Automatic glue cutting machine

A technology of rubber cutting machine and rubber cutting knife, applied in the direction of metal processing, etc., can solve the problems of unsuitable automation and continuous transformation, low production efficiency, poor operation safety, etc., achieve high production efficiency, increase production efficiency, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

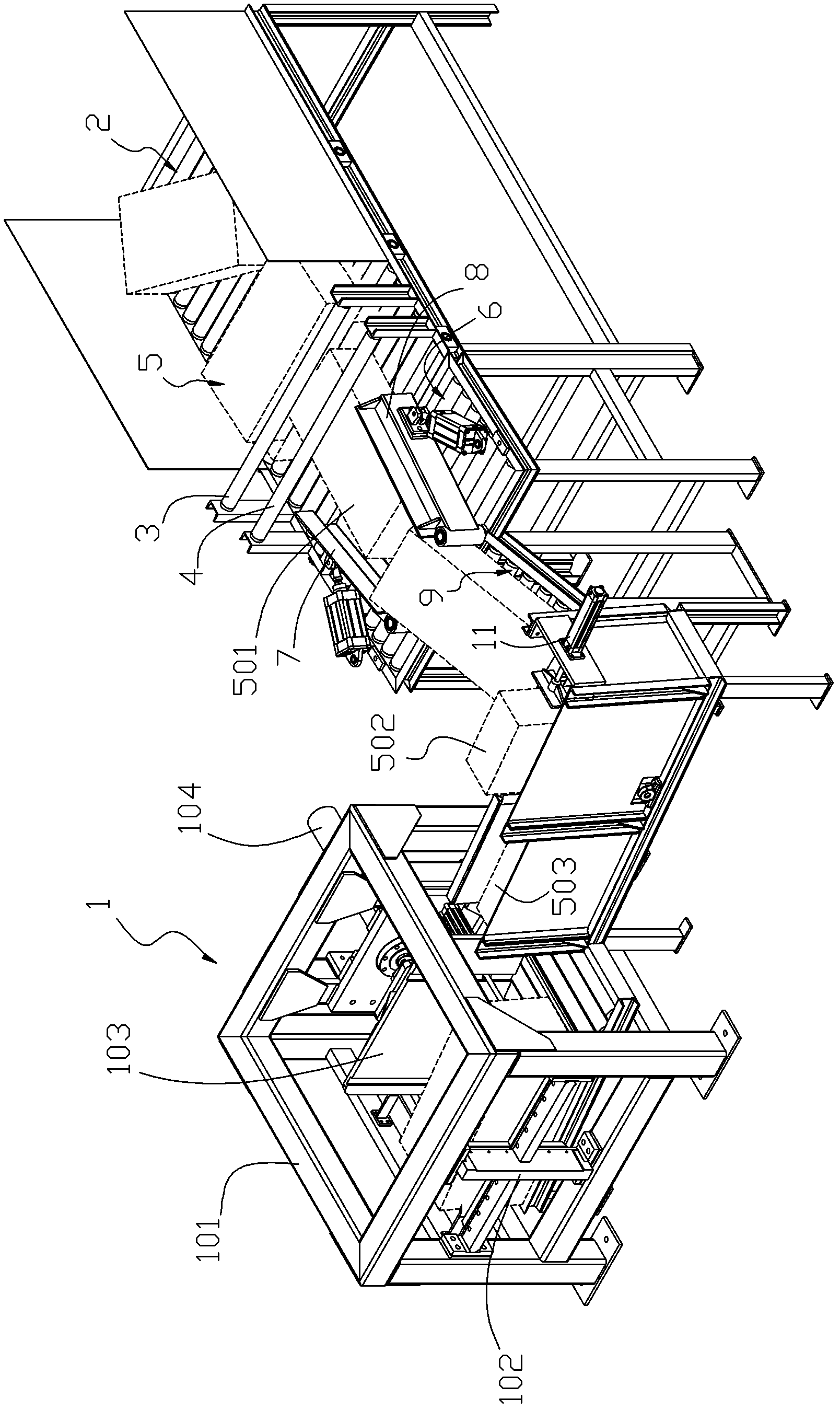

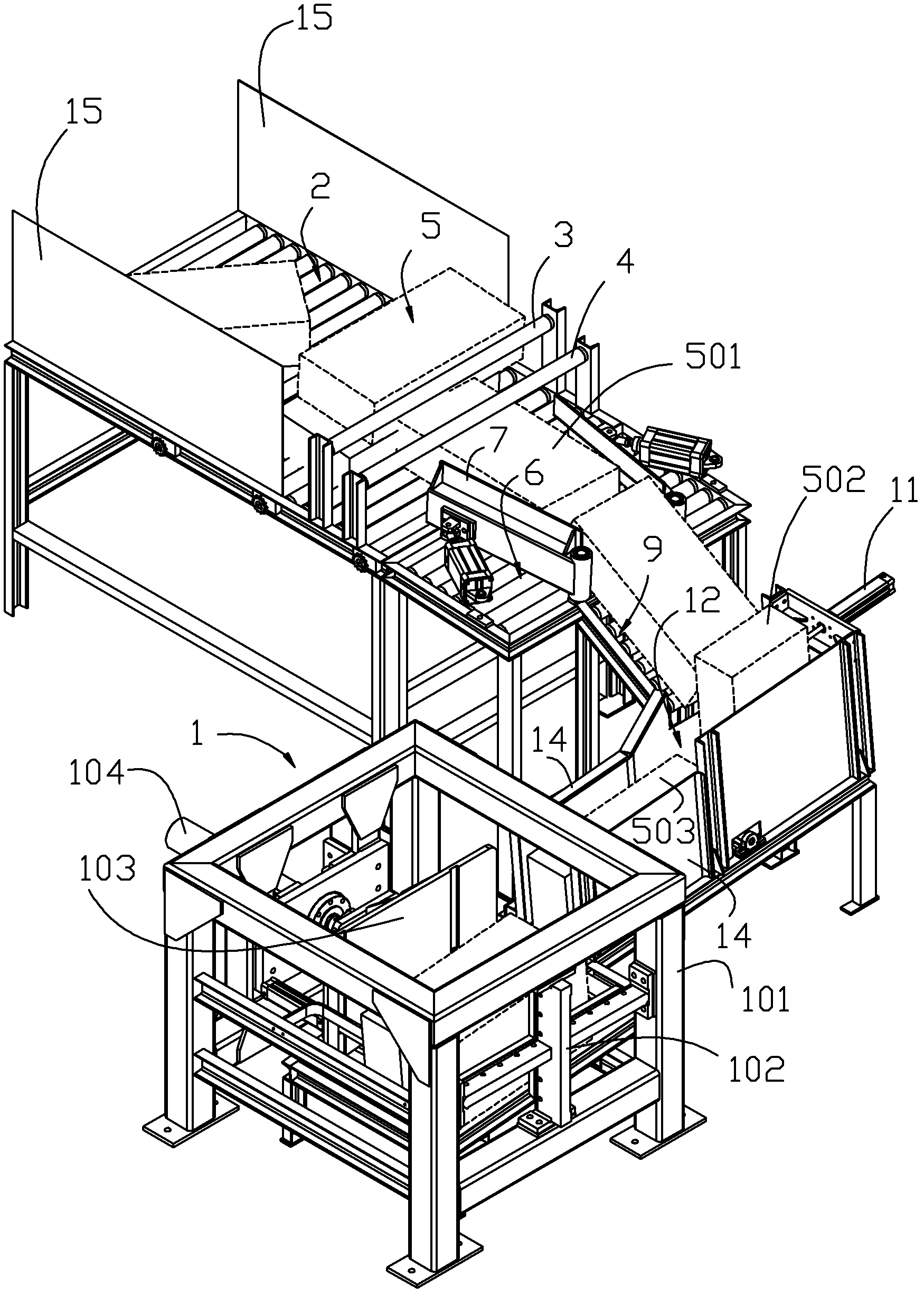

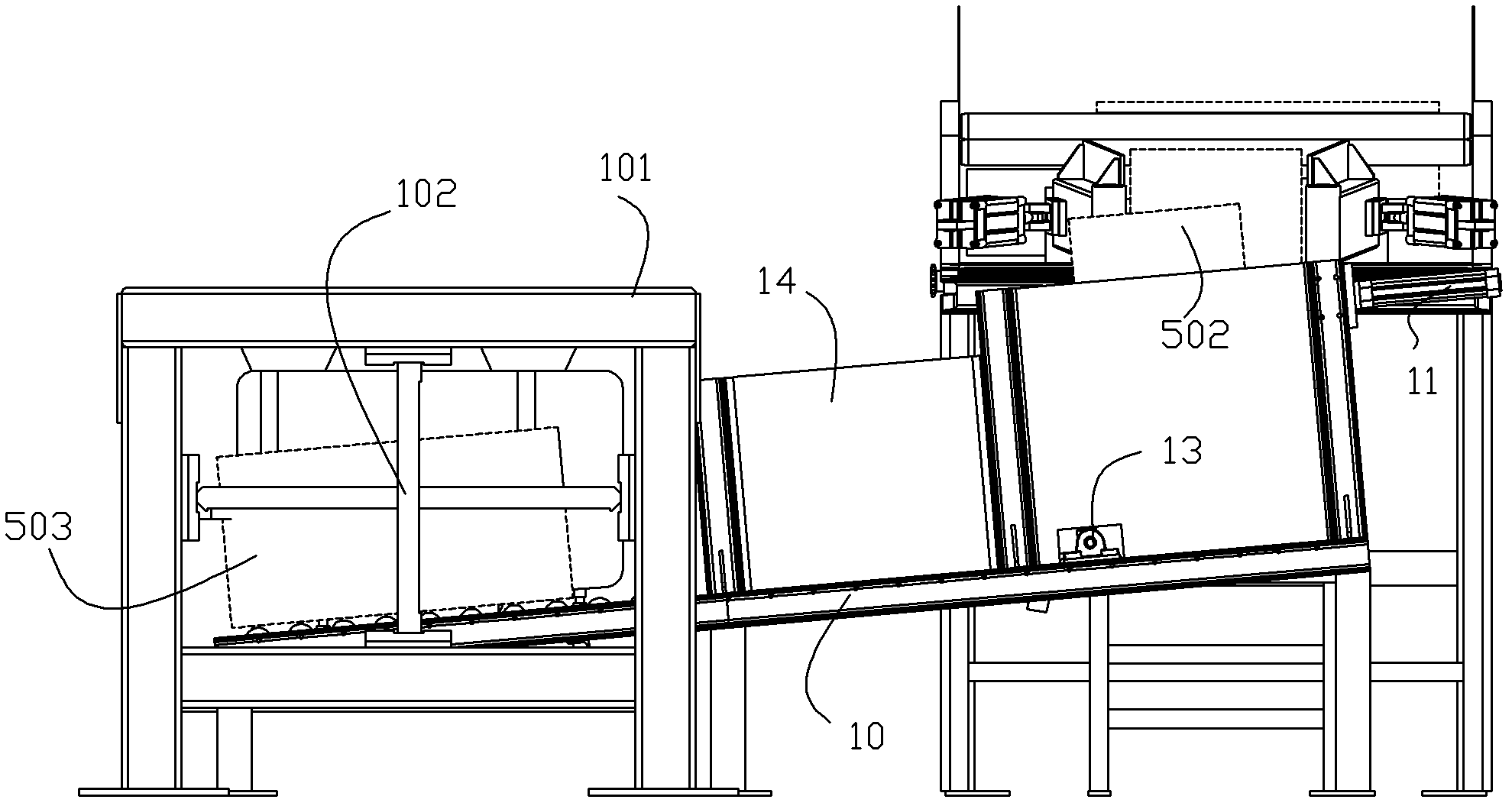

[0025] combine figure 1 , figure 2 , image 3 and Figure 4 , a rubber cutting machine, comprising a rubber cutting machine body 1 and a bulk rubber material storage and conveying mechanism. The above-mentioned rubber cutting machine body includes a rubber cutting knife 102 fixed on the frame 101 and a vertical cutting board 103 capable of reciprocating laterally on the frame. The quasi-cutting area is between the vertical cutting board and the rubber cutting knife. The blocky rubber in the area is in a side-lying posture. When the vertical cutting board moves to the rubber cutter, the blocky rubber that enters the quasi-cutting area can be pushed to the rubber cutter until it is cut into at least two small rubber blocks. The small rubber blocks fall out through the knife gap and enter the next process. Above-mentioned vertical chopping block is equipped with the chopping block hydraulic cylinder 104 that can drive it to move back and forth, certainly also can select air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com