Patents

Literature

118results about How to "Increase the rotation angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

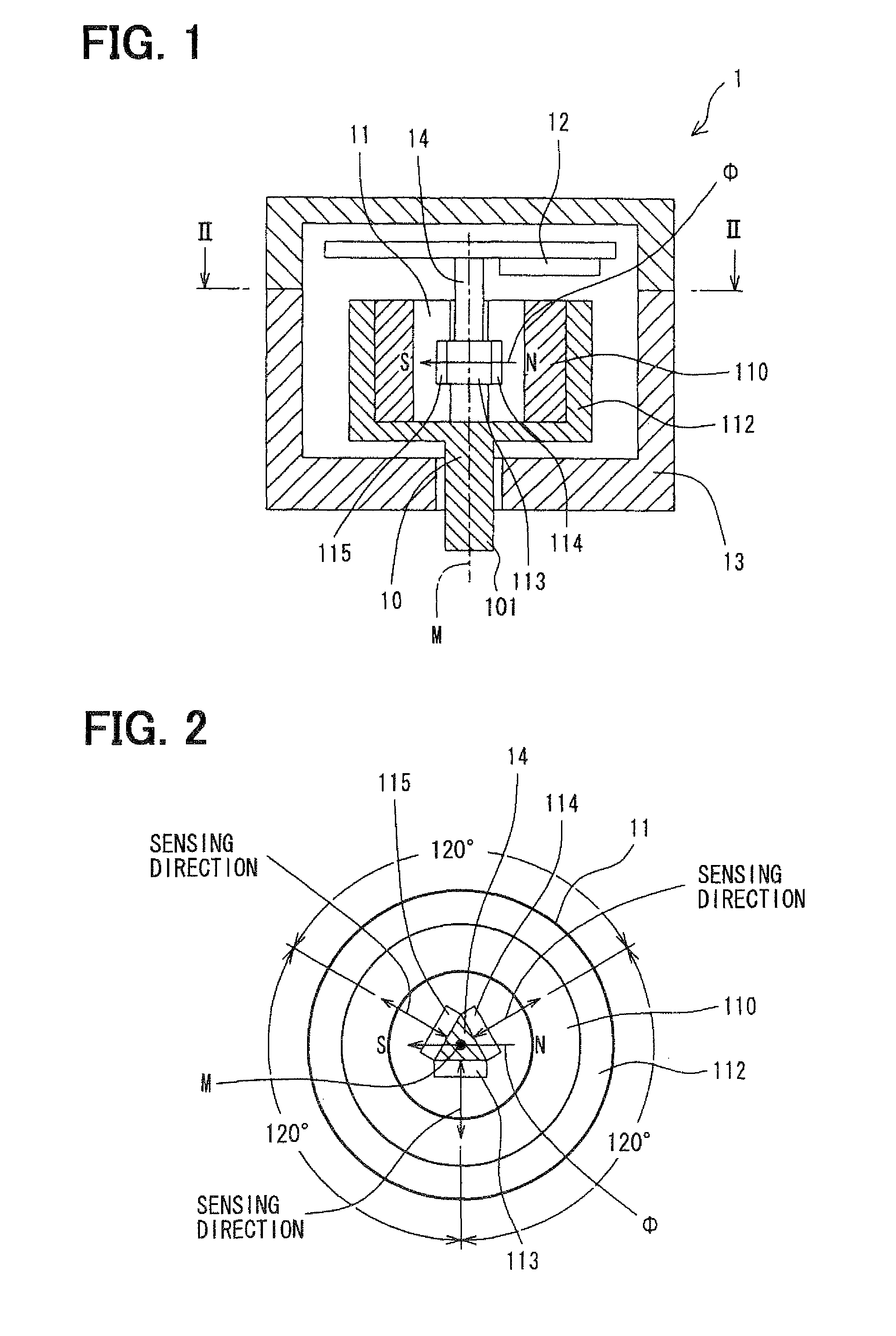

Rotation angle detecting device

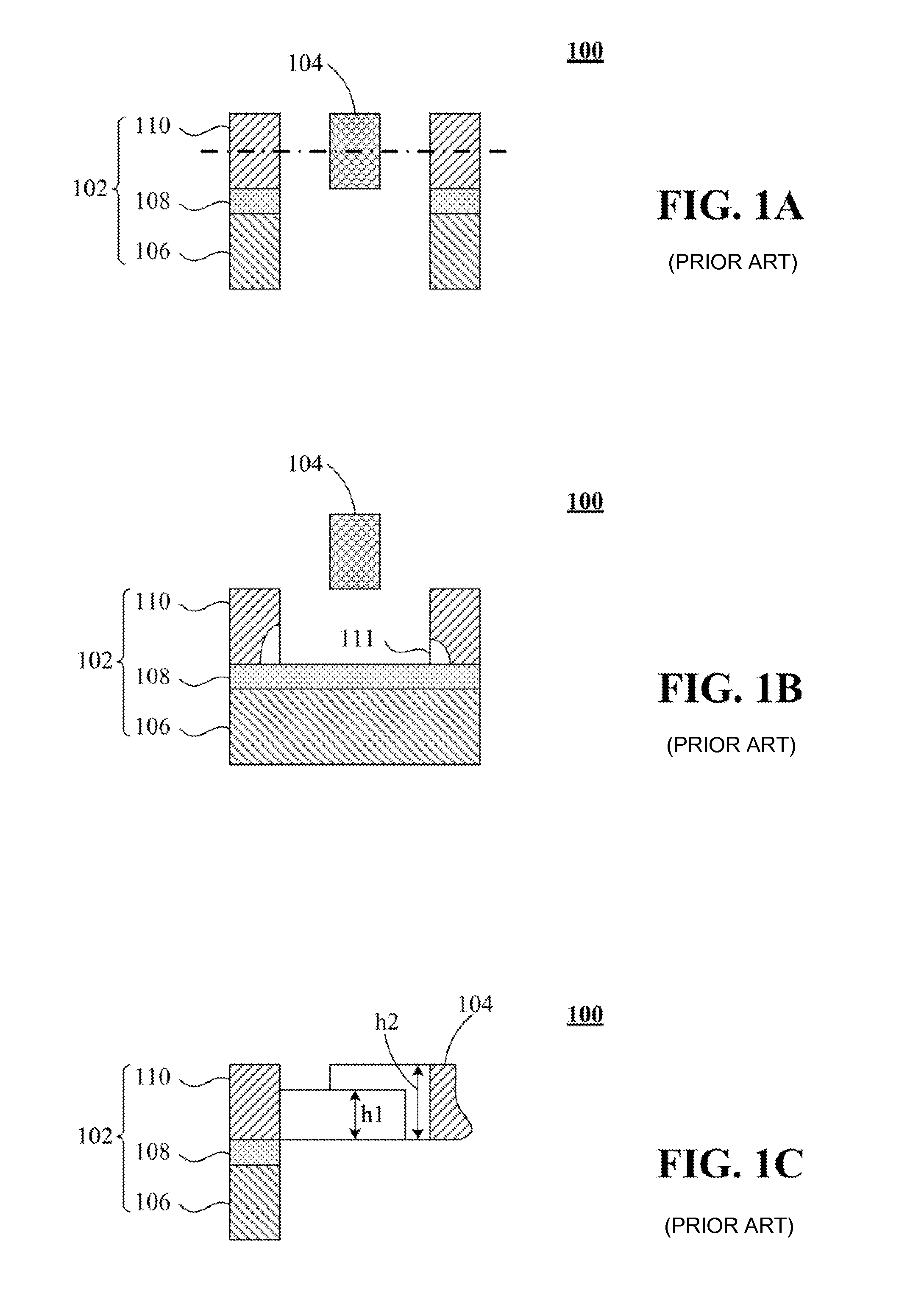

InactiveUS20060028203A1Increase the rotation angleDetection errorUsing electrical meansConverting sensor outputMagnetic polesAxial distance

