Patents

Literature

117results about How to "Smooth gliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

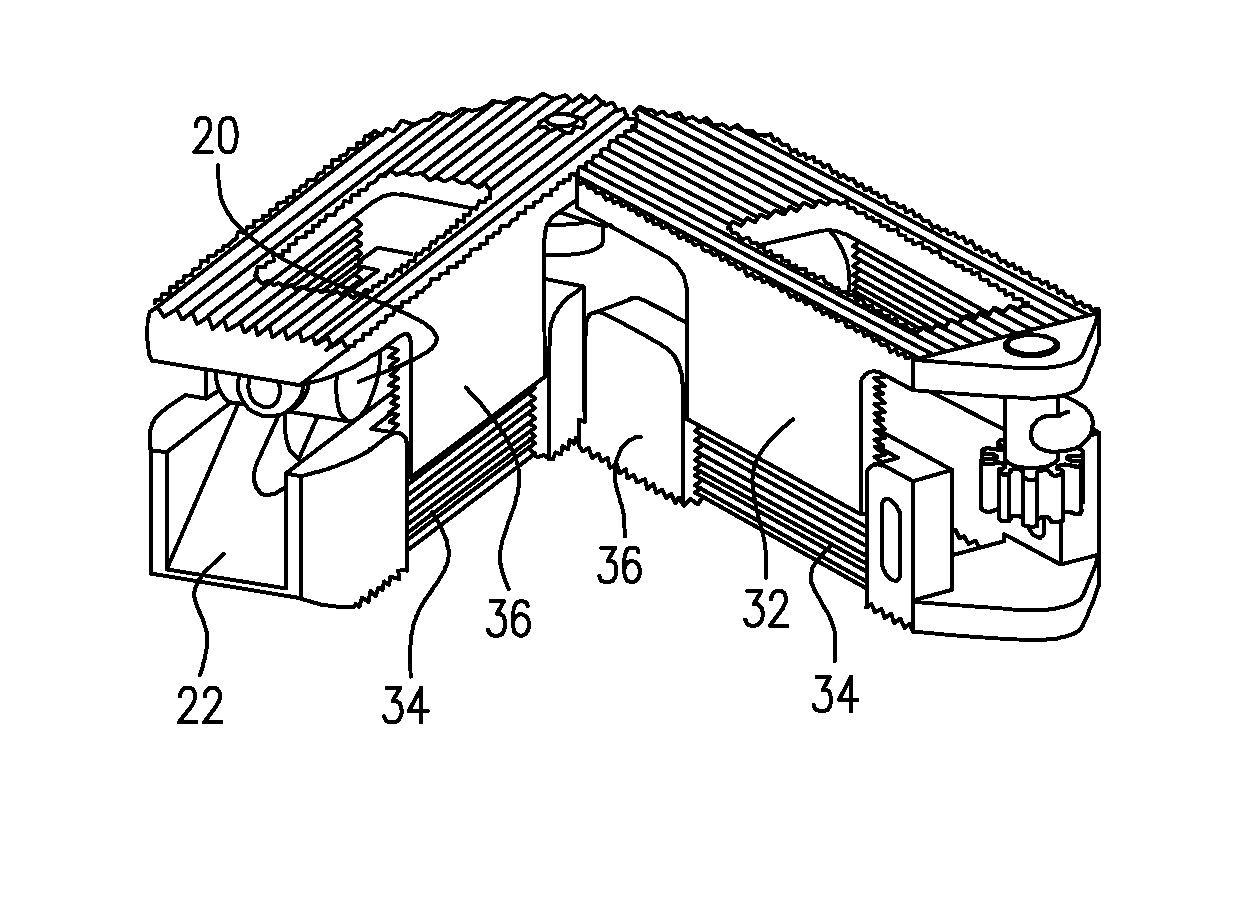

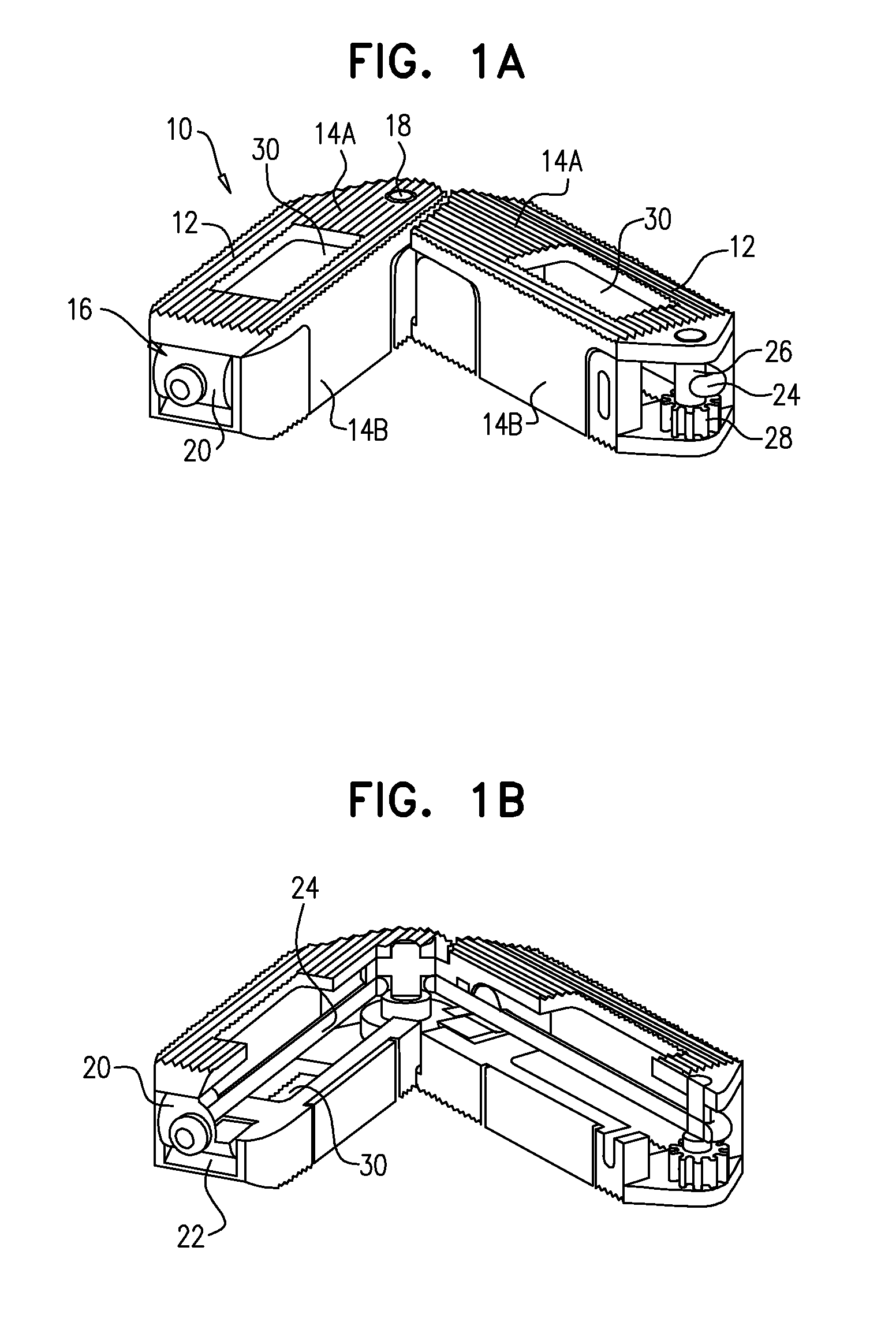

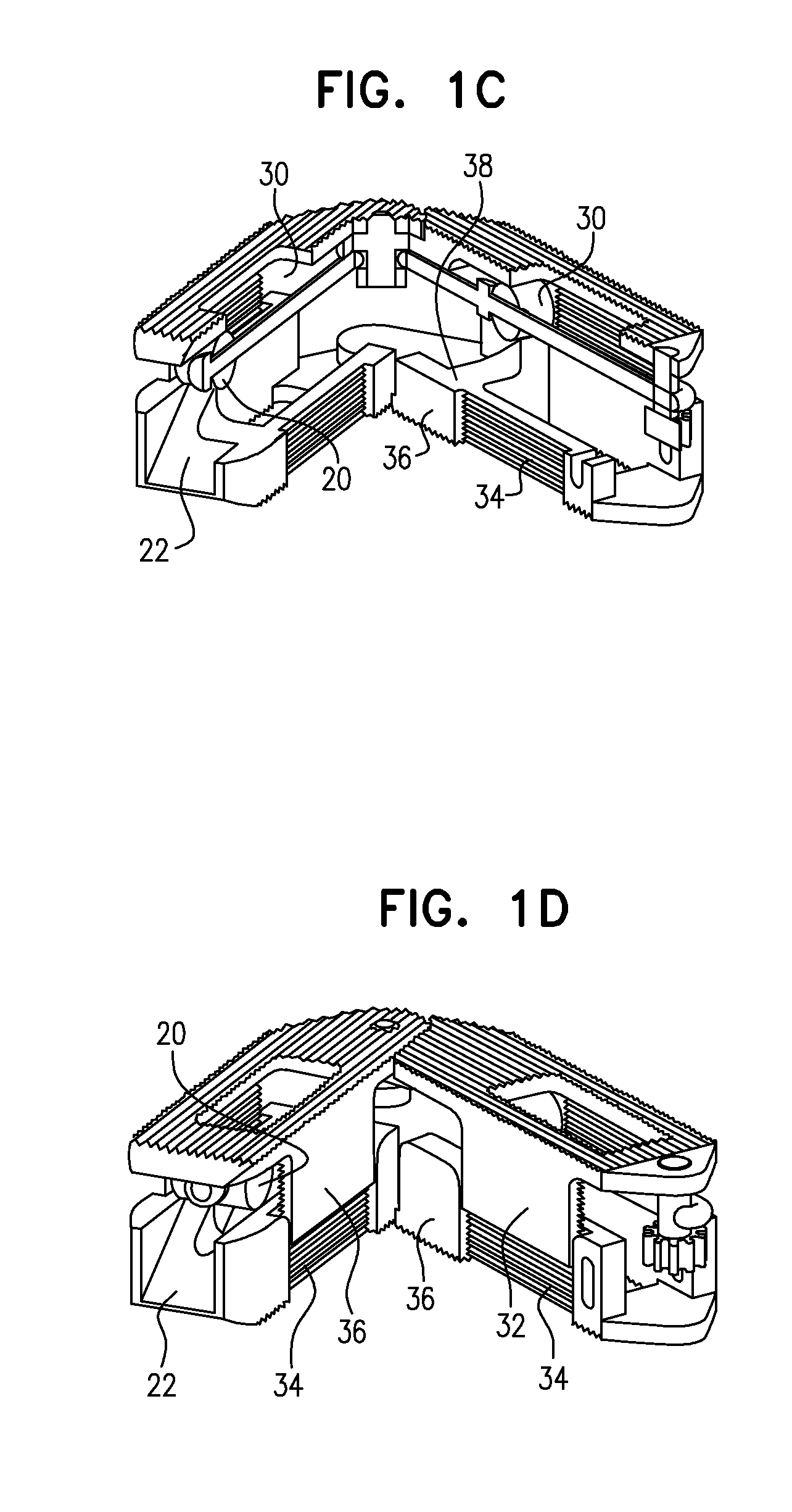

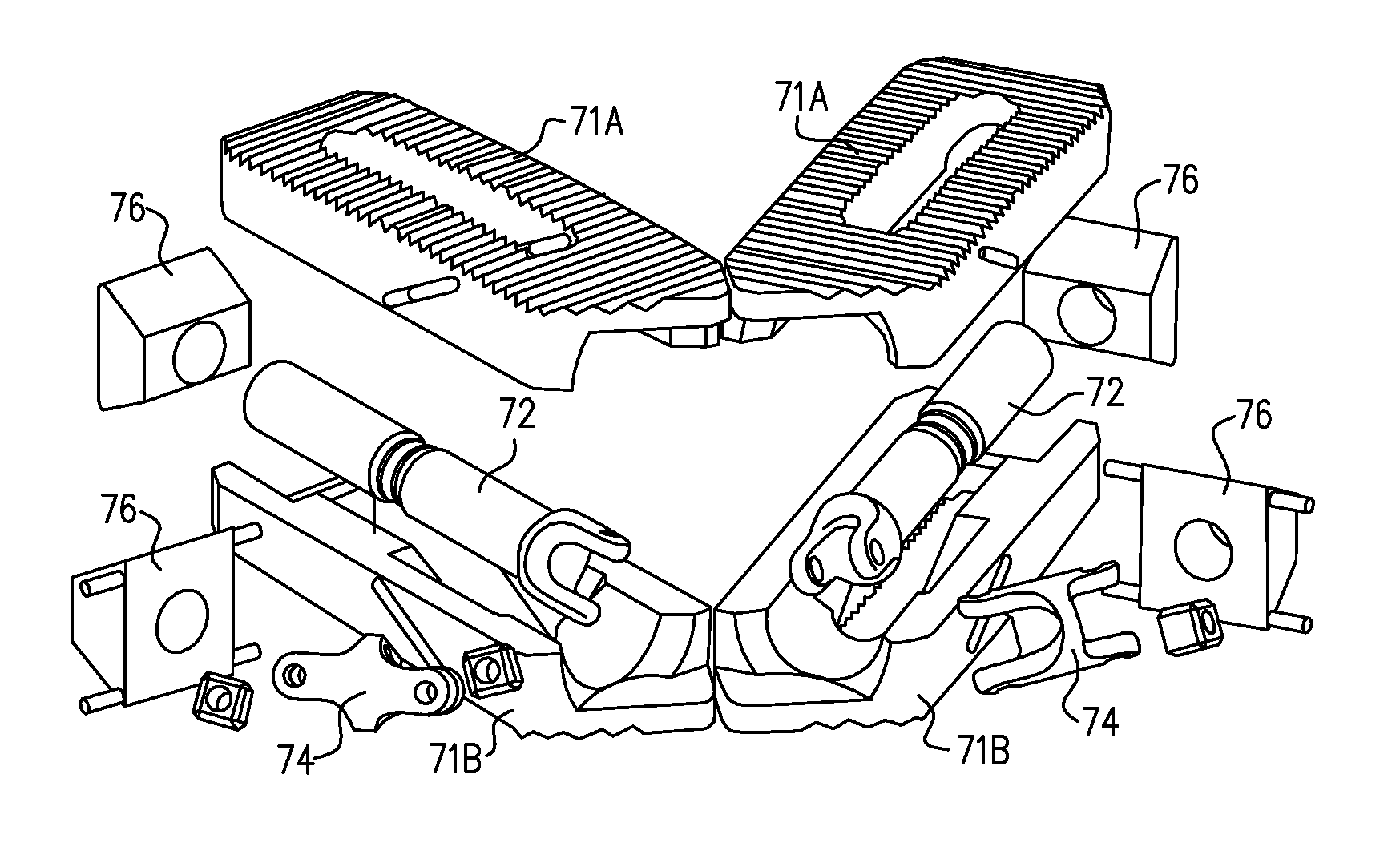

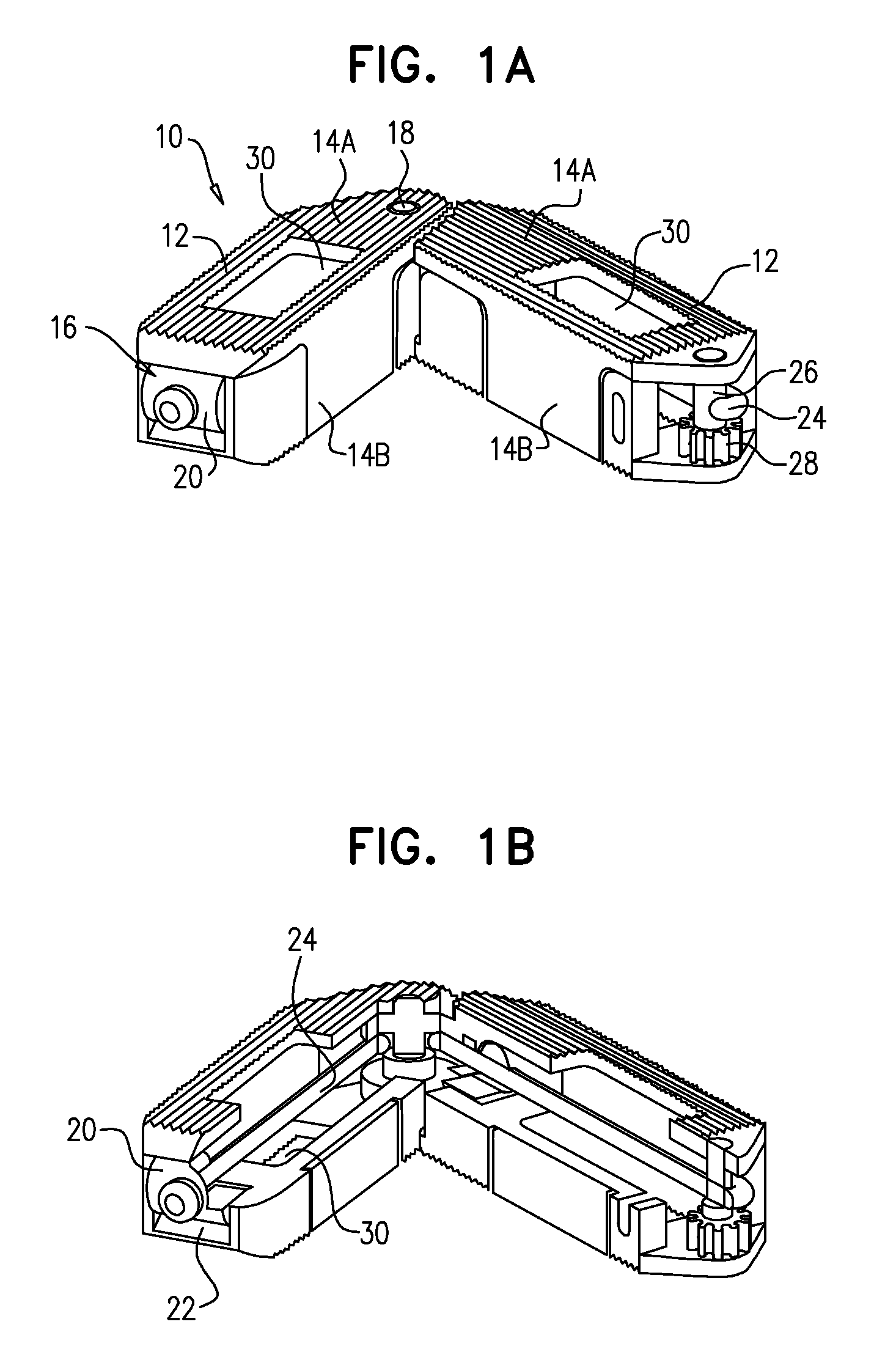

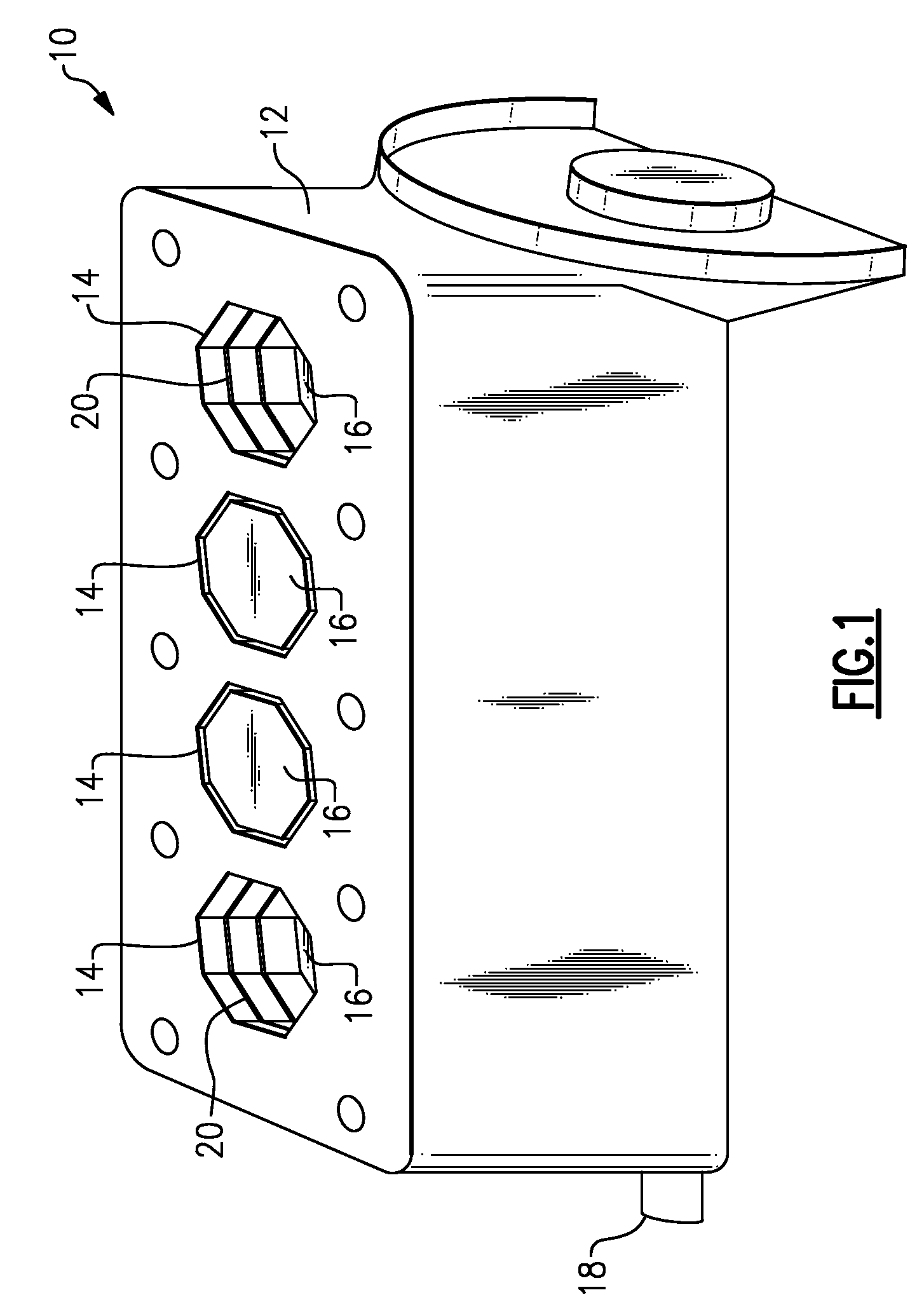

Orthopedic expandable devices

ActiveUS20150257894A1Easy to controlAvoid seizuresBone implantSpinal implantsBiomedical engineeringHinge angle

Owner:CORELINK

Orthopedic expandable devices

ActiveUS9463099B2Easy constructionImprove continuityBone implantJoint implantsBiomedical engineeringHinge angle

Owner:CORELINK

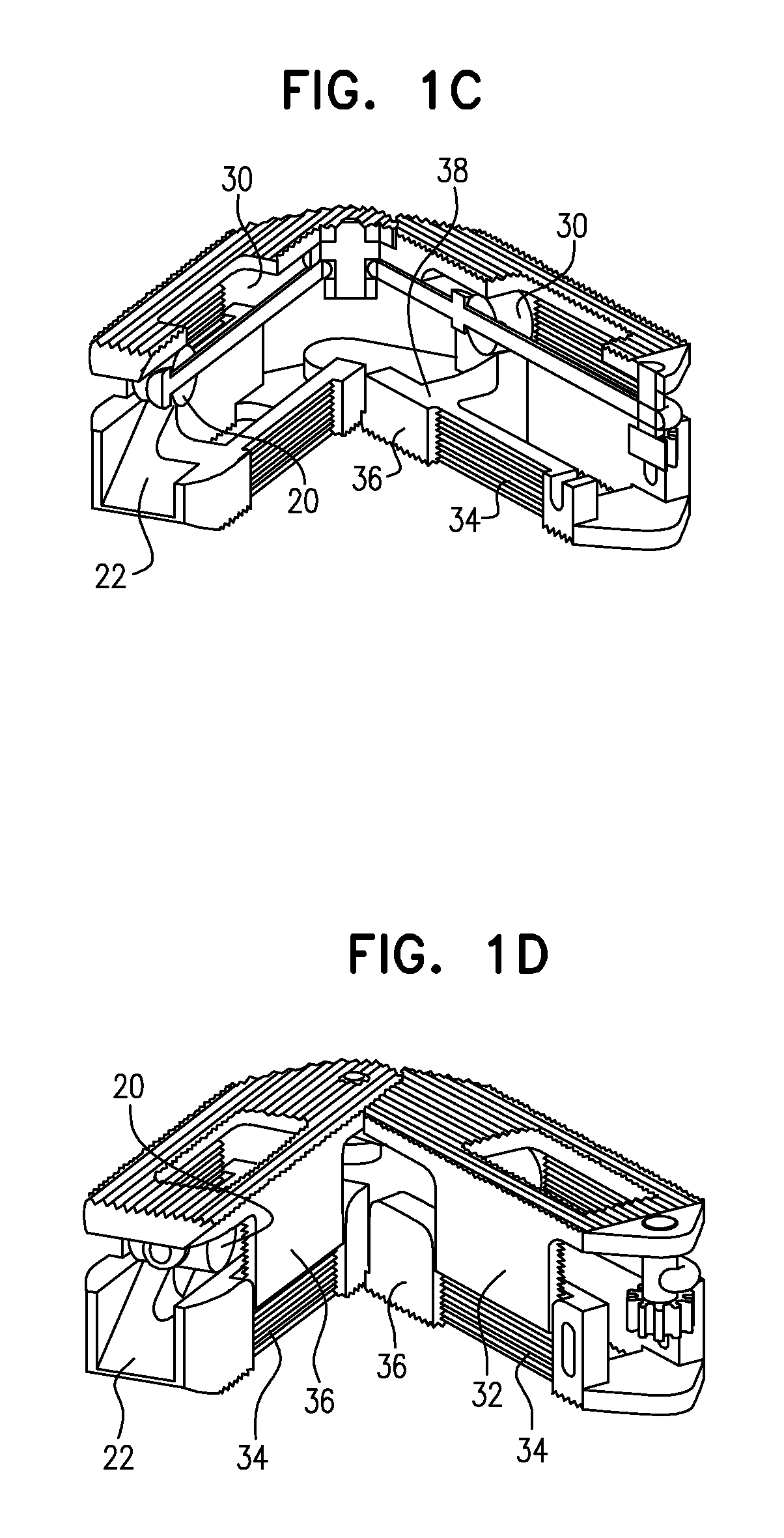

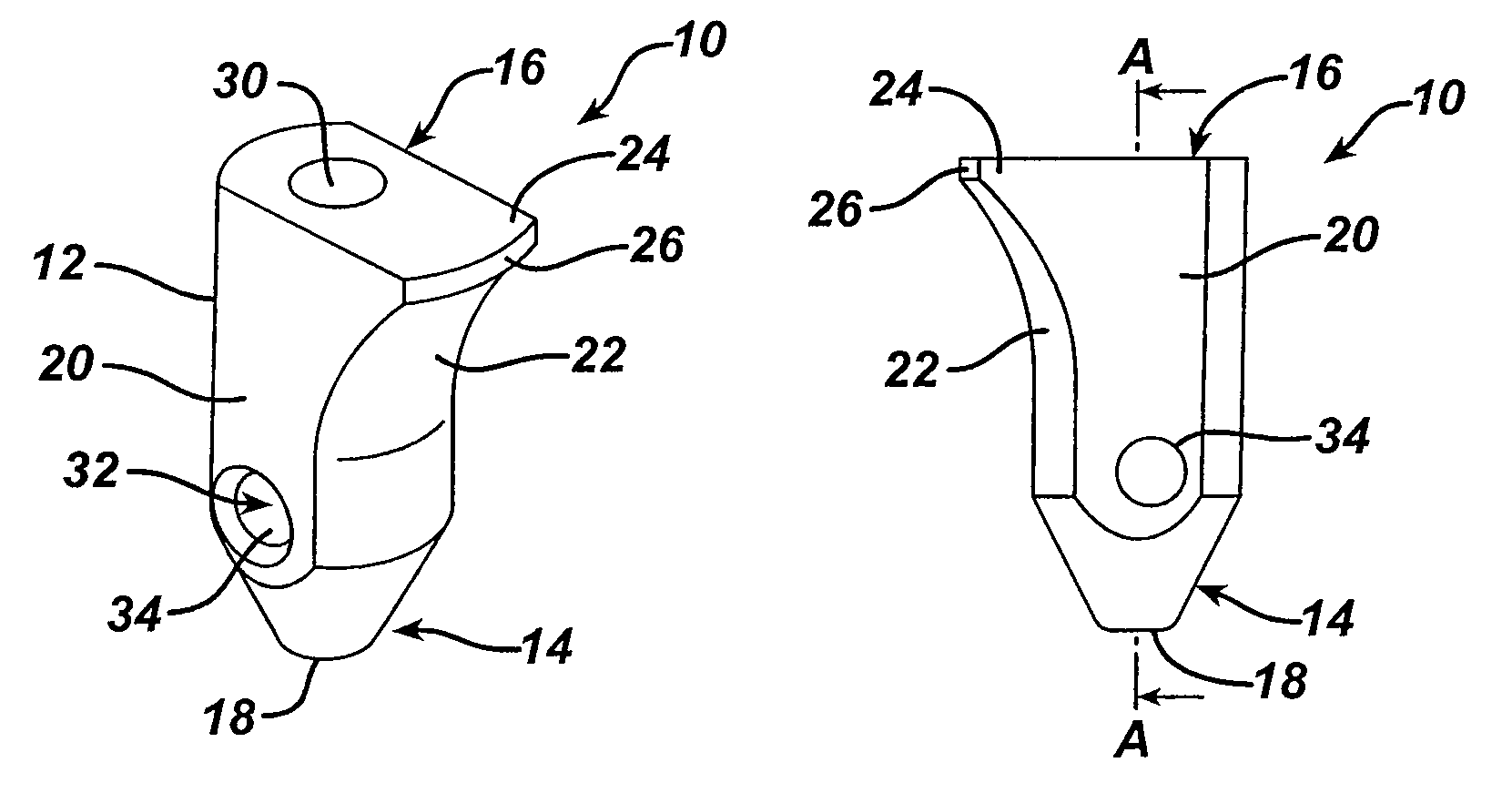

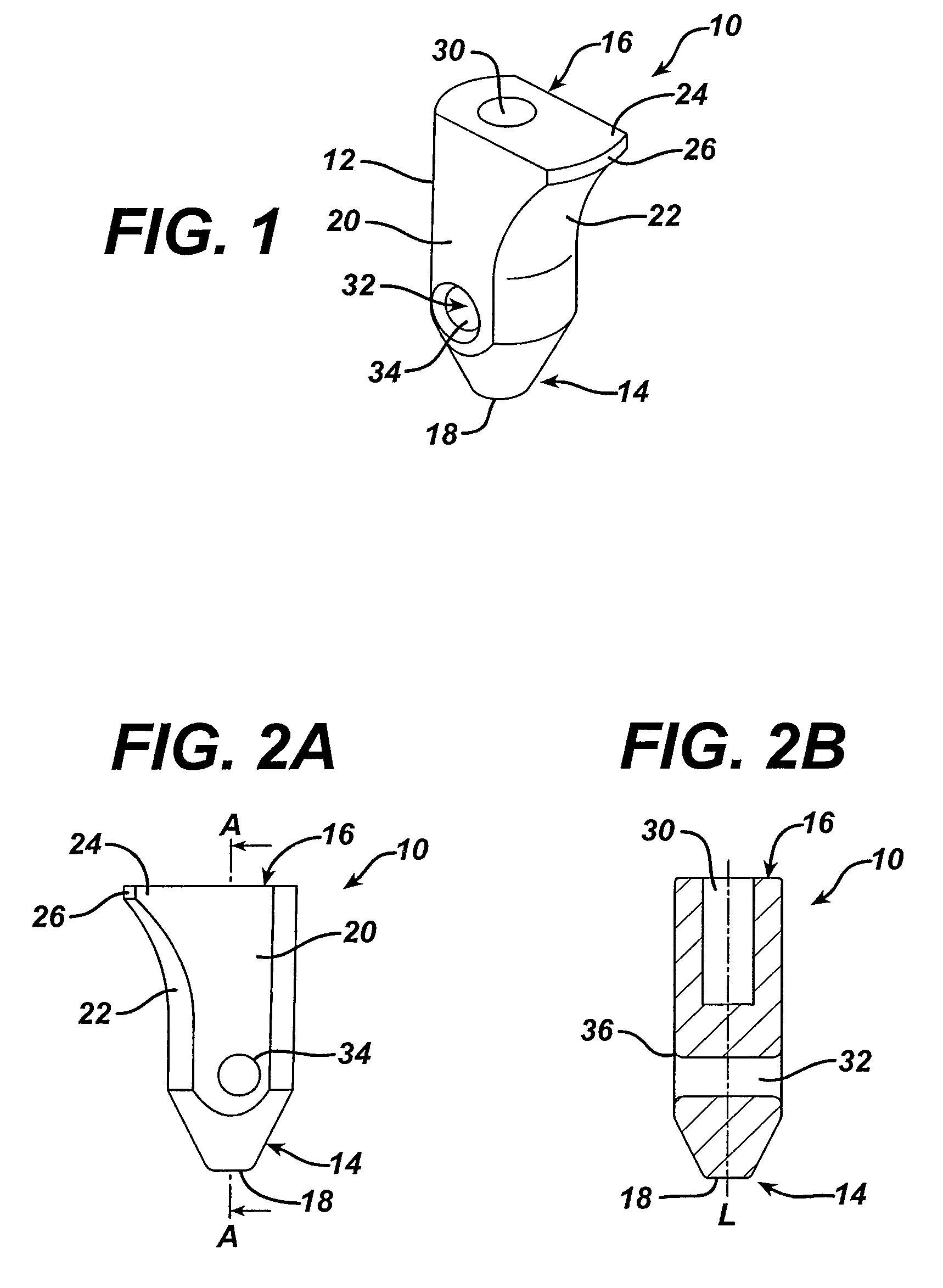

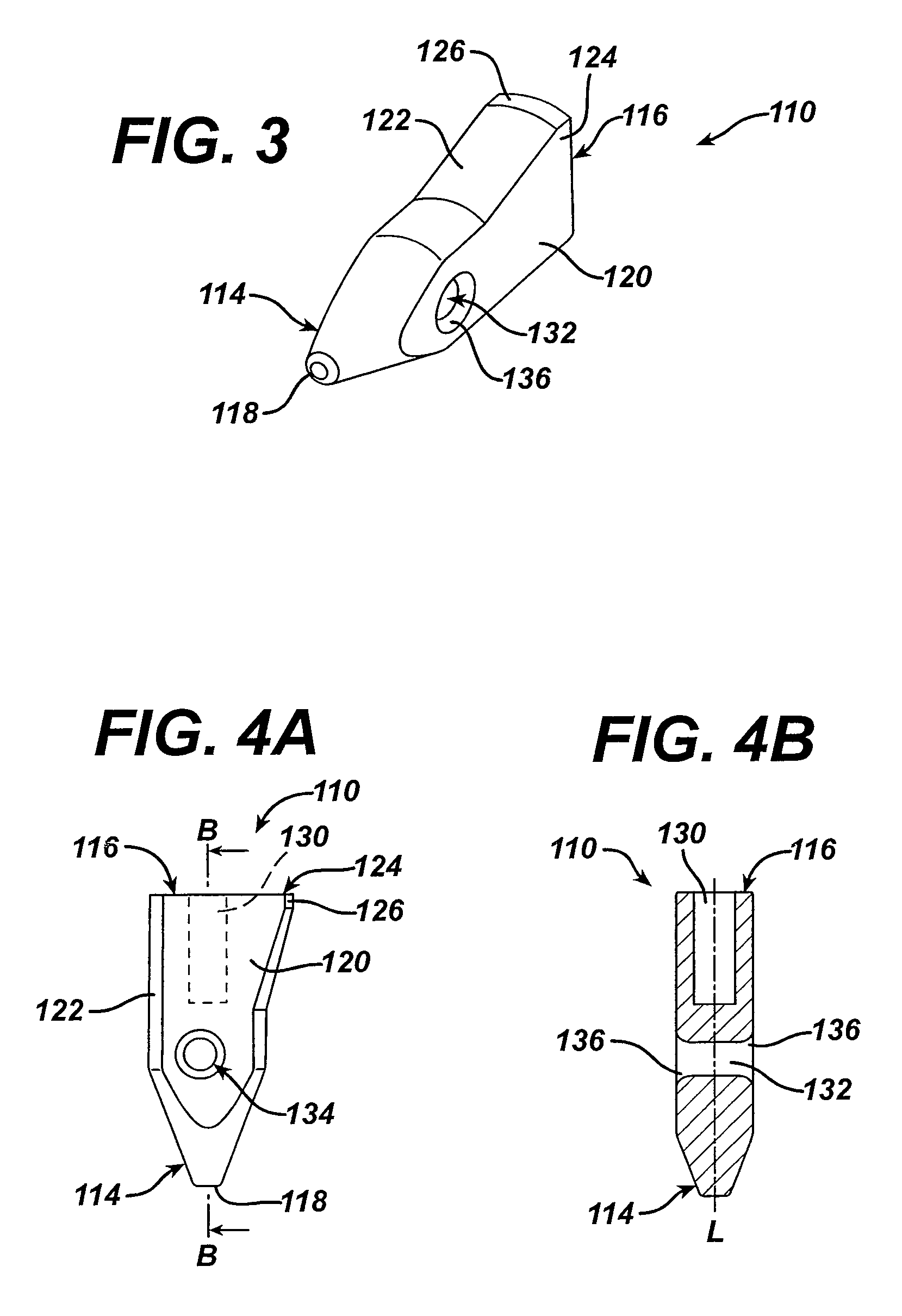

Bioabsorbable suture anchor system for use in small joints

A bioabsorbable suture anchor for anchoring soft tissue to a bone is provided. The suture anchor is configured to toggle and anchor itself inside a bone cavity of a small joint. The anchor comprises an elongate body defined by a longitudinal axis, a first, leading end and a second, trailing end. The elongate body also has two opposed surfaces between the first and second ends, and a plurality of sidewalls extending between the two opposed surfaces. Extending from one of the sidewalls is a flared portion that is formed on the second end of the elongate body. The flared portion is adapted to engage and anchor into bone tissue upon toggling. A suture channel extends between the two opposed surfaces. The suture channel is formed in the elongate body for passage of a suture strand therethrough, such that pulling on an attached suture strand effects toggling of the anchor inside a bone cavity.

