Patents

Literature

47results about How to "Play the role of linking the previous and the next" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

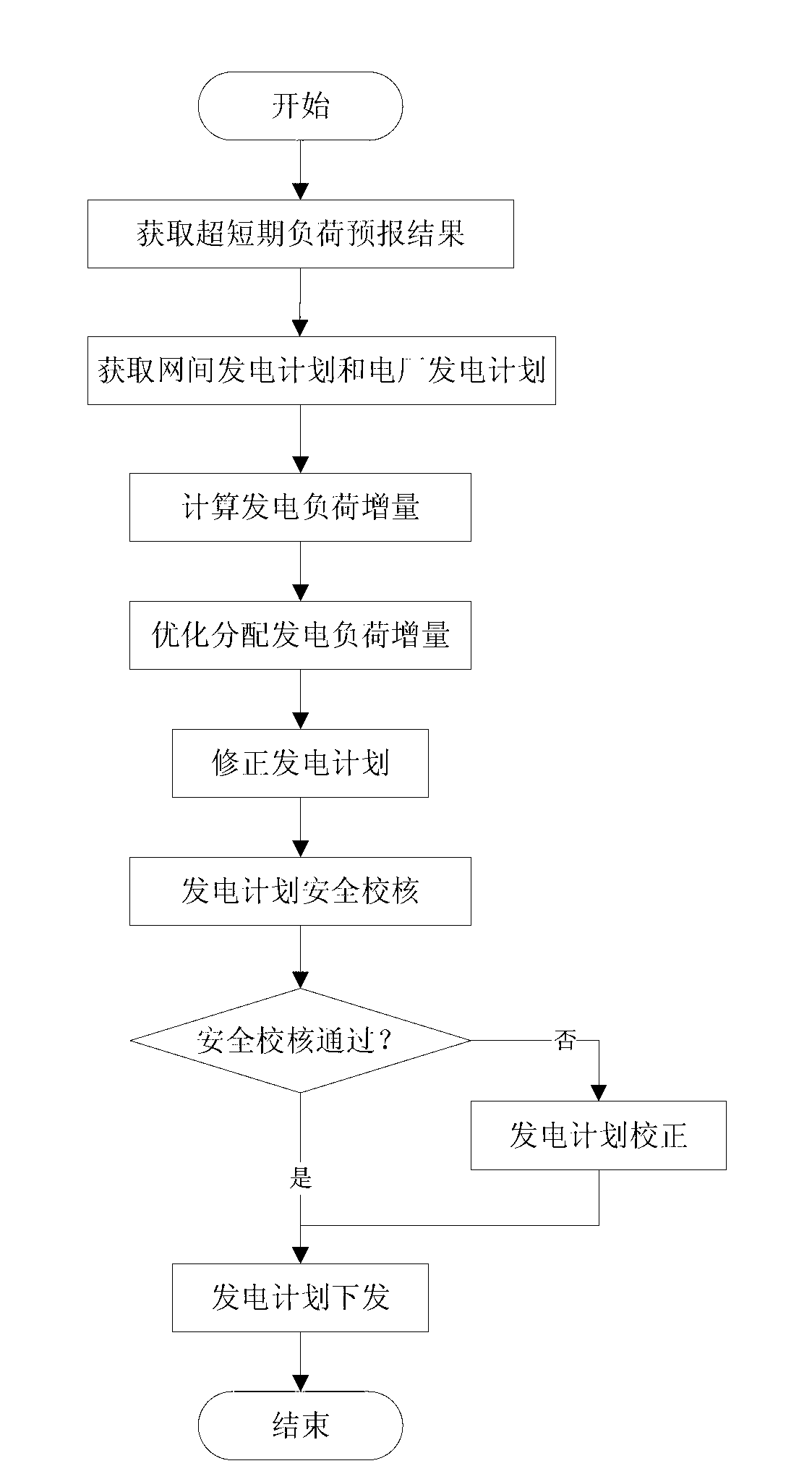

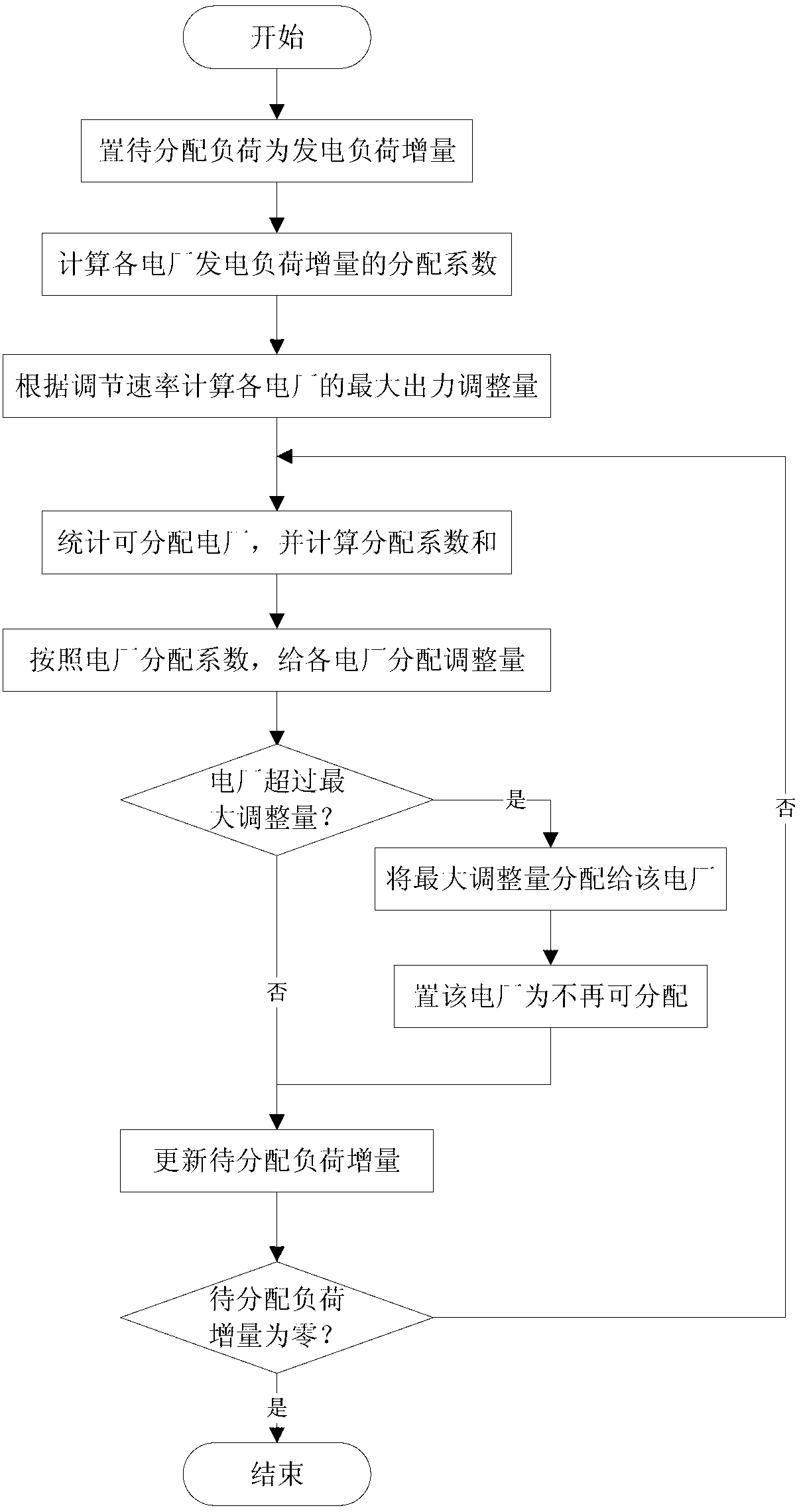

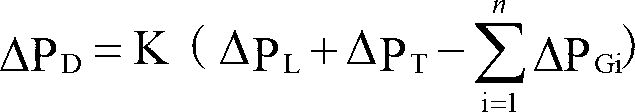

Real-time power generation schedule correcting method of power plant

ActiveCN102969740AReduce workloadPlay the role of linking the previous and the nextSingle network parallel feeding arrangementsAutomatic Generation ControlReal time prediction

The invention discloses a real-time power generation schedule correcting method of a power plant. The real-time power generation scheduling correcting method comprises the steps of: obtaining a real-time prediction result of the whole network load; forming an internetwork power generation schedule and a power plant power generation schedule; calculating a power generation load increment of a system within a period of time in future; comprehensively considering the coal consumption characteristic difference and the real-time control margin of each thermal power plant, on the premise of meeting the constraint conditions of the unit regulating rate and the regulating upper-lower limit, optimally allocating the power generation load increment among all thermal power plants; correcting the power generation schedule of each thermal power plant; carrying out tide checking, stable section checking and static safety analysis checking on the corrected real-time power generation schedules to ensure that the corrected power generation schedules do not go against the power grid safety constraint; and sending the corrected real-time power generation schedules to an AGC (Automatic Generation Control) or issuing the corrected real-time power generation schedules to all thermal power plants to be executed. According to the method, the economical efficiency and safety of power grid operation are comprehensively considered, the day-ahead power generation schedules are optimized and regulated, and real-time power generation schedules meeting the power grid operation demands are provided to the AGC or issued to all thermal power plants to be executed.