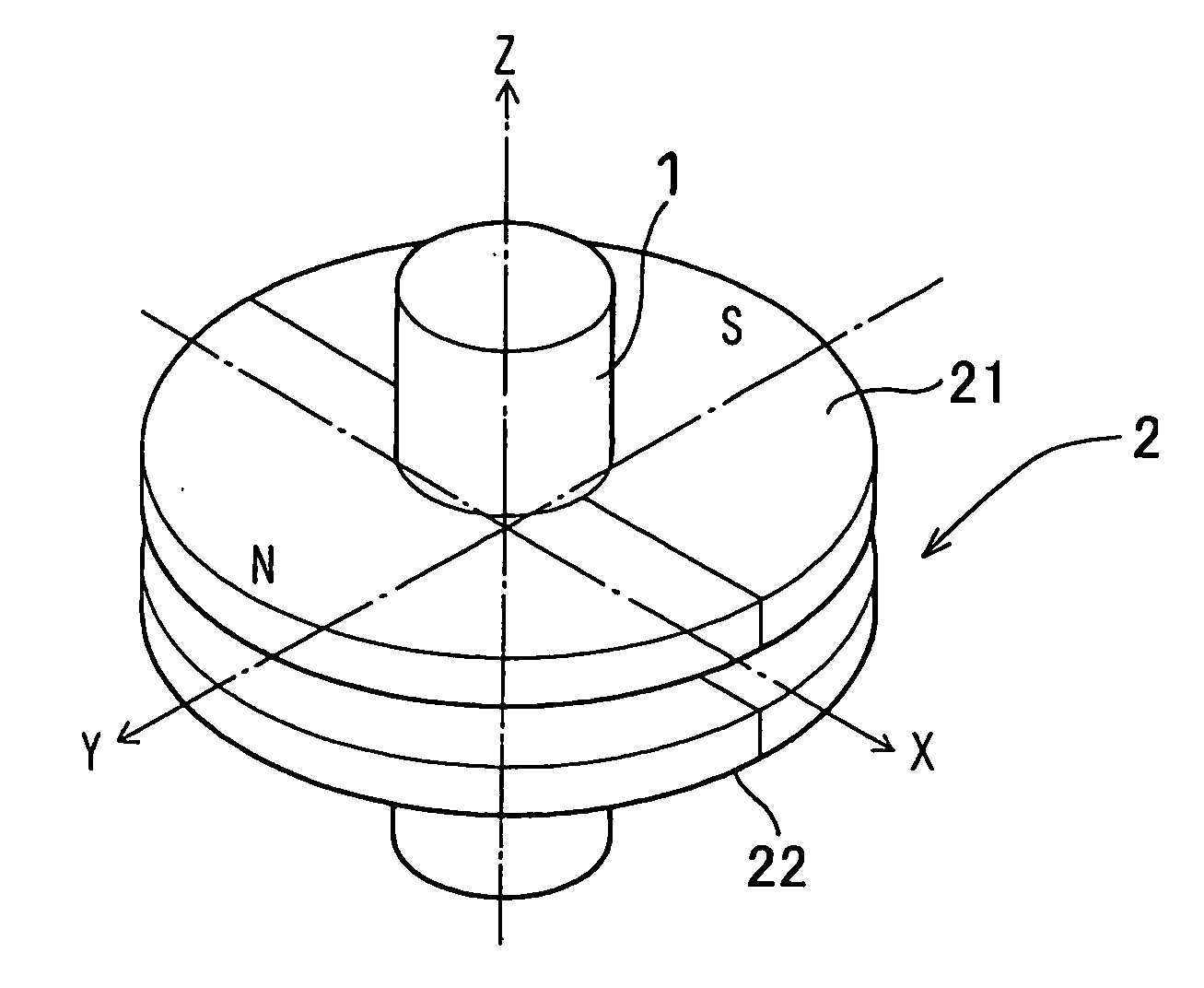

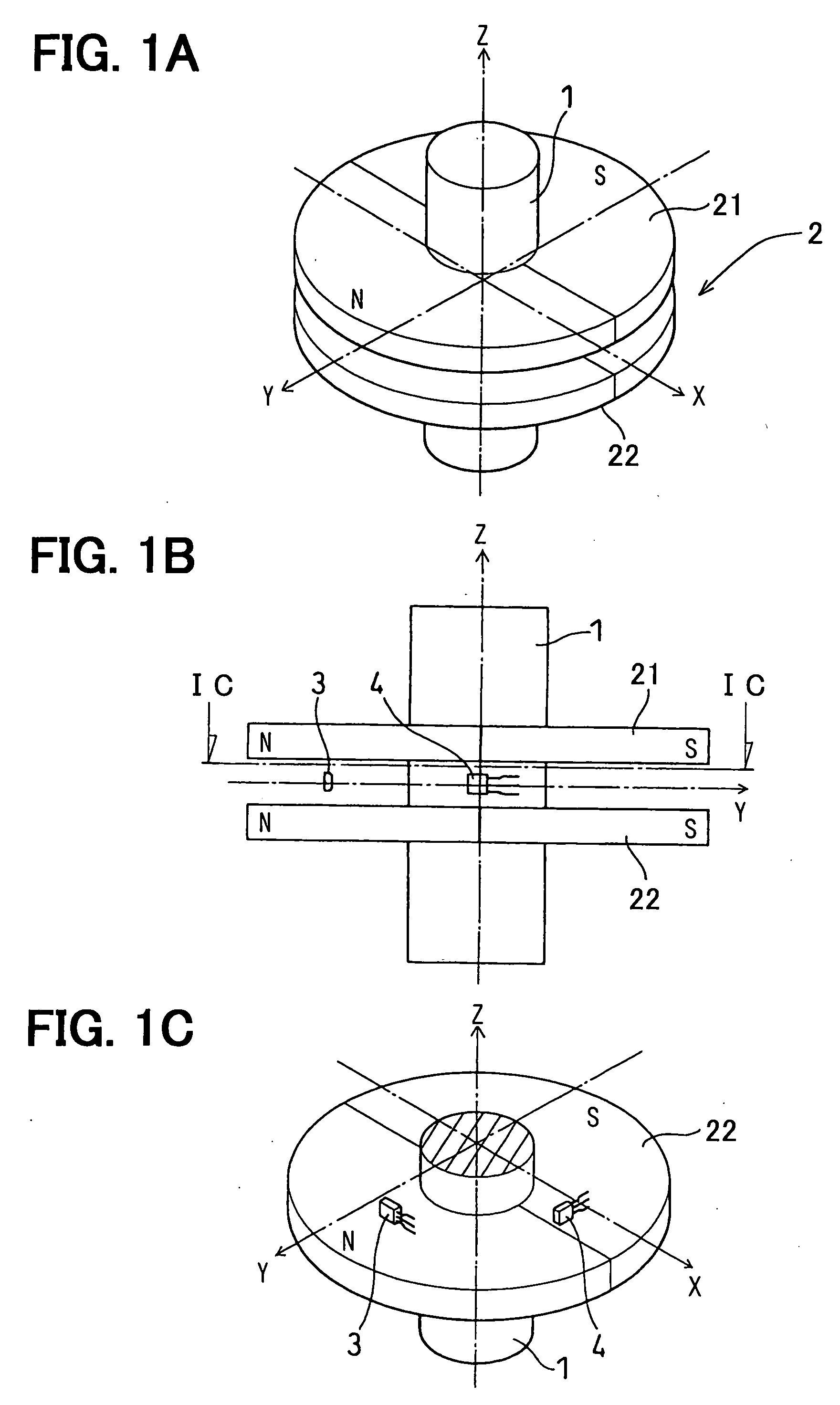

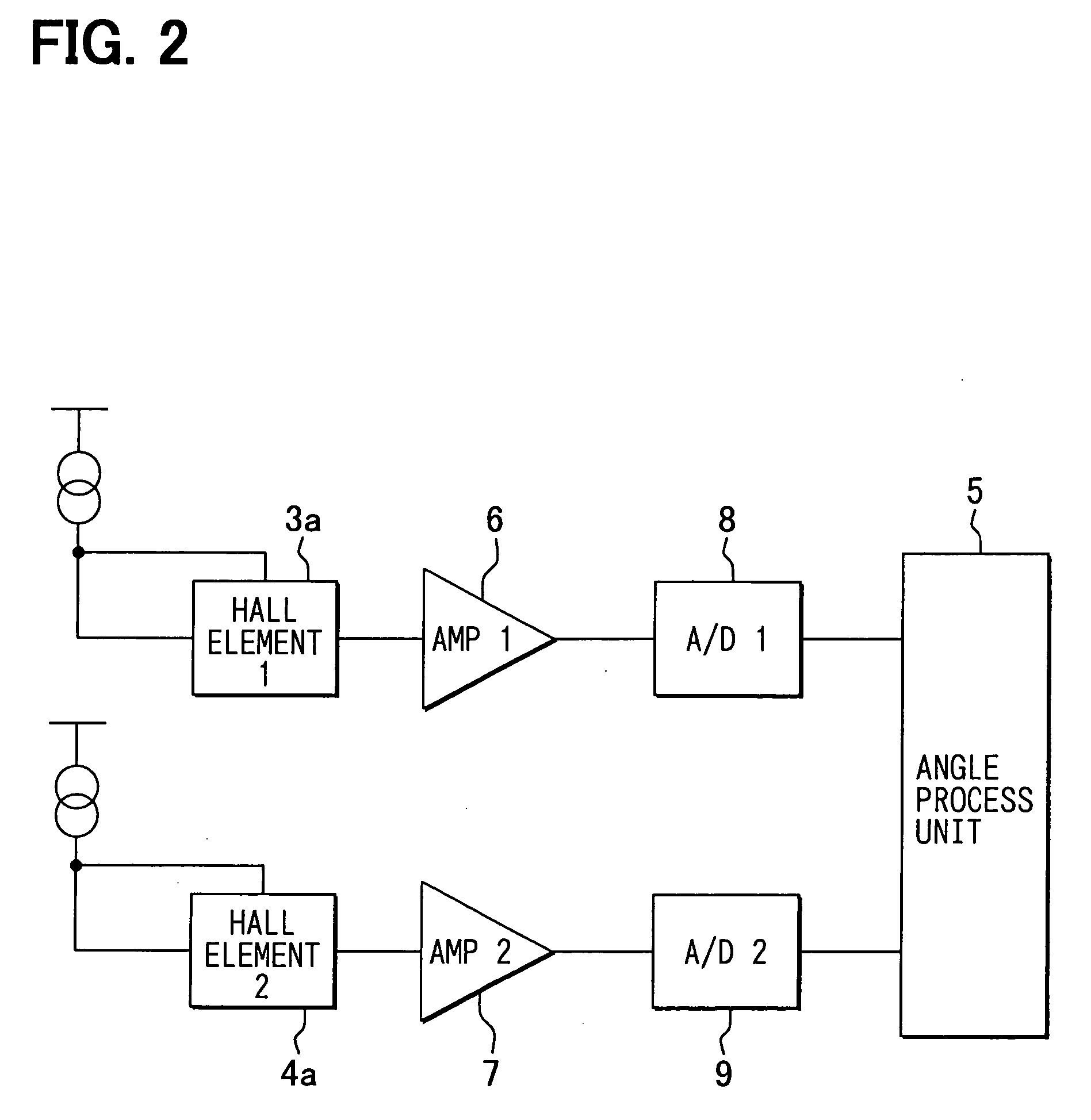

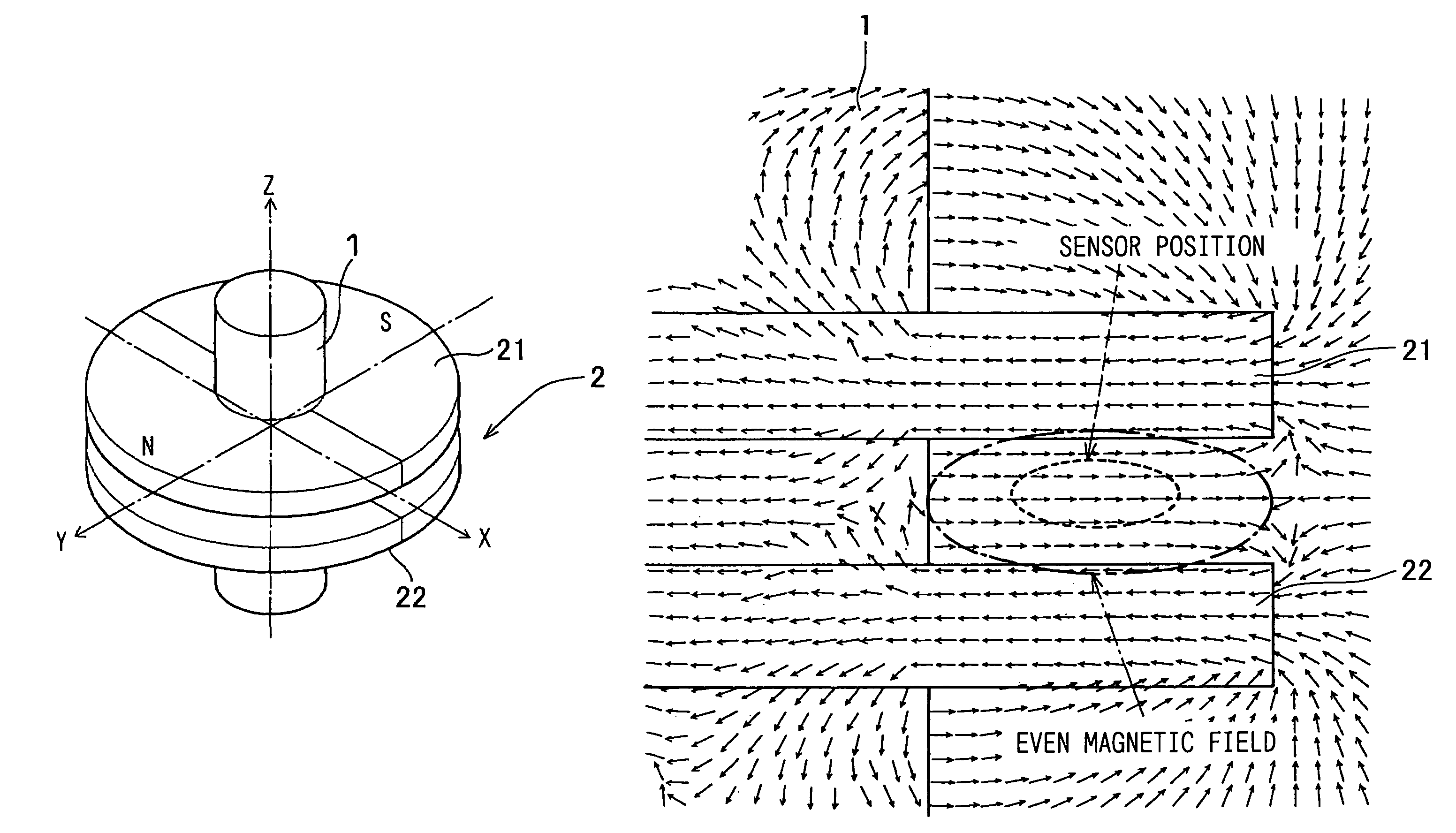

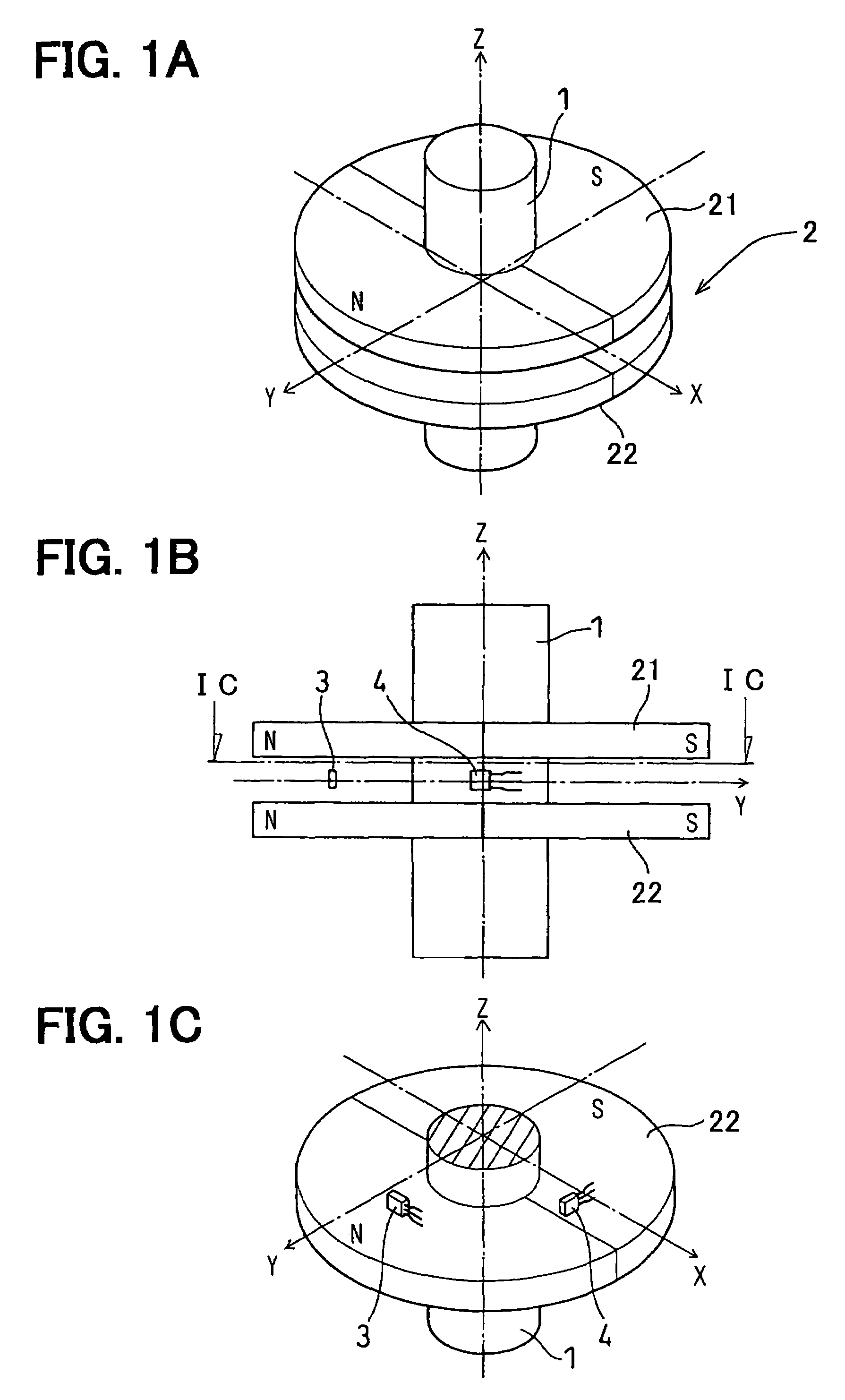

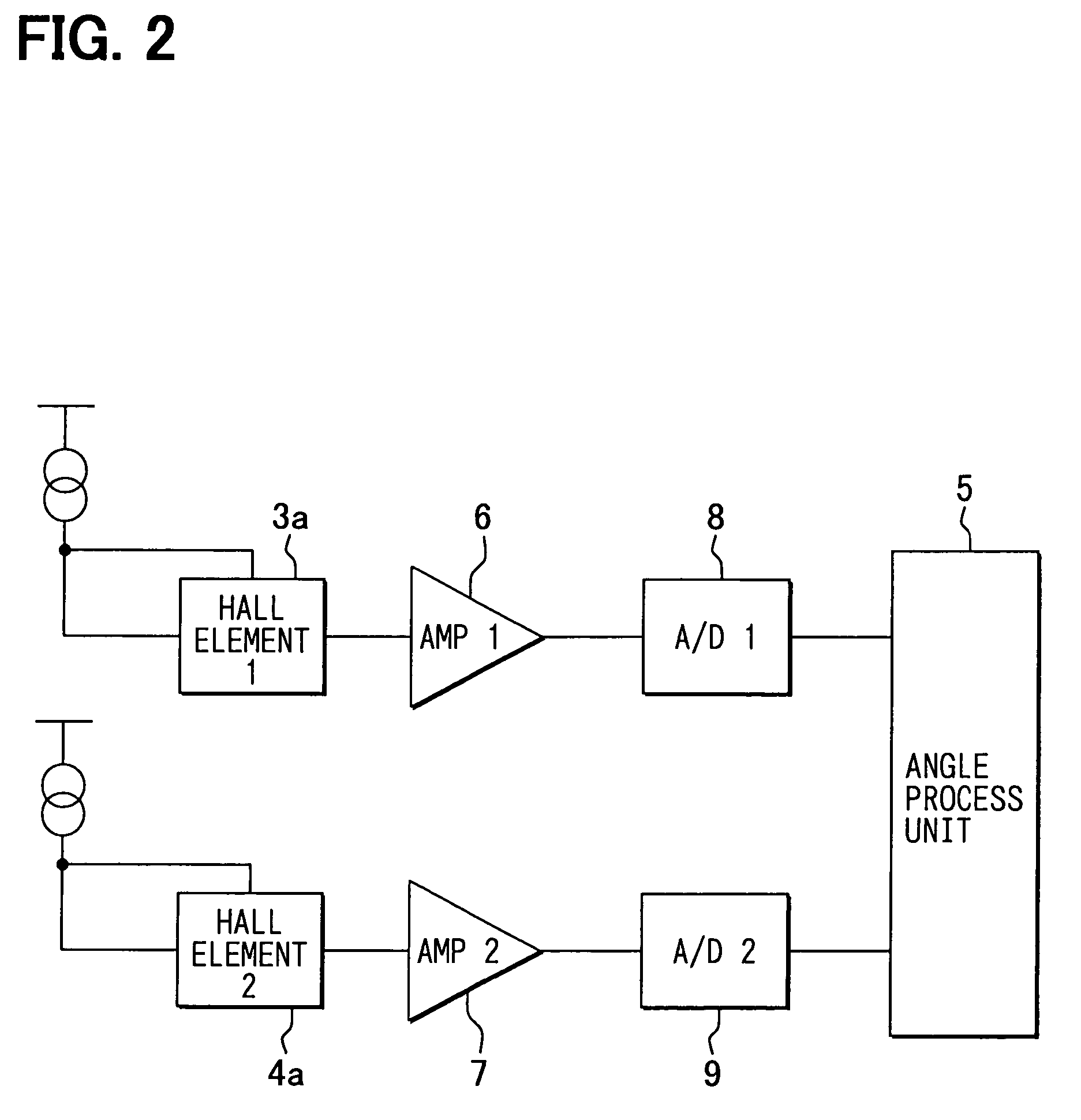

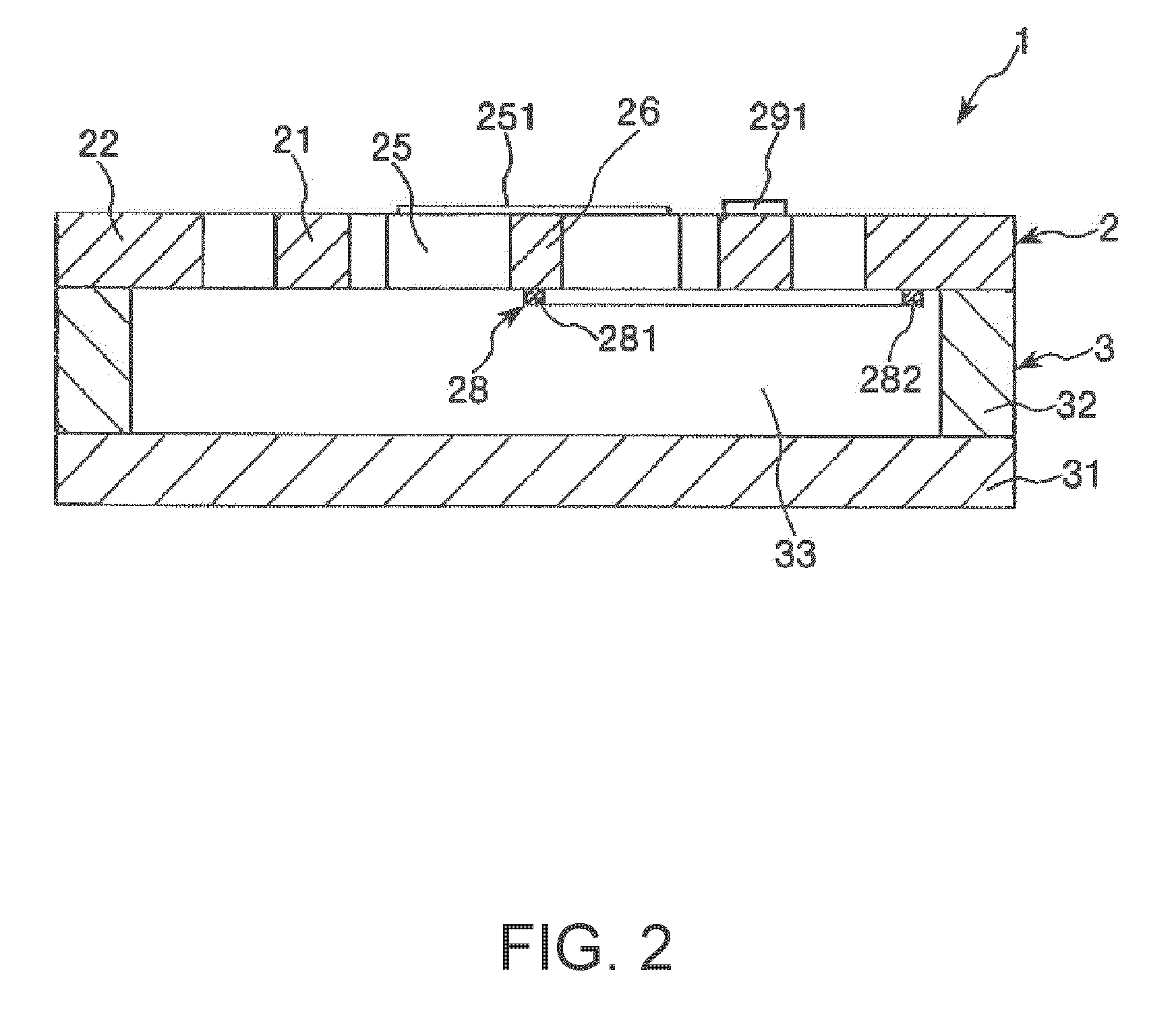

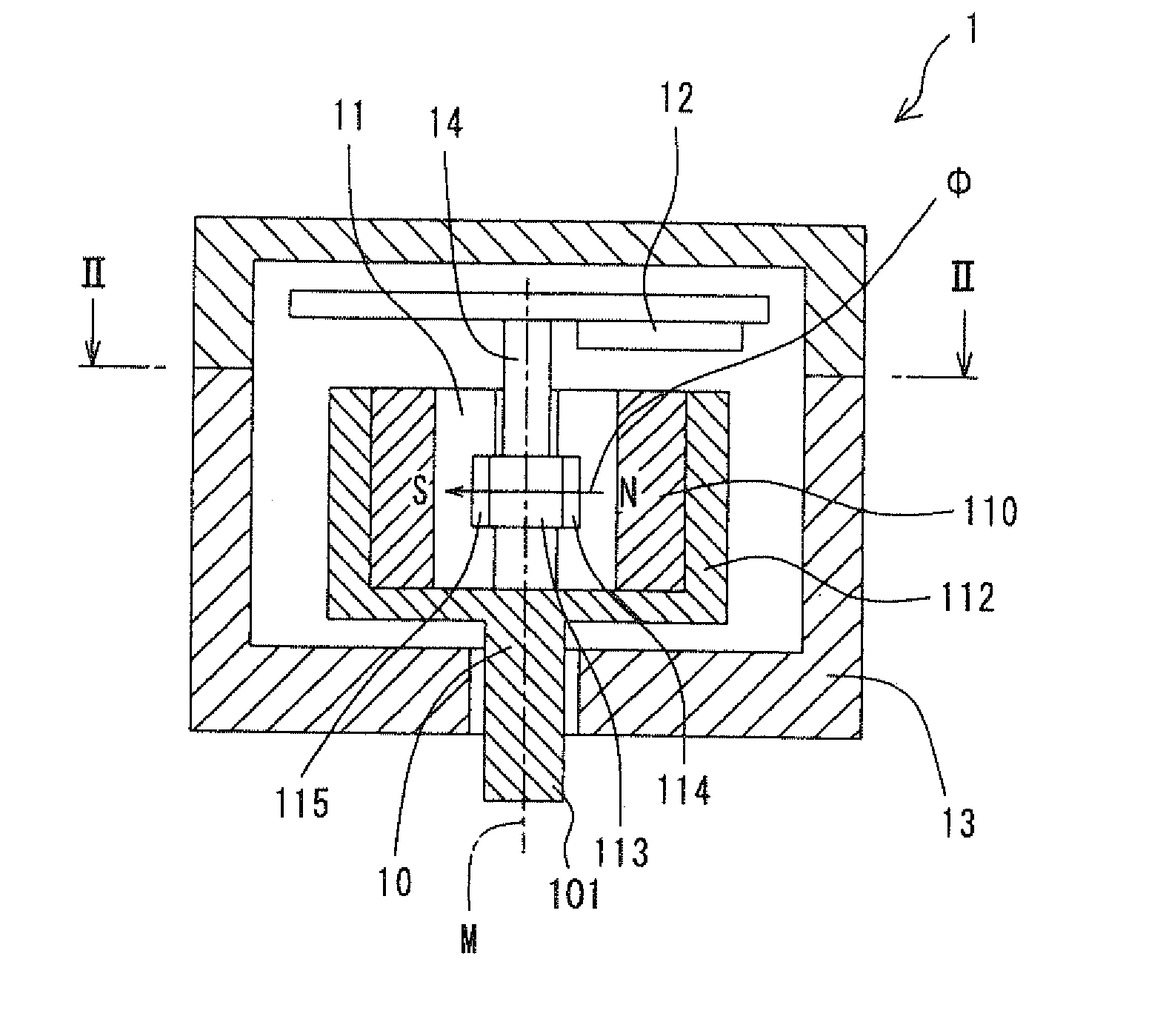

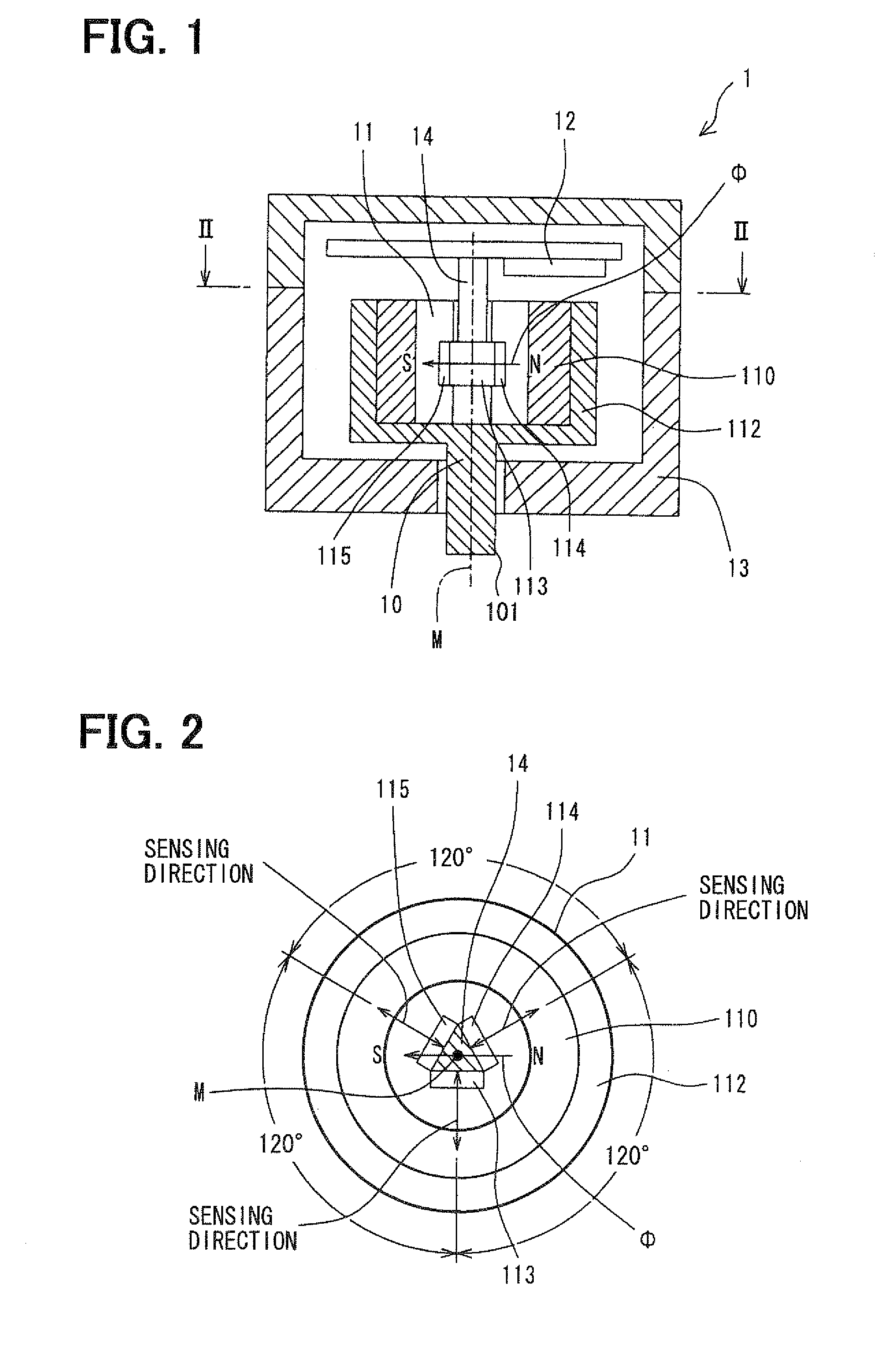

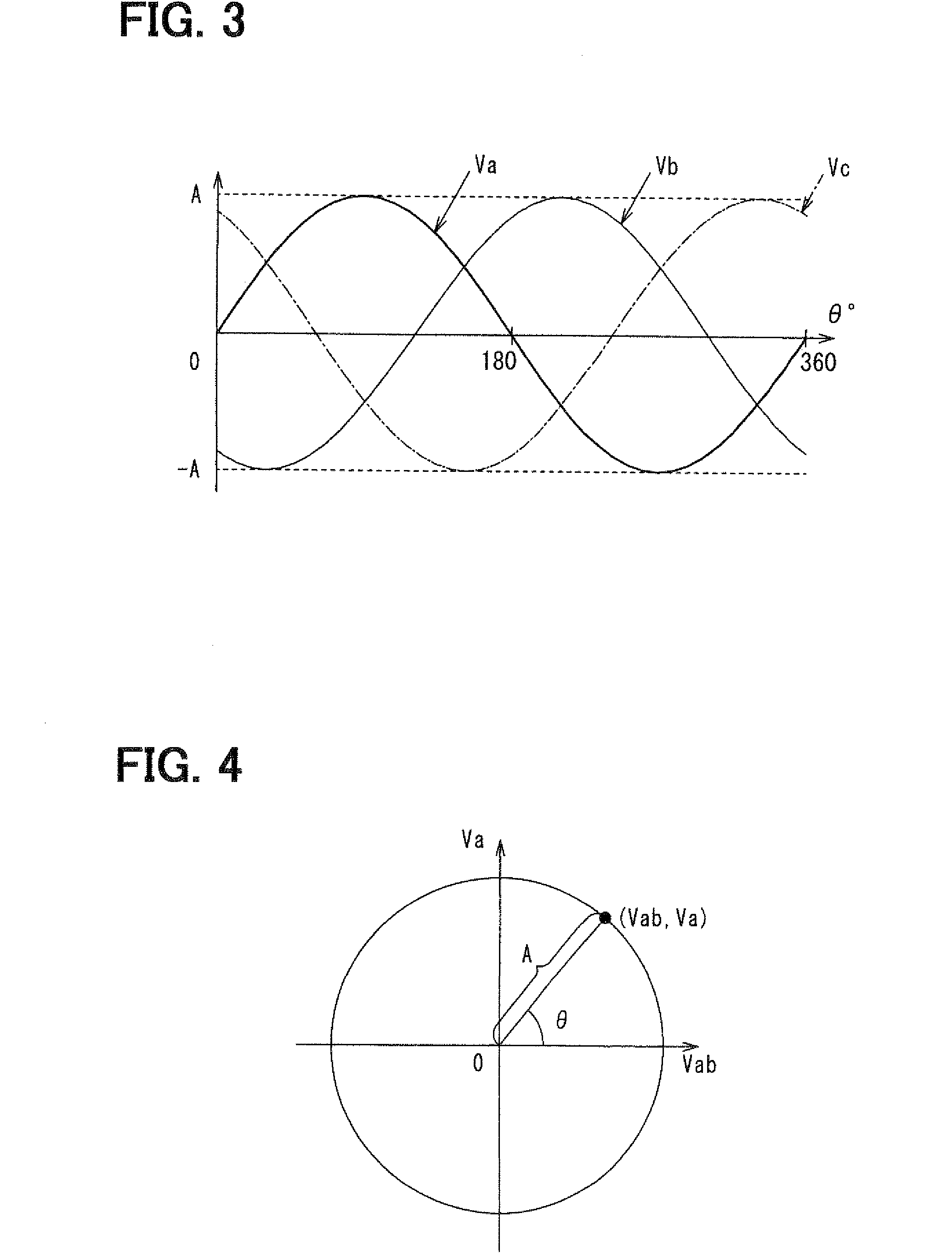

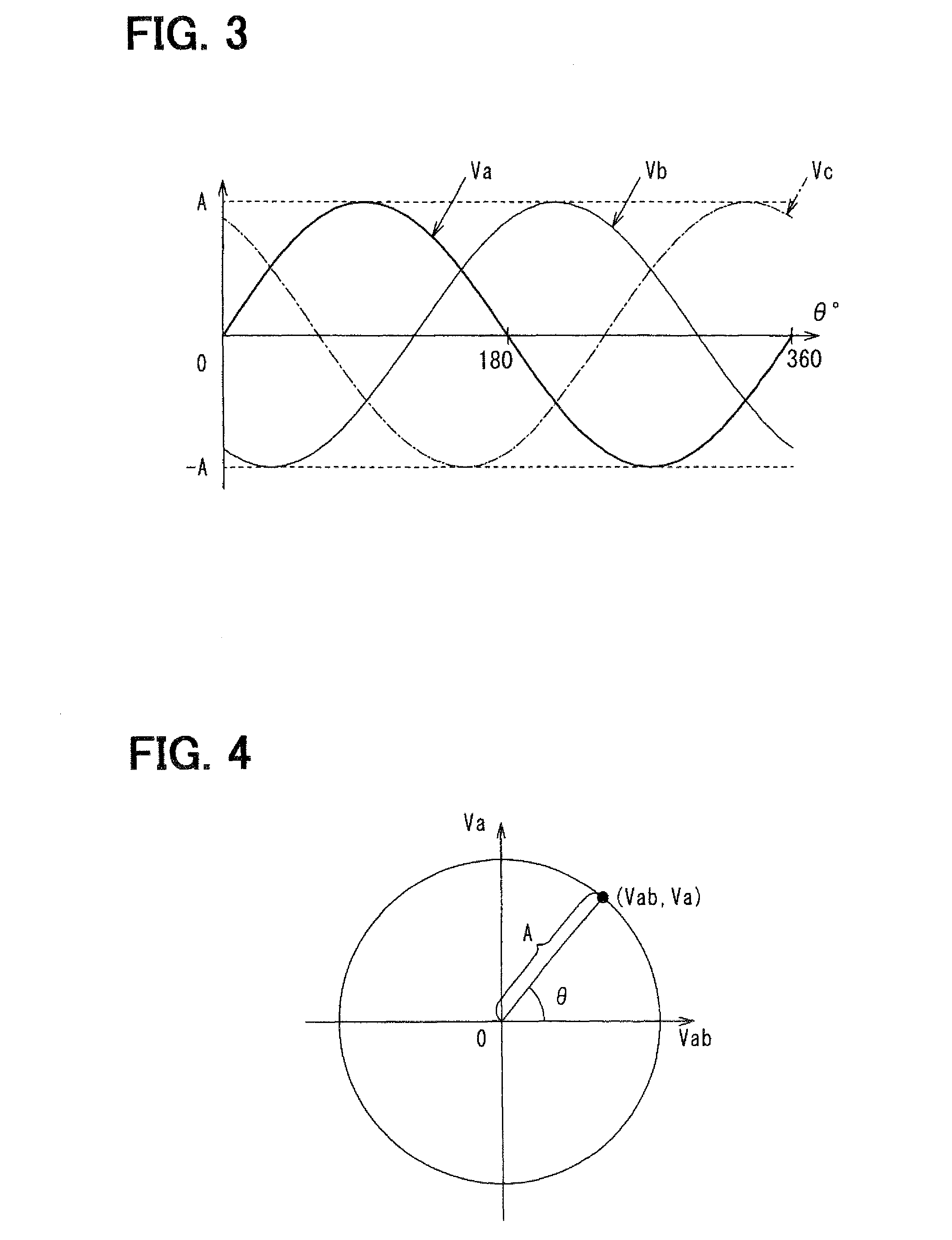

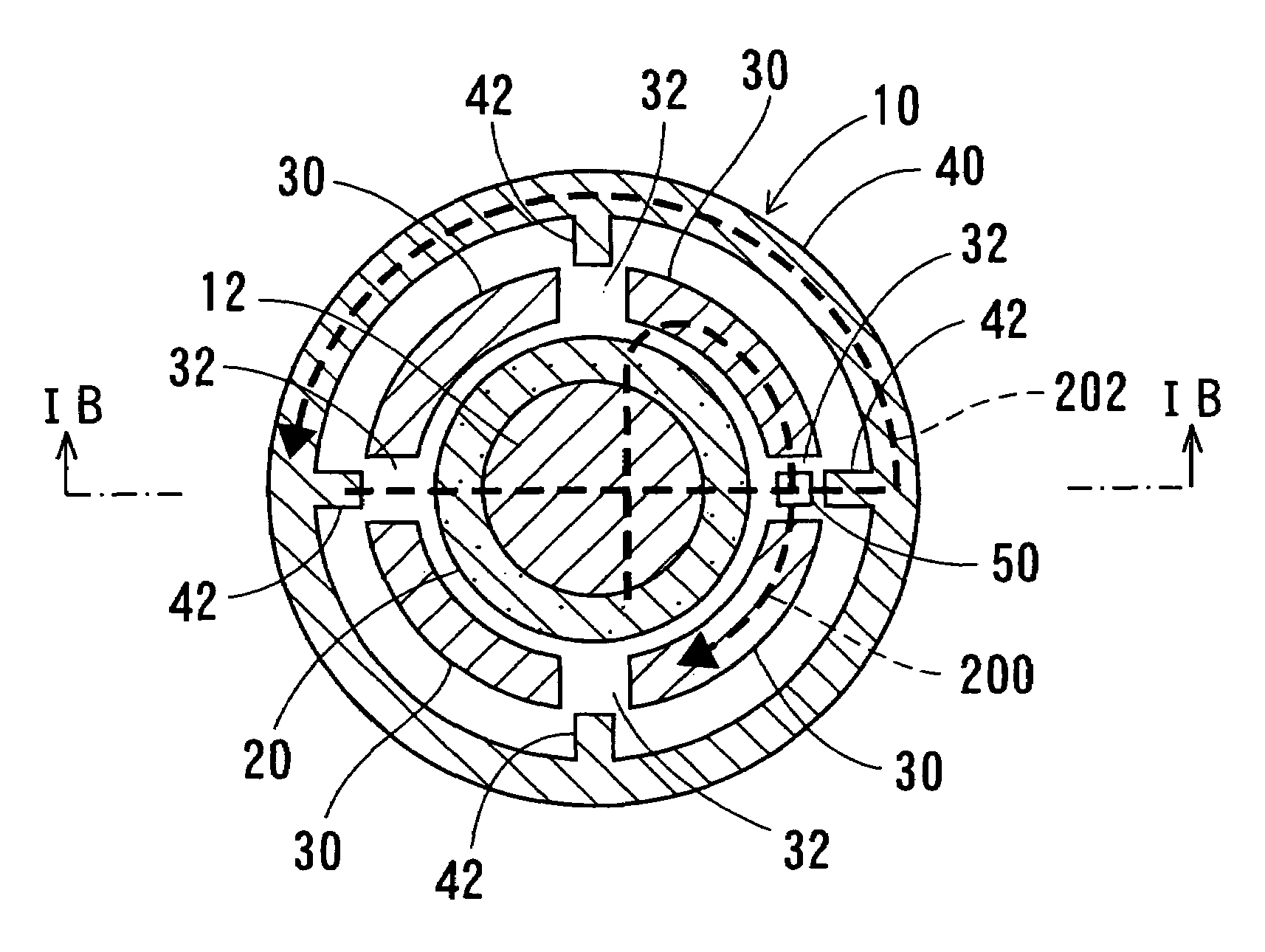

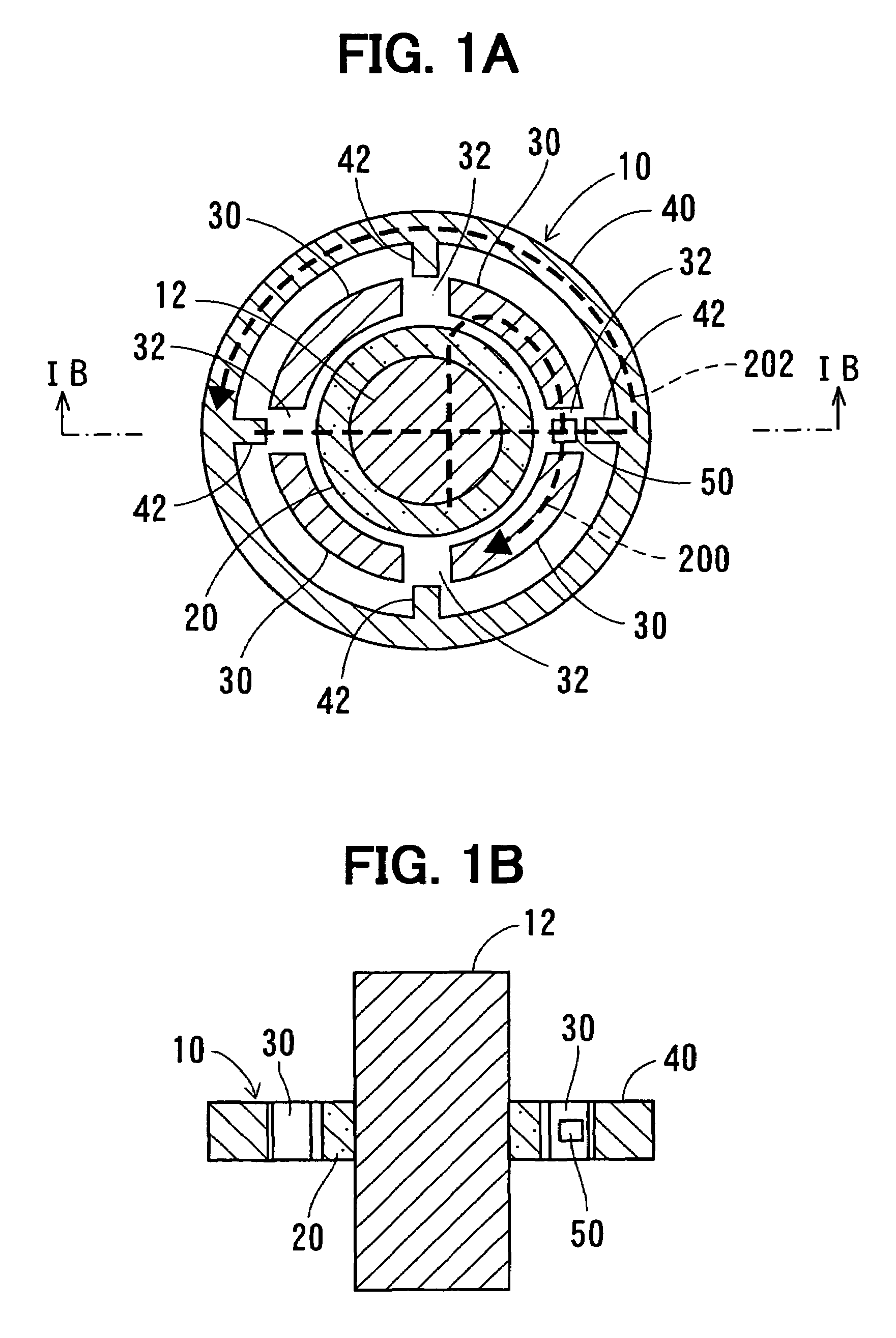

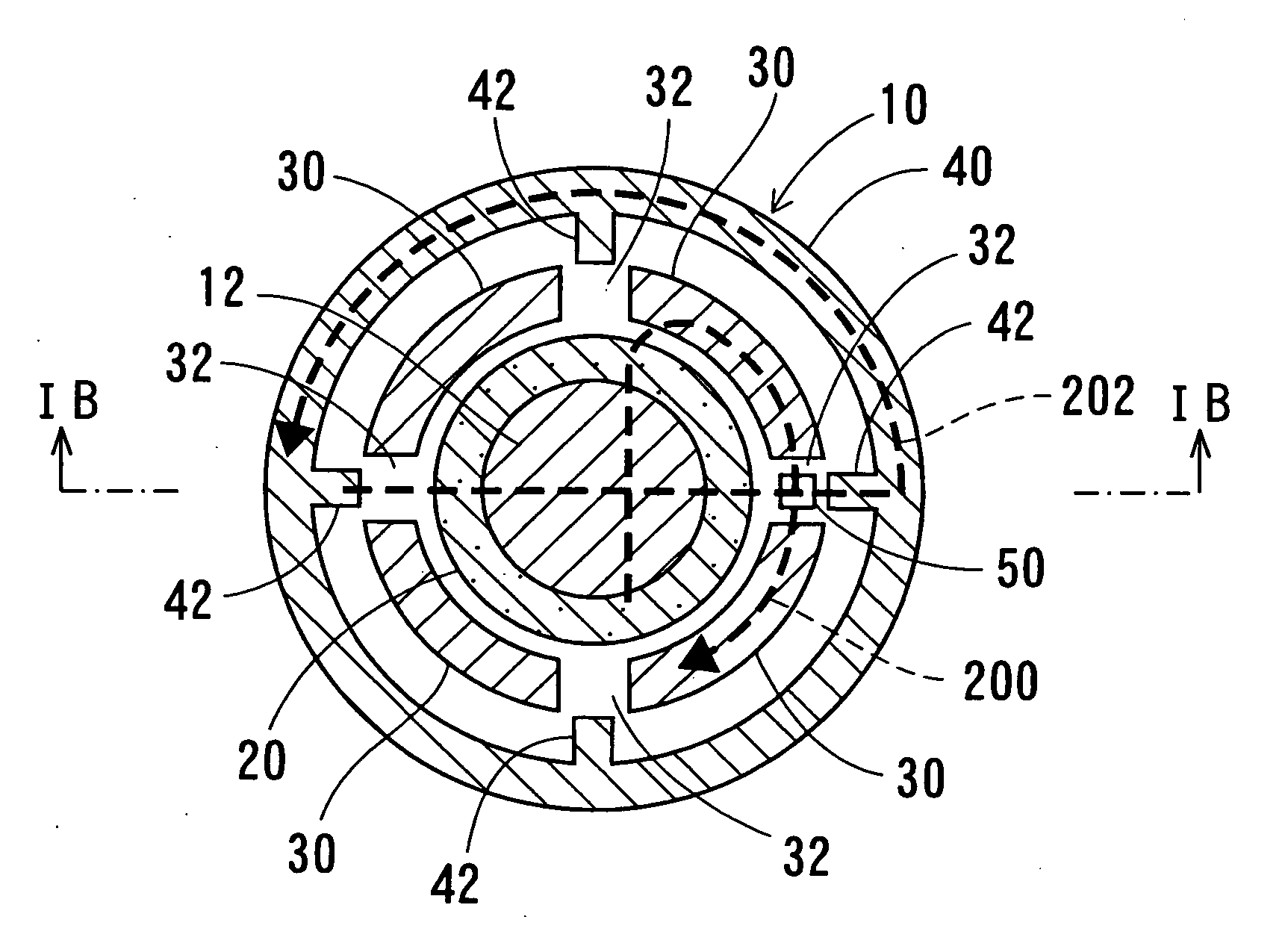

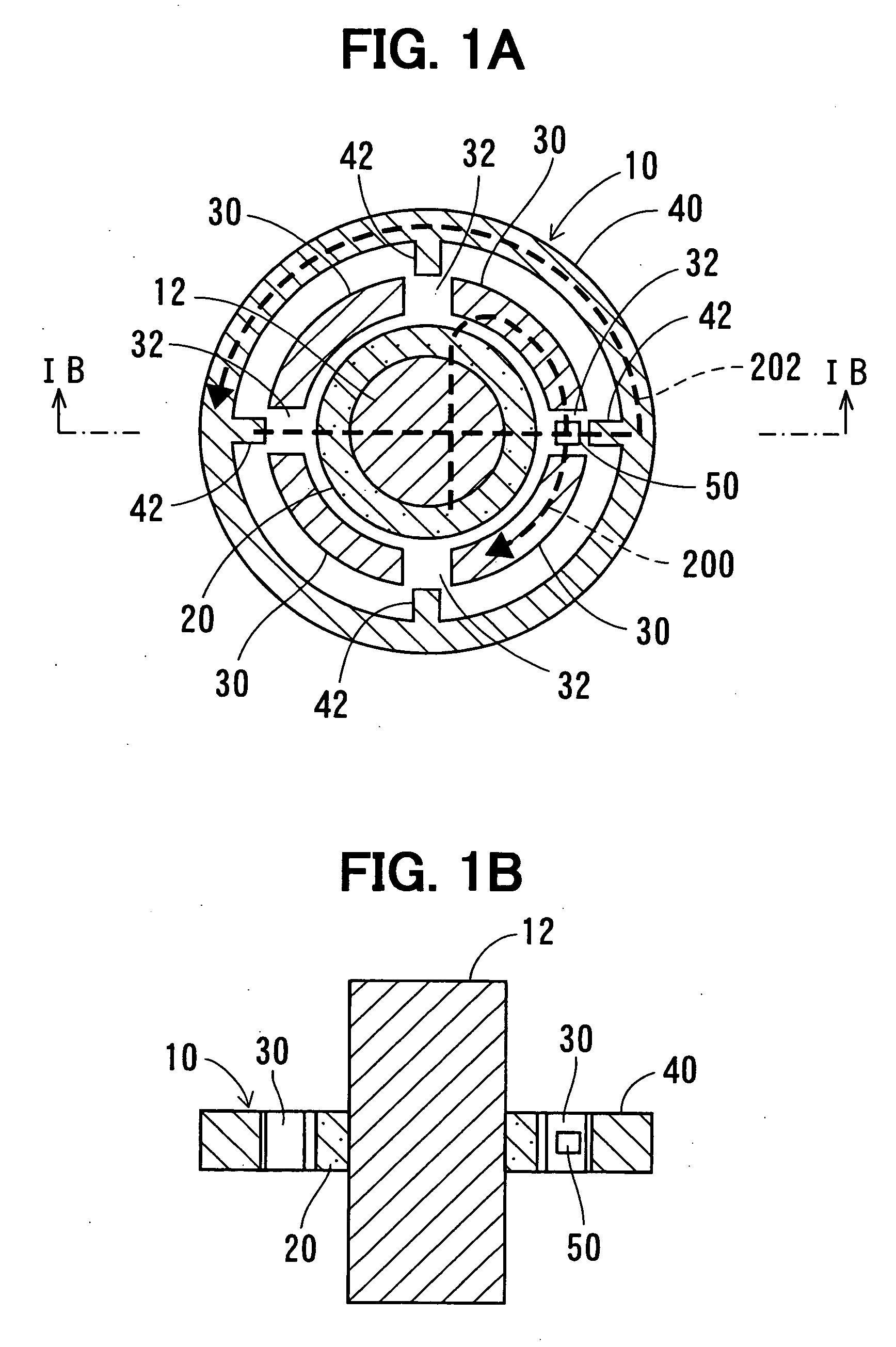

An improved rotation angle detecting device that detects a rotation angle of a first member relative to a second member is proposed. The rotation angle detecting device includes a magnet unit fixed to the first member and a pair of magnetic sensors fixed to the second member to provide output signals whose phase is different from each other at 90 degrees in angle. The magnet unit includes a pair of disk plates that has the same magnetic poles at the same circumferential positions and is disposed at a prescribed axial distance and a shaft that is made of magnetic material to support the disk plates at the center thereof. The magnetic unit provides a uniform magnetic field in a space around the shaft between the pair of disk plates, and a pair of magnetic sensors is disposed in the space.

Owner:DENSO CORP +1

Rotation angle detecting device

InactiveUS7319320B2Increase the rotation angleDetection errorMagnetic-field-controlled resistorsMagnetic field measurement using galvano-magnetic devicesMagnetic polesAxial distance

