Multi-station plier numerical control milling machine

A CNC milling machine and multi-station technology, applied to milling machine equipment, milling machine equipment details, manufacturing tools, etc., can solve problems such as instability, low labor efficiency, and time consumption, and achieve quality assurance, reliable processing accuracy, and labor productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

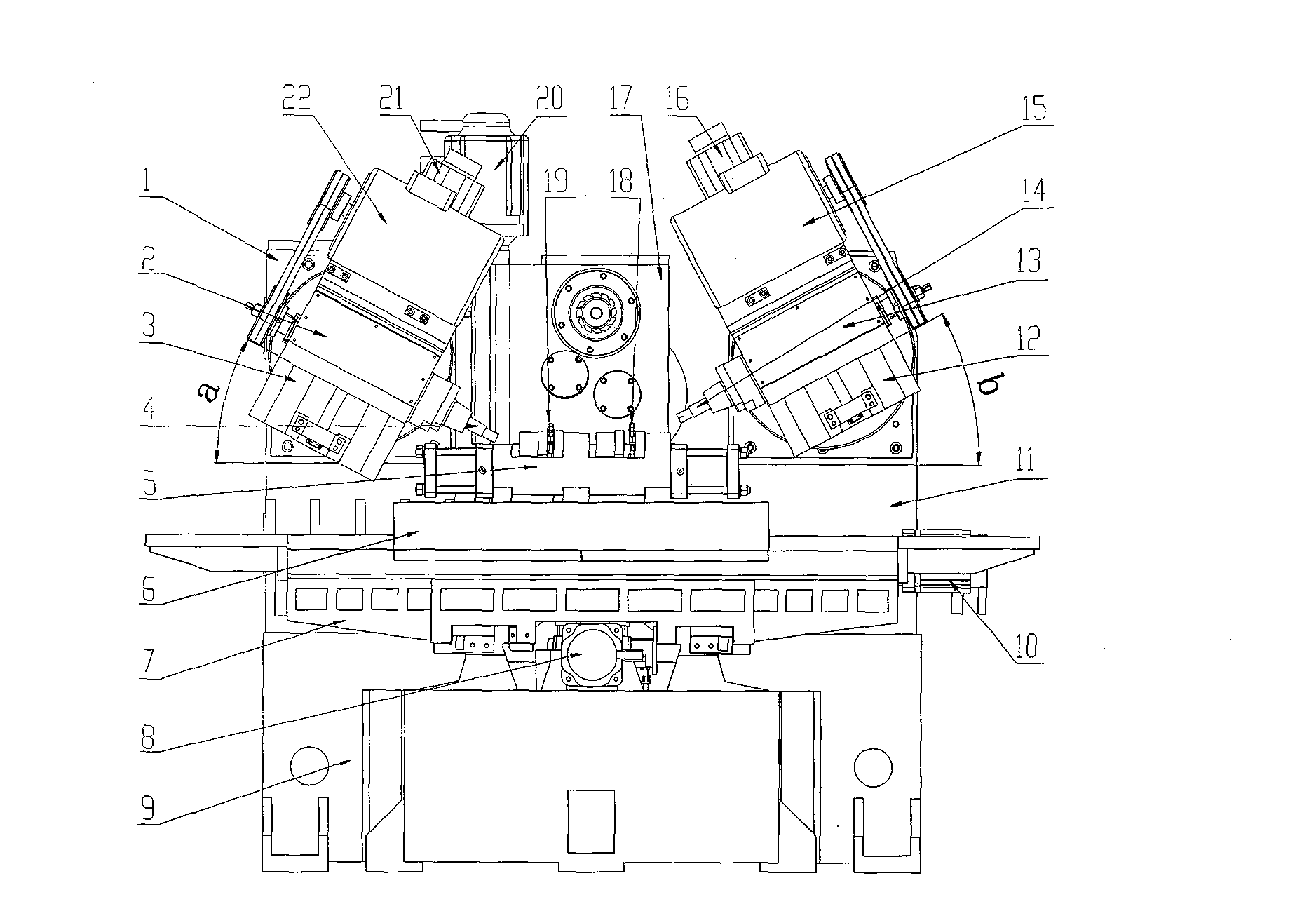

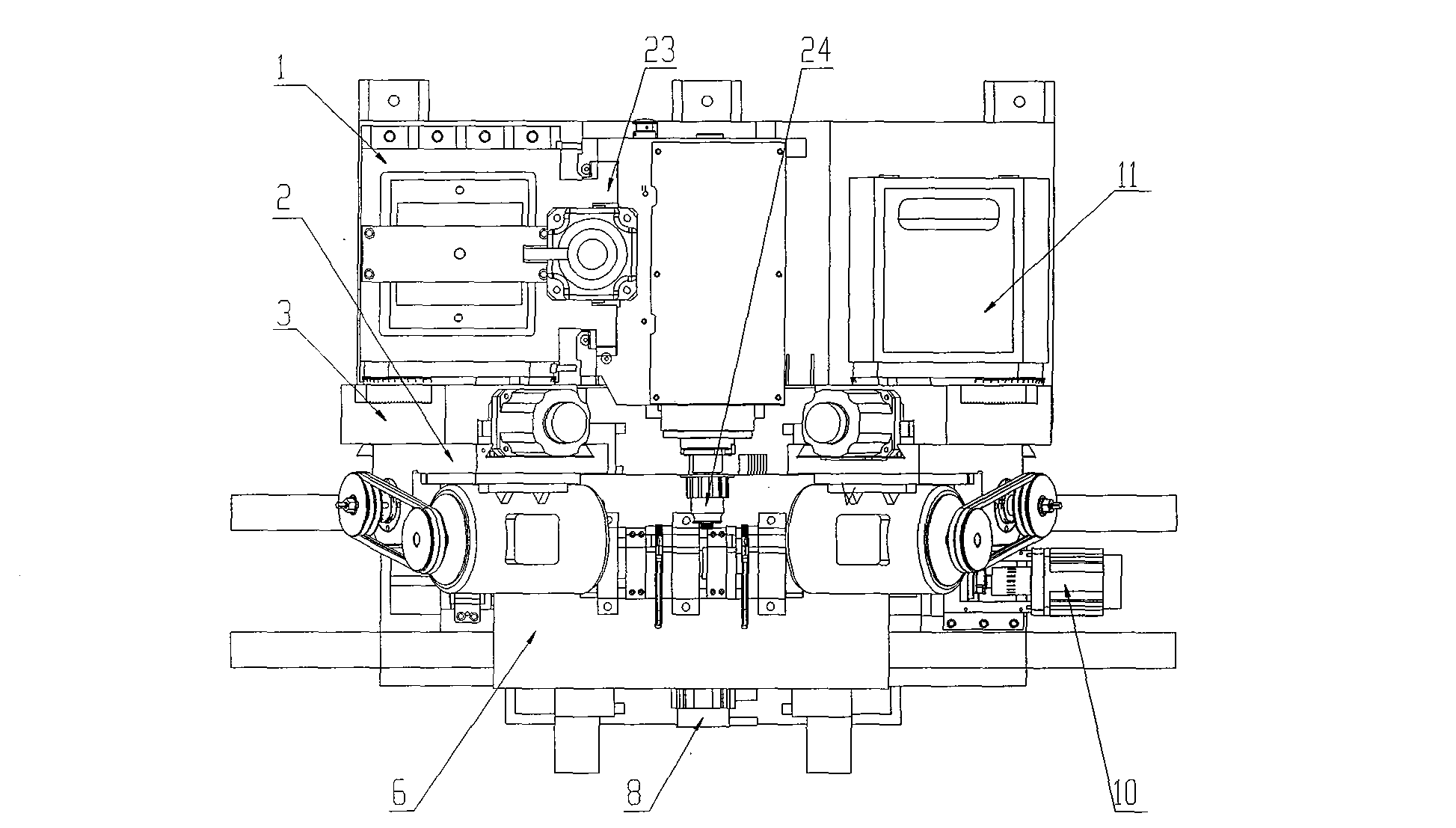