Owner:NR ELECTRIC CO LTD +1

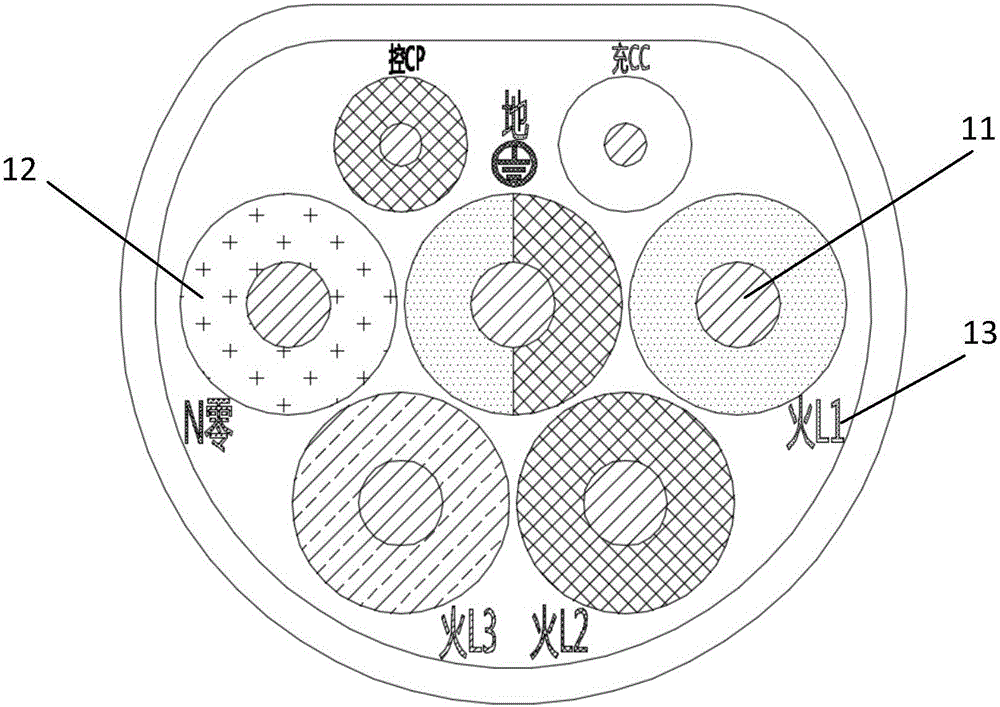

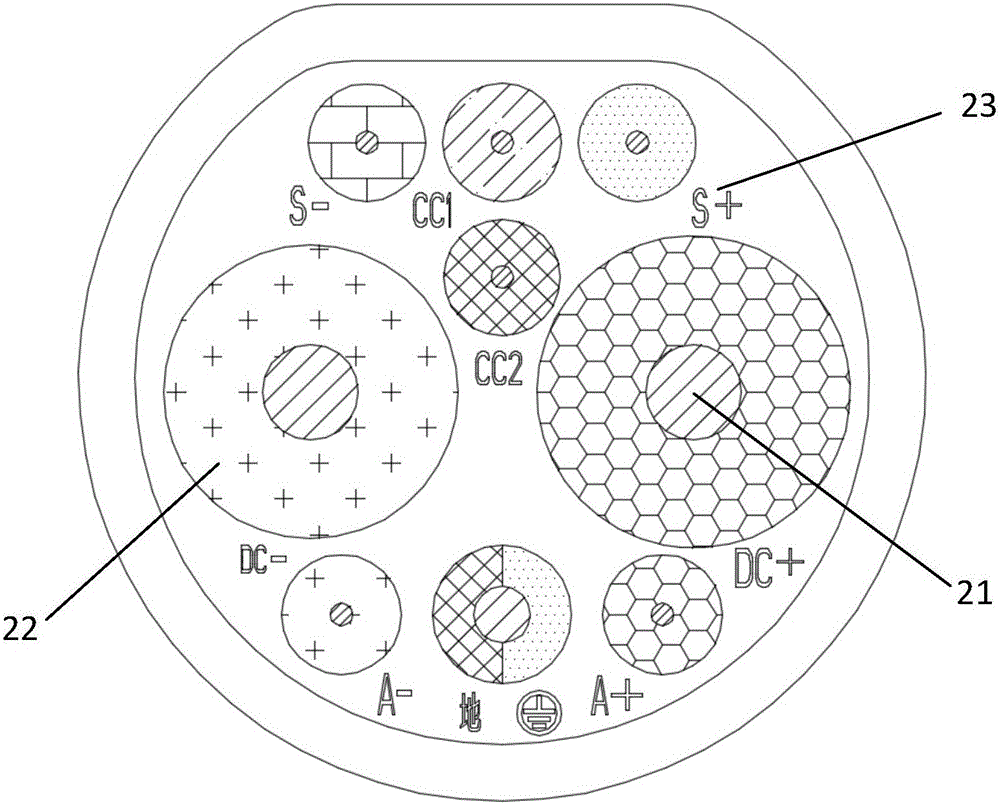

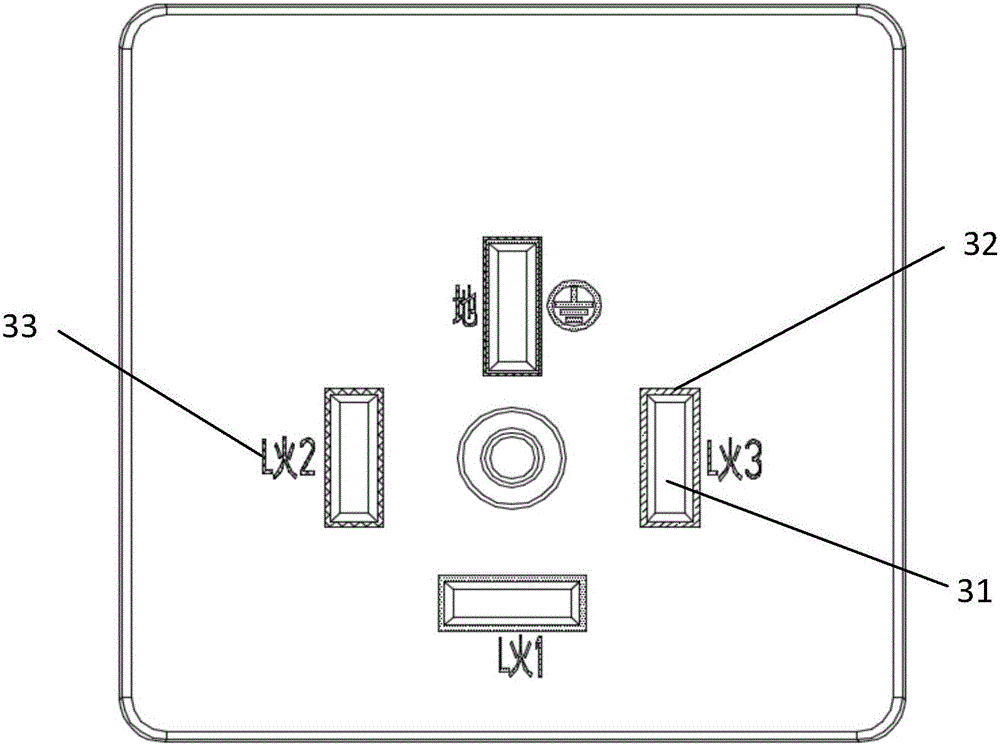

Wiring terminal with characteristic of convenient correct wiring identification

PendingCN106025658AImprove convenienceImprove efficiencyInsulated cablesCouplings bases/casesTransformerGround line

