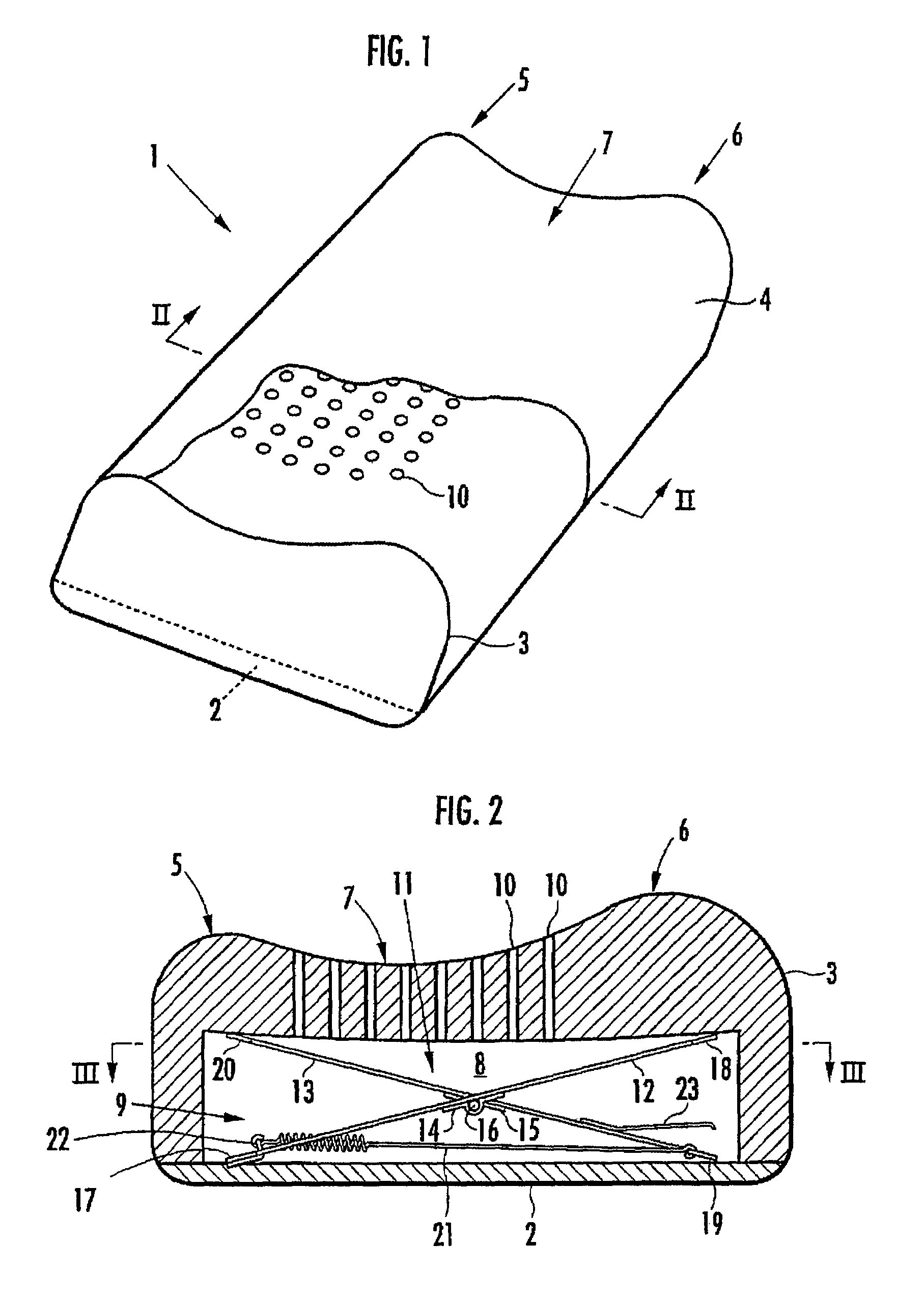

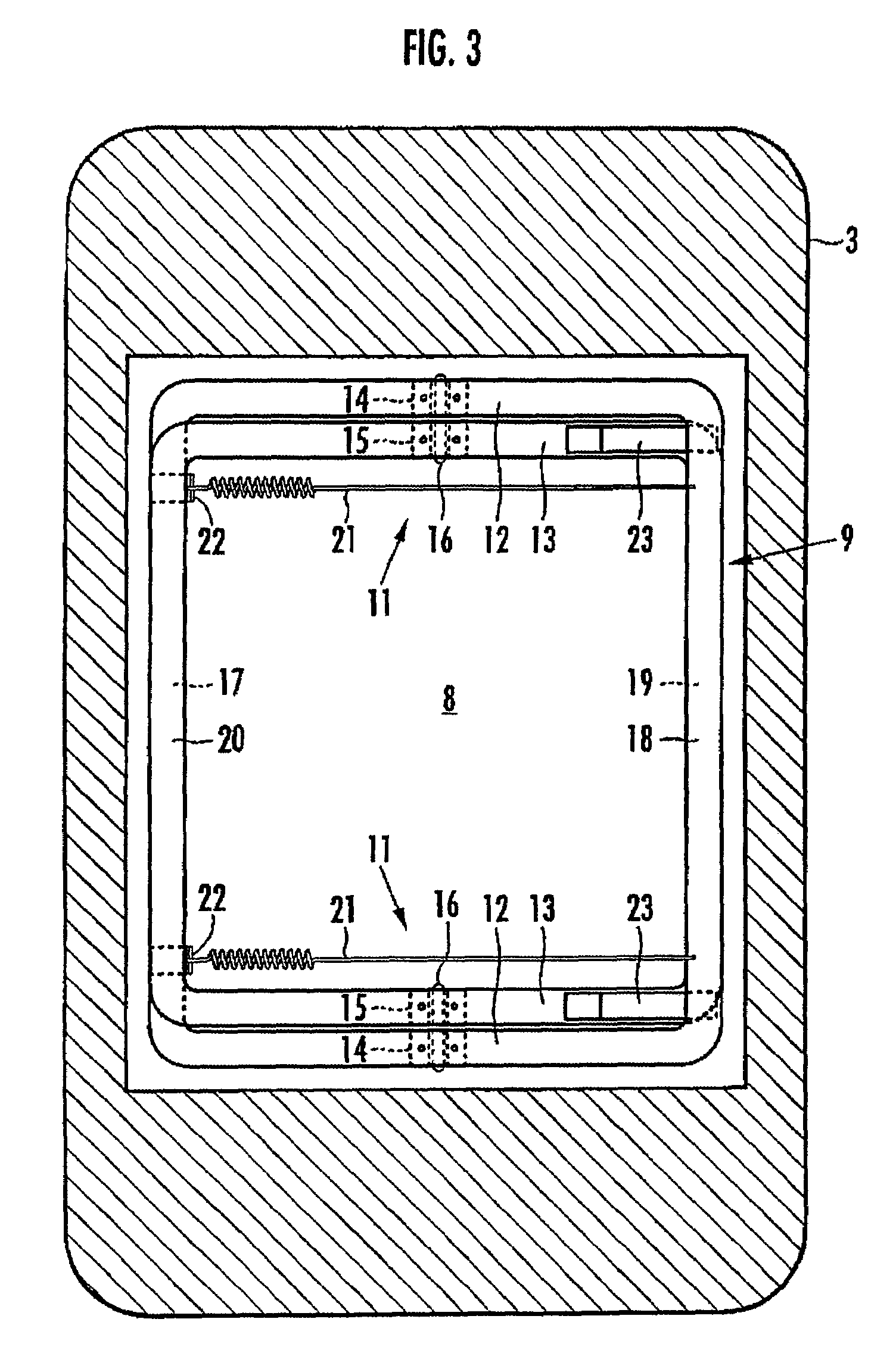

Pillow

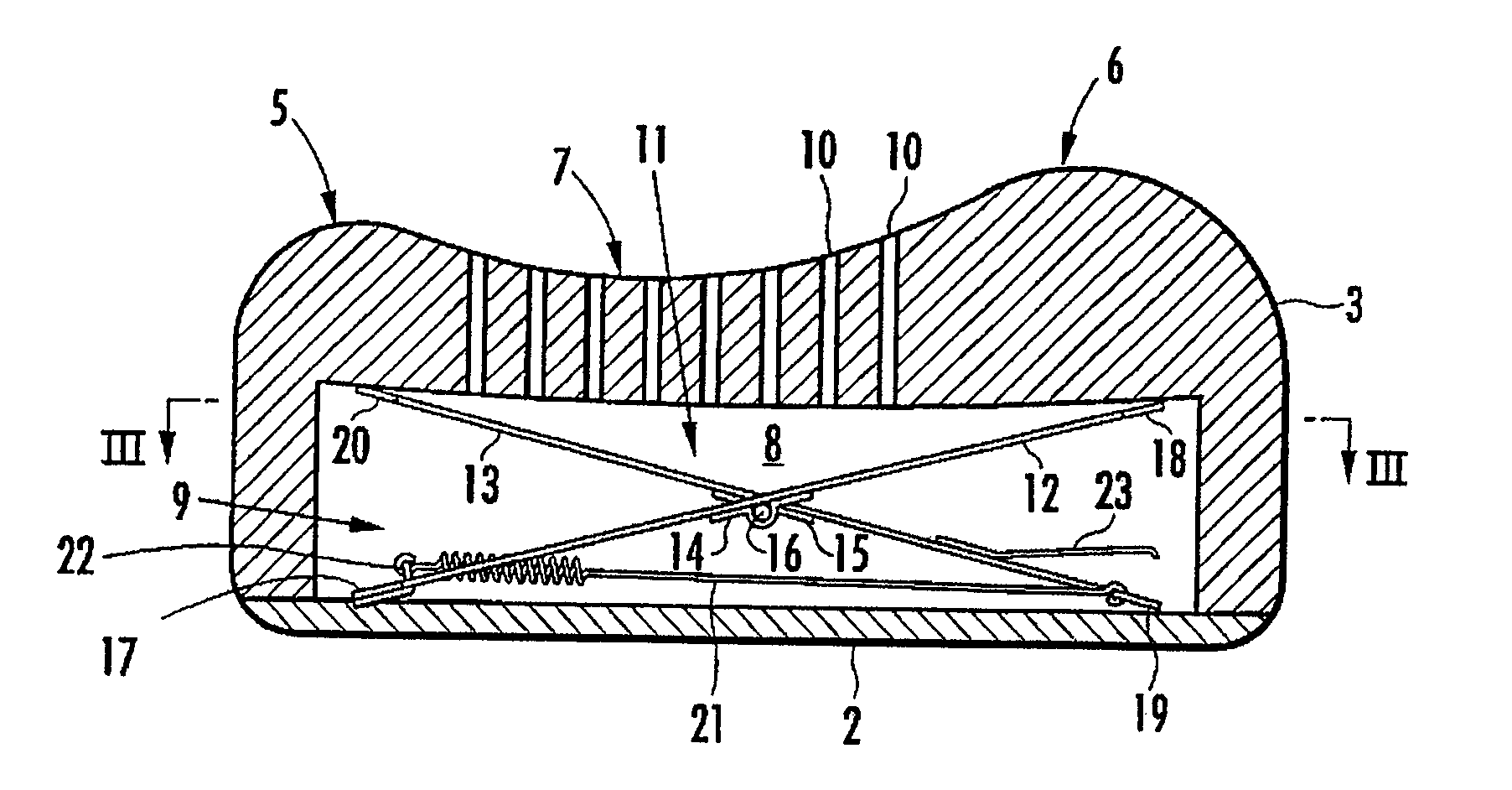

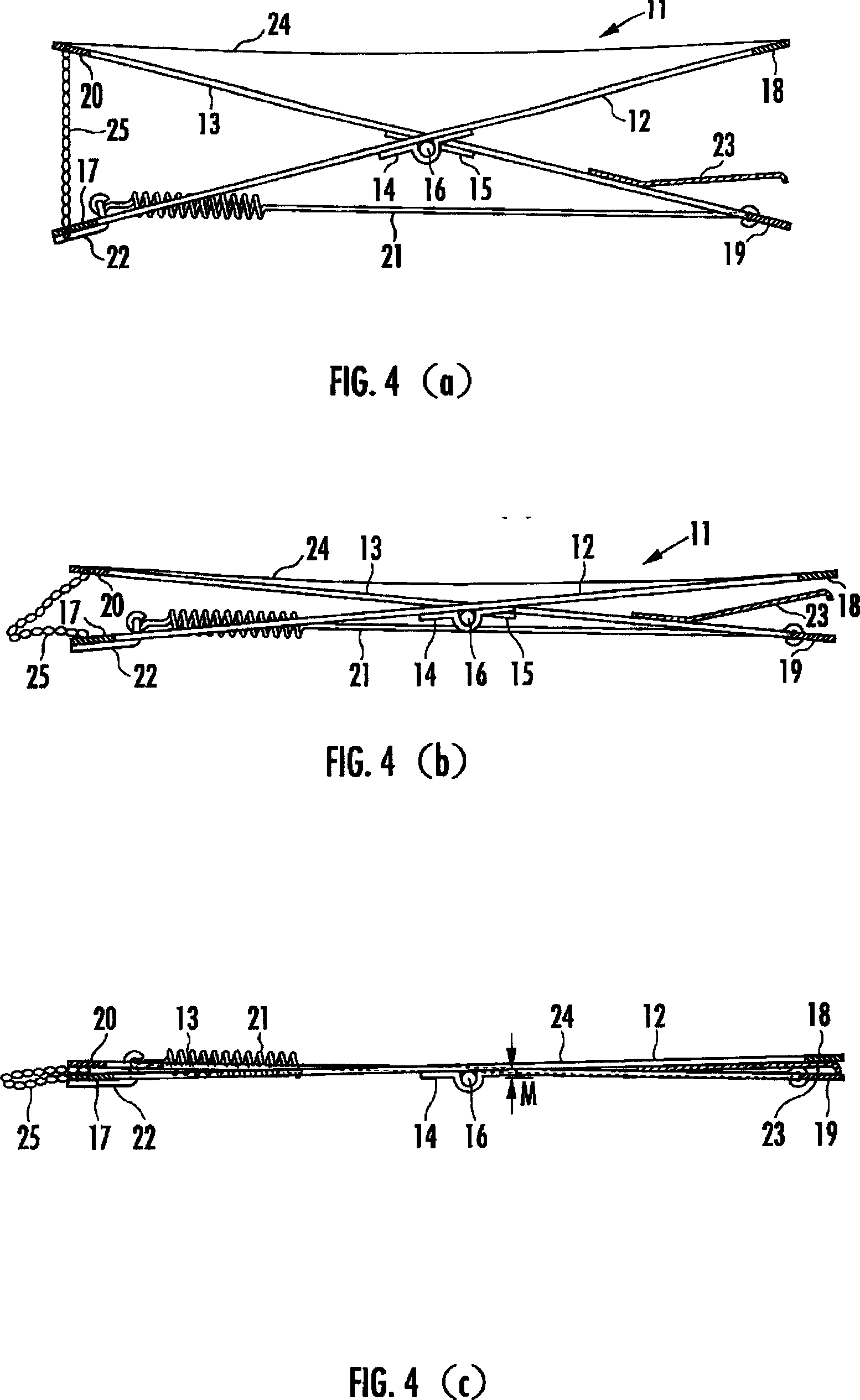

The invention provides a pillow capable of having the height thereof adjusted automatically so that the height of the back of the head of a user in a face-up lying position is slightly higher than his / her back, and also capable of having the height thereof varied automatically between a face-up lying position and a side lying position. A hollow portion 8 having a biasing mechanism 9 disposed therein is formed in a head placement member 3, and when the head is placed face-up on the head placement member 3, the hollow portion 8 is depressed so that the distance between the lowermost portion of the head and the bottom member 2 is in the range of 10 mm to 30 mm. The biasing mechanism has X-shaped links 11 disposed laterally spaced apart in the hollow portion 8. Each X-shaped link is composed by pivotally connecting a first link member 12 slanted upward toward the front and a second link member 13 slanted upward toward the rear by an intermediate link shaft 16. The biasing mechanism further comprises a front-side upper connecting member 18 for connecting the front ends of the first link members of the X-shaped links, a rear-side upper connecting member 20 for connecting the rear ends of the second link members of the X-shaped links, and a spring member 21 providing a spring force for approximating the link members of each X-shaped link in the frontward / rearward direction along a line of action in the frontward / rearward direction with respect to the X-shaped links.

