Step-up transformer with dual-body structure for ultra-high-voltage generator

A technology for step-up transformers and generators, applied in transformers, fixed transformers, transformers/inductor coils/windings/connections, etc., can solve the problems of increasing load loss, increasing the transportation height of transformers, and increasing transportation costs, etc., to achieve Improve safety and reliability, improve short-circuit resistance, and improve the effect of potential distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the technical solution will be described in detail below in conjunction with the accompanying drawings.

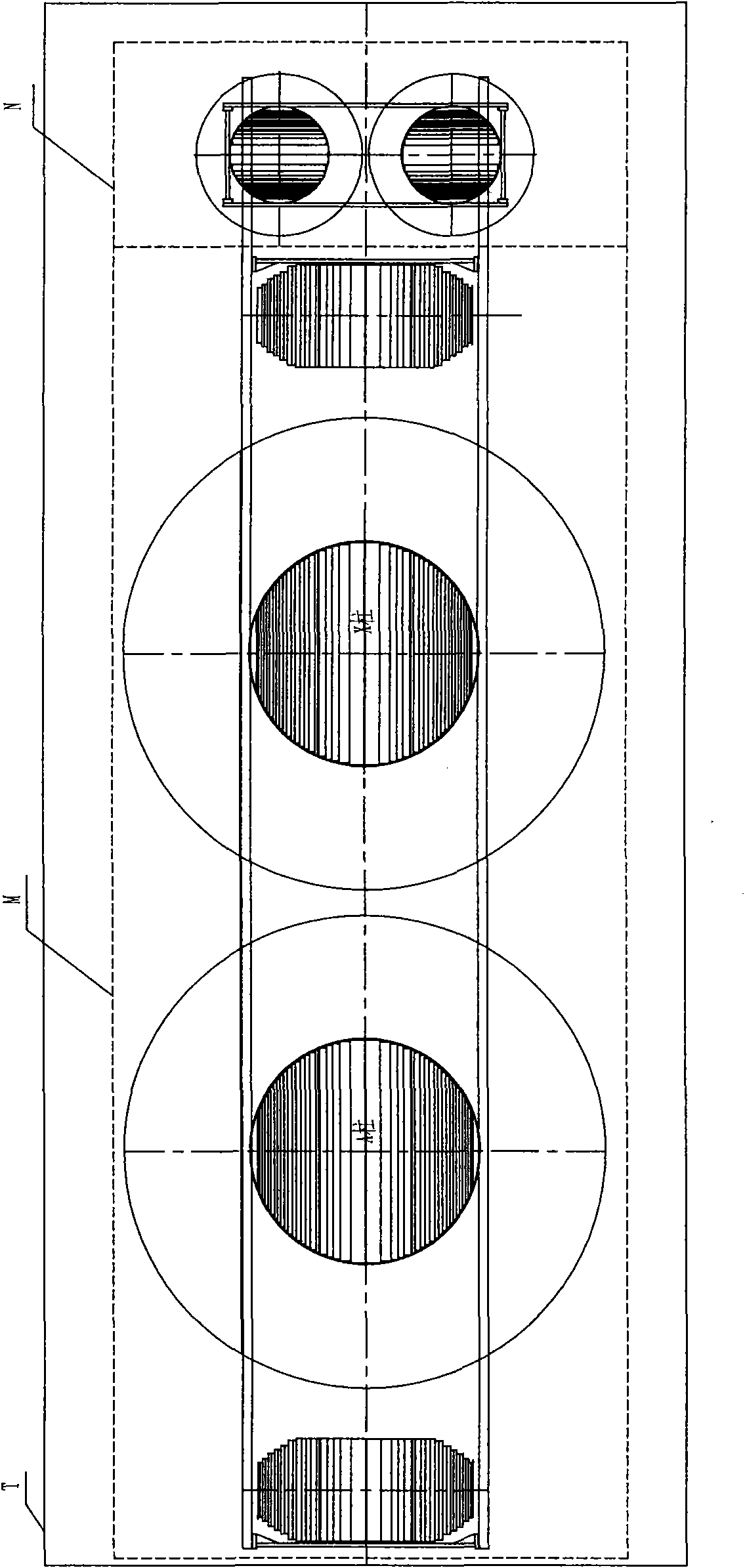

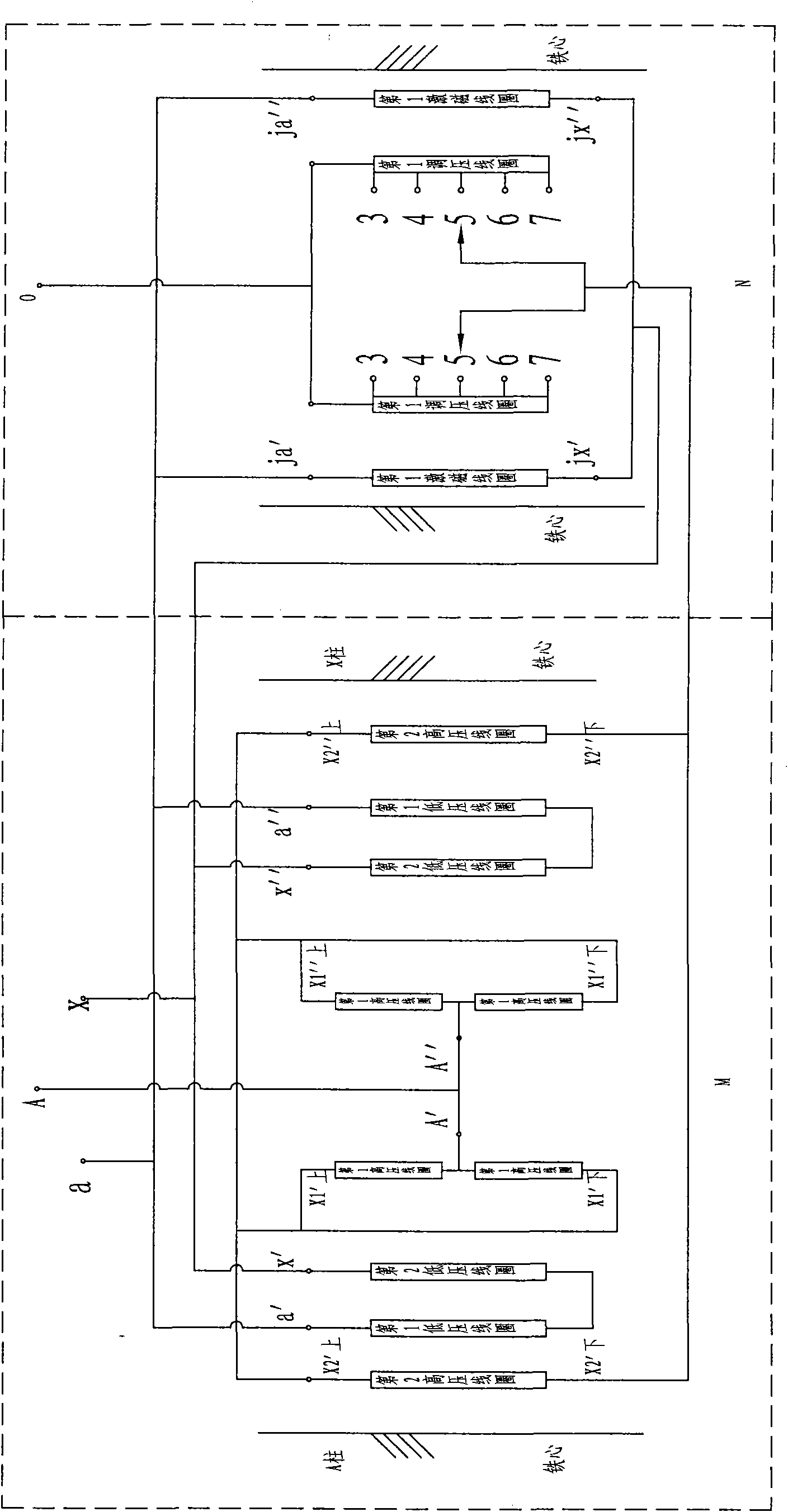

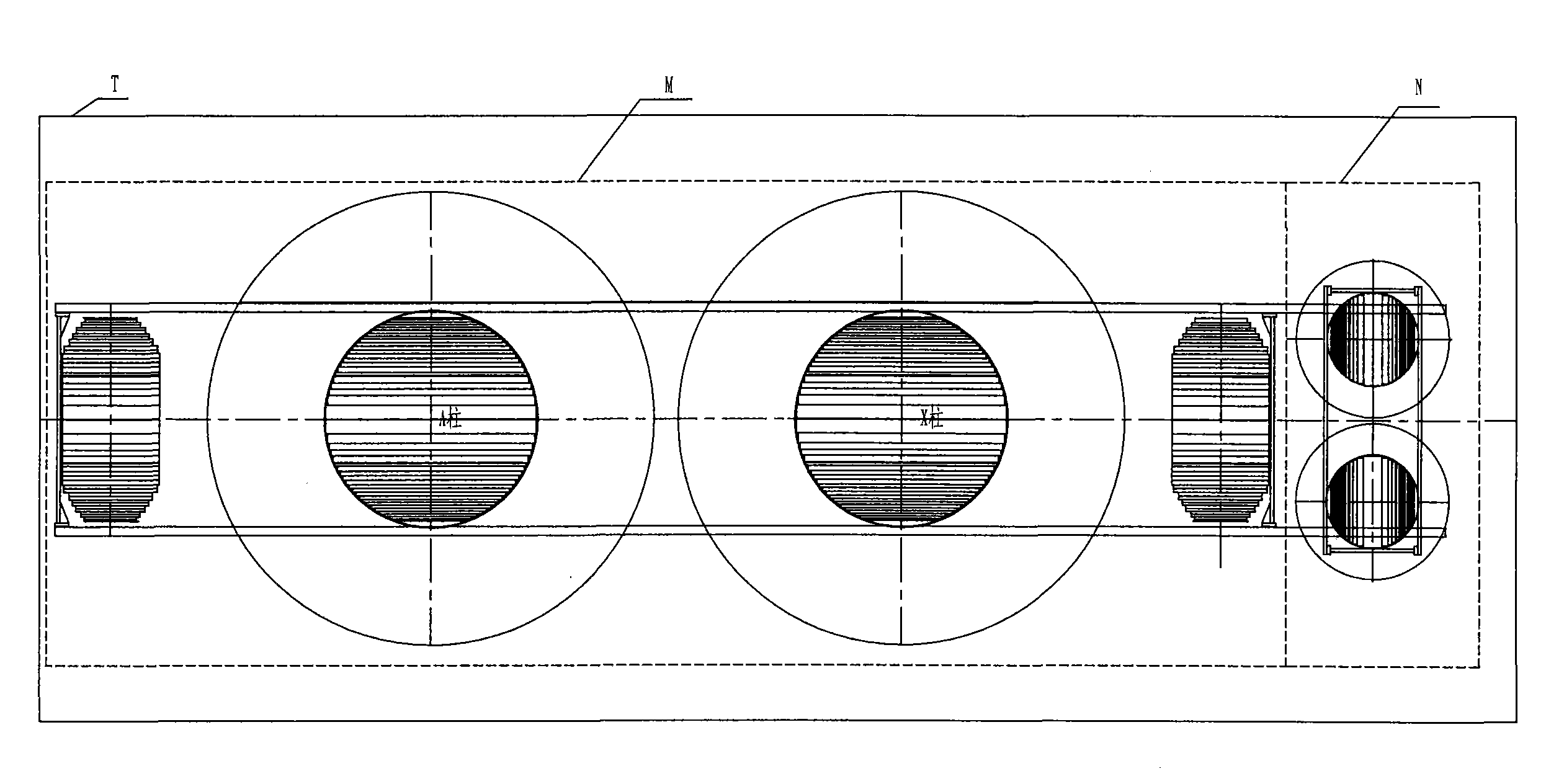

[0017] Such as figure 1 As shown, the UHV generator step-up transformer with double body structure of the present invention includes a main body M and a voltage regulator body N, which are arranged in the same oil tank T of the transformer, wherein the iron core of the voltage regulator body N is two cores Column structure, one core column is covered with the first exciting coil and the first voltage regulating coil, the other core column is covered with the second exciting coil and the second voltage regulating coil, the first exciting coil and the second exciting coil are connected in parallel to form a The excitation coil is connected in parallel with the low-voltage coil in the main body.

[0018] The iron core of the main body M is a single-phase four-column structure, including two core columns, namely A column, X column and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com