Owner:DEPUY SYNTHES PROD INC

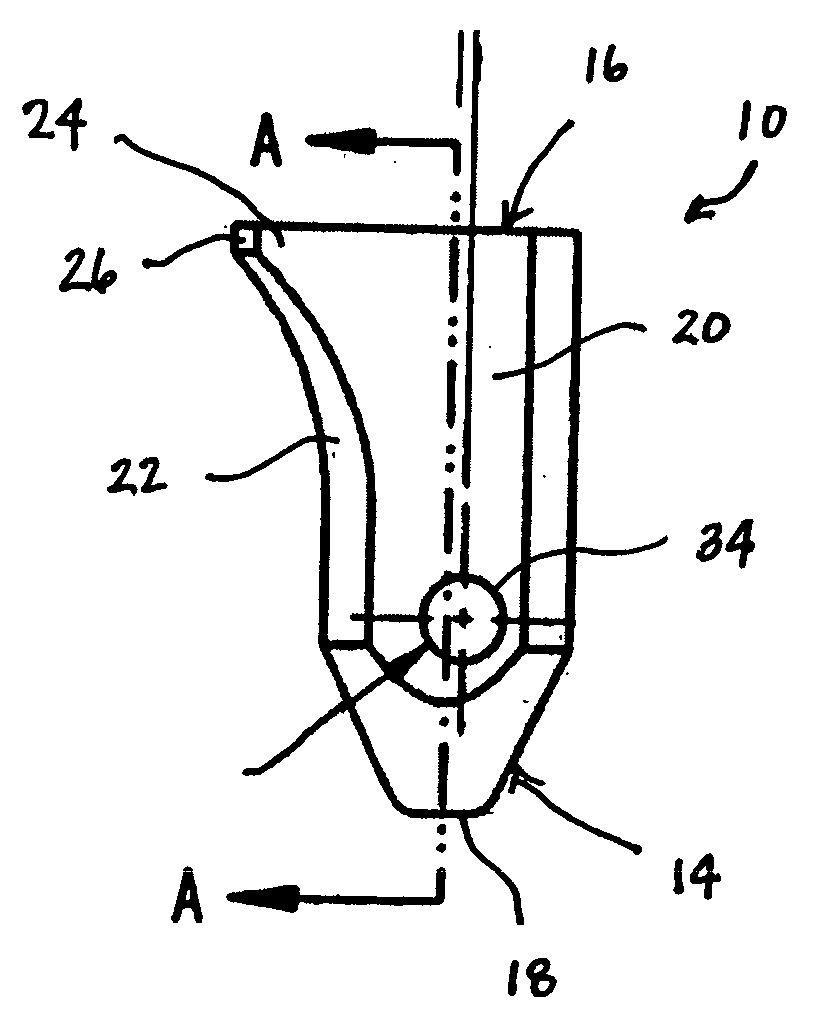

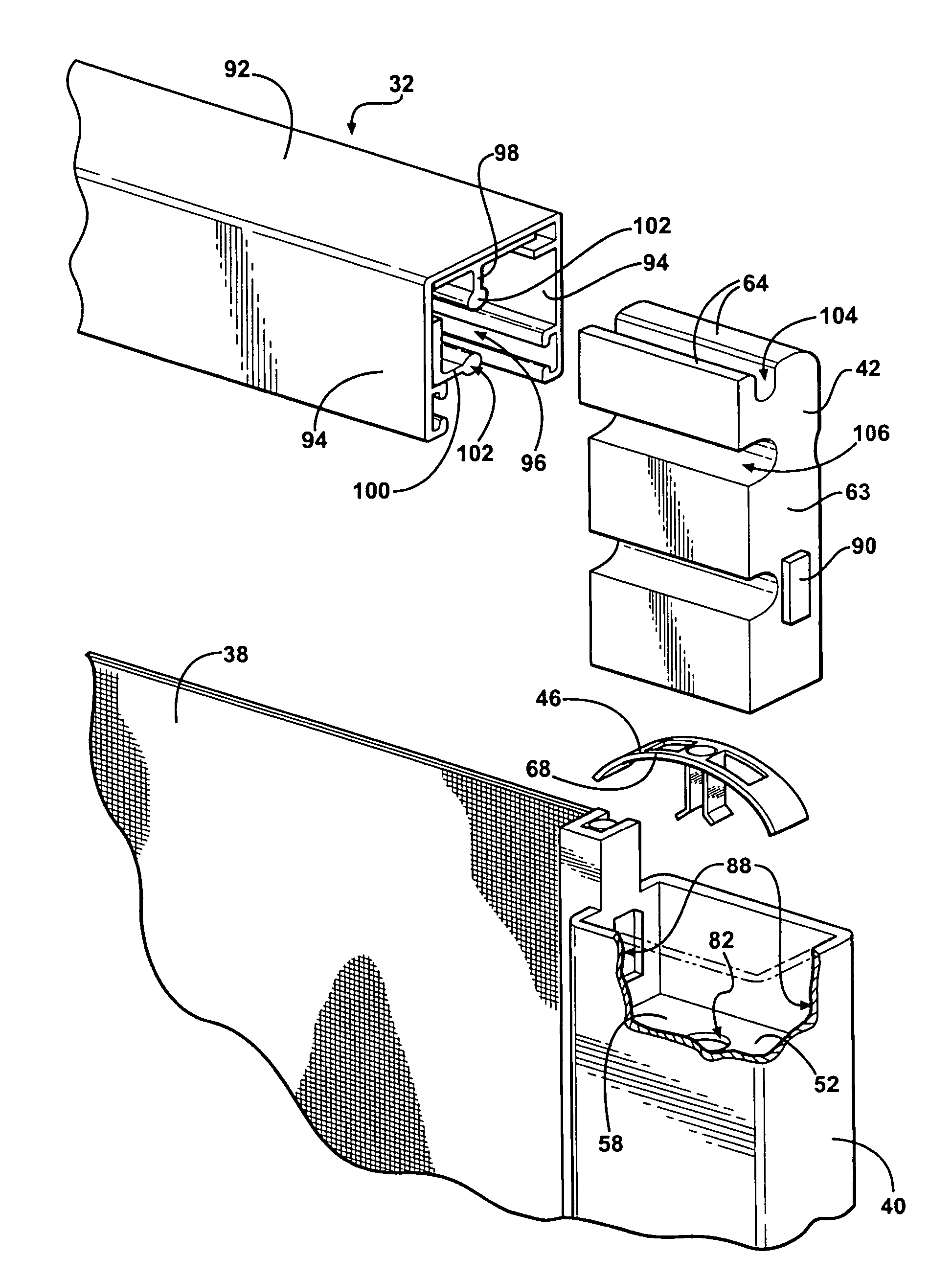

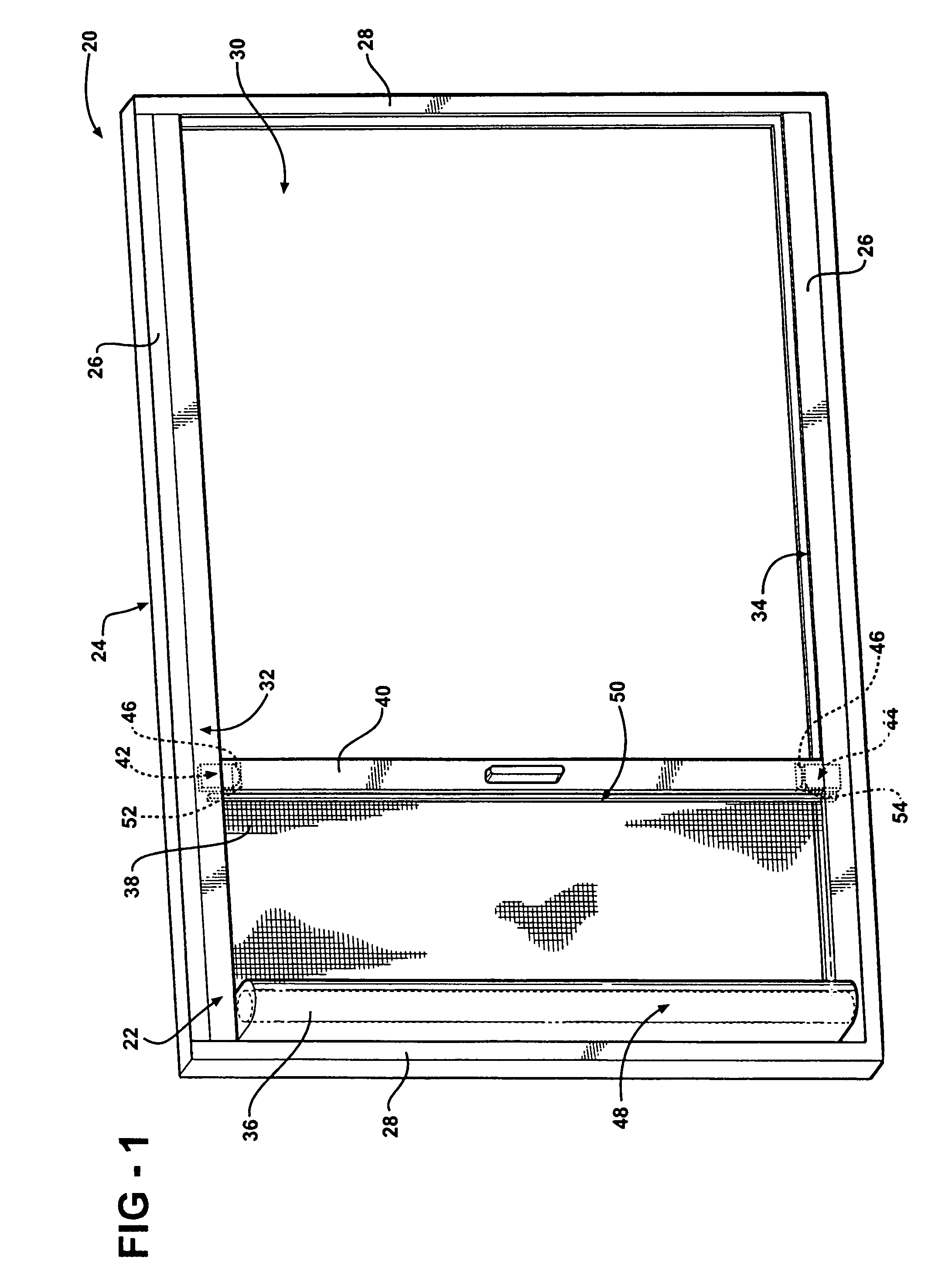

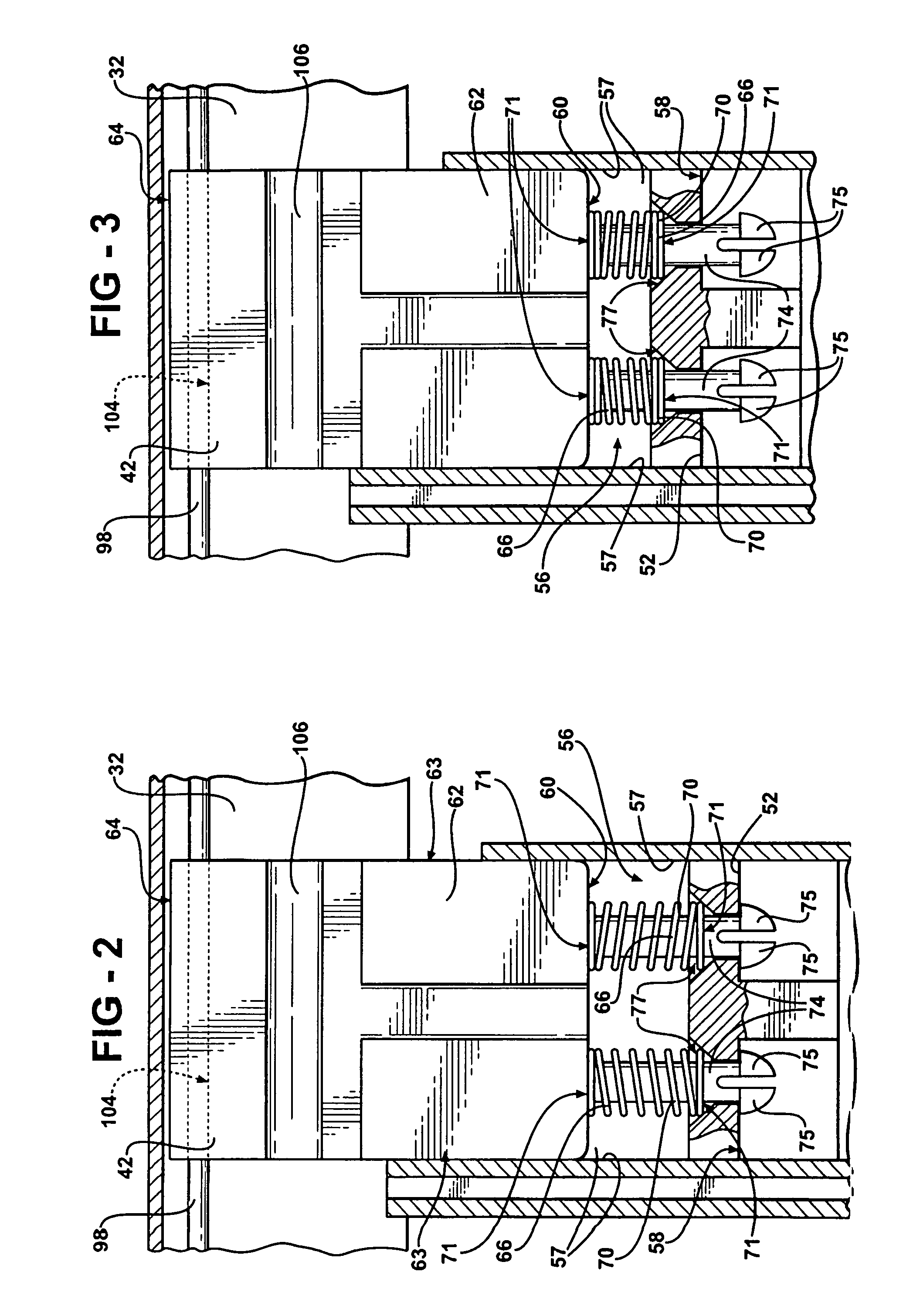

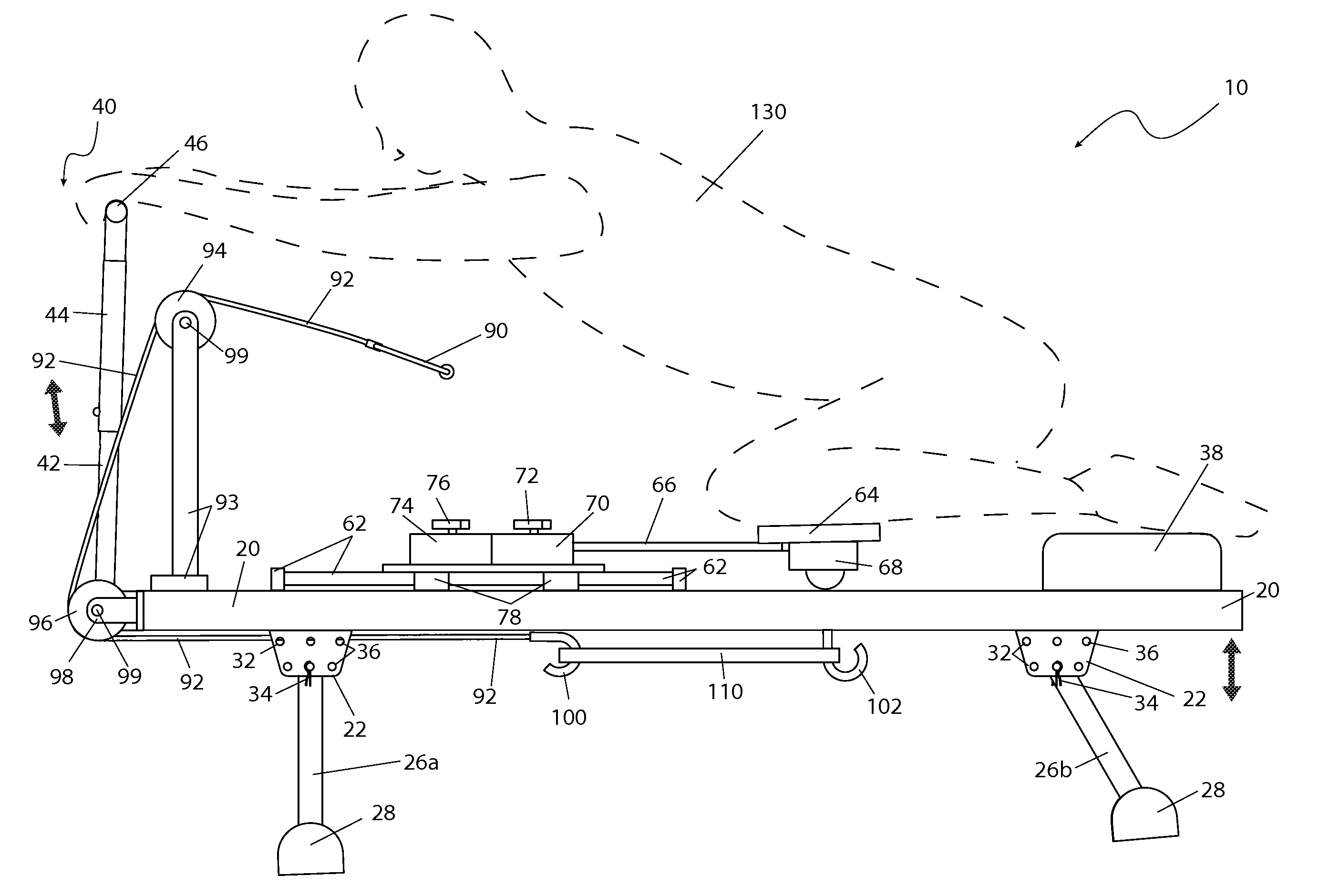

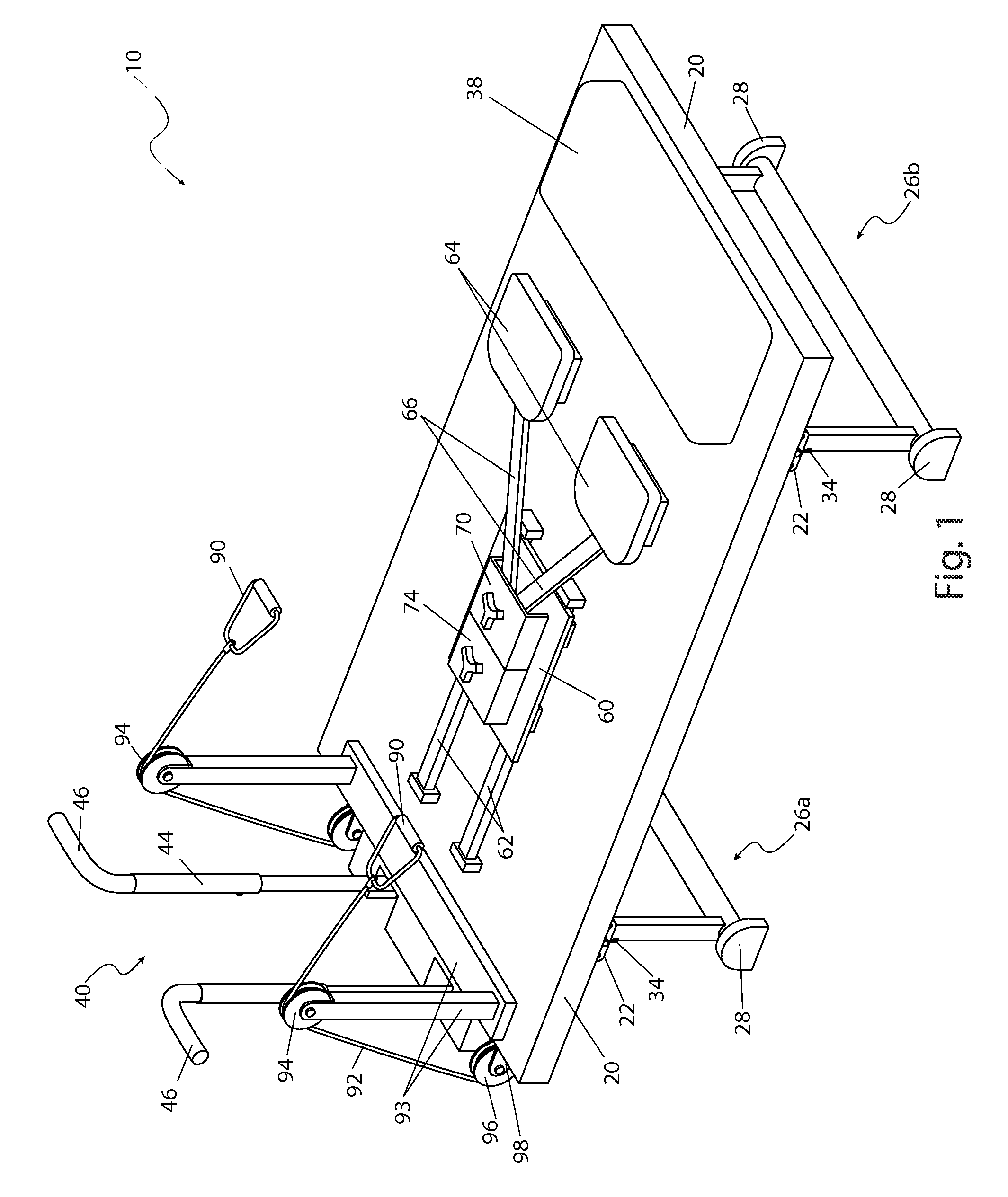

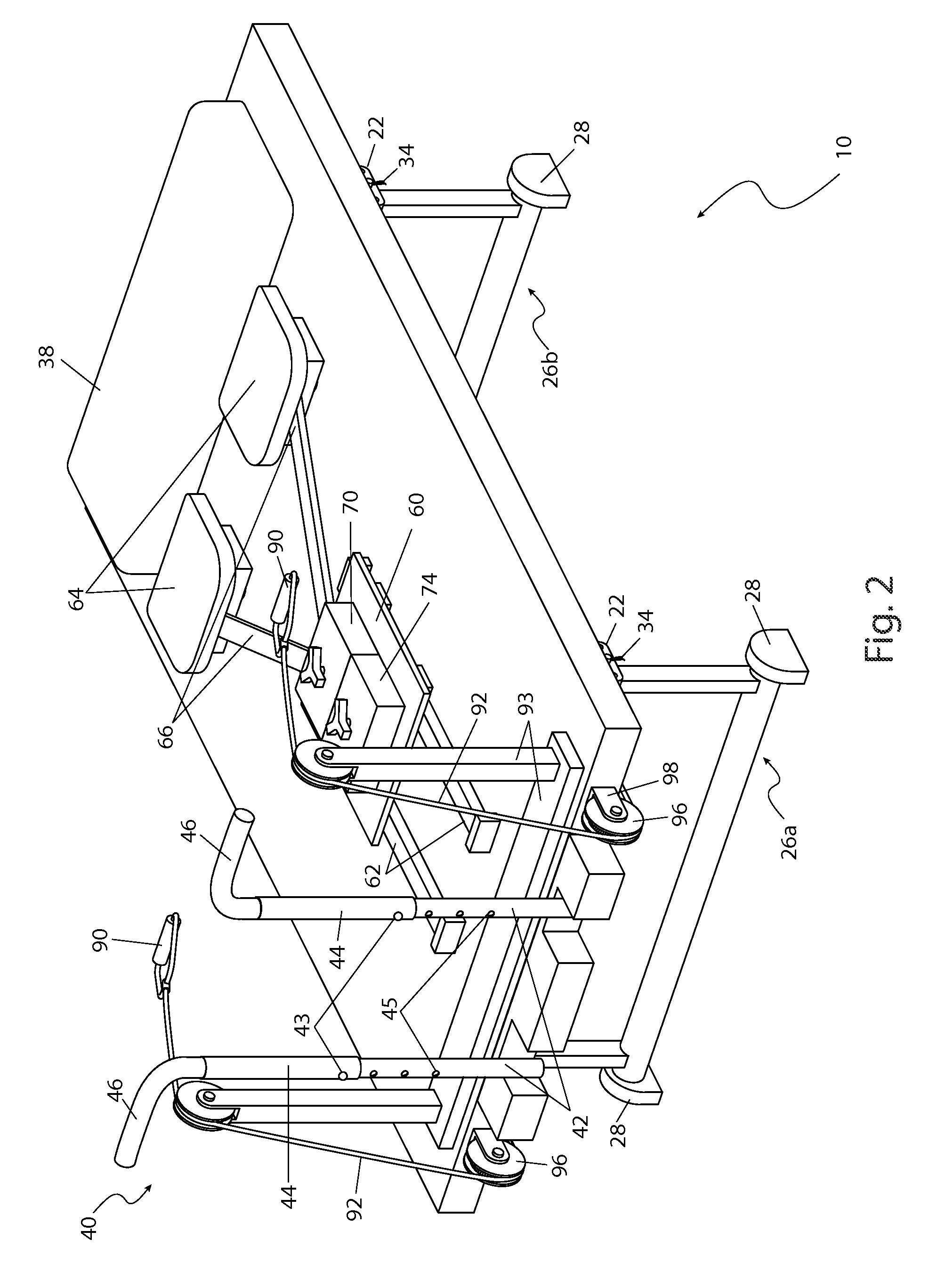

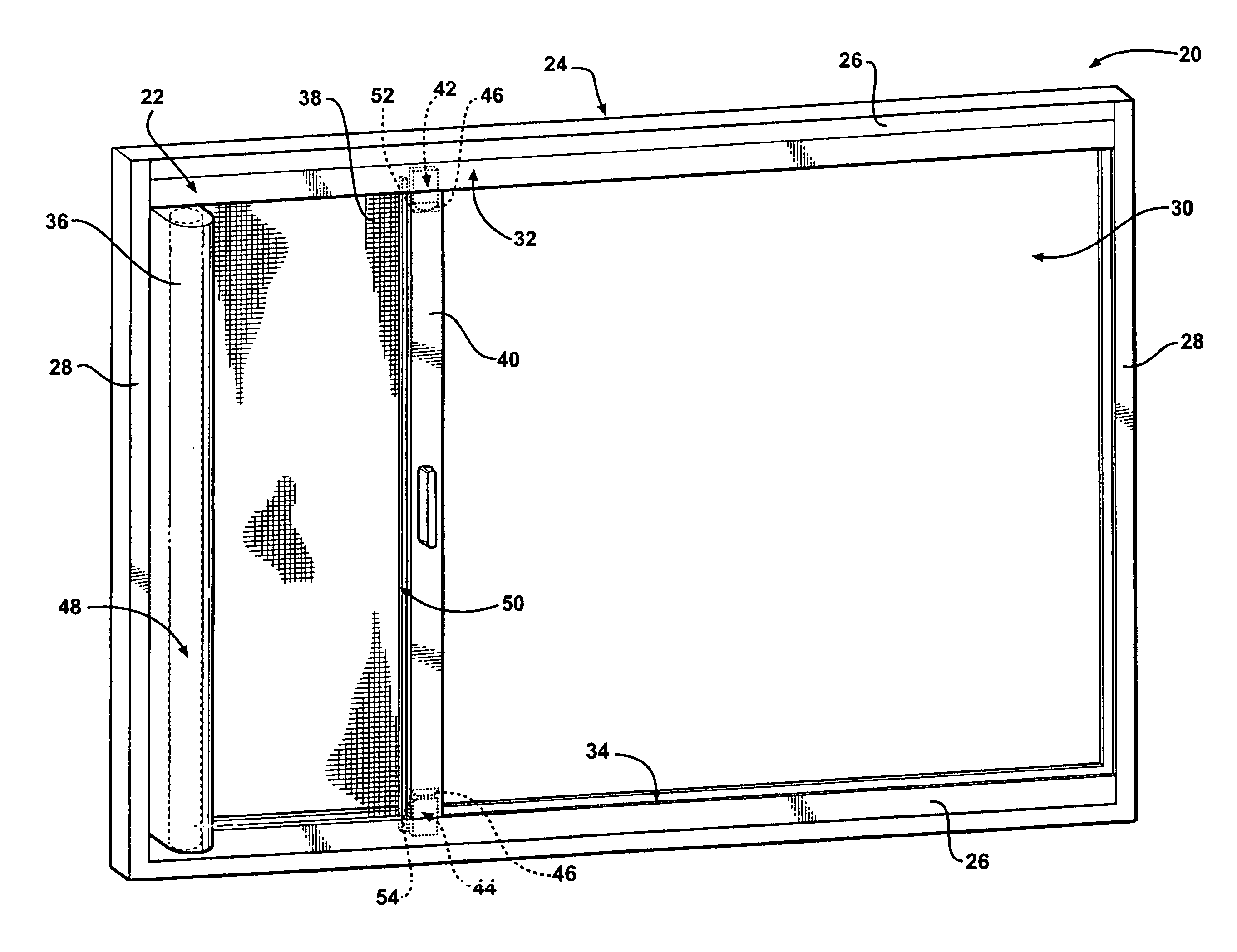

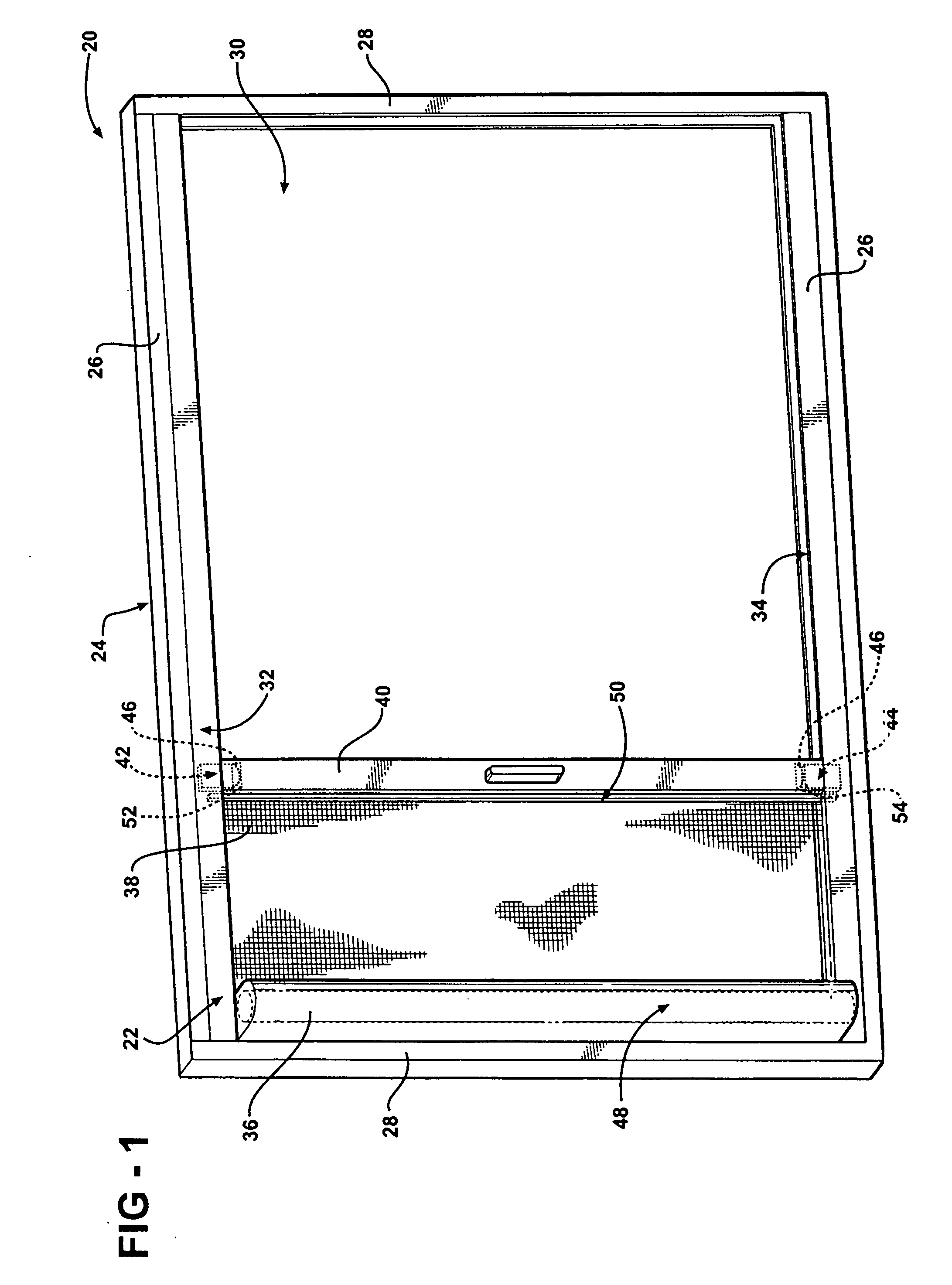

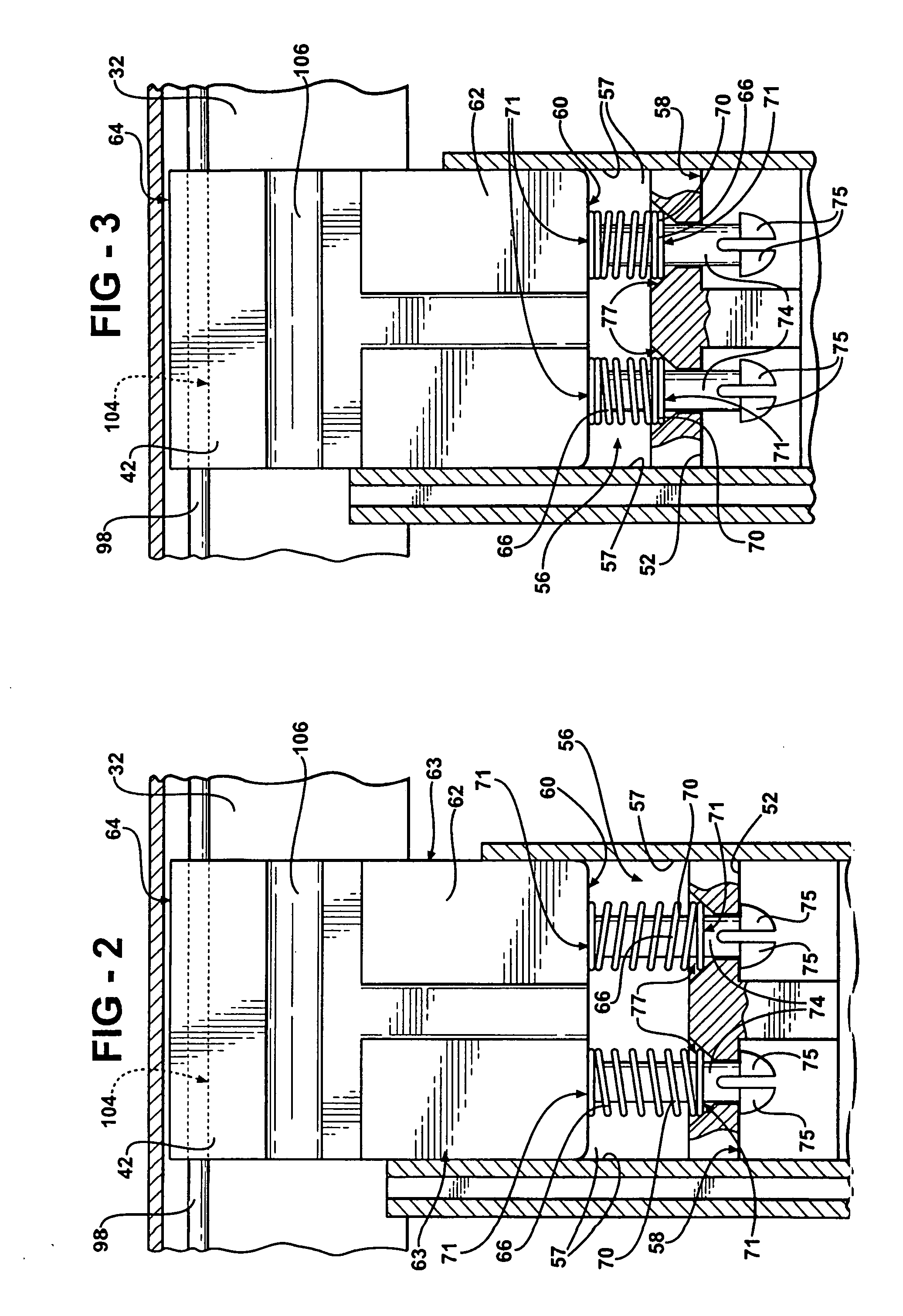

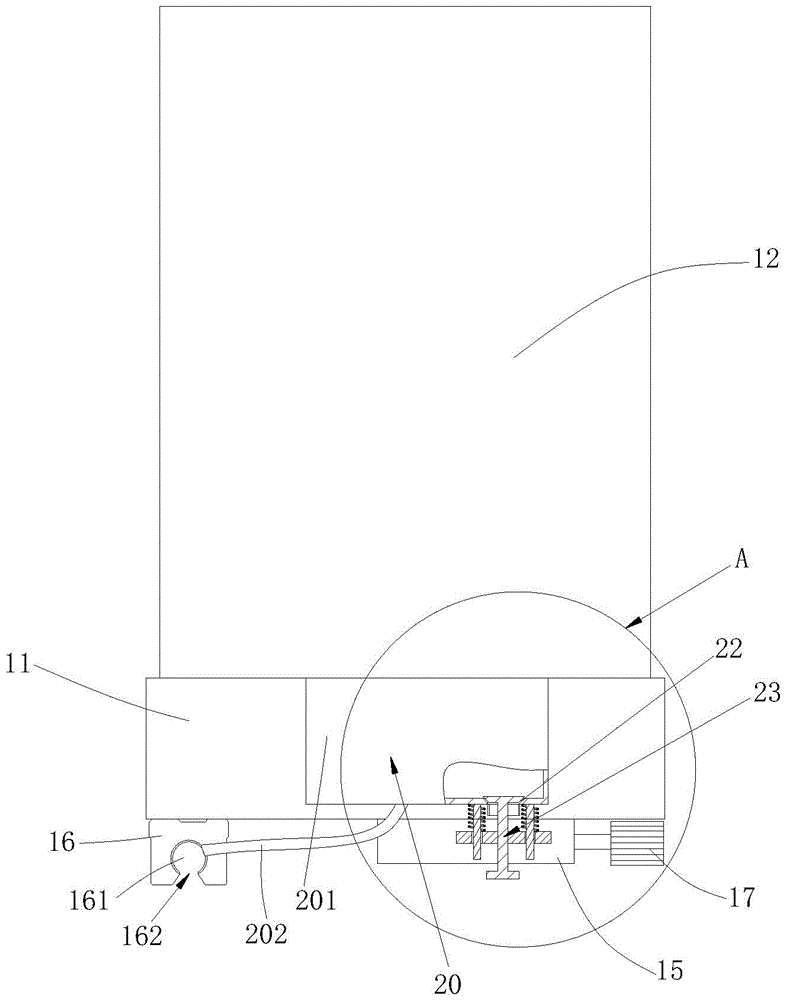

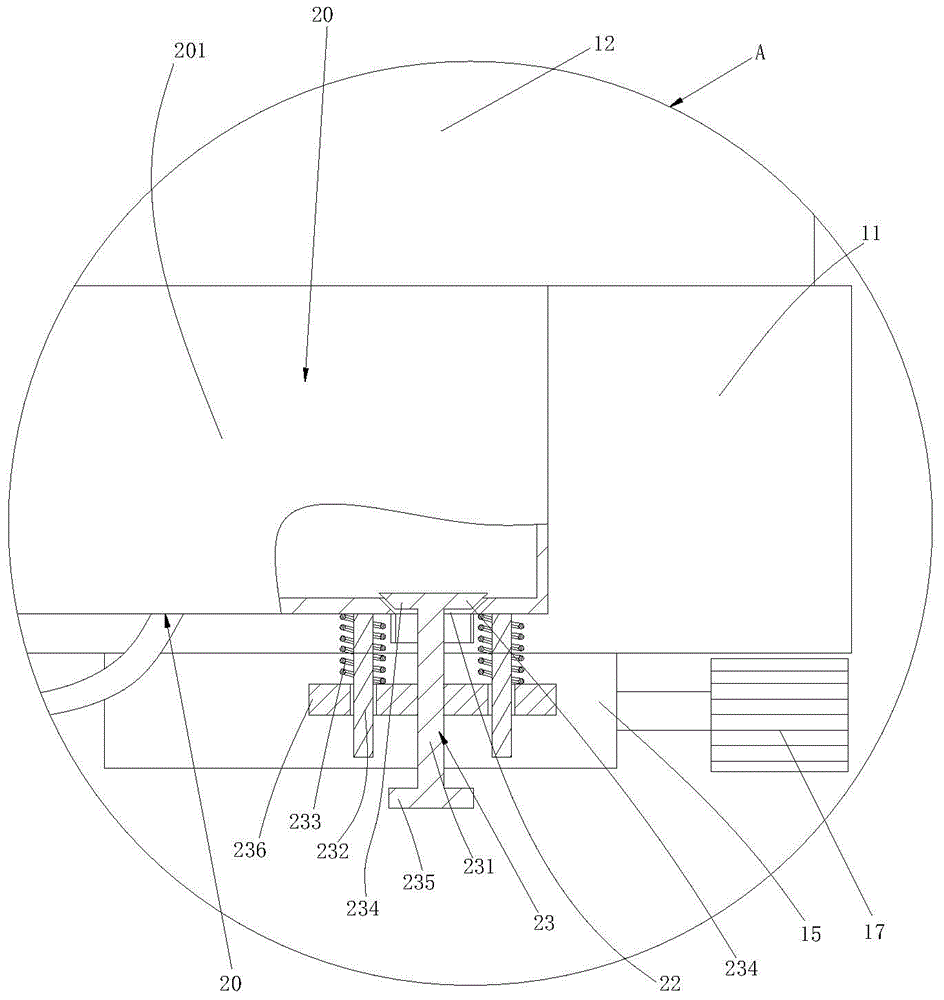

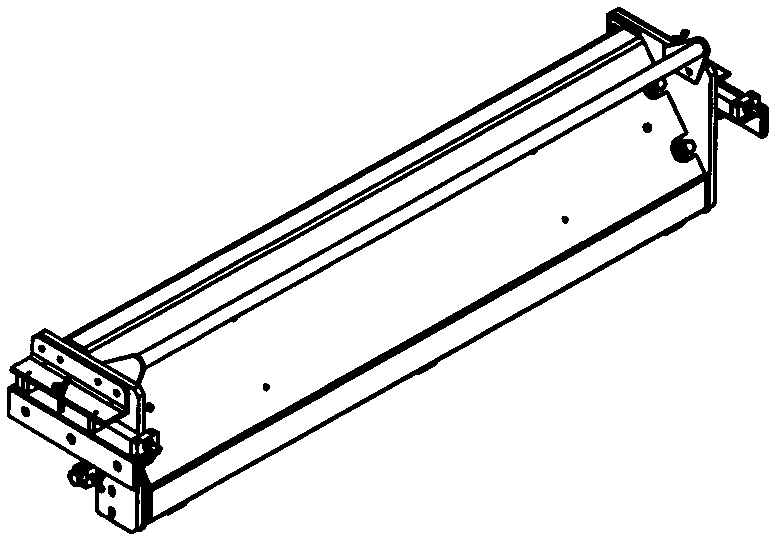

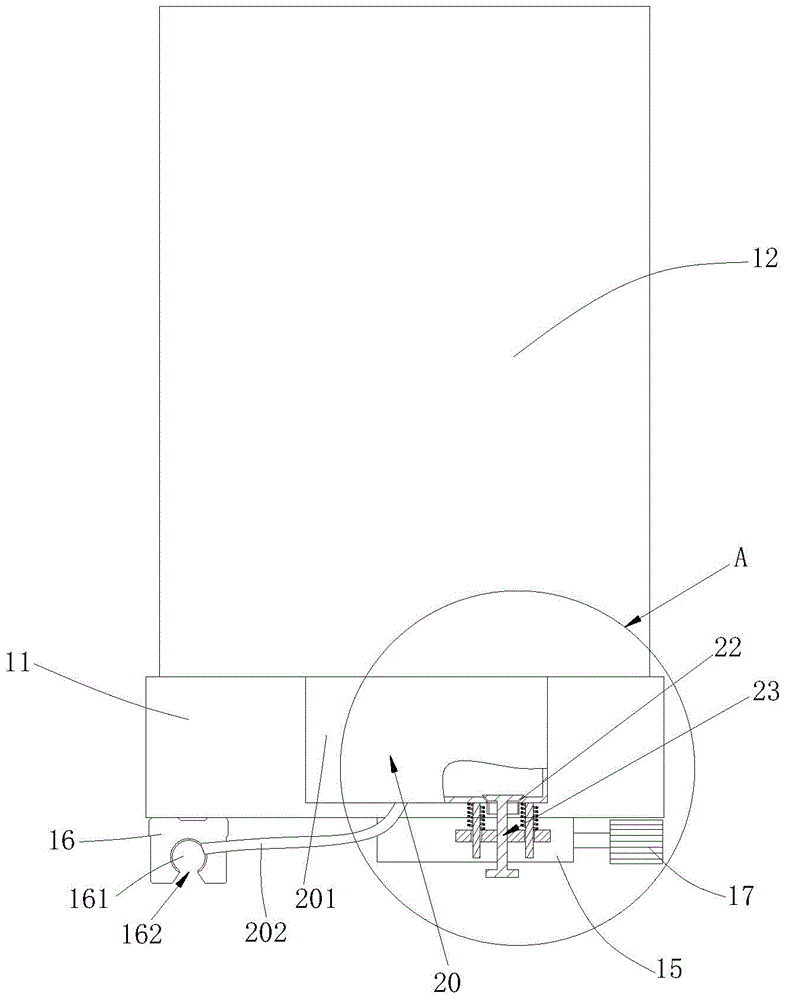

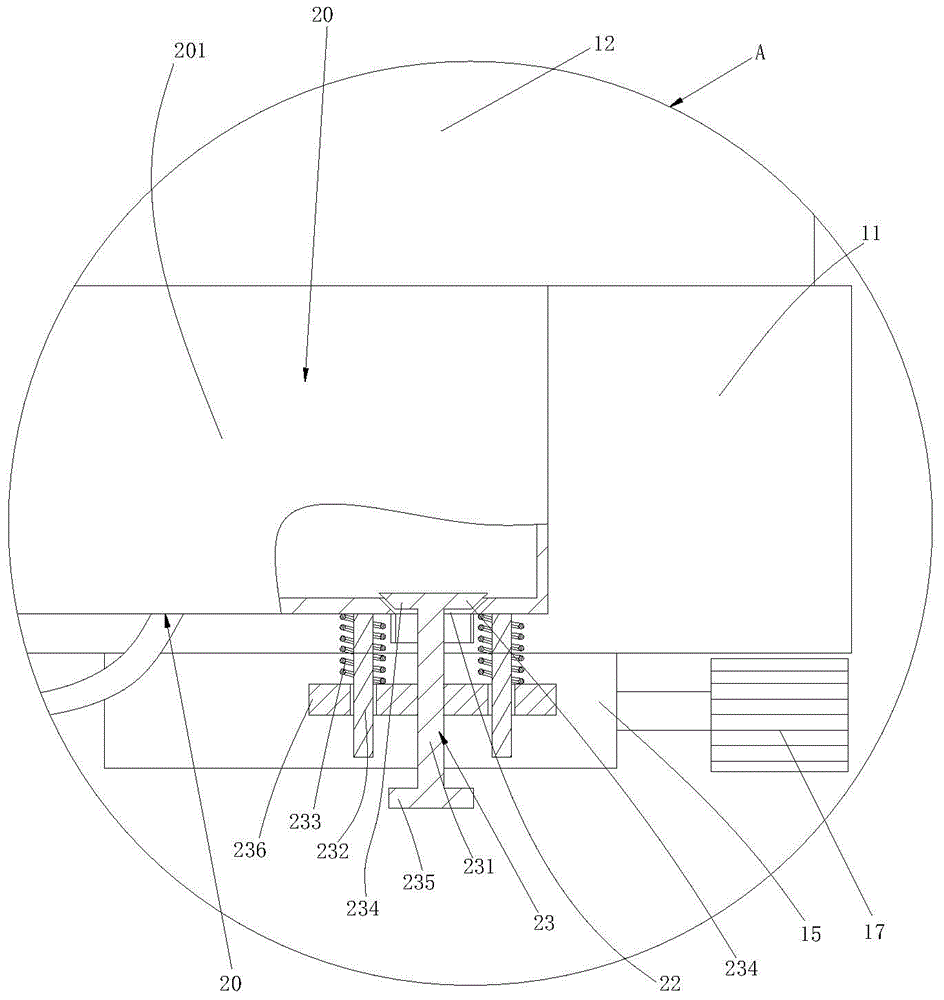

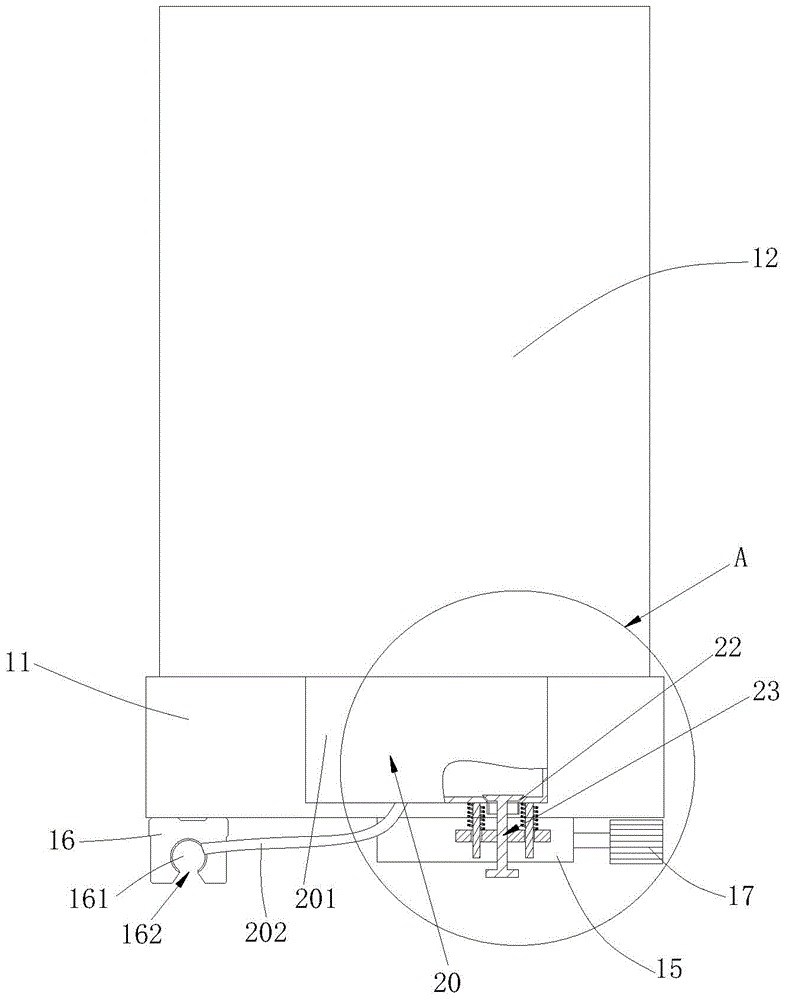

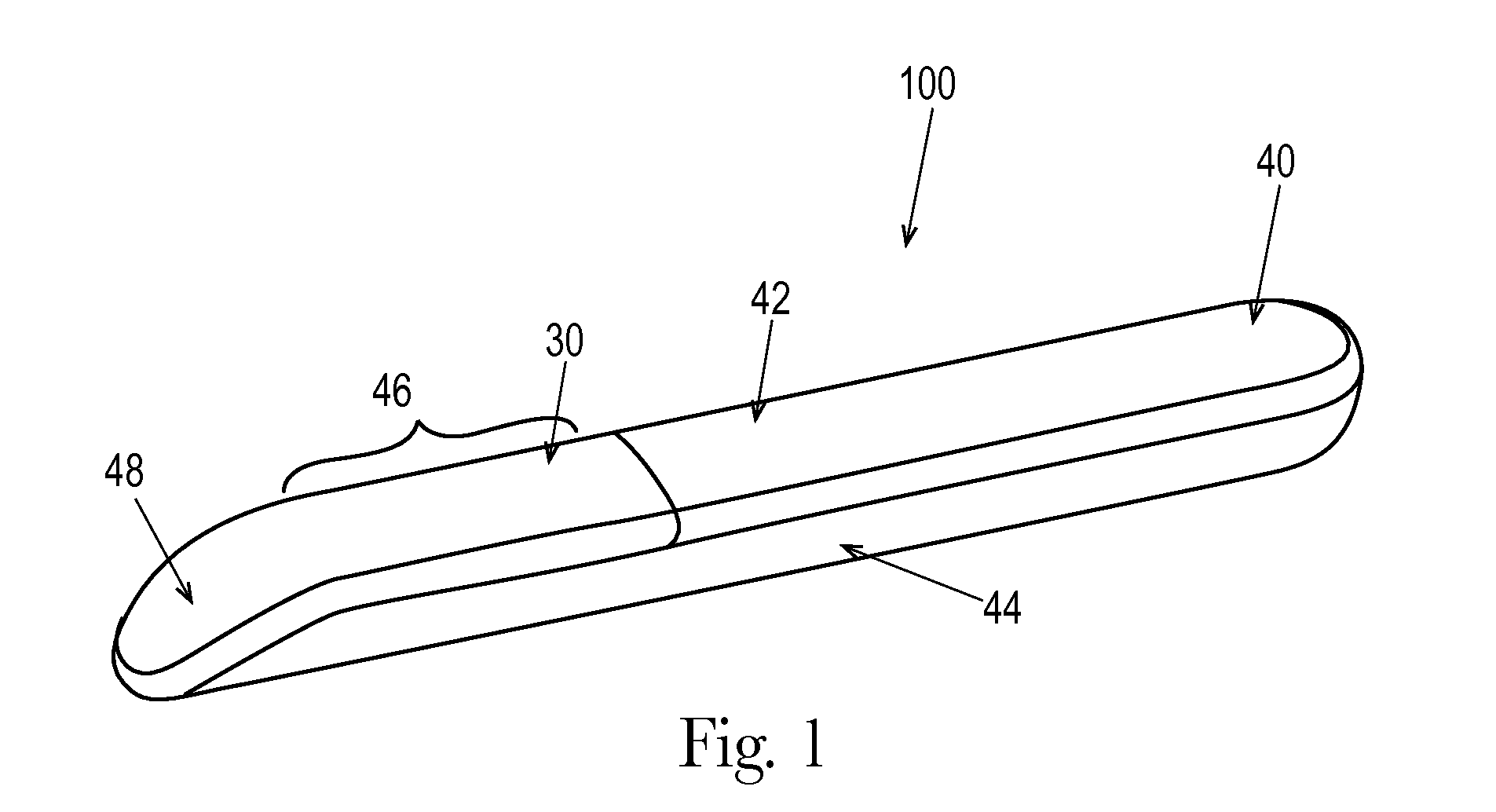

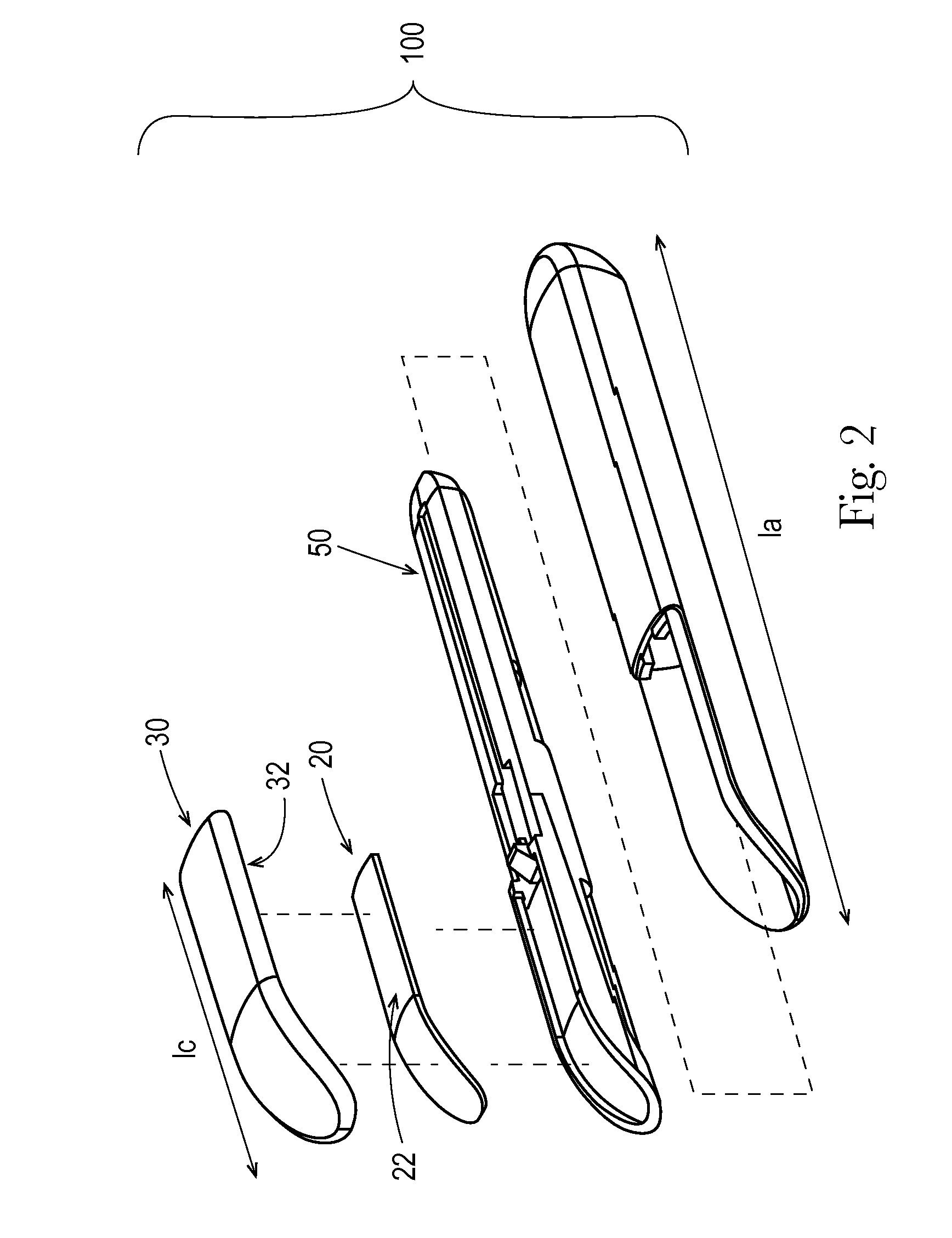

Retractable screen and frame assembly

The present invention is a retractable screen (22) and frame (24) assembly (20). The frame (24) includes a first track (32) and a second track (34) in spaced and parallel relationship to the first track (32). The retractable screen (22) includes a canister (36), a screen cloth (38), a control bar (40), a first glide (42), a second glide (44), and a biasing device (46). The biasing device (46) is disposed between a first end (52) of the control bar (40) and the first glide (42). The first glide (42) is inserted into the first track (32) and the second glide (44) is inserted into the second track (34). The glides (42, 44) slide along the respective tracks (32, 34) while the biasing device (46) biases the first end (52) of the control bar (40) with respect to the first track (32). The biasing provided by the biasing device (46) prevents the control bar (40) from binding with the tracks (32, 34) as the control bar (40) and the glides (42, 44) are slid along the tracks (32, 34).

Owner:QUANEX HOMESHIELD LLC

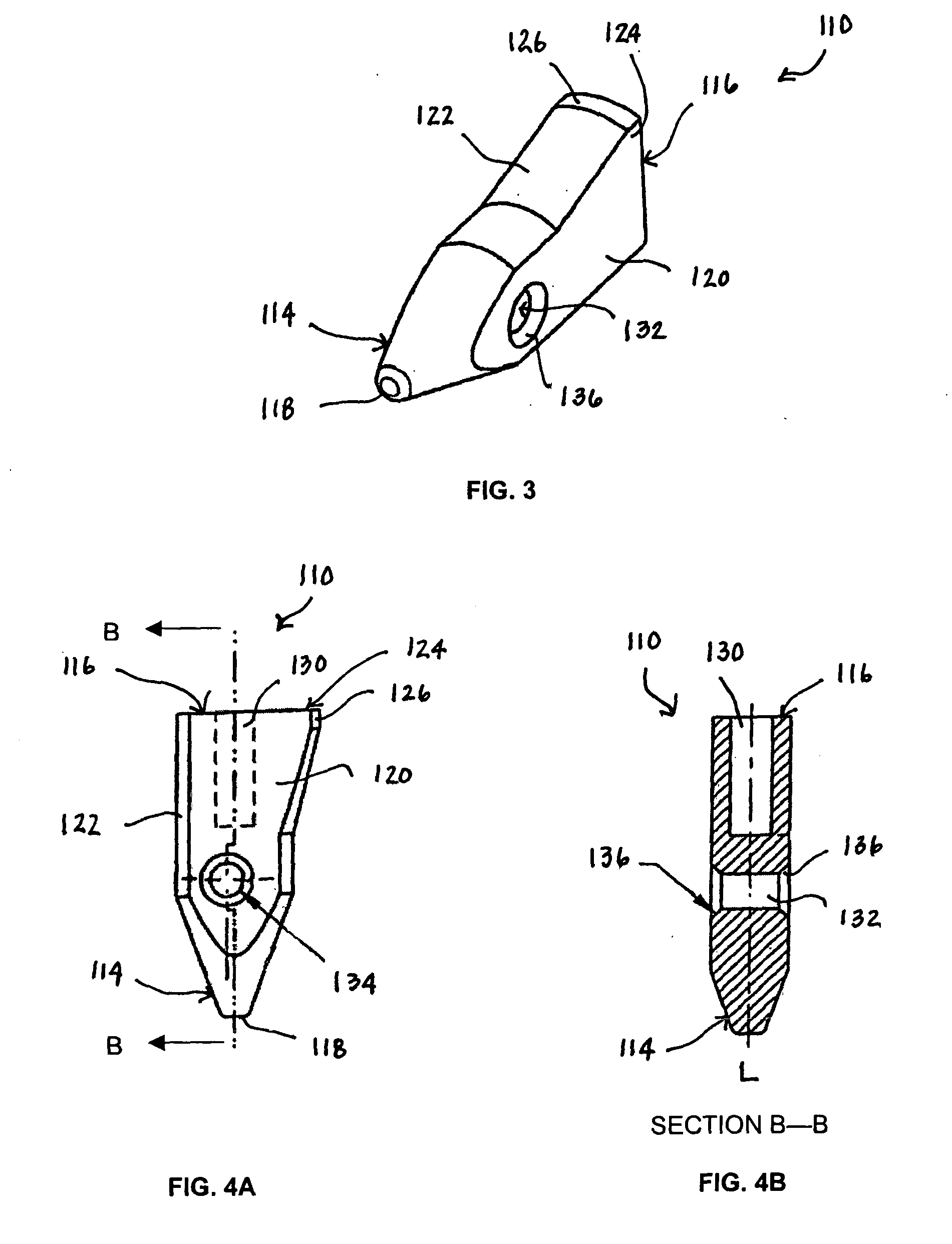

Bioabsorbable suture anchor system for use in small joints