Owner:NAKAYAMA SHINICHIRO

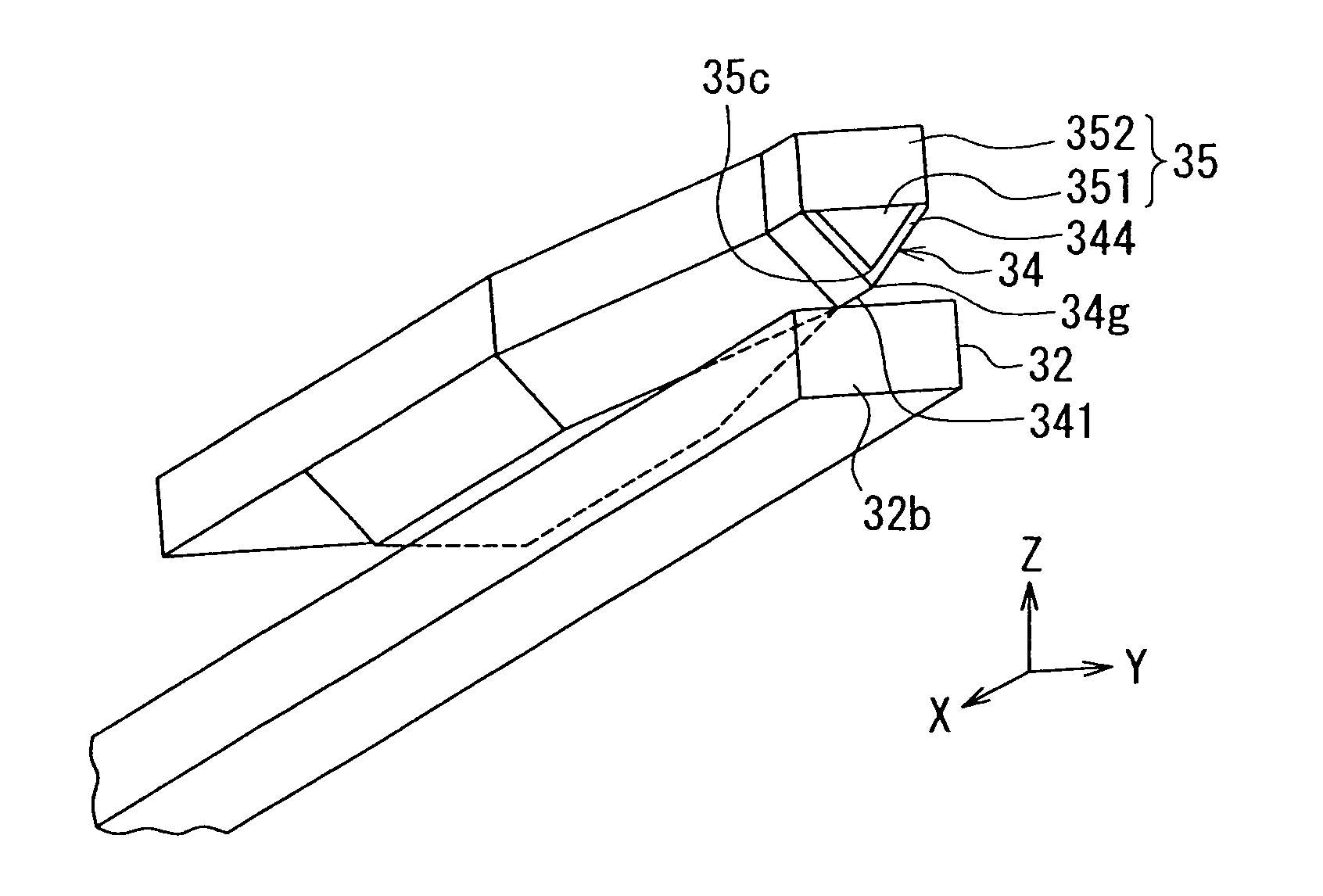

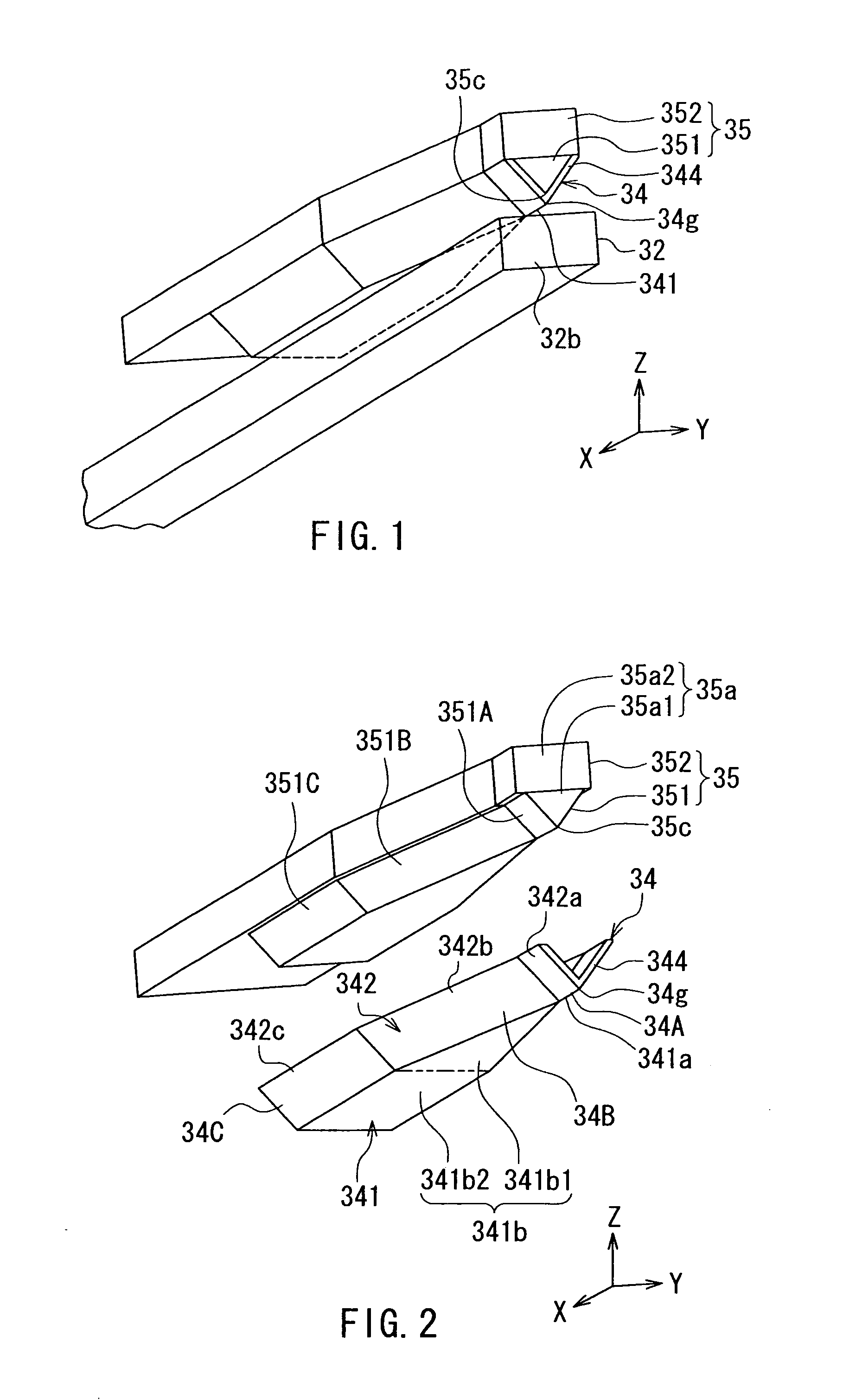

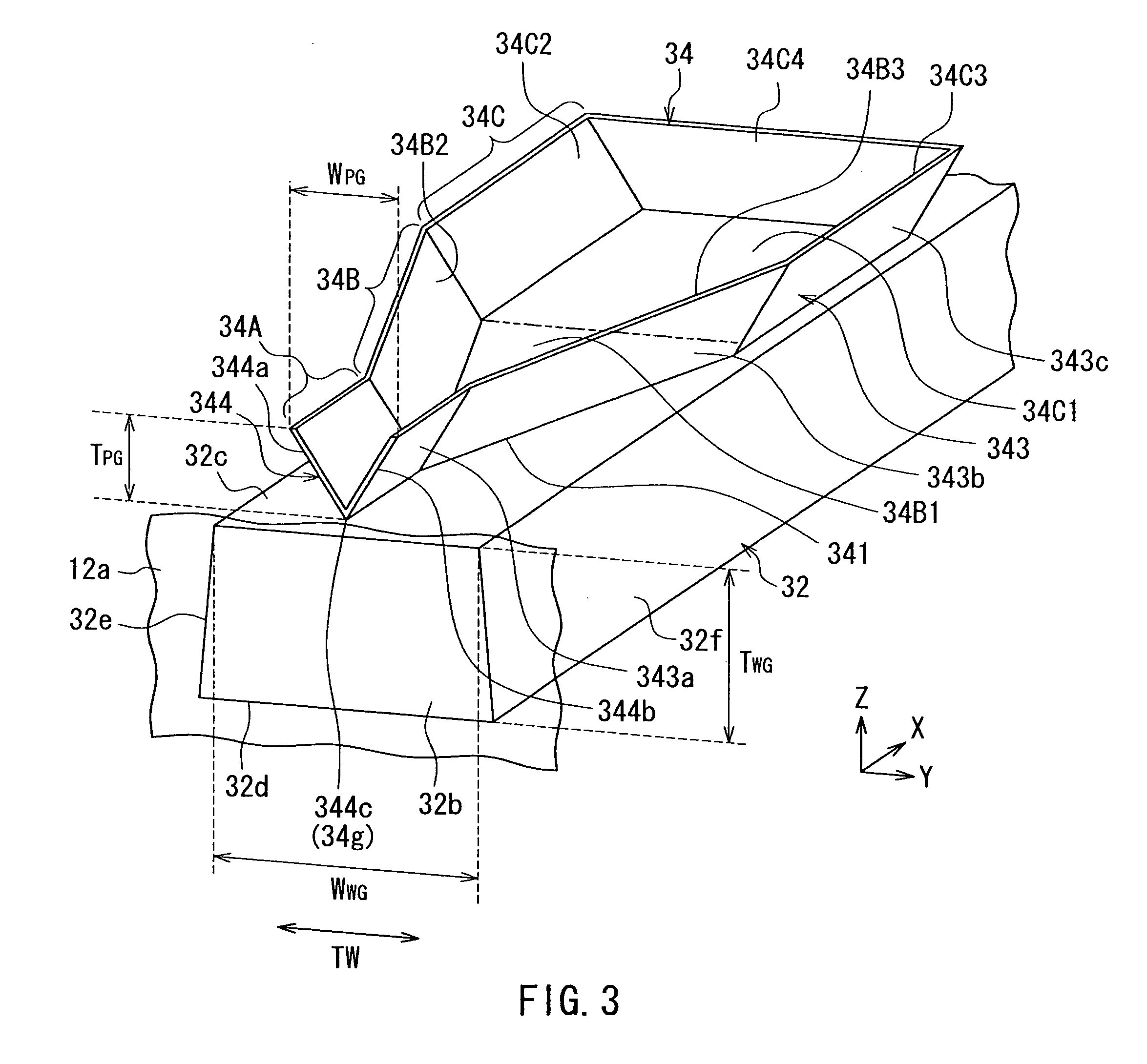

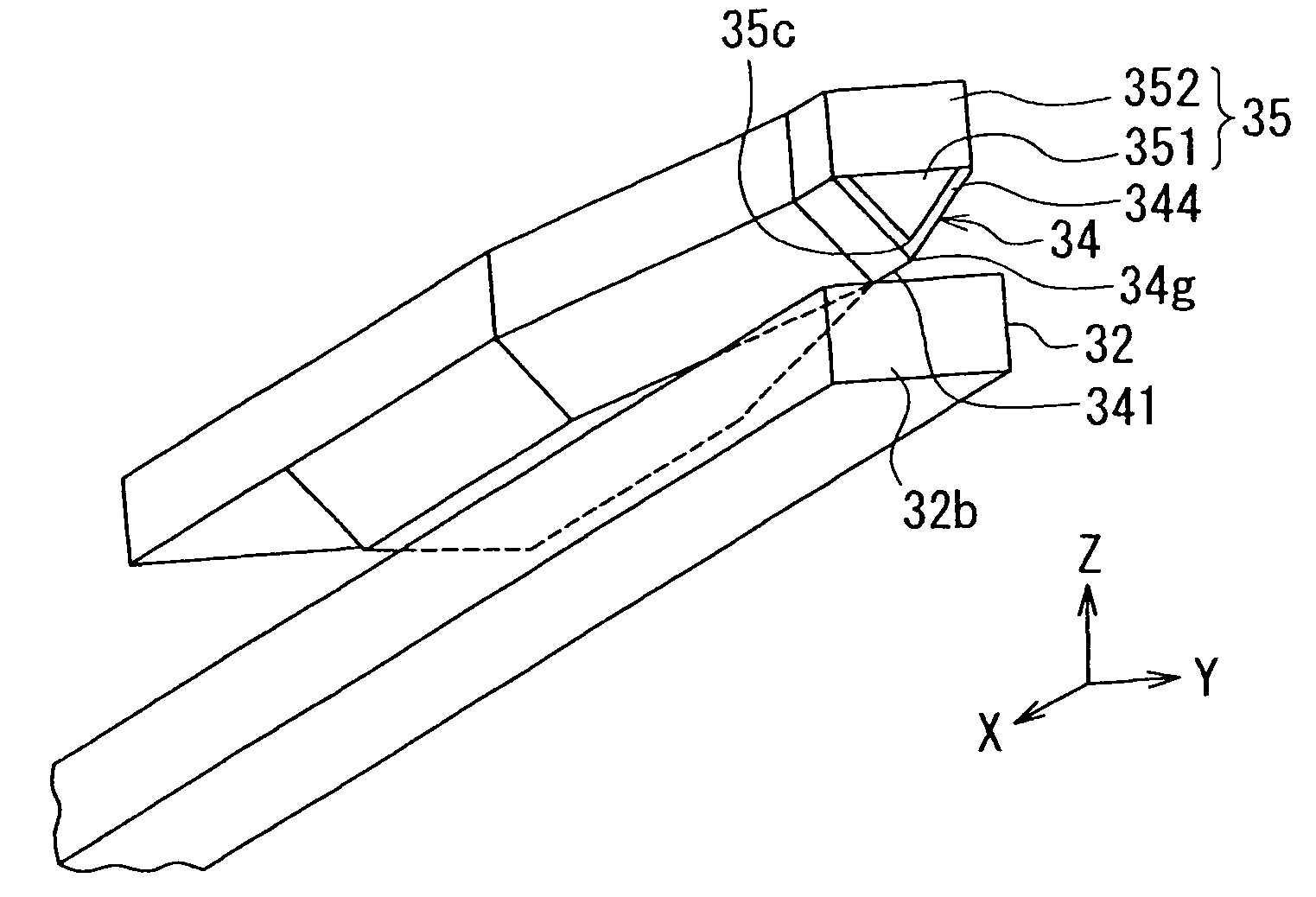

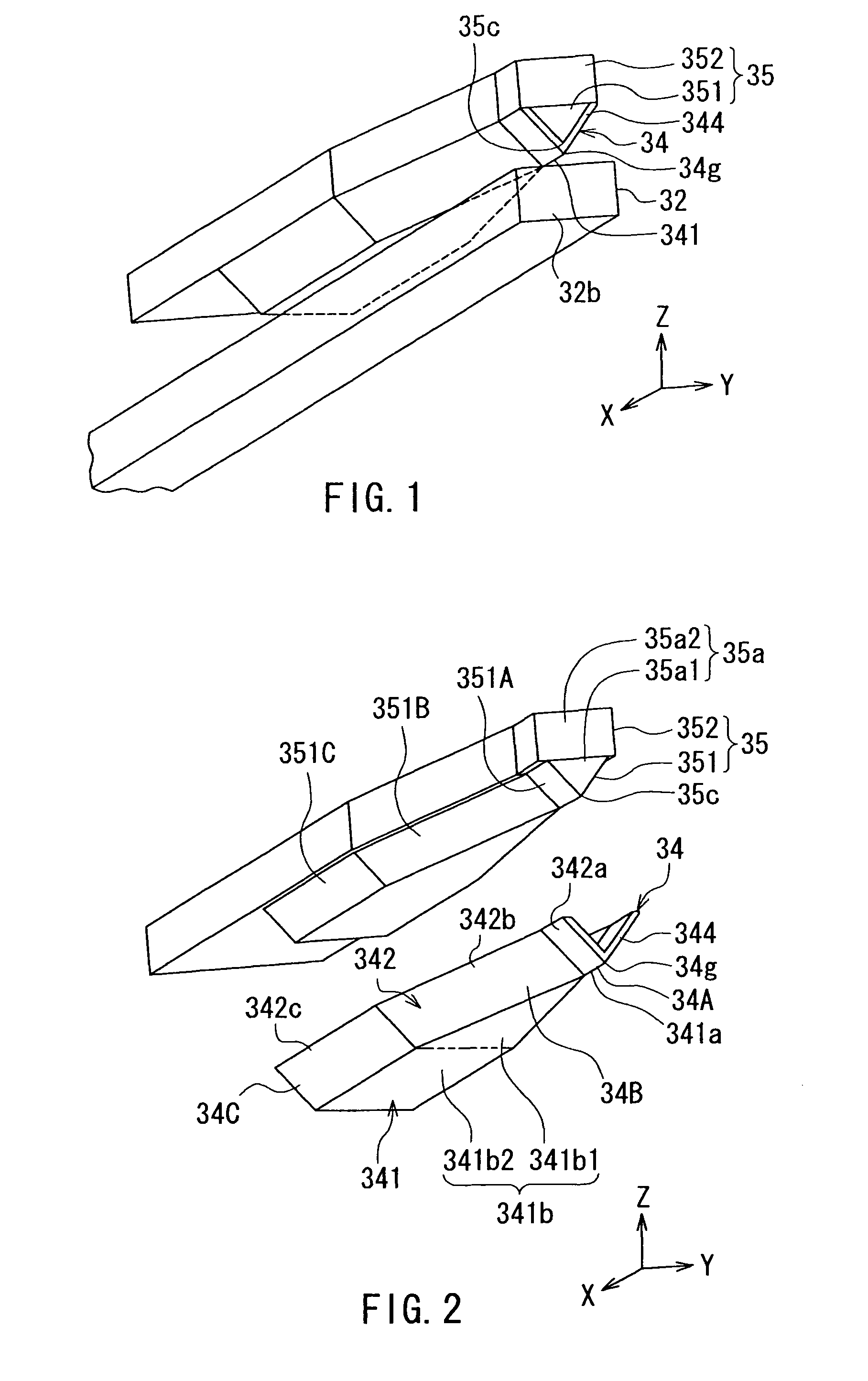

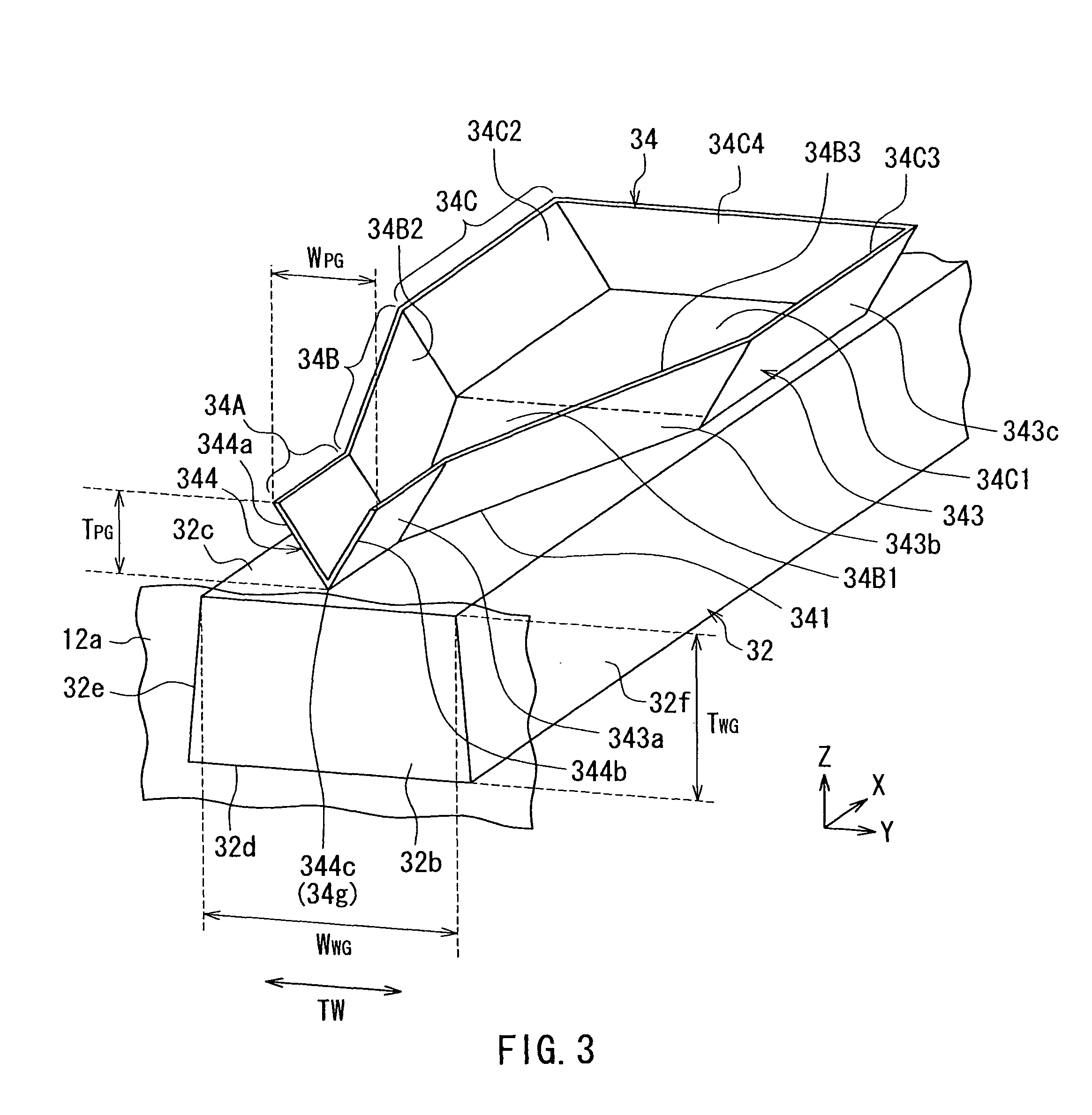

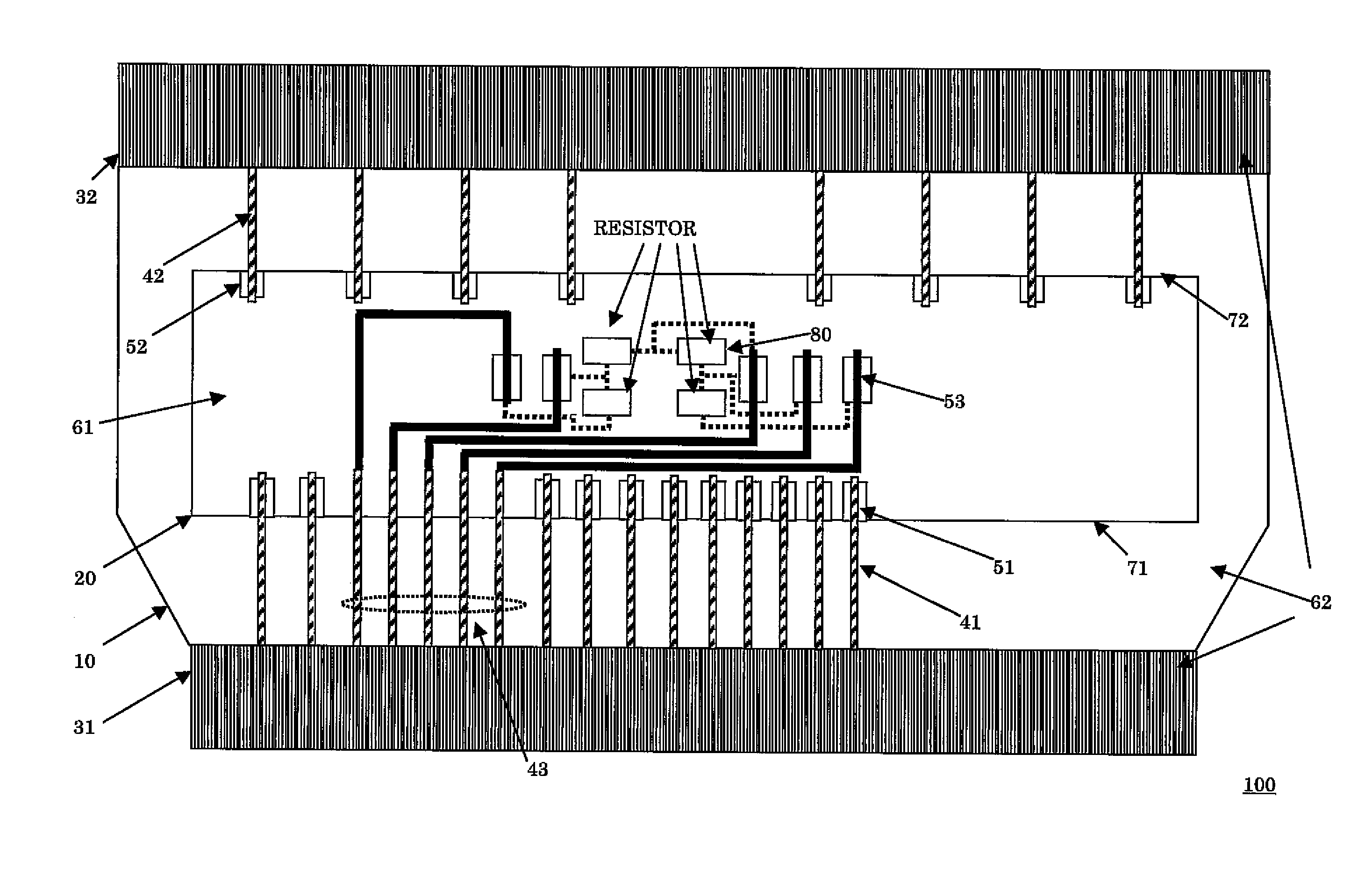

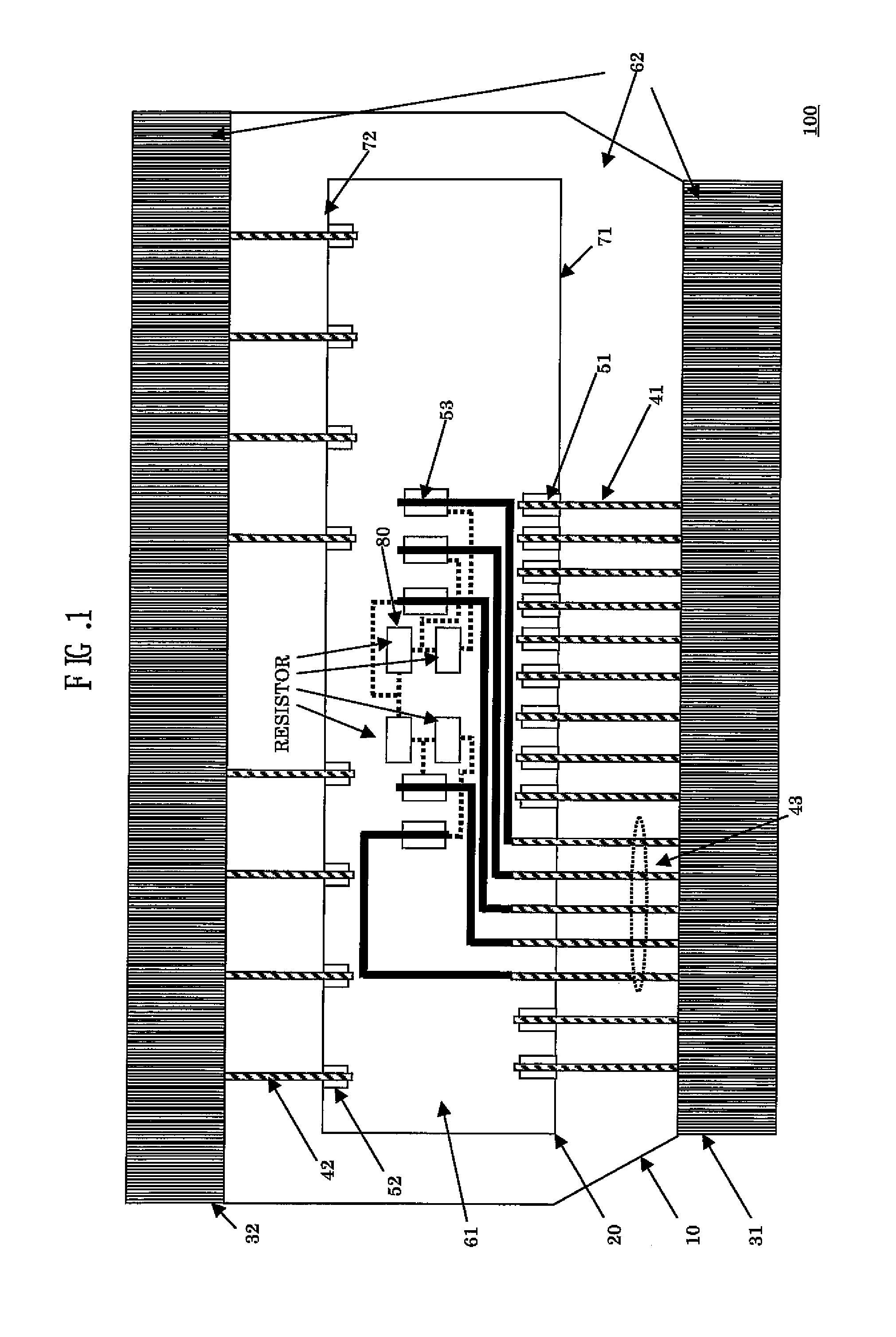

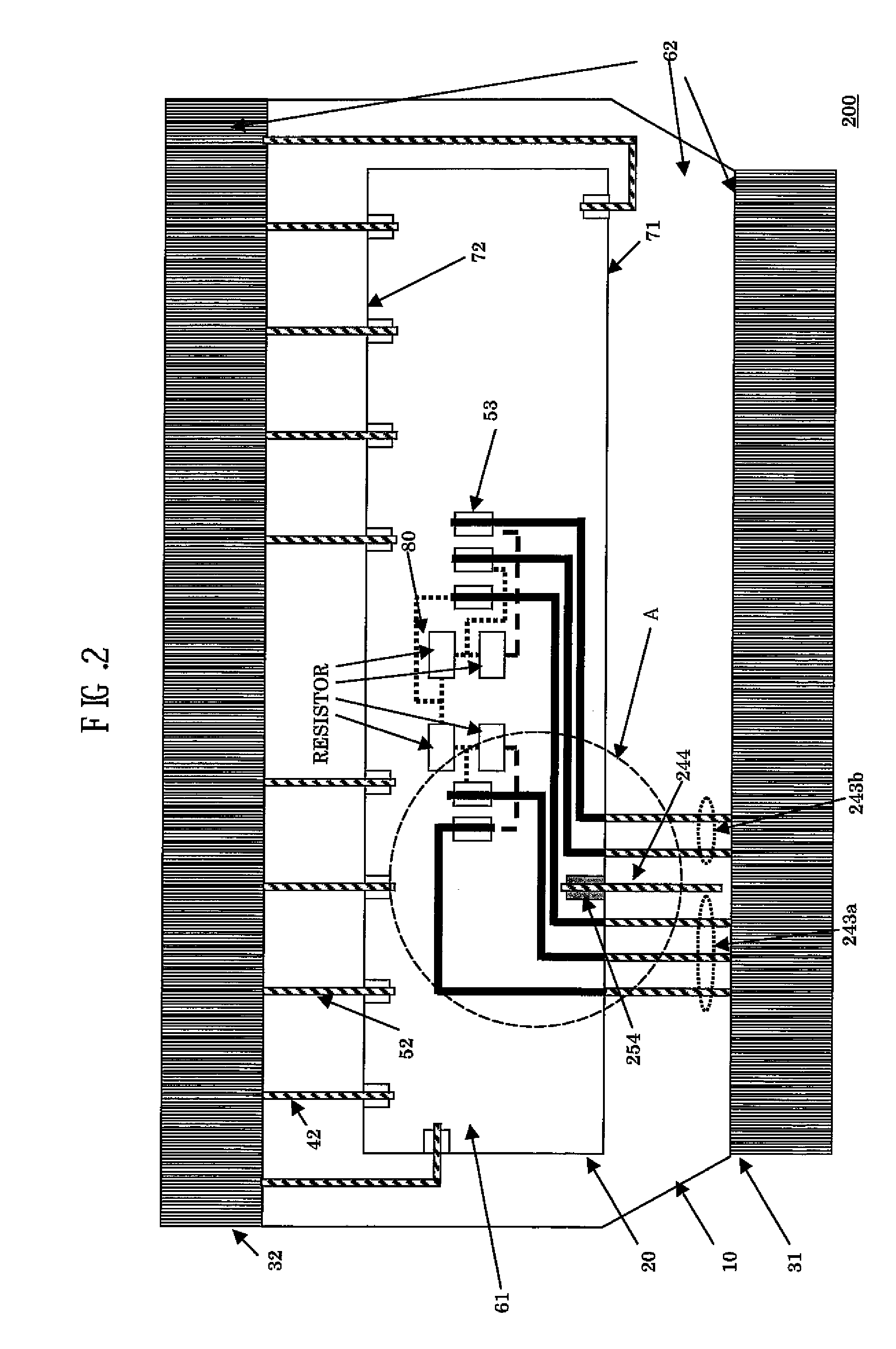

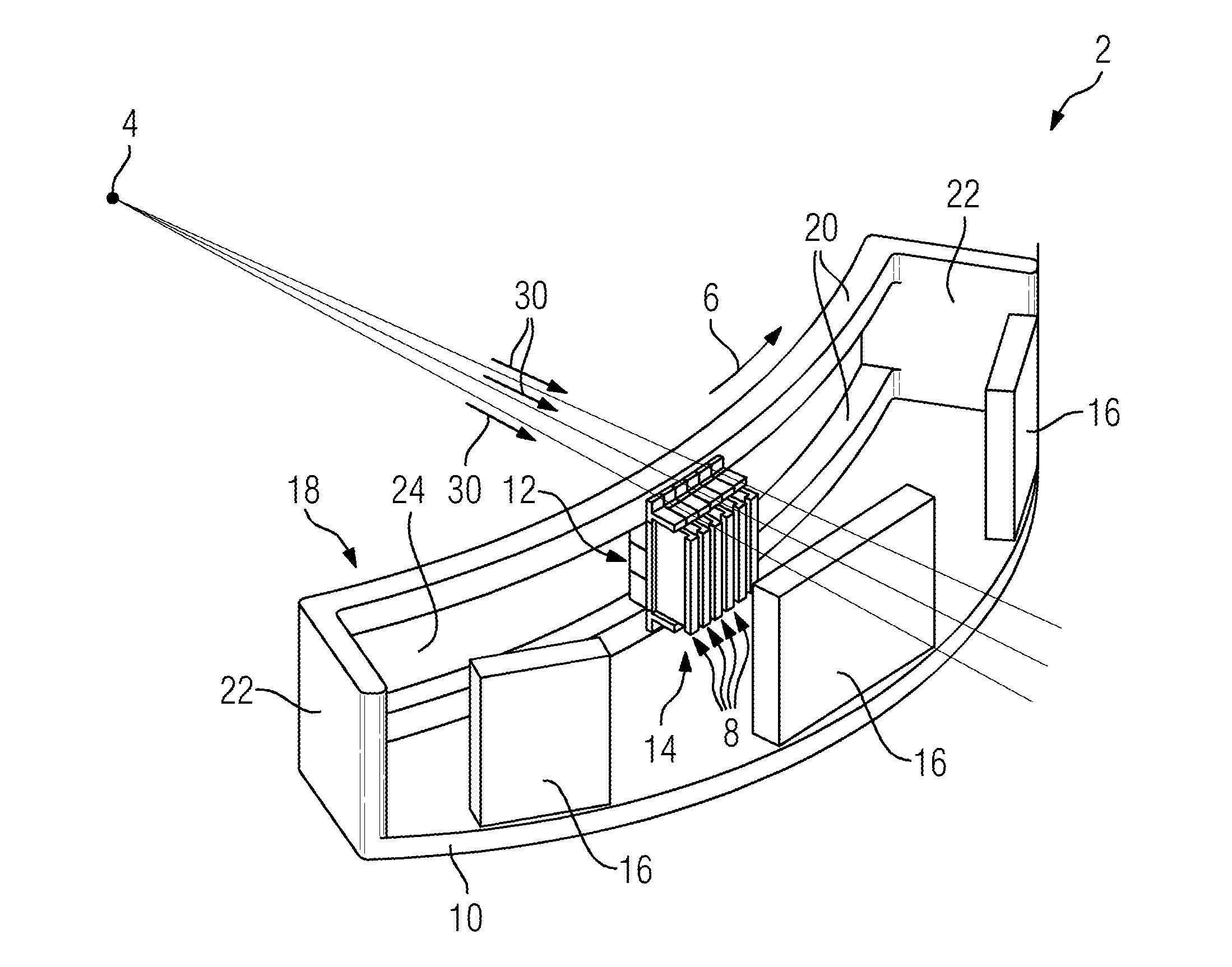

Thermally-assisted magnetic recording head including plasmon generator

ActiveUS20110286128A1Easy to useSmall spot diameterCombination recordingElectrical transducersHeat-assisted magnetic recordingPlasma generator

A plasmon generator has an outer surface including a plasmon exciting part that faces an evanescent light generating surface of a waveguide. The outer surface further includes first and second inclined surfaces that increase in distance from each other with increasing distance from the plasmon exciting part, and a front end face. The front end face has first and second portions that are connected to each other into a V-shape. The first portion includes a first side lying at an end of the first inclined surface. The second portion includes a second side lying at an end of the second inclined surface. An angle formed between a lower part of the first side and a lower part of the second side is smaller than that formed between an upper part of the first side and an upper part of the second side.