Owner:XIAN BLUE DIAMOND ELECTRONICS

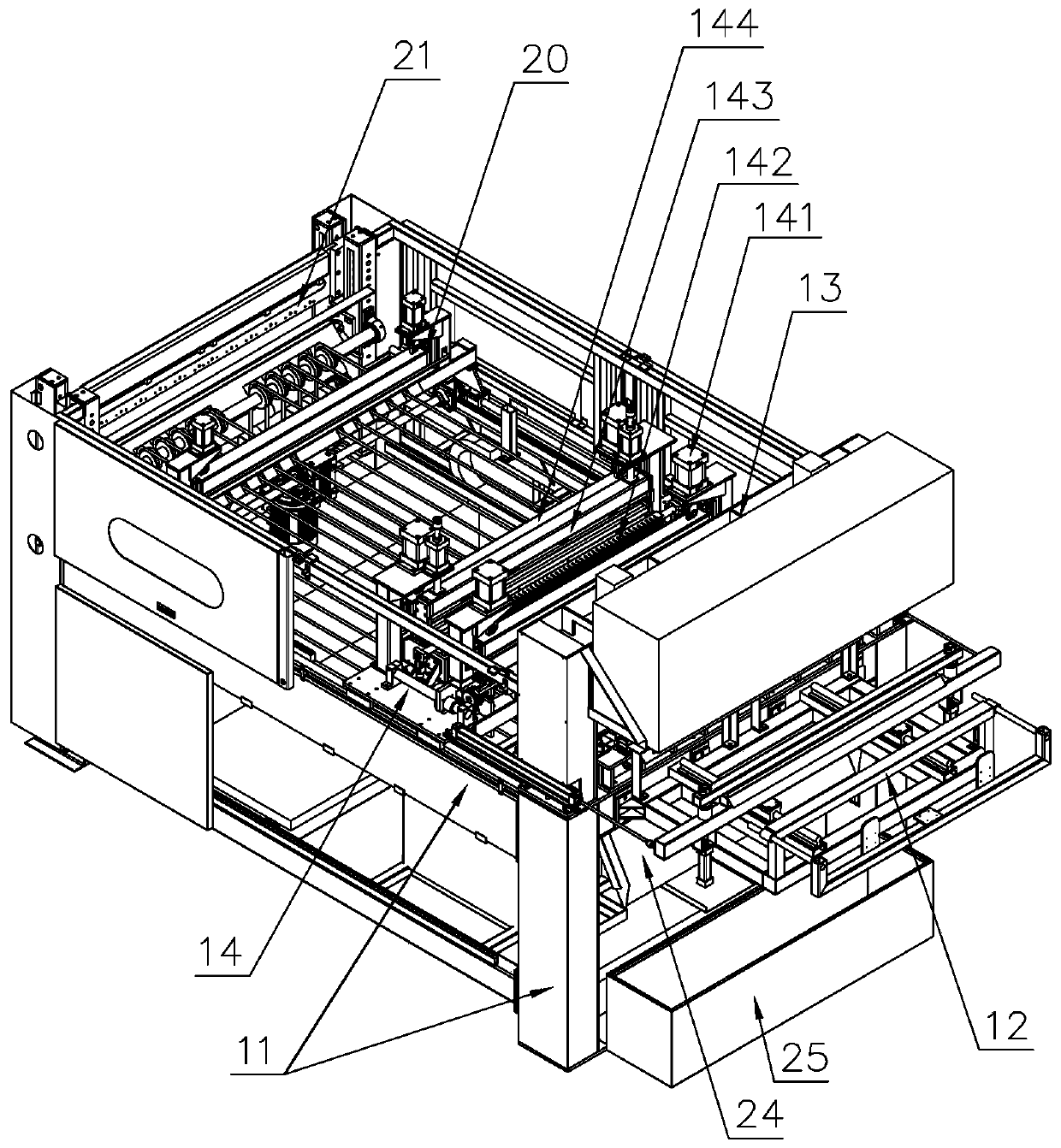

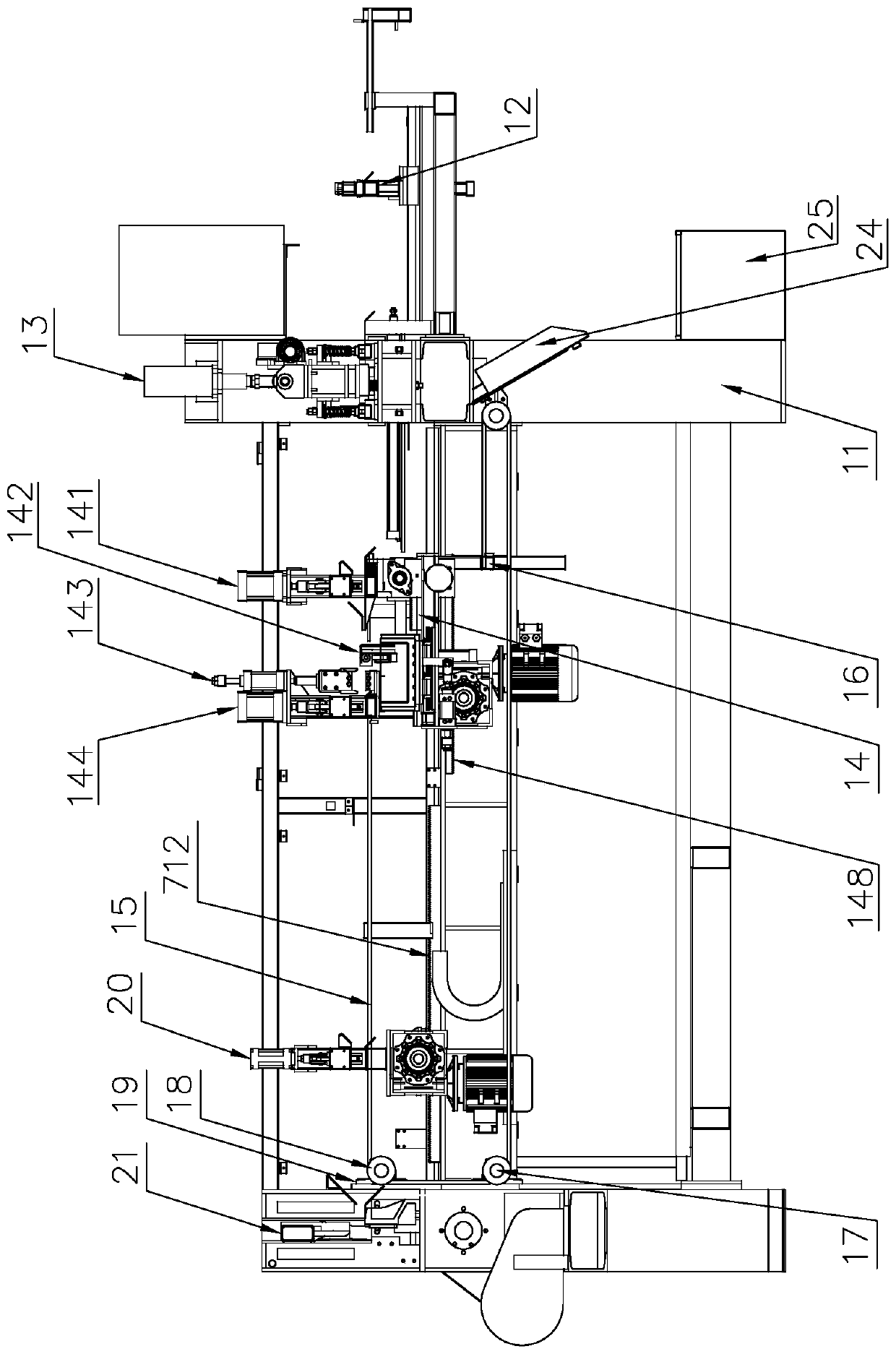

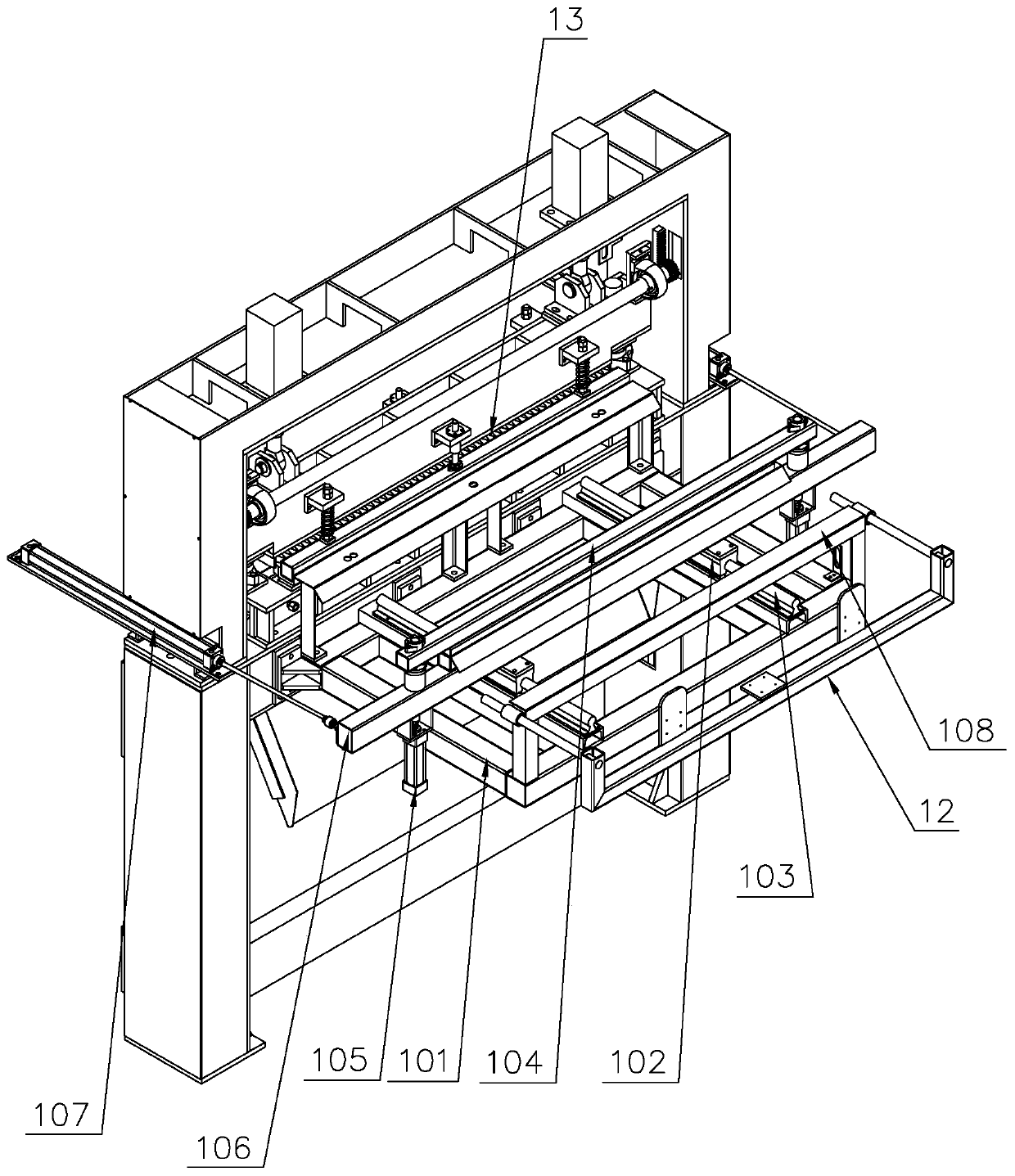