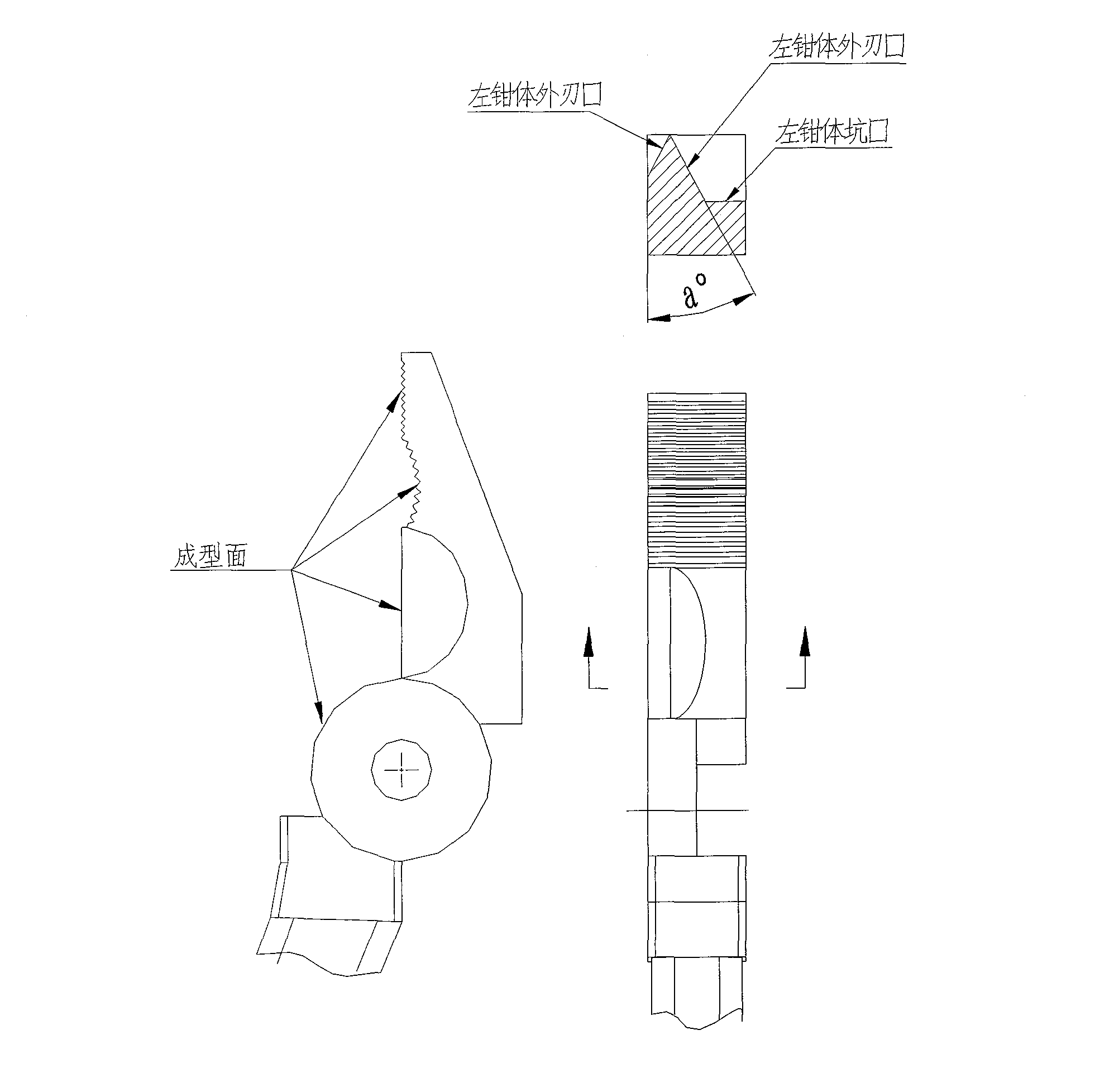

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown:

[0019] The left vertical milling cutter 4 is connected with the left end mill headstock 2 through the left end mill spindle (omitted in the figure, not shown), and rotates on the left end mill headstock 2; the left end mill headstock 2 passes through the ball screw and the nut (omitted in the figure, not drawn) is movably connected with the guide rail of the left-handed slide 3, and driven by the left end milling servo motor 21, and the left-handed slide 3 is connected with the left column 1 by bolts, and the left-handed slide 3 is connected with the left column. There is an installation angle a between the left columns 1, and the installation angle a can be adjusted by rotating the left rotary slide seat 3, and the left column 1 is fixed on the bed 9.

[0020] The workbench 6 is movably connected with the guide rail on the cross slide 7 through a ball screw and a nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com