A bioabsorbable suture anchor for anchoring soft tissue to a bone is provided. The suture anchor is configured to toggle and anchor itself inside a bone cavity of a small joint. The anchor comprises an elongate body defined by a longitudinal axis, a first, leading end and a second, trailing end. The elongate body also has two opposed surfaces between the first and second ends, and a plurality of sidewalls extending between the two opposed surfaces. Extending from one of the sidewalls is a flared portion that is formed on the second end of the elongate body. The flared portion is adapted to engage and anchor into bone tissue upon toggling. A suture channel extends between the two opposed surfaces. The suture channel is formed in the elongate body for passage of a suture strand therethrough, such that pulling on an attached suture strand effects toggling of the anchor inside a bone cavity.

Owner:DEPUY SYNTHES PROD INC

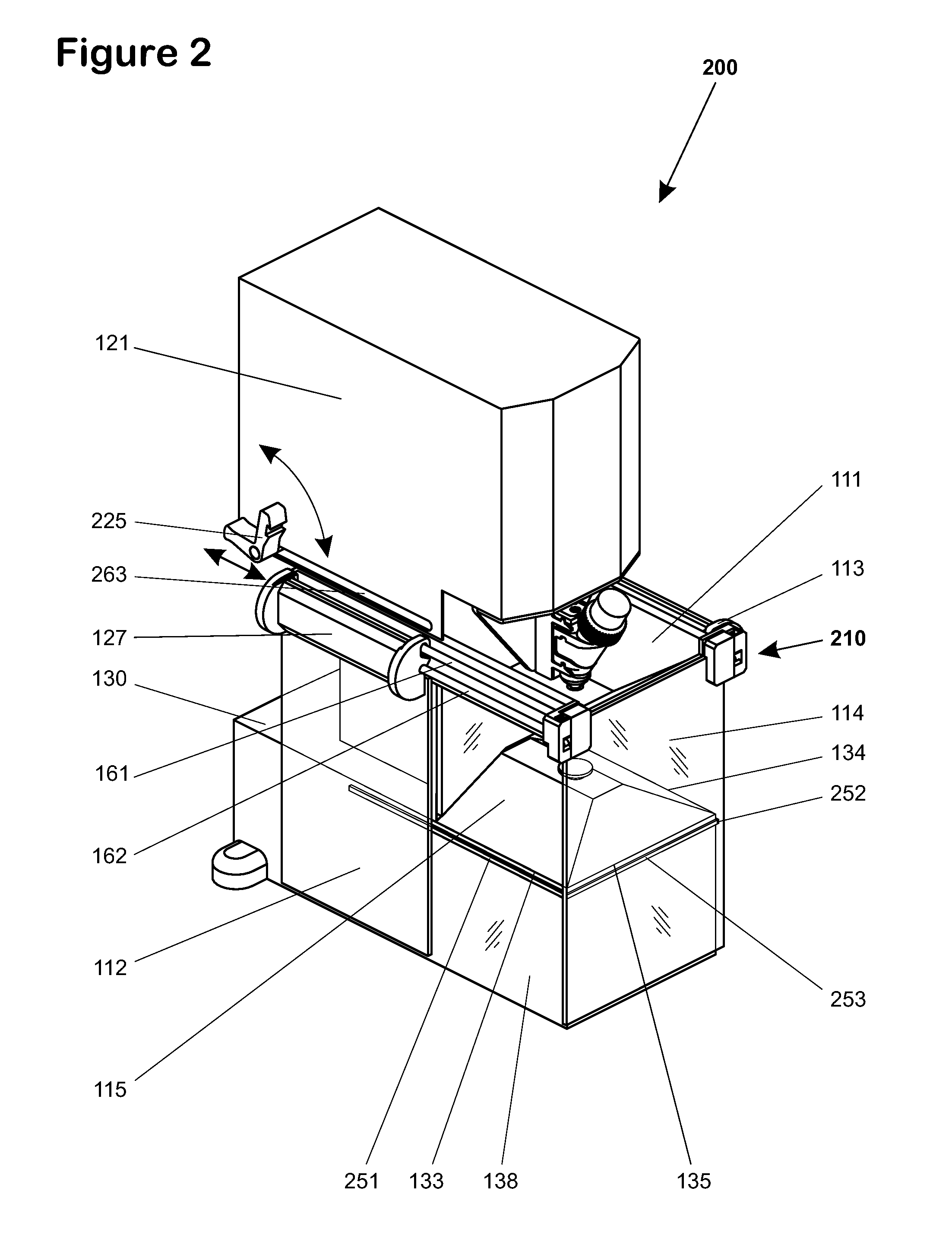

Exercise resistance machine

InactiveUS8808152B1Improve the immunitySmooth glidingFrictional force resistorsMovement coordination devicesThighIndependent motion

An exercise machine that facilitates exercises for a user's abdominal area, inner and outer thigh areas, upper body, and back areas includes a frame and a plurality of height adjustable legs which allow a user to selectively provide a comfortable height or inclined surface for personal exercise. The apparatus further includes a movable sliding platform assembly providing adjustable resistance. A pair of knee pads is pivotally affixed to the movable platform assembly and allows independent motioning in respective arcuate paths to exercise the user's oblique muscles. When the knee pads are motioned separately, the apparatus exercises the user's inner thigh, outer thigh, and stomach muscles. Additionally, the movable features of the apparatus enable a user to exercise various other specific body areas.