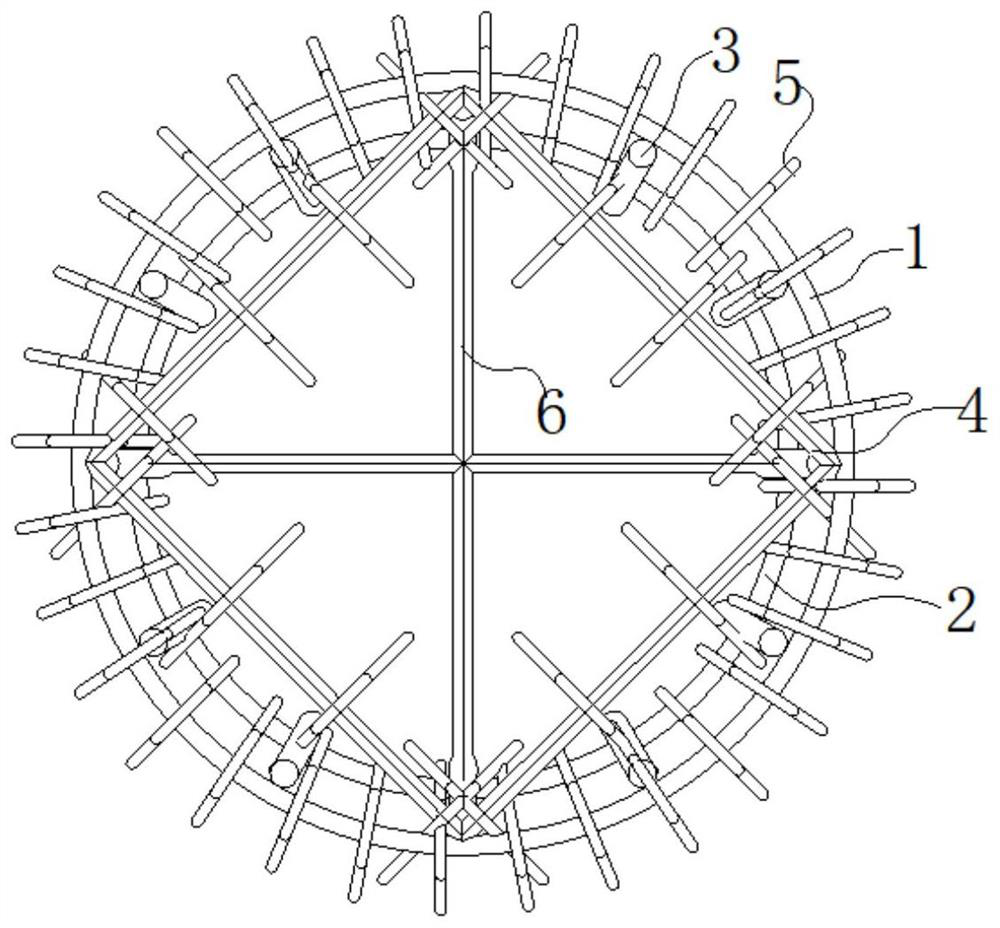

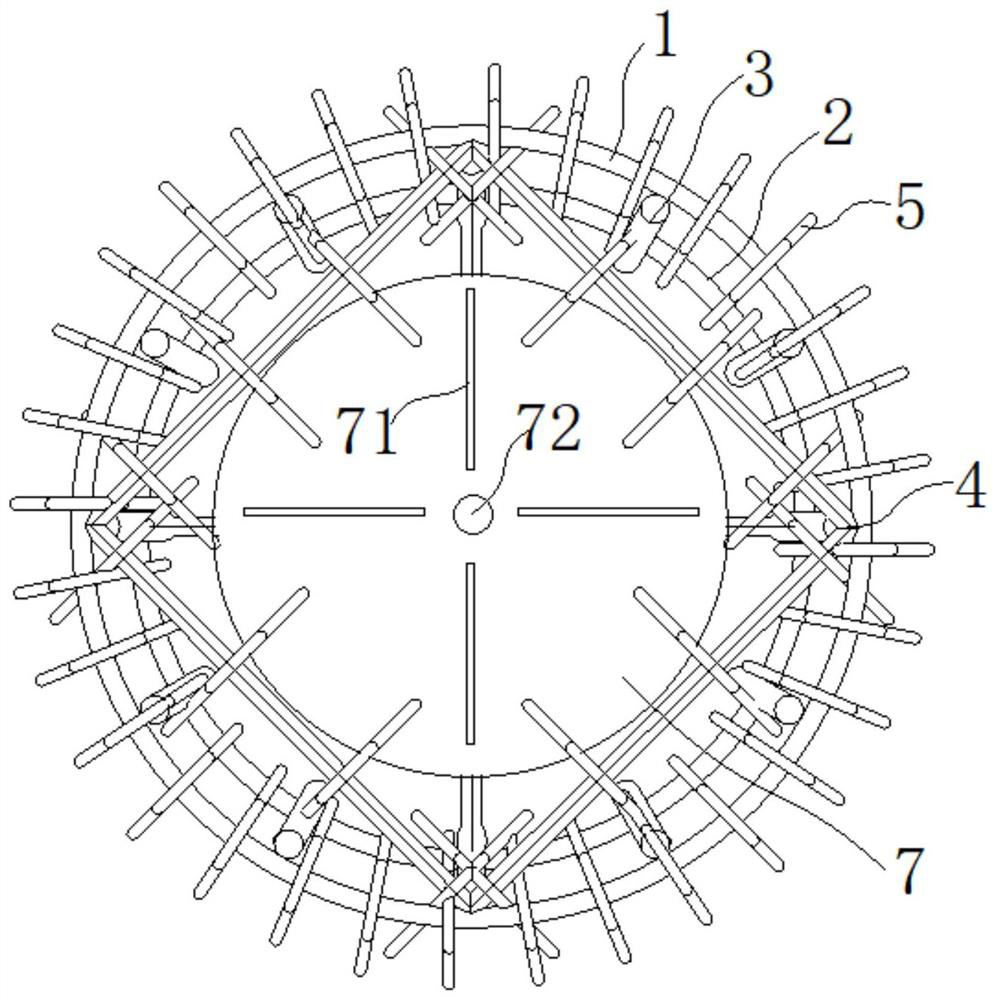

Full-automatic middle plate continuous gear coupling vertical splicing machine

PendingCN109940719APromote the process of full automationPlay the role of linking the previous and the nextWood veneer joiningAdhesive application devicesFixed frameButt joint