Owner:TDK CORPARATION

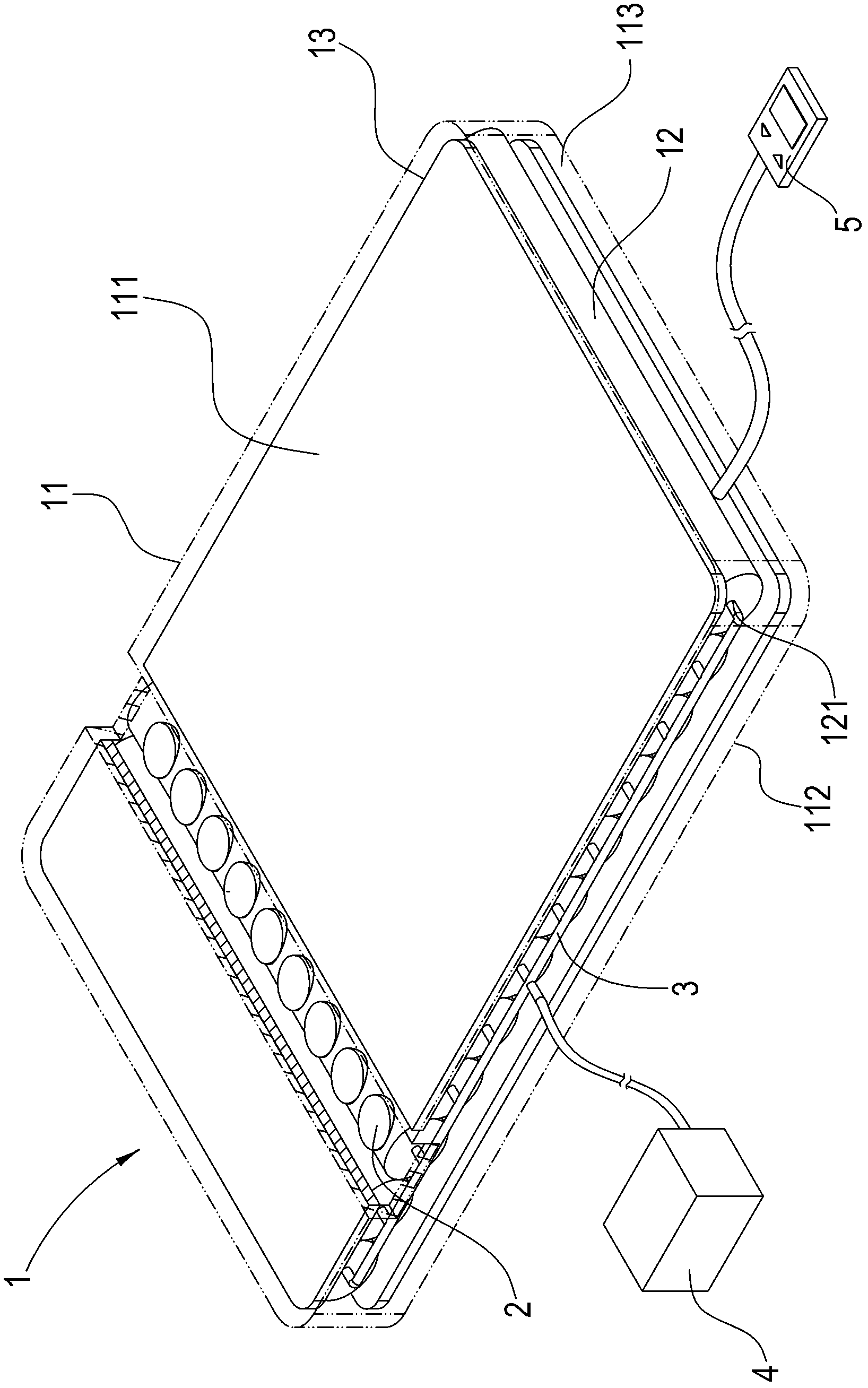

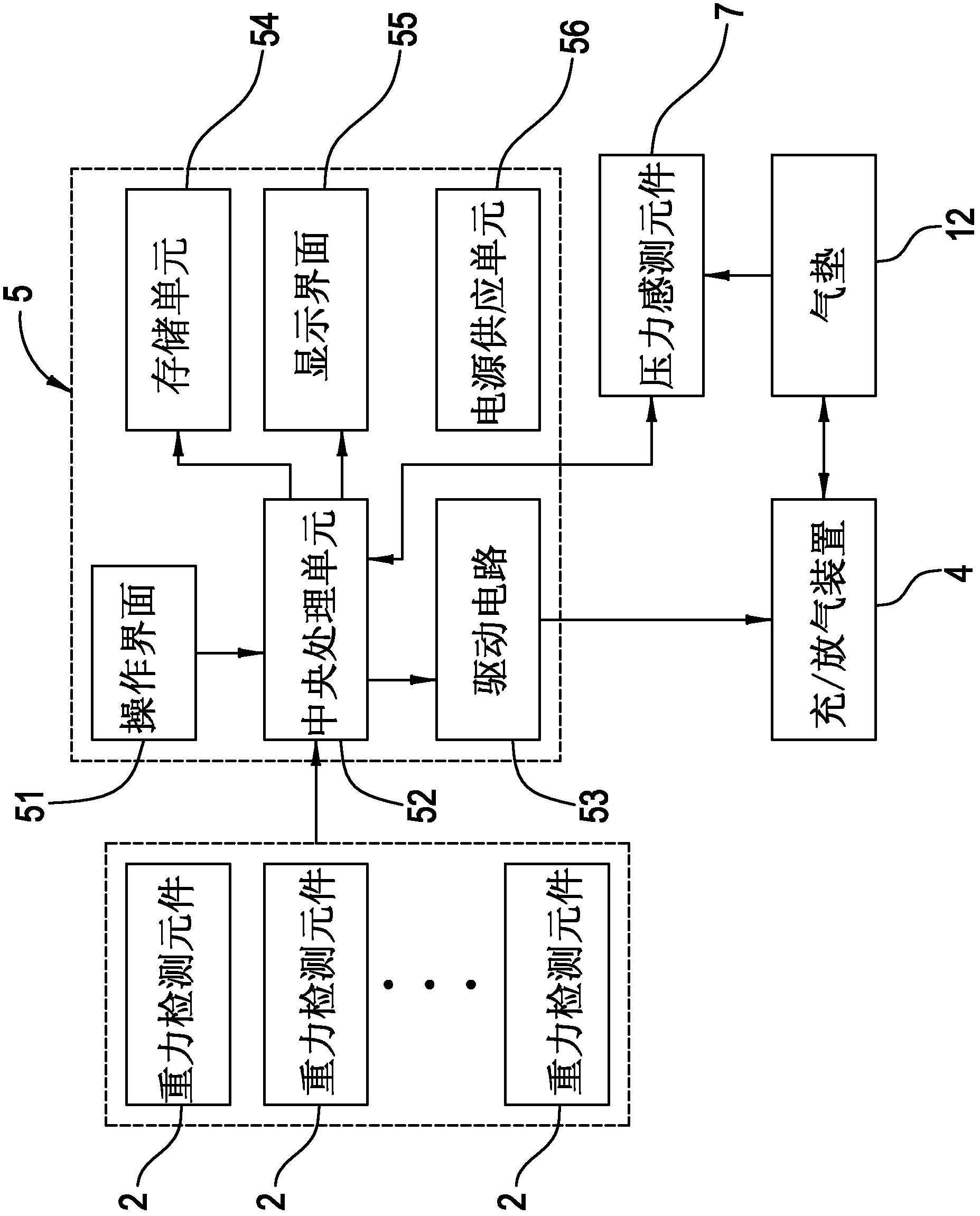

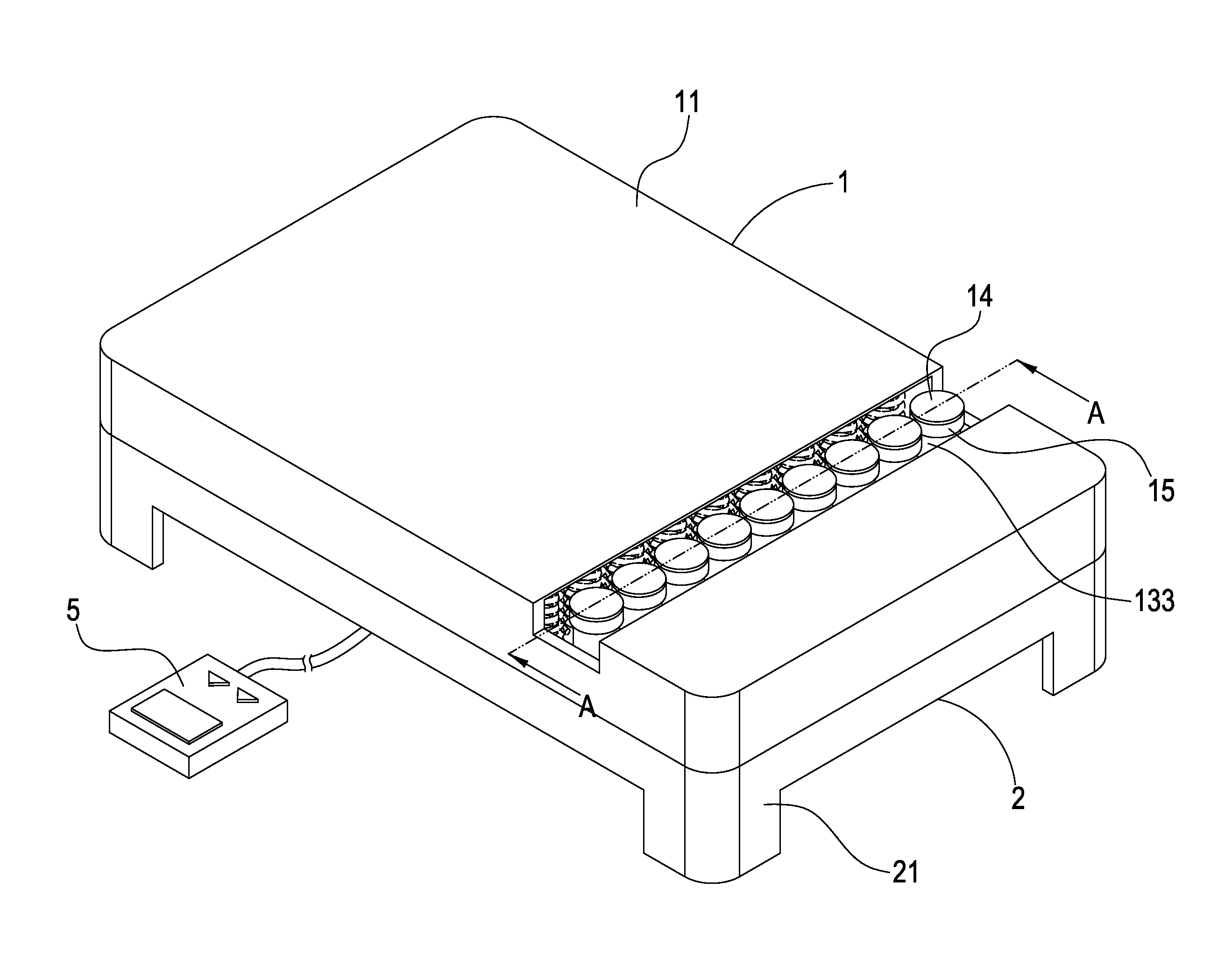

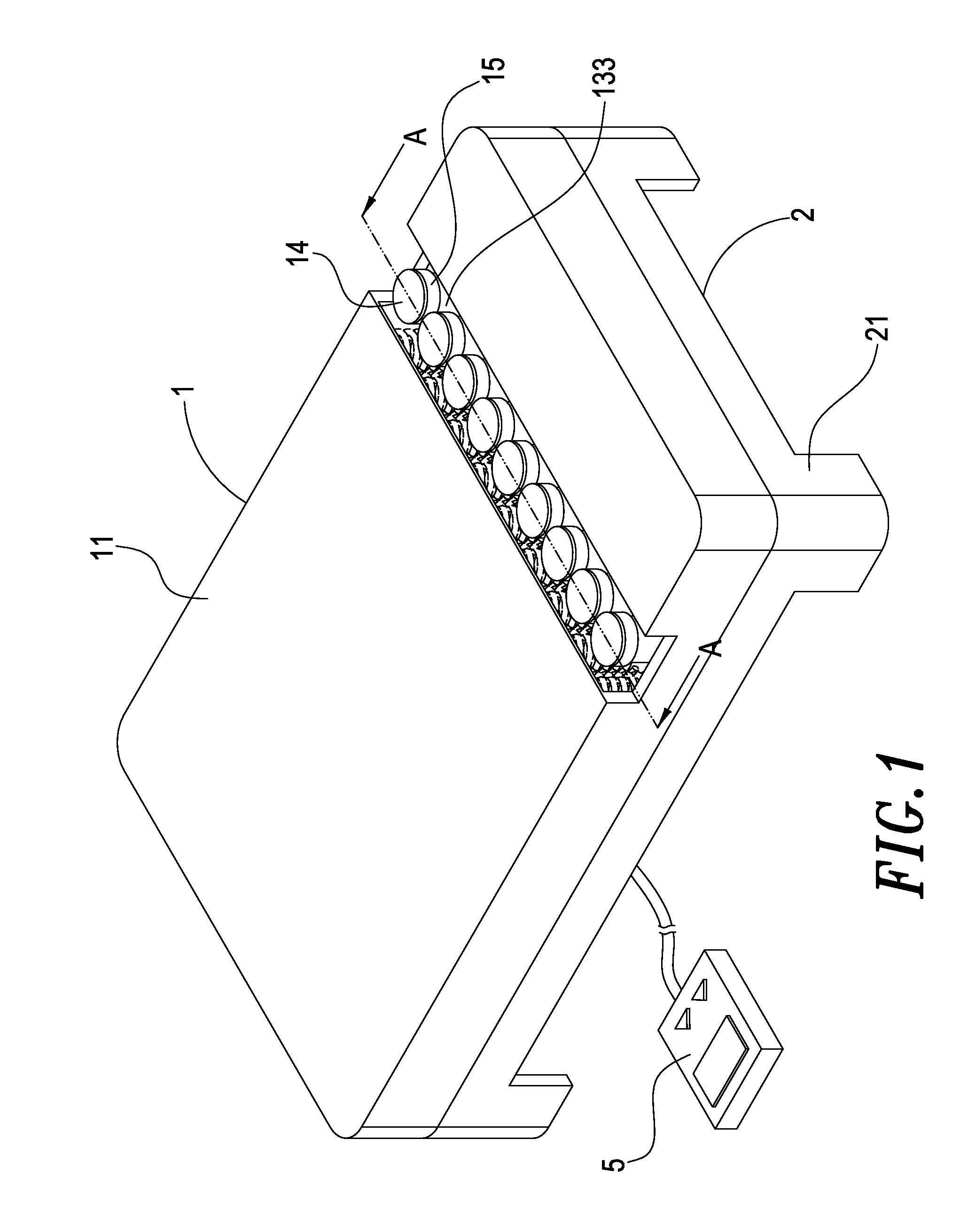

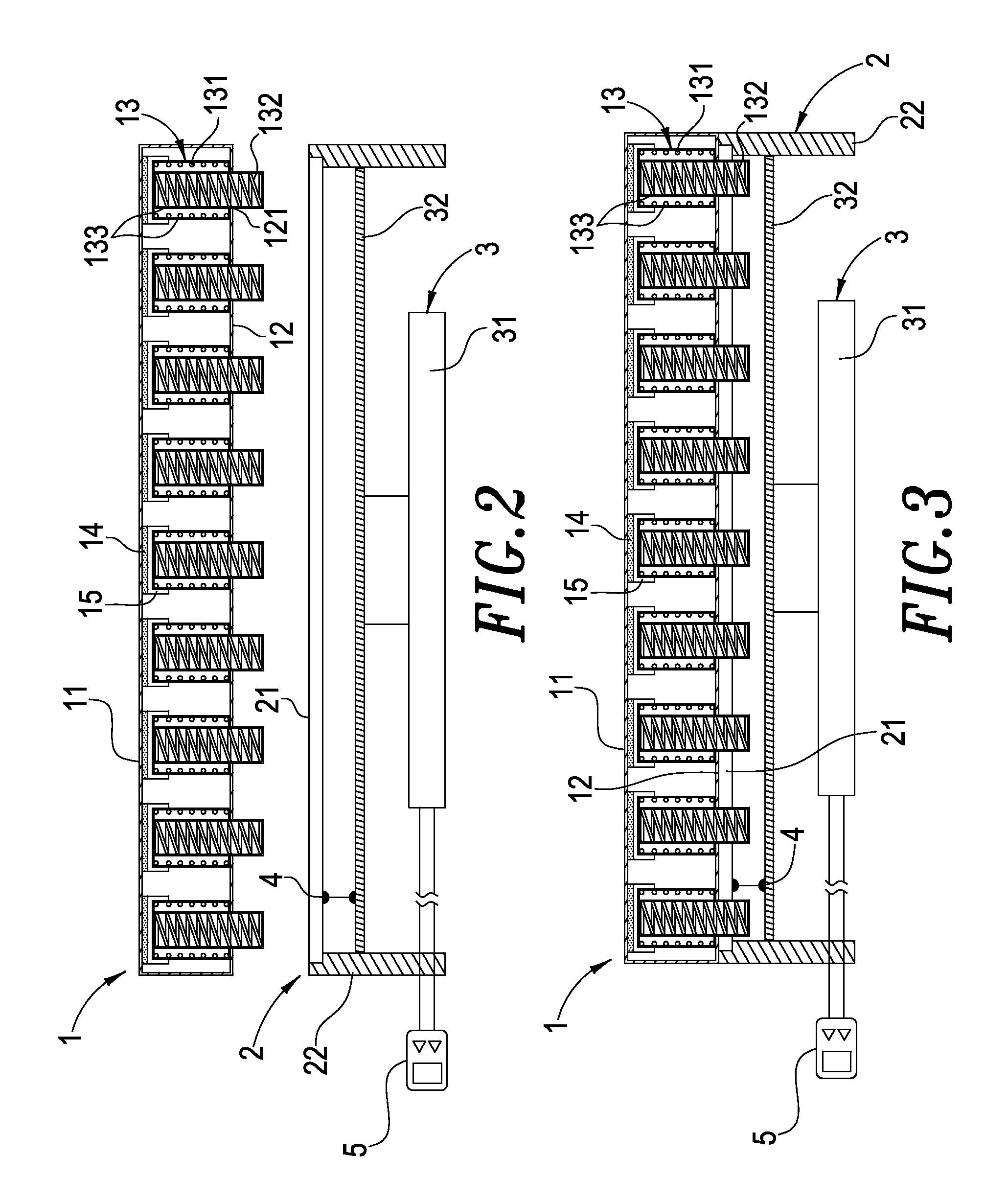

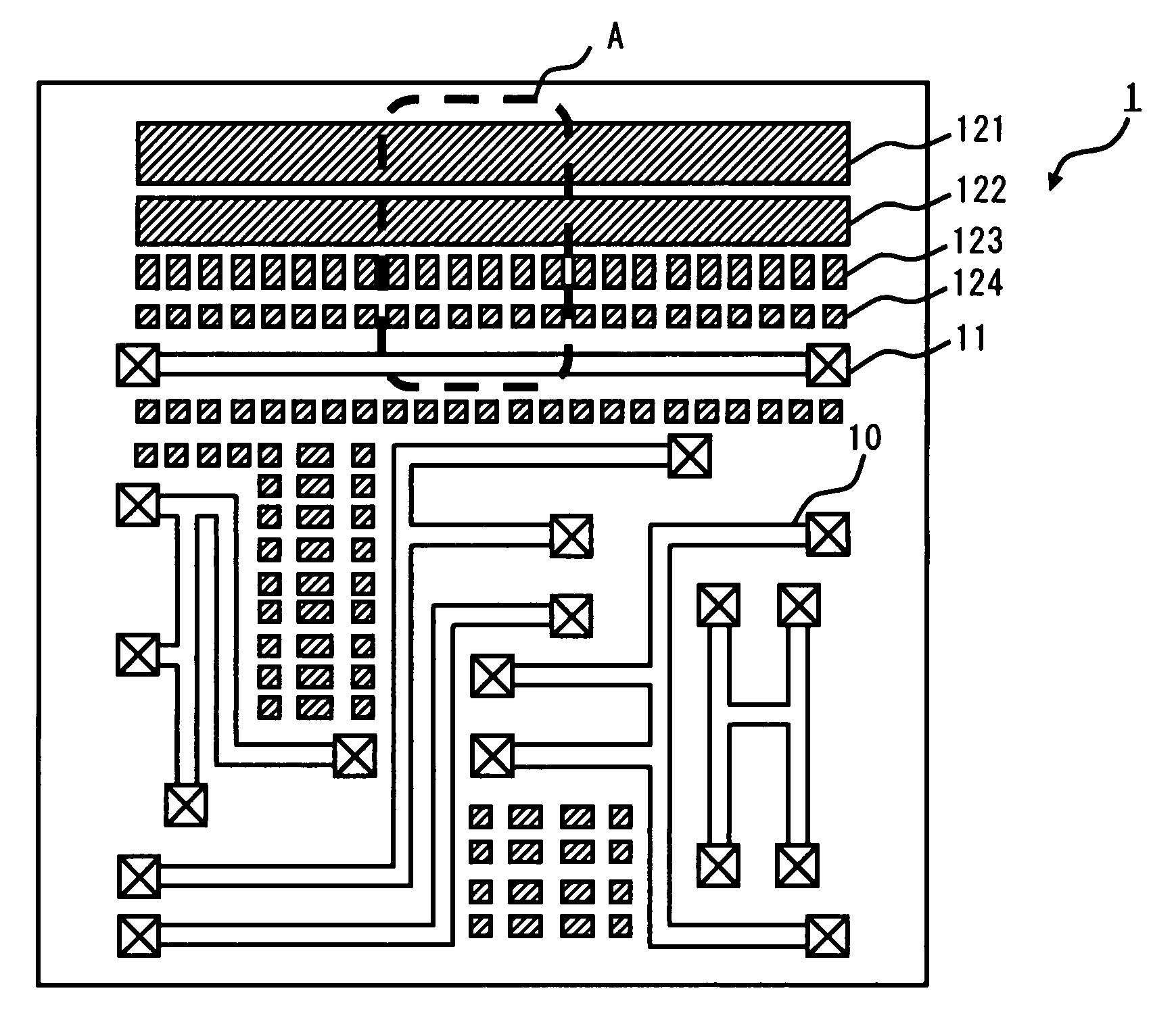

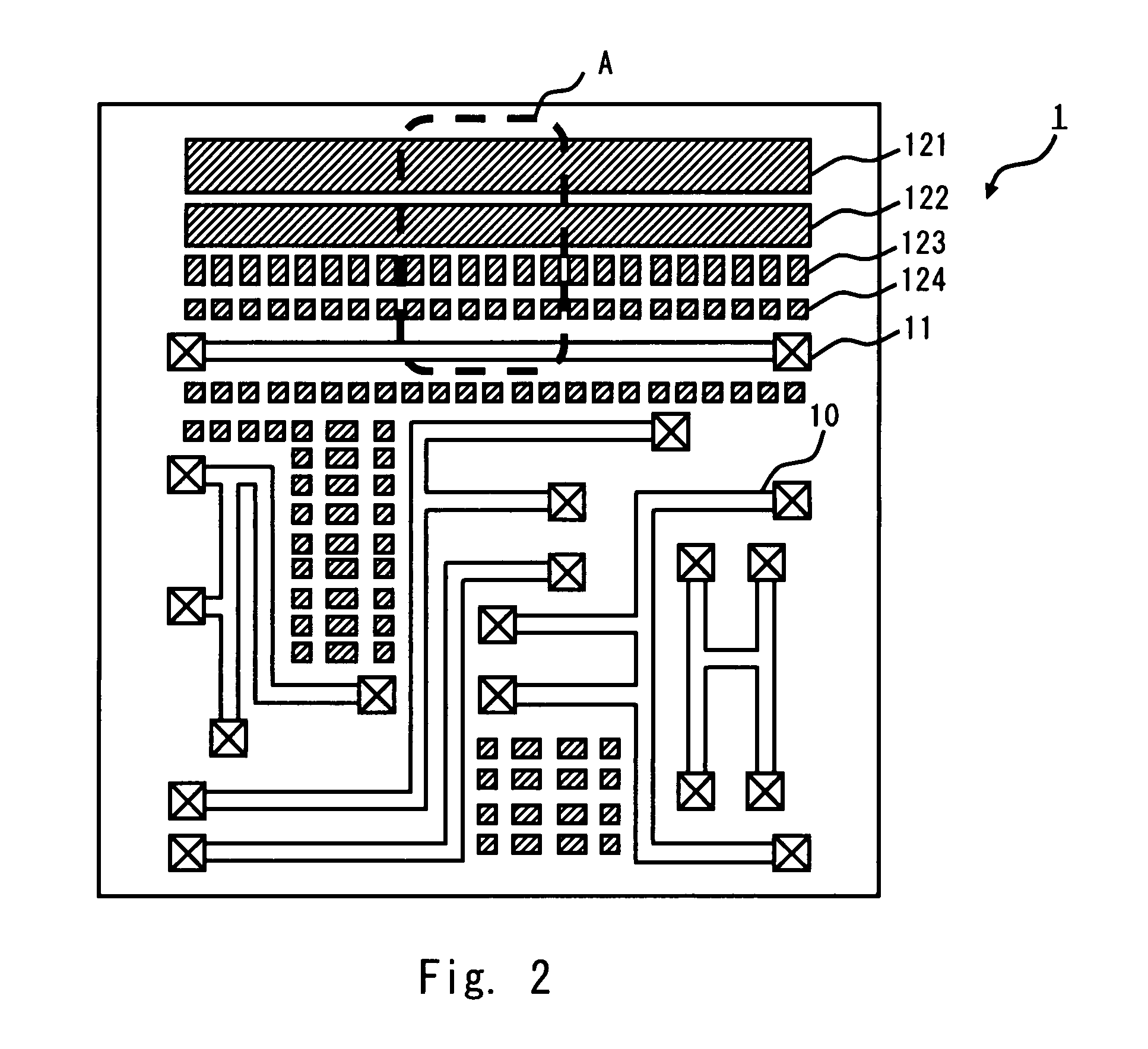

Apparatus for automatically adjusting hardness of air cushion bed according to supine or side lying sleeping positions, and method thereof

The invention discloses an apparatus for automatically adjusting the hardness of an air cushion bed according to the supine or side lying sleeping positions, and a method thereof. The apparatus comprises a mattress body, a plurality of air cushions are arranged in the mattress body and are combined with a plurality of gravity detection elements in a transverse arrangement way in the mattress body, the air cushions are connected with an air inflation / deflation device through a tube to aerate or deflate the air cushions, and the gravity detection elements and the air inflation / deflation device are connected with a control device. The supine or side lying condition of a user is determined through the trigger number of the gravity detection elements, and the control device drives the aeration / deflation device to aerate or deflate the air cushions to make the mattress body have different hardnesses when a user is in a supine lying position or a side lying position to reach the purpose of automatic adjustment of the hardness of the air cushion bed.

Owner:许汉忠

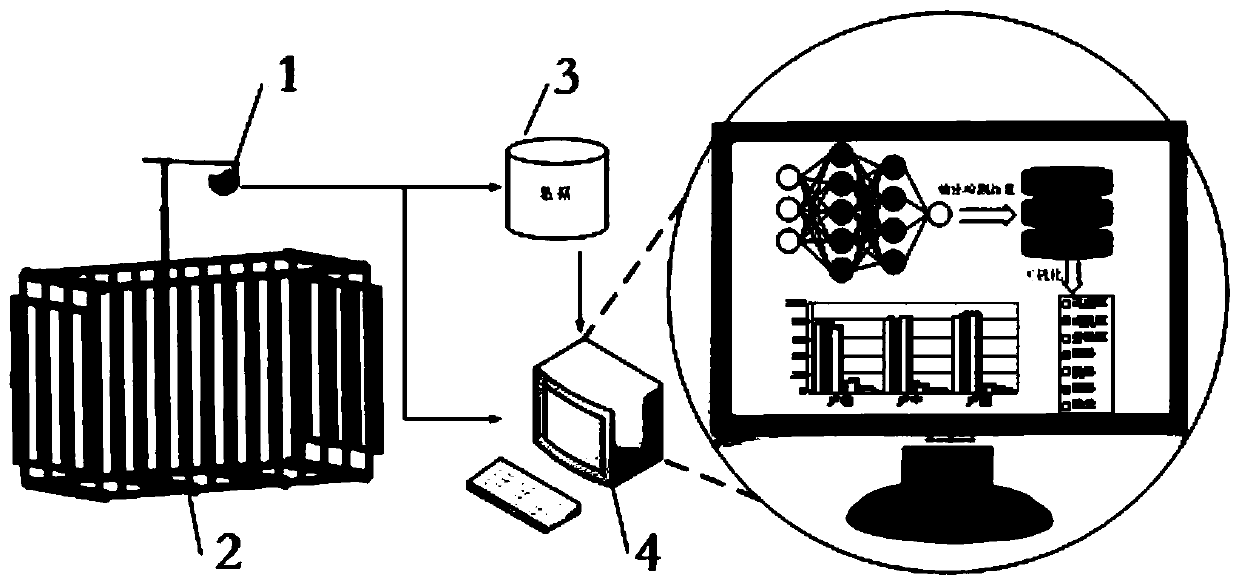

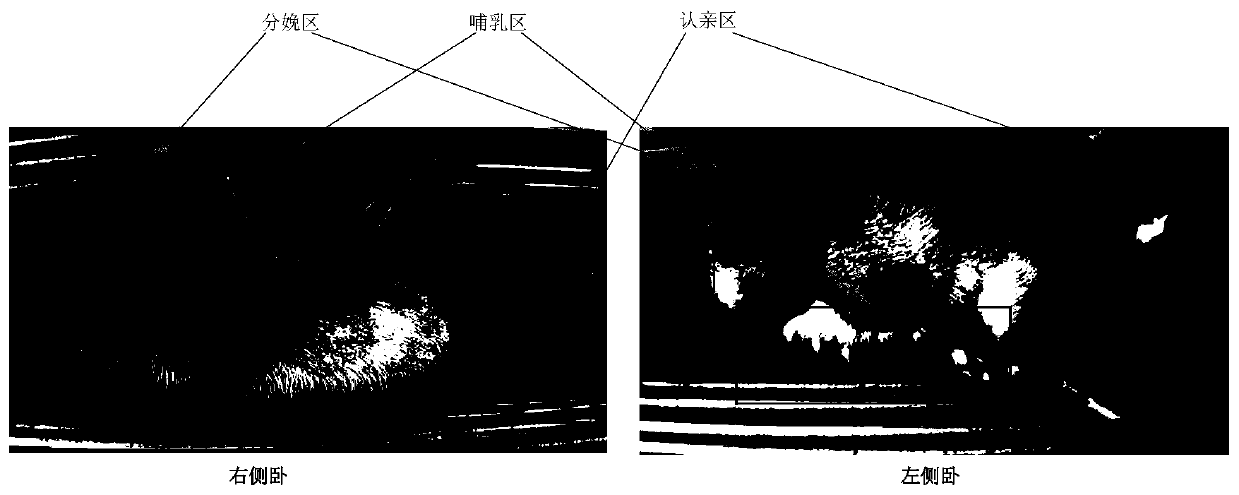

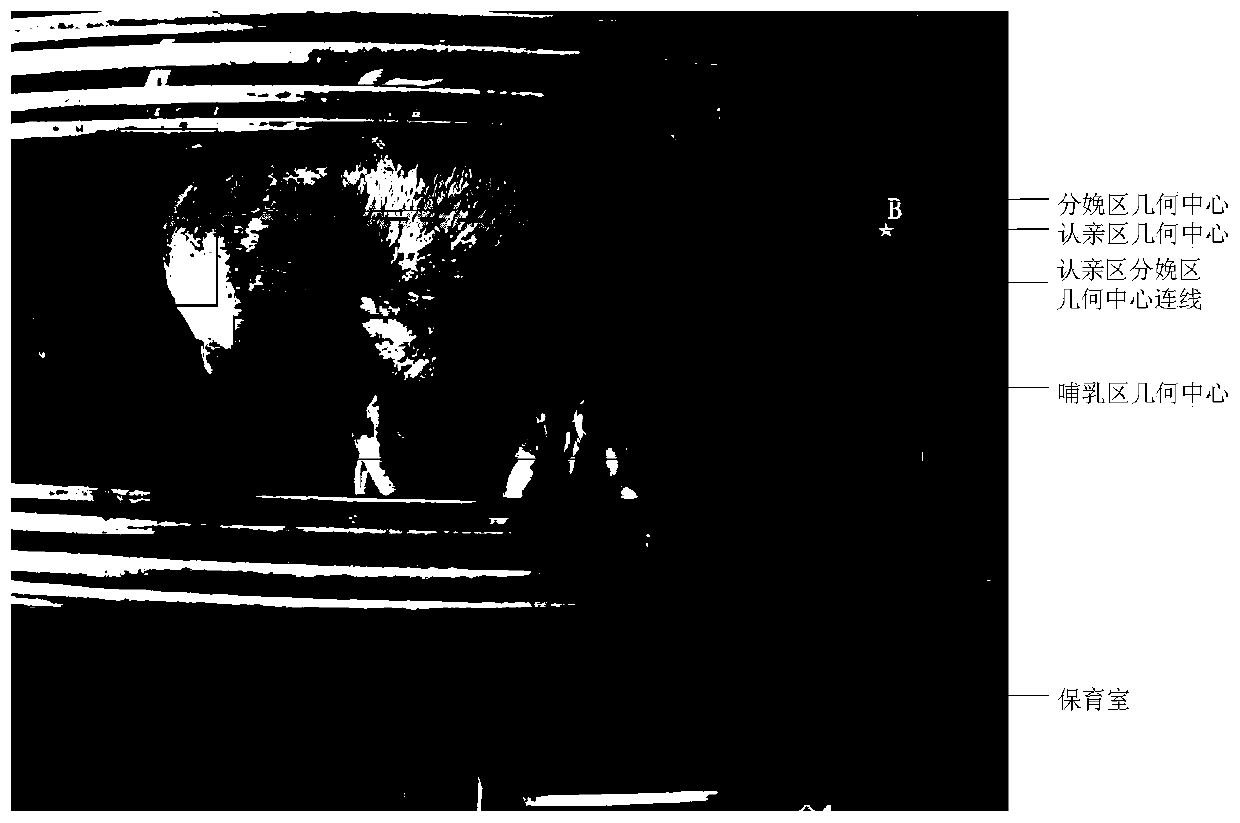

Sow side-lying posture real-time detection system based on joint partitioning of sow key parts and environment