Owner:DENSO CORP +1

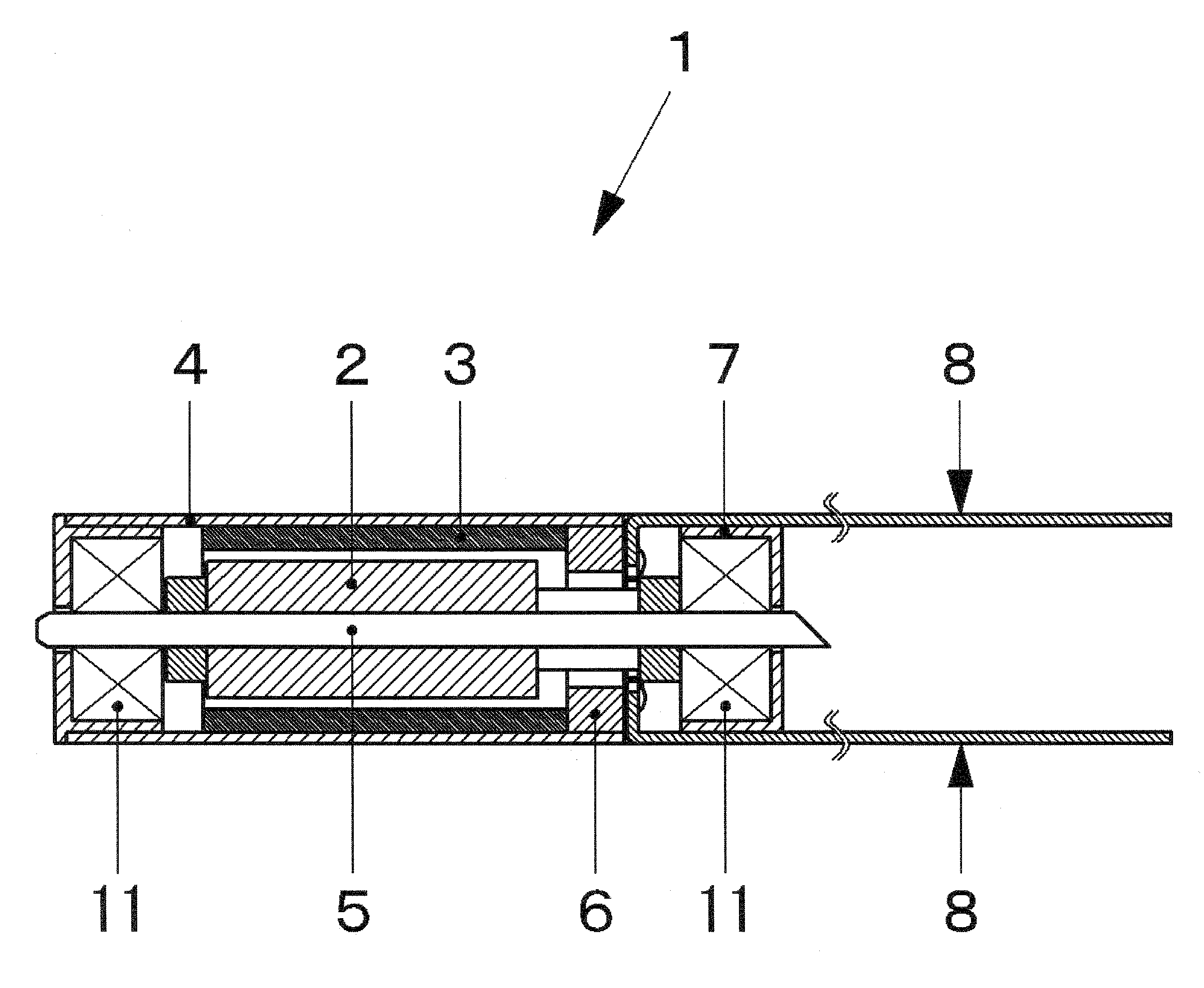

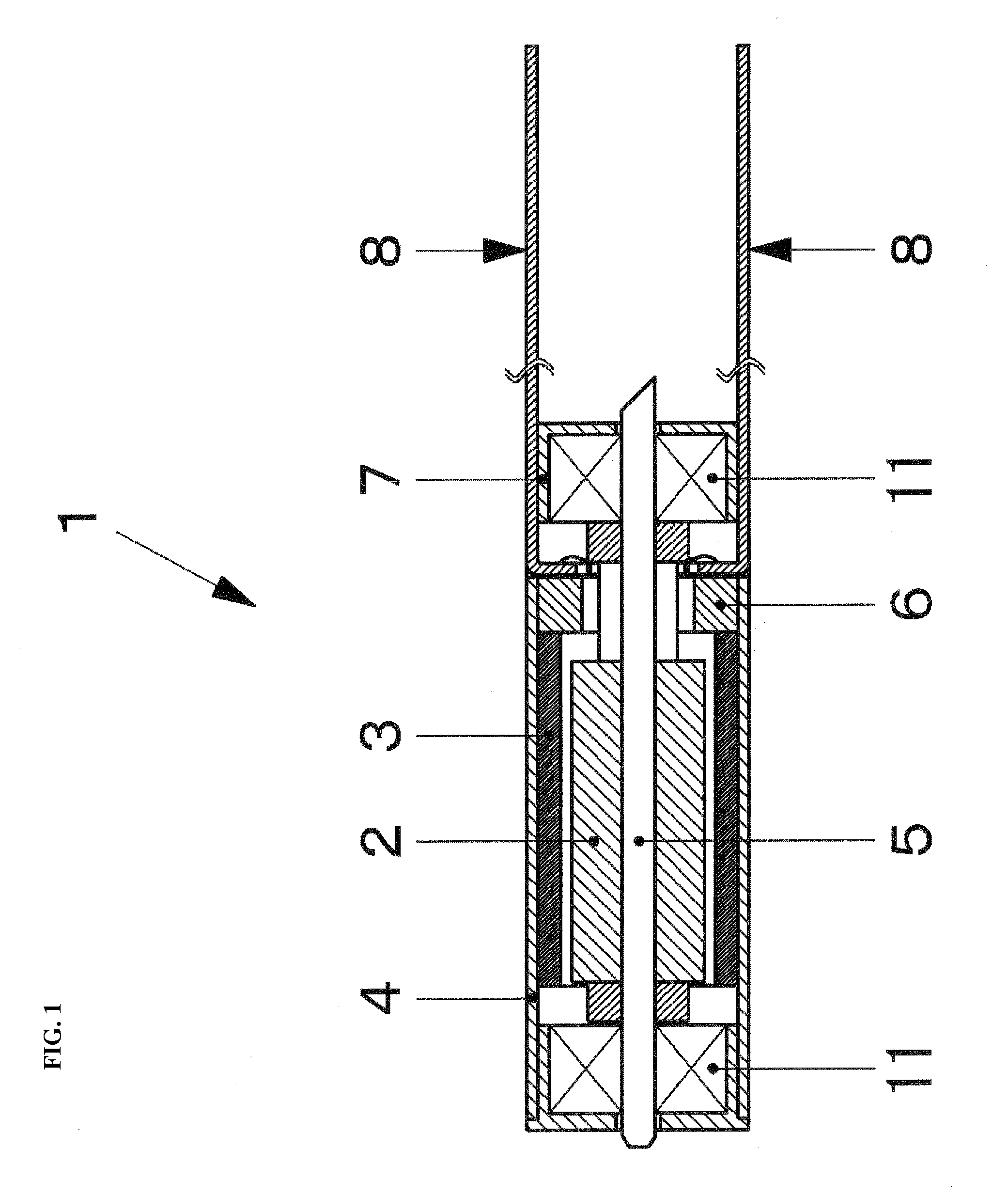

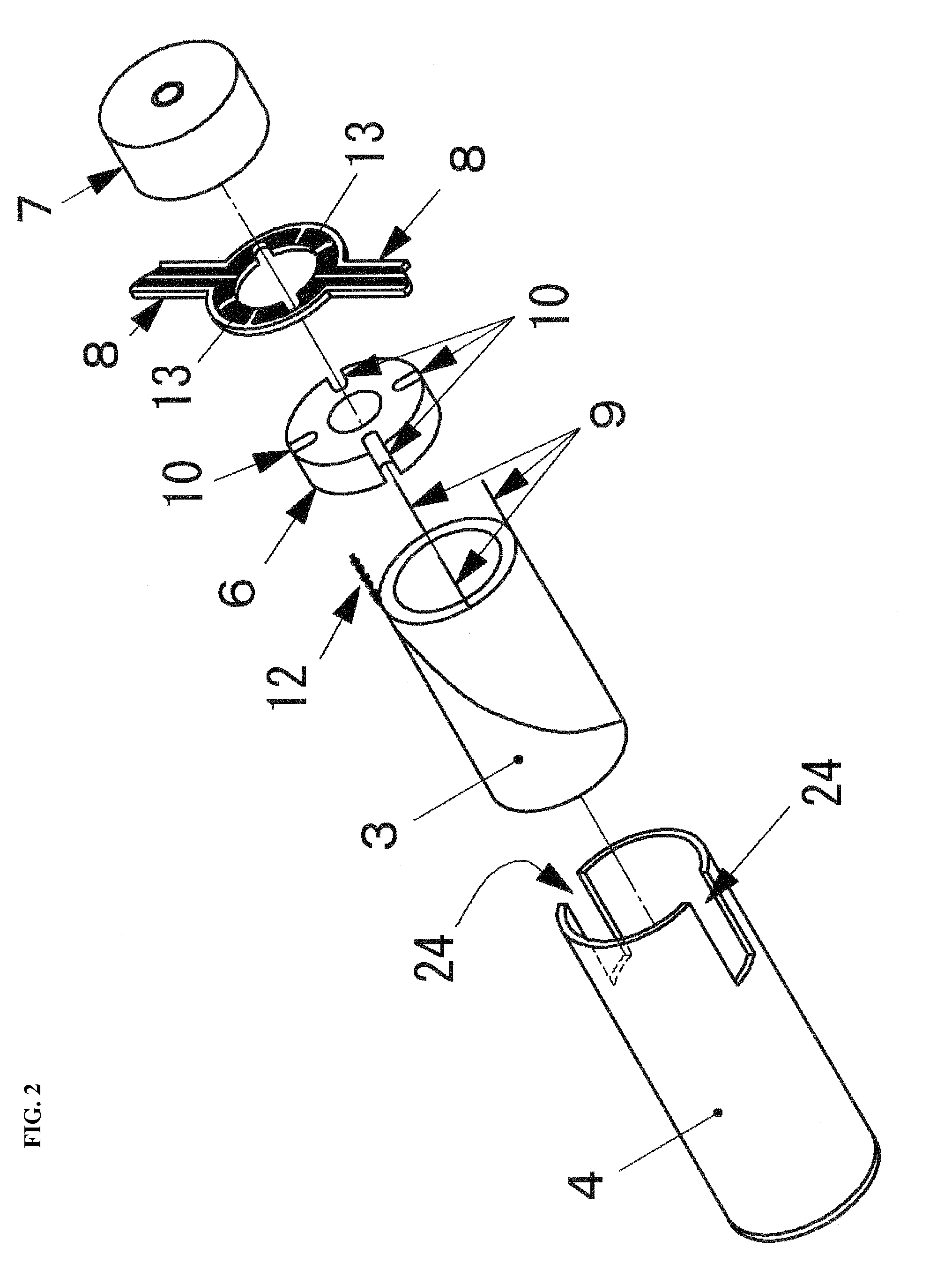

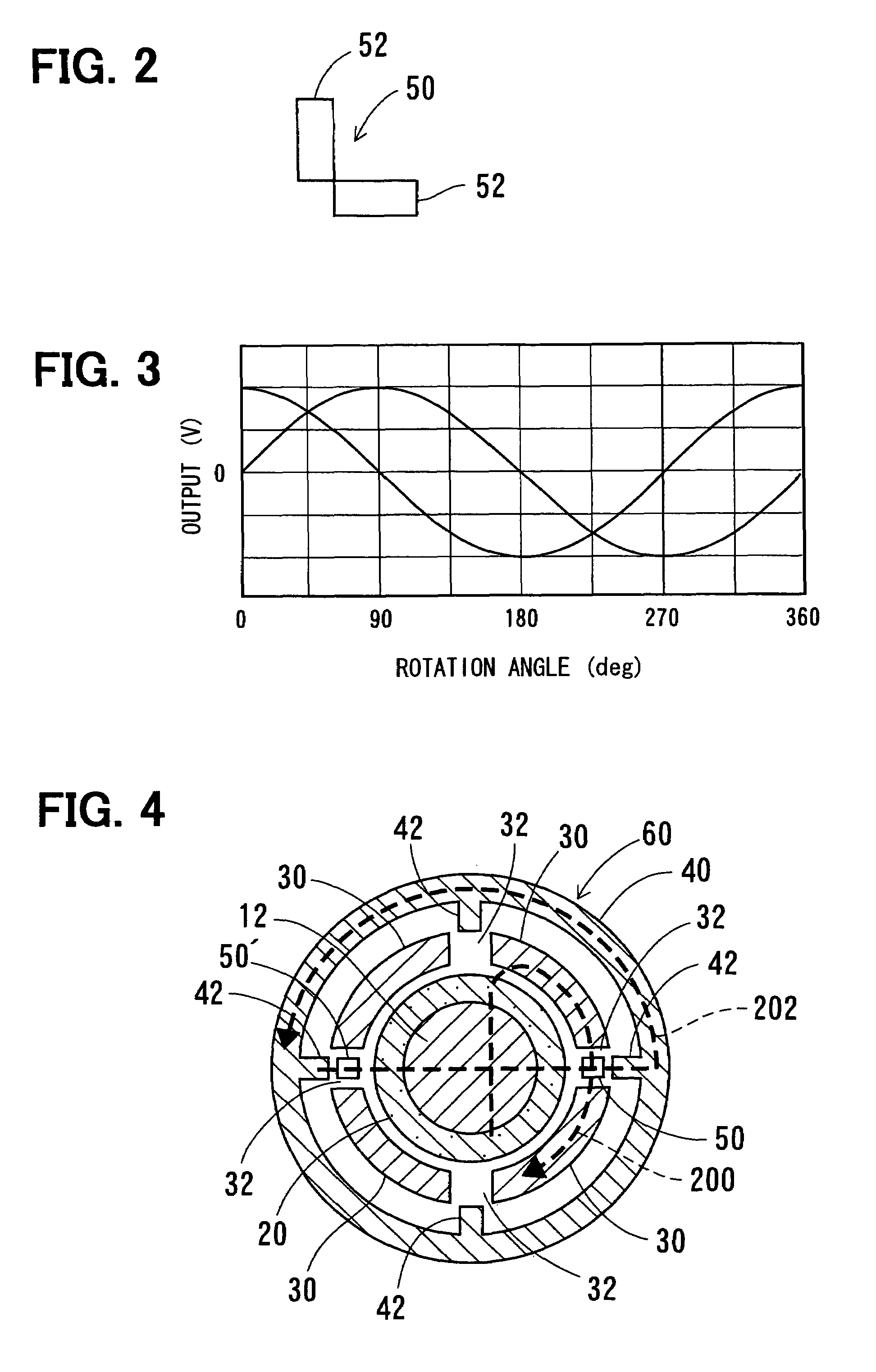

Motor and endoscope probe equipped with motor

A motor which can be mounted in an endoscope probe without bending an electric power supply wire in an endoscope probe body, and an endoscope probe using the motor are provided. The motor includes a magnet, a field coil, a housing, an electric power supply wire, and a shaft. A lead wire from the field coil is connected to the electric power supply wire. A cutout is provided in a housing end, and the electric power supply wire is received along the cutout and led out to the outside of the motor in the direction in which a shaft projects. When the motor is mounted in the endoscope probe, the motor is placed in the endoscope probe body so that the shaft projects in the direction opposite to the direction of the front end of the endoscope probe, and the electric power supply wire, which is led out to the outside of the motor, is routed along the longitudinal direction of the endoscope probe.

Owner:NAMIKI PRECISION JEWEL CO LTD

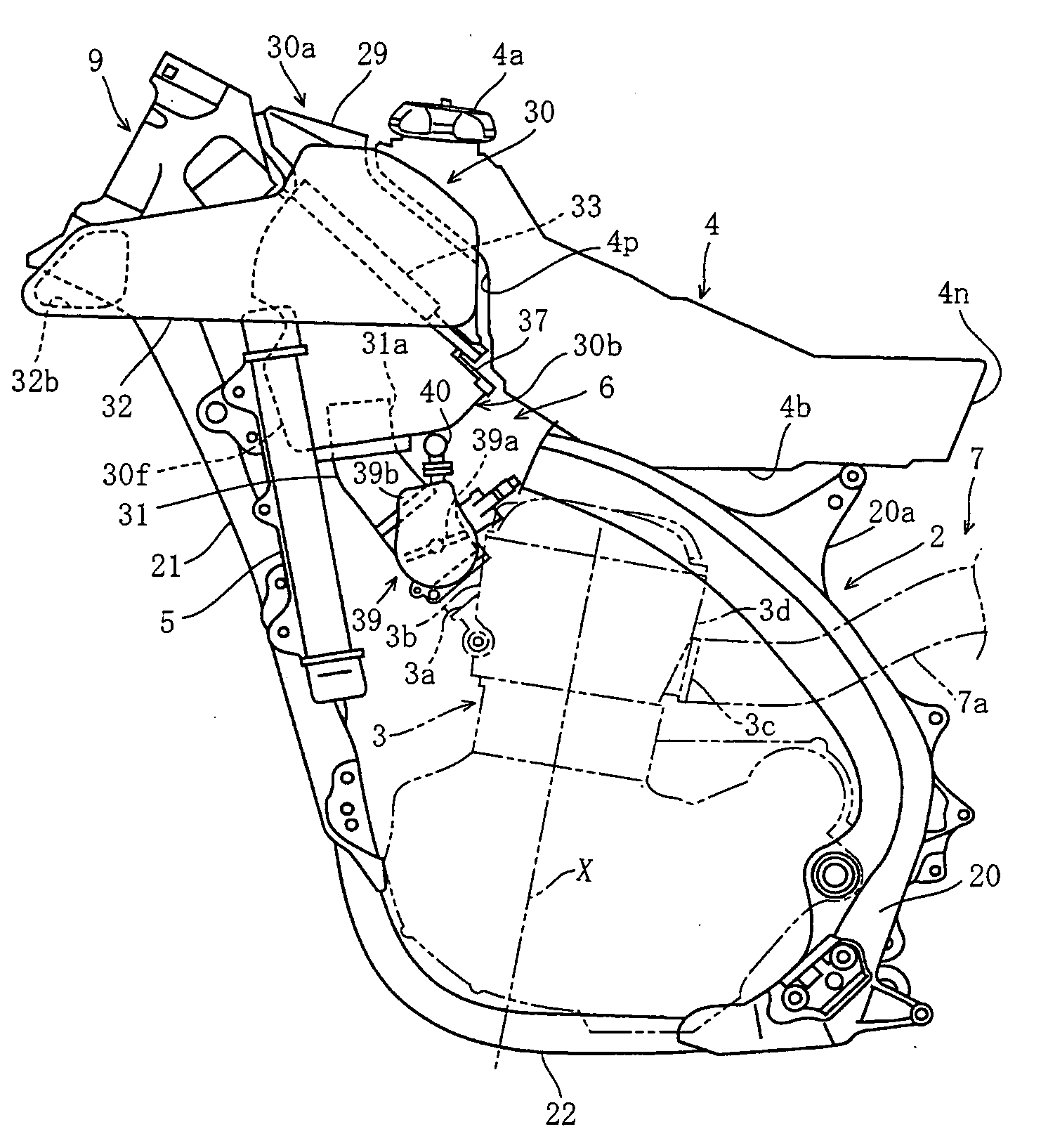

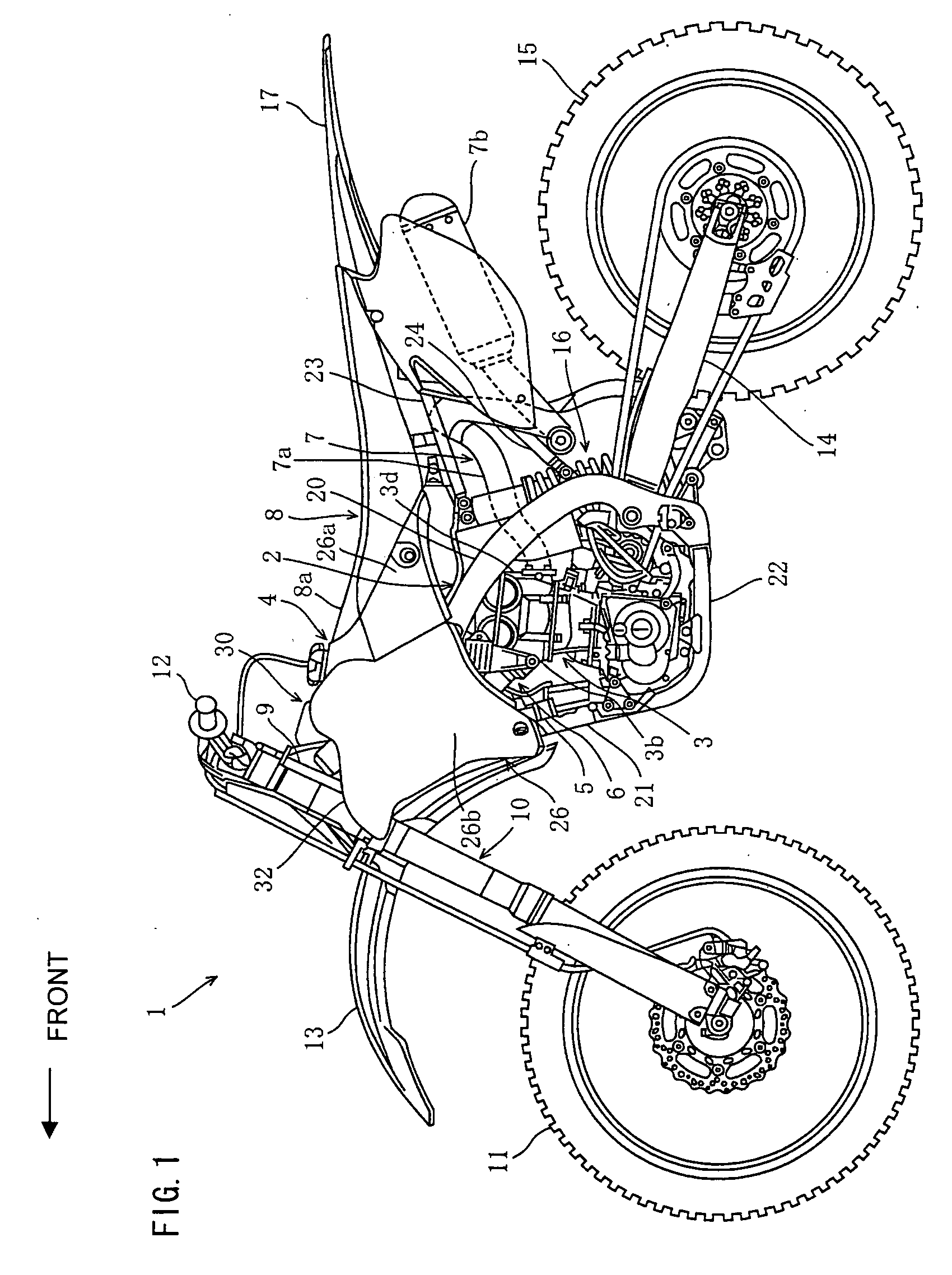

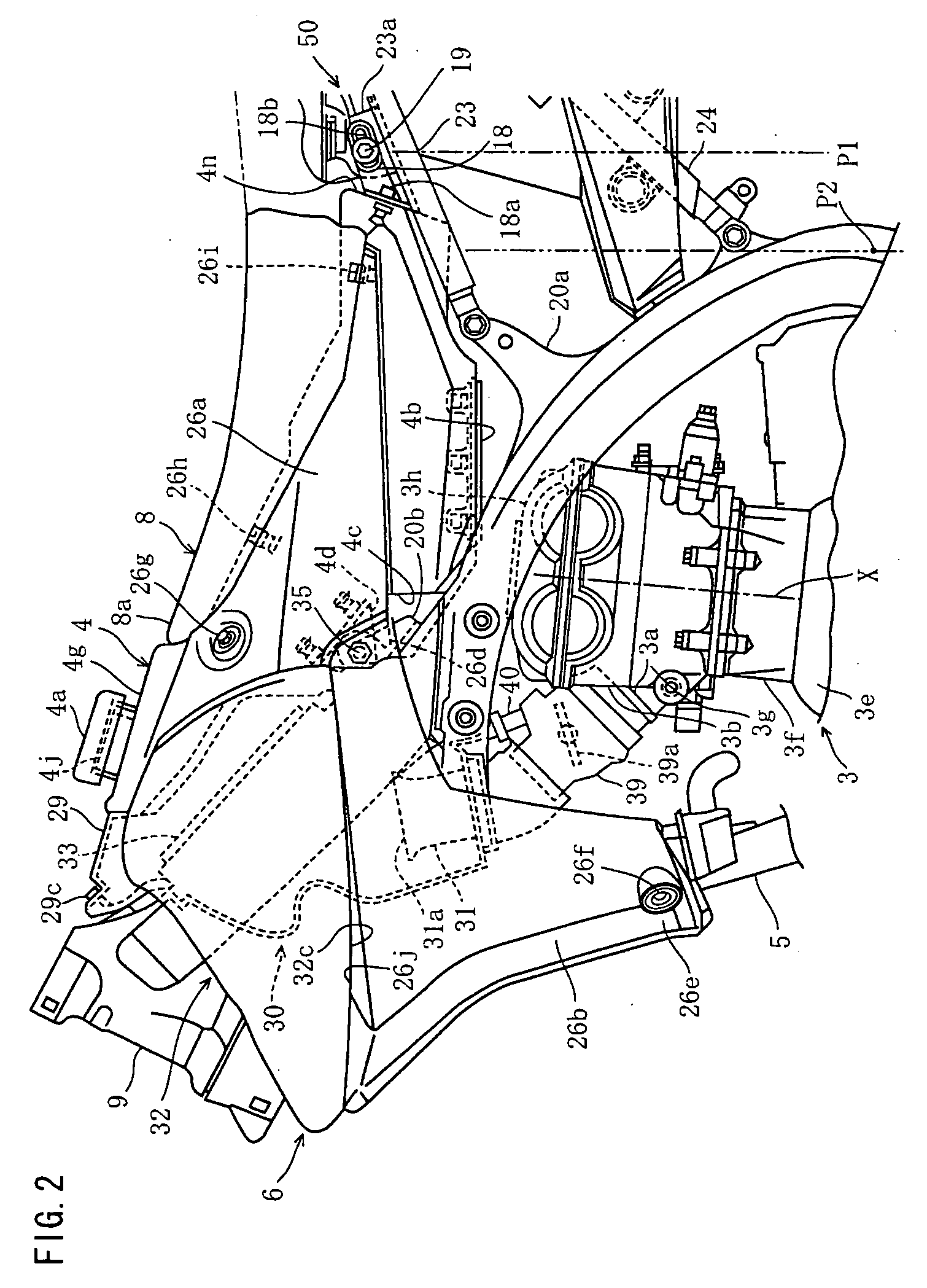

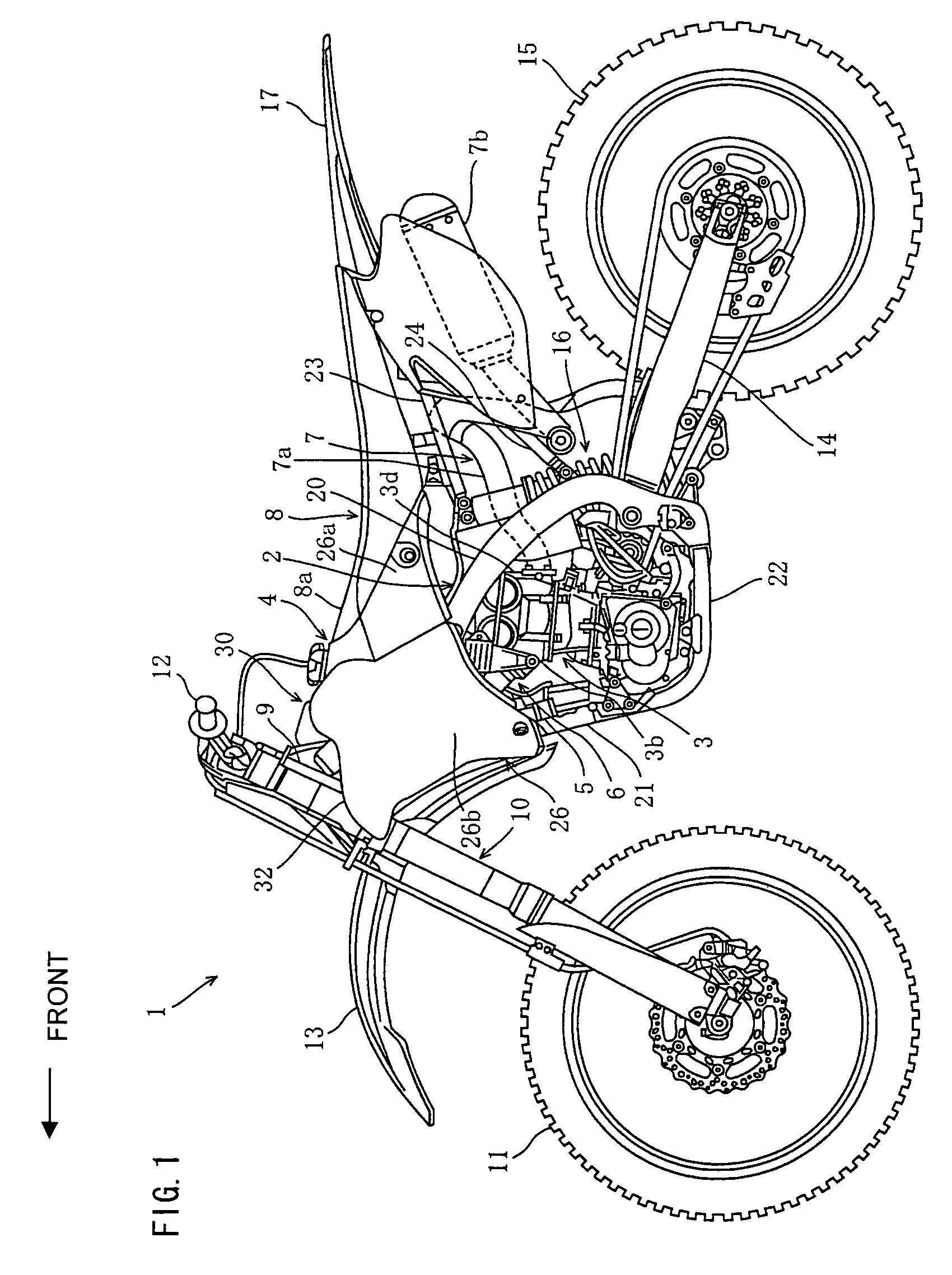

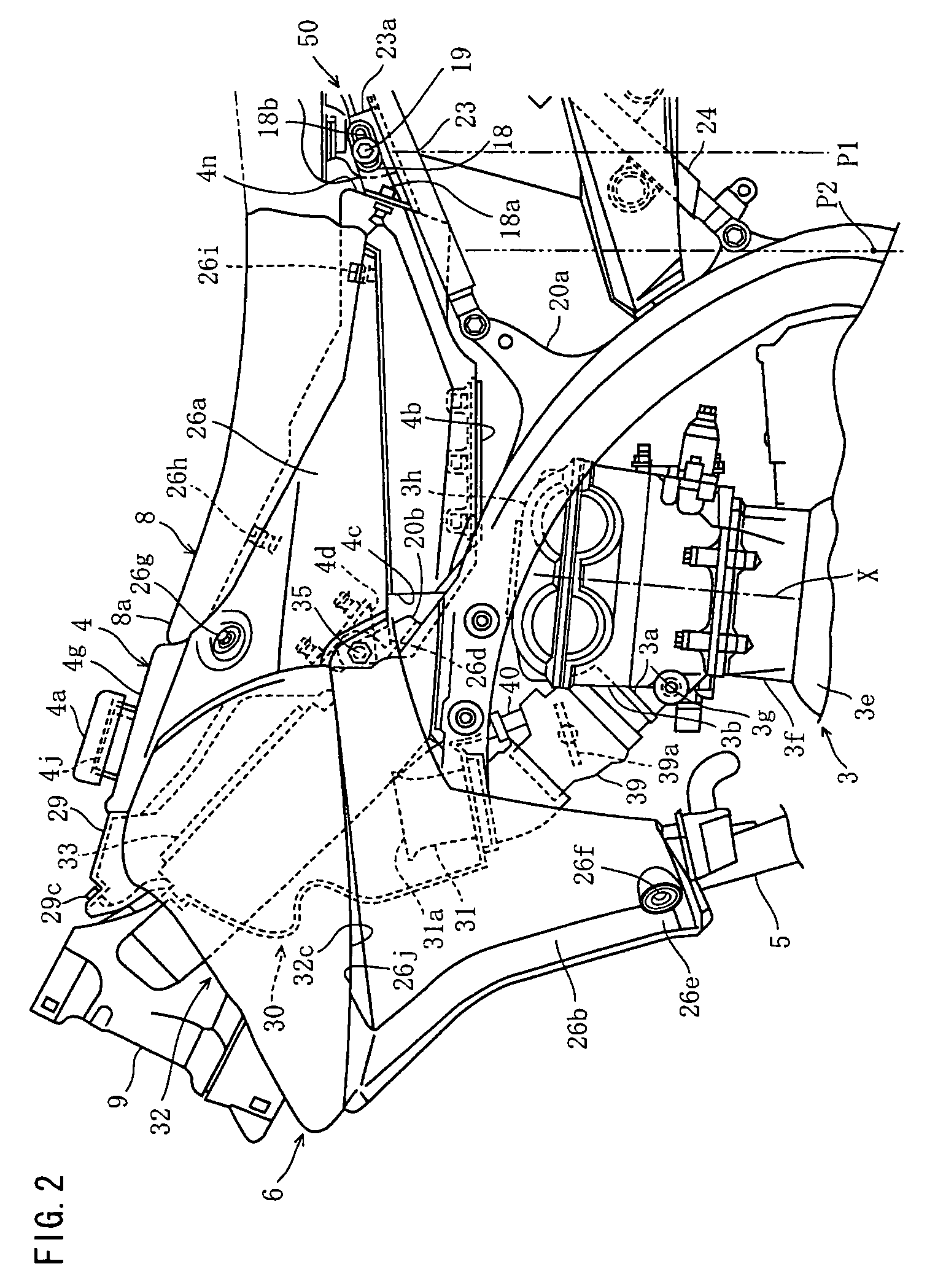

Vehicle with rotatable fuel tank

InactiveUS20090322069A1Easy maintenanceFacilitate of regionTank vehiclesFuel tanksCushioningFuel tank

A vehicle, such as a motorcycle, can facilitate maintenance of an air cleaner without complicating a peripheral structure of a fuel tank. The vehicle can include a body frame, a rear arm attached to the body frame to support a rear wheel, a rear cushioning member provided between the body frame and the rear arm, and an engine fixed to the body frame. The vehicle can further include a fuel tank supported rotatably at a supporter arranged closer to a rear side of the vehicle than a substantially central position of an axis of the rear cushioning member.

Owner:YAMAHA MOTOR CO LTD

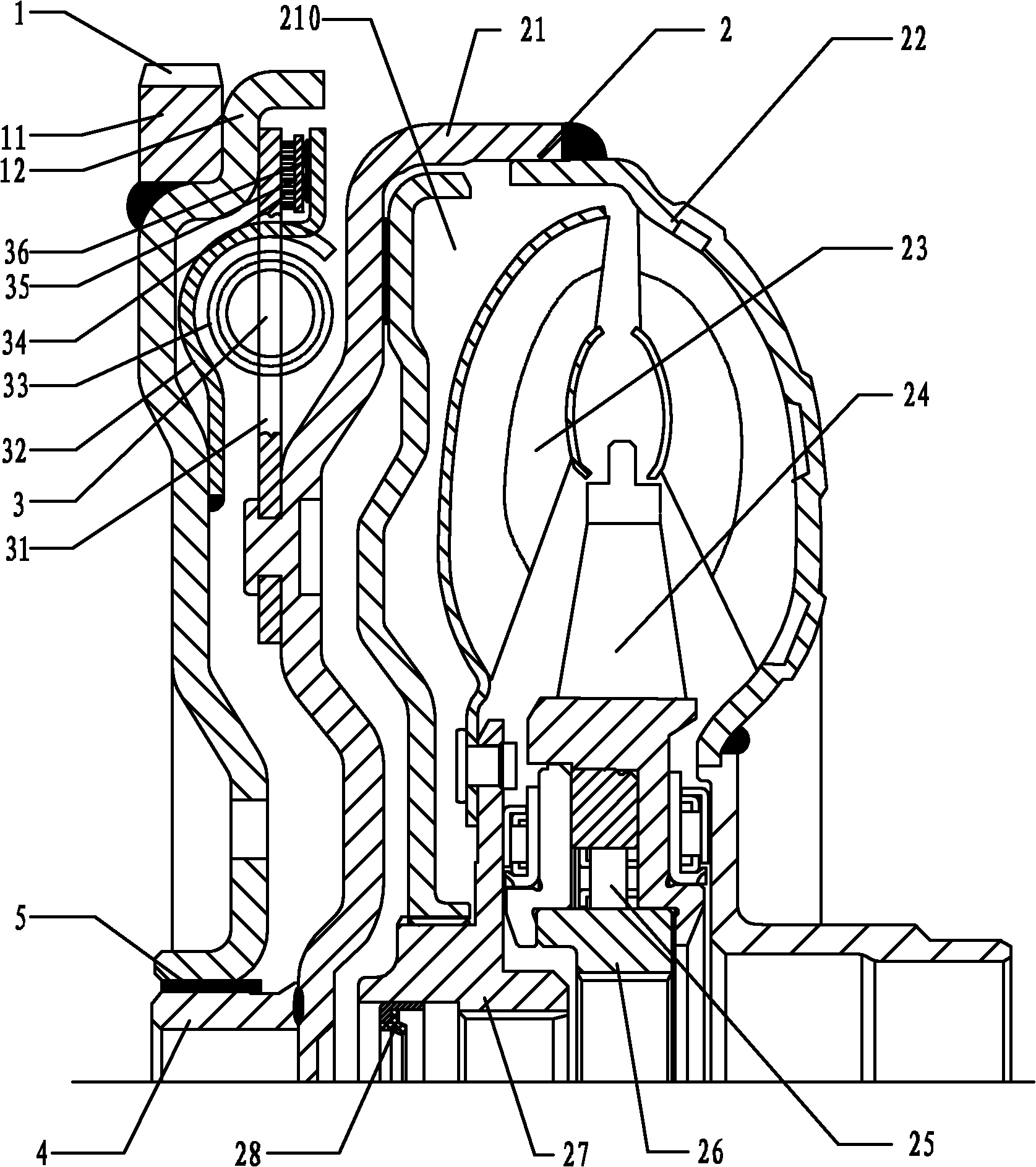

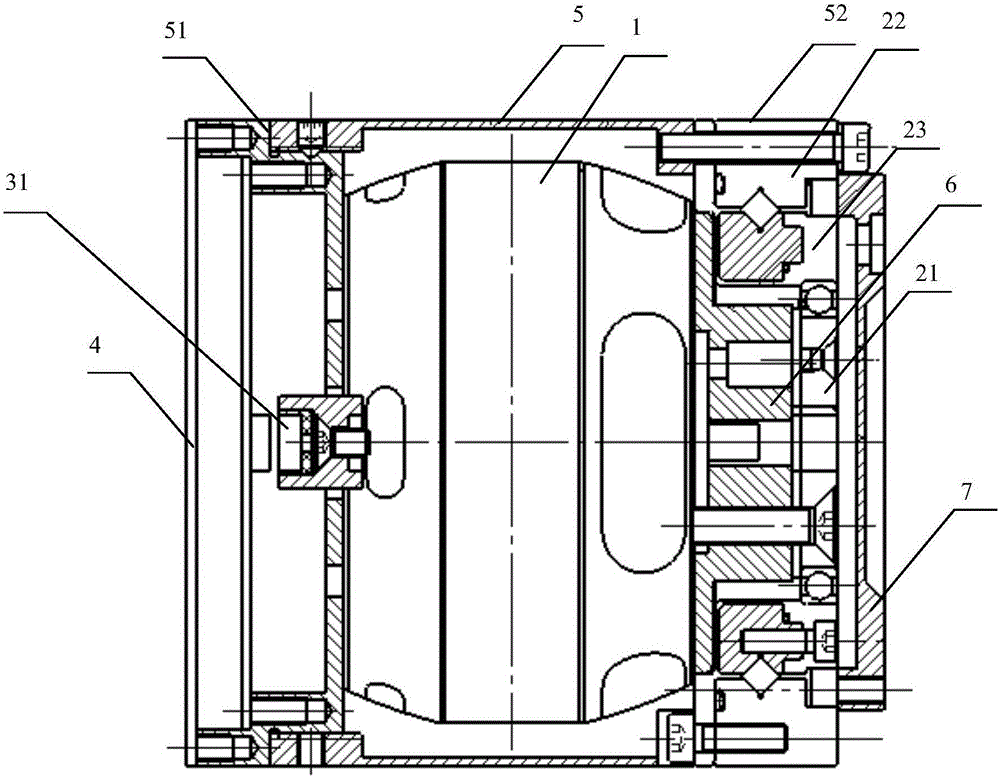

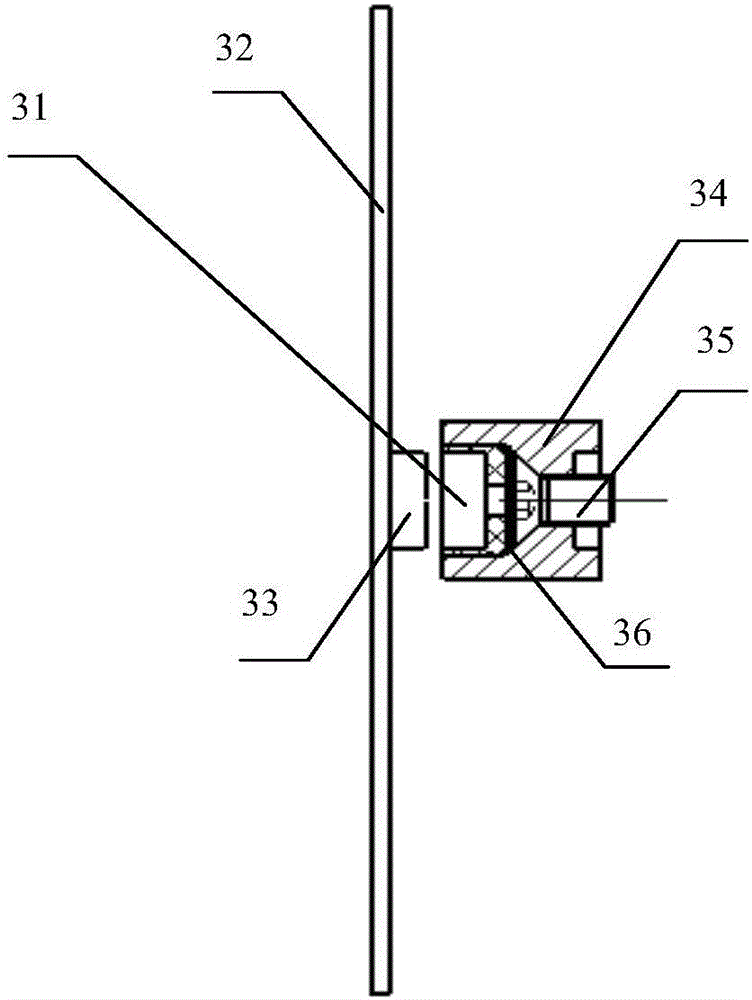

Automobile dual-mass hydraulic torque converter

ActiveCN101988569AIncrease the rotation angleReduce the resonance speedFluid gearingsVibration suppression adjustmentsFlywheelControl theory

The invention provides an automobile dual-mass hydraulic torque converter which belongs to the technical field of machinery and solves the technical problem that the traditional hydraulic torque converter easily causes sympathetic vibration between an engine and a speed variator. The automobile dual-mass hydraulic torque converter is arranged between the engine and the speed variator and comprises a first-mass flywheel assembly and a second-mass hydraulic torque converter, wherein an elastic damping mechanism which can reduce the sympathetic vibration is arranged between the first-mass flywheel assembly and the second-mass hydraulic torque converter. The invention has the advantages of long service life and lower cost and can effectively reduce the sympathetic vibration between the engineand the speed variator.