The invention discloses a full-automatic middle plate continuous gear coupling vertical splicing machine. The machine comprises a machine frame, a first feeding mechanism, a gear combing mechanism, amovable splicing mechanism, a rear transmission mechanism, a sizing mechanism and a transfer mechanism, wherein the first feeding mechanism is arranged at the front end of the machine frame; the gearcombing mechanism is arranged on one side of the first feeding mechanism; the transfer mechanism is arranged on the machine frame; the transfer mechanism comprises a conveyor belt, a fixing frame, a first transmission shaft, a transmission roller and a first bearing seat; the movable splicing mechanism comprises a front transmission mechanism, a first gluing mechanism, a butt joint mechanism and arear clamping mechanism; the conveyor belt of the transfer mechanism is connected with the movable splicing mechanism end to end; the conveyor belt is lapped on the transmission roller; the first transmission shaft is arranged in the center of the transmission roller; the two ends of the first transmission shaft are provided with first bearing seats; the first bearing seats are fixedly connectedto the side walls of stand columns of the machine frame; one side of the movable splicing mechanism is provided with the rear transmission mechanism; and one side of the rear transmission mechanism isprovided with the sizing mechanism. By means of the machine, the production efficiency and the production quality are greatly improved.

Owner:SHANDONG CHANGXING WOOD MACHINERY CO LTD

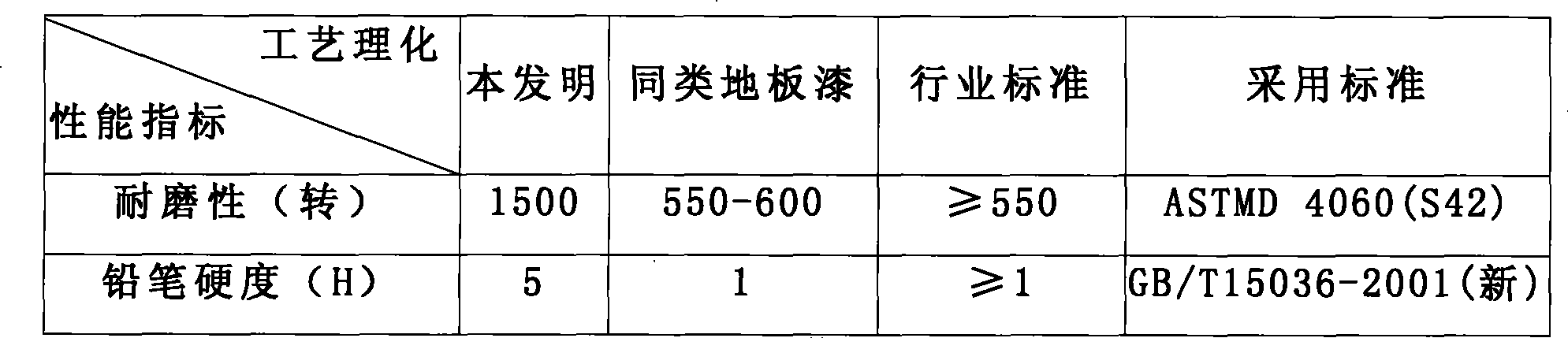

Floor paint

ActiveCN101412887AImprove wear resistanceExcellent abrasion resistance and scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsLacquerAcrylic resin

The invention discloses floor paint formed by aqueous primer and UV finishing coat. The solid content of aqueous polyurethane in the primer is between 25 and 45 percent, and is formed by oligomer polylol and isocyanate through hydrophilic chain extender by chain extension, wherein the ligomer polylol has molecular weight of between 500 and 3,000, and is selected from tetrahydrofuran polylol, polybutanediol adipate polylol and polycaprolactone polylol; and the hydrophilic chain extender is ethylenediamine with anionic sulphonate or anionic carboxylate groups. The finishing coat uses butanone as a solvent, and contains epoxy mondified acrylic resin, trifunctional monomer, 1,6-hexanediol diacrylate, silicon dioxide powder, light initiator, active amine assistant initiator, organic fluorine foam suppressor and aluminum oxide powder, wherein a diluent monomer is selected from trimethylolpropane triacrylate, trifunctional extractant acid ester, pentaerythritol triacrylate, and propoxylated propanetriol triacrylate. The floor paint has the advantages of good wear resisting property and scraping resisting property and splitting resisting property.