ActiveCN110147771ARich semantic informationImprove accuracyCharacter and pattern recognitionVideo storageSide lying

The invention discloses a sow side-lying posture real-time detection system based on joint partitioning of sow key parts and environment, and the system comprises a delivery room, a camera, a video storage unit, and a server, and the delivery room is used for placing a to-be-delivered sow; the camera monitors and obtains video data of a delivery room, continuously stores the video data to the video storage unit on one hand, and is directly connected with the server on the other hand; the server calls the backup video data and analyzes the monitoring data in real time; the working steps of thedetection system are as follows: monitoring the postures of the sows in real time, simultaneously detecting three areas of an approval area, a lactation area and a delivery area through a convolutional neural network area identification model, identifying the sows as lying postures when more than two areas are simultaneously detected, and outputting an identification result to a database. Comparedwith a method for recognizing the posture of the sow through a sensor technology, the computer vision technology avoids contact with the sow, stress response is reduced, and the method has the advantages of being low in cost and high in efficiency.

Owner:南京慧芯生物科技有限公司

Therapeutic pillow

ActiveUS9757303B2Easy alignmentEasy maintenancePillowsChiropractic devicesSpinal CurvaturesSide lying

The present invention provides devices for neck support and correction, for example, pillows, headrests, or cushions, designed to be placed under the head and neck of a person lying in a supine or side-lying position. Such devices are useful for maintaining or improving cervical and / or thoracic spinal curvature and / or alignment and for reducing pain associated with ailments of the neck or cervical vertebrae. Also provided are methods of improving cervical spinal alignment and for treating or ameliorating ailments of the neck or cervical vertebrae.

Owner:MARINKOVIC JOHN

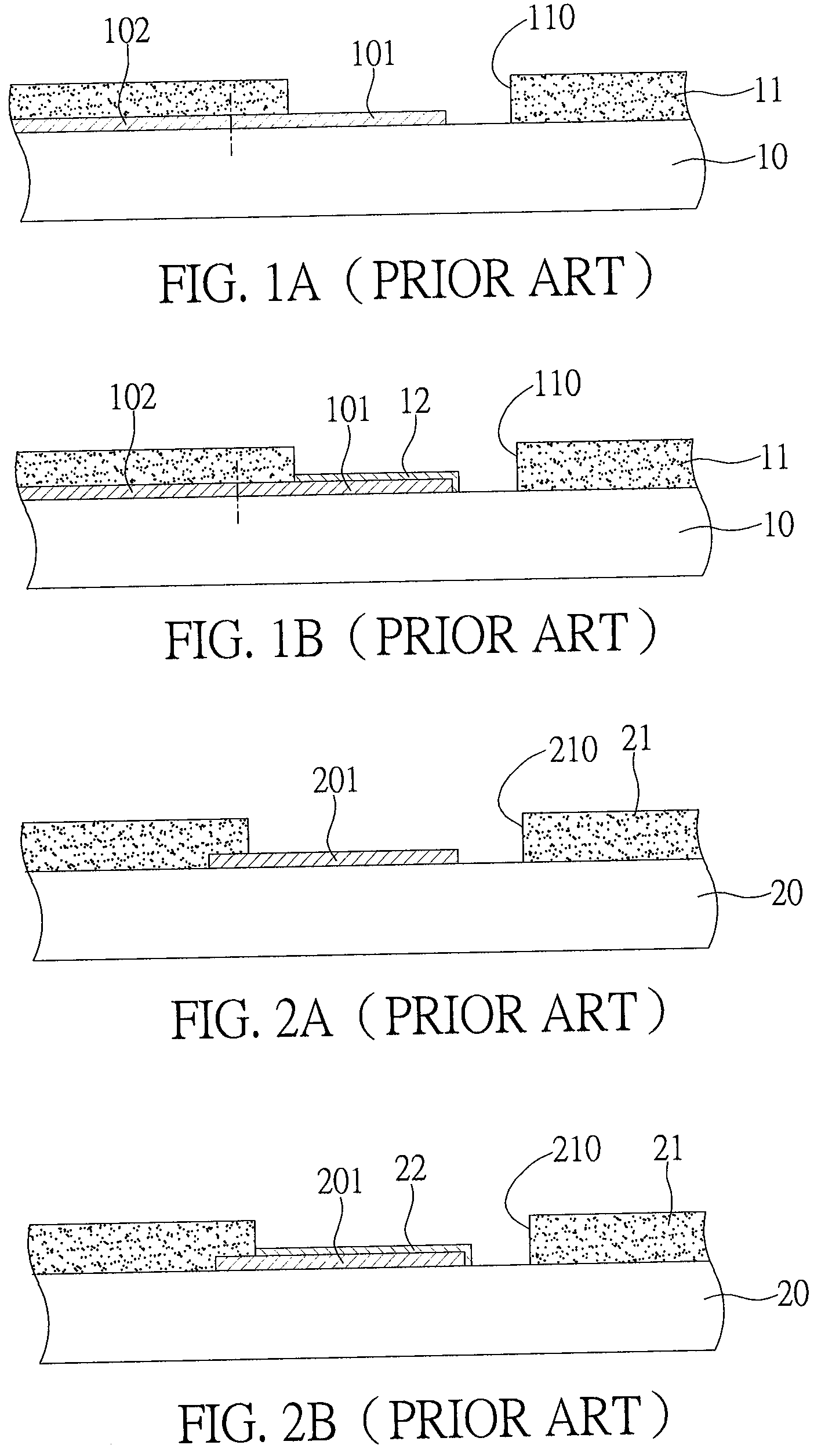

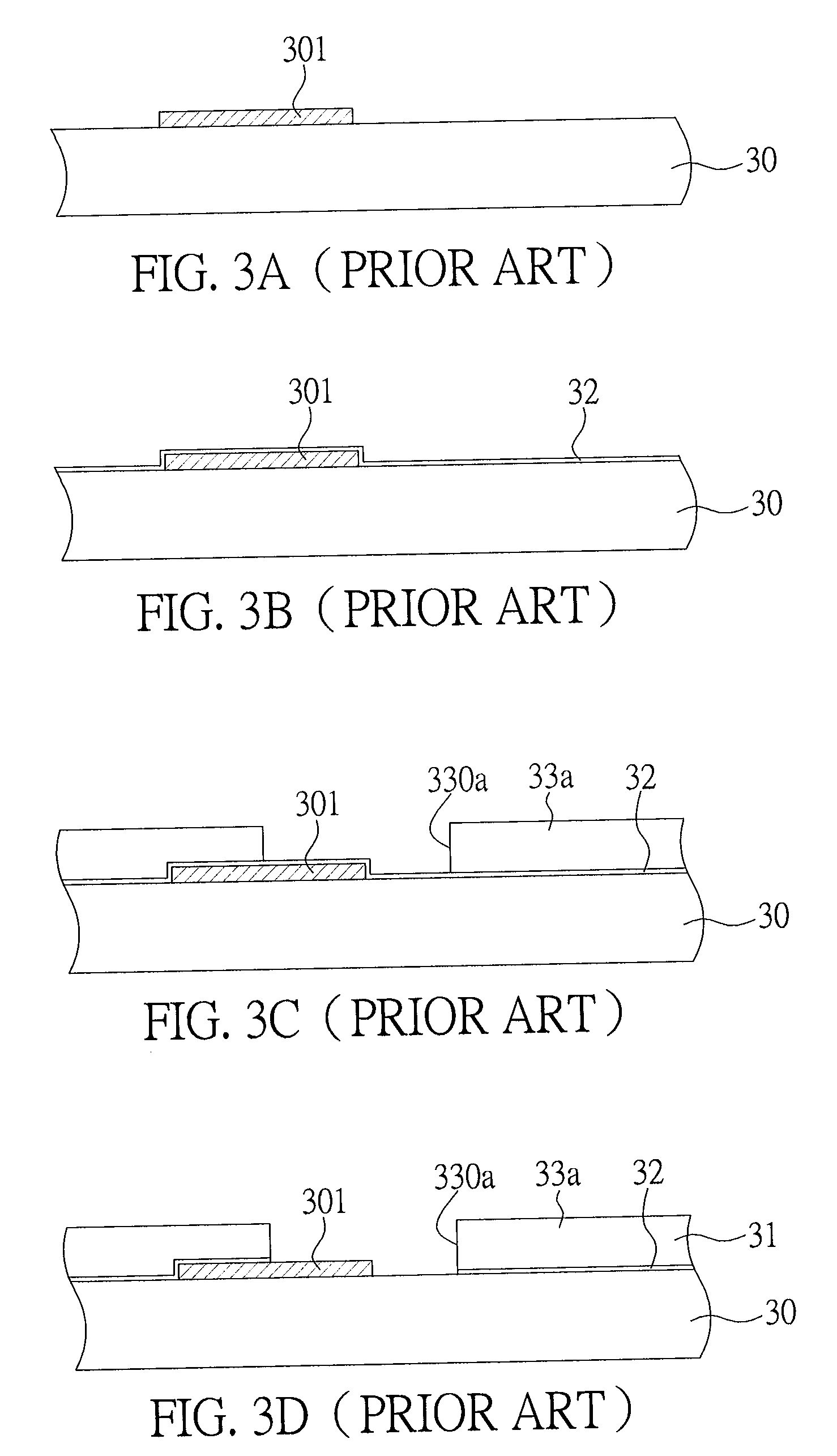

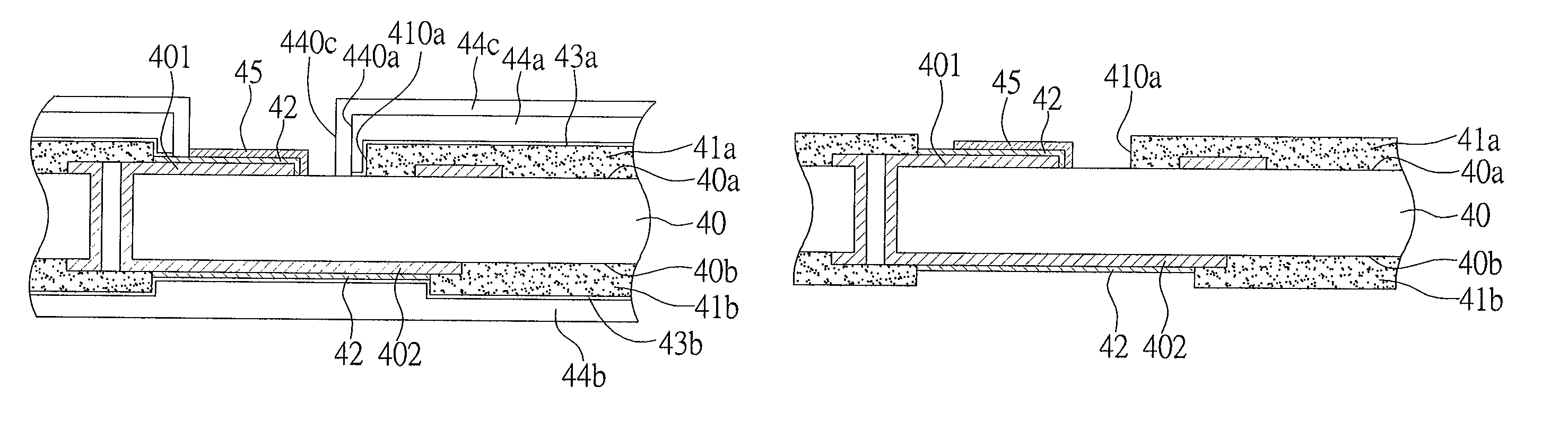

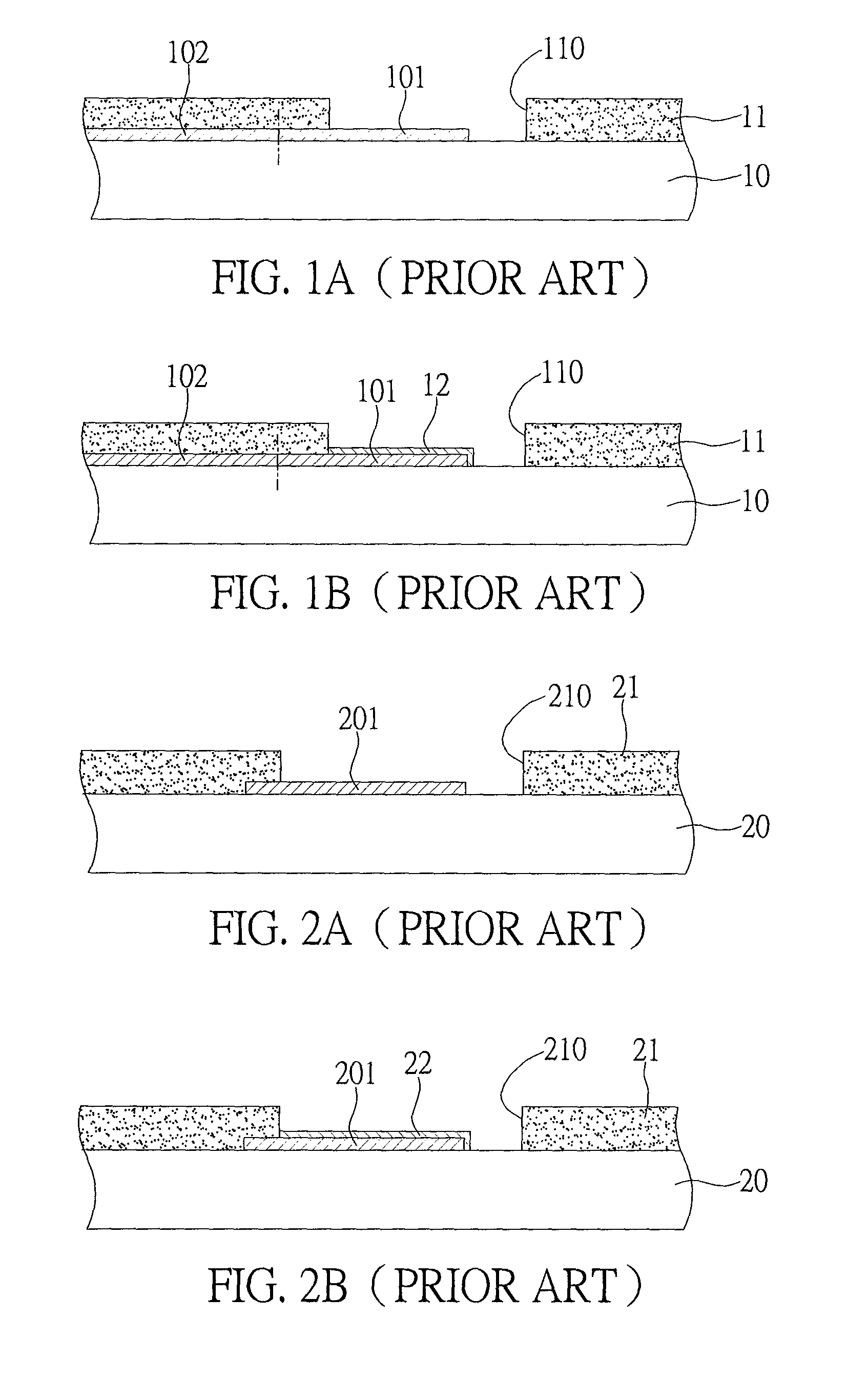

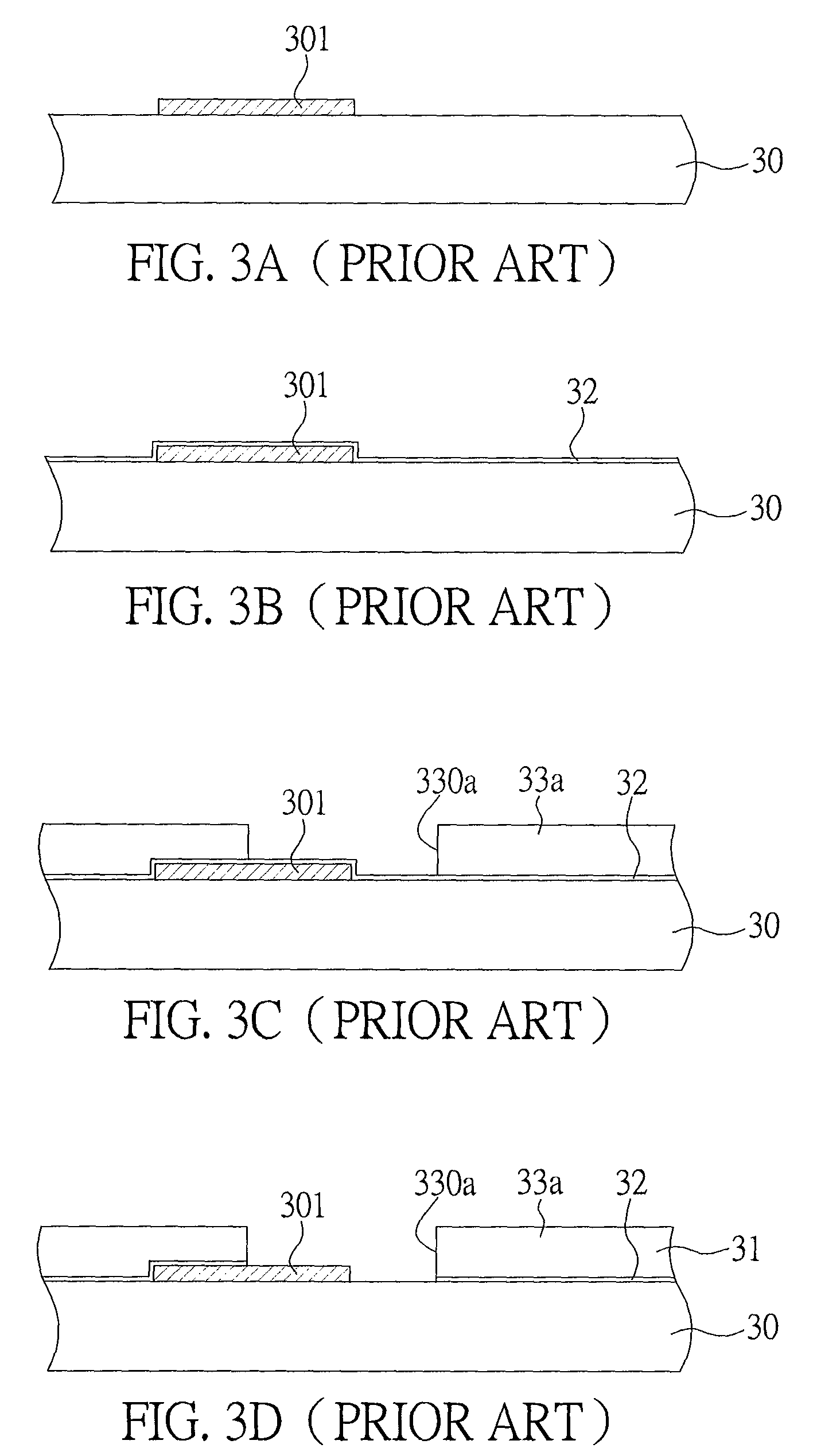

Package substrate and method for fabricating the same

ActiveUS20090096099A1Hard textureImprove bindingSemiconductor/solid-state device detailsStacked resist layersChemical platingLead bonding

A package substrate and a method for fabricating the same are provided according to the present invention. The package substrate includes: a substrate body with a die attaching side and a ball implanting side lying opposite each other, having a plurality of wire bonding pads and a plurality of solder ball pads respectively, and having a first insulating passivation layer and a second insulating passivation layer respectively, wherein a plurality of first apertures and a plurality of second apertures are formed in the first insulating passivation layer and the second insulation passivation layer respectively to corresponding expose the wire bonding pads and the solder ball pads; a chemical plating metal layer formed on the wire bonding pads and solder ball pads respectively; and a wire bonding metal layer formed on a surface of the chemical plating metal layer of the wire bonding metal layer.