Owner:MIDGETT TRUDY R

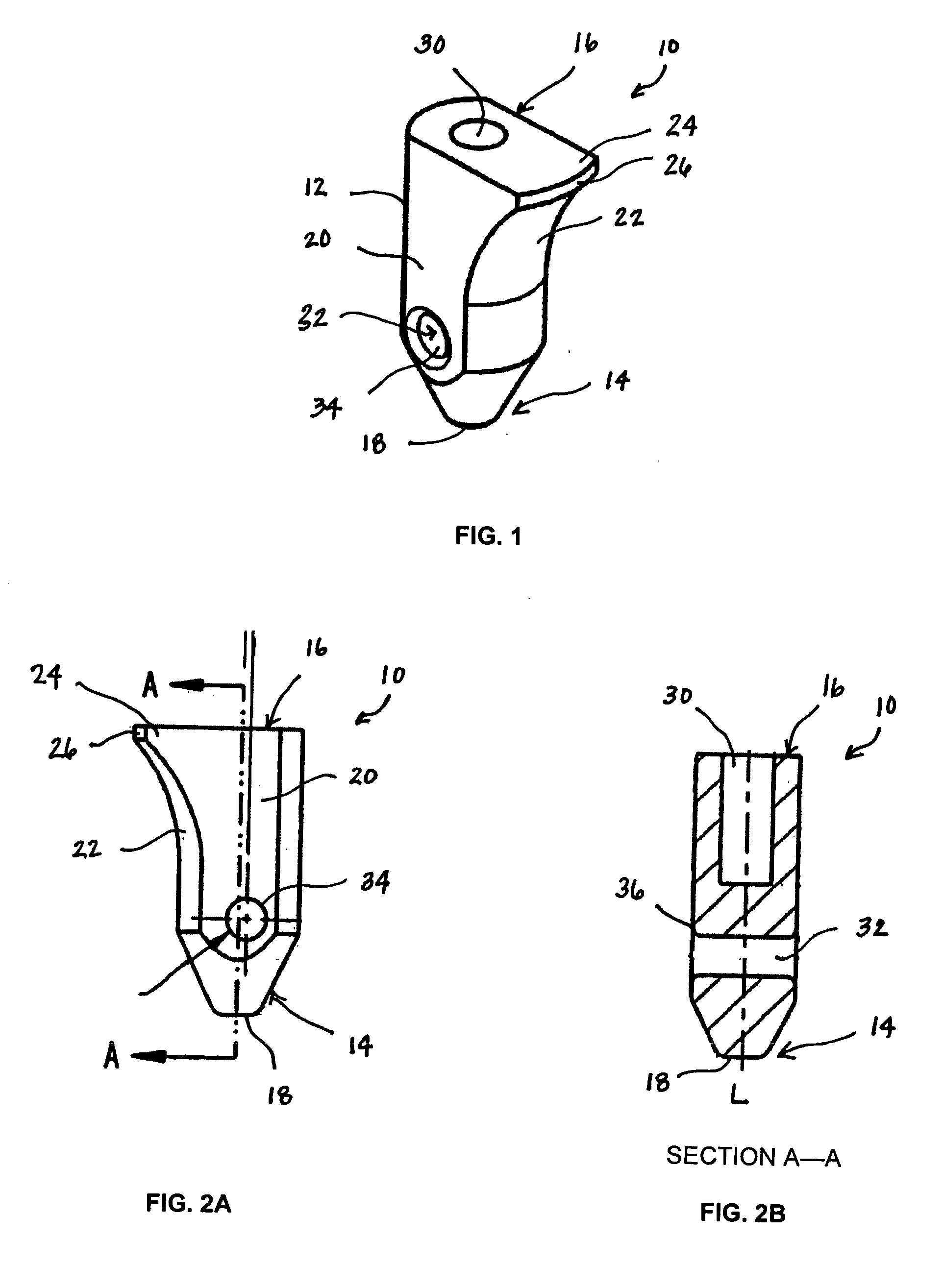

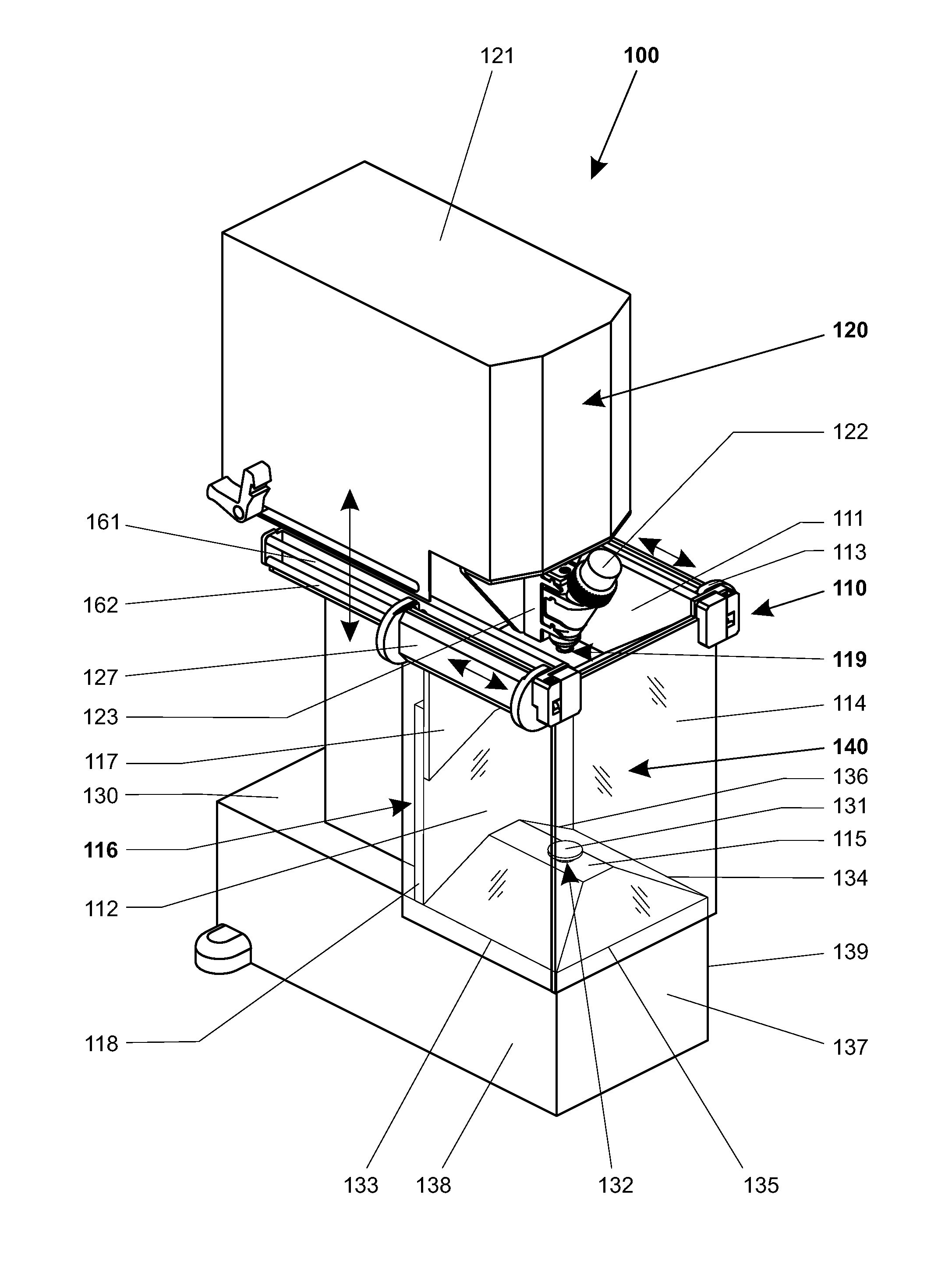

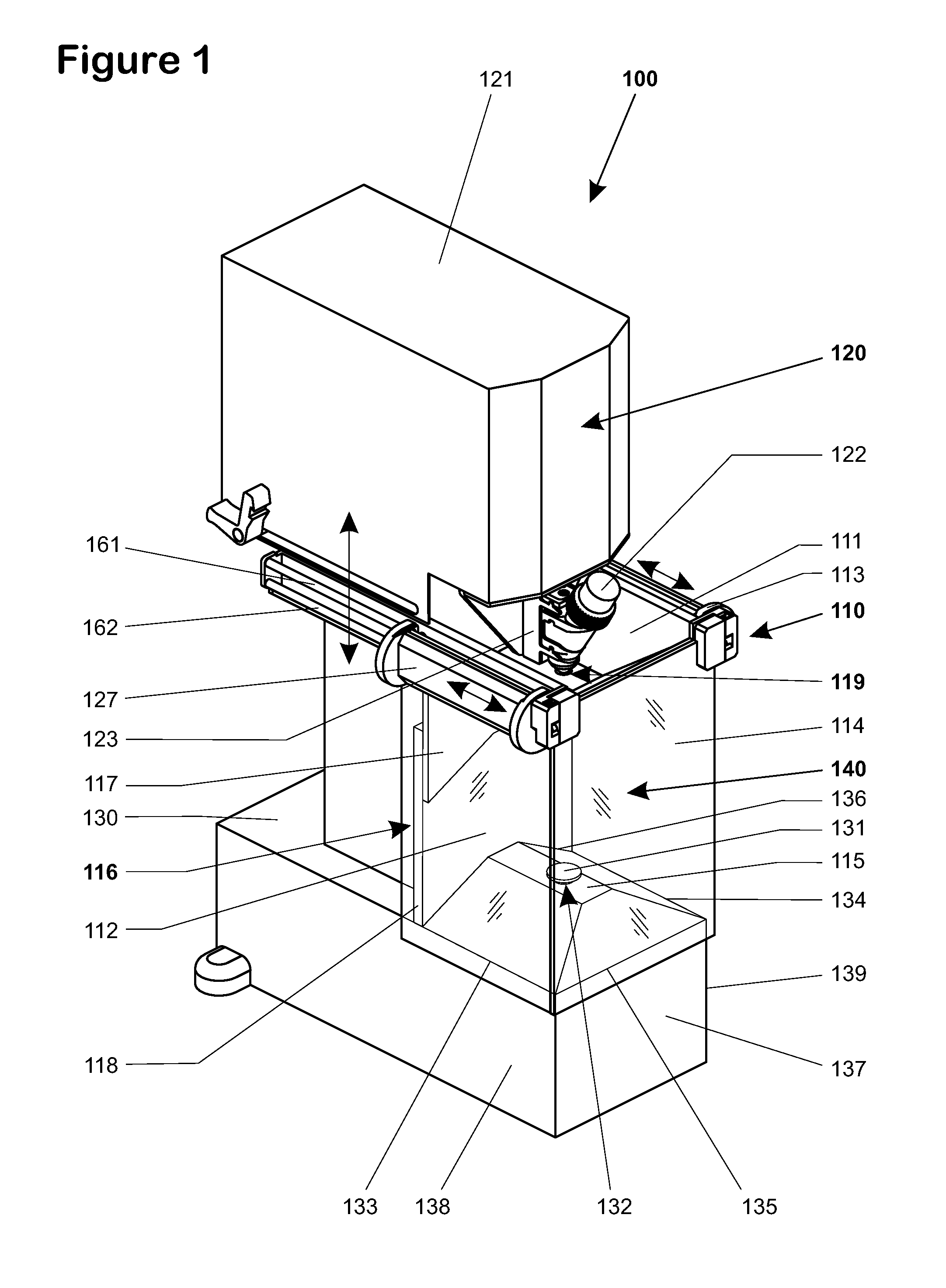

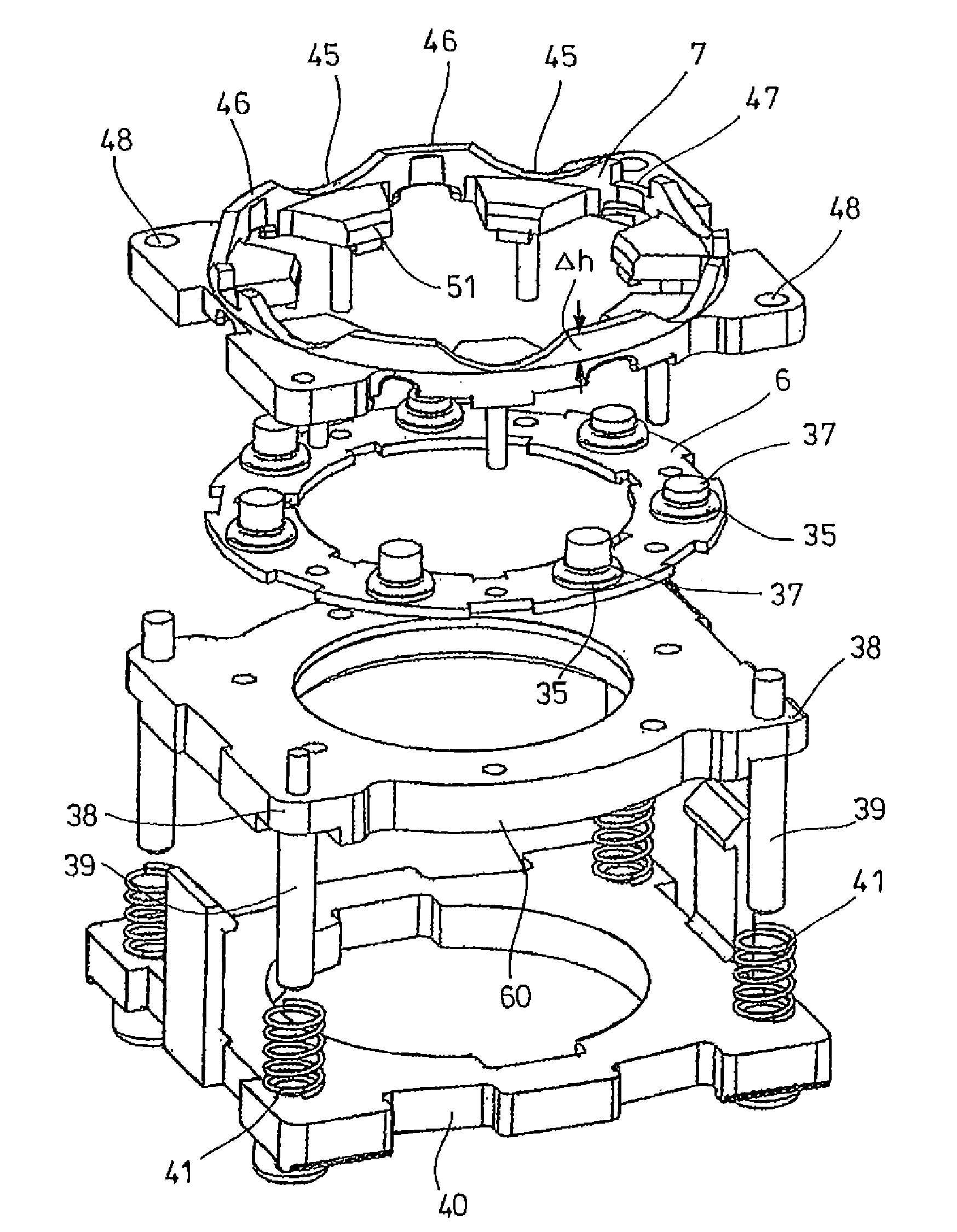

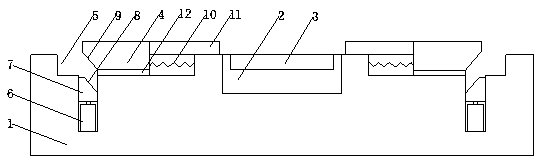

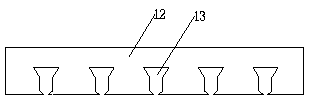

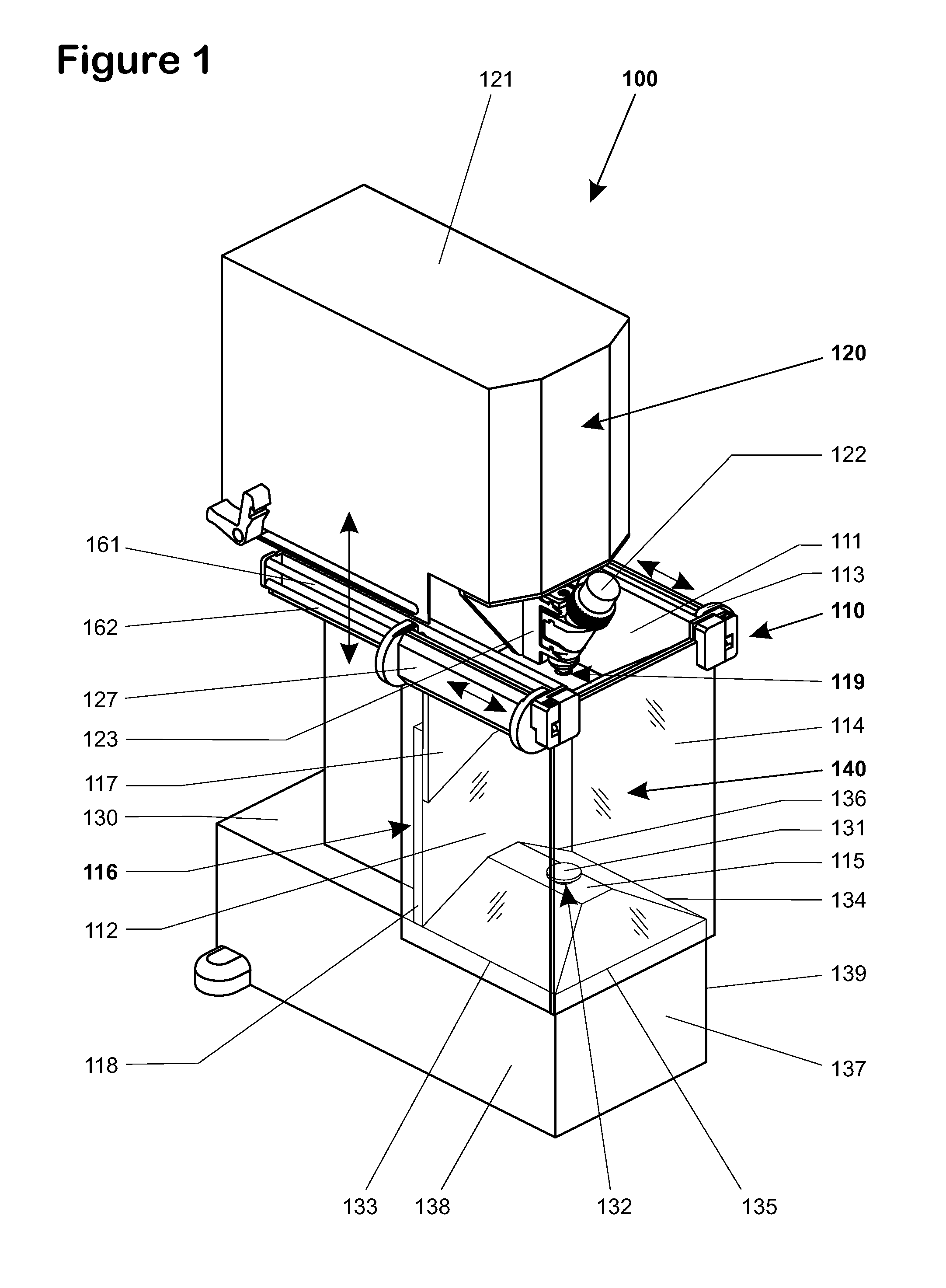

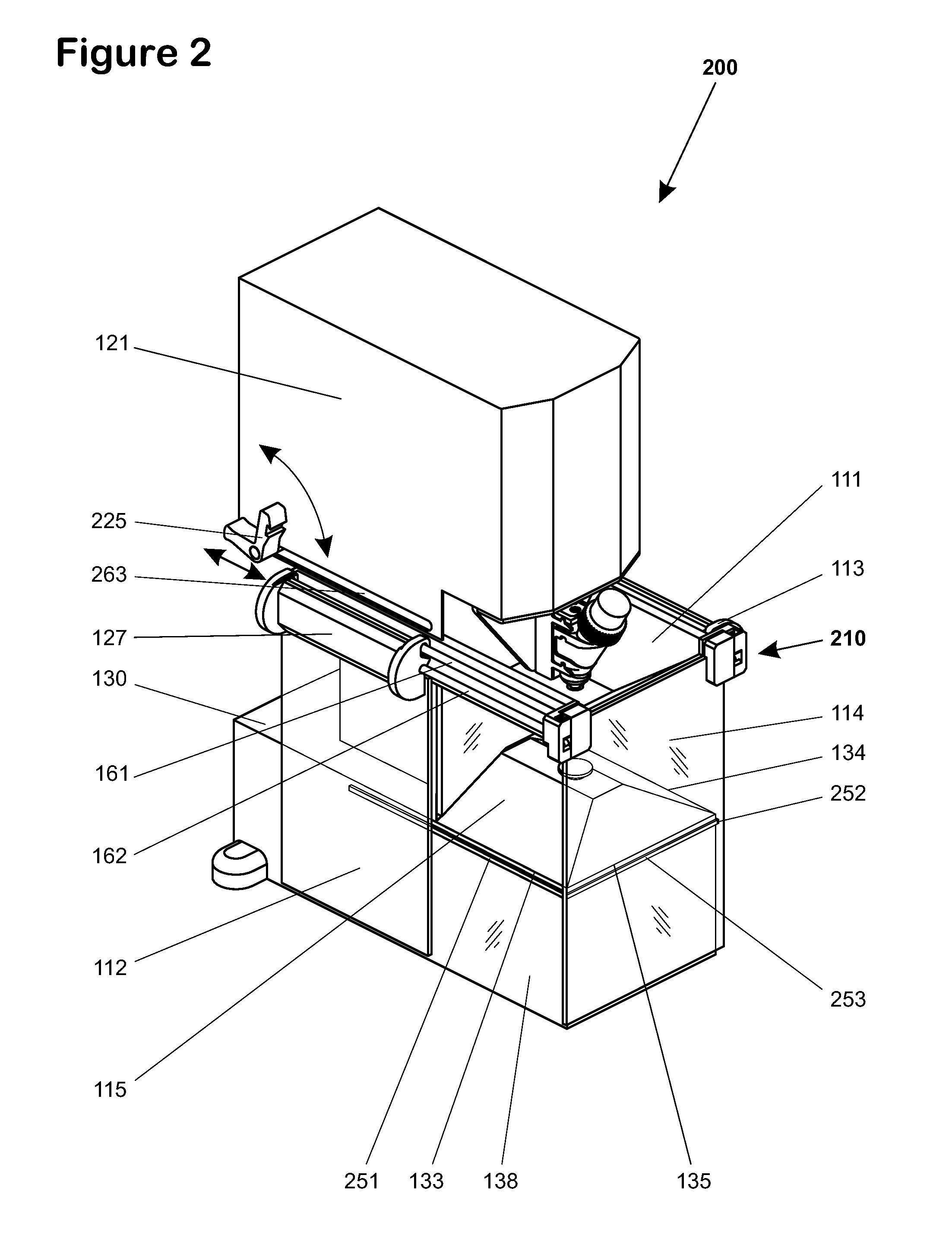

Draft protection device for a laboratory instrument

ActiveUS20100288566A1Smooth glidingAvoid large gapsShow cabinetsWeighing apparatus detailsEngineeringTop cap

