110 kV double-winding vehicle-loaded transformer lead structure

A technology of transformer and double winding, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, transformer/inductor parts, etc. , transformer oil and steel waste, to achieve the effect of reducing the size of the body, reducing the amount of use, and reducing the size of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

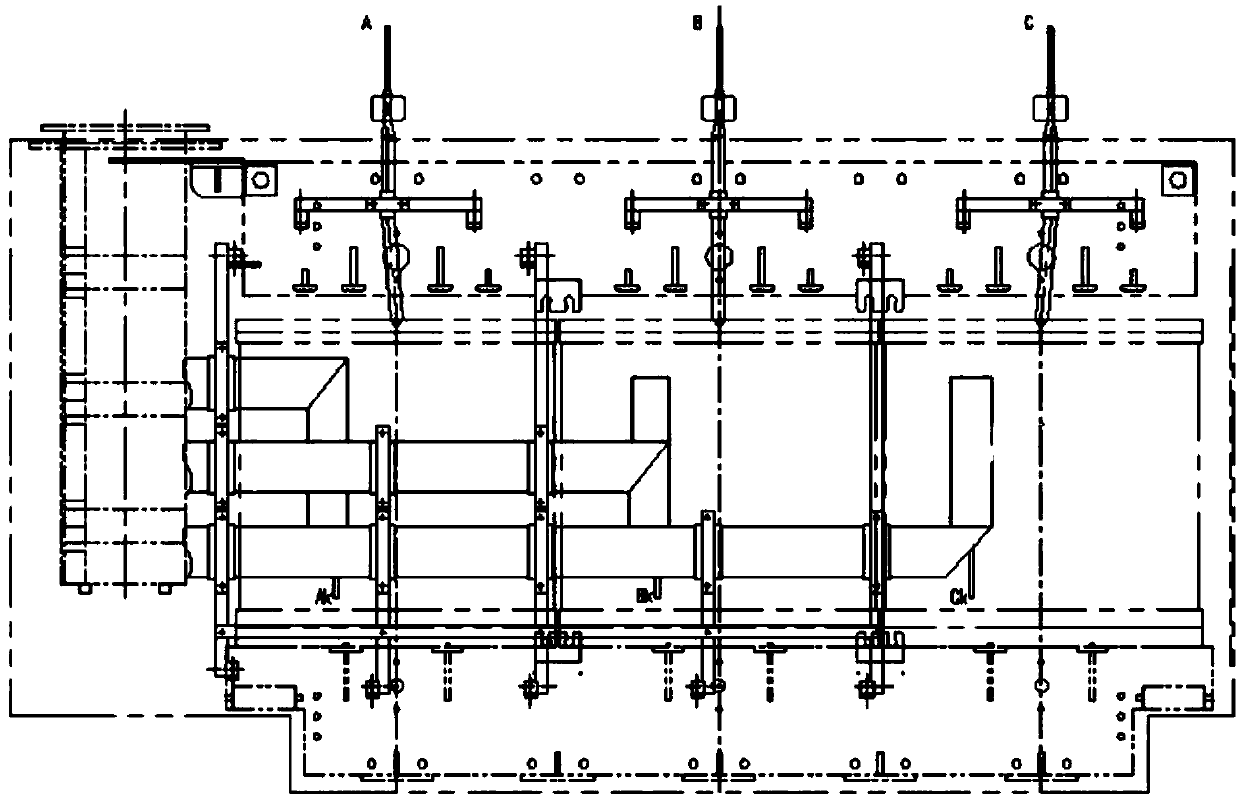

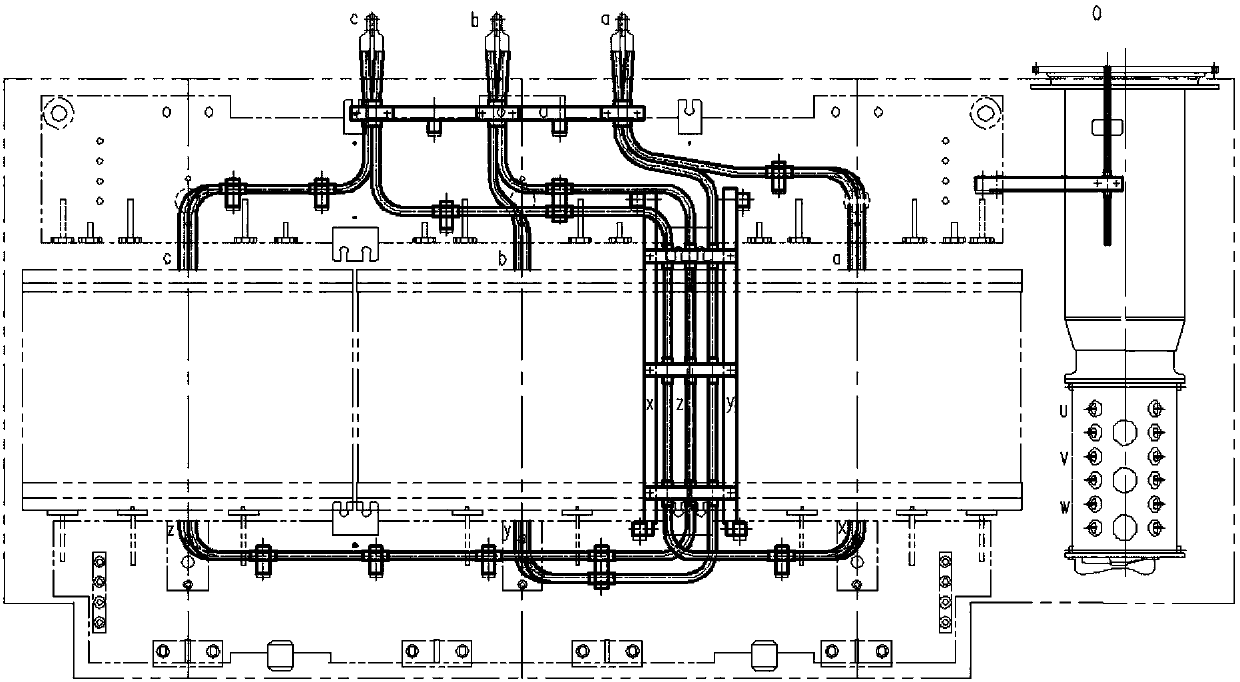

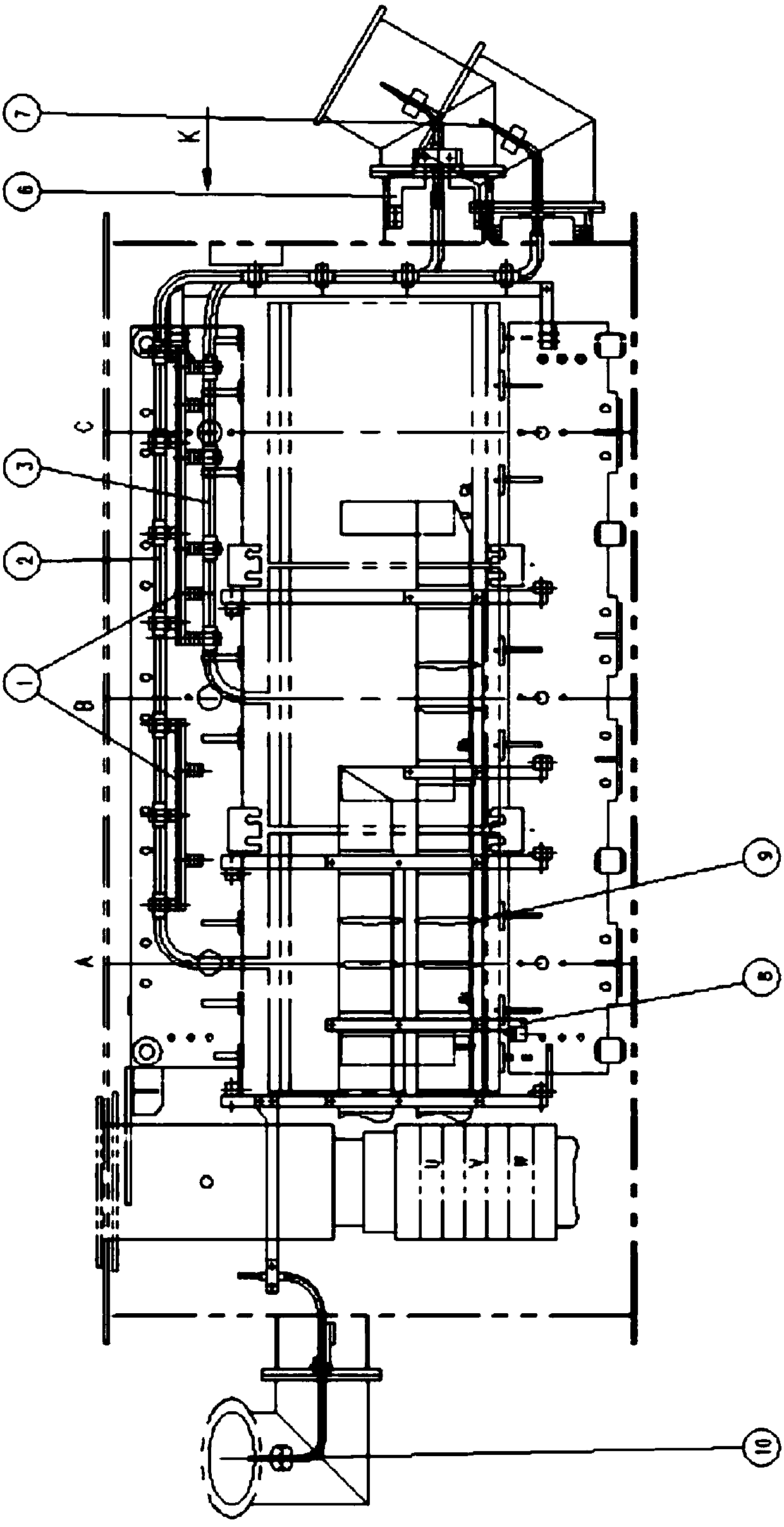

[0019] A 110kV double-winding vehicle-mounted transformer lead structure, including a high-voltage lead structure and a low-voltage lead structure, characterized in that: the high-voltage lead structure includes A-phase, B-phase, and C-phase high-voltage phase lines, such as image 3 , Figure 4 As shown, the high-voltage phase line 2 of phase A and the high-voltage phase line 3 of phase B adopt the axial outlet of the end, and the upper and lower clamping parts along the iron core are used for horizontal wiring, and the wooden part 1 is clamped by the first high-voltage phase line. The end of the fuel tank close to phase C, the high-voltage phase line 4 of phase C adopts the end radial outlet on the short axis side of the fuel tank; The phase line is fixed and led to the position of the lower rising seat, and the high-voltage phase line of A phase, B phase and C phase is fixed and clamped inside the rising seat through the third high-voltage phase line clamping wooden piece 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com