Owner:PHOENIX PRECISION TECH CORP

Thermally-assisted magnetic recording head including plasmon generator

ActiveUS8077558B1Easy to useSmall spot diameterCombination recordingRecord information storageHeat-assisted magnetic recordingSide lying

A plasmon generator has an outer surface including a plasmon exciting part that faces an evanescent light generating surface of a waveguide. The outer surface further includes first and second inclined surfaces that increase in distance from each other with increasing distance from the plasmon exciting part, and a front end face. The front end face has first and second portions that are connected to each other into a V-shape. The first portion includes a first side lying at an end of the first inclined surface. The second portion includes a second side lying at an end of the second inclined surface. An angle formed between a lower part of the first side and a lower part of the second side is smaller than that formed between an upper part of the first side and an upper part of the second side.

Owner:TDK CORPARATION

Near-field light-generating element for producing localized near-field light, near-field optical recording device, and near-field optical microscope

InactiveUS7034277B2Closely placedHigh resolutionOptical flying-type headsNanoinformaticsSide lyingOptical recording

A near-field light-generating element has a support member and a minute aperture having a size smaller than the wavelength of incident light provided on the support member so as to produce near-field light in response to incident light directed thereto. The minute aperture has a contour in a given plane with one side lying along a line perpendicular to a direction of polarization of the incident light and an opposite side in the given plane defining an apex.

Owner:SEIKO INSTR INC

Automatic adjusting method of bed and intelligent control bed

The invention discloses an automatic adjusting method of a bed. The automatic adjusting method comprises the following steps of obtaining basic information of a user, wherein the information comprisesthe age, gender, height, weight and body figure of the user; obtaining sleeping information of the user, wherein the sleeping information comprises the pressure or pressure distribution to the body back of the user under the conditions of different comfortable sleeping gestures, wherein the sleeping gestures comprise lying on the back, left side lying, right side lying, and lying on the stomach;according to the basic information and the sleeping information of the user, establishing a body model and a sleeping pressurizing model for the user; identifying the user on the bed and the sleepinggesture. The automatic adjusting method of the bed has the advantage that the stored programs can be called up to truly realize the automatic adjusting function.

Owner:SHENZHEN ONETHIRD SLEEP TECH CO LTD

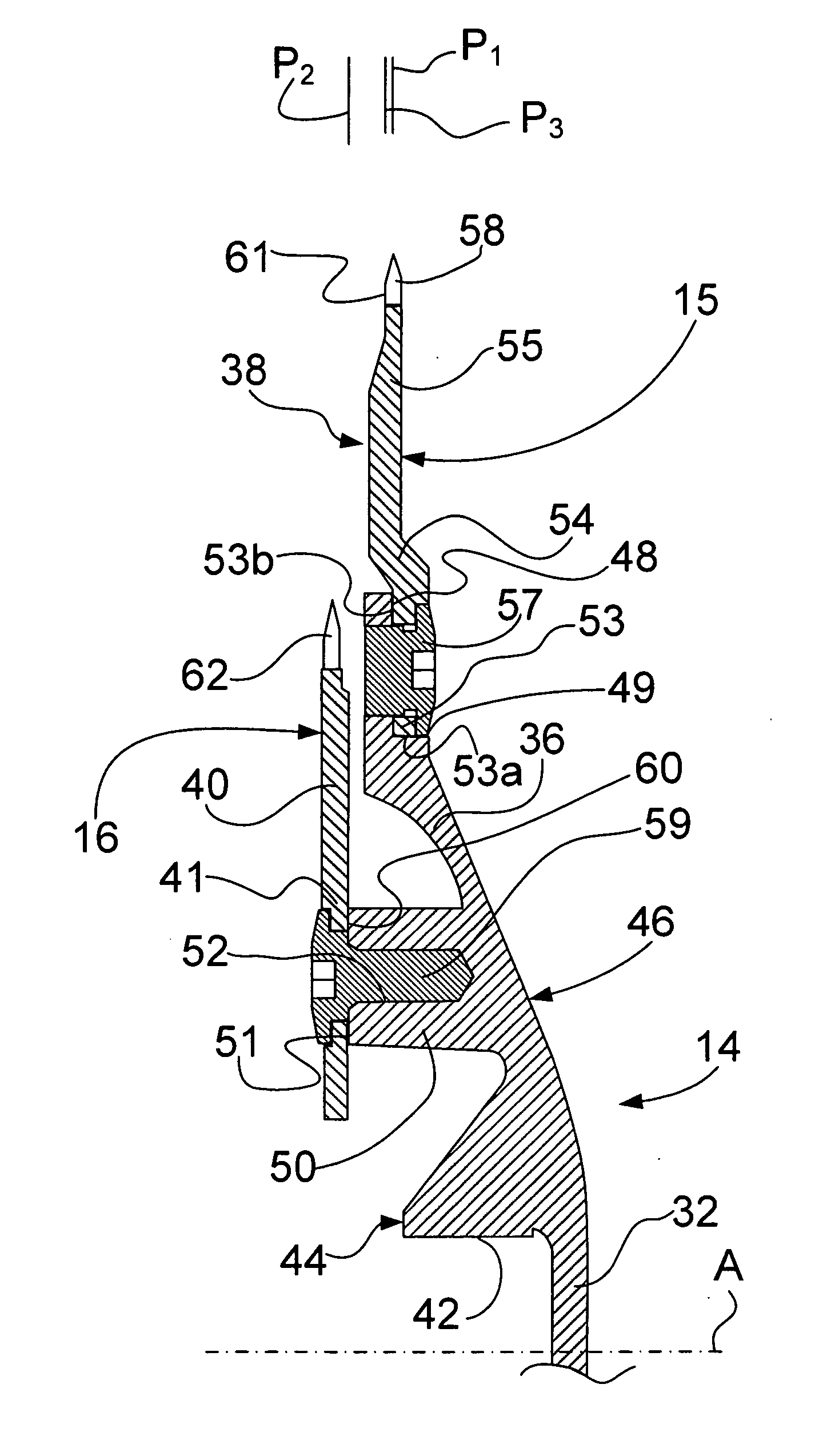

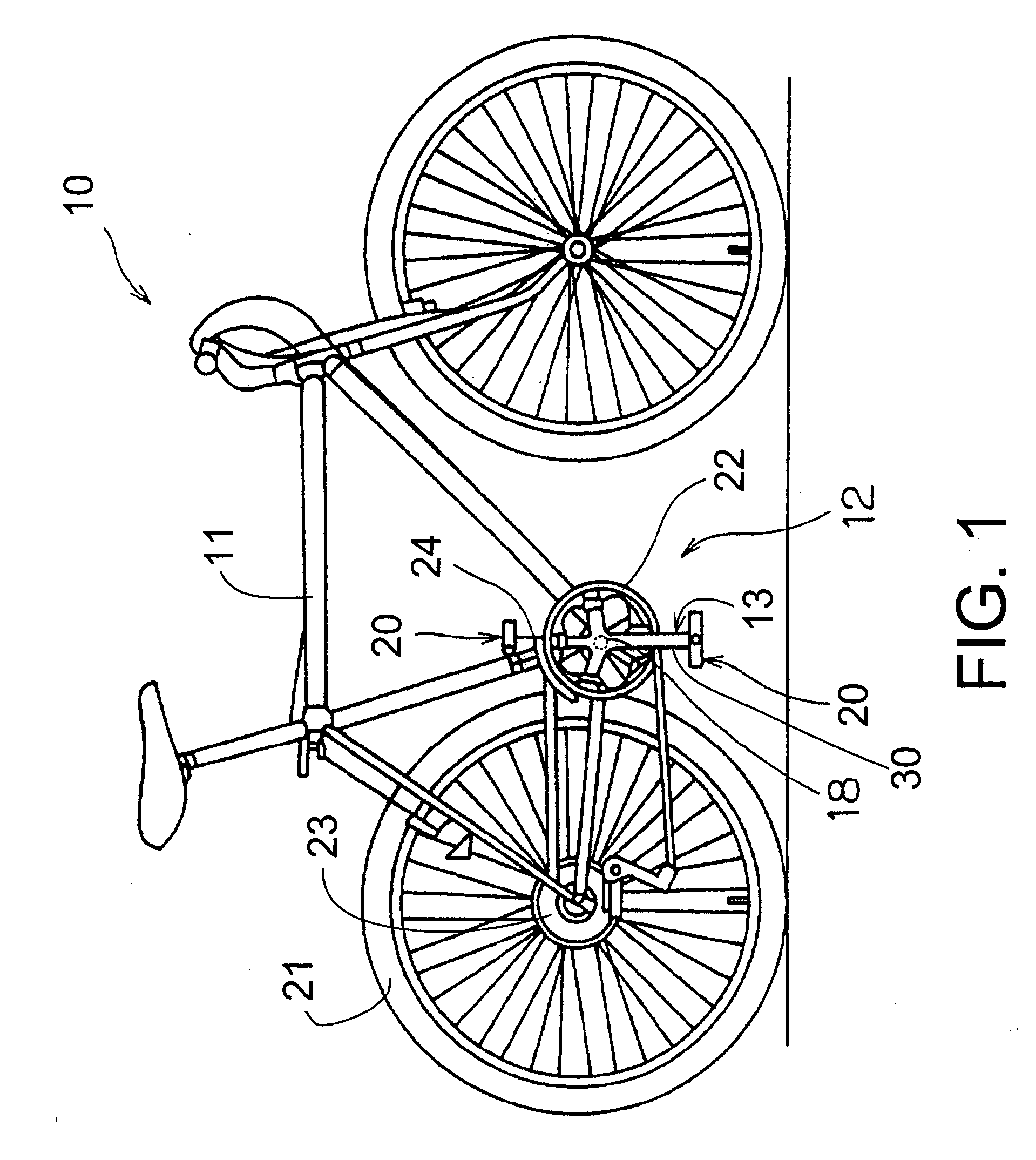

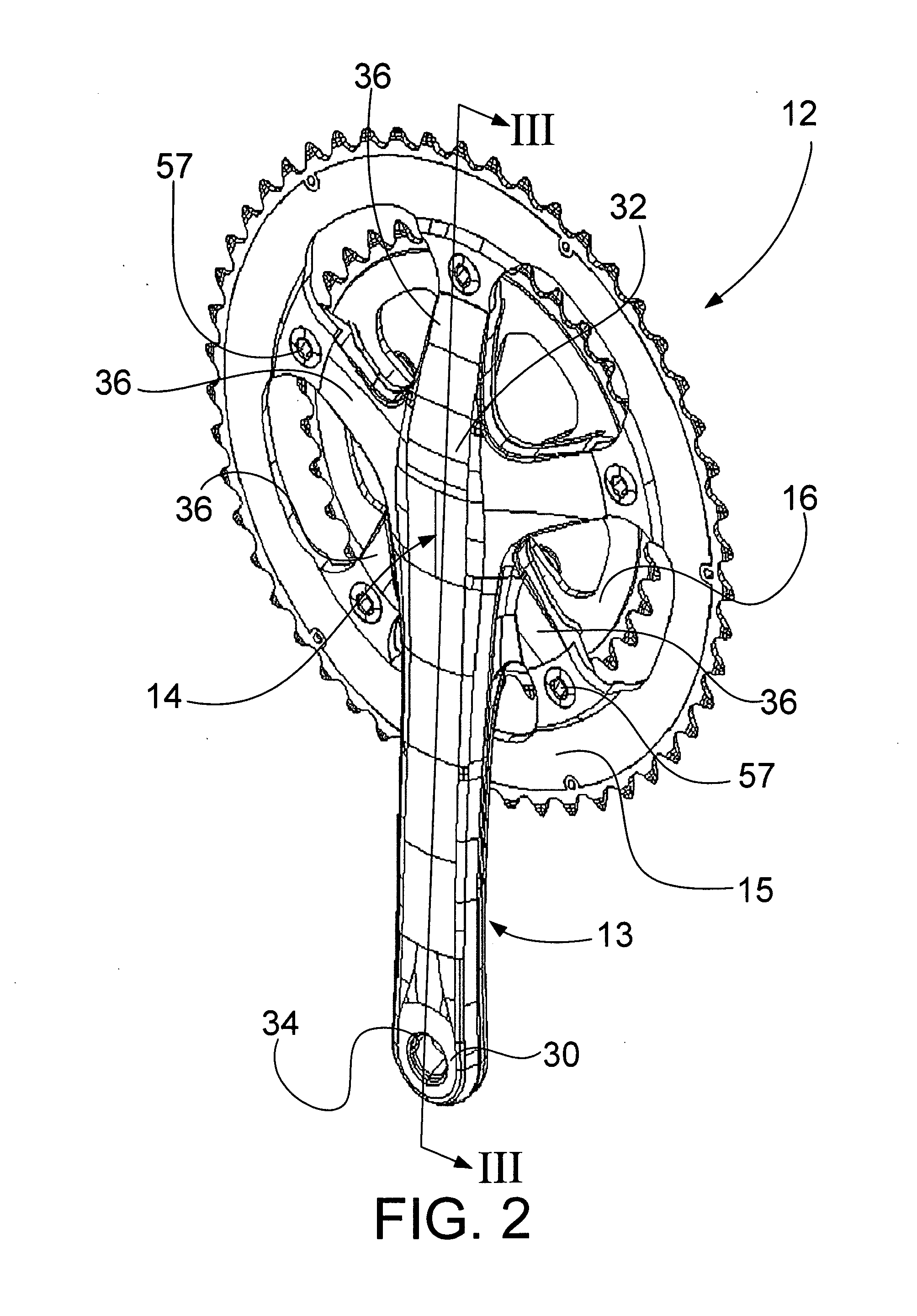

Bicycle crankset

A bicycle crankset has a crank arm portion, a chainring mounting portion and at least a first chainring. The crank arm portion has a pedal attachment end and a crankshaft mounting end with the chainring mounting portion coupled to the crankshaft mounting end. The chainring mounting portion has an inner frame facing side and an outer facing side with a first chainring setting surface of the outer facing side lying in a first vertical plane. The first chainring has an attachment section mounted to the first chainring setting surface and a plurality of gear teeth with an inner gear face lying in a second vertical plane that is axially offset from the first vertical plane in a direction toward the inner frame facing side of the chainring mounting portion.