Owner:METTLER TOLEDO GMBH

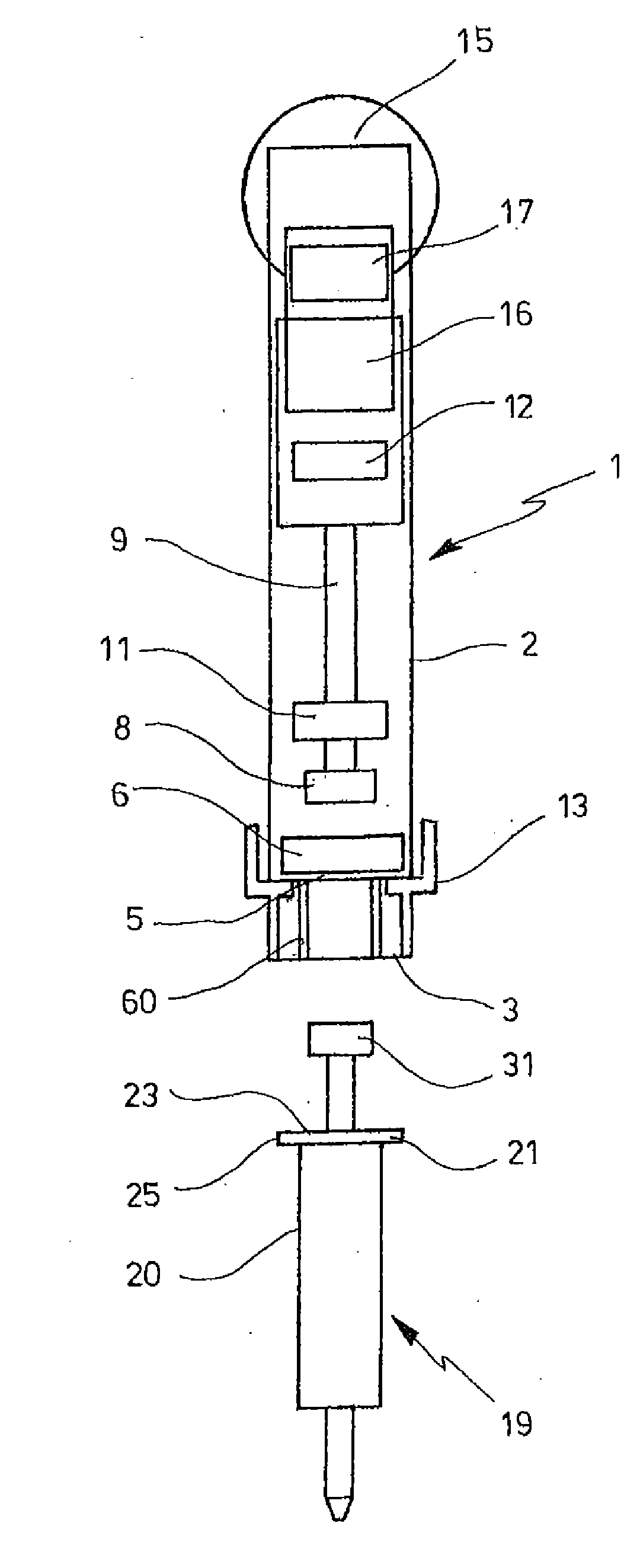

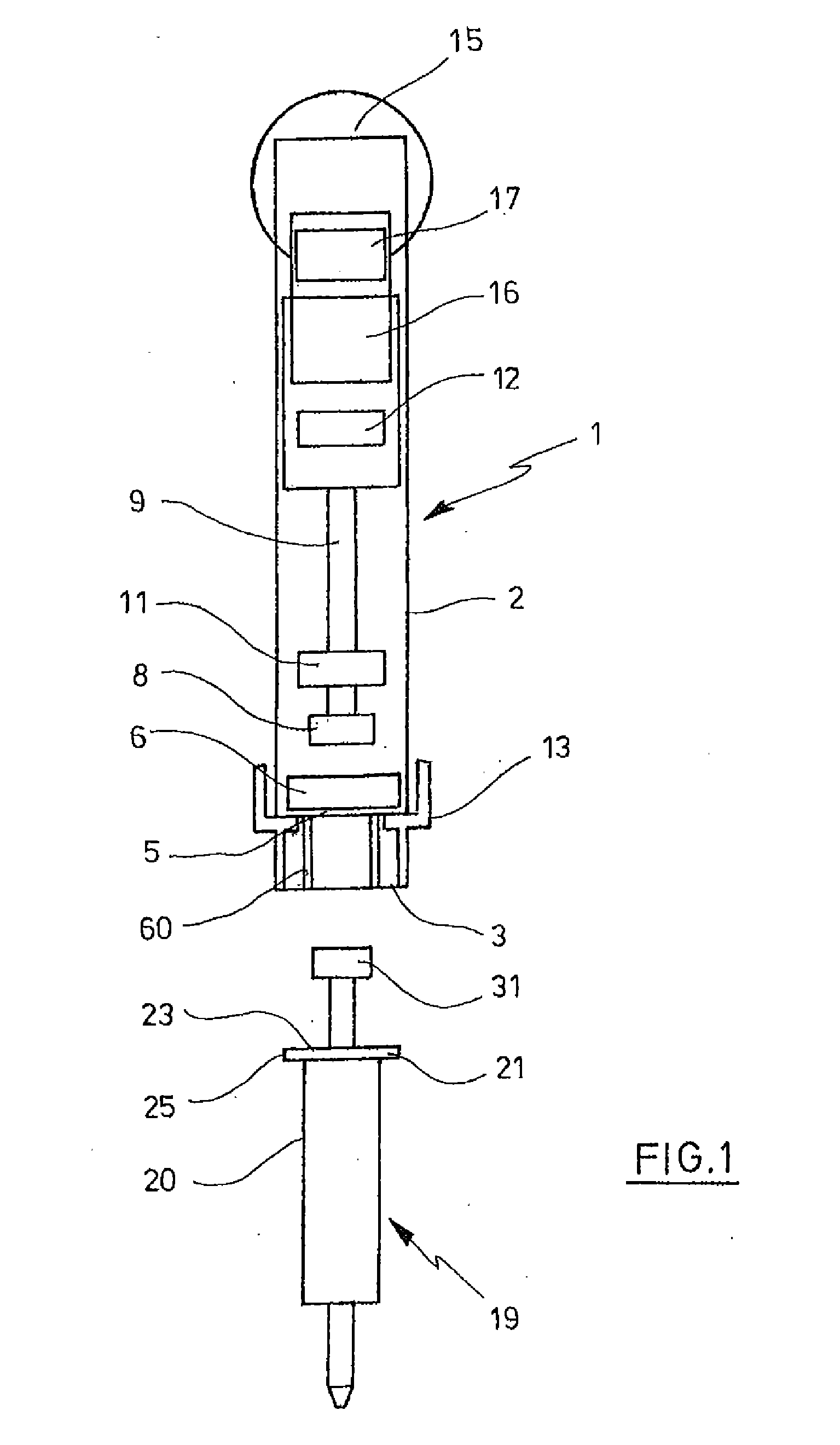

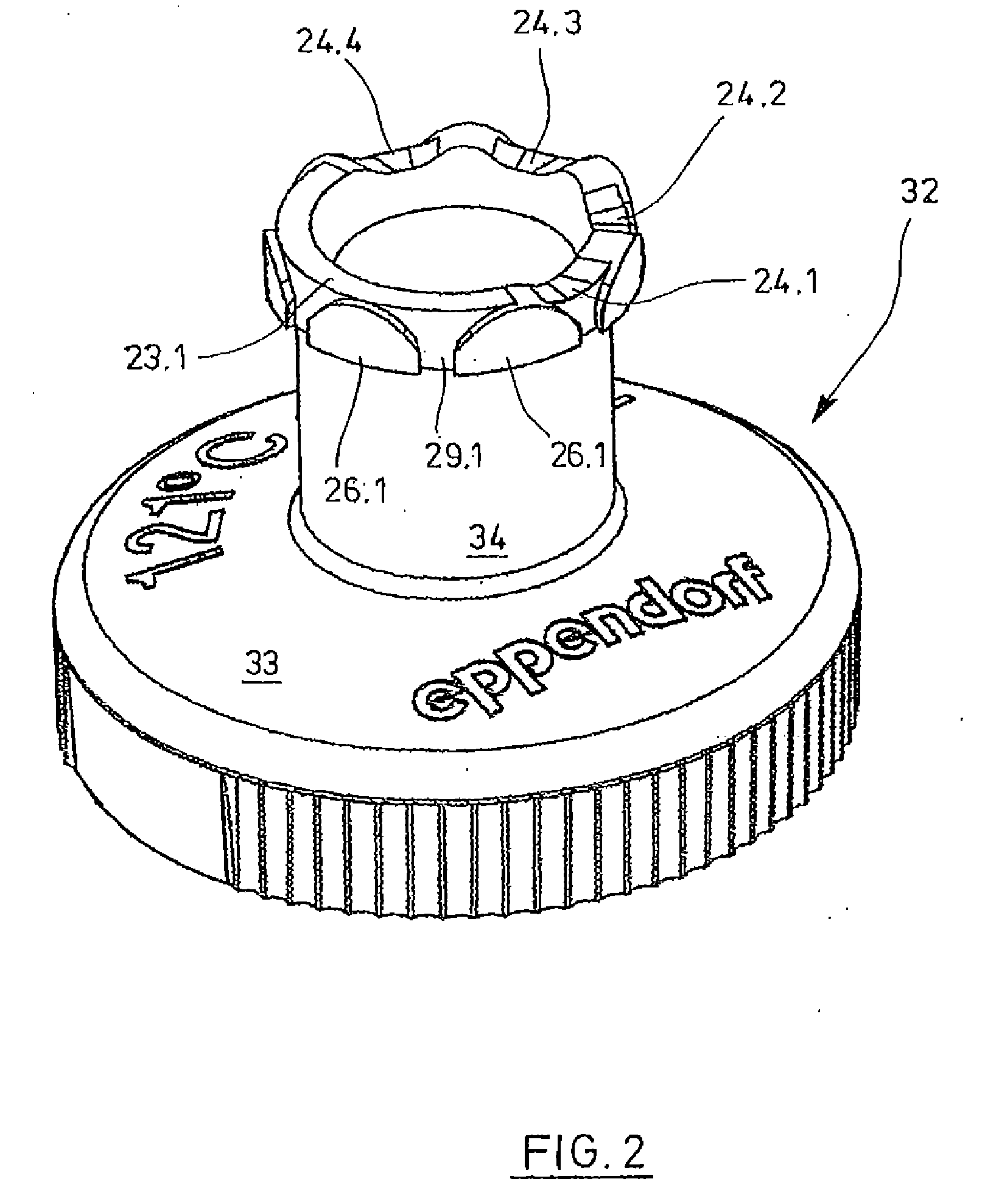

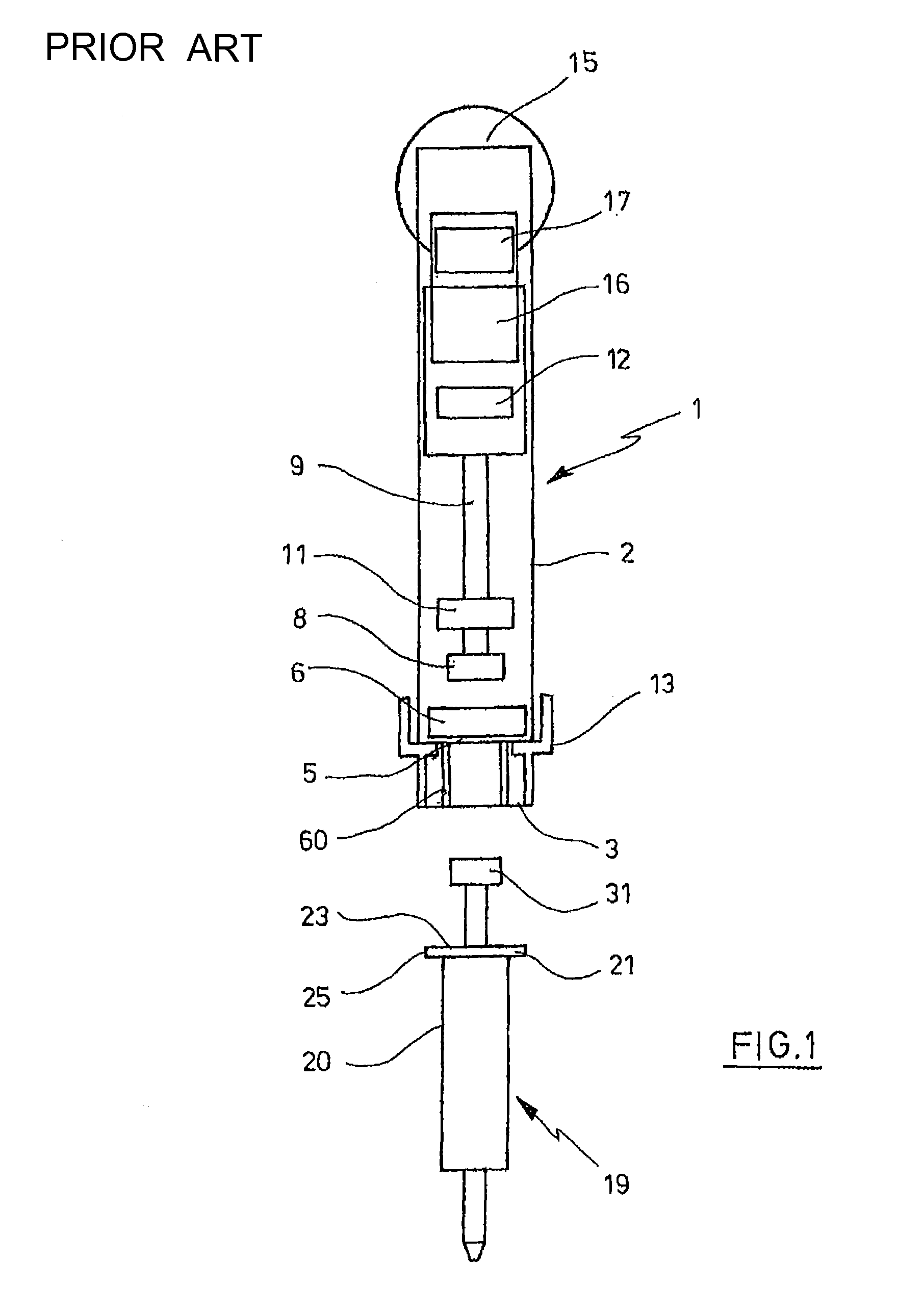

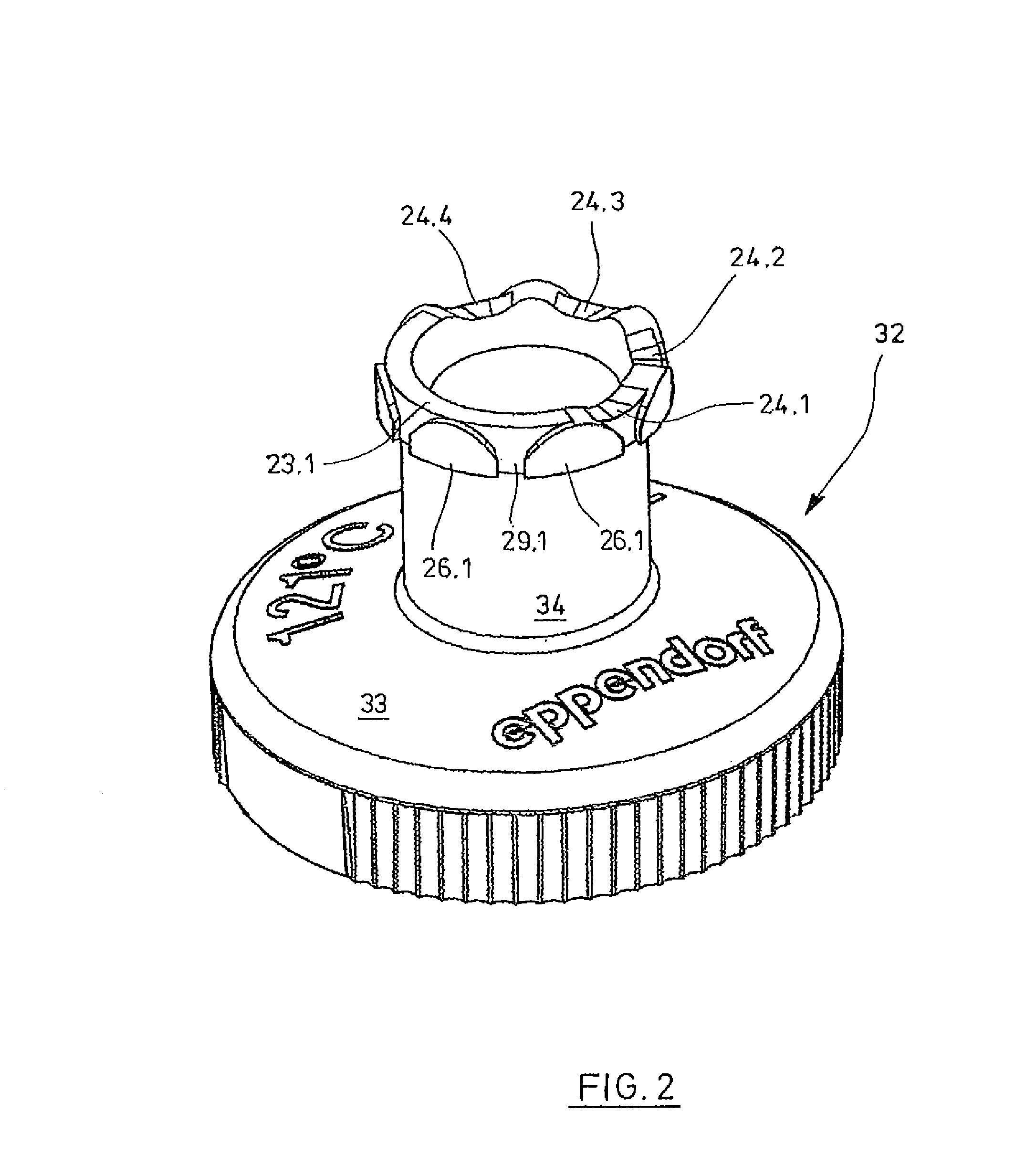

Metering Device

ActiveUS20100266454A1Avoid damageNot to damageWithdrawing sample devicesBurettes/pipettesEngineeringPlunger

A metering device for utilisation with a syringe, which features on a syringe cylinder a fastening portion with at least one axially directed sensing surface projecting from the upside, and at least one alignment nose projecting from the outer perimeter of the fastening portion, and a plunger with a plunger rod, the metering device having an accommodation for the fastening portion of the syringe cylinder, the accommodation having an axial opening for axially inserting the fastening portion into a fastening position, a sensing device disposed in the accommodation with at least one sensing means projecting from a basis surface of the sensing device facing the axial opening, for sensing the at least one sensing surface of a fastening portion inserted in a fastening position.

Owner:EPPENDORF SE

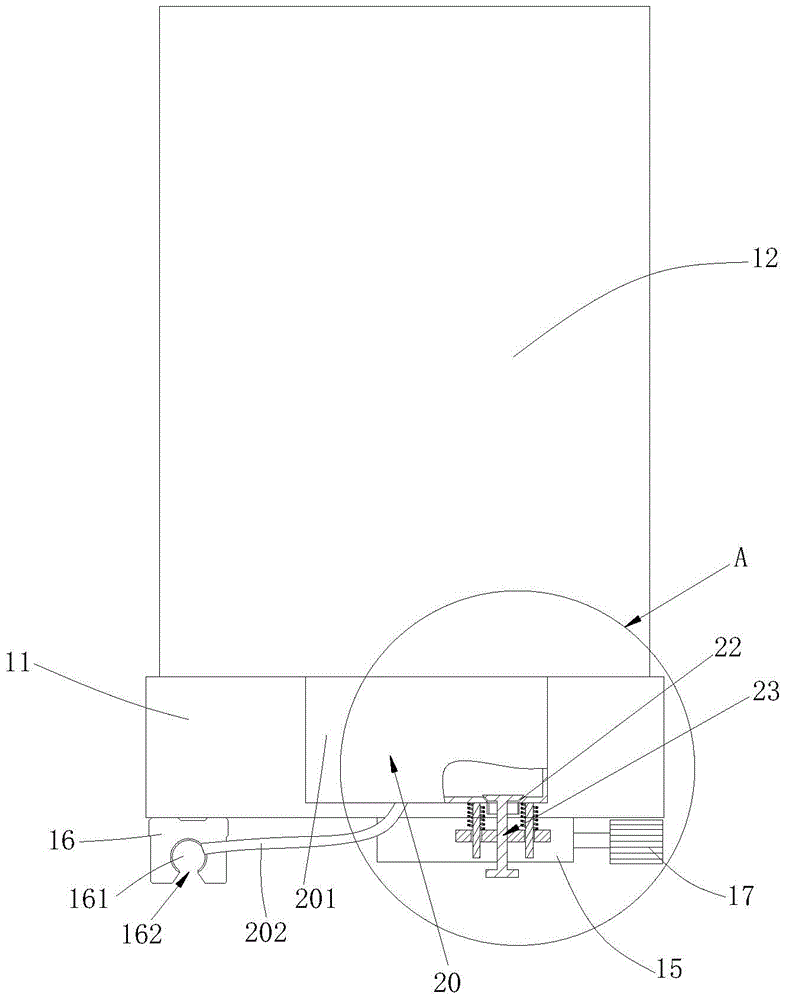

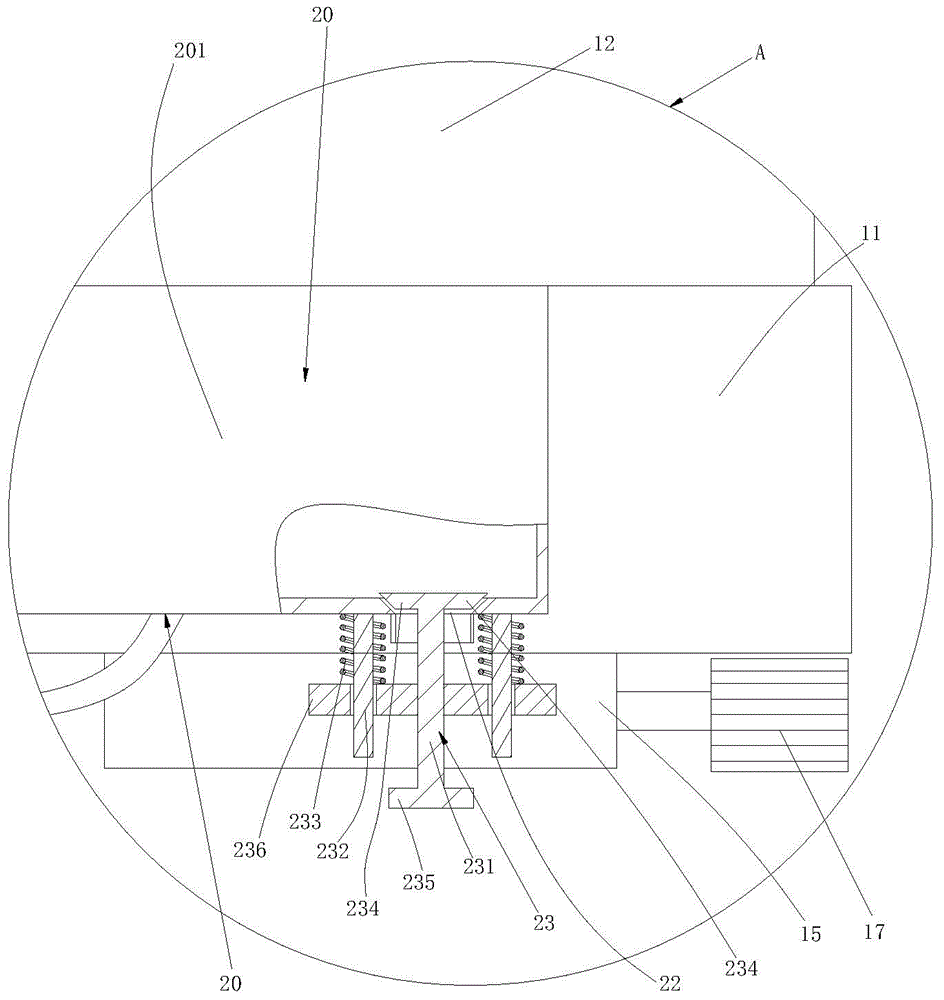

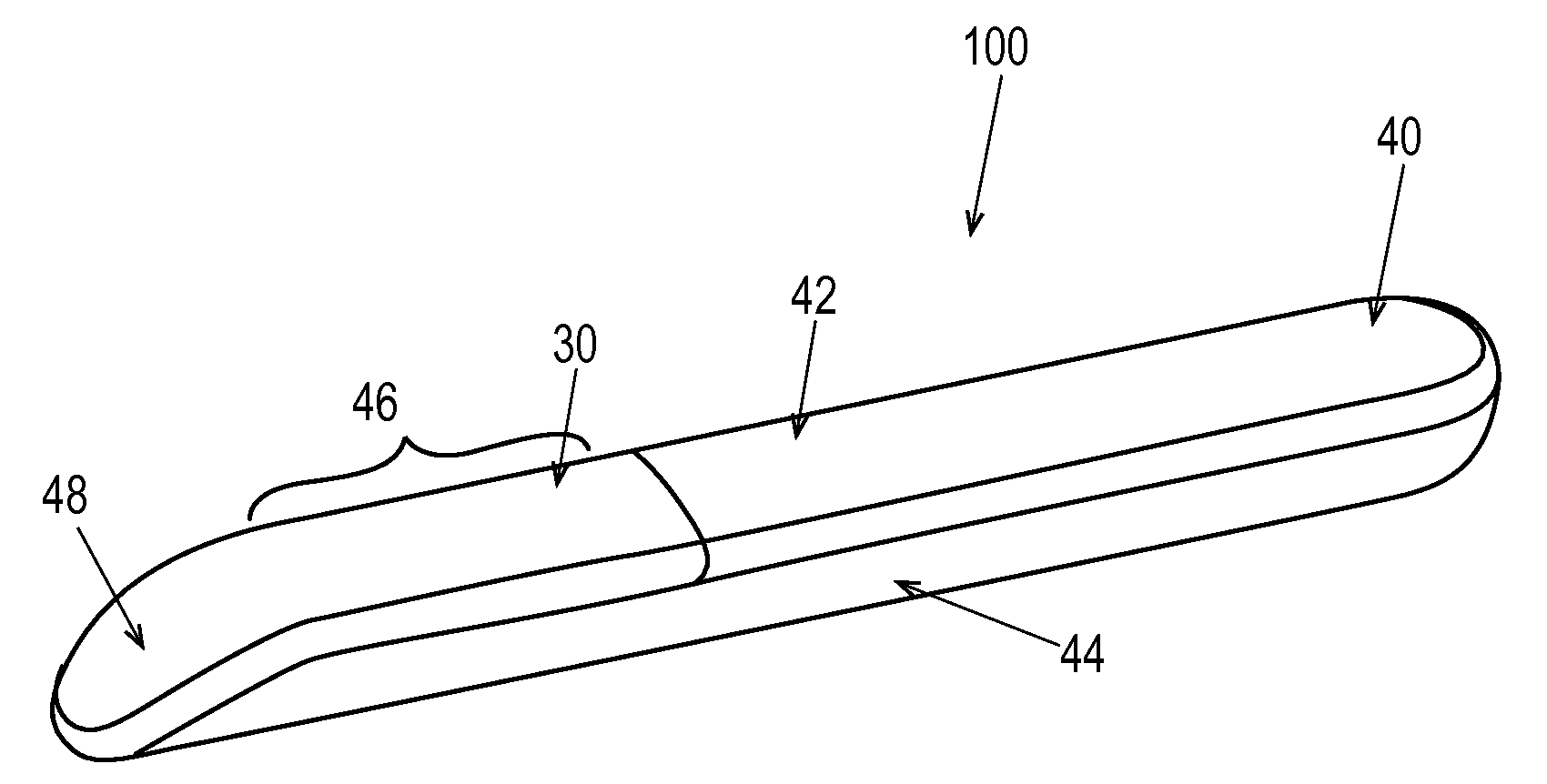

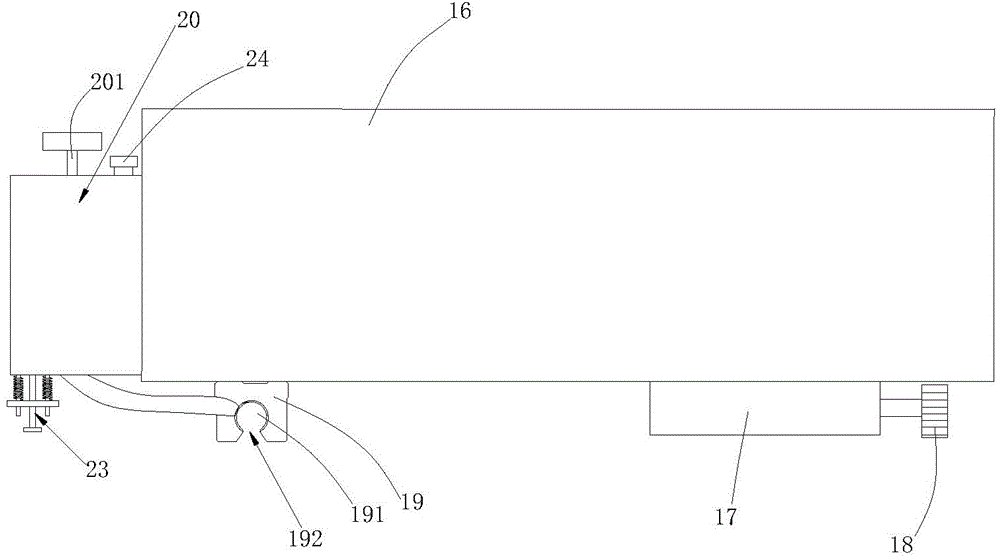

Retractable screen and frame assembly

InactiveUS20070029049A1Smooth slidingSmooth glidingScreensSunshadesEngineeringMechanical engineering

The present invention is a retractable screen (22) and frame (24) assembly (20). The frame (24) includes a first track (32) and a second track (34) in spaced and parallel relationship to the first track (32). The retractable screen (22) includes a canister (36), a screen cloth (38), a control bar (40), a first glide (42), a second glide (44), and a biasing device (46). The biasing device (46) is disposed between a first end (52) of the control bar (40) and the first glide (42). The first glide (42) is inserted into the first track (32) and the second glide (44) is inserted into the second track (34). The glides (42, 44) slide along the respective tracks (32, 34) while the biasing device (46) biases the first end (52) of the control bar (40) with respect to the first track (32). The biasing provided by the biasing device (46) prevents the control bar (40) from binding with the tracks (32, 34) as the control bar (40) and the glides (42, 44) are slid along the tracks (32, 34).

Owner:QUANEX HOMESHIELD LLC

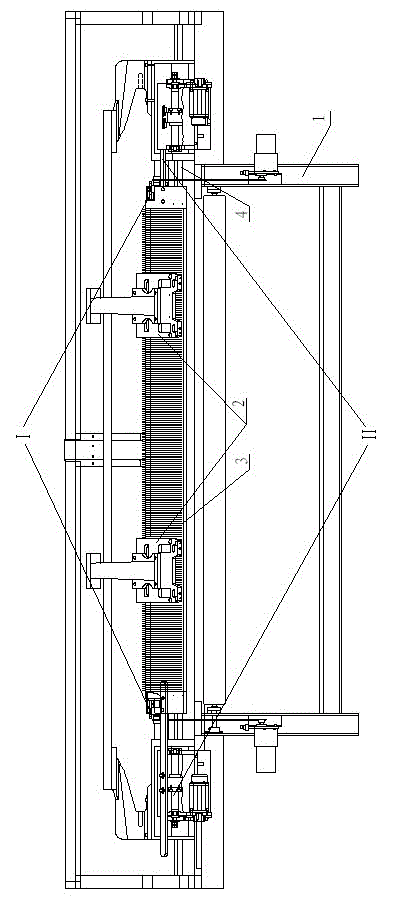

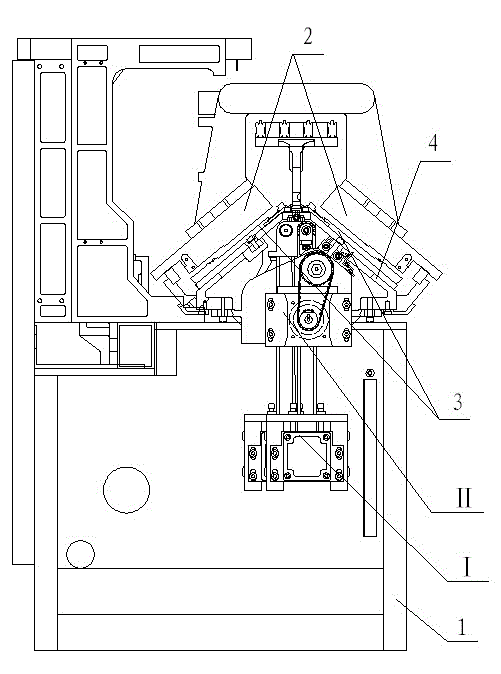

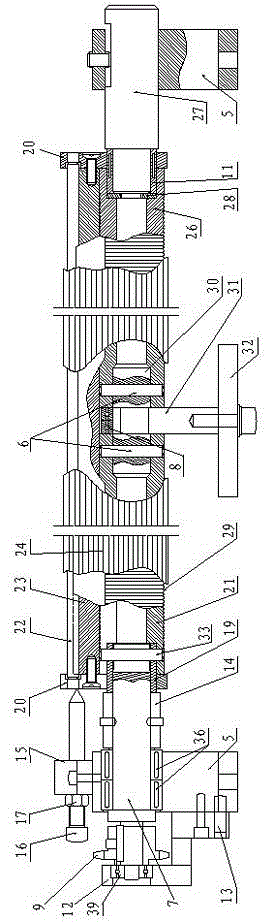

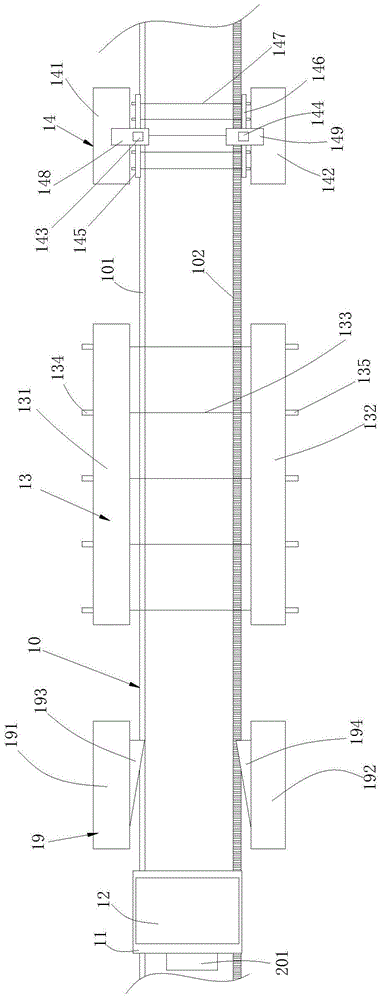

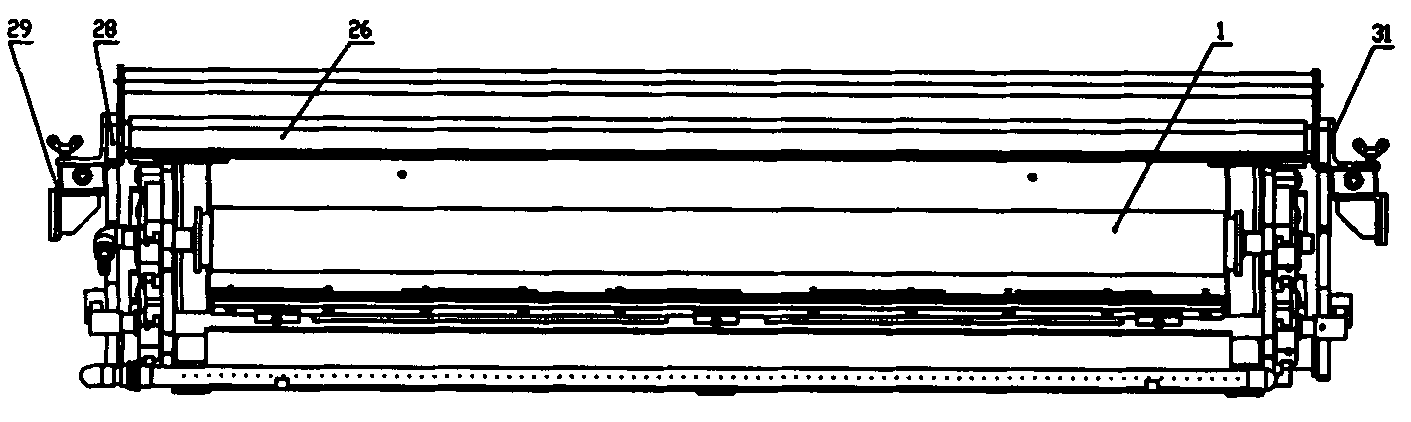

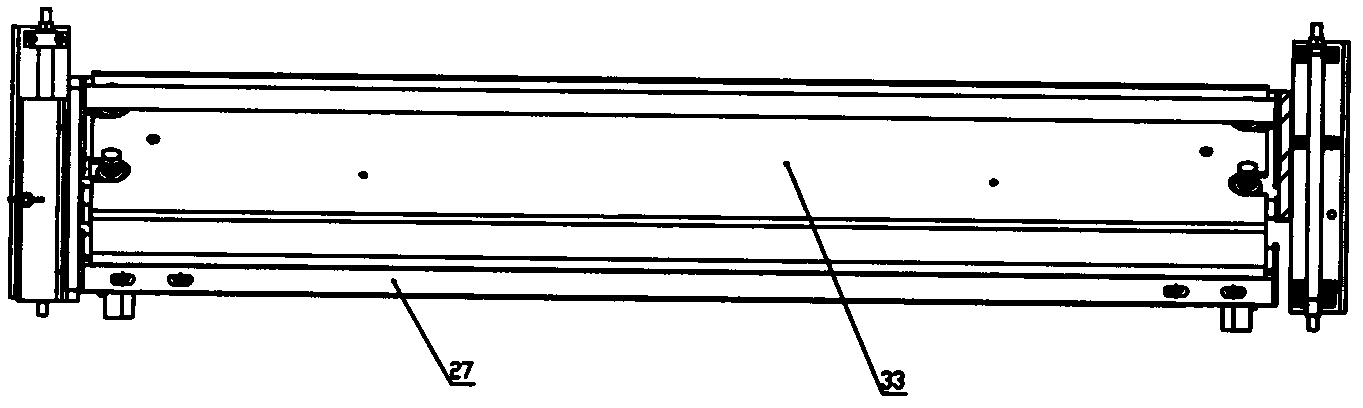

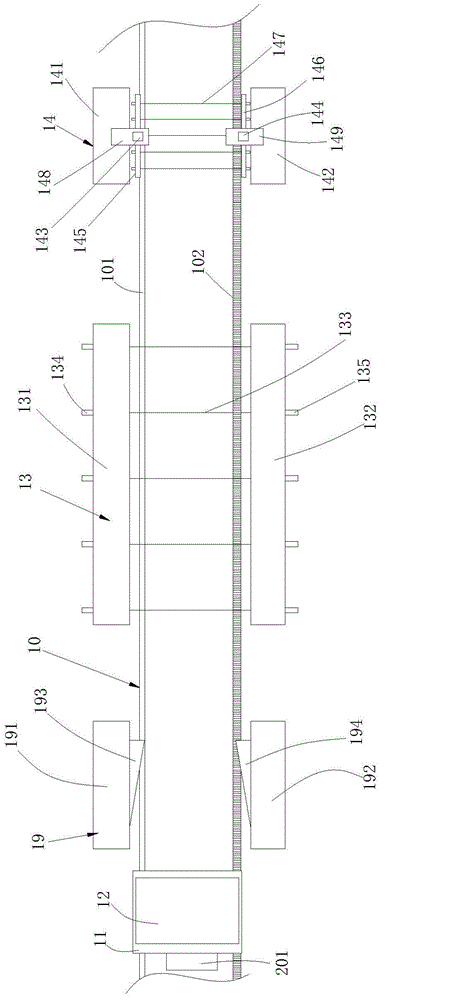

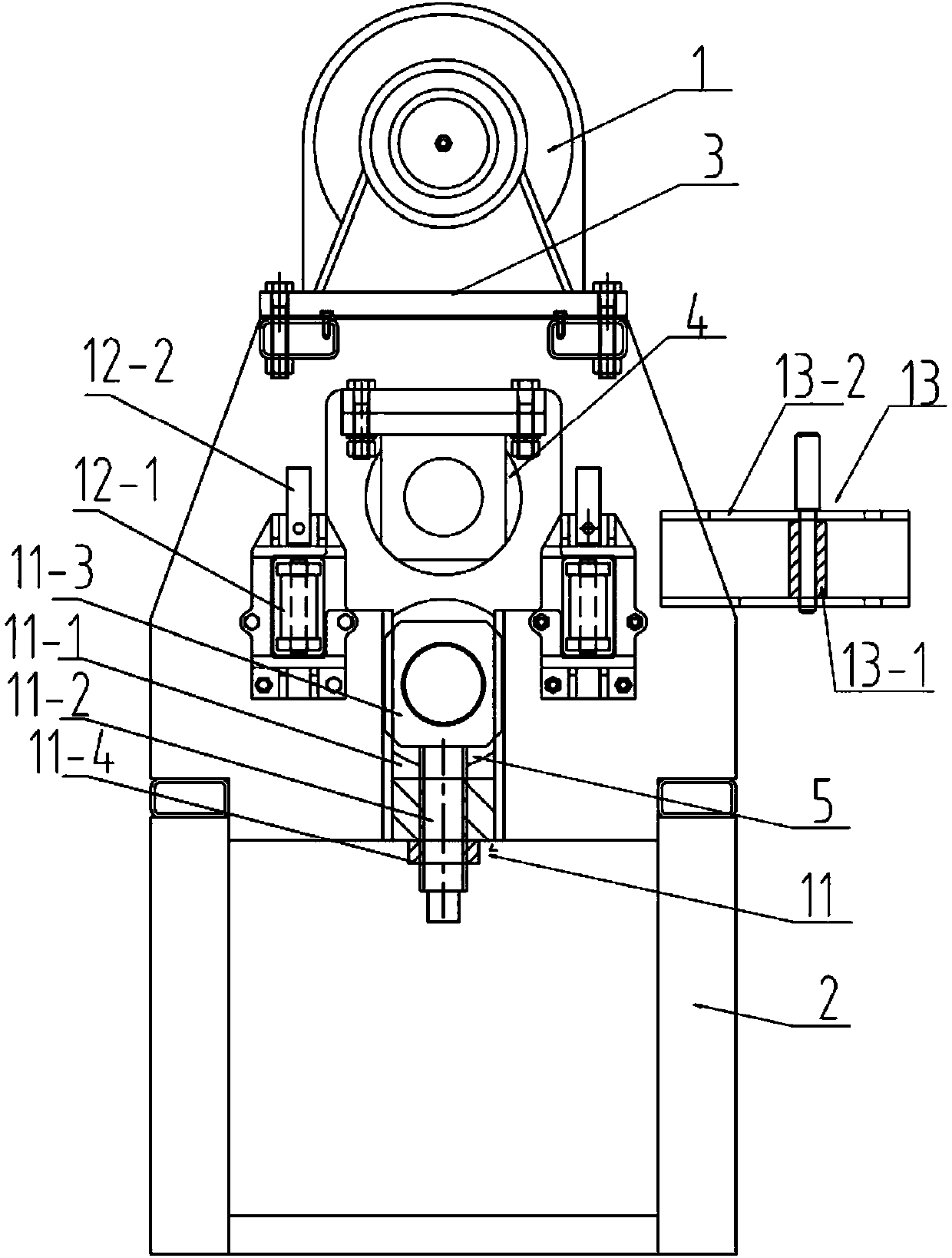

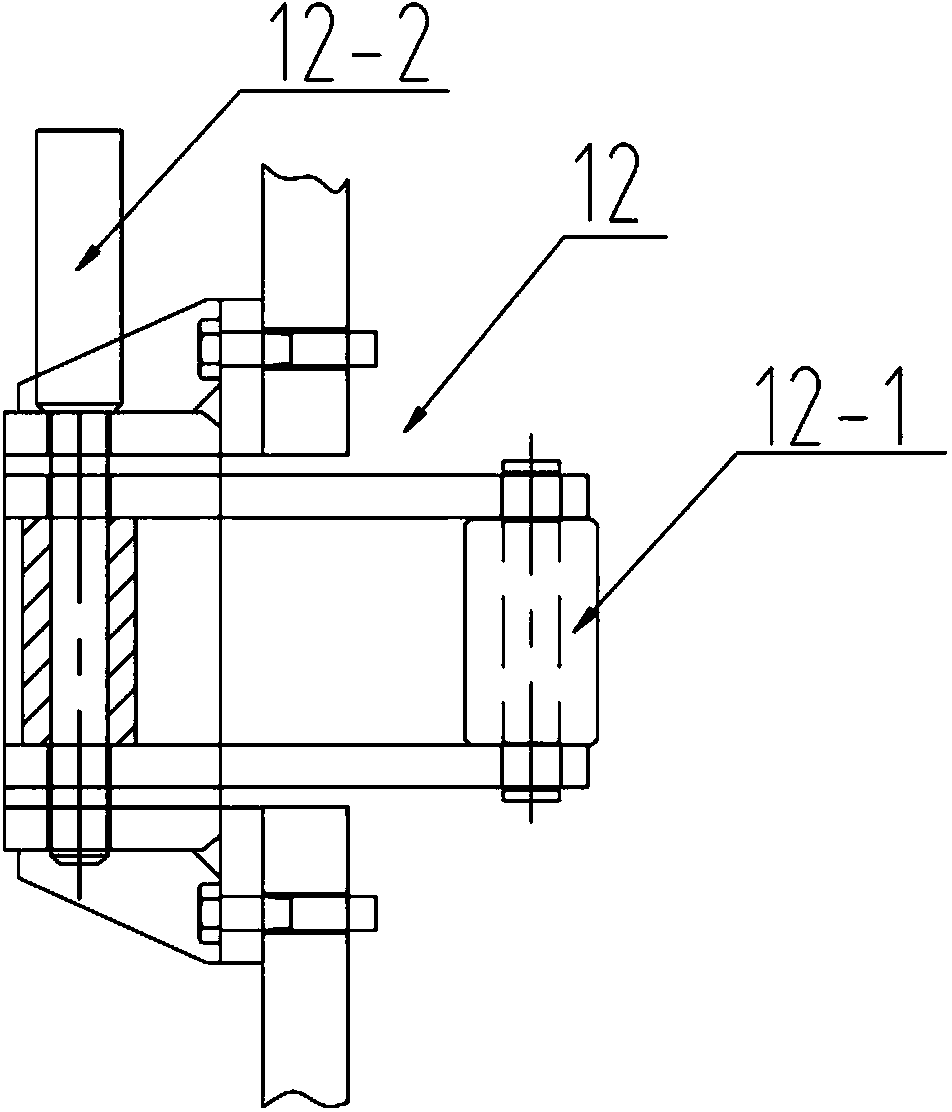

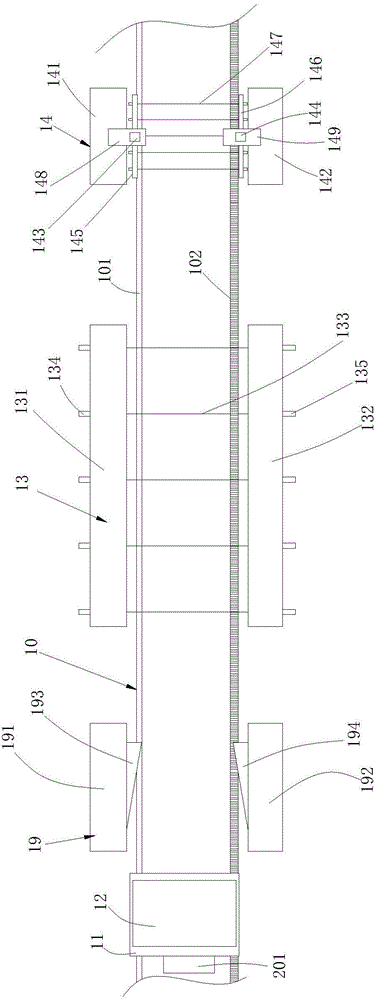

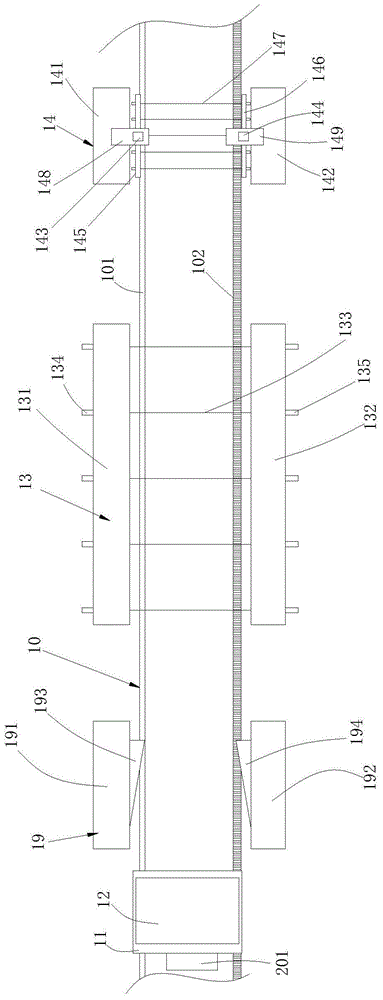

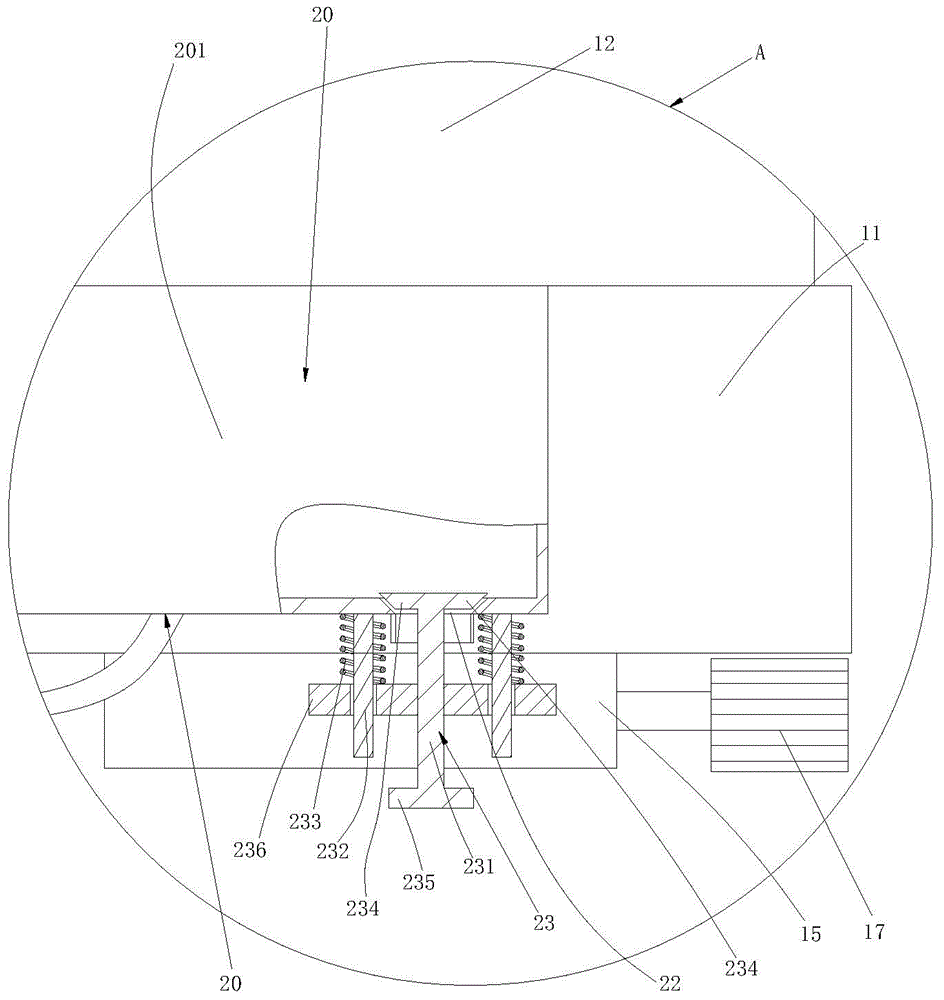

Double-head computerized flat knitter, high roller device and double shaking table devices thereof

ActiveCN102912551AReasonable structural designReduce distanceWeft knittingFixed framePulp and paper industry

The invention discloses a double-head computerized flat knitter, a high roller device and double shaking table devices thereof. The double-head computerized flat knitter comprises a rack component, machine heads, double needle distribution plates, the high roller device and the double shaking table devices, wherein the two needle distribution plates are arranged on two tilting surfaces of a fixed frame respectively in a sliding mode and correspond to the two machine heads; the double shaking table devices comprise two rockers connected with needle distribution plates receptively; the high roller device is provided with a first taper roller rod, a second taper roller rod, a roller support unit and two roller drive units; and each of the first taper roller rod and the second taper roller rod is arranged on the roller support unit and connected with a roller drive unit, and the top of the high roller device is in a taper shape and matched with the tops of the double needle distribution plates. The invention further provides the high roller device and the double shaking table devices. According to the knitter, the high roller device and the double shaking table devices, the design is reasonable, the cost is low, the breaking rate of knitting threads is low, the operation is stable and reliable, the sliding distance between the two needle distribution plates is small, and the swinging speed and the working efficiency are high.