Owner:靖江市华信科技创业园有限公司

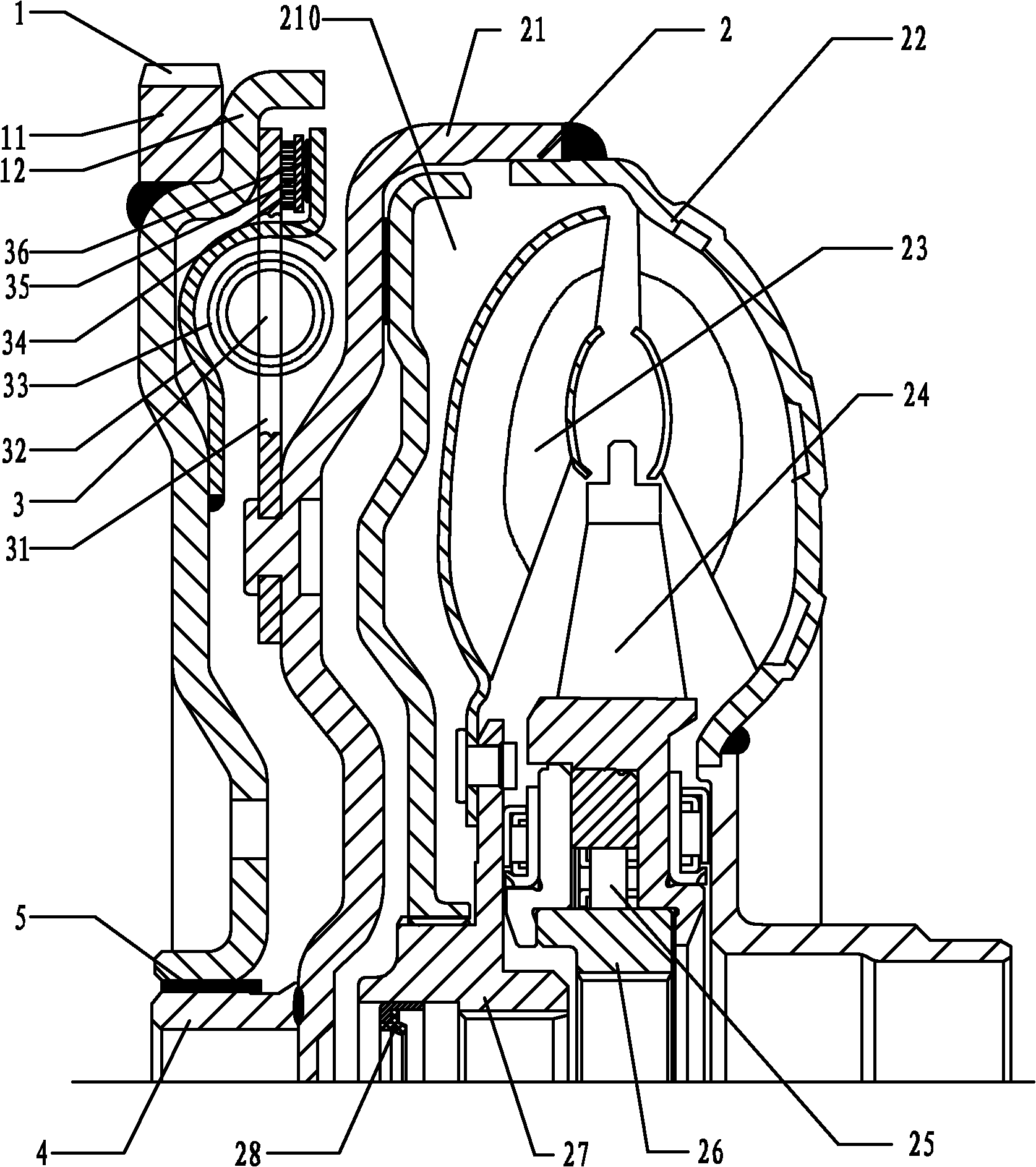

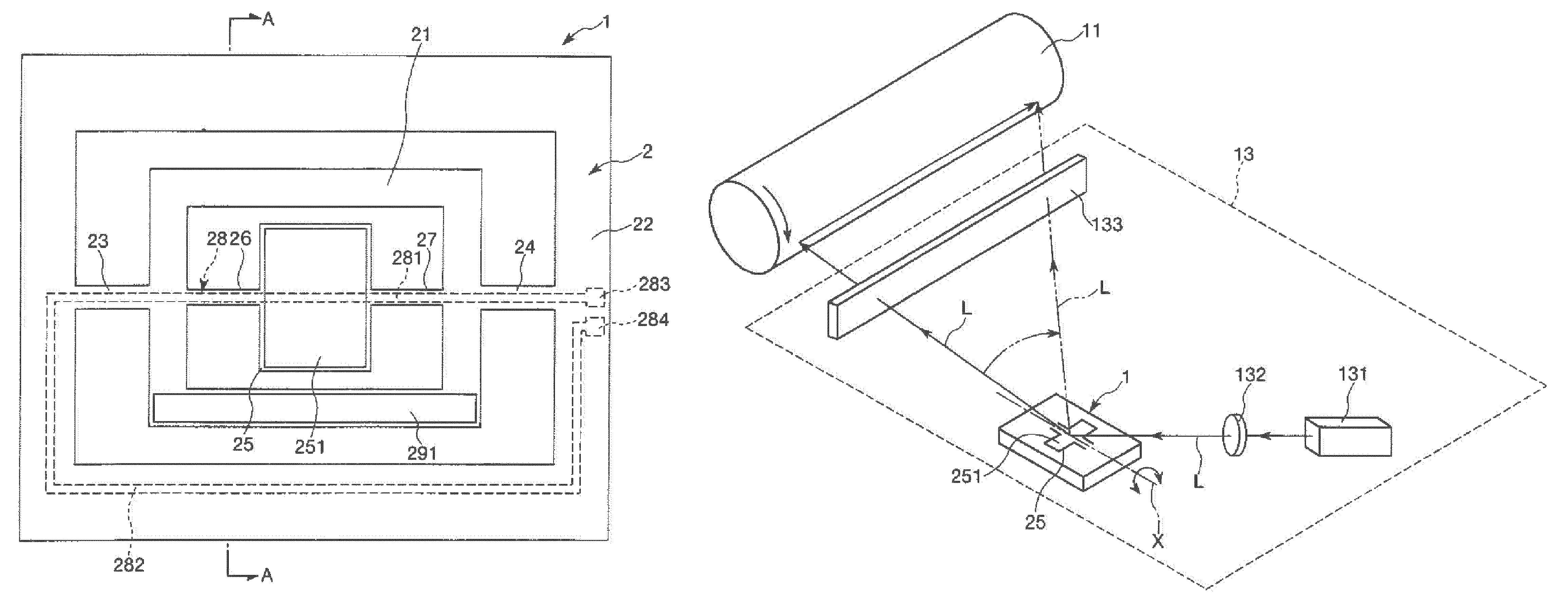

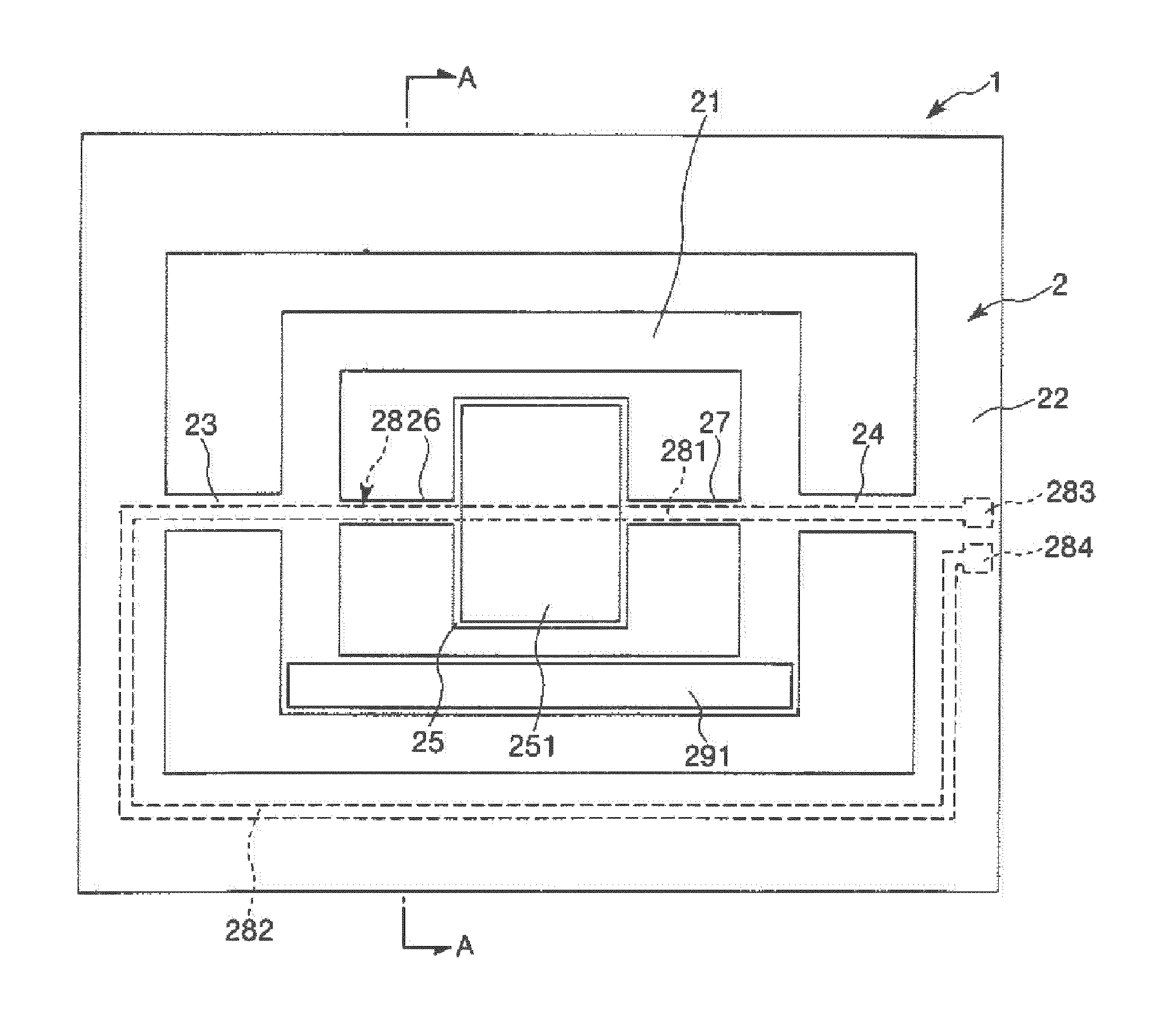

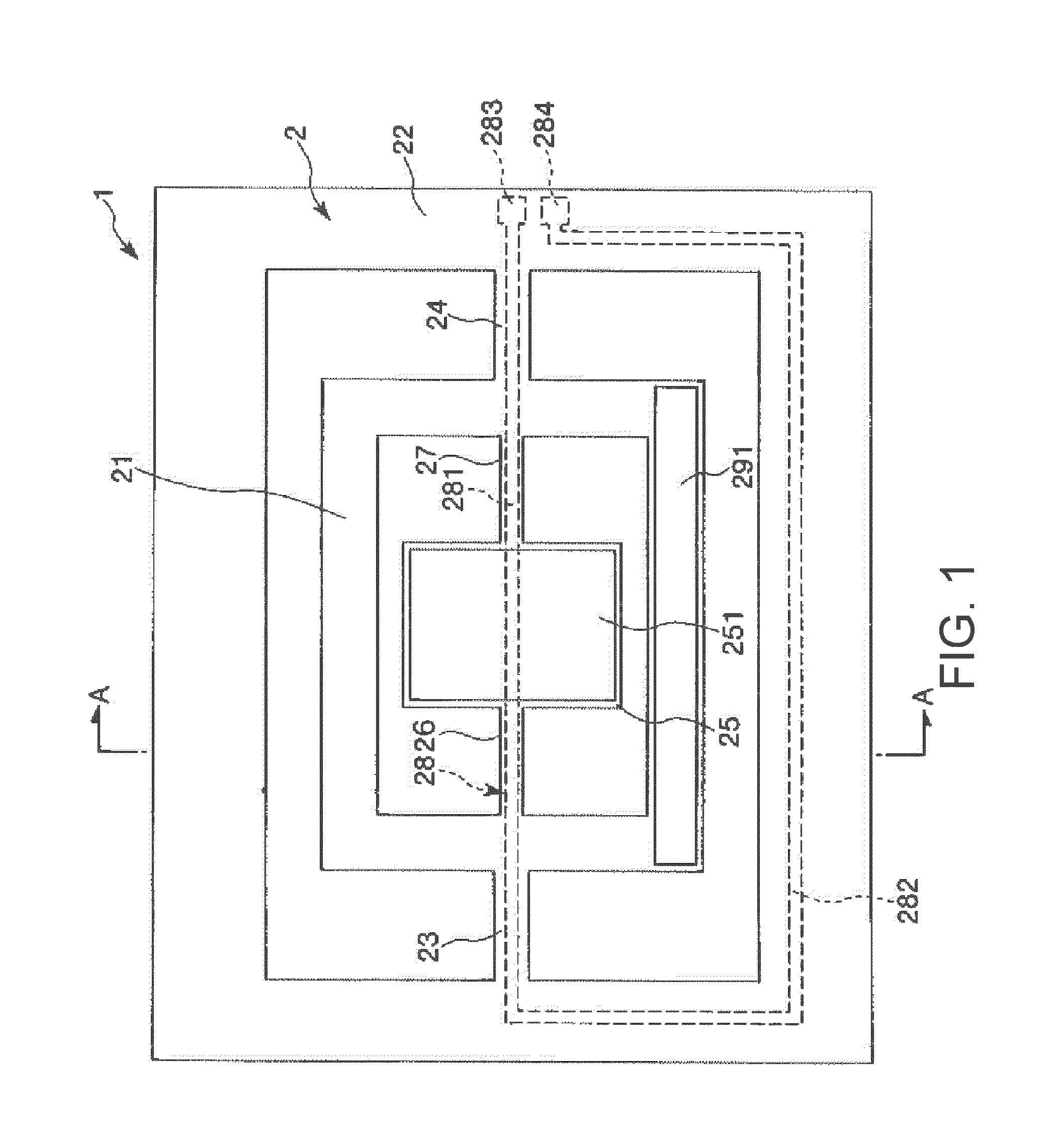

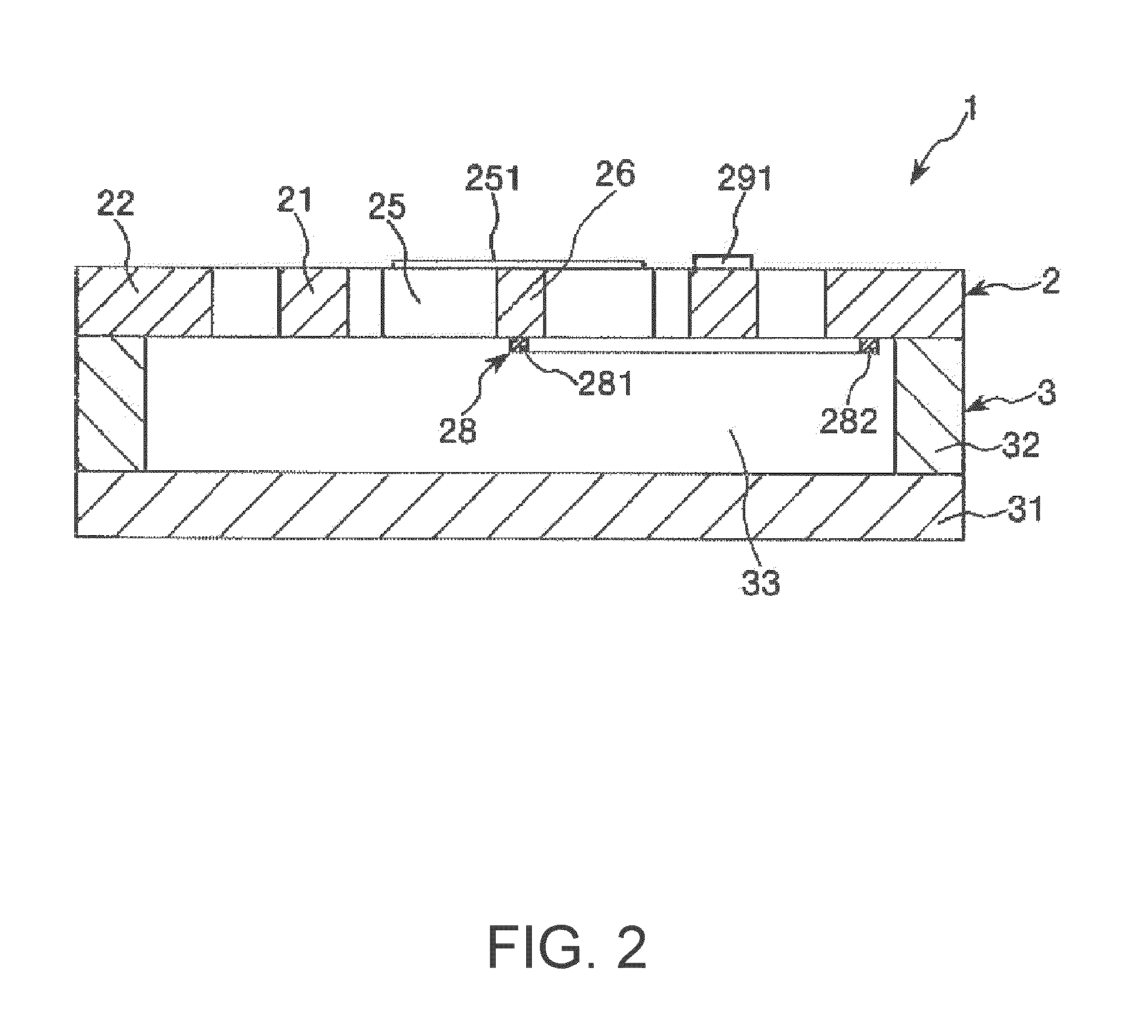

Actuator, optical scanner, and image forming apparatus

ActiveUS7408690B2Increase deflection angleSmall sizeDynamo-electric machinesElectromagnets with armaturesOptical scannersImage formation

An actuator includes a frame-shaped first mass portion; a supporting portion that supports the first mass portion and takes the shape of a frame so as to surround a perimeter of the first mass portion; a pair of first elastic portions coupling between the first mass portion and the supporting portion so that the first mass portion is supported by the supporting portion; a second mass portion provided inside the frame-shaped first mass portion; a pair of second elastic portions coupling between the second mass portion and the first mass portion so that the second mass portion is supported by the first mass portion; and a driver for rotating the first mass portion. The driver includes a ferromagnet provided on the first mass portion in a position separate from a rotation central axis of the first mass portion; a coil formed along the rotation central axis of the first mass portion and the supporting portion so as to surround and orbit a perimeter of the ferromagnet if the first mass portion is seen from above; and a voltage application unit for applying a voltage to the coil. An operation of the voltage application unit included in the driver causes the coil to generate a magnetic field. The generation of the magnetic field causes displacement of the ferromagnet relative to the coil. The displacement of the ferromagnet causes the first mass portion to rotate while torsionally deforming the pair of first elastic portions. The rotation of the first mass portion causes the second mass portion to rotate while torsionally deforming the pair of second elastic portions.

Owner:SEIKO EPSON CORP

Magneto-optic current transducer and manufacturing method thereof

InactiveCN101672870AIncrease the rotation angleImprove sensing accuracyCurrent/voltage measurementVoltage/current isolationCurrent transducerSystems design

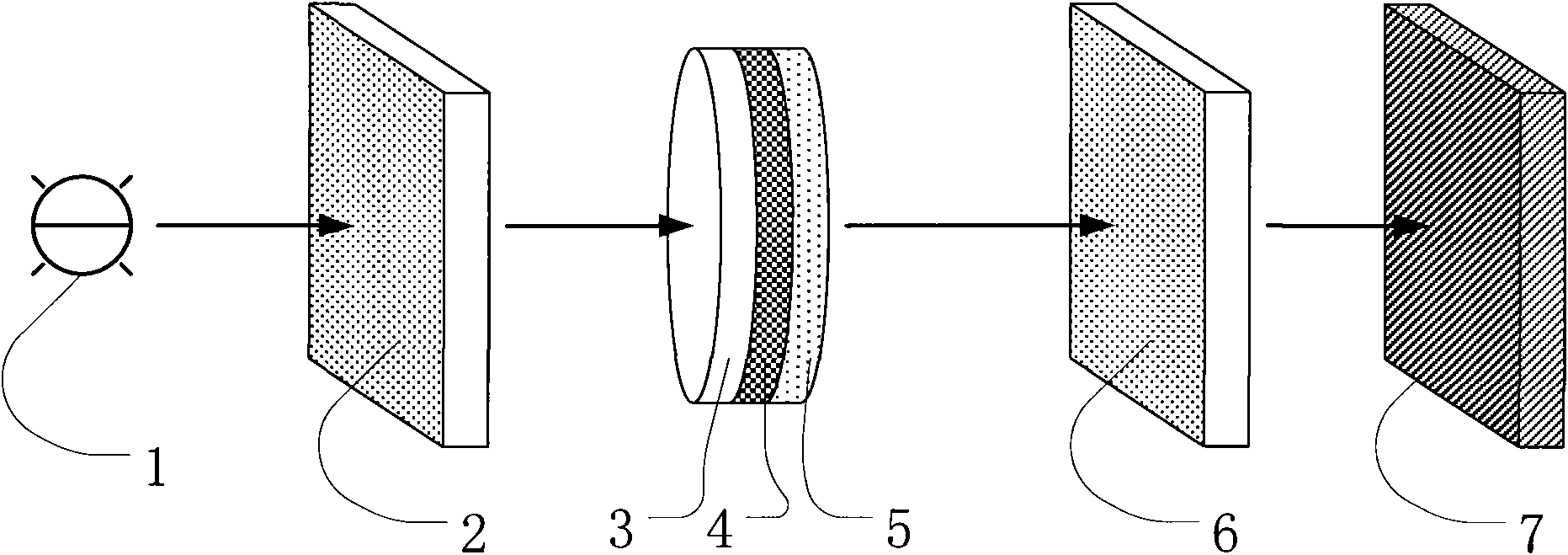

The invention discloses a magneto-optic current transducer and a manufacturing method thereof. The magneto-optic current transducer comprises a light source, a polarizer, a magneto-optic transducer unit, an analyzer and a direction detector which are arranged along the light path, wherein the magneto-optic transducer unit is of an overlapped growth structure composed of a protective layer, a permanent magnetic film and a magneto-optic material layer; the manufacturing method thereof is implemented by firstly preparing clean and dry magneto-optic material, then growing the permanent magnetic film on the magneto-optic material in vacuum, sequentially growing SiN or SiO2 film protective layer on the permanent magnetic film, and finally magnetizing the permanent magnetic film of the magneto-optic transducer unit by using a permanent magnetic machine. The invention uses the permanent magnetic film so that the light path passes through a strong magnetic field and has good parallel degree, thus effectively increasing rotation angle of polarized light and enhancing induction accuracy of the transducer. In addition, the magneto-optic current transducer has less light path elements, more simple and convenient system design, and higher reliability.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

