Double-head computerized flat knitter, high roller device and double shaking table devices thereof

A technology of computerized flat knitting machine and double heads, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of labor-intensive and time-consuming work efficiency, increased production costs, and knitting threads are easy to break, so as to improve efficiency. , save the cost of selvedge, and not easy to deviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

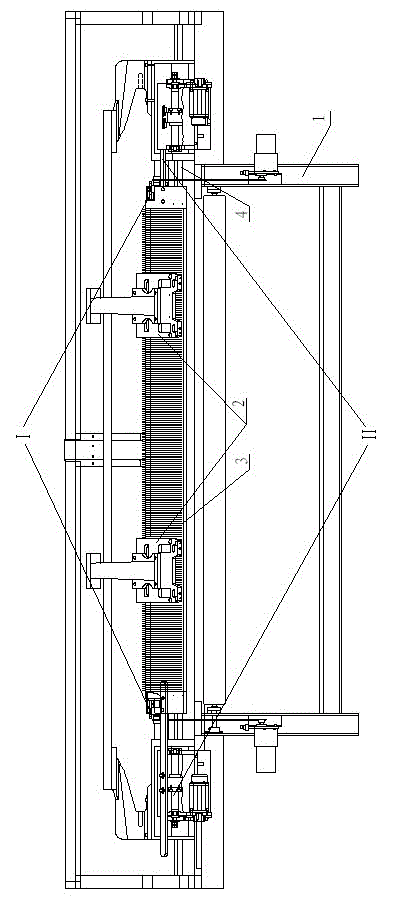

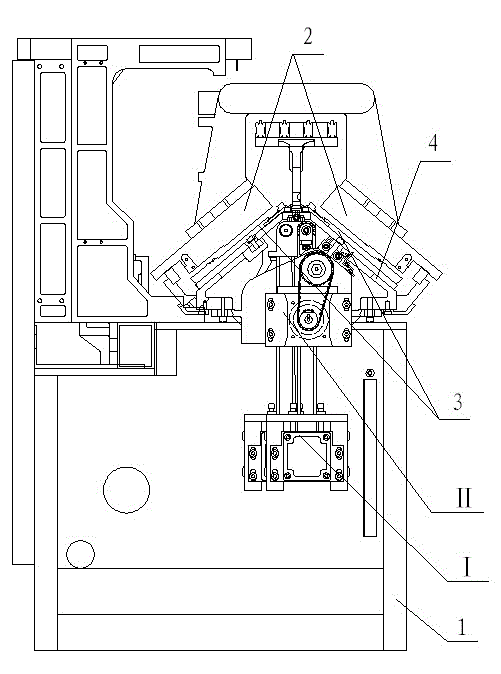

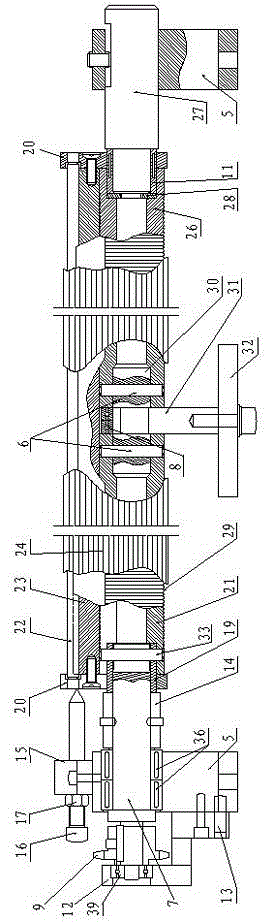

[0027] see Figure 1 to Figure 11 , the double-head computerized flat knitting machine in the embodiment of the present invention is provided with: a frame assembly, a machine head 2, a double row of needle plates, a high-position roller device I, and a double shaker device, and the frame assembly includes a frame 1, a fixed frame 4, Base 5, base plate 32, fixed mount 4 are fixed in the frame 1 with screws, base plate 32 is fixed in the fixed mount 4 by bolt (with spring washer, washer), and two bases 5 are fixed in the fixed mount 4. The double needle row board has two needle row boards 3, and the two needle row boards 3 are respectively front and back (relatively figure 1 the forward and backward direction of figure 2 left and right direction) mounted on the side in a triangular shape (see figure 2) on the two inclined surfaces 10 of the fixed frame 4 and can slide, and the two machine heads 2 are installed on the frame 1 and correspond to the two needle row boards 3 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com