Owner:TONGLU YONGSHENG KNITTING MACHINERY

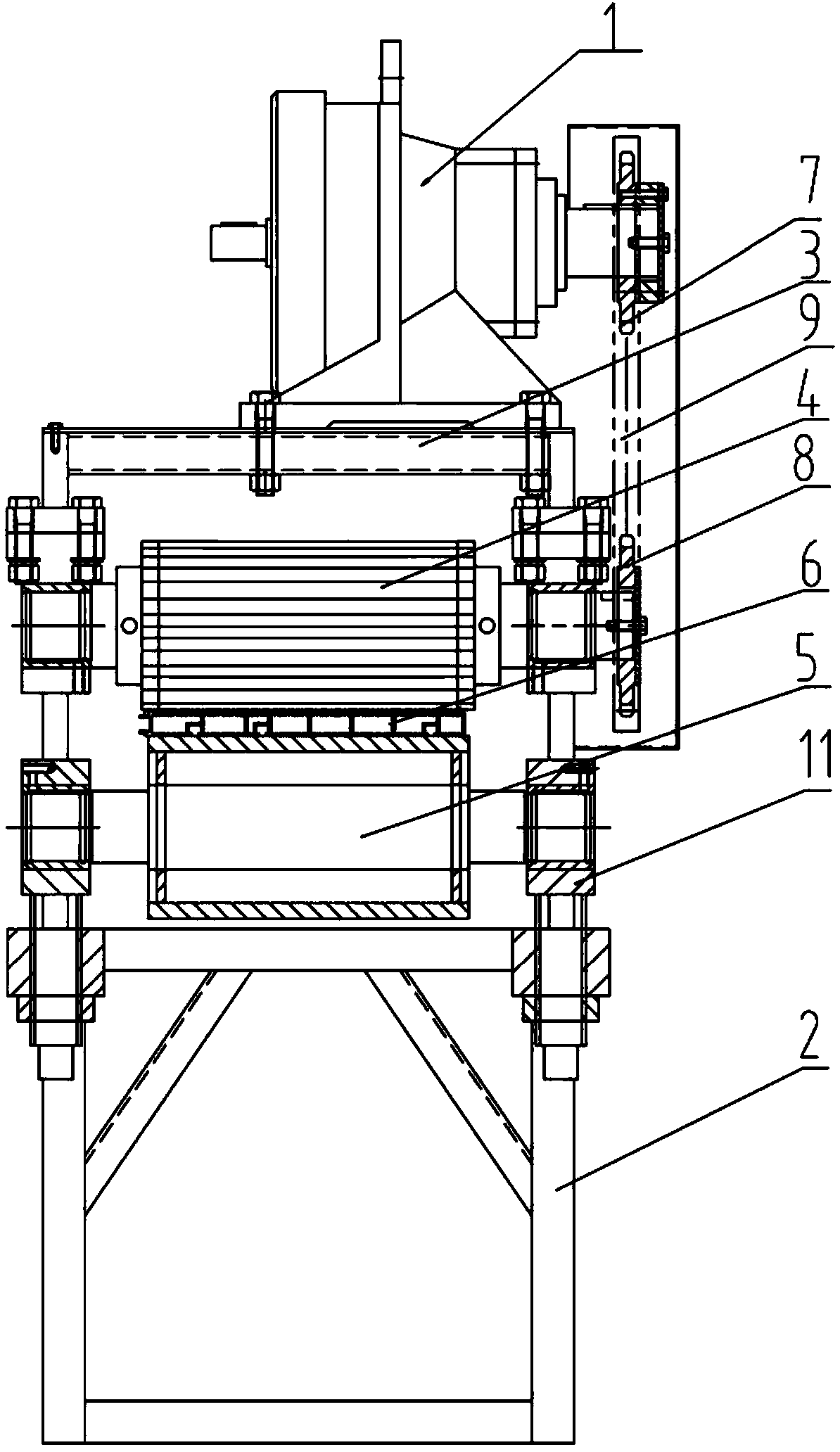

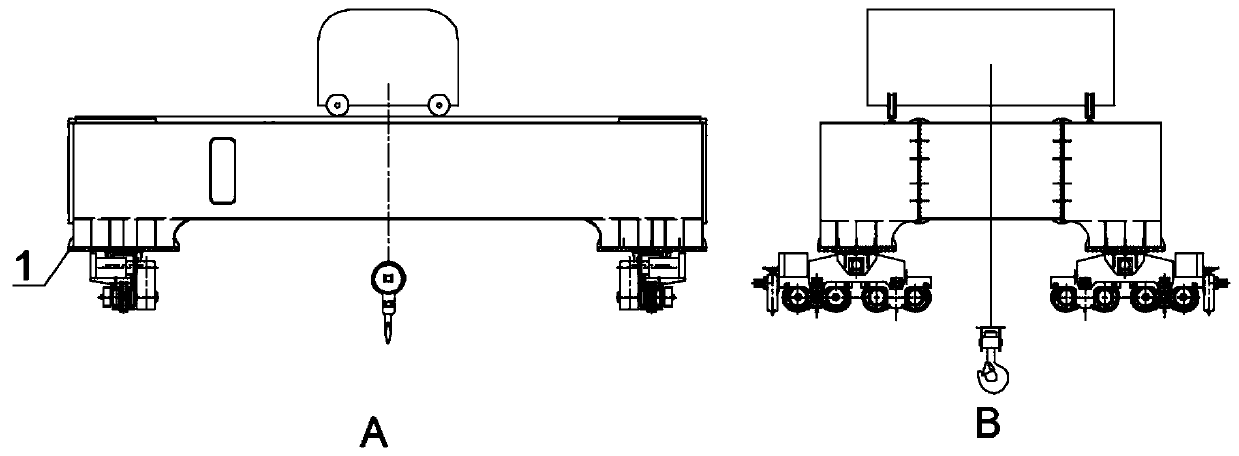

Power assembly for electric passenger car

ActiveCN102653231ASmooth glidingImprove machining accuracyGearing detailsControl devicesLeft halfReduction drive

The invention discloses a power assembly for an electric passenger car. A differential mechanism shell is arranged inside a differential shell, the differential mechanism shell is internally provided with a differential part, a left half shaft and a right half shaft which are connected with the differential part respectively extend left and right; one side of the differential shell is fixedly connected with a driving motor shell, and a transmission mechanism is arranged between a rotor shaft in the driving motor and the differential shell; a first bearing is arranged between the left part of the differential shell and a differential left cover of the differential shell, the right part of the differential shell is connected with a support disk by virtue of a second bearing, and a support shaft is fixedly connected between a differential right cover of the differential shell and the support disk; and the transmission mechanism comprises two outer toothed sleeves and an inner toothed sleeve as well as gears which are matched with the outer toothed sleeves and the inner toothed sleeve. The power assembly for the electric passenger car disclosed by the invention has the advantages of easiness for processing, easiness for assembling, high accuracy, no noise, smoothness and reliability in operation and long service life.

Owner:DALIAN JINHUA GEARBOX MFG

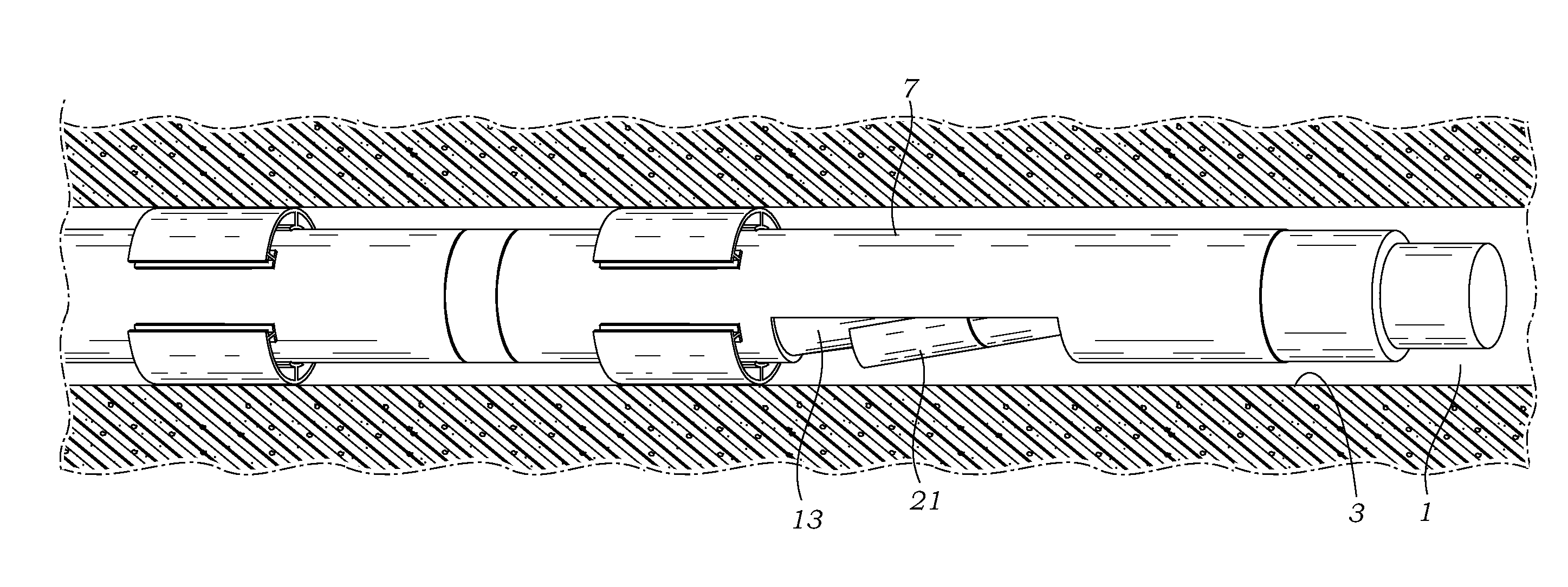

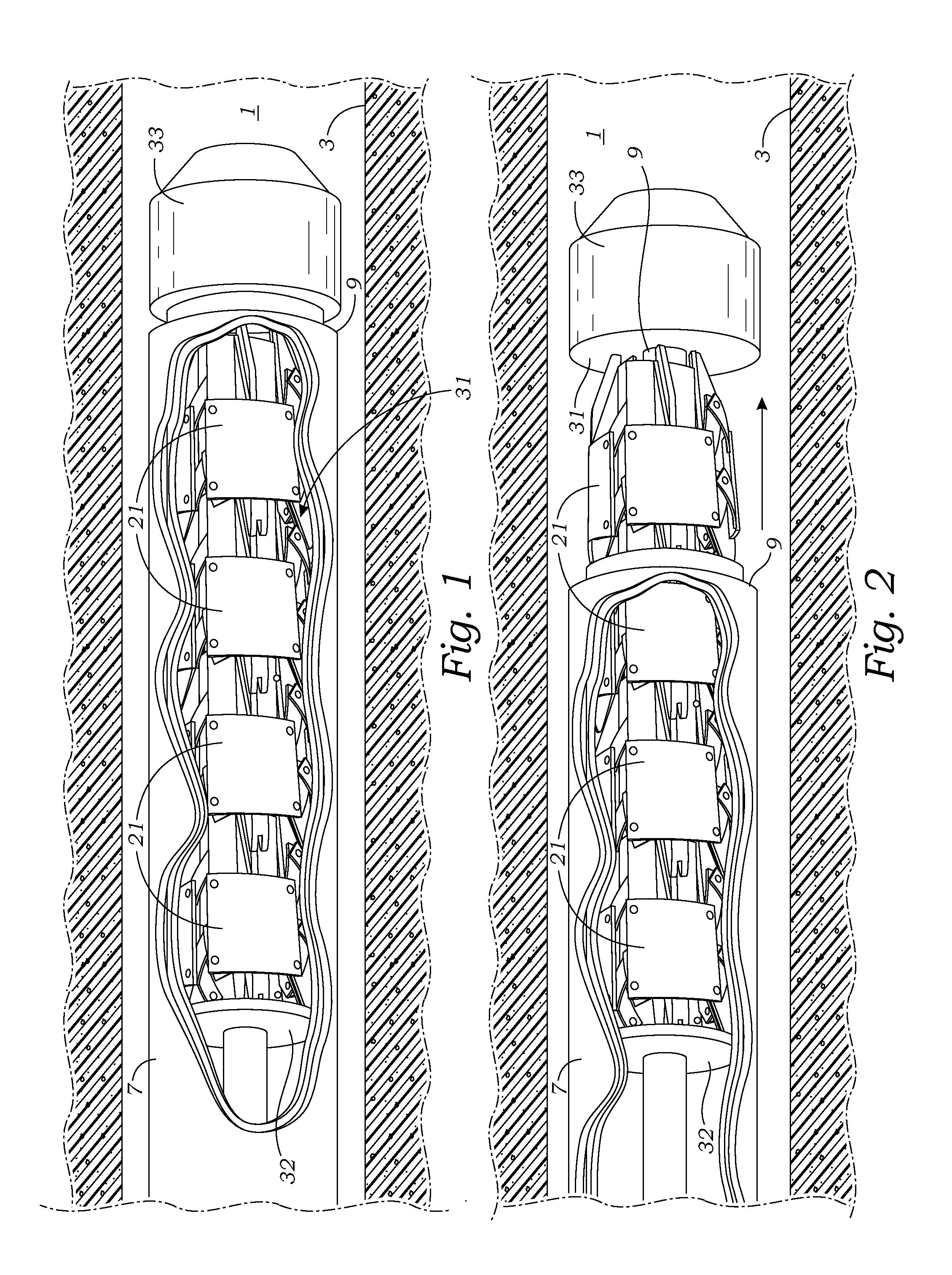

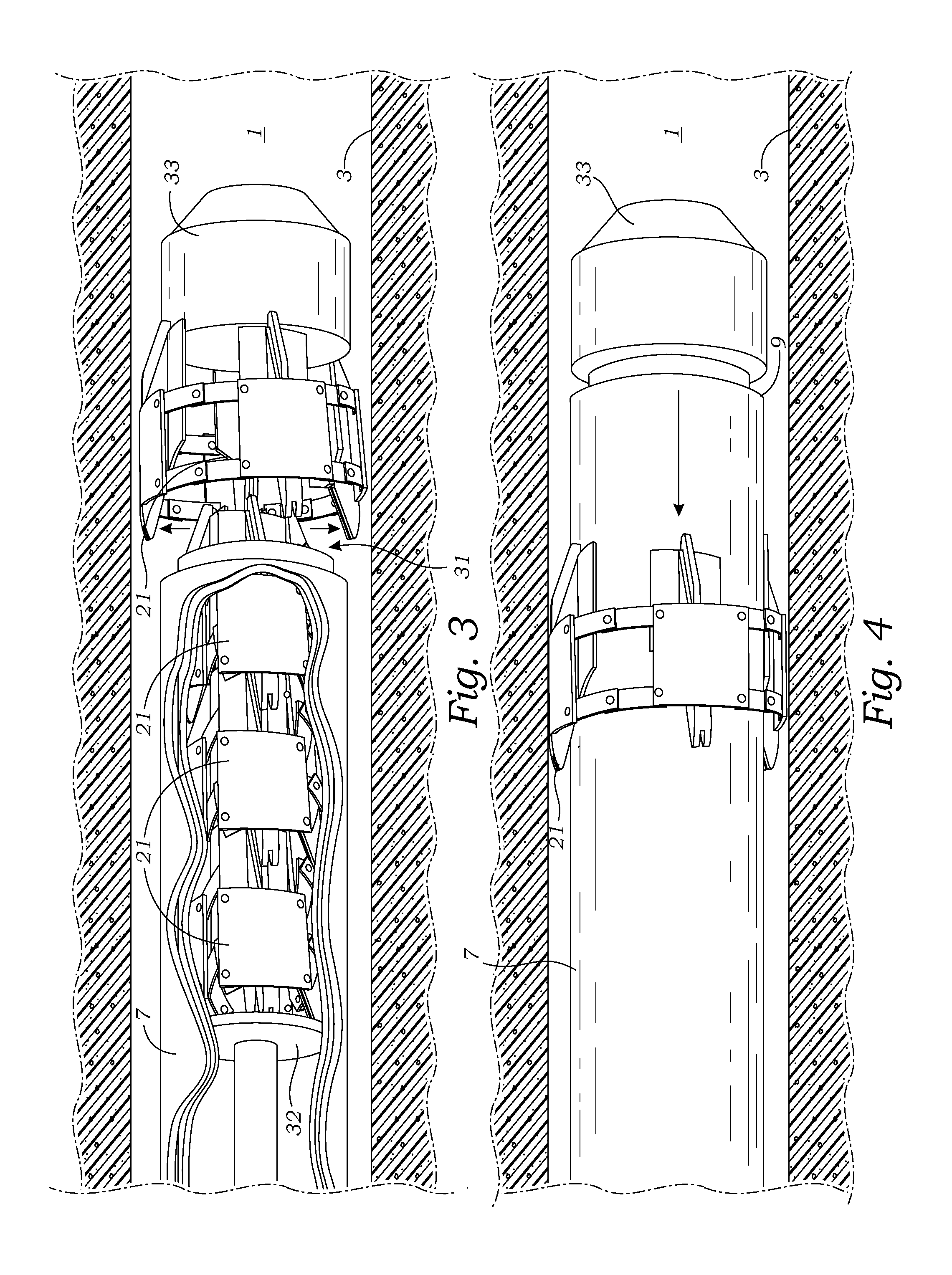

Method and devices for centralizing a casing

InactiveUS20140251639A1Reduce frictionLow regionDrilling rodsFluid removalEngineeringMechanical engineering

New apparatus and methods are provided for positioning and attaching centralizers to the inside sidewalls of a wellbore. One or more centralizers are maintained in the interior of a pipe that is transported downhole into a well for deployment. Preferrably, the pipe is also the wellbore's casing and the centralizers are deposited in a top-down manner as the casing travels downhole. The centralizers of the present invention are constructed to have an at least partially circular structure with a central hole. The preferred centralizer has an expanding circular structure wherein the diameter of the centralizer is substantially uniform so as to form an annular construction. Once deployed, the annular centralizer expands to engage the wellbore sidewall with the central hole expanded for passage of the well casing.

Owner:PORTABLE COMPOSITE STRUCTURES

Metering device

ActiveUS8114361B2Avoid damageNot to damageWithdrawing sample devicesBurettes/pipettesEngineeringPlunger

A metering device for utilization with a syringe, which features on a syringe cylinder a fastening portion with at least one axially directed sensing surface projecting from the upside, and at least one alignment nose projecting from the outer perimeter of the fastening portion, and a plunger with a plunger rod, the metering device having an accommodation for the fastening portion of the syringe cylinder, the accommodation having an axial opening for axially inserting the fastening portion into a fastening position, a sensing device disposed in the accommodation with at least one sensing means projecting from a basis surface of the sensing device facing the axial opening, for sensing the at least one sensing surface of a fastening portion inserted in a fastening position.

Owner:EPPENDORF SE

Foamed brick cutting device for reducing rejection rate

InactiveCN104149180AAvoid no-go situationsReduced Power RequirementsCeramic shaping apparatusBrickEngineering

The invention relates to a foamed brick cutting device for reducing the rejection rate. The foamed brick cutting device comprises a track, a supporting plate on the track in a sliding mode, a foamed brick placed on the supporting board, a transverse cutting device and a vertical cutting device. A side scraping device used for scarping the two side faces of the foamed brick to be flat is arranged in front of the transverse cutting device and comprises a fifth fixing block, a sixth fixing block, a first scraping cutter and a second scraping cutter, the thickness of the first scraping cutter is gradually increased in the direction pointing to the output end of the foamed brick from the inlet end of the foamed brick, and the thickness of the second scraping cutter is gradually increased in the direction pointing to the output end of the foamed brick from the inlet end of the foamed brick. The first scraping cutter and the second scraping cutter of the side scraping device can scrape the two rugged sides of the foamed brick to be flat so that small building blocks on the two sides can conform to specifications, and the rejection rate is lowered. The first scraping cutter and the second scraping cutter scrape and cut the foamed brick gradually, the phenomenon that resistance borne by the foamed brick is too large, and the foamed brick cannot advance is avoided, and the requirement for the power of a motor for pushing the supporting plate is lowered.

Owner:宿迁市名扬建设工程有限公司

Water spraying device of electrolytic copper foil device

InactiveCN103173793AEliminate leveling workSmooth glidingCleaning using liquidsElectroforming processesElectrolysisCopper foil

The invention relates to a water spraying device of an electrolytic copper foil device. The water spraying device comprises a squeeze roll bracket arranged on a fixed plate, a squeeze roll arranged on the squeeze roll bracket, and further comprises a slide rail horizontally arranged on the fixed plate and a sliding sleeve arranged on the squeeze roll bracket. The device provided by the invention solves the technical problem that the current liquid scraping device is large in frictional force and greatly affects the surface quality of the copper foil, and a counterweight is a must to ensure effective contact and the structure is relatively complex, so that the frictional force is greatly reduced and the surface quality of the copper foil is improved, and the counterweight is cancelled due to dead-weight of the roller, so that the structure is more simplified.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

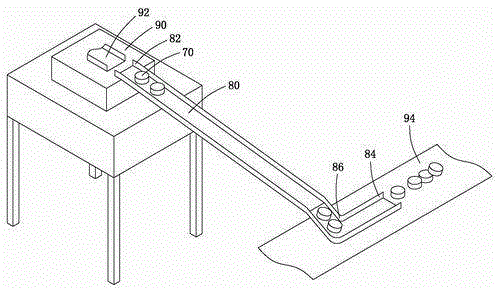

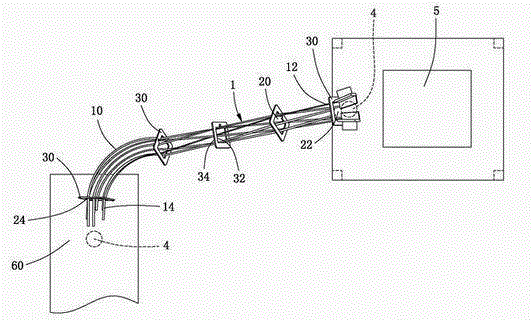

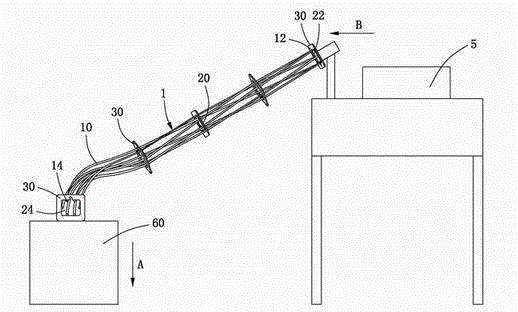

Blanked material transmission guiding mechanism and transmission method of blanked materials

The invention discloses a blanked material transmission guiding mechanism and a transmission method of blanked materials. The blanked material transmission guiding mechanism comprises a plurality of guiding wires with smooth surfaces and twisted to rotate, a sliding way formed by surrounding of the guiding wires and a plurality of fixing rings which are fixedly surrounded on the periphery of the guiding wires. The sliding way is provided with a material inlet and a material outlet, wherein the material inlet is higher than the material outlet. The material inlet of the blanked material transmission guiding mechanism is connected with a product output end of a last work station and can receive products from the last work station. The material outlet of the blanked material transmission guiding mechanism is connected with a product input end of a next work station and can transmit the products to the next work station. The blanked material transmission guiding mechanism can achieve smooth turning and stable sliding of the products and avoids conditions of collision, sliding rail blocking and deviation from the rail.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD +1

Foaming brick cutting device with supporting plate walking more accurately

InactiveCN104149182AReduced Power RequirementsPrecisely control where to stopCeramic shaping apparatusMetal working apparatusMotor driveBrick

The invention relates to a foaming brick cutting device with a supporting plate walking more accurately. The foaming brick cutting device comprises a rail, the supporting plate which is arranged on the rail in a slideable mode, a foaming brick which is placed on the supporting plate, a transverse cutting device and a vertical cutting device. The rail comprises a slide bar and a tooth ripple belt, and the tooth ripple belt is provided with tooth ripples. A servo motor and a sliding block capable of sliding on the slide bar are arranged at the bottom of the supporting plate. An output shaft of the servo motor is provided with a gear which can walk on the tooth ripple belt. The transverse cutting device is arranged at the front end of the vertical cutting device. The foaming brick carried on the supporting plate sequentially passes through the transverse cutting device and the vertical cutting device. According to the foaming brick cutting device with the supporting plate walking more accurately, the servo motor drives the gear to walk on the tooth ripple belt, hence, the stopping position of the supporting plate can be controlled accurately, it is guaranteed that the supporting plate can be accurately stopped below the vertical cutting device, the foaming brick can be cut precisely by the vertical cutting device, and thus the rejection rate is lowered.

Owner:SINO RISING SUN CONSTR GRP

Aluminum profile surface knurling machine

The invention relates to an aluminum profile surface knurling machine which comprises a rack and a speed reduction motor. The rack comprises supporting legs and a frame type door frame arranged on the supporting legs. The aluminum profile surface knurling machine is characterized in that a driving rolling wheel and a driven rolling wheel which are horizontally arranged on the upper portion and the lower portion of the frame type door frame respectively are further included, concave-convex patterns are arranged on the surface of the driving rolling wheel, the driving rolling wheel comprises a rolling wheel shaft, a first chain wheel is arranged at the shaft end of the rolling wheel shaft, a second chain wheel is arranged on a shaft of the speed reduction motor, the first chain wheel and the second chain wheel are connected through a chain, and an adjusting mechanism which can adjust the distance between the driving rolling wheel and the driven rolling wheel is further arranged. A locating roll component and a feeding guide component are further included. The aluminum profile surface knurling machine has the advantages of being high in machining efficiency and easy and convenient to operate and well solving the knurling machining problem of an aluminum profile surface.