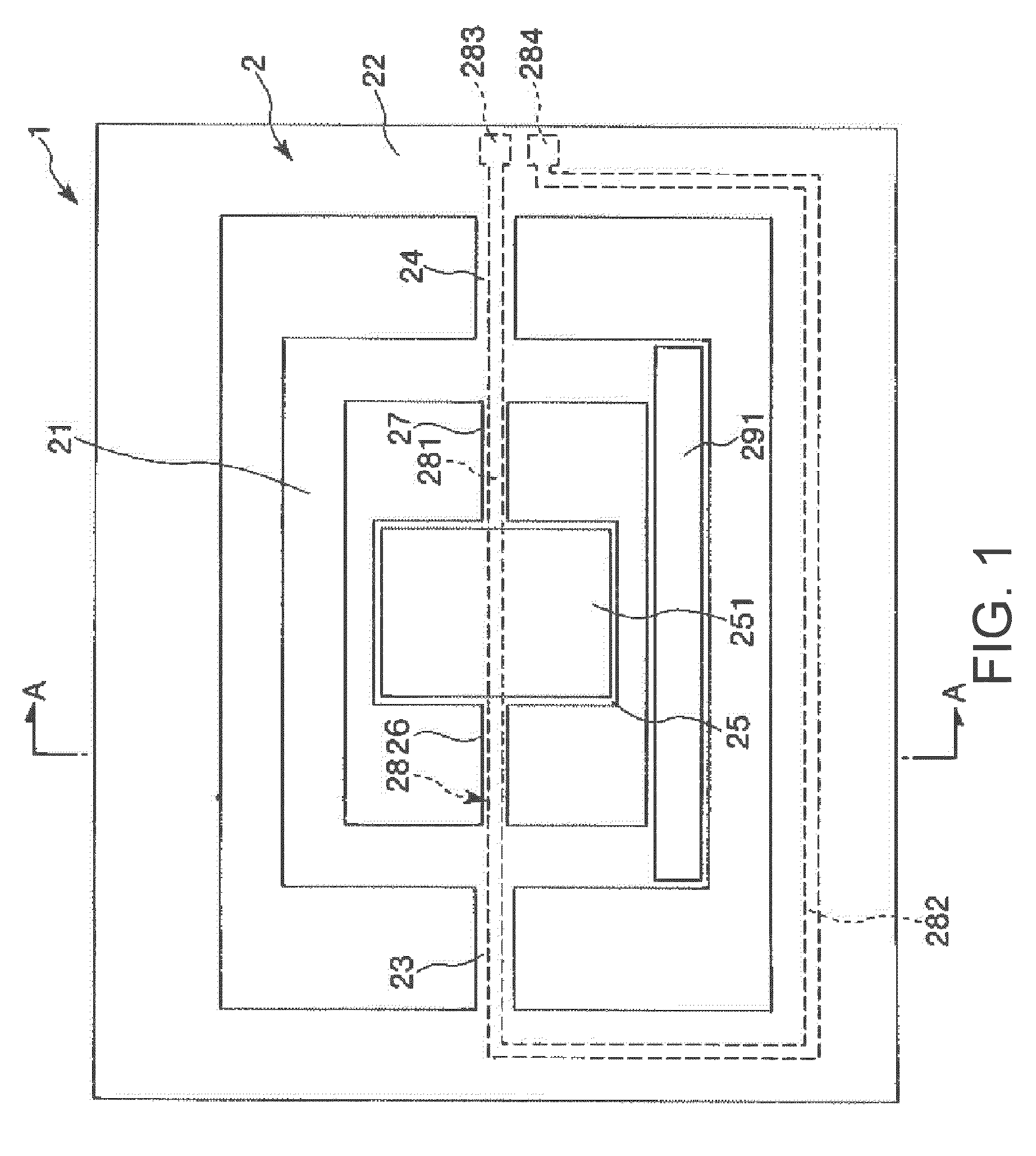

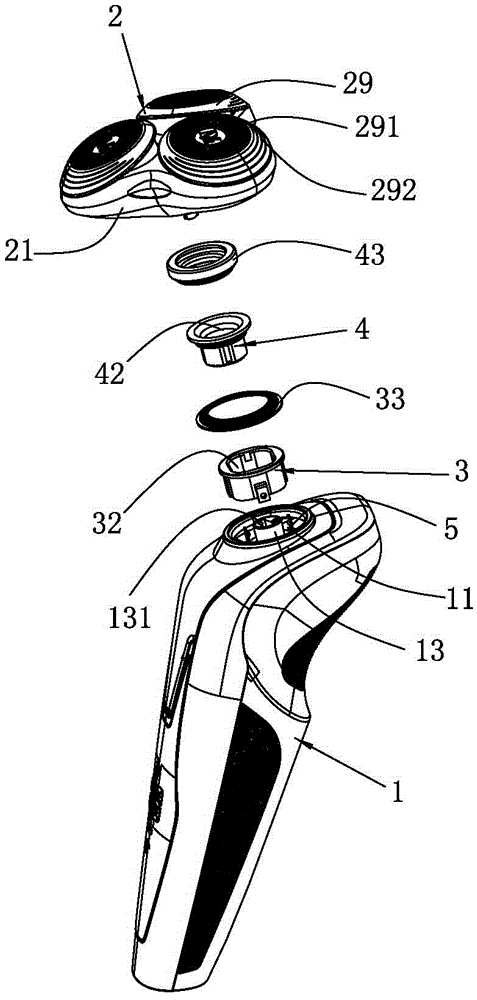

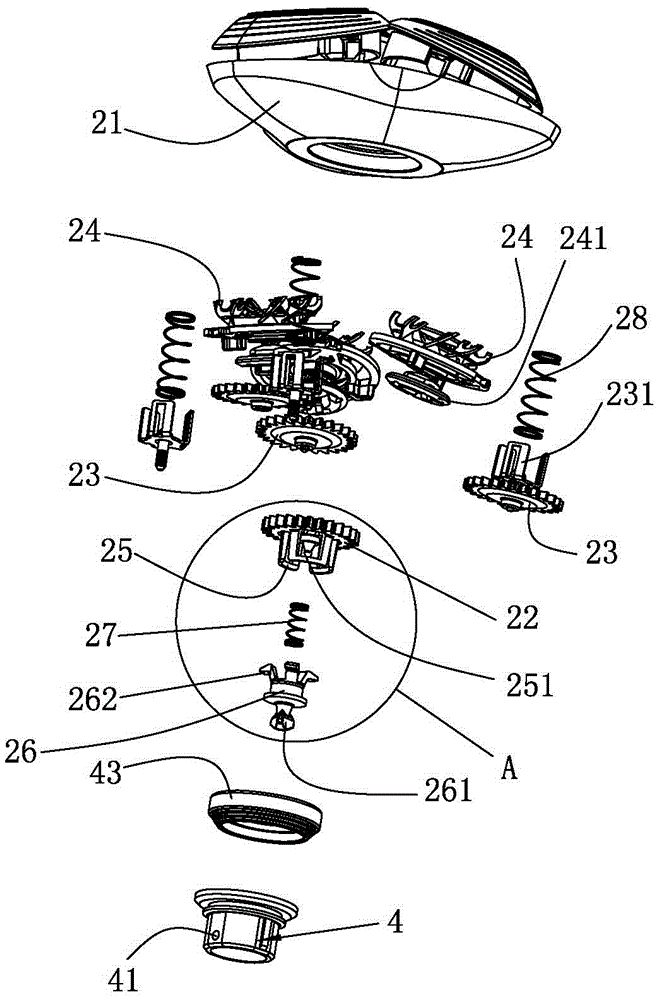

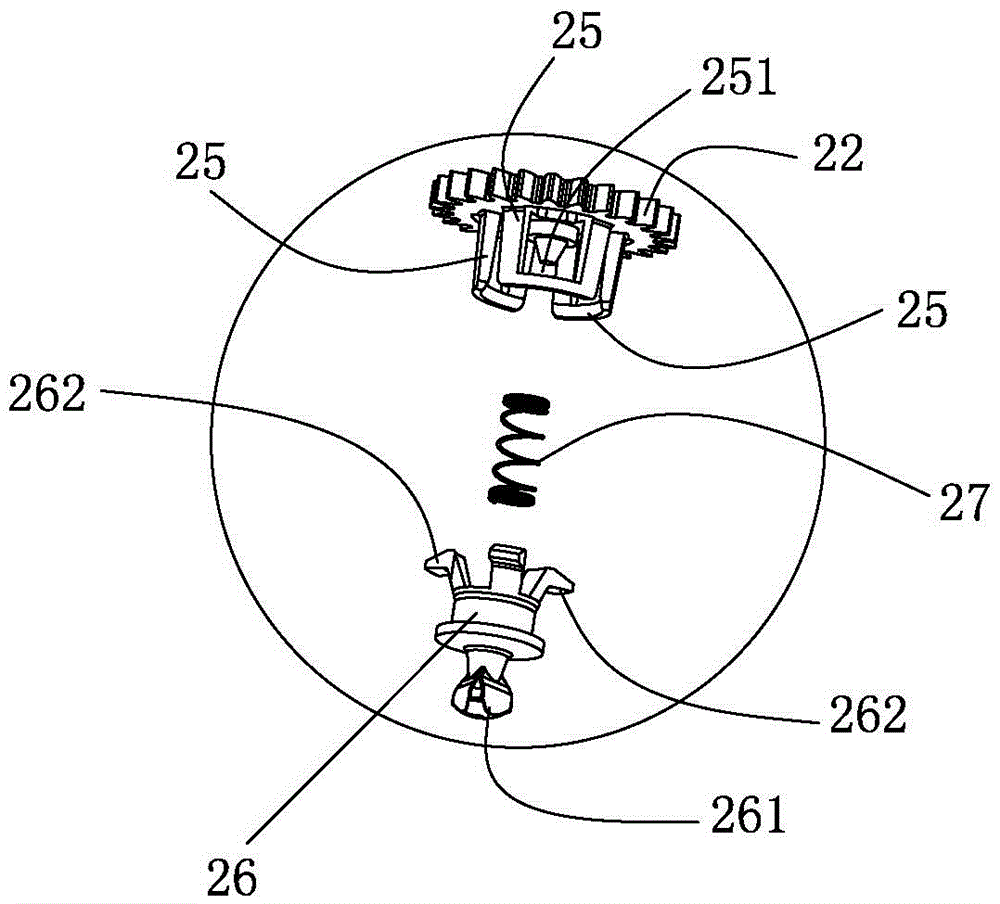

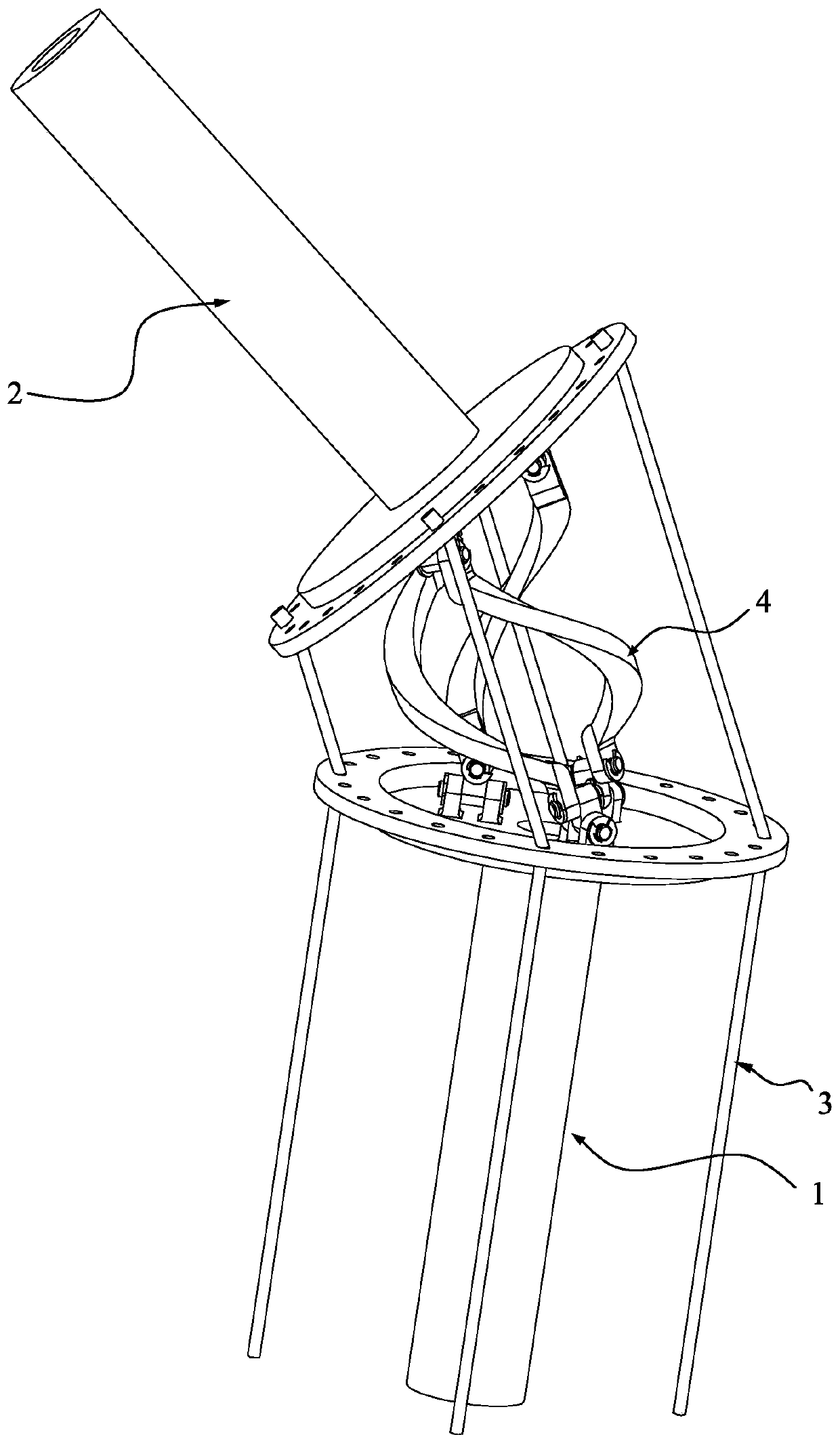

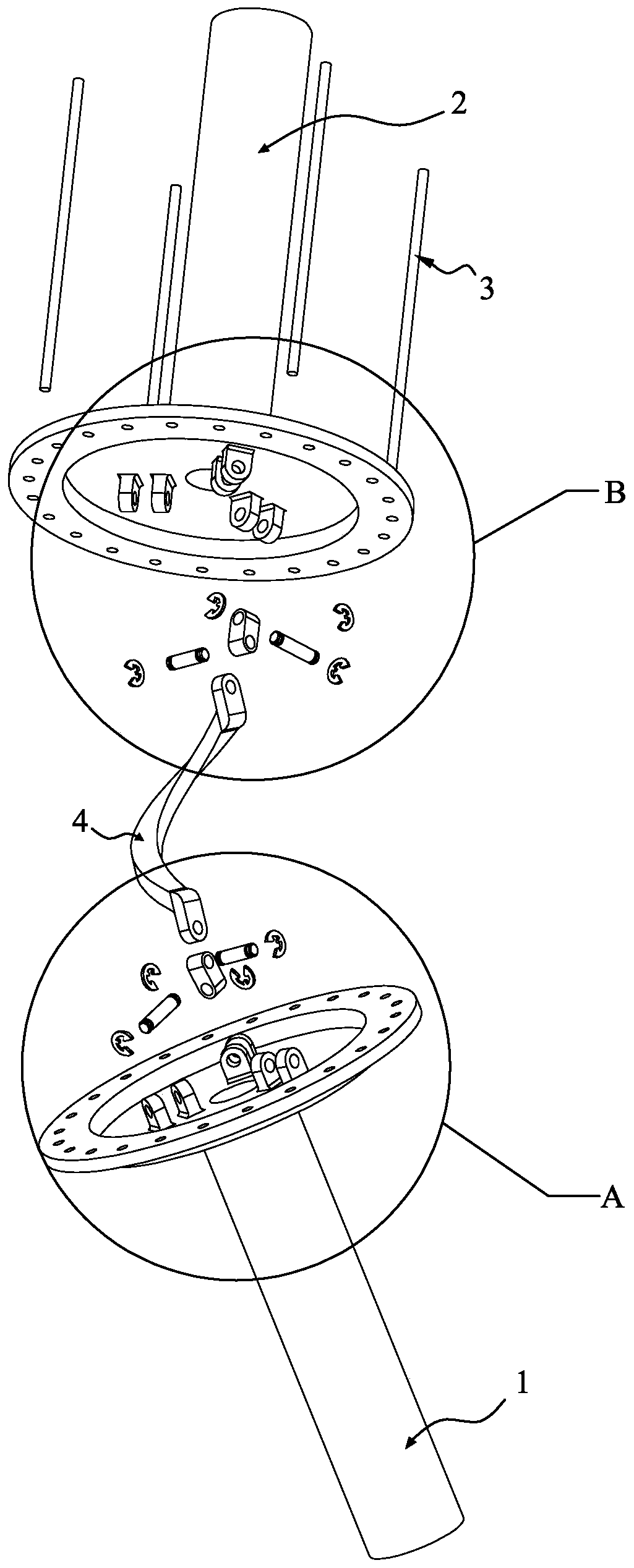

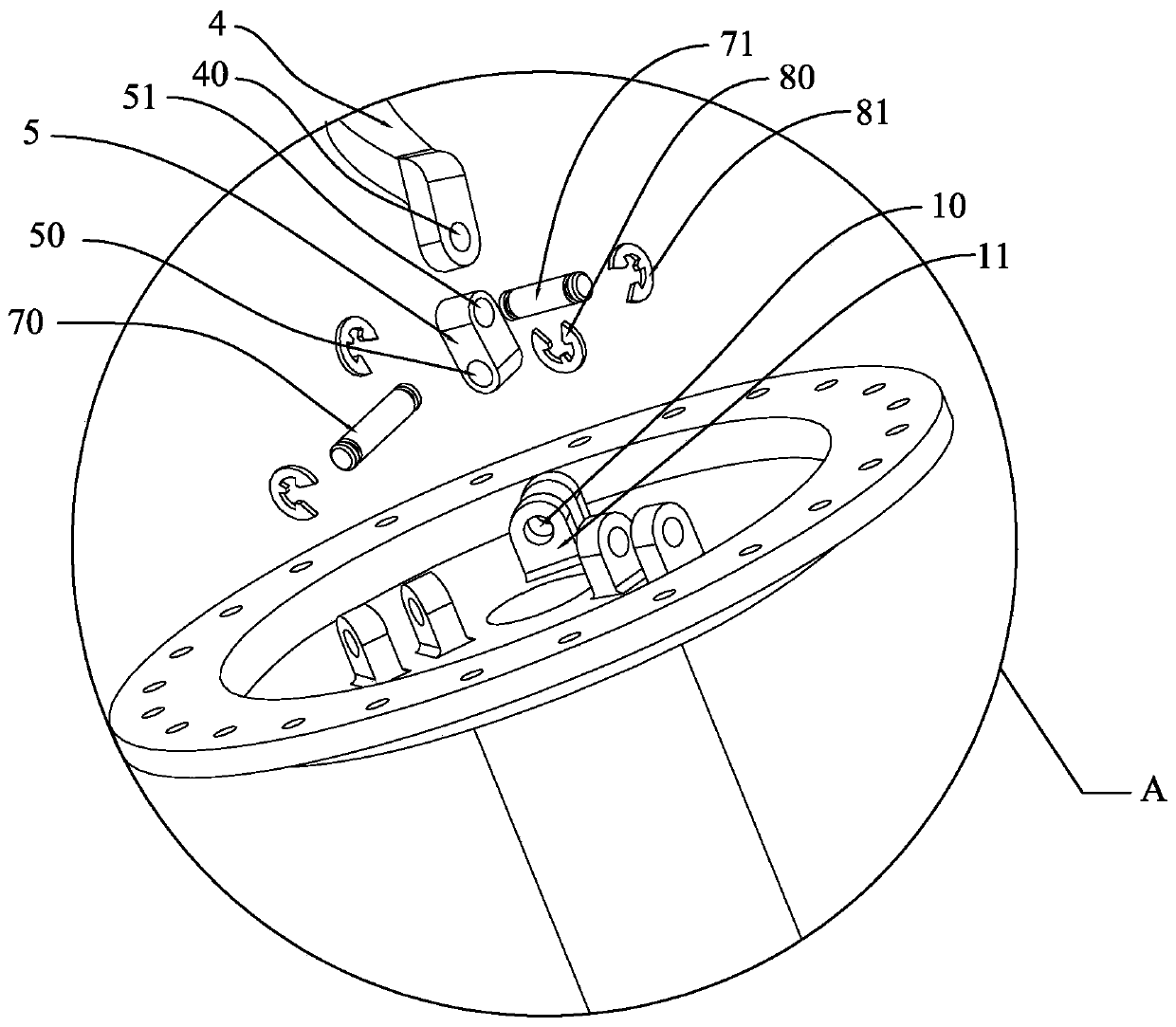

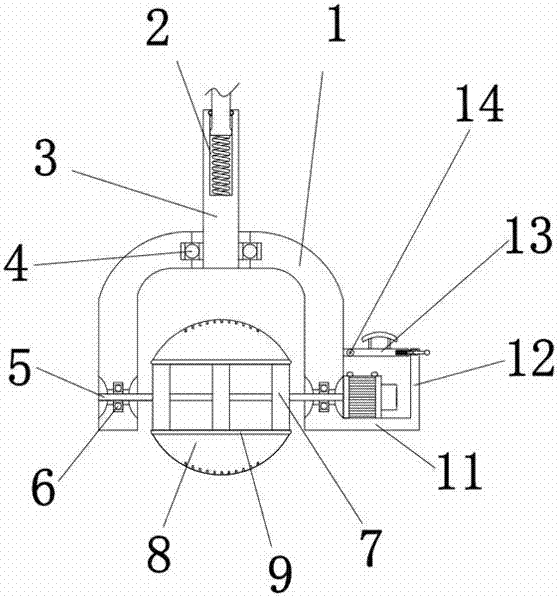

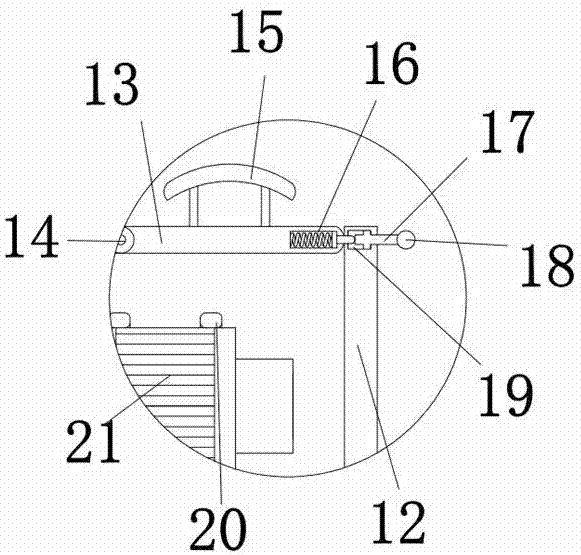

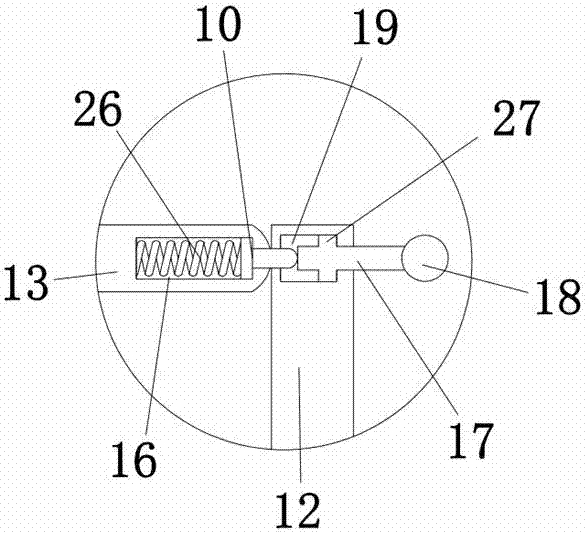

Floating type shaver

ActiveCN106514732ARealize the reset functionTo achieve the reset effectMetal working apparatusRazor stropEngineering

Owner:GUANGDONG ROMAN TECH CO LTD

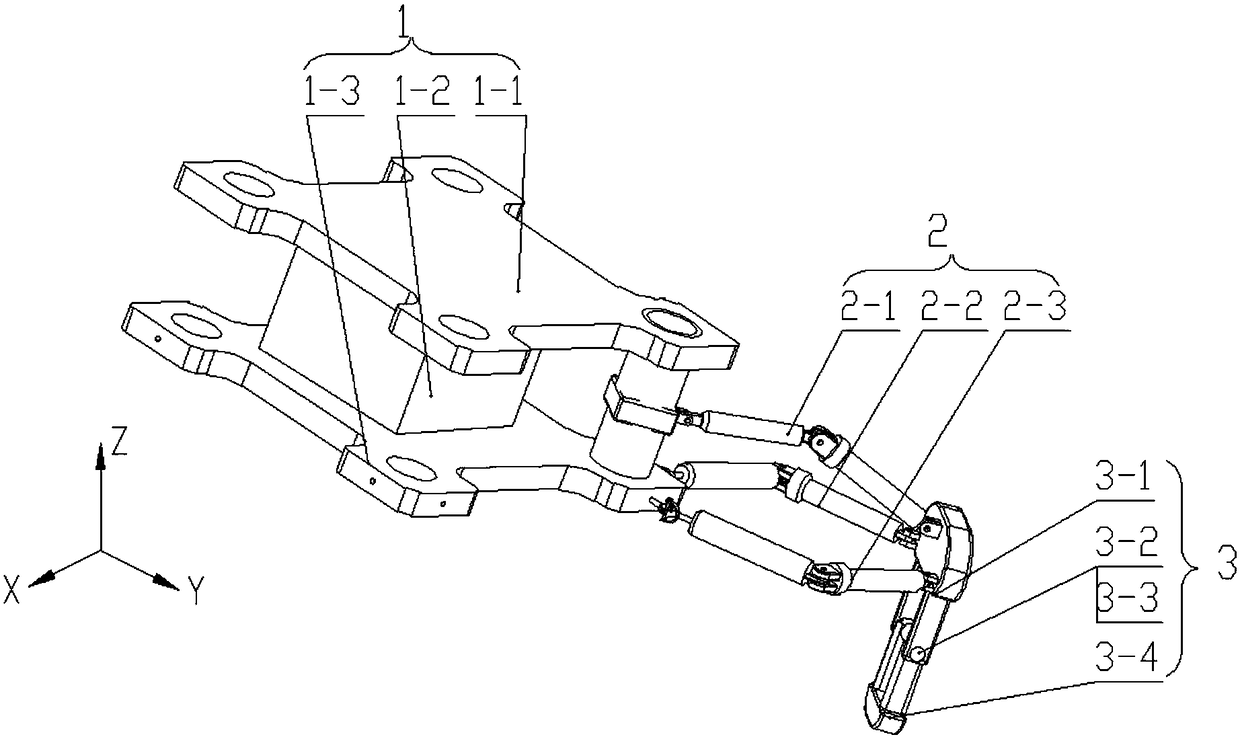

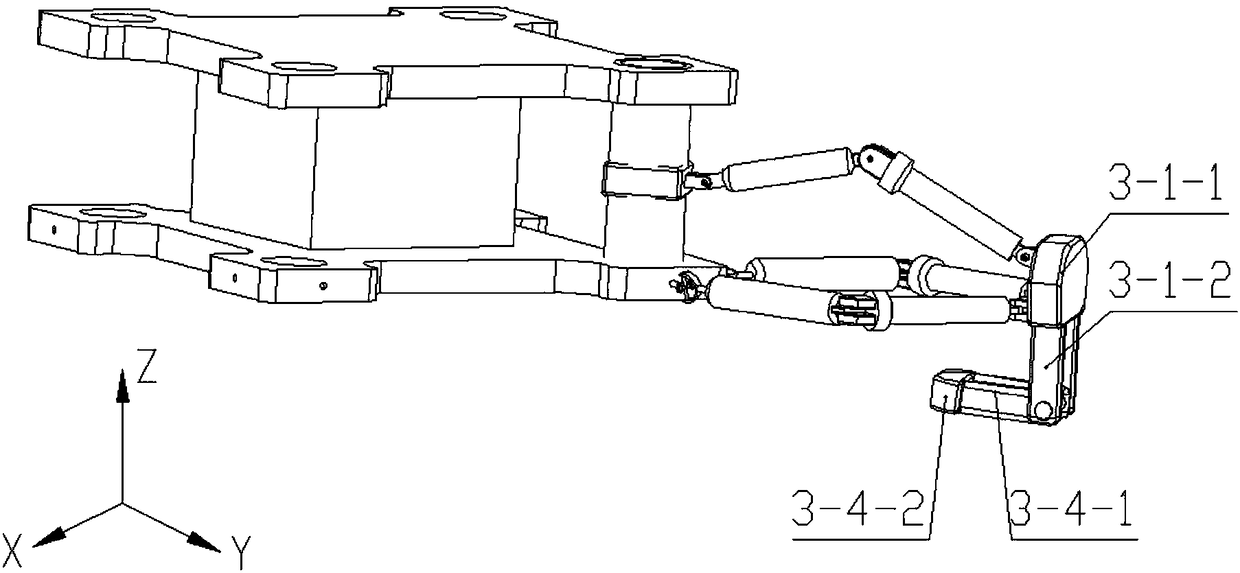

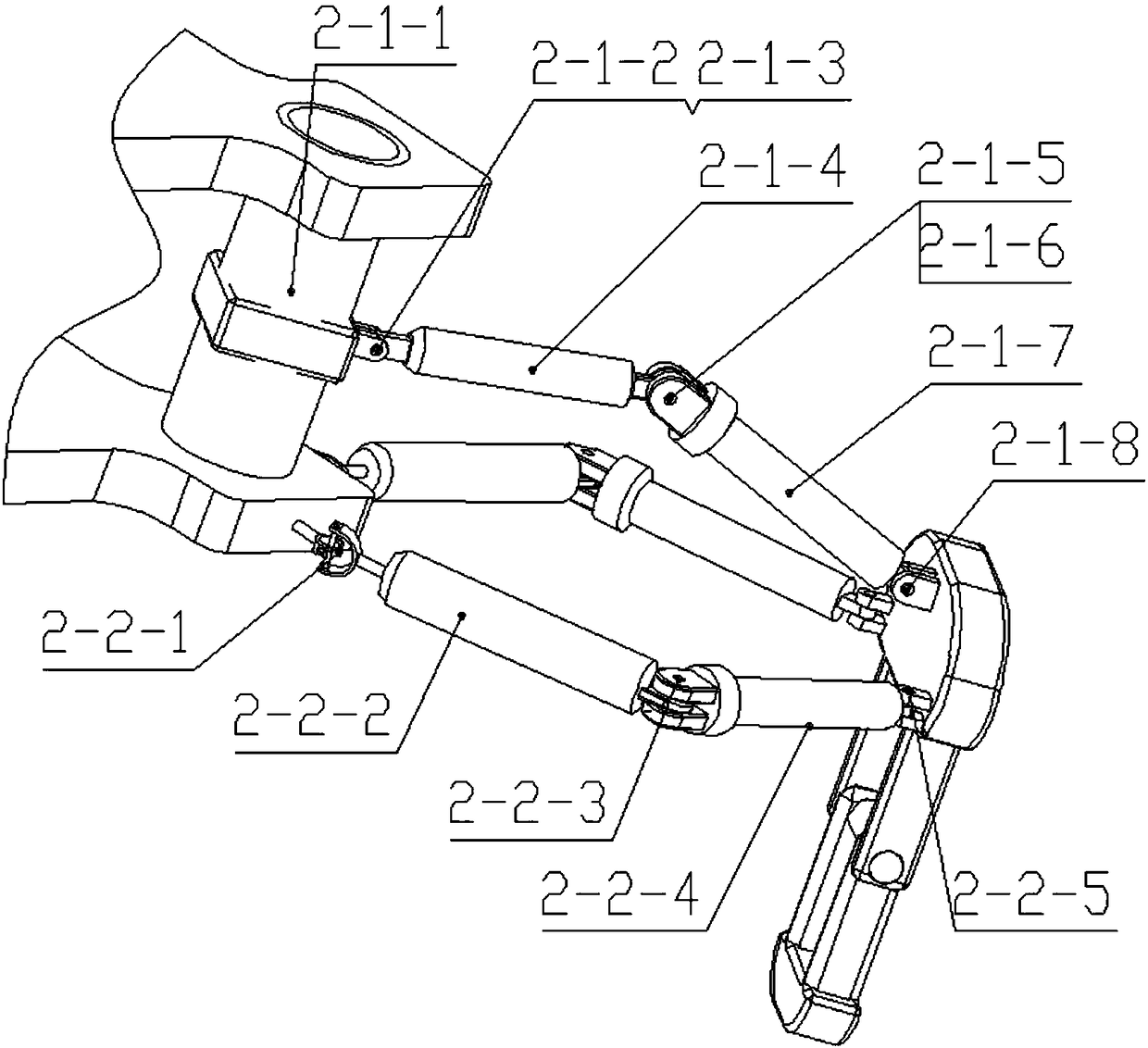

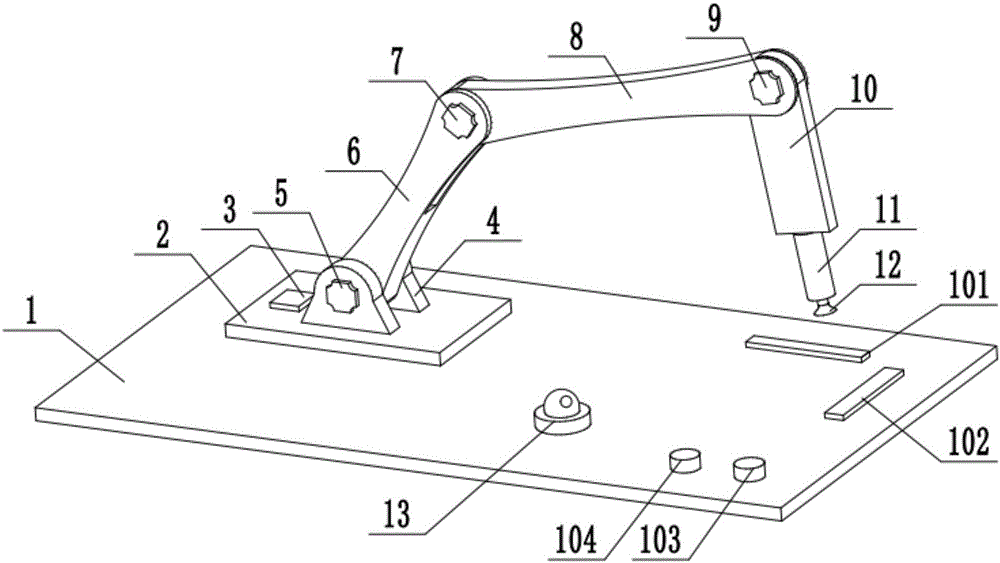

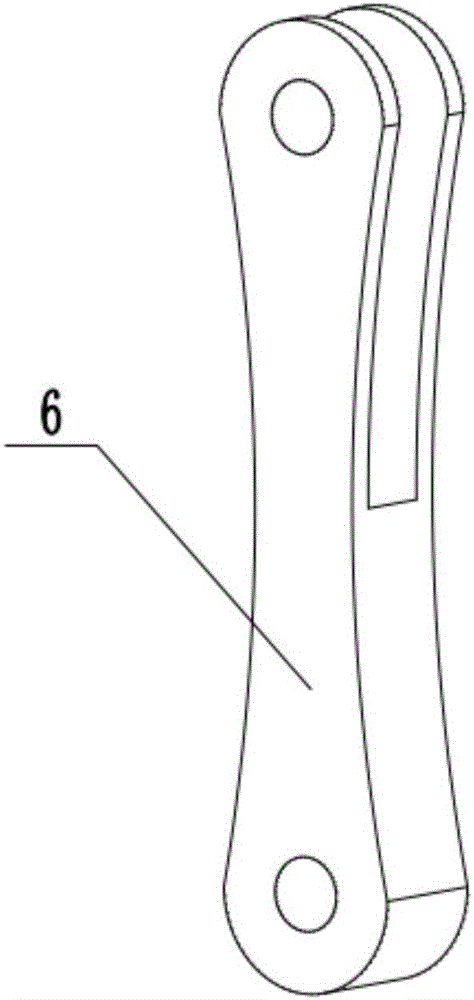

Two-degree-of-freedom large-rotation-angle flexible robot joint based on rope driving and robot

InactiveCN109955281AIncrease the rotation angleIncrease flexibilityProgramme-controlled manipulatorJointsAngular degreesSacroiliac joint

The invention discloses a two-degree-of-freedom large-rotation-angle flexible robot joint based on rope driving and a robot, and belongs to the technical field of robots. The two-degree-of-freedom large-rotation-angle flexible robot joint based on the rope driving comprises a first joint rod, a second joint rod and rotating connecting pieces, wherein first hinged pieces are connected to one ends of the rotating connecting pieces in a hinged mode, the first hinged pieces are connected with the first joint rod in a hinged mode, second hinged pieces are connected to the other ends of the rotatingconnecting pieces in a hinged mode, and the second hinged pieces are connected with the second joint rod in a hinged mode. The two-degree-of-freedom large-rotation-angle flexible robot joint based onthe rope driving has the advantages of large-angle rotation and more flexibility.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

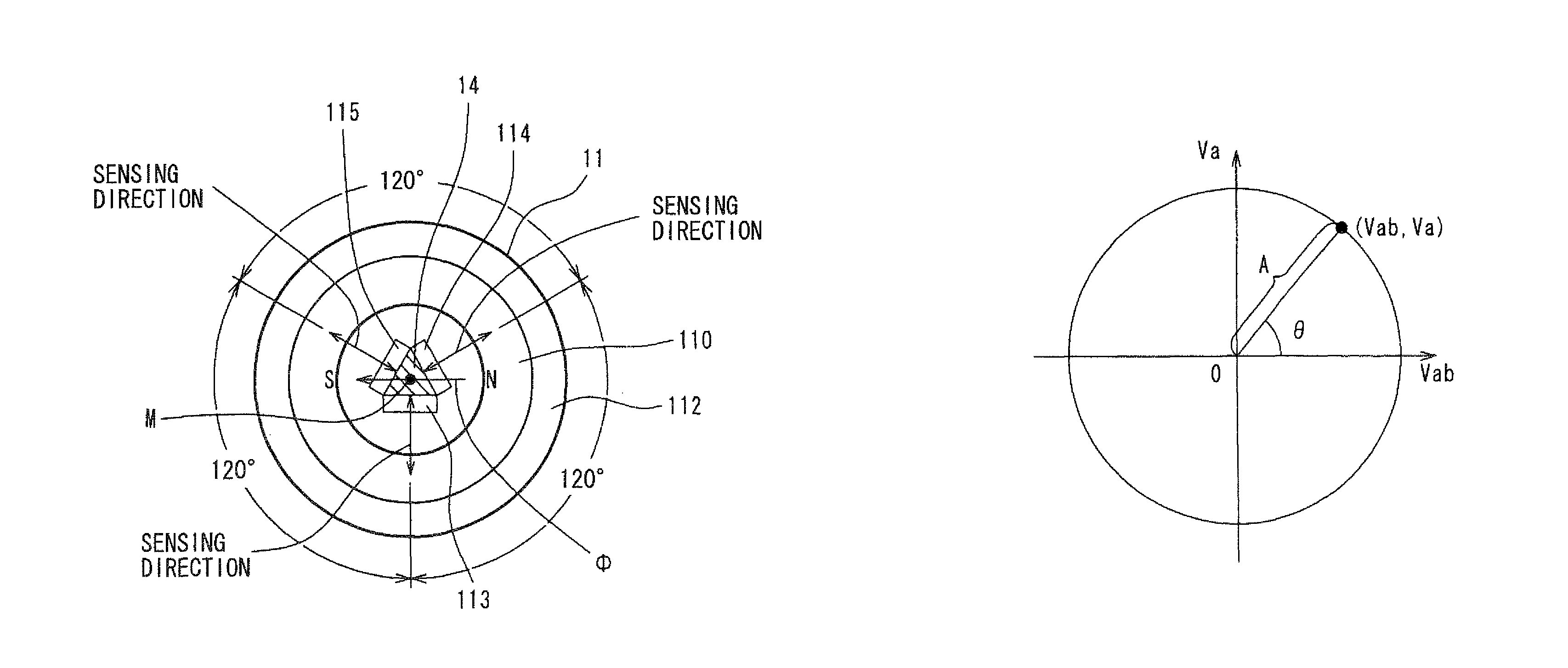

Rotation angle detecting device

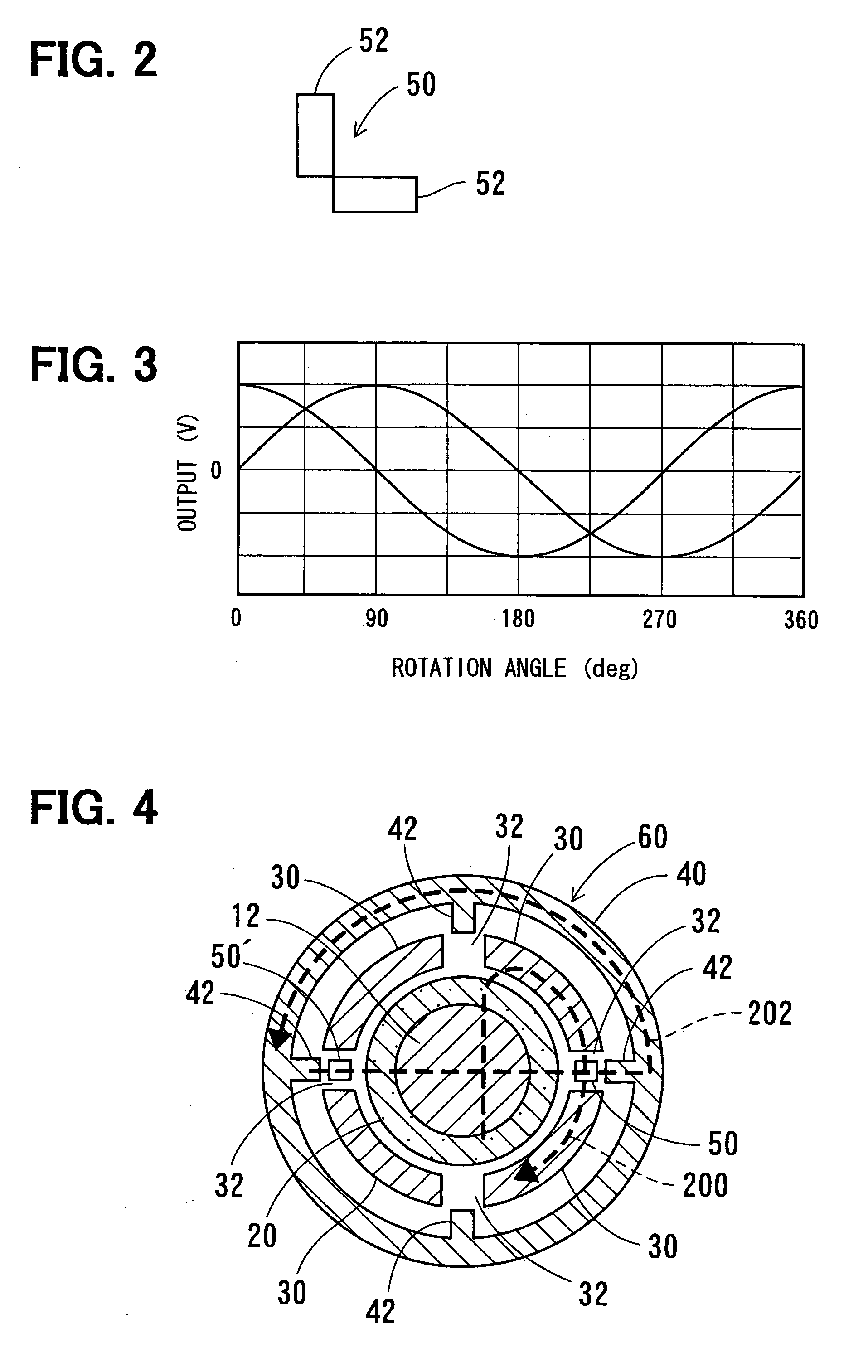

ActiveUS20080284421A1Easy to optimizeIncrease the number ofDigital computer detailsSpeed measurement using gyroscopic effectsClassical mechanicsSignal generator

A rotation angle detecting device includes a signal generator, a magnetic rotor and a rotation angle calculating unit that calculates a rotation angle θ of the rotor based on the output signals of the signal generator. The signal generator includes a magnetic rotor that has a permanent magnet and a shaft connectable with the rotating object and at least three magnetic sensor elements disposed in the magnetic field to generate a plurality of output signals when the rotor rotates. The rotation angle calculating unit calculates a first candidate of the rotation angle θ from a first pair of the three output signals, examines whether the first candidate of the rotation angle θ is normal or not and calculates a next candidate of the rotation angle θ from another pair of the three output signals if the first candidate of the rotation angle θ is not normal, examines whether the next candidate of the rotation angle θ is normal or not, repeats the above two steps until a next candidate of the rotation angle θ is judged normal, and outputs one of the first and next candidates of the rotation angle θ as a formal rotation angle if it is judged normal.