Owner:SHIMANO INC

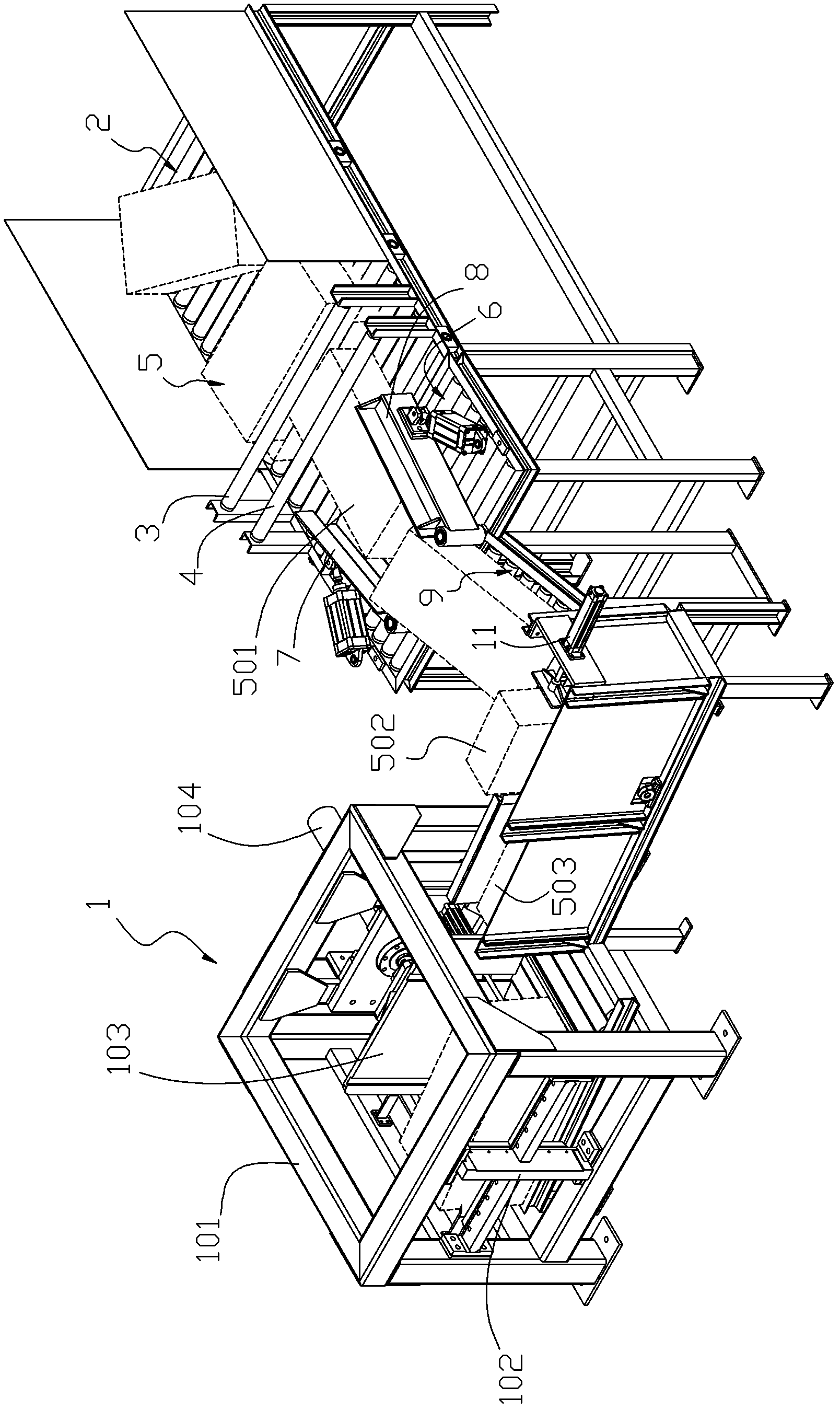

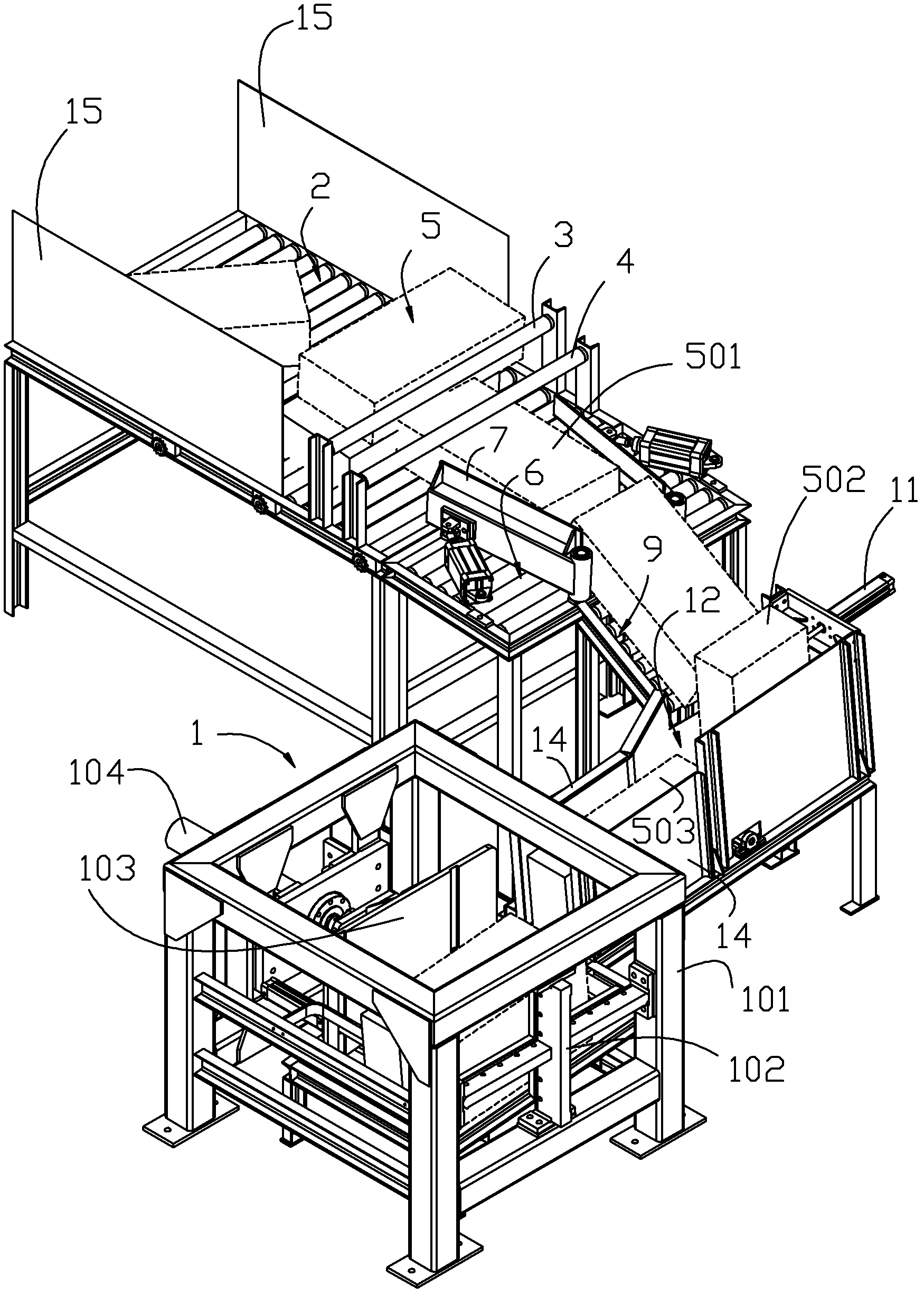

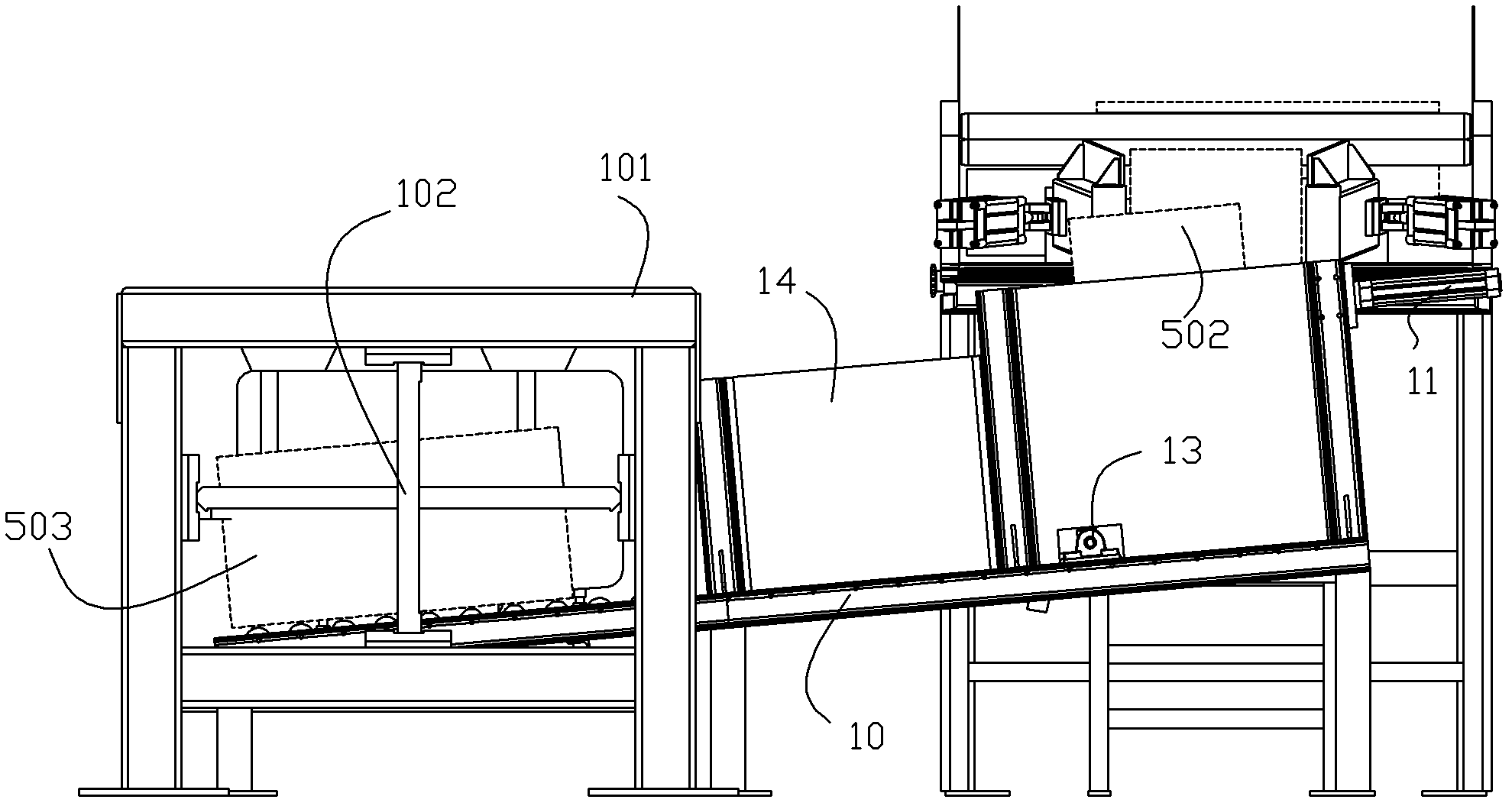

Method for automatically adjusting hardness of mattress based on operator's lying position or operator's side lying position and device thereof

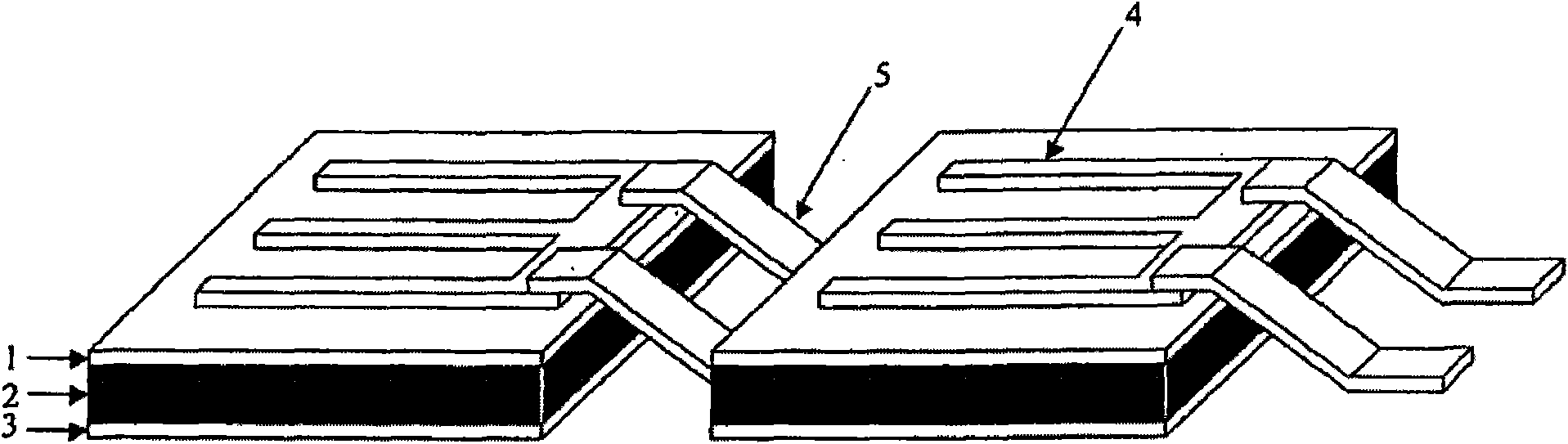

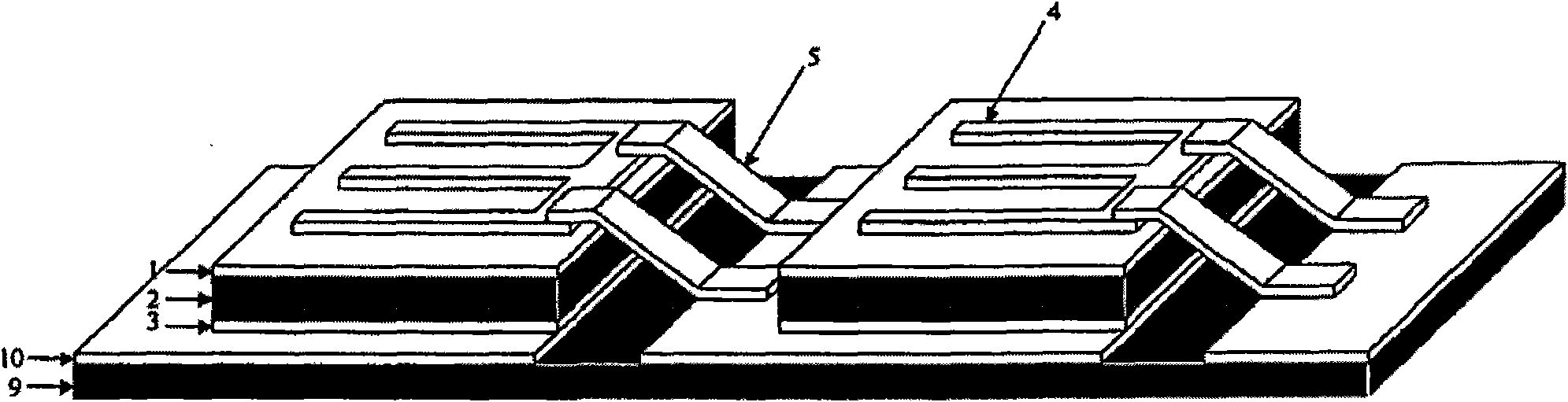

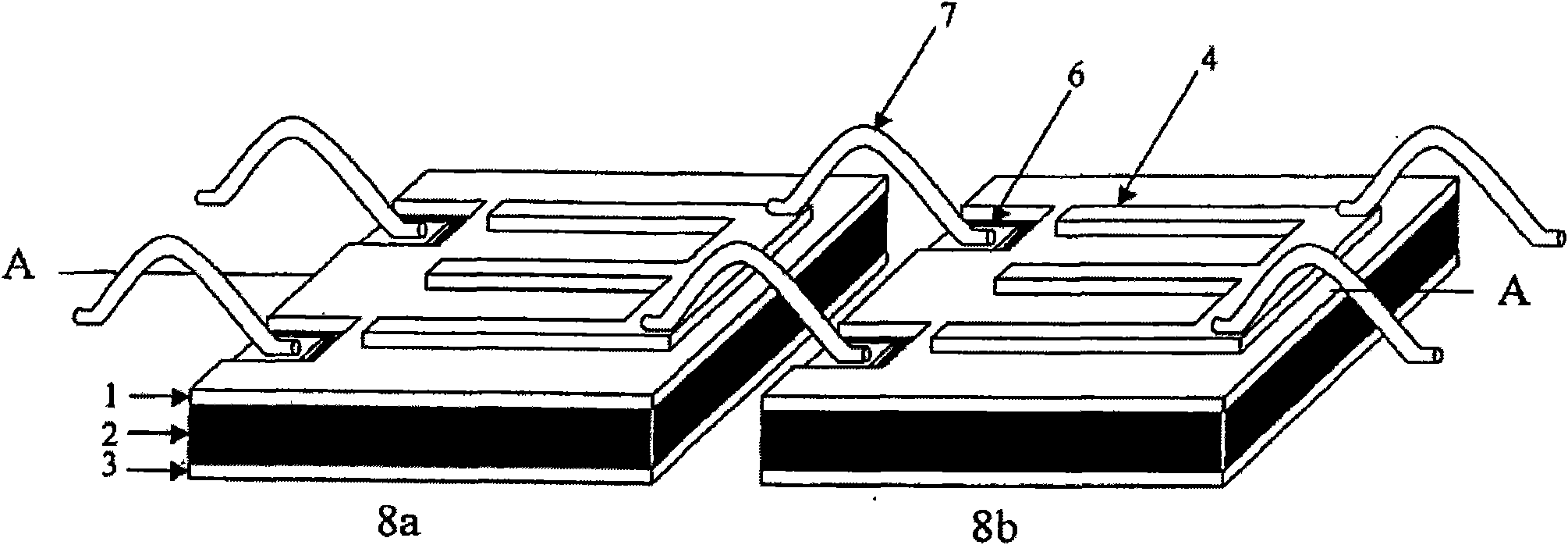

A method for automatically adjusting the hardness of a mattress based on an operator's lying position or an operator's side lying position and a device are disclosed. The device comprises: a base, having hollow platforms that have support legs; a lifting device, below the hollow platforms; a mattress body, disposed on the base and comprising a bed surface, a bed bottom, flexible support units, and gravity sensors, through holes being disposed in the bed bottom and corresponding to the lifting device, the flexible support unit being constructed by a first flexible member female-connected with a second flexible member; and a control device, connected with the lifting device and the gravity sensors, wherein the control device determines that the touching number of the gravity sensors is greater, equal to or less than a preset value and therefore automatically adjusts the hardness of the mattress.

Owner:HSU HAN CHUNG

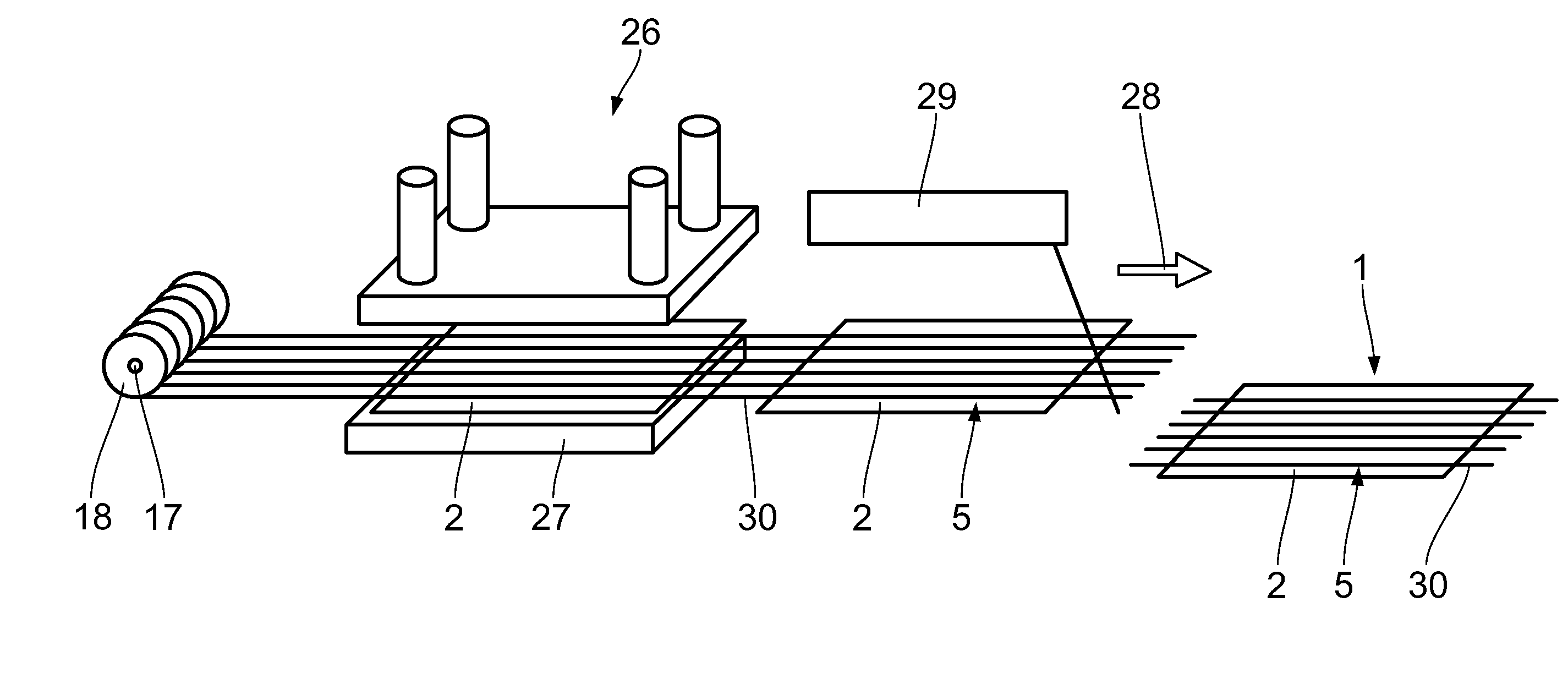

Solar module serially connected in the front

The invention relates to a solar cell element comprising a semiconductor substrate layer (2) that has exactly one first dopant, a layer structure (1) which is disposed on the front side of the substrate layer (2), adjacent thereto, and has at least one dopant complementary to the first dopant, a rear metallization (3) which is arranged on the rear side of the substrate layer (2), adjacent to the substrate layer, said rear side lying across from the layer structure (1), and a first (4) and a second (6) front metallization. The first front metallization (4) electrically contacts the layer structure (1) while the second front metallization (6) is disposed on the front side of the substrate layer, adjacent to the substrate layer, and is electrically insulated from the first front metallizationand the layer structure (1).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Semiconductor component with contacts made of alloyed-in metal wires

InactiveUS20100078073A1Inhibited DiffusionImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationSide lyingEngineering

A semiconductor component, especially a solar cell comprises a semiconductor substrate of a planar design having a first side and a second side lying opposite thereto, at least one contact structure arranged on at least one side of the semiconductor substrate, the at least one contact structure exhibiting a diffusion barrier to prevent the diffusion of ions from the contact structure into the semiconductor substrate.