Owner:龙口市丛林铝合金船舶有限公司

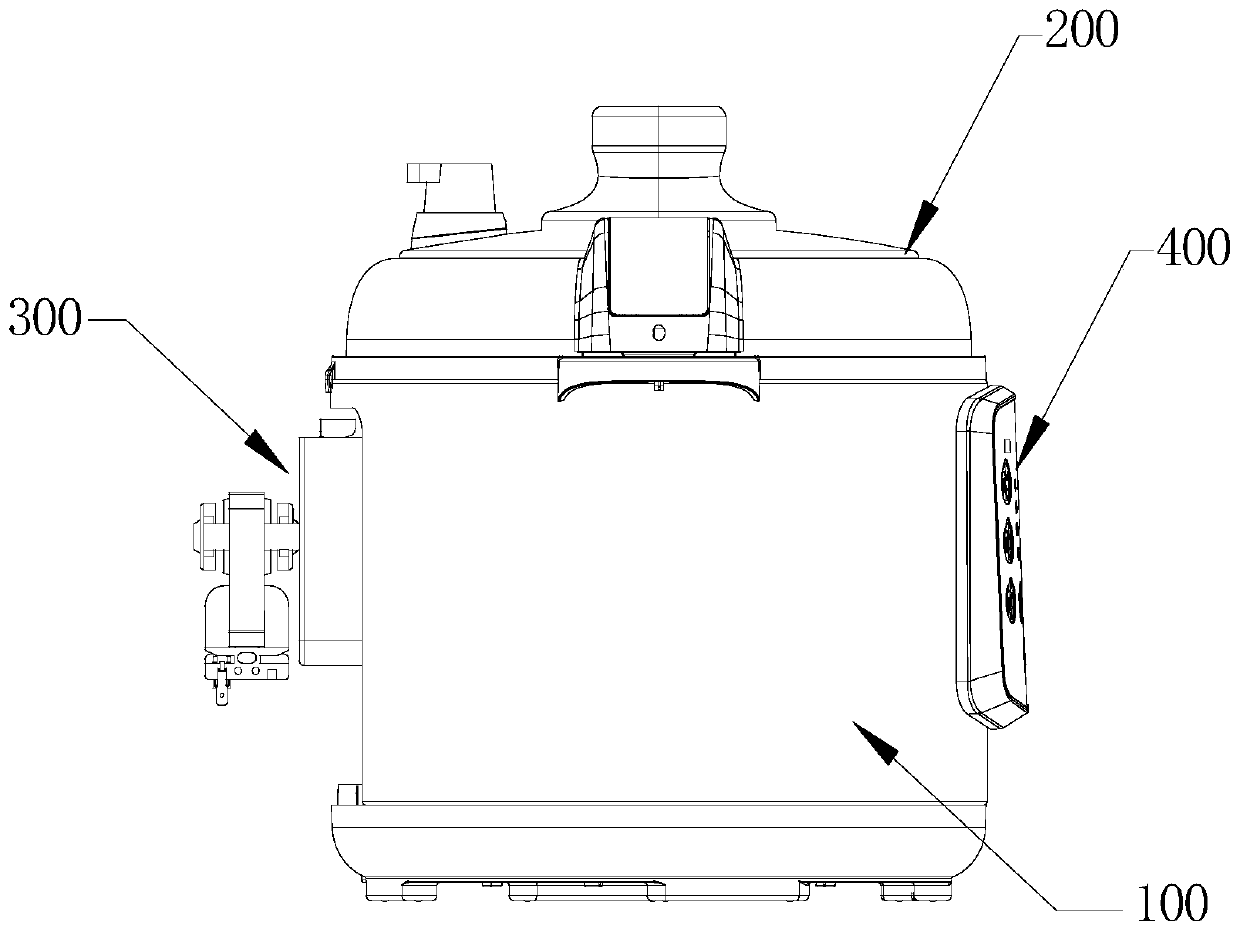

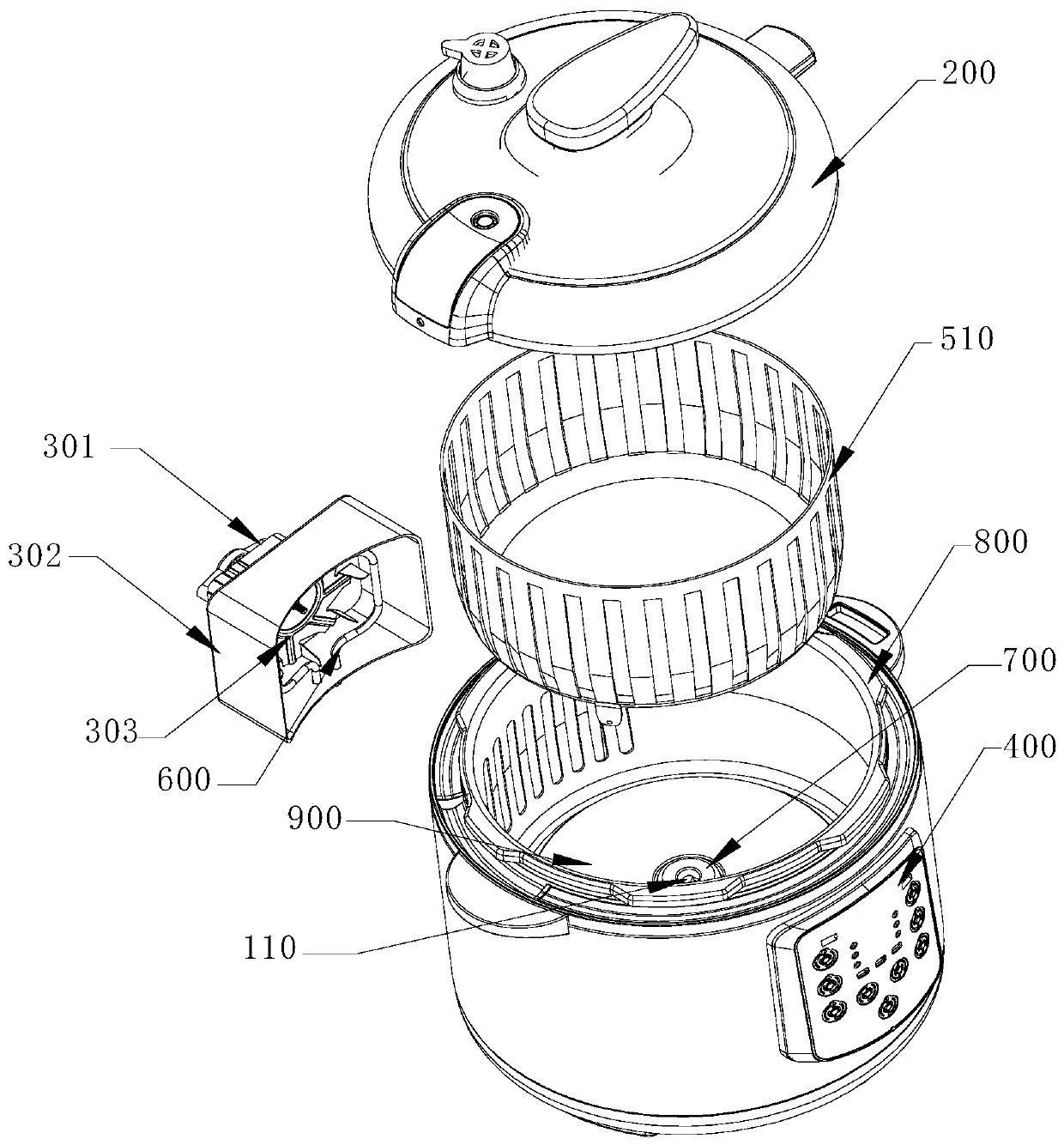

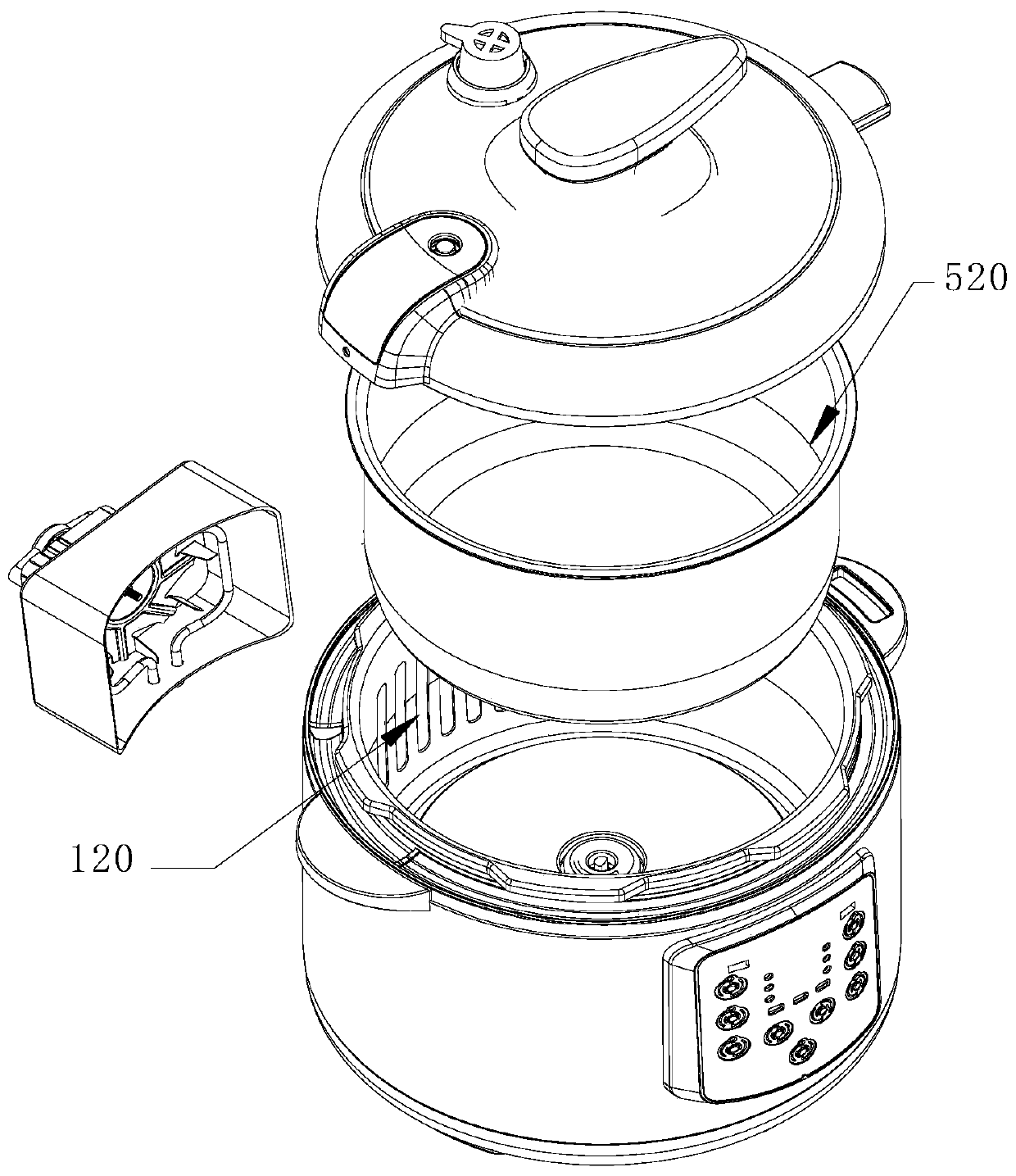

Cooking utensil

PendingCN111248771ASmooth glidingHeating evenlyRoasters/grillsPressure-cookersRotational axisDrive shaft

The invention relates to a cooking utensil. The cooking utensil comprises: a pot cover assembly; a pot body assembly covered with the pot cover assembly; a heating part arranged on the pot body assembly; a base plate located at the bottom of the pot body assembly and provided with a through hole; a rotating part located between the base plate and the bottom of the pot body assembly, wherein a rotating shaft of the rotating part extends into the through hole, and the height of the rotating shaft is smaller than that of the base plate; and a first pot body, wherein a transmission shaft is arranged at the position, corresponding to the through hole, of the bottom of the first pot body, at least two rolling wheels are arranged on the edge of the bottom of the first pot body, and when the firstpot body is placed in the pot body assembly, the transmission shaft stretches into the through hole and is connected with a rotating shaft. The rotating part drives the first pot body to rotate through the rotating shaft and the transmission shaft, so that the heating part uniformly heats the first pot body. Uniform heating can be realized by adopting the cooking utensil.

Owner:RIMOO FOSHAN ELECTRICAL APPLIANCES TECH CO LTD

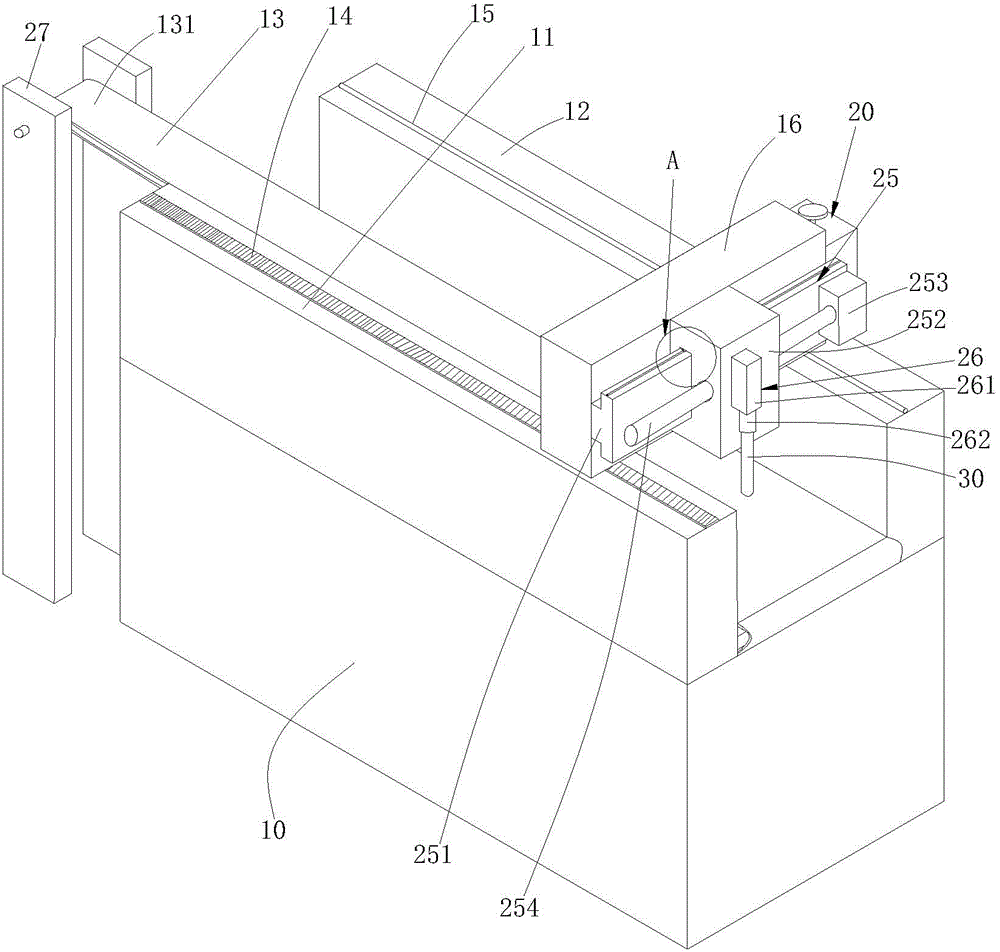

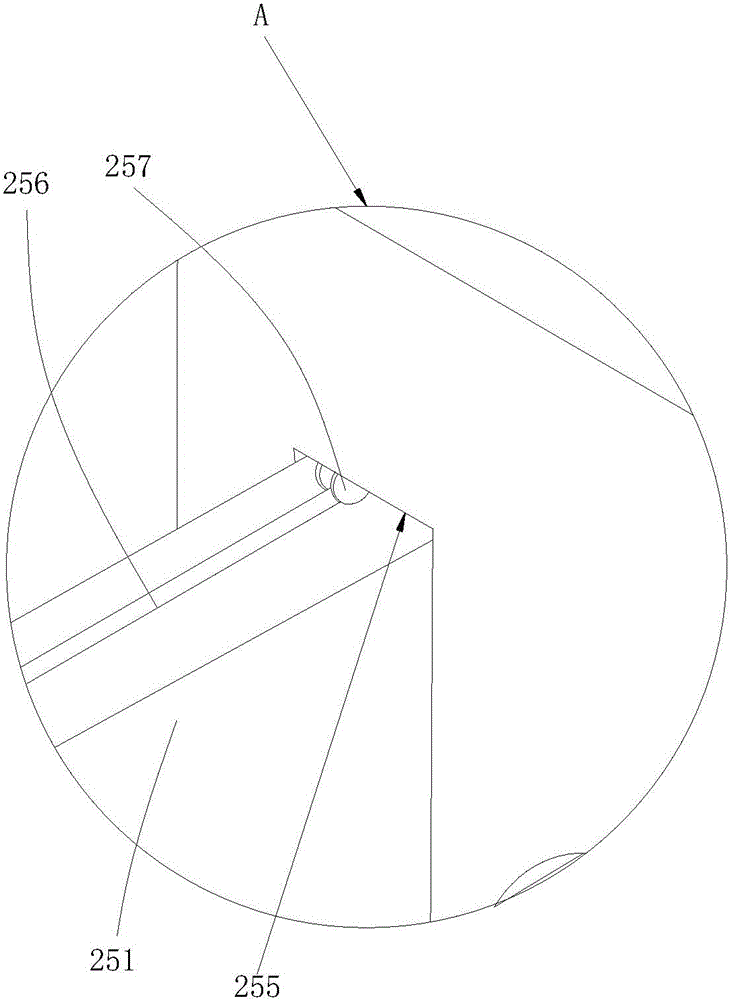

Foamed brick cutting device capable of sliding more smoothly

InactiveCN104128989ASmooth glidingGuaranteed to workCeramic shaping apparatusMetal working apparatusBrickFuel tank

The invention relates to a foamed brick cutting device capable of sliding more smoothly. The foamed brick cutting device capable of sliding more smoothly comprises a rail, a supporting plate arranged on the rail in a sliding mode, a foamed brick arranged on the supporting plate, a transverse cutting device and a vertical cutting device. The rail comprises a sliding rod and a tooth-ripple band. The tooth-ripple band is provided with tooth ripples. A servo motor and a sliding block which can slide on the sliding rod are arranged at the bottom of the supporting plate. A gear which can walk on the tooth-ripple band is arranged on an output shaft of the servo motor. A lubricating device is arranged on the supporting plate. The lubricating device comprises an oil tank, an oil pipe, a timer, a valve and a controller used for controlling the valve to be opened or closed, wherein the oil pipe is connected with the oil tank, a valve used for controlling the oil tube to be communicated or not communicated is arranged in the oil tube, the valve is connected with the controller, the timer is connected with the controller, and the oil outlet end of the oil pipe is connected to the sliding block. The lubricating device can lubricate the sliding block and the sliding rod at regular time, and therefore the sliding block can slide more smoothly. It is guaranteed that the foamed brick cutting device normally operates.

Owner:烟台市广耀新型建材有限公司

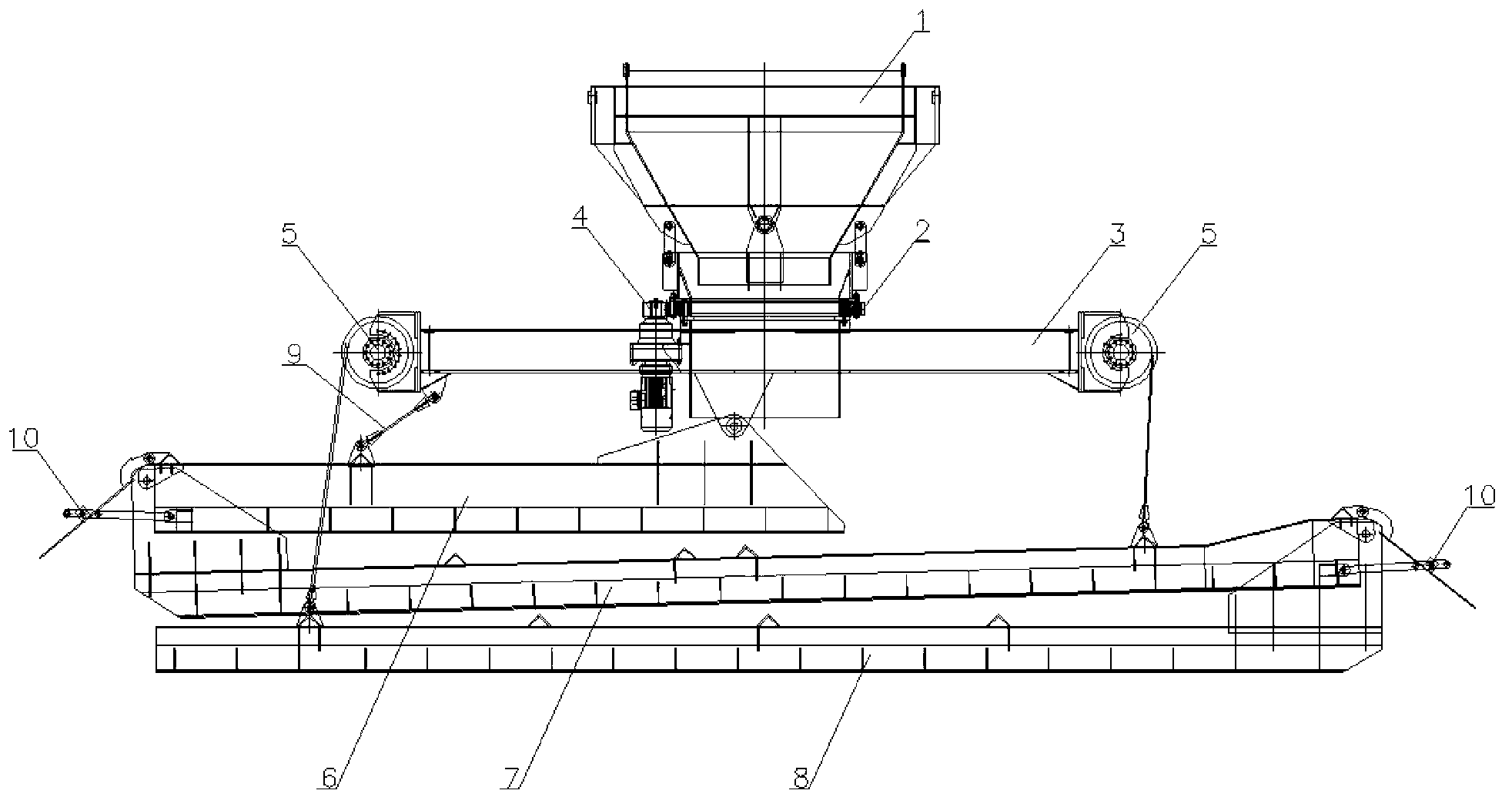

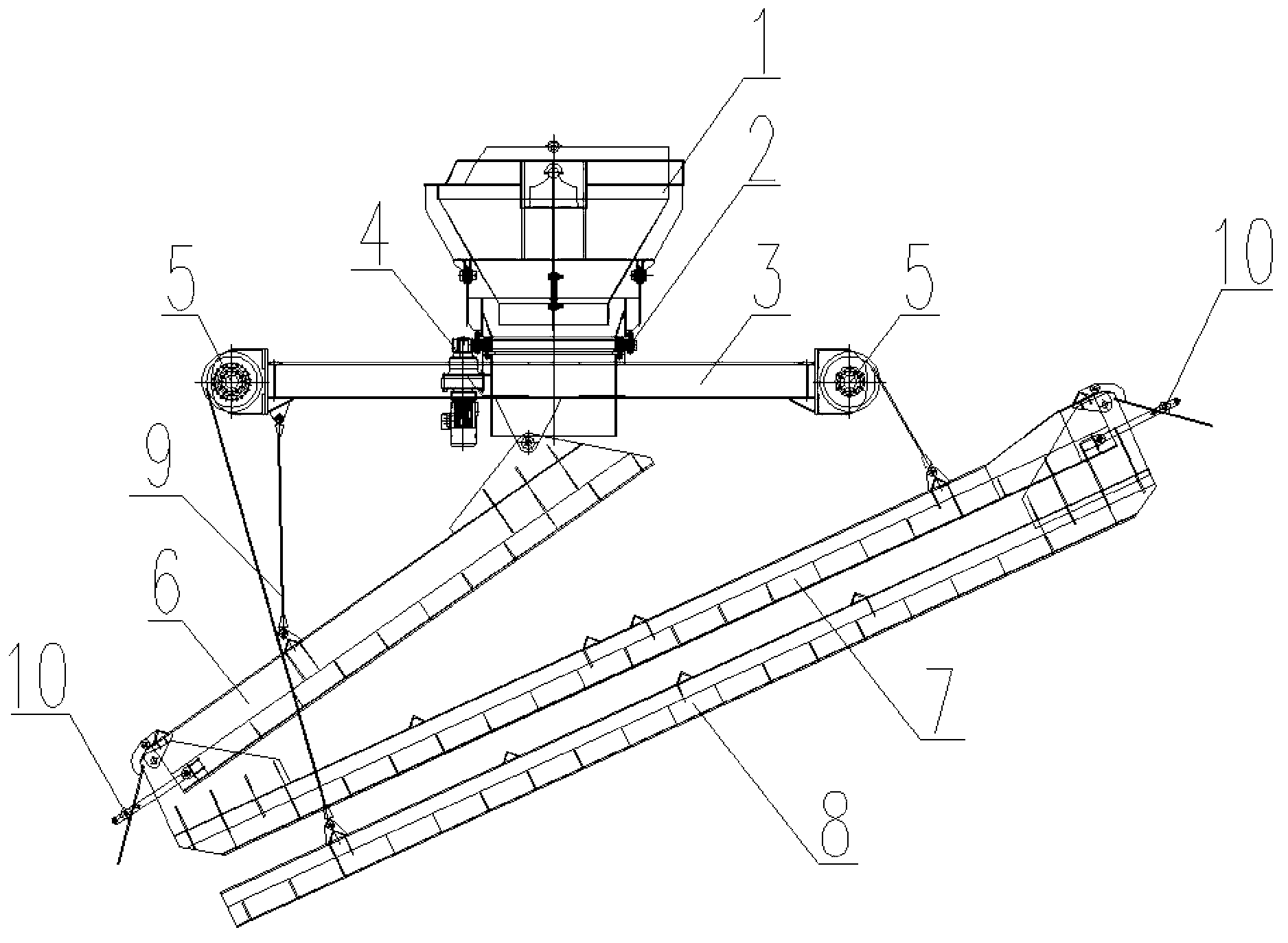

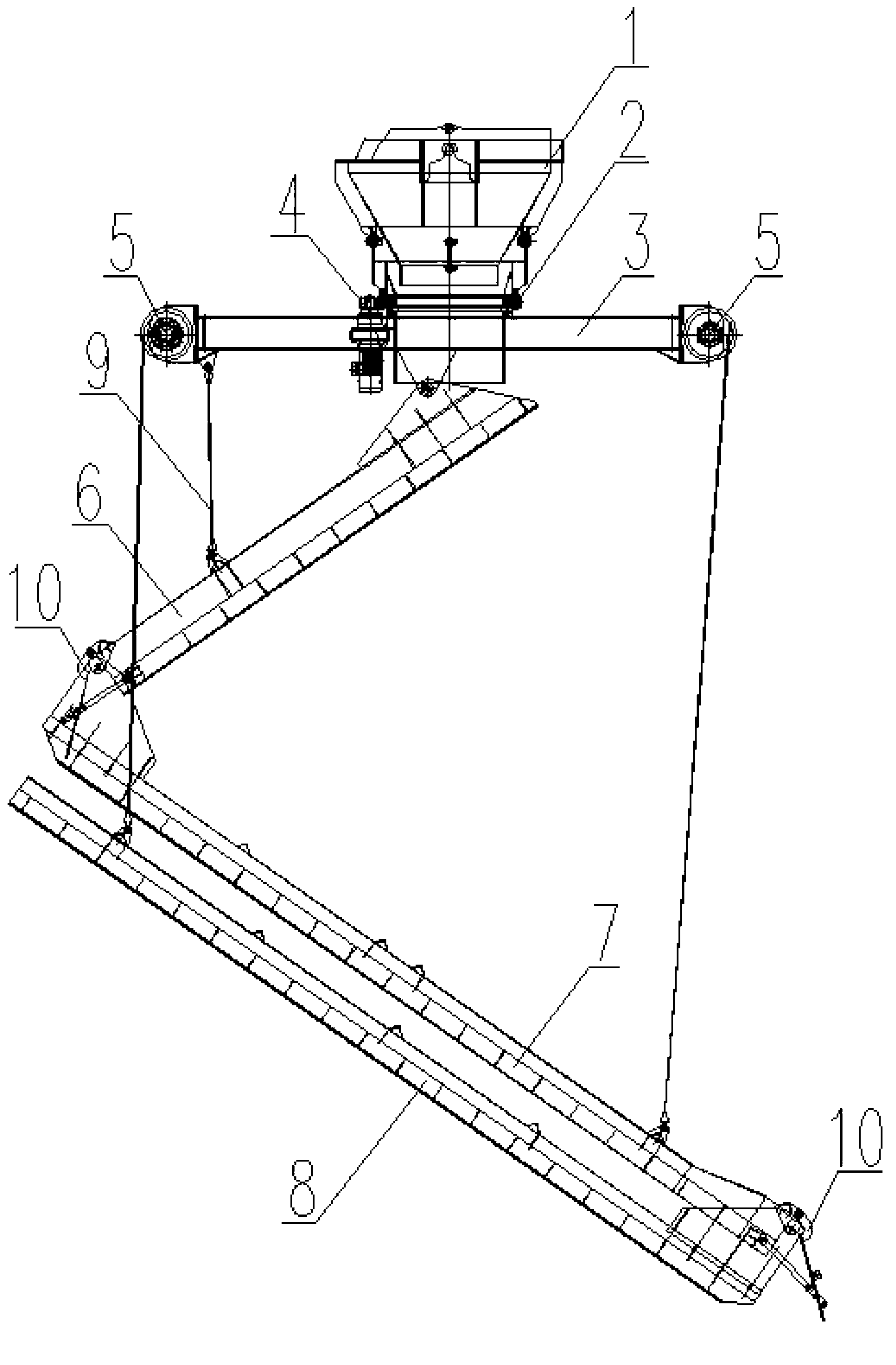

Z-shaped slow-descending chute discharging device

ActiveCN103224148AAchieve coveragePlay the role of linking the previous and the nextLoading/unloadingEngineeringWindlass

The invention provides a Z-shaped slow-descending chute discharging device and relates to a discharging device for bulk materials, particularly for bulk materials, such as bread iron, corn and wheat, which are suitable for loading and unloading by a ship loader. The discharging device adopts the structure that the lower end of a material guide cylinder is connected with a reversing frame through a pivotal bearing; a revolution drive mechanism is mounted on the reversing frame; a pinion wheel of the revolution drive mechanism is meshed with a bearing external gear ring of the pivotal bearing; material guide grooves are formed in the lower part of the reversing frame; two folding windlasses are symmetrically arranged on two ends of the reversing frame respectively; traction steel wire ropes of the two folding windlasses are connected with a secondary material guide groove and a tertiary material guide groove respectively; an iron chain is mounted between the reversing frame and a primary material guide groove of the material guide grooves; and baffles are mounted at the bottom ends of the primary and the secondary material guide grooves. The discharging device has the characteristics of novel structure, simplicity and convenience in processing, convenience in use, safety, reliability, high operating efficiency and the like.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