Owner:DENSO CORP +1

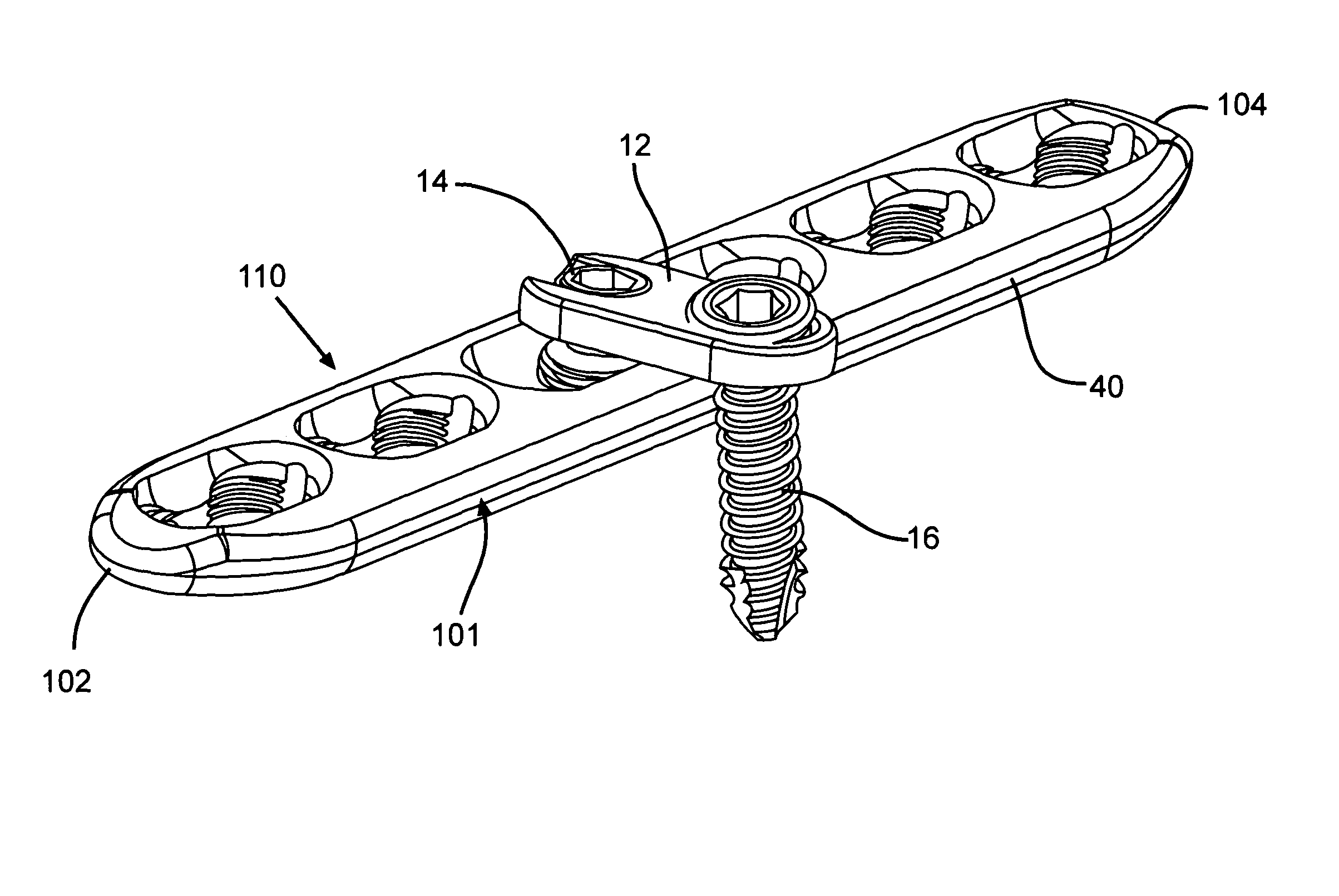

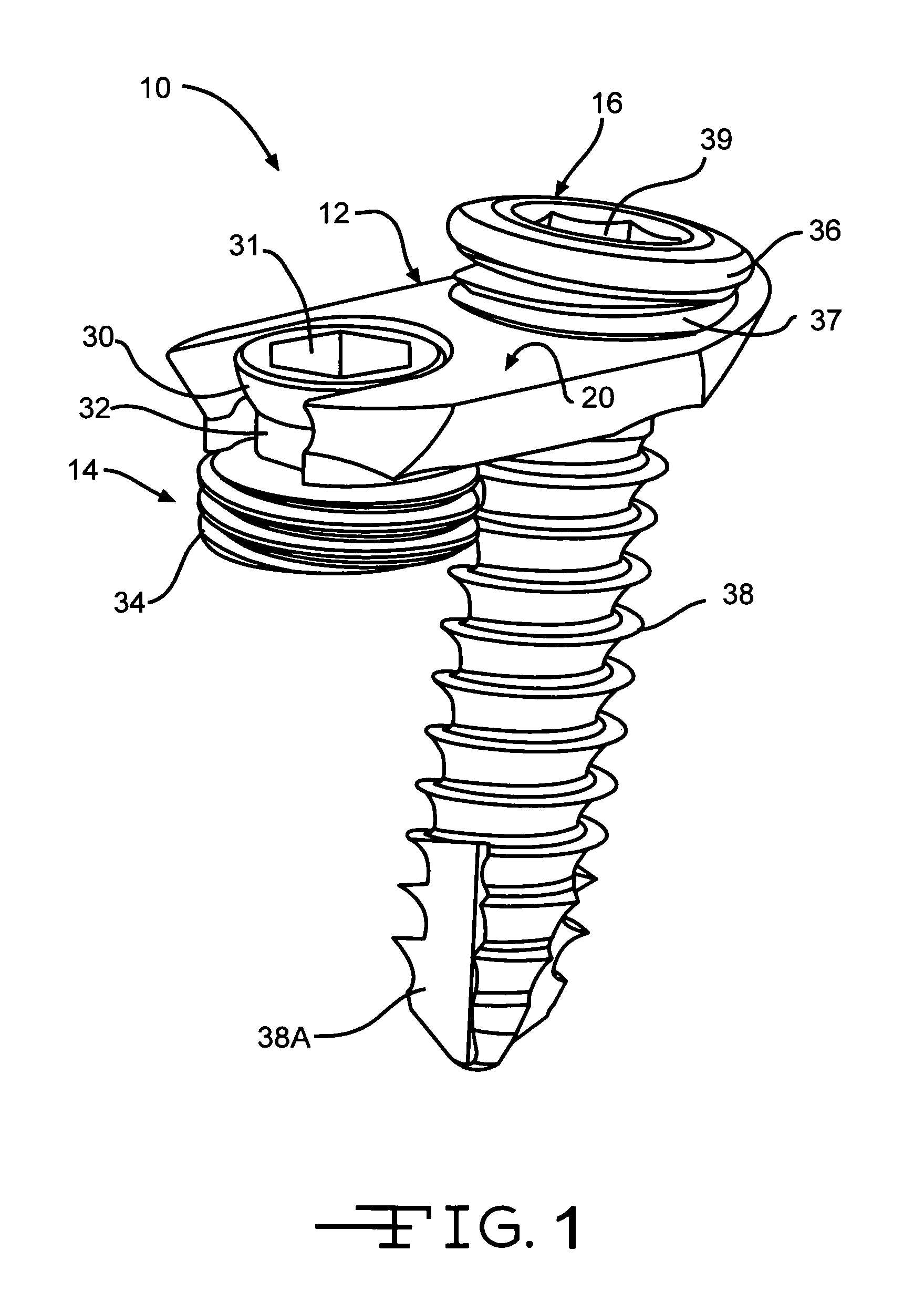

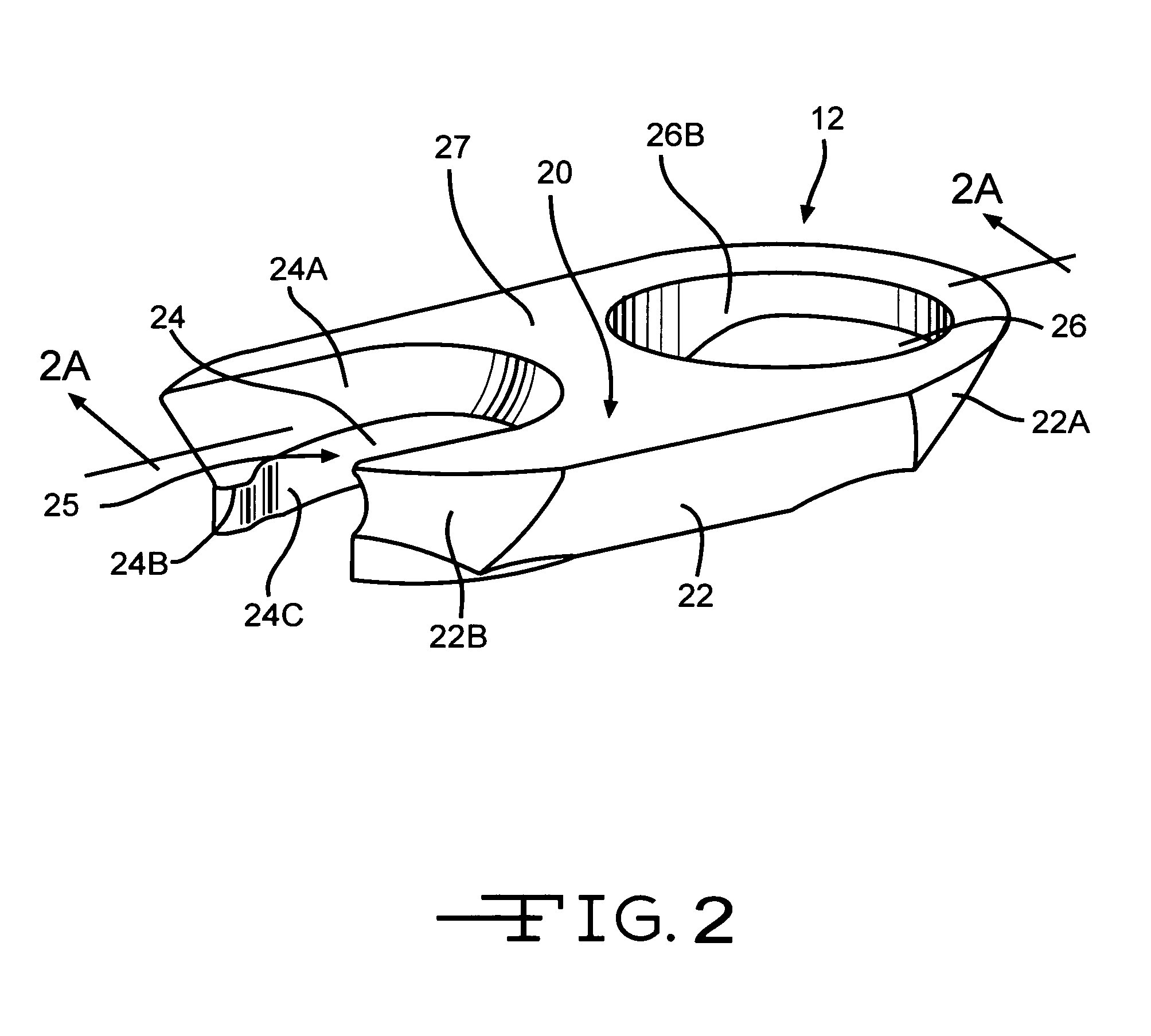

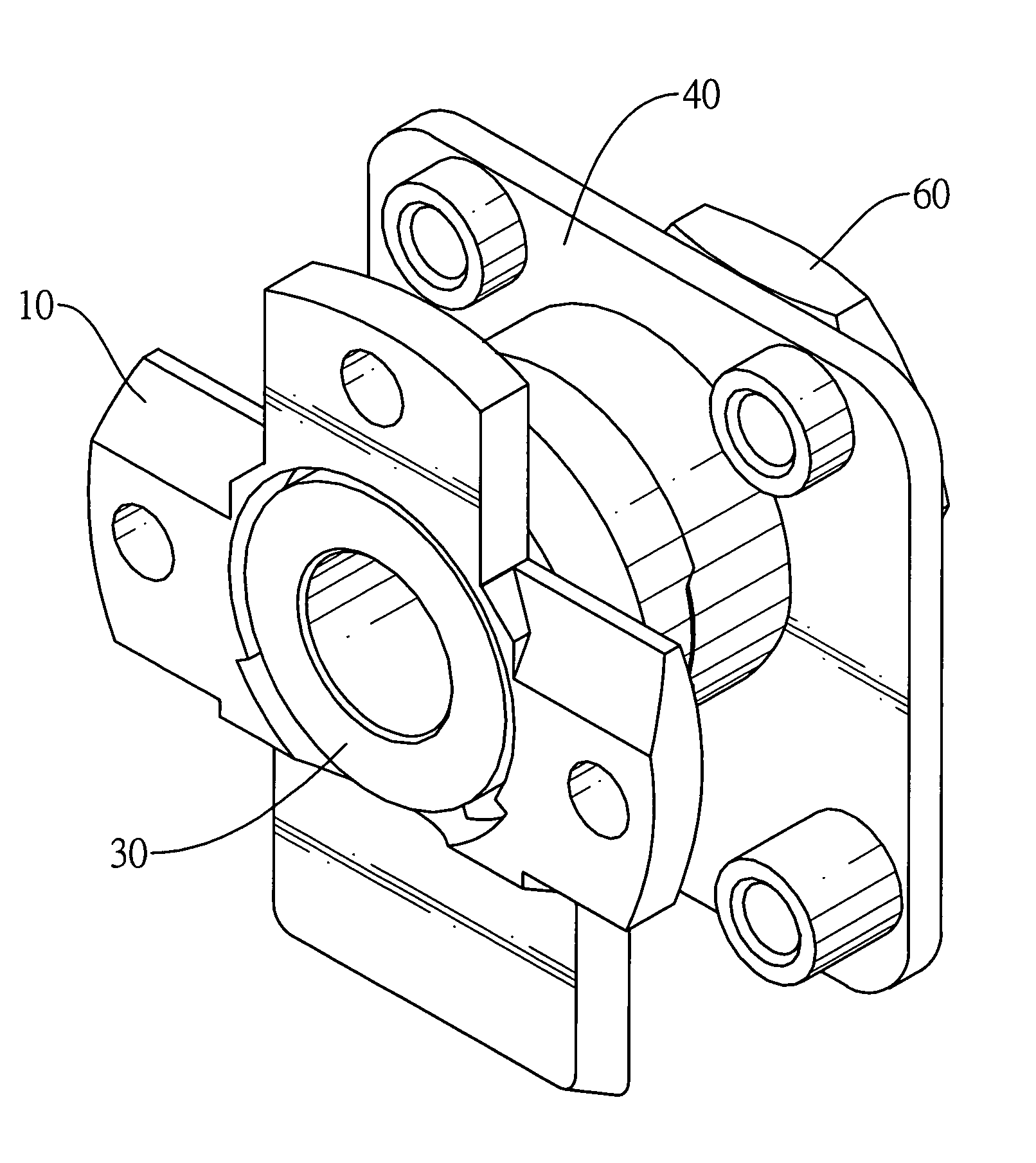

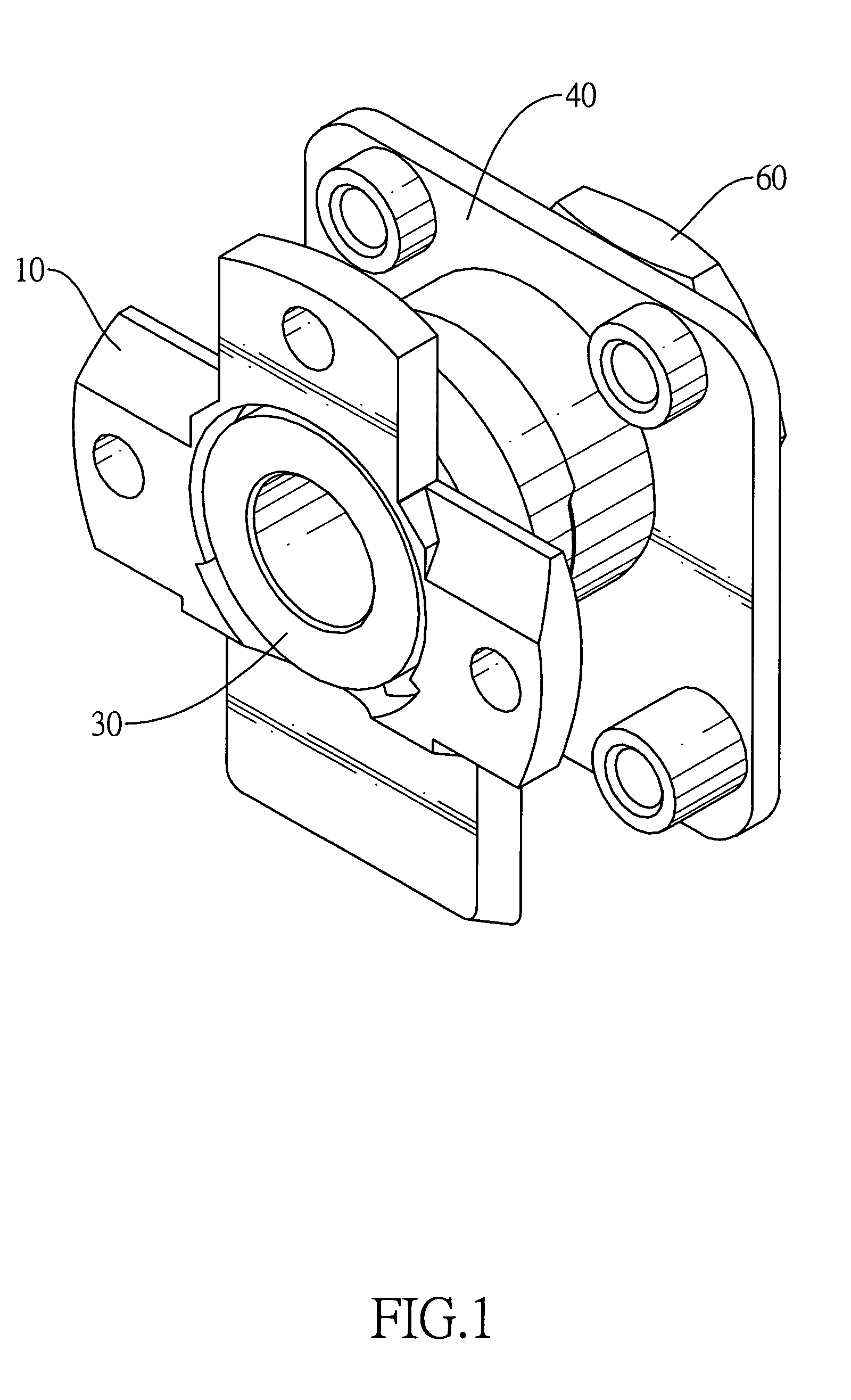

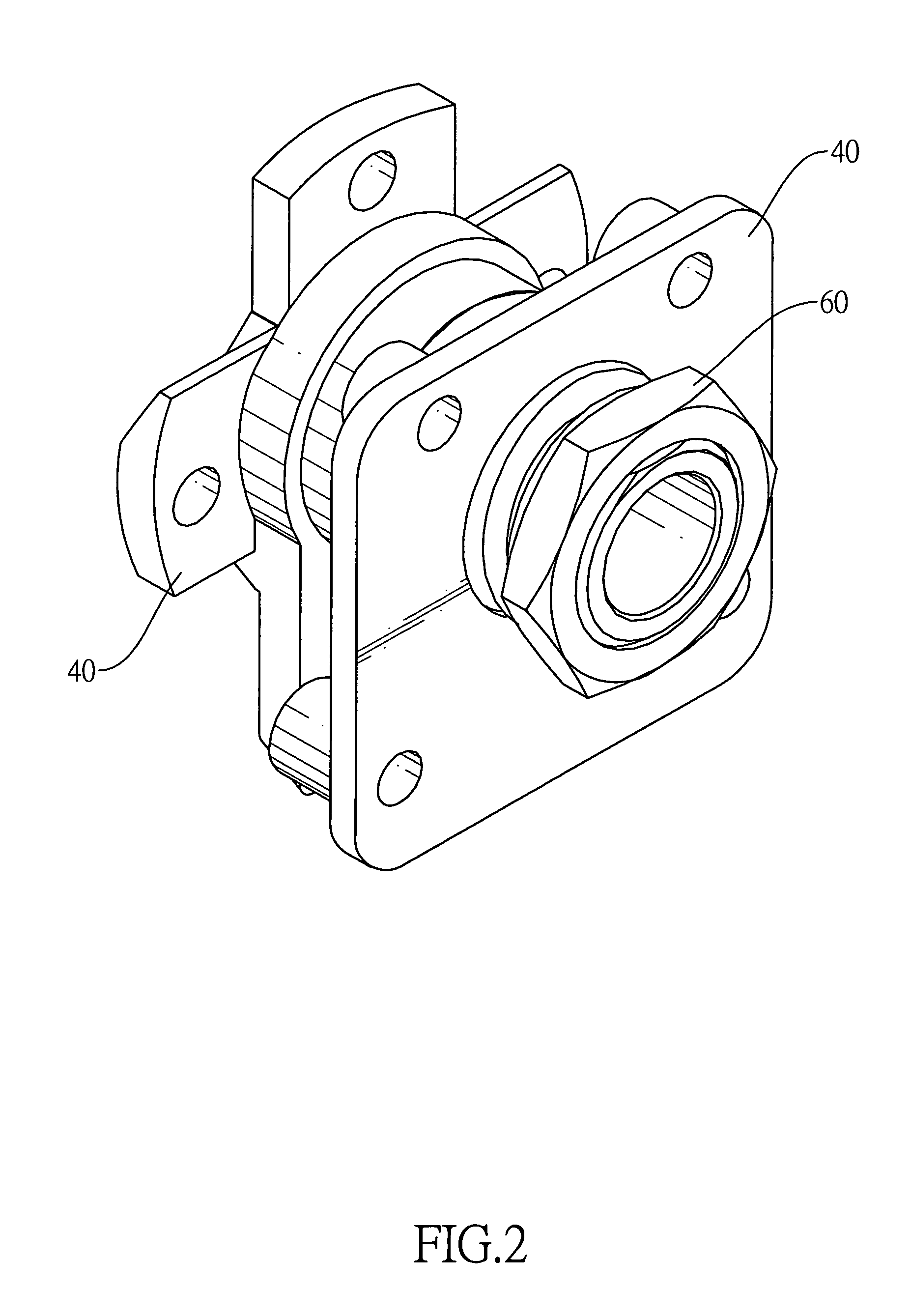

Polyaxial insert for surgical screws

ActiveUS8784458B1Optimization mechanismIncrease the rotation angleBone platesSet screwRelative motion

An improved insert for assembly with a bone plate is described. The insert has a first opening adapted to receive a set screw and a second opening adapted to receive a bone screw. The insert is connectable to the bone plate using a set screw. The insert in conjunction with the set screw provides an improved range of relative motion for placing the bone screw at outboard locations with respect to the bone plate. That way, bone fragments that are not necessarily reachable using the bone plate without the insert can be secured together for improved healing.

Owner:VIANT AS&O HLDG LLC

Rotation angle detecting device including multiple magnetic sensor elements

InactiveUS7969147B2Increase the number ofIncrease the rotation angleDigital computer detailsUsing electrical meansClassical mechanicsSignal generator

Owner:DENSO CORP +1

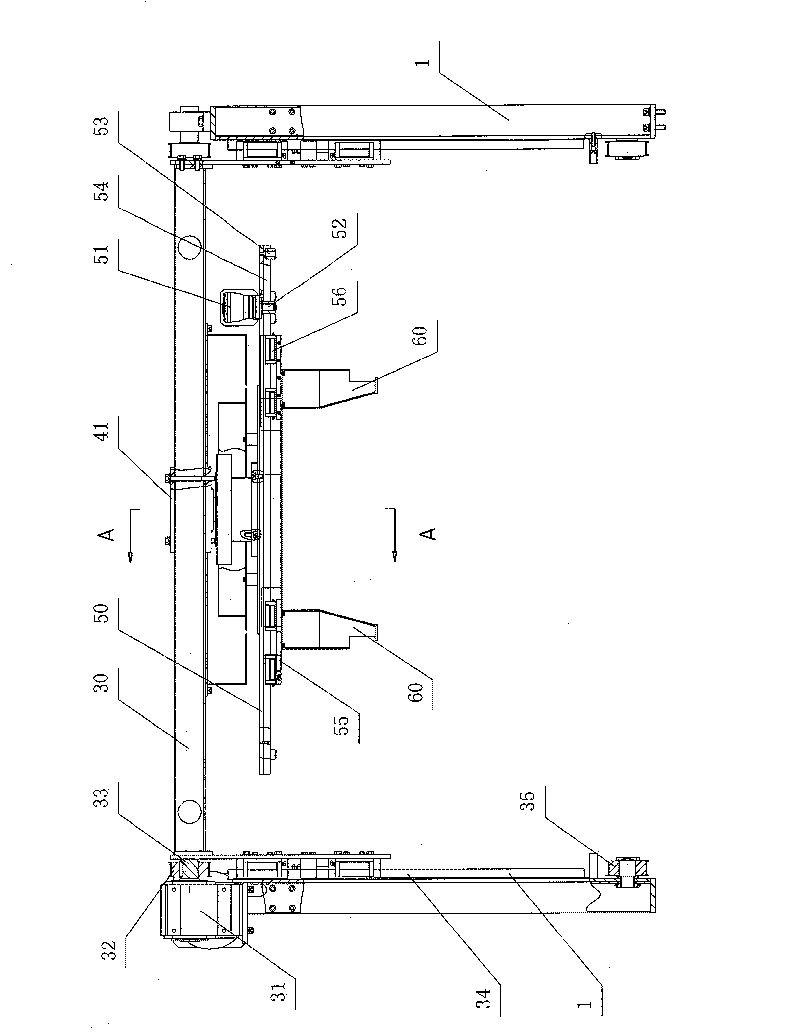

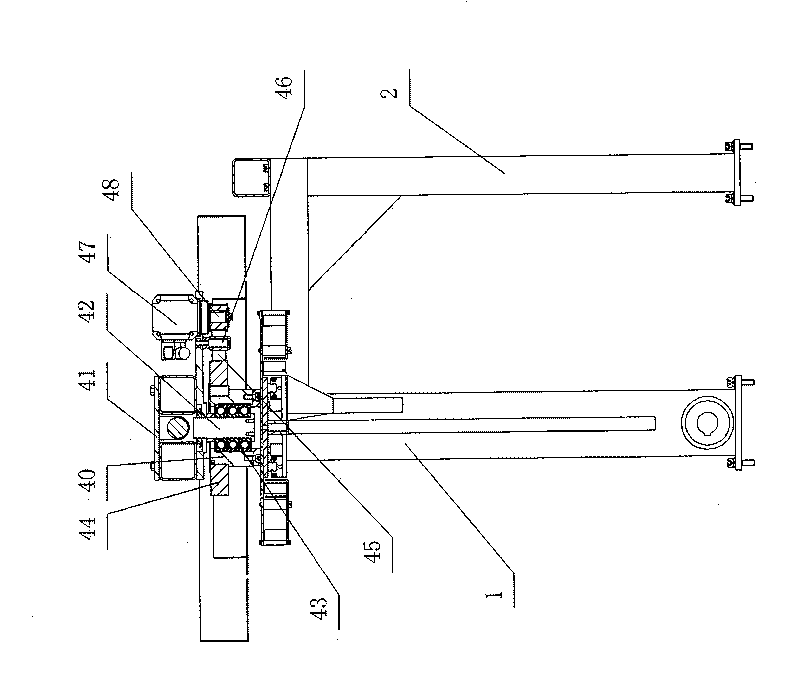

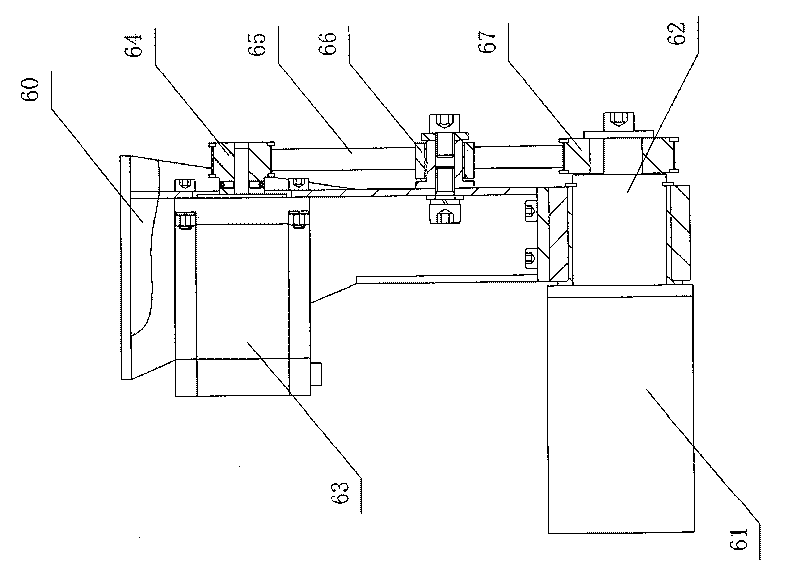

Tyre laser speckle inspection machine and inspection method thereof

ActiveCN101738399AEasy to useImprove inspection efficiencyMaterial analysis by optical meansEngineeringInspection method

The invention relates to a tyre laser speckle inspection machine and an inspection method thereof. A rotating drive part is added in a laser inspection device so as to control laser inspection heads to accurately rotate along the axial directions of locating shafts and to be regulated and located. The omnibearing photo scanning of the tread and the sidewall of a tyre is realized at one station by adopting a laser speckle inspection machine, and equipment has relatively simple overall structure and higher inspection efficiency and can be suitable for inspecting tyres with various types and specifications and sizes. The inspection machine mainly comprises a stand, a support frame, a lifting device, a rotating device, a horizontal reciprocate mobile device and a laser inspection device, wherein the laser inspection device comprises two mounting racks symmetrically connected below fixing plates of the horizontal reciprocate mobile device, and the end part of each mounting rack is provided with one laser inspection head. Each laser inspection head rotates within the range smaller than 90 degrees by the rotating drive part connected with the laser inspection head along the locating shafts arranged at the end parts of the mounting racks.

Owner:MESNAC +1

Body turning-over mechanism of nursing bed

ActiveCN105476775ATurn over coordinationPowerful turning overNursing bedsMedical transportButtocksUniversal joint

The invention provides a body turning-over mechanism of a nursing bed. The body turning-over mechanism of the nursing bed comprises a back turning-over mechanism, a buttock turning-over mechanism and a transmission mechanism. The back turning-over mechanism and the buttock turning-over mechanism are both fixedly connected with the transmission mechanism. The position, connected with the buttock turning-over mechanism, of the transmission mechanism is provided with a universal joint which is fixedly connected with the transmission mechanism. The back and the buttocks are turned over synchronously, the body turning-over action is harmonious, the body turning-over power is large, the body can be turned over at an angle by means of the body turning-over mechanism of the nursing bed, and therefore a patient can be more comfortable when turning over the body.

Owner:FUER INTELLIGENT TECH NANTONG CO LTD

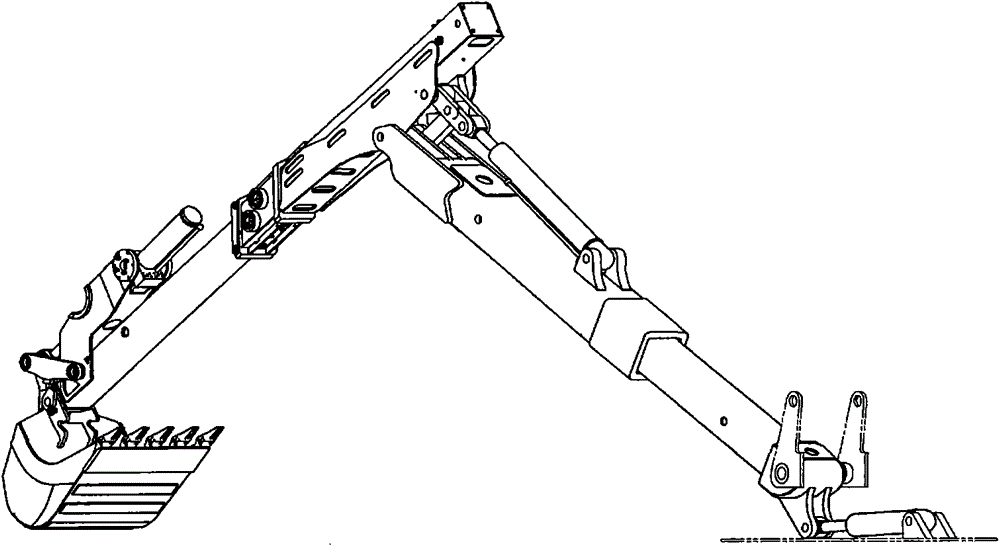

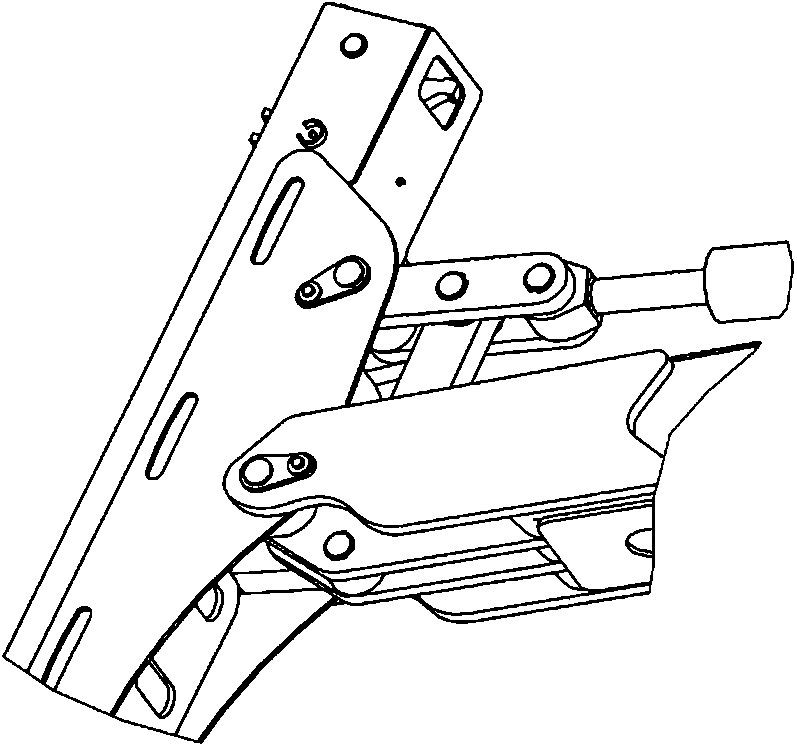

Novel working device and excavator

ActiveCN103603386AExpand the scope of workIncrease the rotation angleMechanical machines/dredgersWorking rangeEngineering

The invention belongs to the field of excavator technology and particularly discloses a working device and an excavator. A telescopic bucket rod and a telescopic moving arm in the working device greatly improve the working range of the working device. A four-connecting-rod mechanism greatly improves the rotatable angle of the bucket rod and the working range of the whole working device. A moving arm oil cylinder is placed in a platform and enables the bucket rod to be possibly restored to the lower surface of the moving arm at a large angle, thus, the restoration angle and the restoration range of the working device are improved, and the condition that an operation machine tool scrapes the moving arm oil cylinder in the restoration state of the bucket rod is avoided. The excavator has the large-range operation capacity which a small excavator does not have, has the characteristics, of being light in weight, small in size and flexible, which a large excavator does not have, and is especially suitable for large-area operation by the small excavator or superlarge-area operation occasions of the large excavator. Meanwhile, when the working device is in a completely restored state, the excavator is small in size, light in weight, low in transportation and driving height, and small in rotary radius, and can be driven and transferred easily.

Owner:XCMG CONSTR MACHINERY

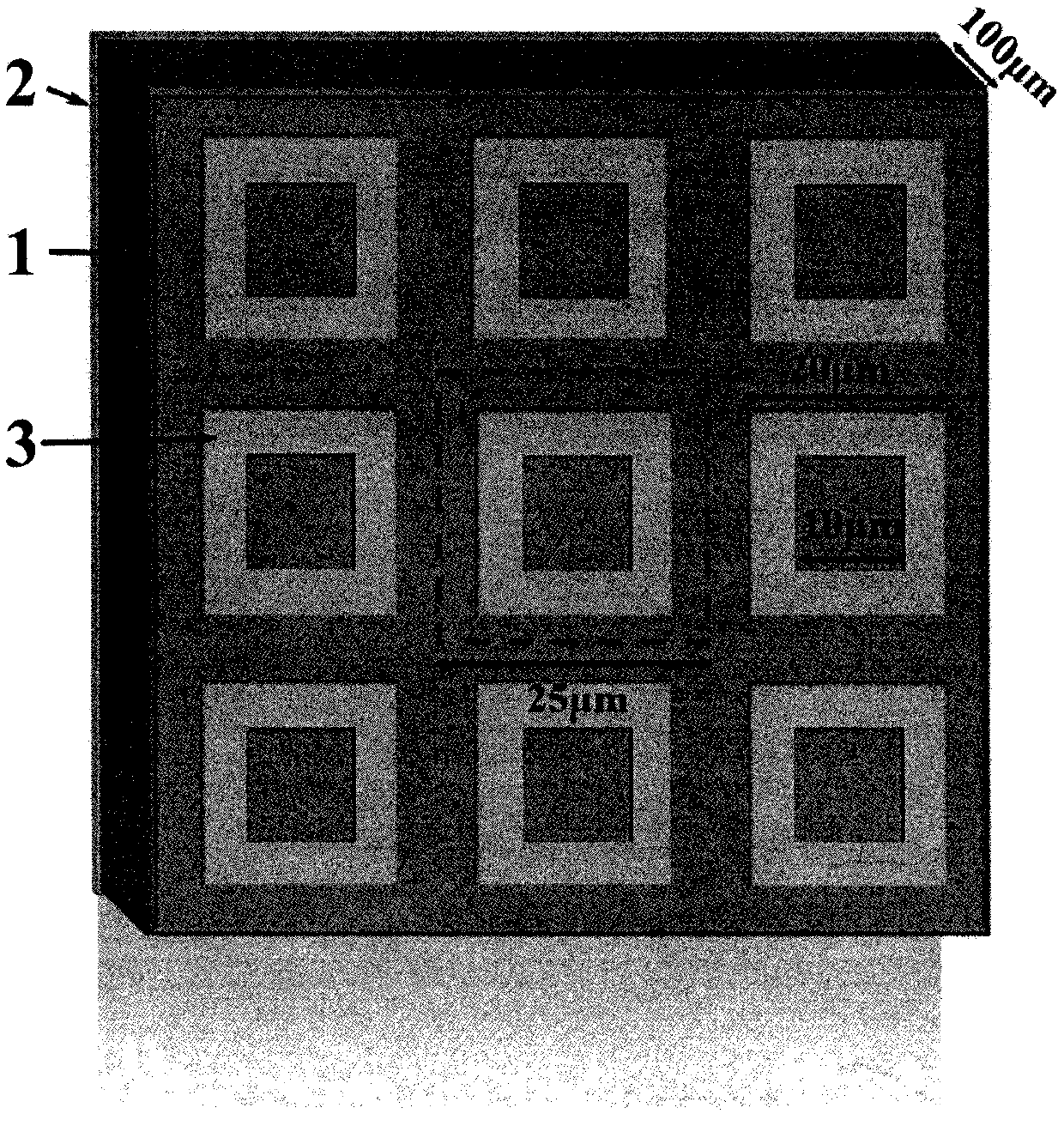

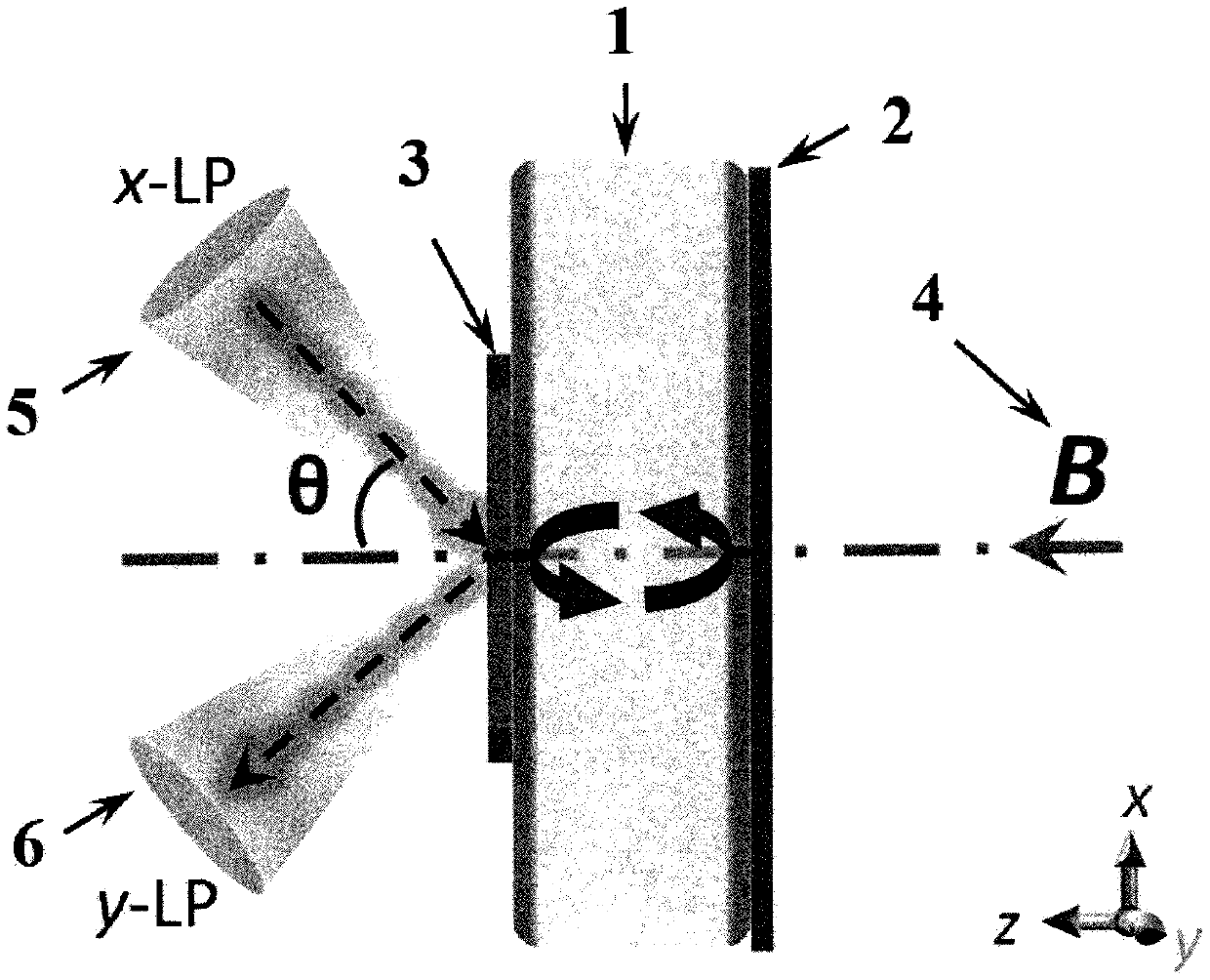

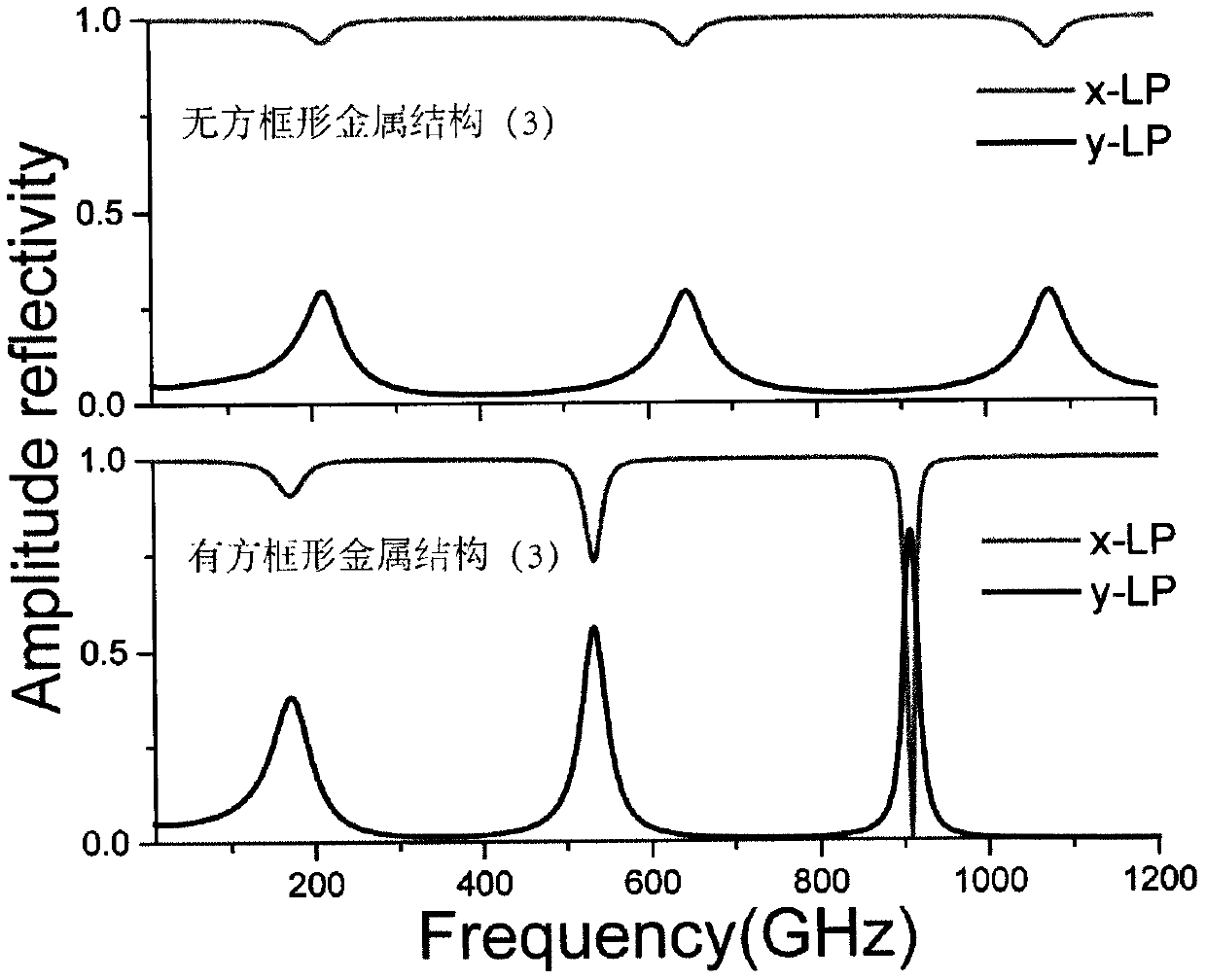

Terahertz metasurface magneto-optical Kerr polarization converter

InactiveCN110058431AEnhance the optical rotation effectImprove transmittance and linear polarization conversion rateNon-linear opticsOptical elementsLinear polarizationNuclear magnetic resonance

The invention discloses a terahertz metasurface magneto-optical Kerr polarization converter. Metal reflection back plates and square metal metasurface structures are attached on two sides of a YIG ferrite to form a fabry-perot cavity microcavity structure, so that incident terahertz wave generates resonance in the cavity, and a magneto-optical Kerr effect of the YIG ferrite (1) is greatly improved; compared with the structure without the metal metasurface, the optical rotation angle and the polarization conversion rate of the terahertz wave are increased. The terahertz metasurface magneto-optical Kerr polarization converter is capable of rotating the polarization state of original linear polarization to a certain angle; a function of converting orhtogonal linear polarization is achieved when the magnetization intensity reaches 4000Gs; an obvious frequency spectrum with a high Q value and high transmittance is shown; the maximum transmittance and polarization conversion rate are greaterthan 80%; and the Q value is greater than 70.