Owner:SOLARWORLD IND GMBH

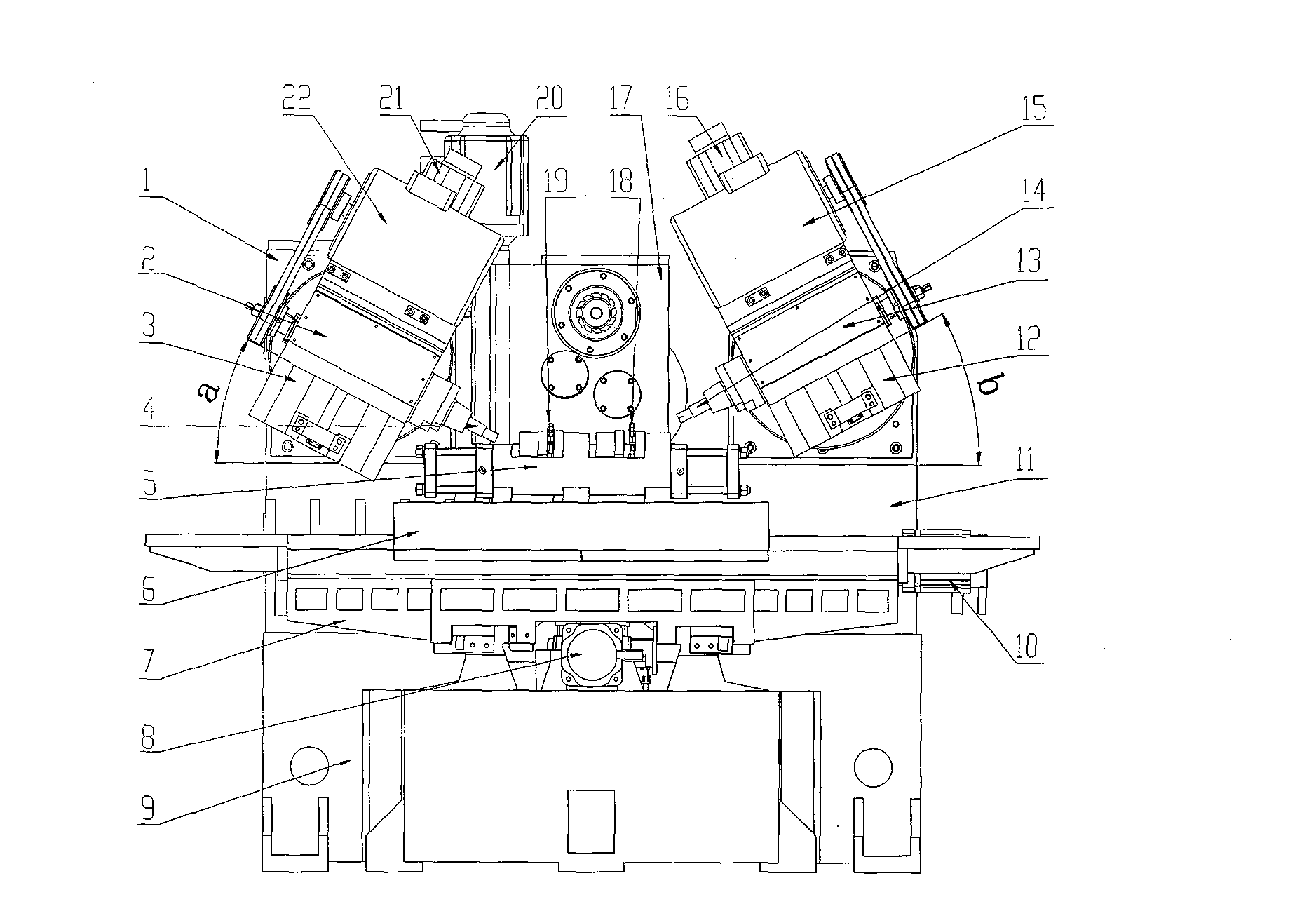

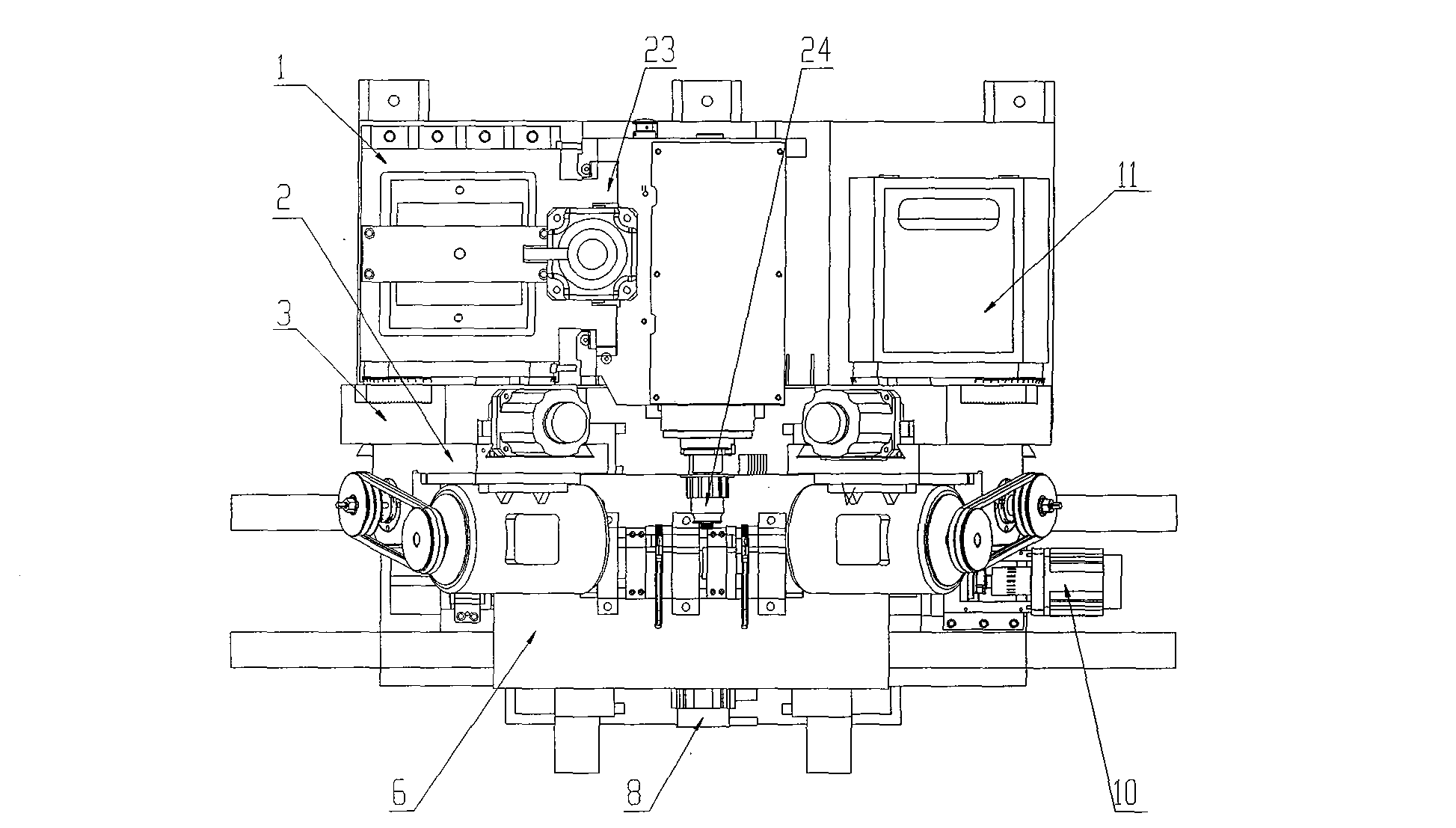

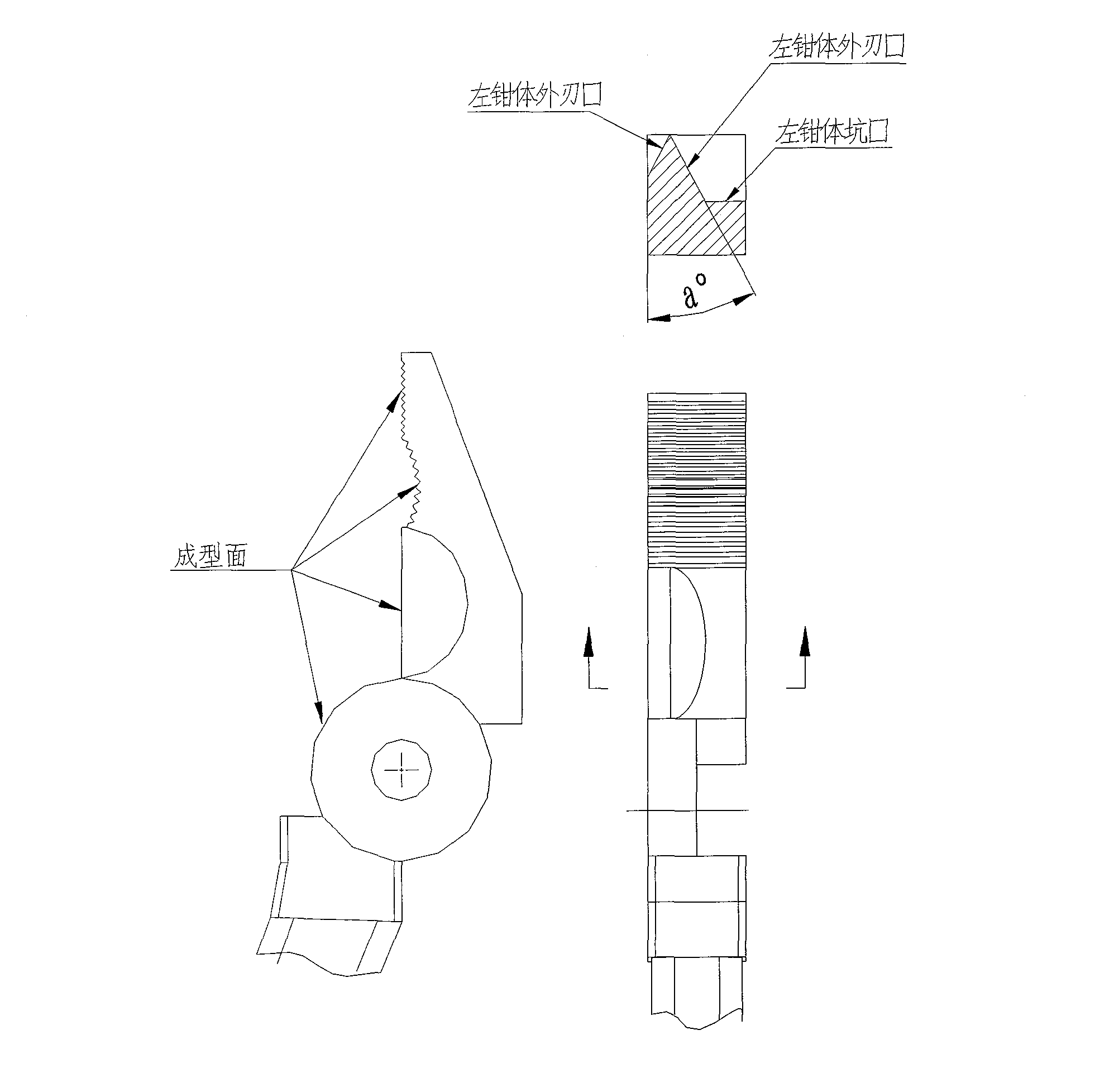

Multi-station plier numerical control milling machine

InactiveCN102909415AImprove machining accuracyQuality assuranceLarge fixed membersMilling equipment detailsNumerical controlMilling cutter

The invention relates to a multi-station plier numerical control milling machine. The multi-station plier numerical control milling machine has the following structure that a left vertical milling spindle box is rotationally connected with a left vertical shaft milling cutter, is connected with a left rotating sliding seat and is movably connected on a left rotating sliding seat guide rail; a working table is connected with a crossed sliding seat and is movably connected on a crossed sliding seat guide rail; the crossed sliding seat is movably connected on a bed guide rail; a right vertical milling spindle box is rotationally connected with a right vertical shaft milling cutter, is connected with a right rotating sliding seat and is movably connected on a right rotating sliding seat guide rail; a side-lying milling forming cutter is rotationally connected with a side-lying milling spindle box; and the side-lying milling spindle box is connected with a left upright and is movably connected on a left upright side guide rail. The invention overcomes the defects of low labor efficiency, time consumption, difficulty in control on the quality of a product and the like which are brought by the case that three elements and a forming surface on a cutting edge of pliers need to be completed by four people through four processes. According to the invention, the labor productivity is improved by over twice; a workpiece is clamped in one step, the four-process machining is completed and each machining element is controlled in a numerical control manner; and the workpiece has a reliable machining accuracy and the quality is ensured.

Owner:NANJING NINGQING CNC MACHINE TOOL MFRCO

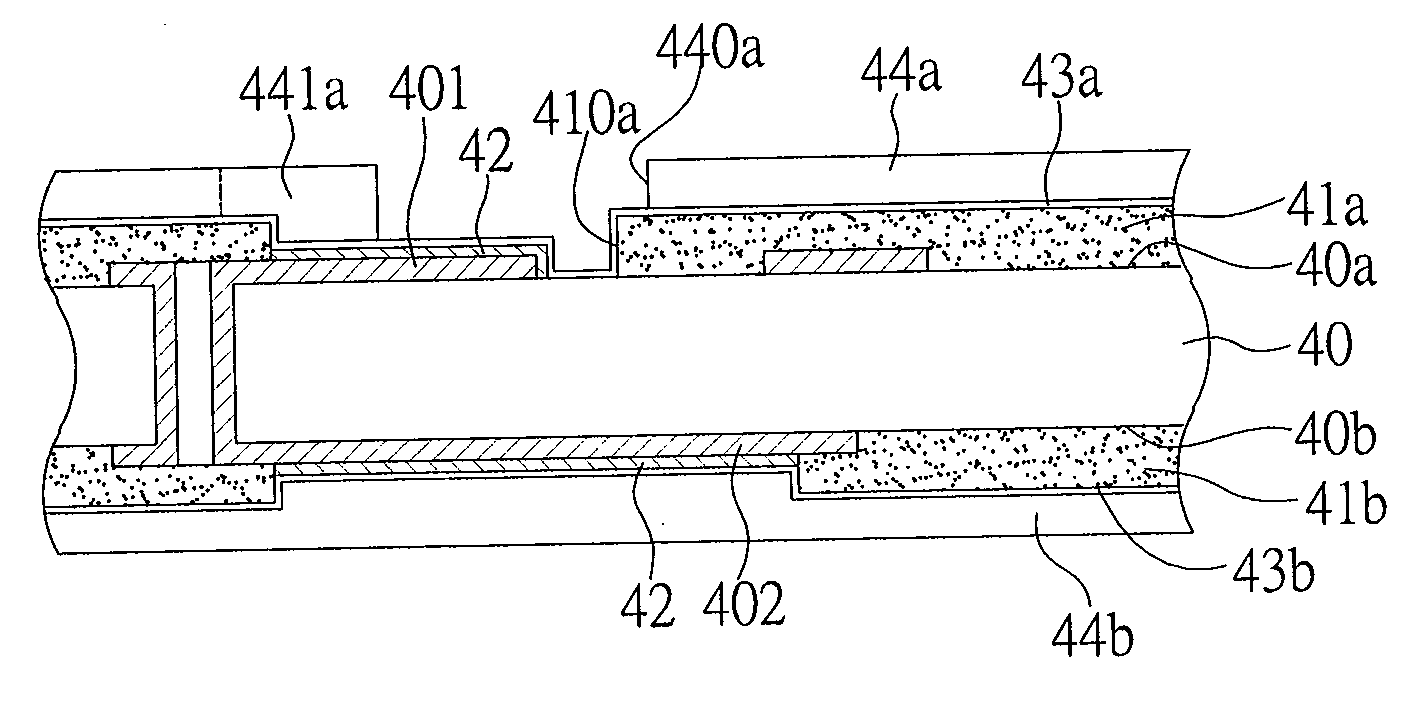

Cof package and tape substrate used in same

ActiveUS20090079047A1Improve reliabilitySmall sizeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSide lying

The present invention provides a COF package which comprises a tape substrate including a plurality of external input terminals and a plurality of external output terminals provided in a chip non-mounting area, a plurality of input wirings connected to the external input terminals respectively, a plurality of output wirings connected to the external output terminals respectively, a plurality of internal input wirings which are provided from the chip non-mounting area to a chip mounting area and provided between the input wirings and which are connected to the external input terminals, respectively, and a dummy wiring provided from the chip non-mounting area to the chip mounting area and provided between the internal input wirings; and a semiconductor chip including a plurality of input electrodes connected to the input wirings respectively, a plurality of output electrodes connected to the input wirings respectively, internal input electrodes connected to the internal input wirings respectively, and a dummy electrode provided with being spaced from each input electrode along one side lying over a chip surface, and connected to the dummy wiring.

Owner:LAPIS SEMICON CO LTD

Package substrate and method for fabricating the same

ActiveUS7718470B2High densityLarge spacingSemiconductor/solid-state device detailsStacked resist layersChemical platingLead bonding

A package substrate and a method for fabricating the same are provided according to the present invention. The package substrate includes: a substrate body with a die attaching side and a ball implanting side lying opposite each other, having a plurality of wire bonding pads and a plurality of solder ball pads respectively, and having a first insulating passivation layer and a second insulating passivation layer respectively, wherein a plurality of first apertures and a plurality of second apertures are formed in the first insulating passivation layer and the second insulation passivation layer respectively to corresponding expose the wire bonding pads and the solder ball pads; a chemical plating metal layer formed on the wire bonding pads and solder ball pads respectively; and a wire bonding metal layer formed on a surface of the chemical plating metal layer of the wire bonding metal layer.

Owner:PHOENIX PRECISION TECH CORP

X-ray detector

InactiveUS20130306877A1Small installation space requirementEasy to undertakeMaterial analysis by optical meansPhotometry using electric radiation detectorsSide lyingX-ray

An x-ray detector, especially for a computed tomograph, includes a number of detector modules arranged next to one another in a stacking direction with a front side, which during operation is oriented towards an x-ray source, and with a rear side lying opposite the front side. For screening against x-rays which pass during operation through an installation between two adjacent detector modules, an absorption element is positioned on the rear side of the two adjacent detector modules.

Owner:SIEMENS HEALTHCARE GMBH

Pillow

A pillow whose height can be automatically adjusted so that, when a user is in a face-up lying position, the back of the user's head is slightly higher than his or her back, and in addition, whose height can be automatically varied between a face-up lying position and a side lying position. A cavity section (8) is formed in a head placement member (3), and the cavity section (8) sags so that, when the head is placed on the pillow with the face up, the distance between the lowermost section of the head and a bottom member (2) is in the range of 10 - 30 mm. An urging mechanism (9) is placed in the cavity section, and the urging mechanism has X-shaped links (11) arranged in the cavity section (8), separated in the lateral direction. Each of the X-shaped links is constructed by pivotally connecting, by an intermediate link shaft (16), a first link member (12) sloping forwardly upward and a second link member (13) sloping backwardly upward. The urging mechanism further has a front side upper connection member (18) for connecting front end sections of the first members of both X-shaped links to each other, a back side upper connection member (20) for connecting rear end sections of the second link members of both X-shaped links to each other, and a spring member (21) for applying a spring force to both X-shaped links, the spring force acting in the direction that causes both link members of each X-shaped link to approach each other in the forward / backward direction along an action line in the forward / backward direction.

Owner:IKEN KOUGYO +1

Automatic glue cutting machine

ActiveCN102275176AReduce labor intensityIncrease productionMetal working apparatusSide lyingEngineering

The invention discloses a full-automatic rubber cutting machine, which comprises a rubber cutting machine body and a block rubber storage and transport mechanism, and is characterized in that: the rubber cutting machine body comprises a rubber cutting knife fixed on a frame and a vertical chopping block capable of reciprocating transversely on the frame; an allowed cutting area is formed between the vertical chopping block and the rubber cutting knife; block rubber entering the allowed cutting area is positioned in a side lying posture; in the process of moving the vertical chopping block to the rubber cutting knife, the block rubber entering the allowed cutting area can be pushed to the rubber cutting knife until the block rubber is cut into at least two small rubber blocks, and the small rubber blocks fall through a knife gap and enter the next process; and the block rubber storage and transport mechanism comprises a block rubber storage unit, a block rubber horizontal passing unit,a block rubber alternative passing unit, a block rubber turning and erecting unit and a block rubber side lying conversion unit. By the full-automatic rubber cutting machine, the labor intensity of aworker can be greatly reduced, and the full-automatic rubber cutting machine has high operating safety, high yield and high production efficiency and is particularly suitable for production process automation and continuous modification.

Owner:双星东风轮胎有限公司

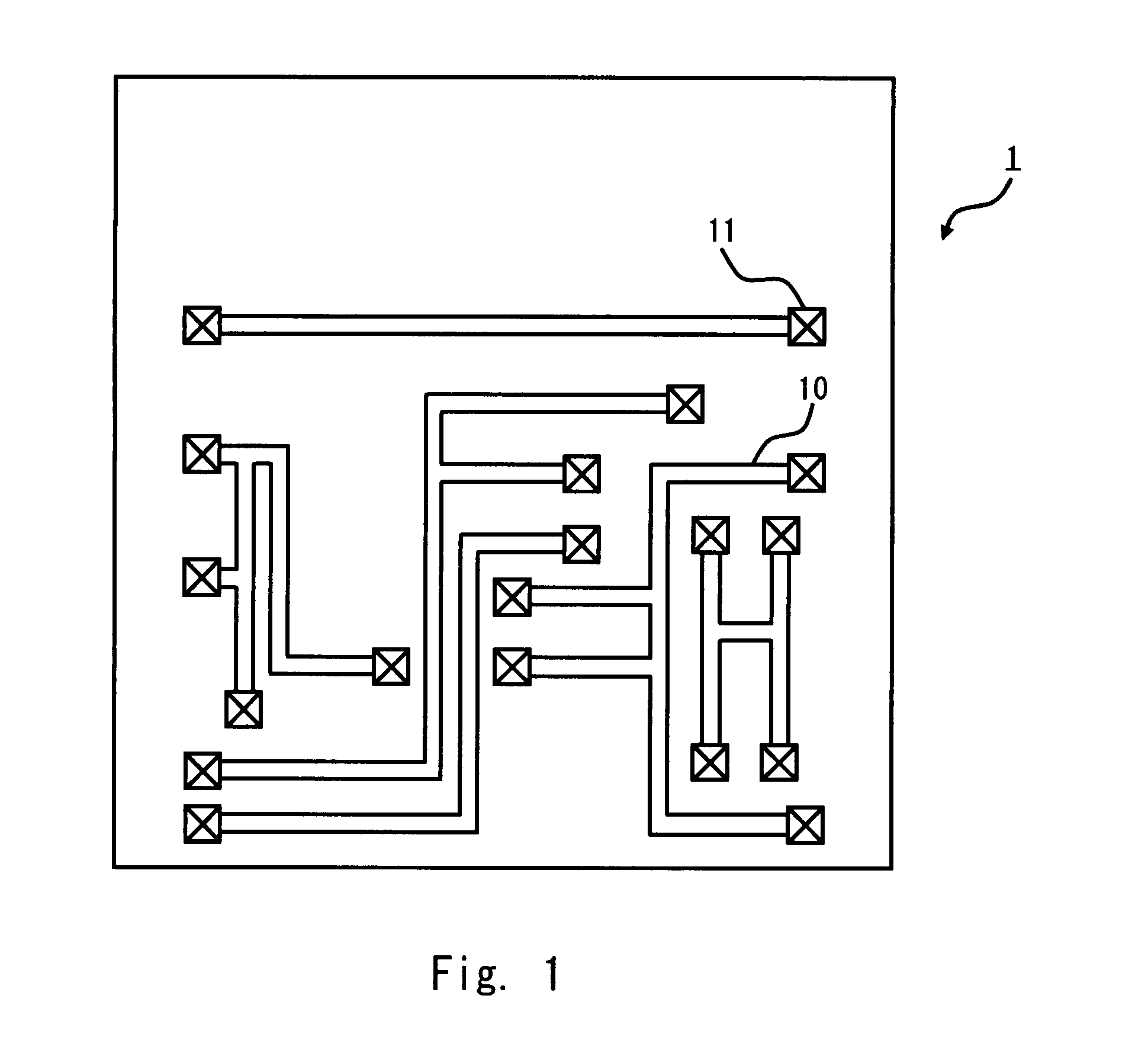

Semiconductor apparatus design method and execution program therefor

ActiveUS20070288879A1Reduce parasitic capacitanceImprove reliabilitySemiconductor/solid-state device manufacturingComputer aided designLower limitSide lying

A design method places a dummy line in floating state in a line layer of a semiconductor apparatus by using a computer. The method includes a first step of reading layout data and placing a dummy line with a longitudinal side lying in parallel with a signal line in an area where a pattern density of the signal line in a prescribed area is equal to or lower than a density lower limit, and a second step of dividing a dummy line placed in an area where a distance from the signal line is equal to or shorter than a dummy dividing distance.

Owner:RENESAS ELECTRONICS CORP

Pillow

The invention provides a pillow capable of having the height thereof adjusted automatically so that the height of the back of the head of a user in a face-up lying position is slightly higher than his / her back, and also capable of having the height thereof varied automatically between a face-up lying position and a side lying position. A hollow portion 8 having a biasing mechanism 9 disposed therein is formed in a head placement member 3, and when the head is placed face-up on the head placement member 3, the hollow portion 8 is depressed so that the distance between the lowermost portion of the head and the bottom member 2 is in the range of 10 mm to 30 mm. The biasing mechanism has X-shaped links 11 disposed laterally spaced apart in the hollow portion 8. Each X-shaped link is composed by pivotally connecting a first link member 12 slanted upward toward the front and a second link member 13 slanted upward toward the rear by an intermediate link shaft 16. The biasing mechanism further comprises a front-side upper connecting member 18 for connecting the front ends of the first link members of the X-shaped links, a rear-side upper connecting member 20 for connecting the rear ends of the second link members of the X-shaped links, and a spring member 21 providing a spring force for approximating the link members of each X-shaped link in the frontward / rearward direction along a line of action in the frontward / rearward direction with respect to the X-shaped links.

Owner:NAKAYAMA SHINICHIRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com