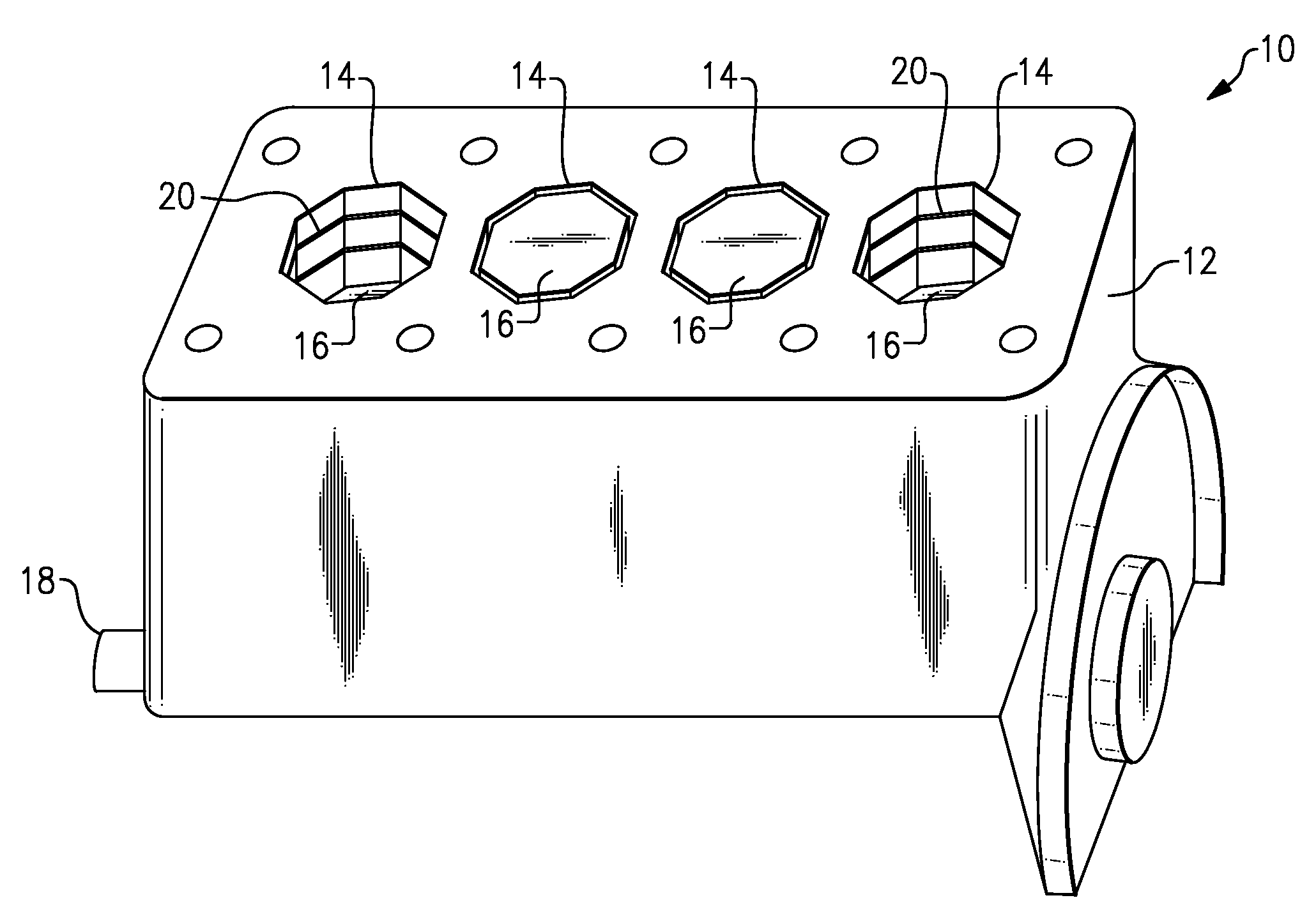

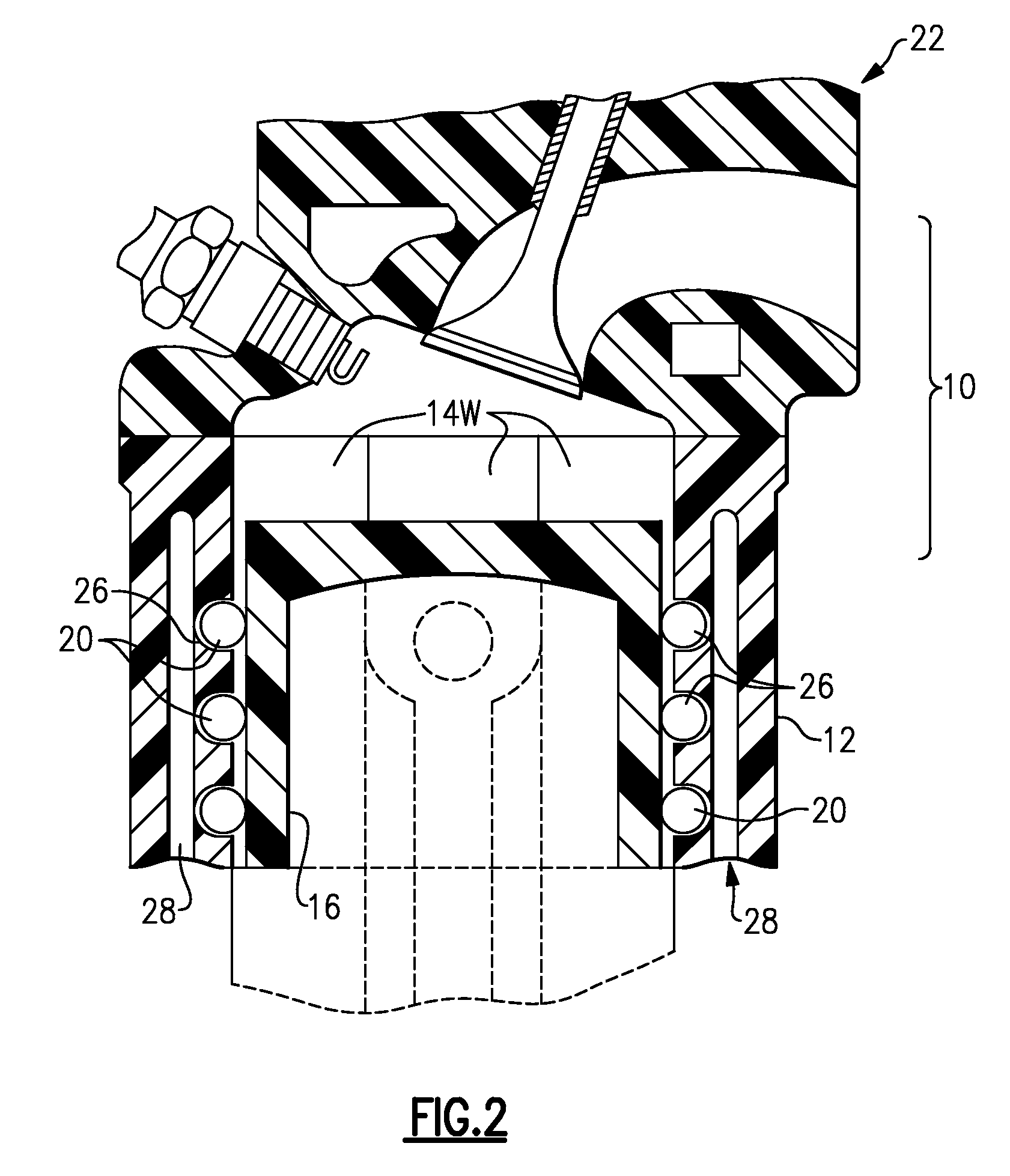

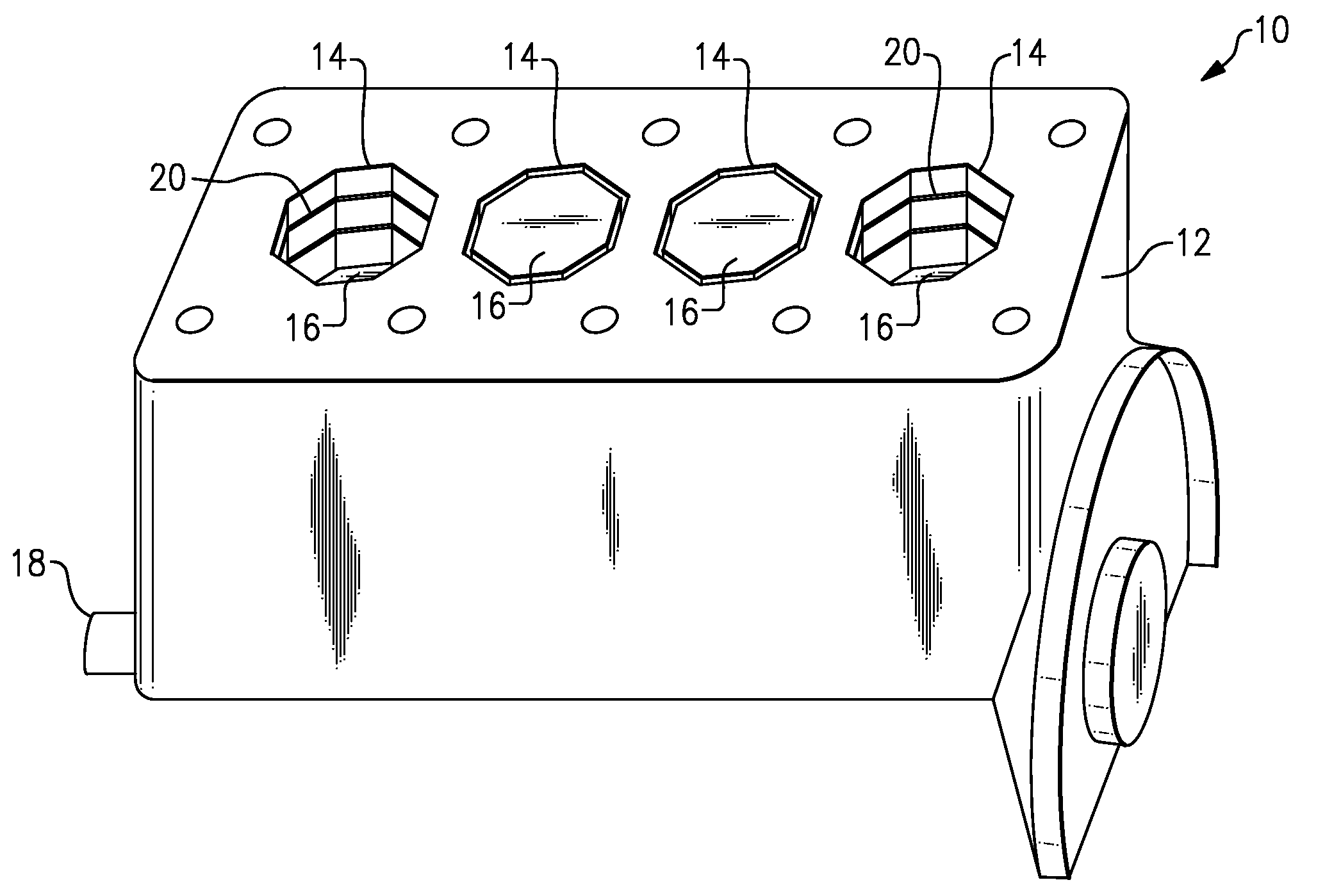

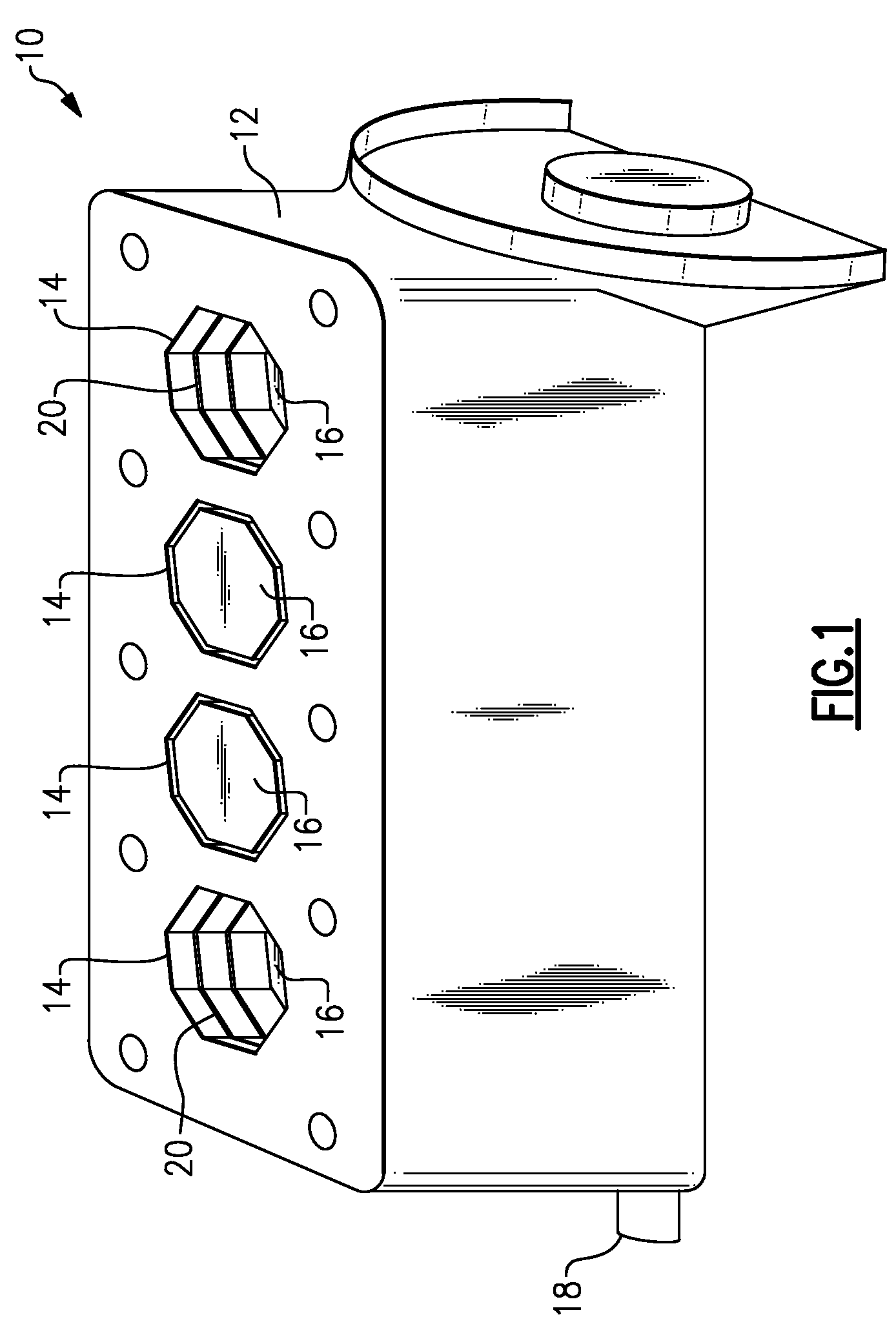

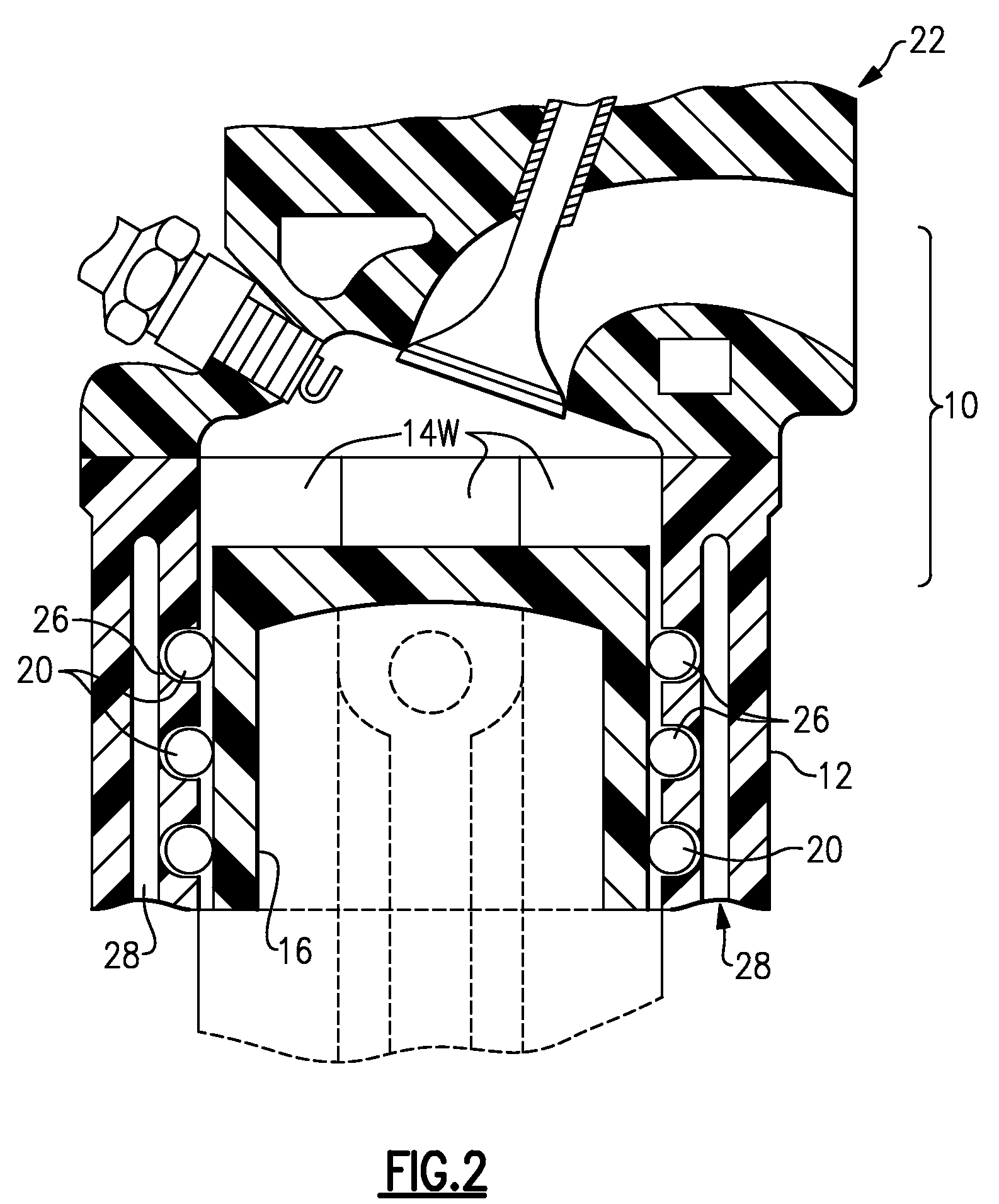

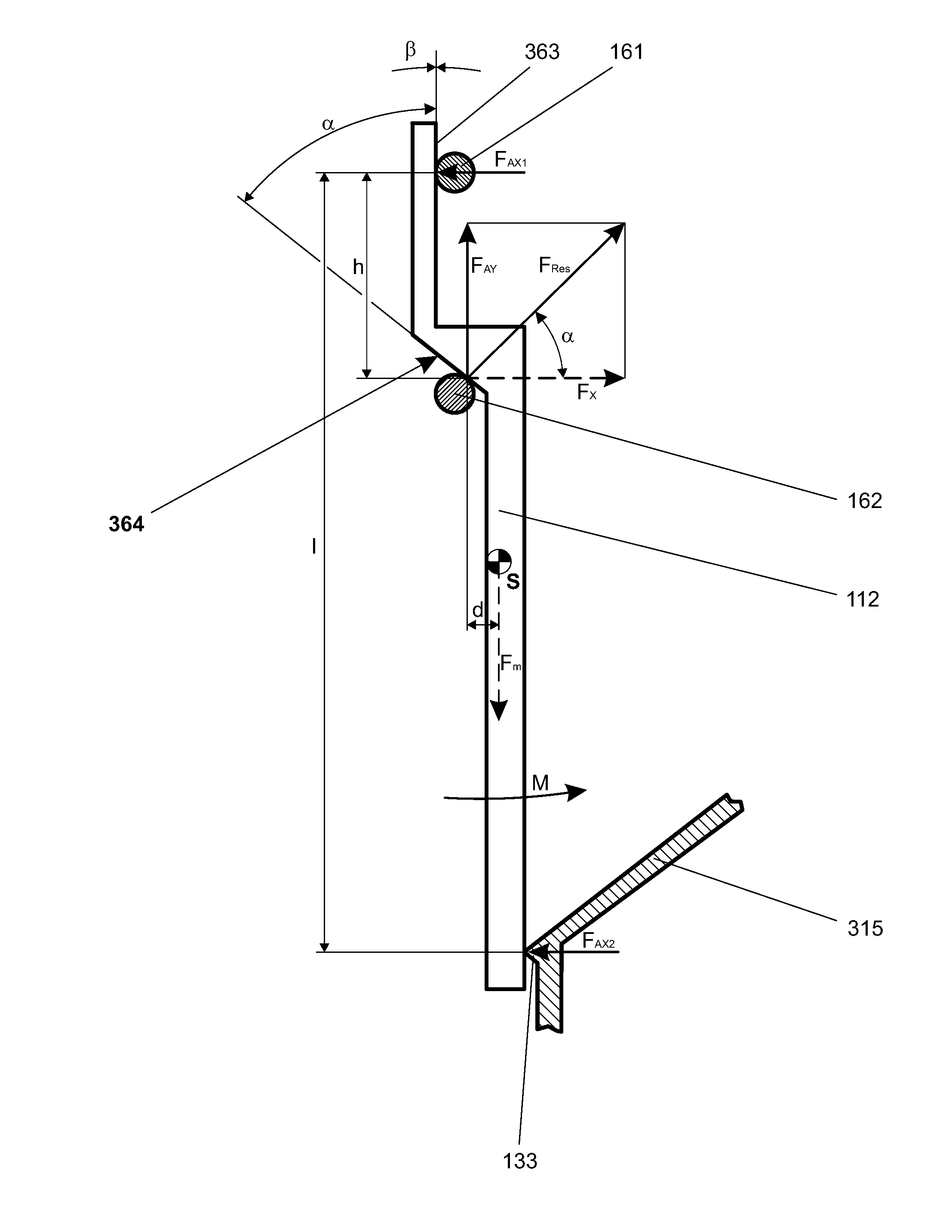

High Performance Resin Piston Internal Combustion Engine

ActiveUS20100251988A1Avoid disadvantagesAvoid compressionCasingsPiston ringsNeedle roller bearingEngineering

A piston-type internal combustion engine is formed of a high performance synthetic resin material. The cylinders and pistons have an octagonal profile. Two or three rows of pin roller bearings are positioned in transverse semi-cylindrical grooves formed on the cylinder walls, to afford smooth, low-friction rolling contact and to seal the compression from leaking around the piston. There are angle support pieces fitted within the annular channels at respective vertices or corners, and are adapted for rotationally supporting the ends of adjacent pin roller bearings.

Owner:DHARANI MURAD +1

Foamed brick cutting device capable of cutting out building blocks of different specifications

ActiveCN104149179AAdjustable tightnessAvoid Under-Push SituationsCeramic shaping apparatusBrickEngineering

The invention relates to a foamed brick cutting device capable of cutting out building blocks of different specifications. The foamed brick cutting device comprises a track, a supporting plate, a foamed brick placed on the supporting plate, a transverse cutting device and a vertical cutting device. The foamed brick carried by the supporting plate passes through the transverse cutting device and the vertical cutting device in sequence. The transverse cutting device comprises a third fixing block, a fourth fixing block and a plurality of transverse cutting steel wires, a first adjusting cap and a second adjusting cap are arranged at the two ends of each transverse cutting steel wire respectively, each first adjusting cap is connected with one end of the corresponding transverse cutting steel wire through threads, each second adjusting cap is connected with the other end of the corresponding transverse cutting steel wire through threads, a plurality of adjusting holes allowing the first adjusting caps to be vertically adjusted are formed in the third fixing block, and a plurality of adjusting holes allowing the second adjusting caps to be vertically adjusted are formed in the fourth fixing block. The tightness degree of the transverse cutting steel wires can be adjusted through the first adjusting caps and the second adjusting caps. The distance between the transverse cutting steel wires is adjusted, and the small building blocks of the needed specifications and sizes can be cut out.

Owner:广东新立晟环保科技股份有限公司

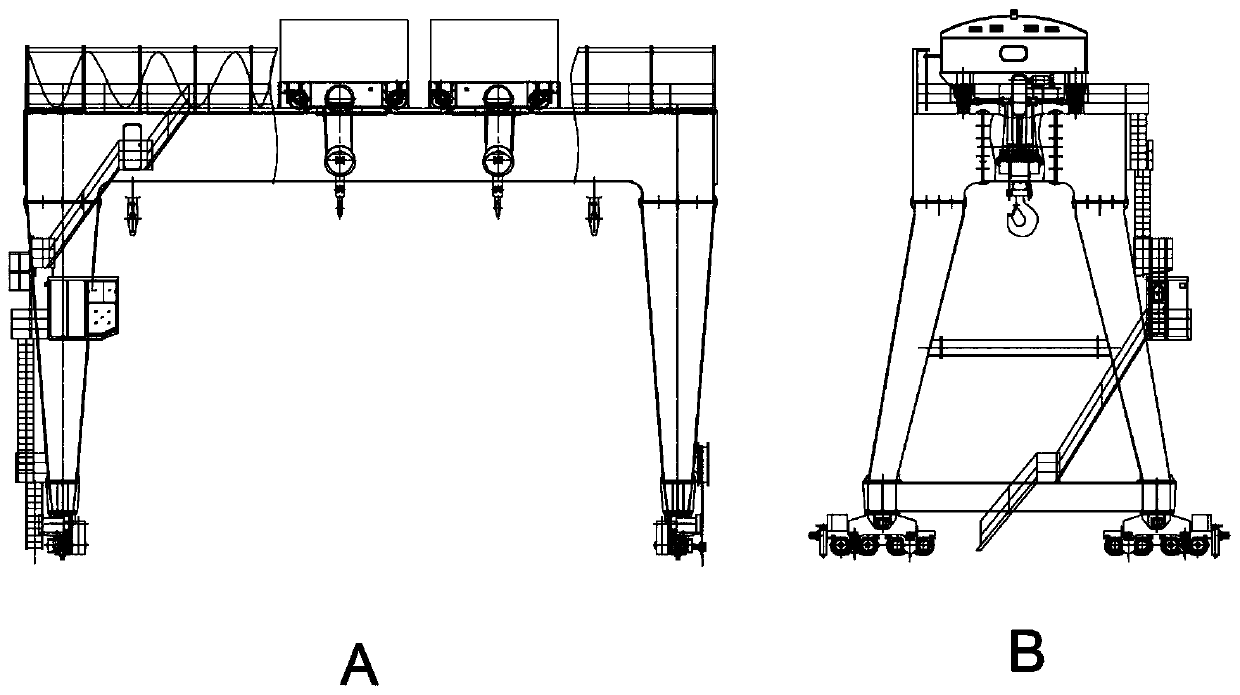

Implementation method for detaching TBM in tunnel

ActiveCN111472797AIncrease the rotation angleSmooth glidingTunnelsUnderground transportPower stationGeotechnical engineering

The invention discloses an implementation method for detaching a TBM in a tunnel. The implementation method comprises the following steps of arranging a detaching chamber; after TBM tunneling is finished, separating a TBM shield body and a rear supporting facility from a traction oil cylinder, and then making the TBM shield body and the rear supporting facility slide to the detaching chamber separately; making the shield body slide; making the rear supporting facility slide; laying a track II, then installing a winch, and utilizing the winch for enabling all sections of a trolley to slide on the tack; arranging an overhead crane at the top of the detaching chamber; after the shield body slides to the detaching chamber, utilizing the overhead crane for detaching a cutterhead, a main drive and a supporting jack of the shield body in sequence; and after the rear supporting facility slides to the detaching chamber, detaching equipment on the trolley, and disassembling the trolley. According to the implementation method for detaching the TBM in the tunnel, the TBM shield body and the rear supporting facility are separated from the traction oil cylinder and then slide to the detaching chamber separately, then dynamic electricity and cooling water are introduced, and a hydraulic power station of an advanced bore system is transformed to be connected with a high-pressure oil pipe of anoil cylinder in a tail shield to finish advancing of the shield body; and meanwhile, a rotatable wheel carrier is adopted so that the trolley can slide on an arc section.

Owner:SINOHYDRO BEREAU 10 CO LTD

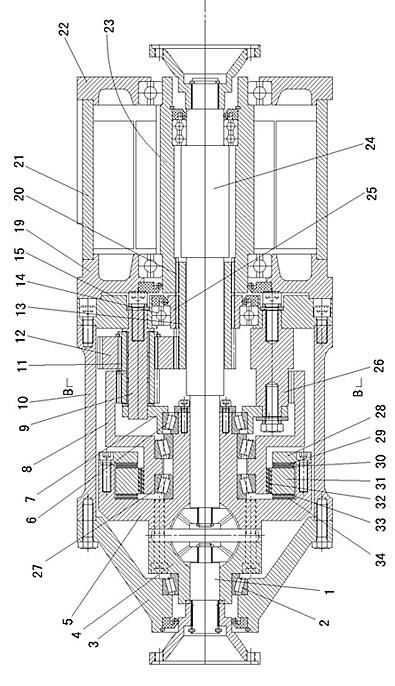

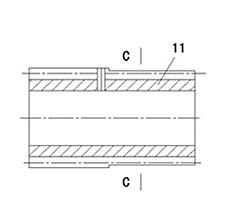

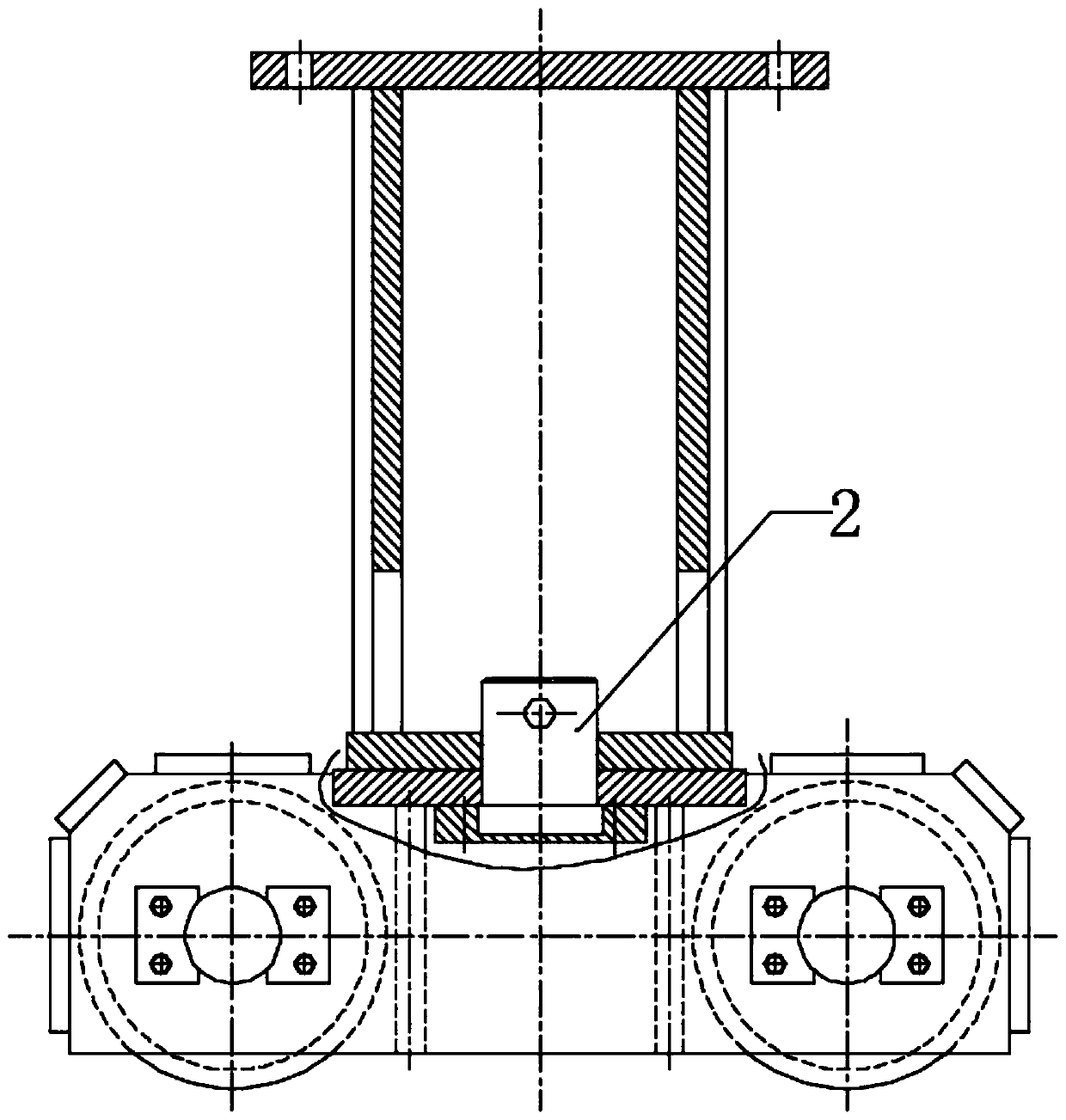

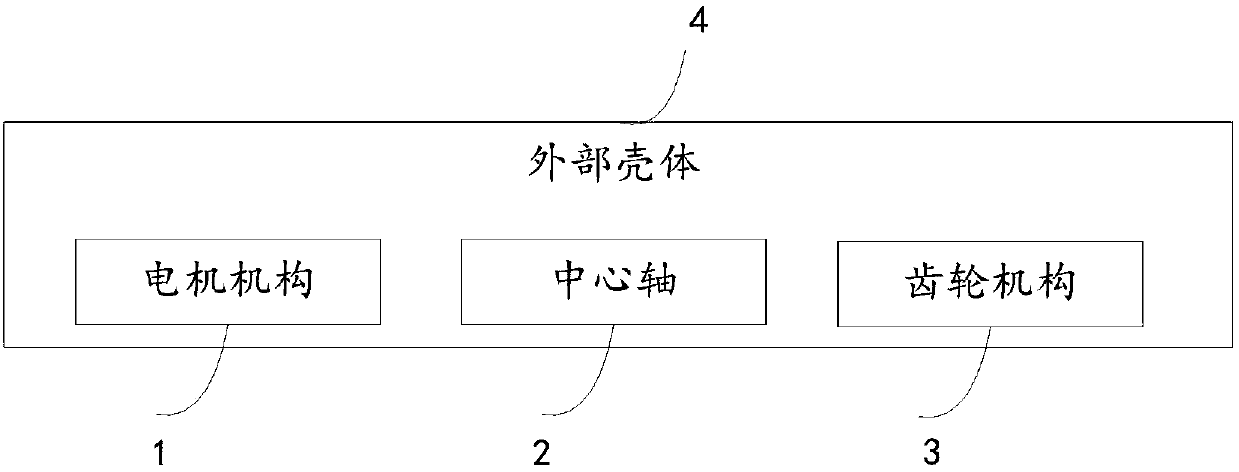

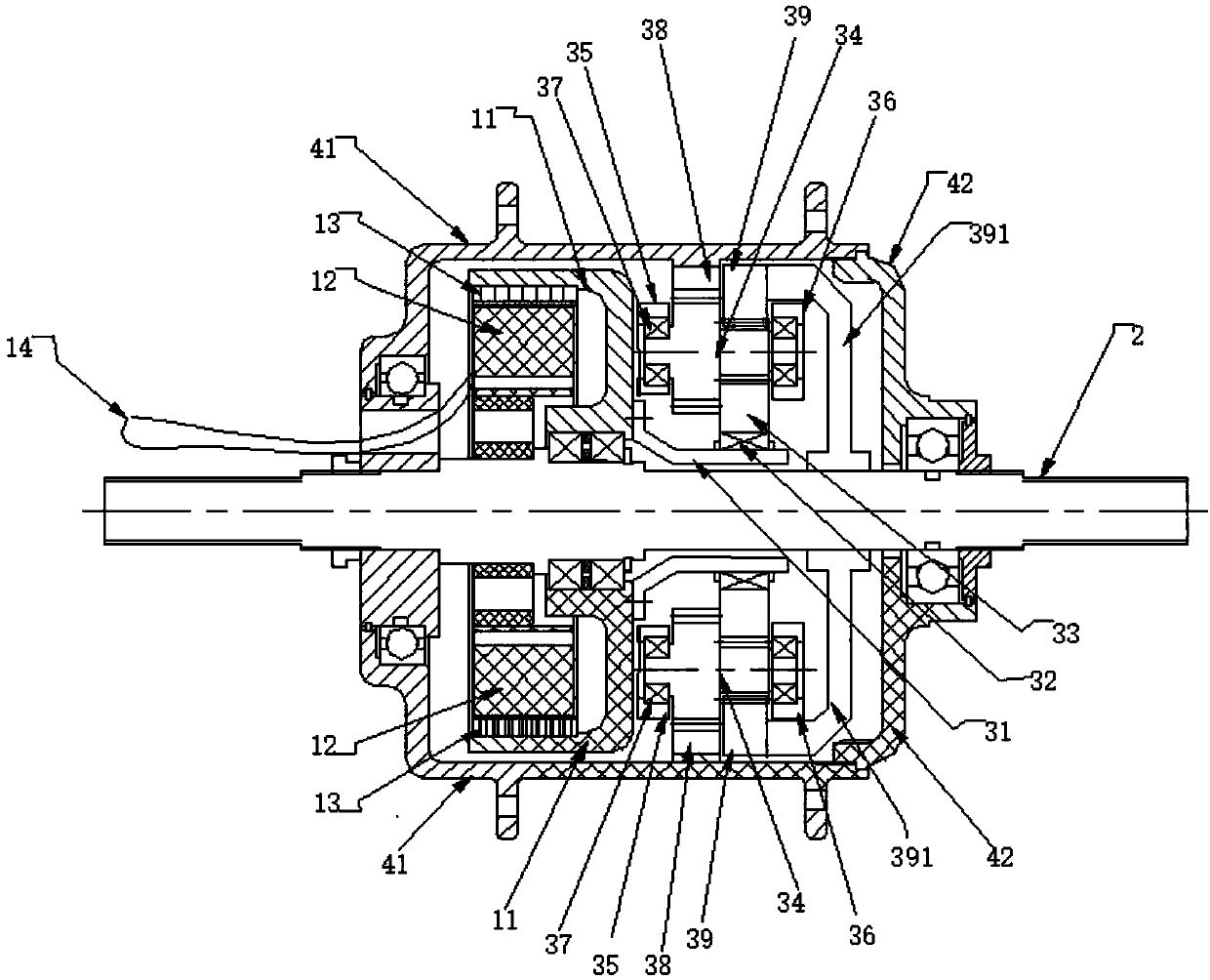

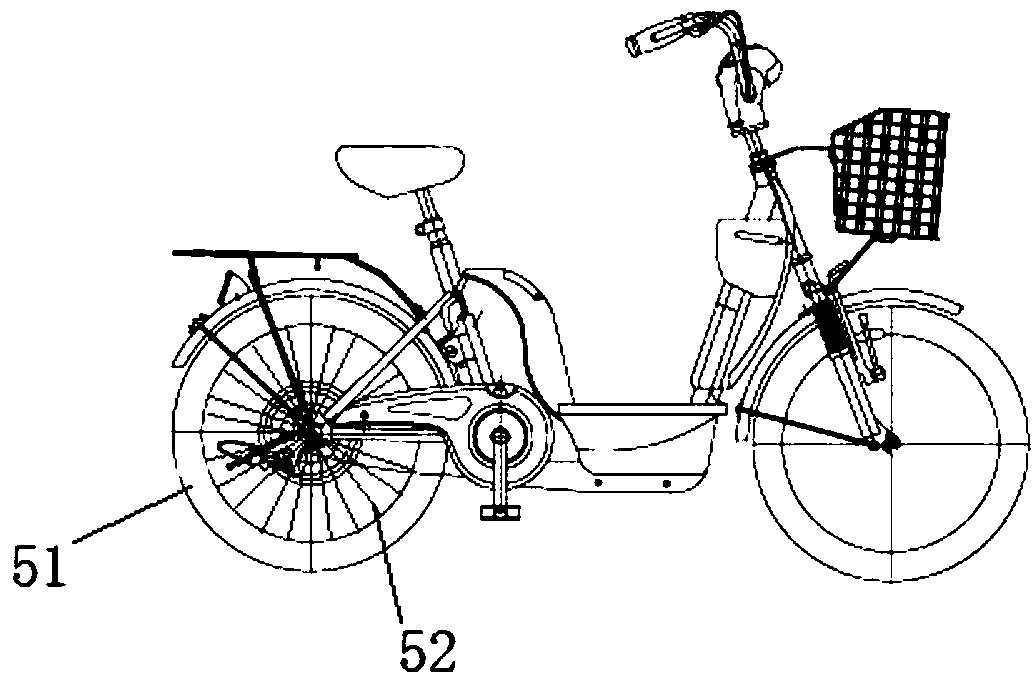

Novel hub power device and electric bicycle

PendingCN110027663ASmall structureHigh strengthWheel based transmissionMechanical energy handlingElectric machineSpur gear

The invention discloses a novel hub power device and an electric bicycle. The novel hub power device comprises a motor mechanism, a central shaft, a gear mechanism and an outer shell; the gear mechanism comprises a hollow shaft sleeve, a one-way clutch, a sun gear and a duplex planetary gear which are sequentially arranged on the central shaft outwards in a sleeving mode; the gear mechanism further comprises a planet carrier assembly and a gear ring assembly; the planet carrier assembly comprises a left planet carrier and a right planet carrier which are fixedly connected; the gear ring assembly comprises a left gear ring and a right gear ring, and the left gear ring and the right gear ring are meshed with the duplex planetary gear in the middle of the outer side of the duplex planetary gear; the left gear ring is fixed to the outer shell, and the right gear ring is connected with the central shaft through an auxiliary piece. The power device has a small structural size and can achievea larger transmission ratio; and the central shaft is of a whole-shaft structure, so that the strength of the central shaft (fixed shaft) cannot be reduced, and the safety coefficient is high.

Owner:M& SE DRIVING SYST CO LTD

Skin Care Applicator

ActiveUS20160074642A1Minimize distanceImprove permeabilityElectrotherapySurgeryThermal conductivityBiomedical engineering

An applicator for use with a skin care composition, comprising a magnetic element disposed inside the applicator and a cover that at least partially covers the magnetic element. The cover has a thickness of between 0.1 mm and 0.55 mm and is formed of a material having a thermal conductivity of at least 50 W / mK.

Owner:THE PROCTER & GAMBNE CO

Double-color mold capable of preventing products from falling off

Owner:创意塑胶工业(苏州)有限公司

High performance resin piston internal combustion engine

ActiveUS8061324B2Avoid disadvantagesAvoid compressionPiston ringsCylinder headsNeedle roller bearingEngineering

A piston-type internal combustion engine is formed of a high performance synthetic resin material. The cylinders and pistons have an octagonal profile. Two or three rows of pin roller bearings are positioned in transverse semi-cylindrical grooves formed on the cylinder walls, to afford smooth, low-friction rolling contact and to seal the compression from leaking around the piston. There are angle support pieces fitted within the annular channels at respective vertices or corners, and are adapted for rotationally supporting the ends of adjacent pin roller bearings.

Owner:DHARANI MURAD +1

Enclosure for a laboratory balance with a sliding side wall mounted such that the top guide sliding mechanism imparts a turning moment on the lower edge of the wall to press it against an abutment of the weighing compartment to form a seal

ActiveUS8294046B2Avoid Insufficient SealingSmooth glidingShow cabinetsWeighing apparatus detailsEngineeringAbutment

Owner:METTLER TOLEDO GMBH

Glue spraying device preventing slide block from disengaging from slide rod

InactiveCN104146443ANot easy to break awayOut of precisionShoe gluingEngineeringMechanical engineering

The invention relates to a glue spraying device preventing a slide block from disengaging from a slide rod. The glue spraying device comprises an installation platform and a controller. A left protruding edge and a right protruding edge are arranged on the left side of the top of the installation platform and the right side of the top of the installation platform respectively. A conveying belt is installed between the left protruding edge and the right protruding edge. A toothed grain belt is arranged on the left protruding edge. Toothed grains are arranged on the toothed grain belt. The slide rod is arranged on the right protruding edge. The glue spraying device further comprises a first installation block. A first servo motor is arranged on the left side of the bottom of the first installation block. A gear capable of walking on the toothed grain belt is arranged on an output shaft of the first servo motor. The slide block capable of sliding on the slide rod is arranged on the right side of the first installation block. A slide hole is formed in the slide block and provided with an opening. The linear distance of the opening of the slide hole is smaller than the diameter of the slide rod. The linear distance of the opening of the slide hole is smaller than the diameter of the slide rod, and therefore the slide block can not easily disengage from the slide rod, it is ensured that the first installation block can normally move forwards or backwards, and a glue gun can be normally adjusted forwards or backwards.

Owner:启东市东泰纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com