Owner:NANKAI UNIV

Actuator, optical scanner, and image forming apparatus

ActiveUS20080068688A1Increase deflection anglePromoting power-savingDynamo-electric machinesElectromagnets with armaturesOptical scannersImage formation

An actuator includes a frame-shaped first mass portion; a supporting portion that supports the first mass portion and takes the shape of a frame so as to surround a perimeter of the first mass portion; a pair of first elastic portions coupling between the first mass portion and the supporting portion so that the first mass portion is supported by the supporting portion; a second mass portion provided inside the frame-shaped first mass portion; a pair of second elastic portions coupling between the second mass portion and the first mass portion so that the second mass portion is supported by the first mass portion; and a driver for rotating the first mass portion. The driver includes a ferromagnet provided on the first mass portion in a position separate from a rotation central axis of the first mass portion; a coil formed along the rotation central axis of the first mass portion and the supporting portion so as to surround and orbit a perimeter of the ferromagnet if the first mass portion is seen from above; and a voltage application unit for applying a voltage to the coil. An operation of the voltage application unit included in the driver causes the coil to generate a magnetic field. The generation of the magnetic field causes displacement of the ferromagnet relative to the coil. The displacement of the ferromagnet causes the first mass portion to rotate while torsionally deforming the pair of first elastic portions. The rotation of the first mass portion causes the second mass portion to rotate while torsionally deforming the pair of second elastic portions.

Owner:SEIKO EPSON CORP

Rotation angle using orthogonal magnetic sensing elements in close proximity to each other

InactiveUS7560919B2Accurate detectionIncrease the rotation angleMagnetic-field-controlled resistorsSolid-state devicesHall elementAtomic physics

A rotation angle detecting device that detects a rotation angle of a rotating object includes a permanent magnet that generates magnetic fields in response to rotation of the rotating object, a magnetic sensor, a first yoke and a second yoke. The magnetic sensor includes a pair of close integrated magnetic sensing elements, such as hall elements, disposed at a position around the permanent magnet so that one of the sensing elements senses magnetic field at a phase different from the other. The first yoke and the second yoke forms two magnetic paths crossing each other at the magnetic sensor.

Owner:DENSO CORP +1

Continuous-rotation high-angular position accuracy digital motor

ActiveCN105846610AHigh precisionIncrease torqueAssociation with control/drive circuitsMechanical energy handlingControl signalEngineering

The invention relates to a continuous-rotation high-angular position accuracy digital motor. The continuous-rotation high-angular position accuracy digital motor includes a driving motor, a harmonic reducer, a magnetic encoder, a servo driving controller and a shell; the stator of the driving motor, the magnetic encoder and the servo driving controller are fixed on the shell; the first output end of the rotor of the driving motor is connected with one end of the harmonic reducer through screw threads; the other end of the harmonic reducer is the torque output end of the driving motor; magnets of the magnetic encoder are fixed to the second output end of the rotor of the driving motor; the input end of the servo driving controller is connected with the output end of the magnetic encoder; the output end of the servo driving controller is connected with external connection control signals; and the power supply end of the servo driving controller is connected with the input end of the driving motor. The rotation precision, rotation angle and output torque of the continuous-rotation high-angular position accuracy digital motor are higher than those of a general servo. The continuous-rotation high-angular position accuracy digital motor has the advantages of low cost, high precision and high output torque.

Owner:SHENYANG AIKESHEN ROBOT TECH DEV

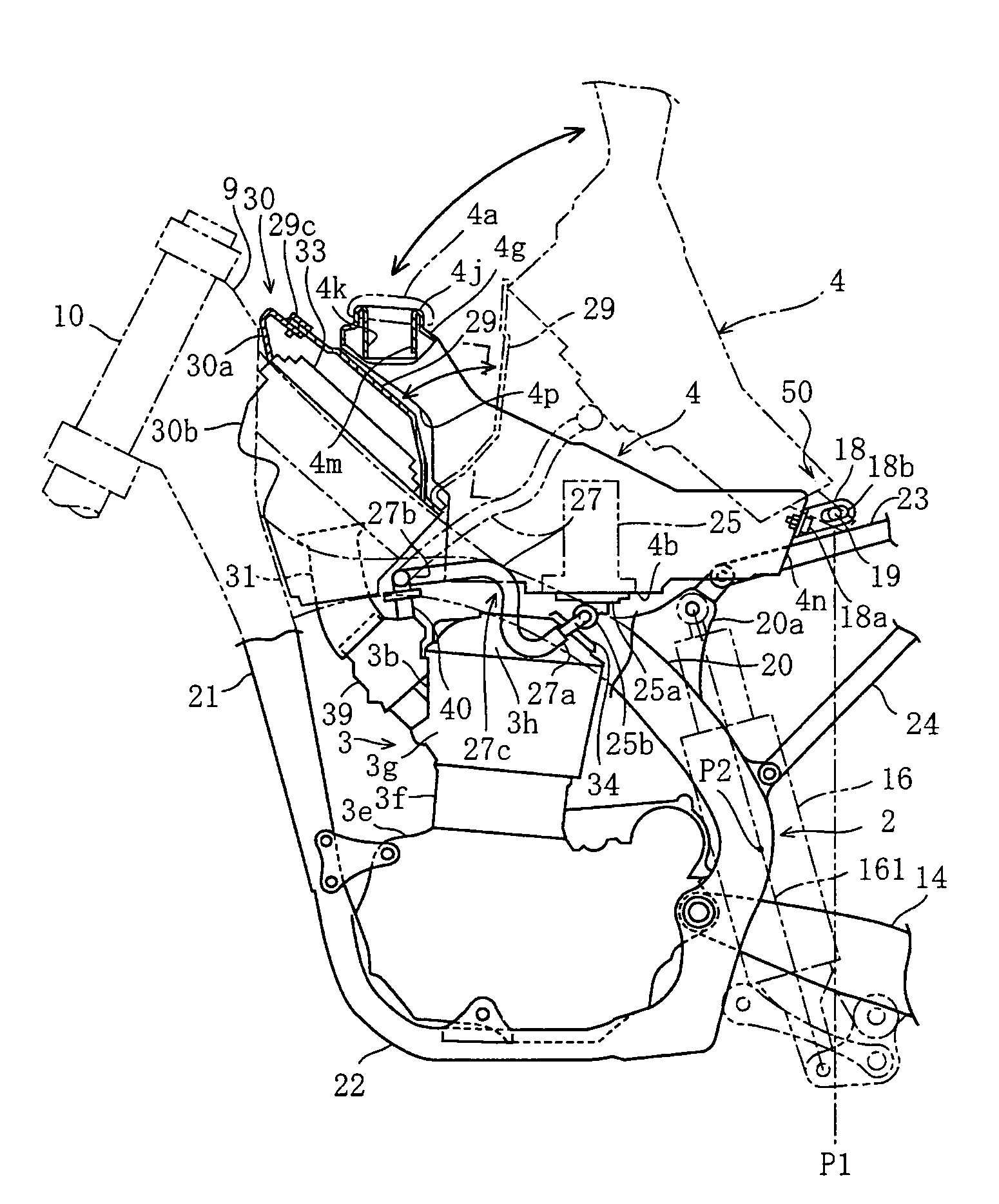

Vehicle with rotatable fuel tank

InactiveUS8662518B2Easy maintenanceFacilitate of regionTank vehiclesAxle suspensionsCushioningFuel tank

A vehicle, such as a motorcycle, can facilitate maintenance of an air cleaner without complicating a peripheral structure of a fuel tank. The vehicle can include a body frame, a rear arm attached to the body frame to support a rear wheel, a rear cushioning member provided between the body frame and the rear arm, and an engine fixed to the body frame. The vehicle can further include a fuel tank supported rotatably at a supporter arranged closer to a rear side of the vehicle than a substantially central position of an axis of the rear cushioning member.

Owner:YAMAHA MOTOR CO LTD

Rotating mechanism for an electronic device and an electronic device with the same

InactiveUS8250709B2Increase the rotation angleVarious usagesManual control with multiple controlled membersWing fastenersEngineeringElectron device

Owner:KYE SYST CORP

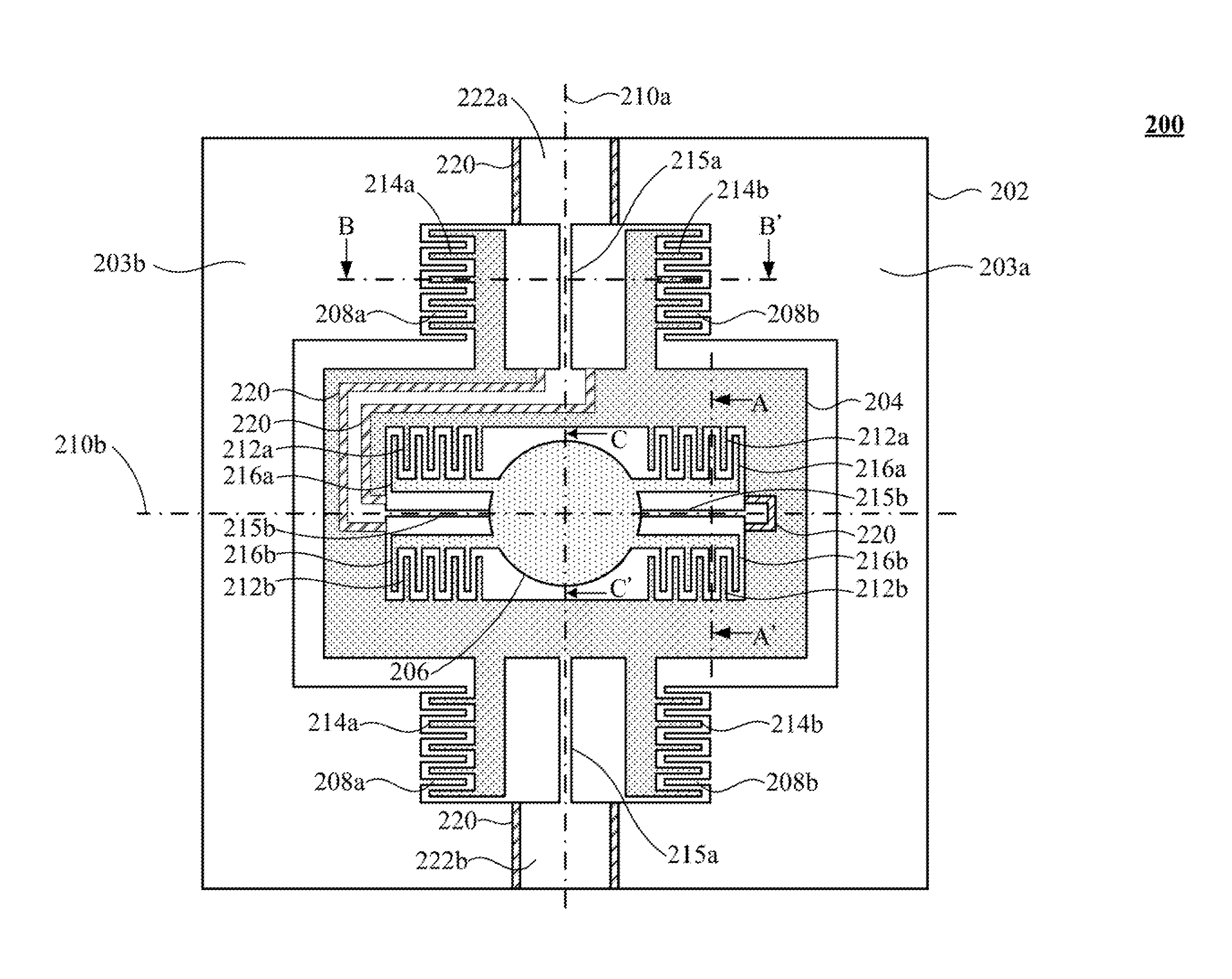

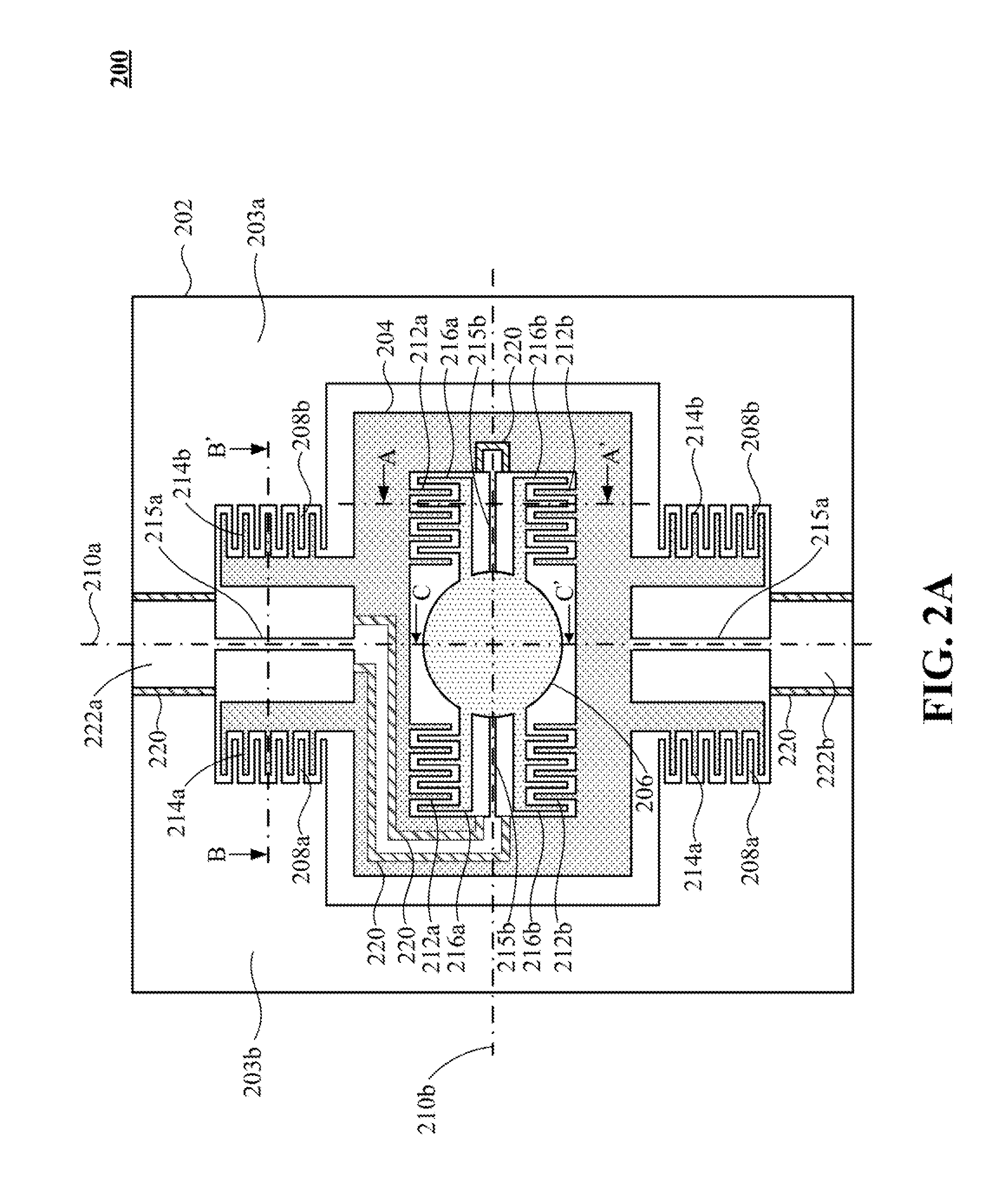

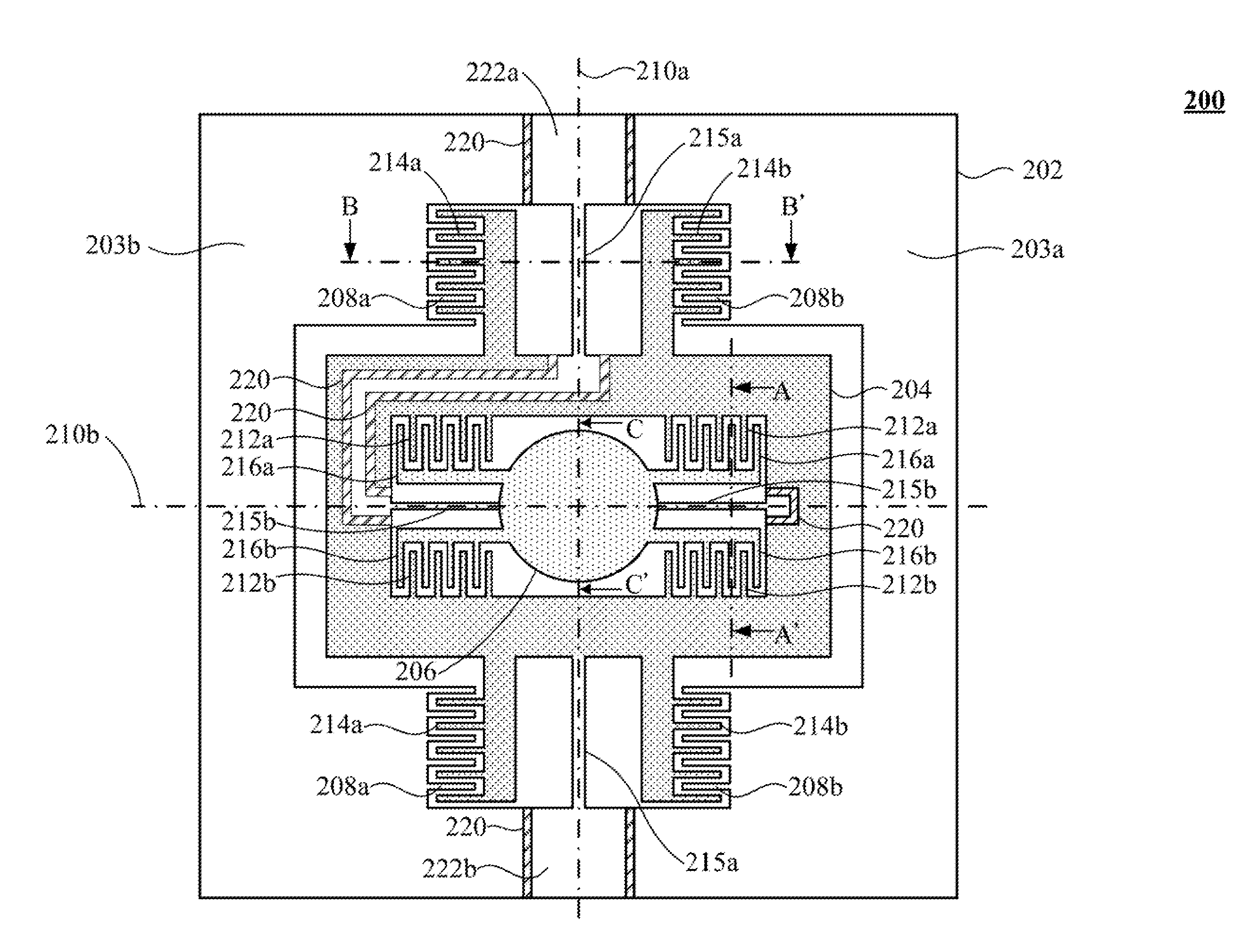

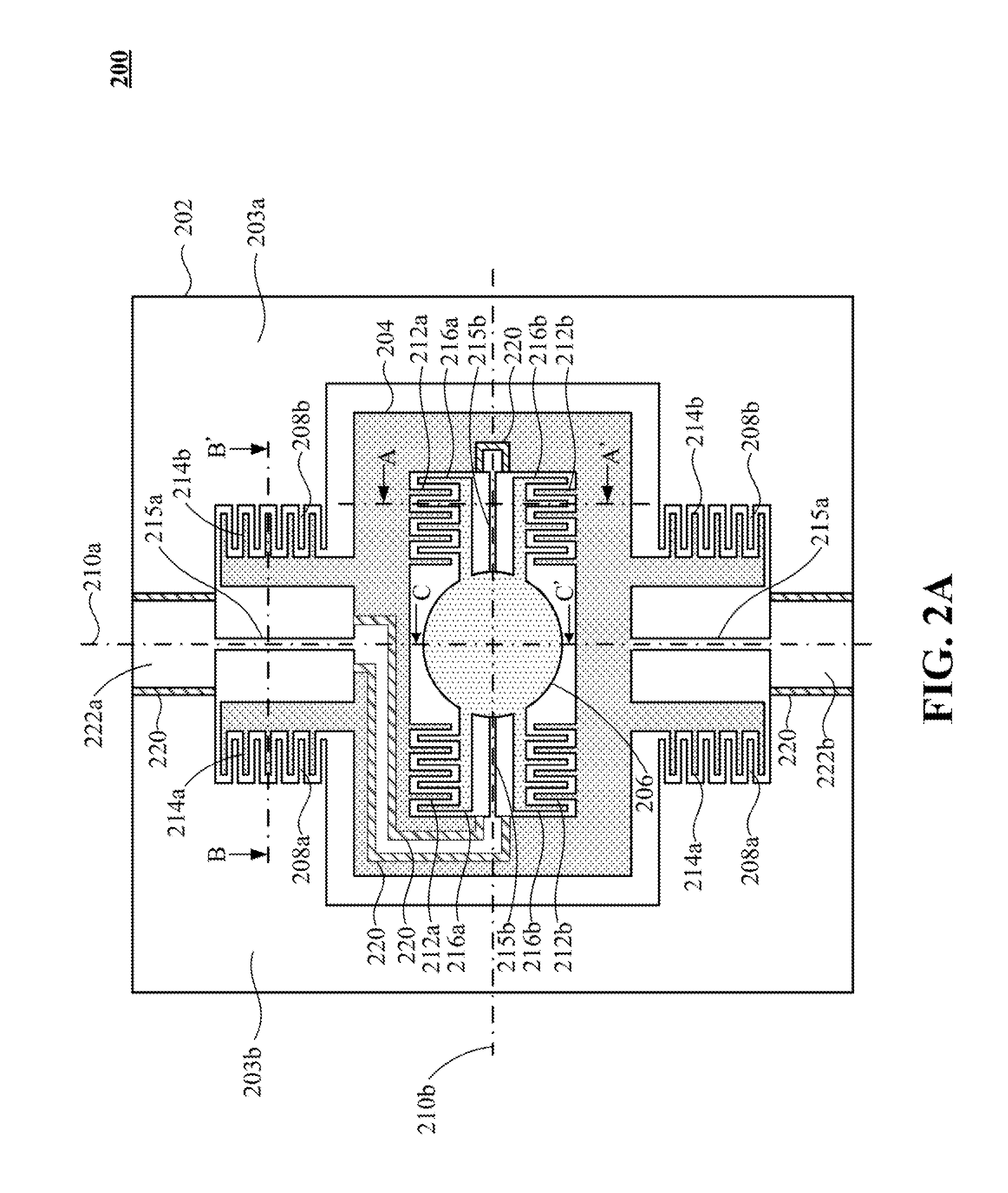

Two-dimensional comb-drive actuator and manufacturing method thereof

ActiveUS8816565B2Increase overlap areaIncrease the rotation angleSemiconductor/solid-state device manufacturingPropulsion systemsEngineeringActuator

A two-dimensional comb-drive actuator and manufacturing method thereof are described. The two-dimensional comb-drive actuator includes a supporting base, a frame and a movable body. The supporting base has first comb electrodes and the frame has internal comb electrodes and external comb electrodes. The external comb electrodes of the frame are interdigitated to the first comb electrodes of the supporting base. The movable body has second comb electrodes which are interdigitated to the internal comb electrodes of the frame. The thicknesses of the second comb electrodes of the movable body are unequal to the internal comb electrodes of the frame and the external comb electrodes of the frame are unequal to the first comb electrodes of the supporting base. The two-dimensional comb-drive actuator utilizes a conducting layer for the above-mentioned comb electrodes in order to increase the rotation angle and operation frequency thereof.

Owner:AURISE INVESTMENT CO LTD

Two-dimensional comb-drive actuator and manufacturing method thereof

ActiveUS20110309717A1Increase overlap areaIncrease the rotation angleSemiconductor/solid-state device manufacturingElectrostatic motorsEngineeringActuator

A two-dimensional comb-drive actuator and manufacturing method thereof are described. The two-dimensional comb-drive actuator includes a supporting base, a frame and a movable body. The supporting base has first comb electrodes and the frame has internal comb electrodes and external comb electrodes. The external comb electrodes of the frame are interdigitated to the first comb electrodes of the supporting base. The movable body has second comb electrodes which are interdigitated to the internal comb electrodes of the frame. The thicknesses of the second comb electrodes of the movable body are unequal to the internal comb electrodes of the frame and the external comb electrodes of the frame are unequal to the first comb electrodes of the supporting base. The two-dimensional comb-drive actuator utilizes a conducting layer for the above-mentioned comb electrodes in order to increase the rotation angle and operation frequency thereof.

Owner:AURISE INVESTMENT CO LTD

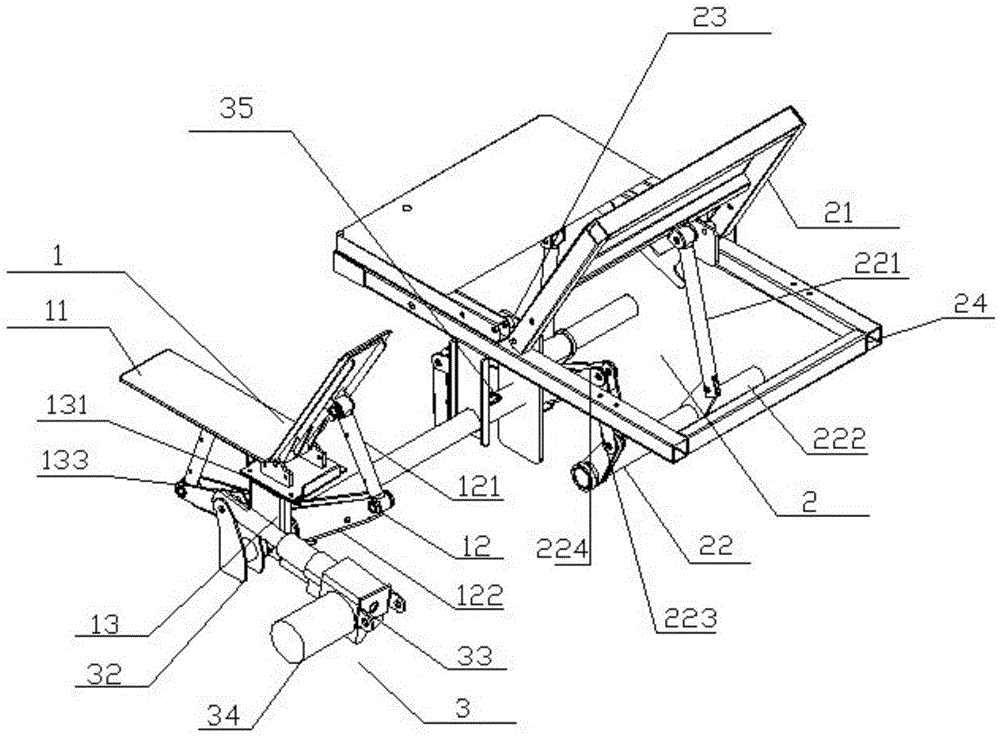

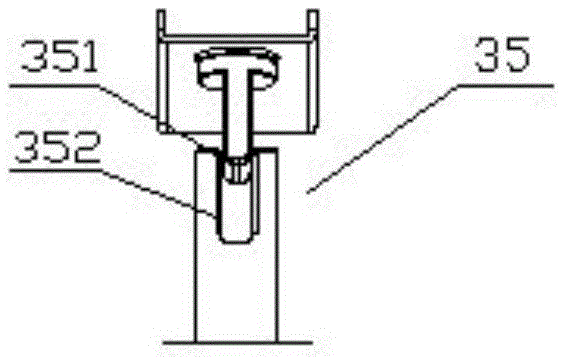

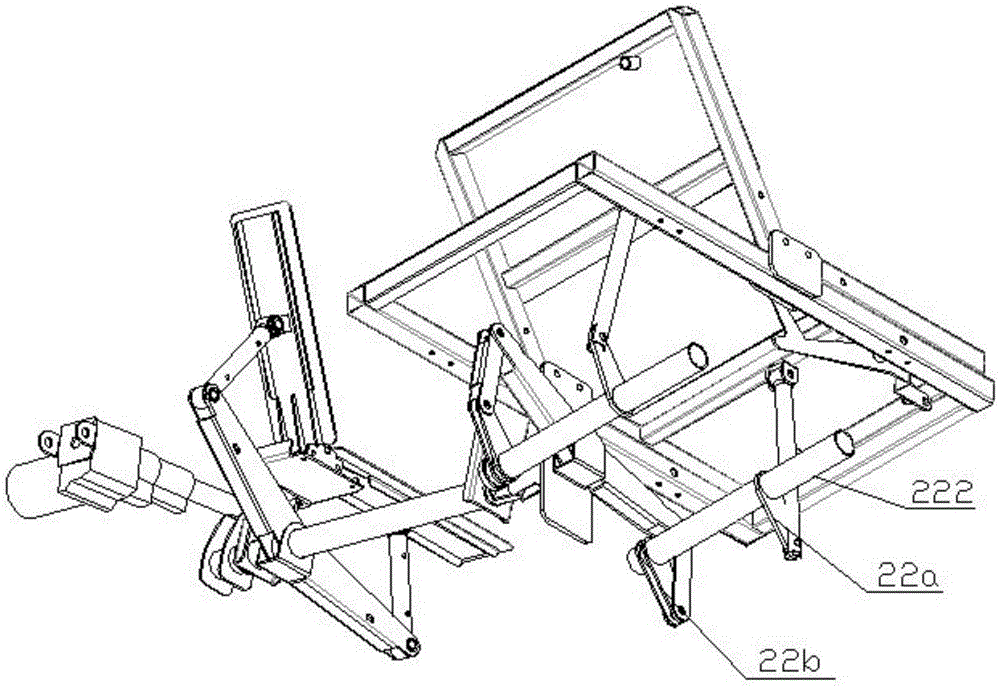

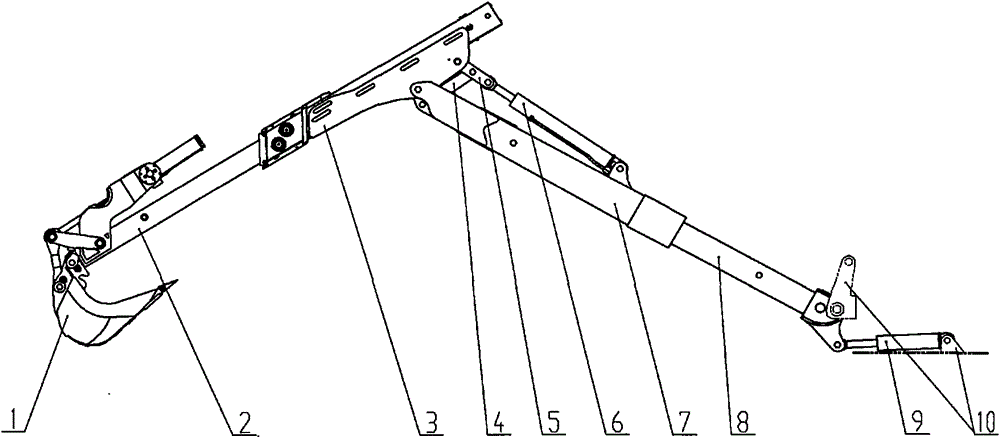

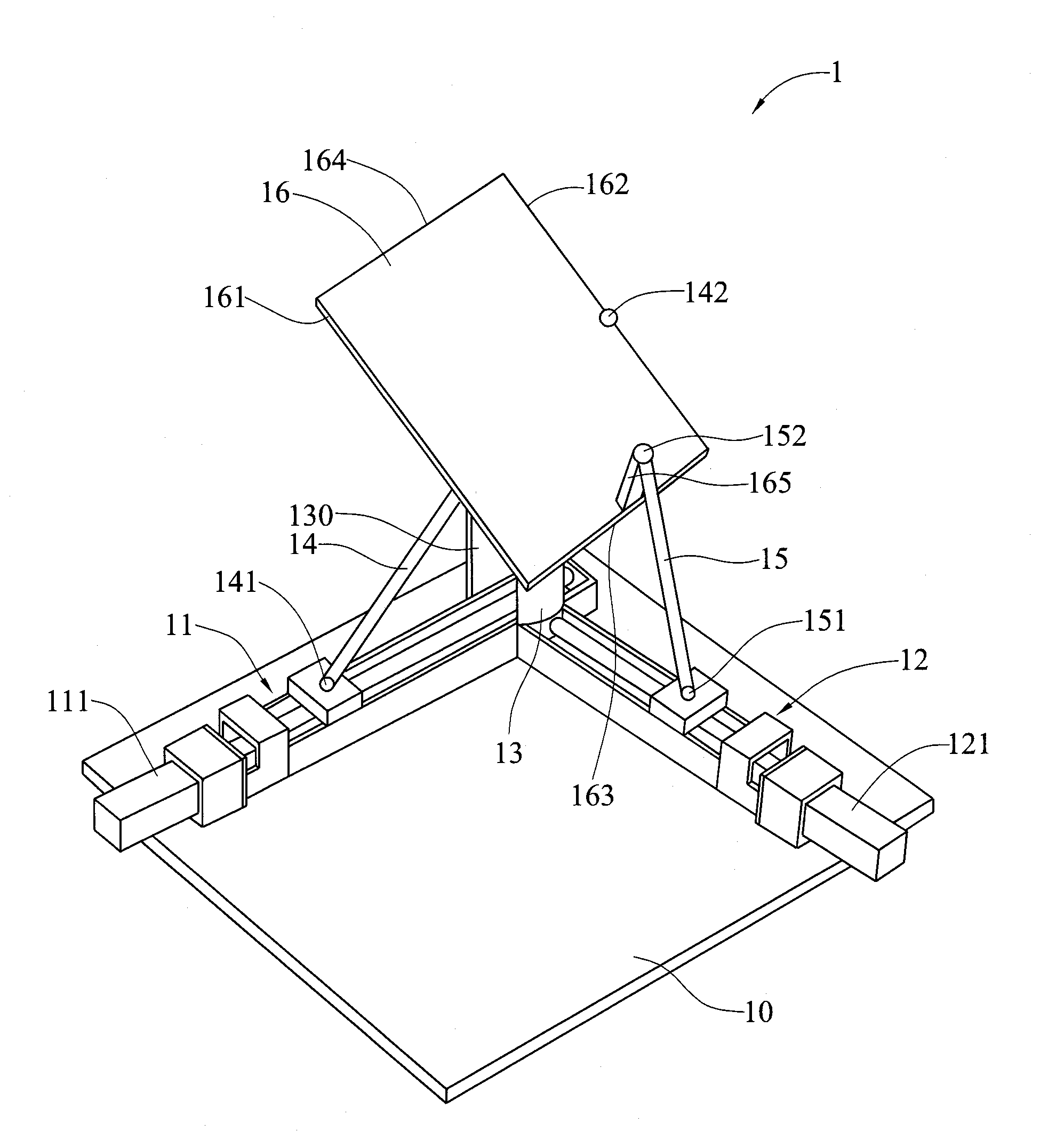

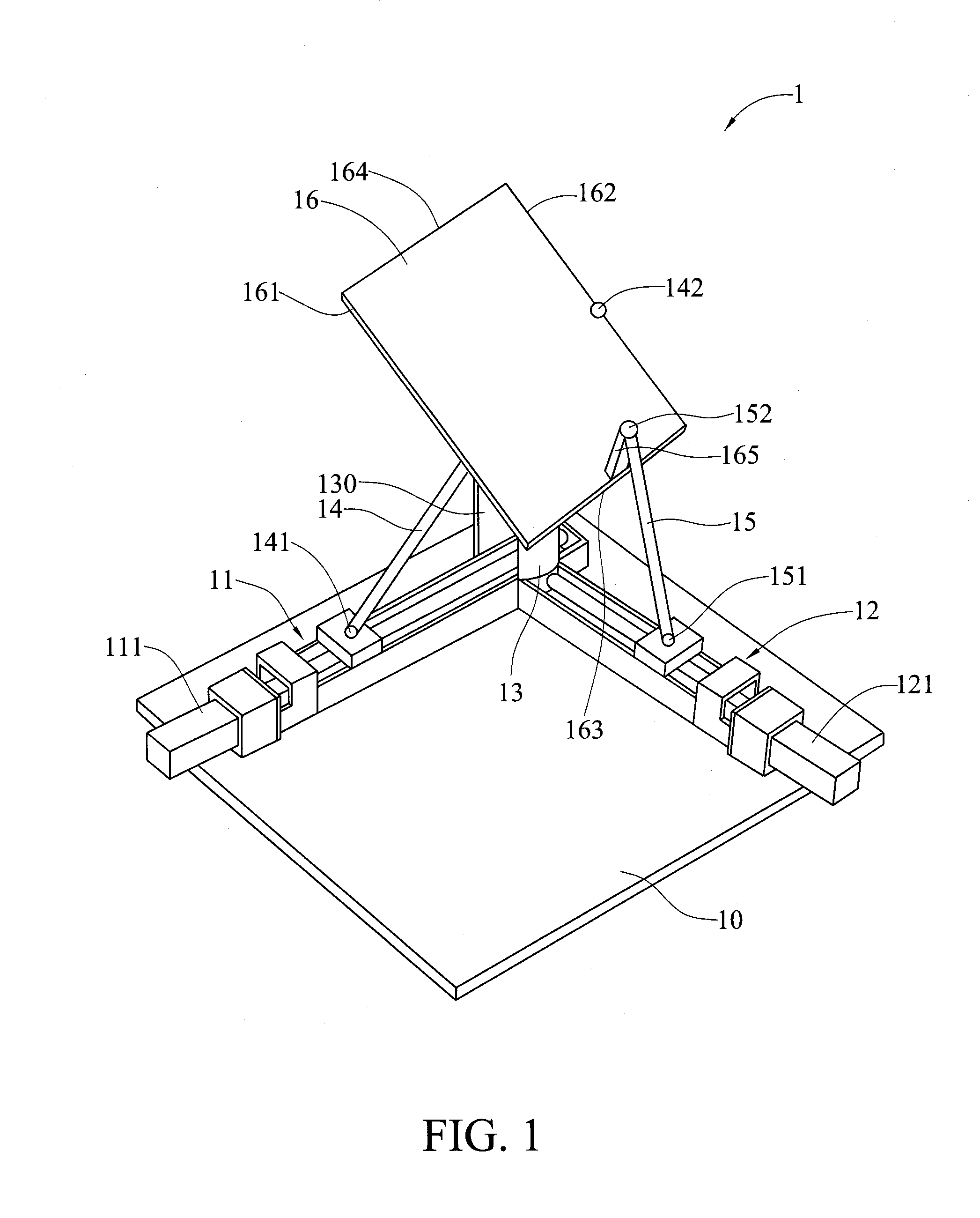

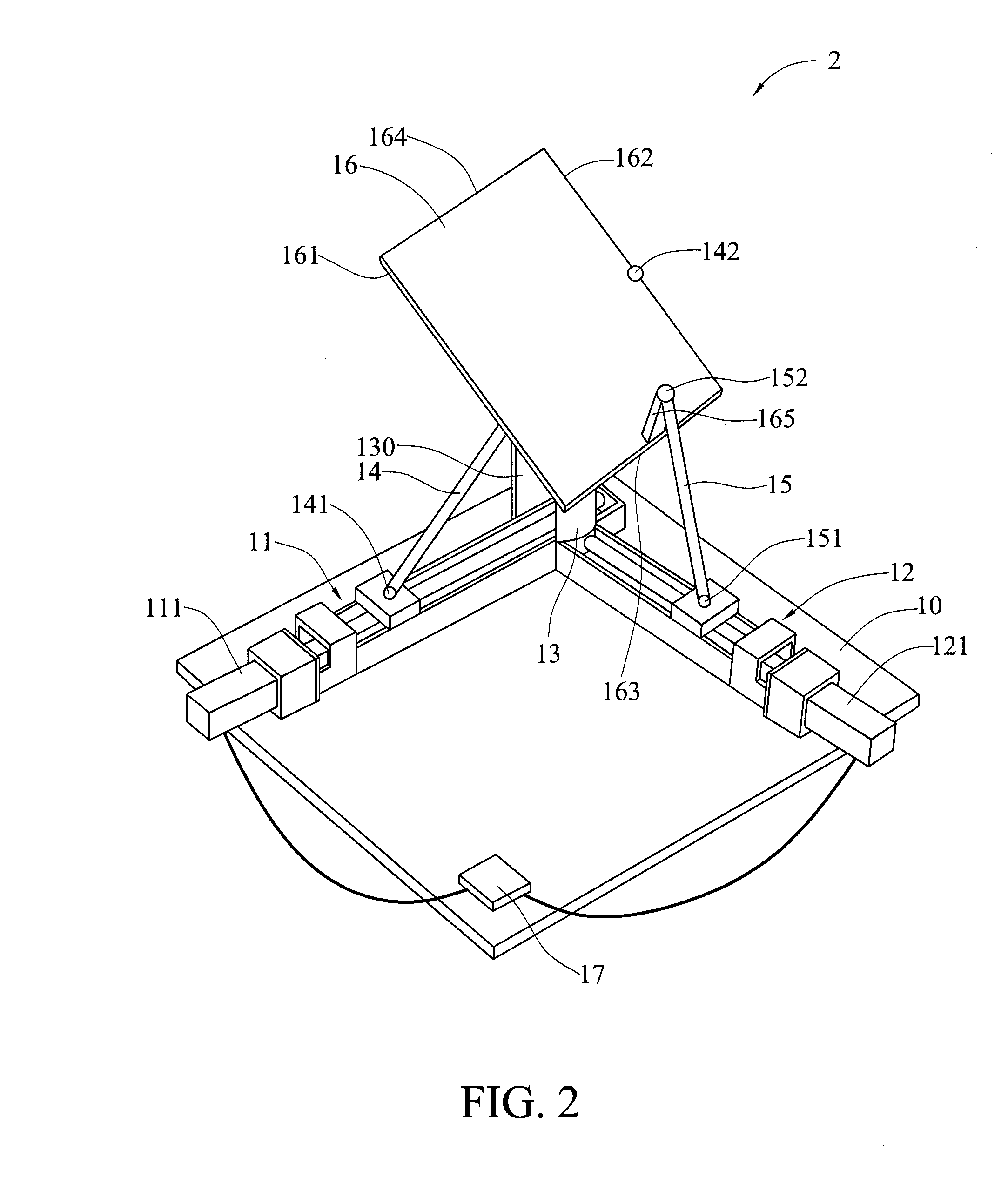

Sun-chasing device

ActiveUS20130306829A1Improve rigidityHigh carrying abilitySolar heating energySolar heat collector controllersComputer moduleTransmitter

A sun-chasing device is provided, including a base, a first transmitter disposed on the base, a second transmitter, a support, a carrier pivotally connected to the support for carrying a solar module, a first supporting component pivotally connected to the first transmitter and the carrier, and a second supporting component pivotally connected to the second transmitter and the carrier. The sun-chasing device has great rigidity and carrying ability against strong wind, and has great precision and rotation angle, such that a solar plate can precisely aim at sun for long time and thus the efficiency of a solar module is significantly increased.

Owner:NAT CHIAO TUNG UNIV

Rotation angle detecting device

InactiveUS20070069719A1Accurate detectionIncrease the rotation angleMagnetic-field-controlled resistorsSolid-state devicesNuclear magnetic resonanceHall element

A rotation angle detecting device that detects a rotation angle of a rotating object includes a permanent magnet that generates magnetic fields in response to rotation of the rotating object, a magnetic sensor, a first yoke and a second yoke. The magnetic sensor includes a pair of close integrated magnetic sensing elements, such as hall elements, disposed at a position around the permanent magnet so that one of the sensing elements senses magnetic field at a phase different from the other. The first yoke and the second yoke forms two magnetic paths crossing each other at the magnetic sensor.

Owner:DENSO CORP +1

Series-parallel hybrid robot leg configuration, walking robot and motion method thereof

The invention discloses a series-parallel hybrid robot leg configuration, a walking robot and a motion method thereof, and belongs to the field of robots. The series-parallel hybrid robot leg configuration includes a static platform, a movable platform and a serial-parallel hybrid mechanism; the movable platform includes legs and feet; the legs and the feet are connected through first rotating pairs; first rotating drivers are disposed on the first rotating pairs; the serial-parallel hybrid mechanism includes an active driving branch and two driven driving branches; the active driving branch includes a second rotating driver, a first connecting rod, and a second connecting rod which are successively connected through rotating pairs; the second rotating driver is vertically arranged on oneend of the static platform; a third rotating driver and a fourth rotating driver are arranged on a second rotating pair and a third rotating pair respectively. The series-parallel hybrid robot leg configuration has large movement space, small rotation moment of inertia, flexible movement of the leg mechanisms, can prevent interference, and can realize basic functions such as advancement, turning,obstacle avoidance of the robot, and is suitable for underwater work.

Owner:SHANDONG UNIV

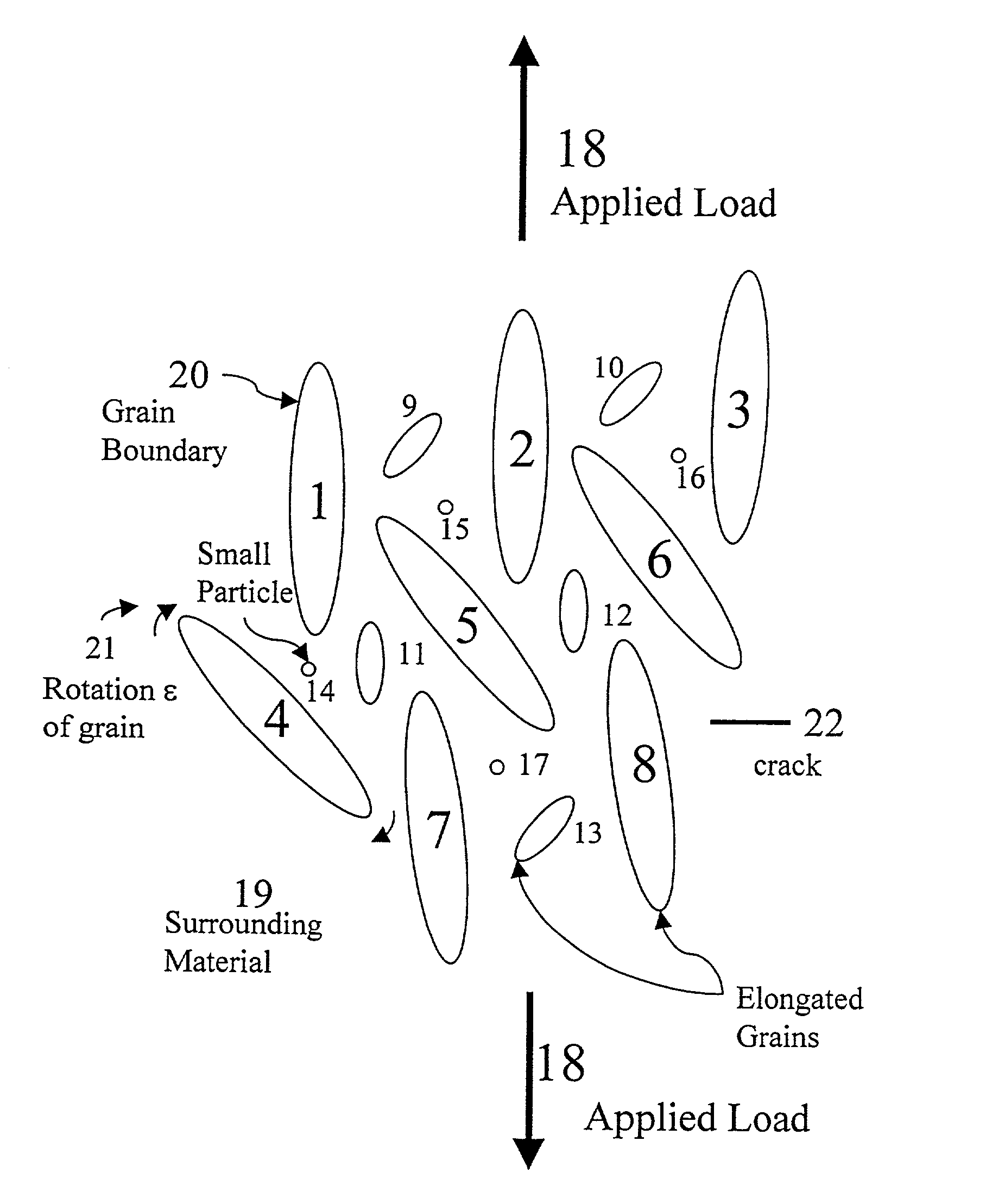

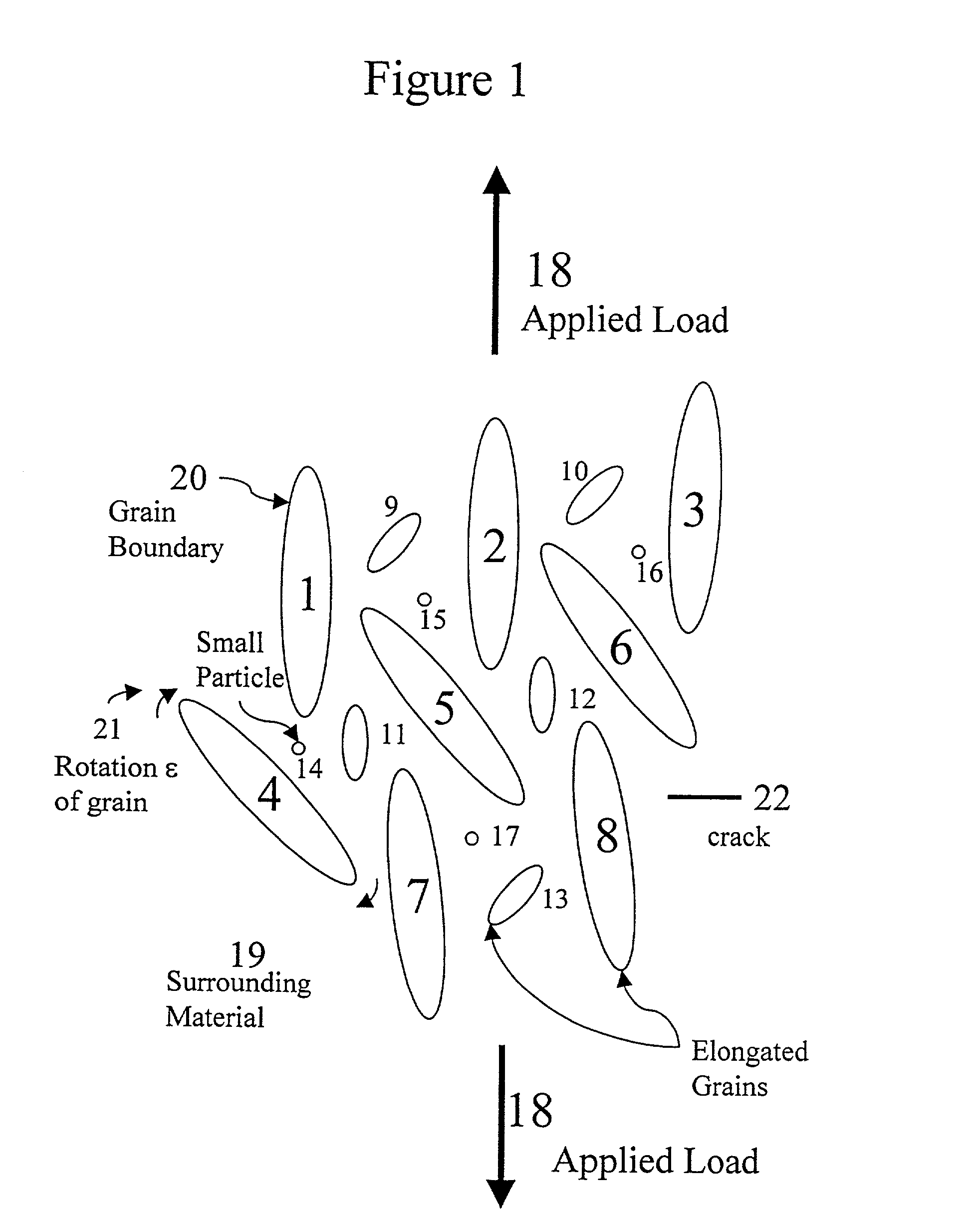

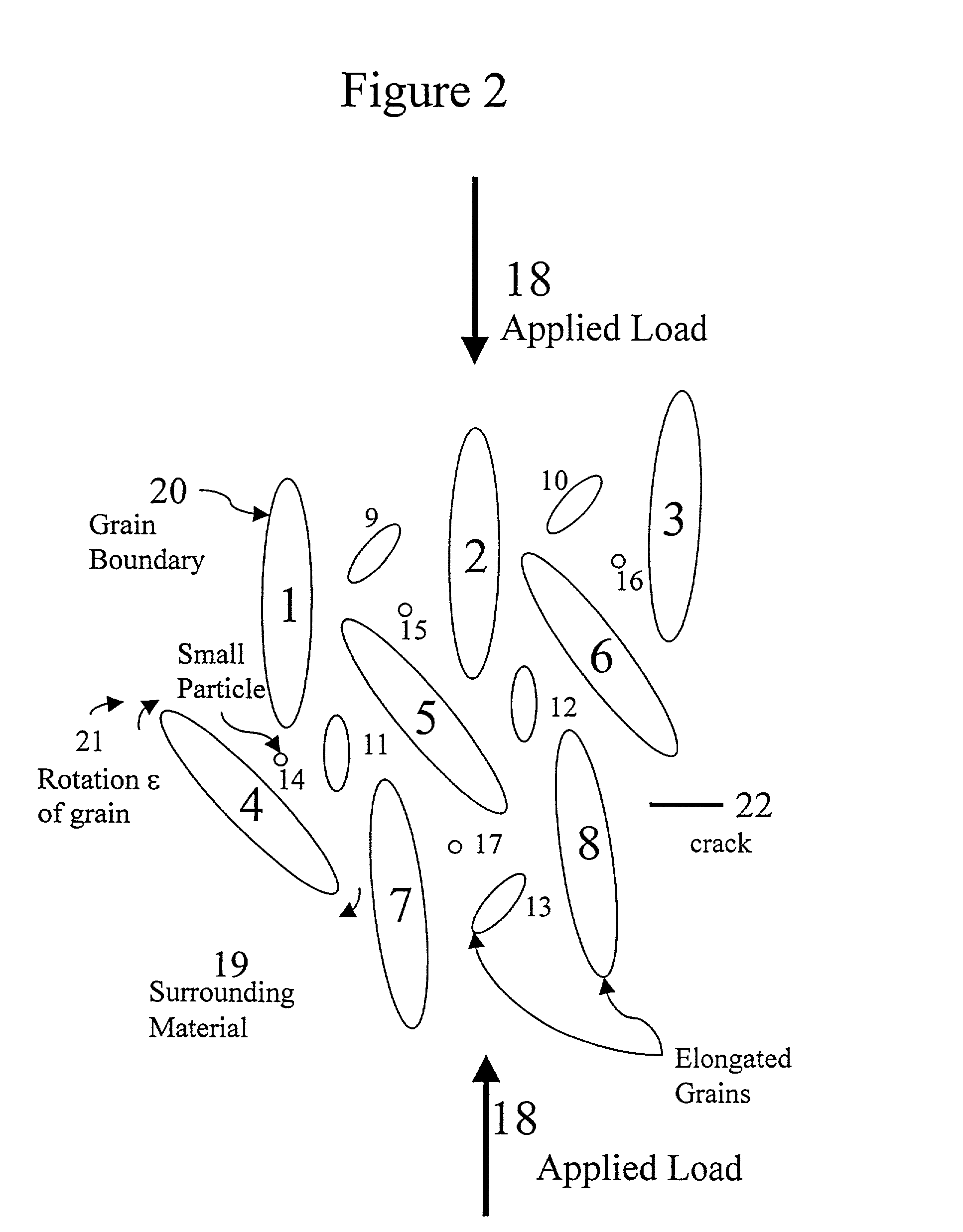

Microstructure containing entities rotating under an applied load to enhance toughening against fracture

InactiveUS6983226B2Reduce strain energy promoting fractureReduce strainForce measurementWork measurementStress inducedUltrasound attenuation

A composite material having a microstructure model is provided with a continuous matrix of microstructure entities such as particles and grains that rotate under both remotely applied stresses and induced concentrated stresses from nearby cracks, pores and smaller particles, all networked within the matrix. The rotation microstructure entities are smooth closed contours that are elliptically-shaped. A net moment results on the boundaries of the microstructure entities effecting fracture toughening of the material. Small particles and other microstructural entities may reduce the attenuation of, transmit, and counteract the stresses induced by the rotating microstructure entities. The induced stresses counteract those stresses and strain energy densities that promote crack propagation. The result is a microstructure free of laminates, coatings, fibers and fiber architectures that effect toughening of the material against fracture.

Owner:KENNEFICK CHRISTINE M

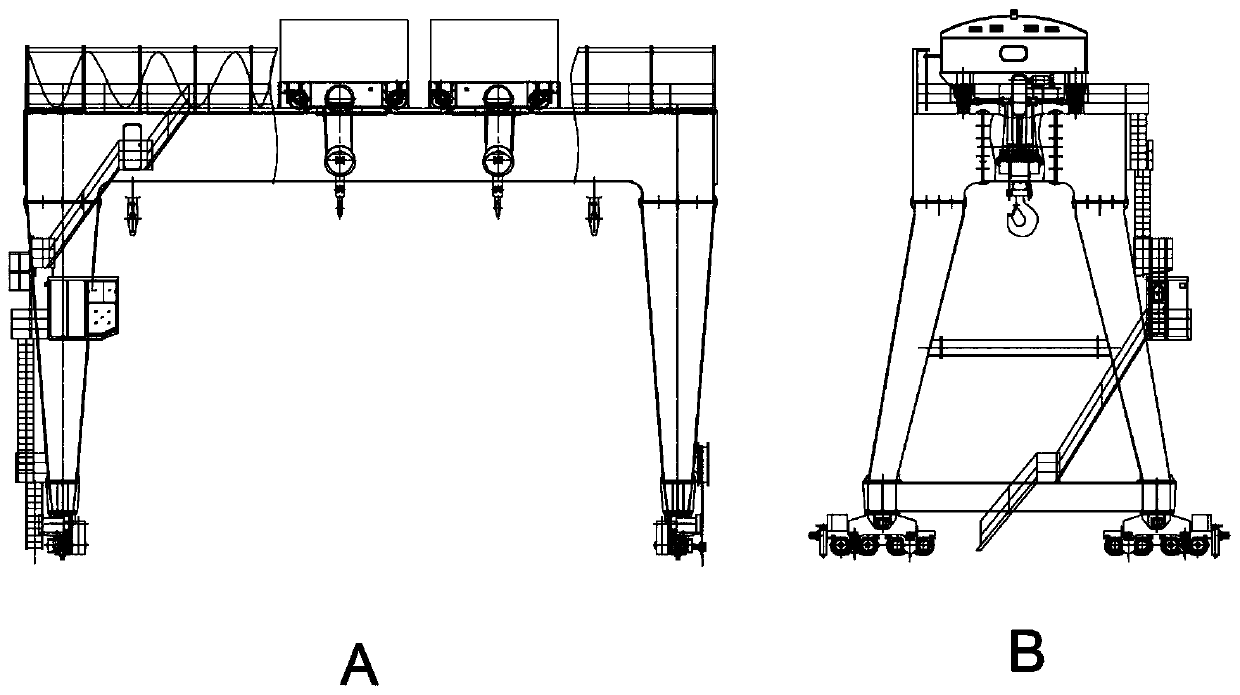

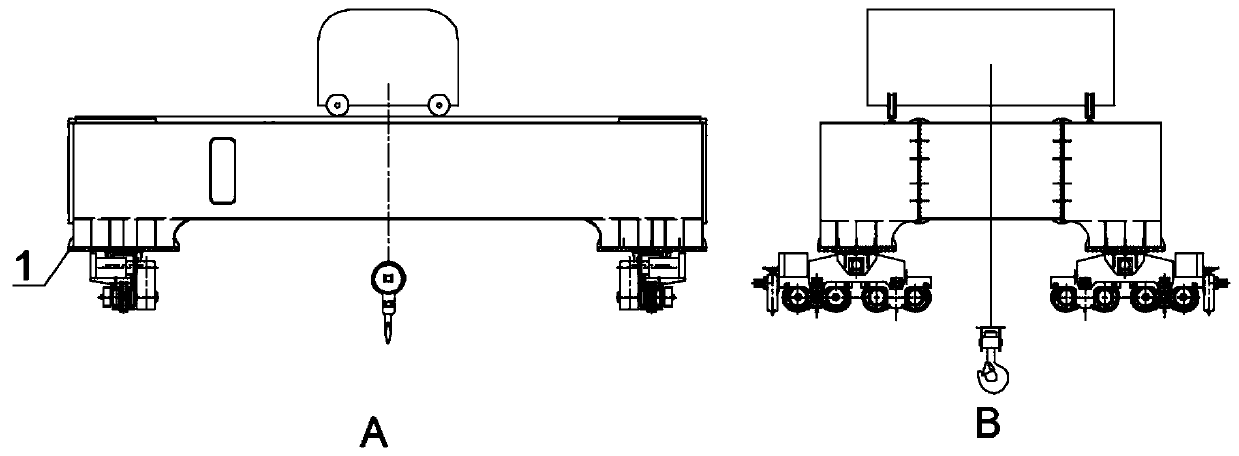

Implementation method for detaching TBM in tunnel

ActiveCN111472797AIncrease the rotation angleSmooth glidingTunnelsUnderground transportPower stationGeotechnical engineering

The invention discloses an implementation method for detaching a TBM in a tunnel. The implementation method comprises the following steps of arranging a detaching chamber; after TBM tunneling is finished, separating a TBM shield body and a rear supporting facility from a traction oil cylinder, and then making the TBM shield body and the rear supporting facility slide to the detaching chamber separately; making the shield body slide; making the rear supporting facility slide; laying a track II, then installing a winch, and utilizing the winch for enabling all sections of a trolley to slide on the tack; arranging an overhead crane at the top of the detaching chamber; after the shield body slides to the detaching chamber, utilizing the overhead crane for detaching a cutterhead, a main drive and a supporting jack of the shield body in sequence; and after the rear supporting facility slides to the detaching chamber, detaching equipment on the trolley, and disassembling the trolley. According to the implementation method for detaching the TBM in the tunnel, the TBM shield body and the rear supporting facility are separated from the traction oil cylinder and then slide to the detaching chamber separately, then dynamic electricity and cooling water are introduced, and a hydraulic power station of an advanced bore system is transformed to be connected with a high-pressure oil pipe of anoil cylinder in a tail shield to finish advancing of the shield body; and meanwhile, a rotatable wheel carrier is adopted so that the trolley can slide on an arc section.

Owner:SINOHYDRO BEREAU 10 CO LTD

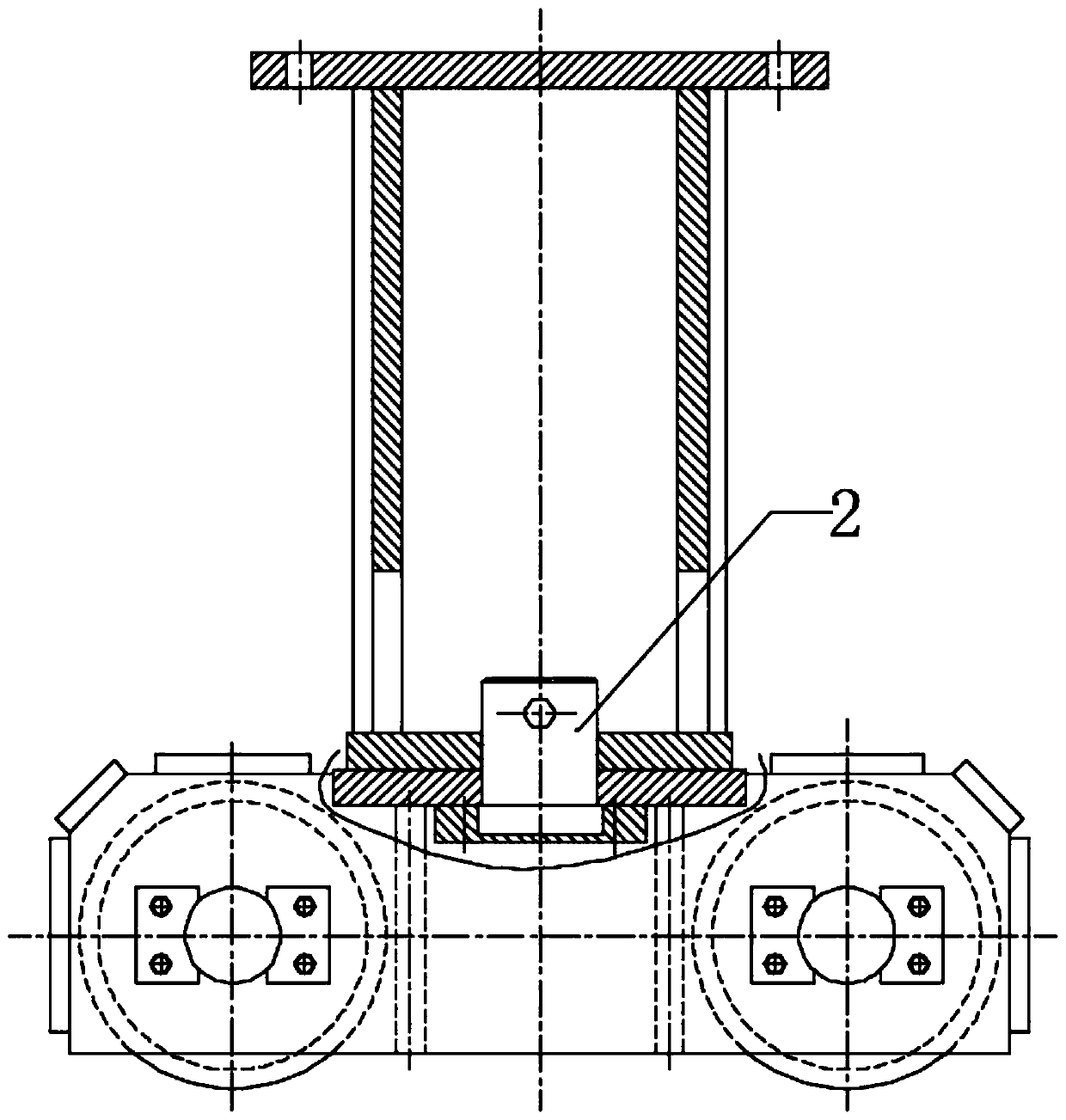

Spherical tire and driving device thereof

The invention discloses a spherical tire and its driving device, comprising a bracket and a first bearing, the first bearing is installed above the bracket, and a strut is arranged inside the first bearing, and the lower end of the bracket has Both sides are provided with a second bearing, the left side of the chute is provided with a top plate, the left end of the top plate is provided with a hinge, the top plate is connected with the bracket through the hinge, and the right side of the top plate is provided with a second spring A second spring is arranged inside the second spring groove, and a locking block is arranged at the right end of the second spring. The spherical tire and its driving device drive the rotating shaft to rotate through the motor, and the rotating shaft rotates around the second bearing, and the rotation of the rotating shaft drives the disc to rotate to avoid damage to the motor due to accidental impact. The motor can be effectively protected by installing the top plate The safety improves the service life, and the use of spherical wheels can make turns more convenient.

Owner:广州酷刻科技有限公司

User-friendly automatic page turning device

The invention provides a user-friendly automatic page turning device, and belongs to the field of daily articles. The user-friendly automatic page turning device is composed of a large plate, a small plate, a controller, a machine frame, a first servo motor, a first arm, a second servo motor, a second arm, a third servo motor, a third arm, a vacuum generator, a suction nozzle, a CCD camera, a first book-fixing clamping strip, a second book-fixing clamping strip, a hand-operated page turning button and a stop button. The user-friendly automatic page turning device has the beneficial effects that the machine vision technology is used for the device, facial features of a reader are collected through the CCD camera, the blinking action of eyes is recognized, the page turning action is achieved when the reader closes the eyes for 3 or more seconds, the design is quite user-friendly, the angle by which a motor needs to rotate during each time of action is calculated through the controller by directly and inversely calculating position parameters between different positions, and the action is smooth and reliable.

Owner:玉环览众科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com