Owner:SINO MAPLE JIANGSU CO LTD

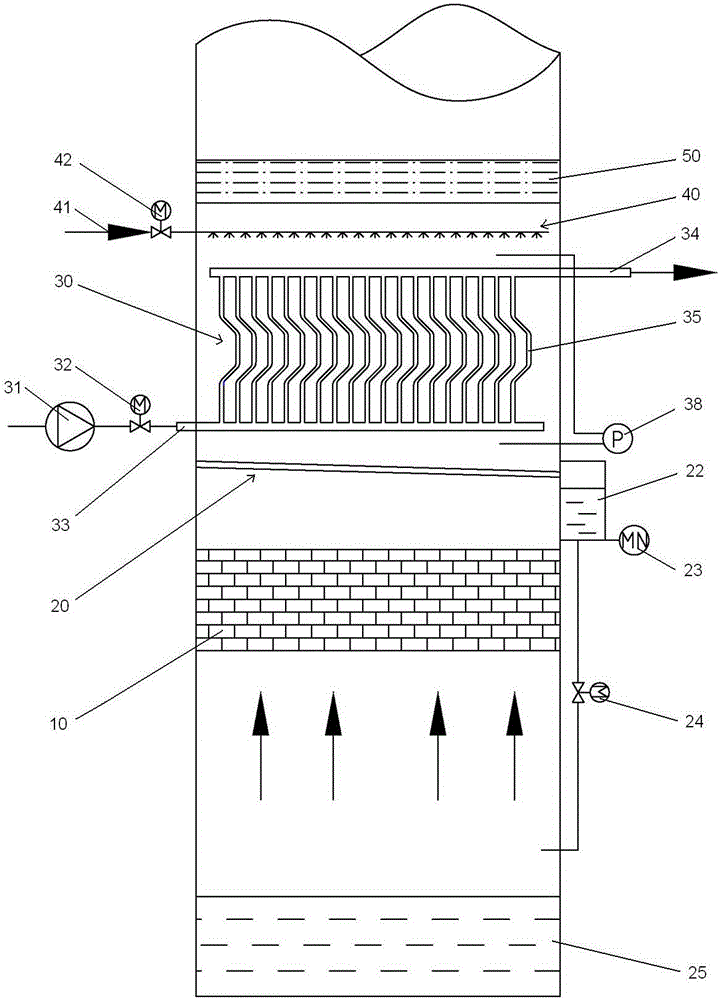

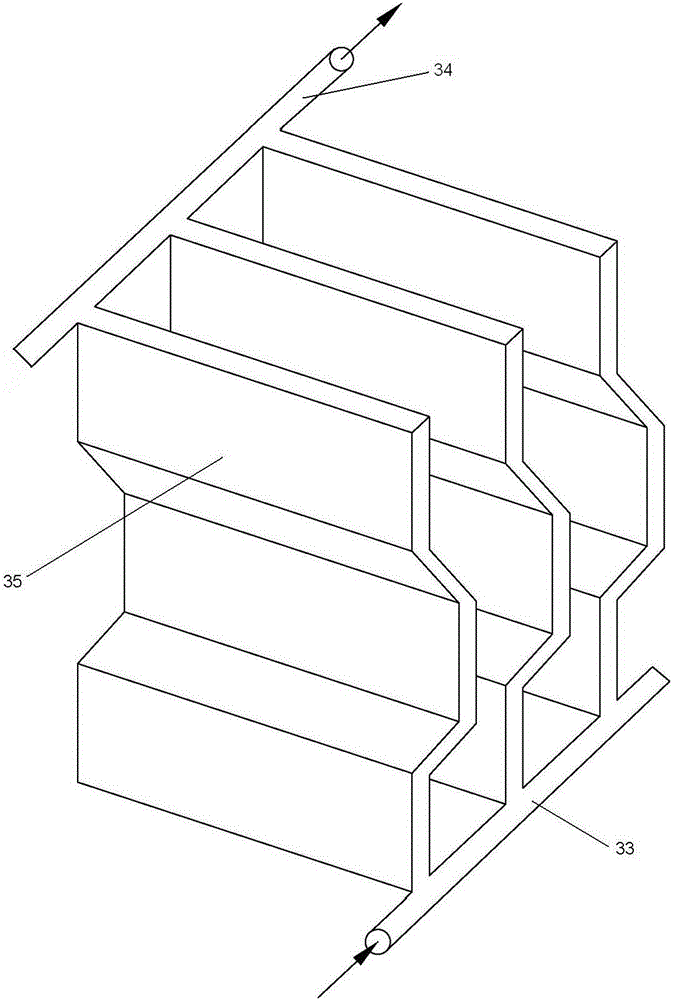

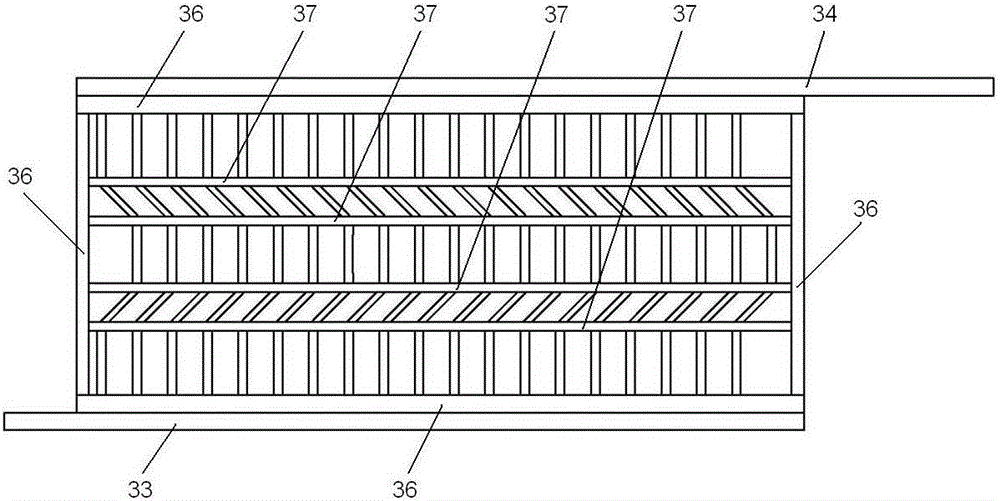

Fluoroplastic waste heat recycling and ultra-low emission integrated device

InactiveCN105157051AGood heat exchange performancePromote absorptionEnergy industryIncreasing energy efficiencyEngineeringRecuperator

The invention relates to a fluoroplastic waste heat recycling and ultra-low emission integrated device which is located above a catalytic reaction area in a desulfurizing tower and below a demister. The fluoroplastic waste heat recycling and ultra-low emission integrated device comprises a heat exchanger used for carrying out smoke waste heat exchange and capturing dust, a water flushing assembly used for flushing the surface of the heat exchanger, and a water collecting assembly used for collecting waste water and dust falling down from the surface of the heat exchanger. The water flushing assembly and the water collecting assembly are located above and below the heat exchanger respectively. The heat exchanger is a fluoroplastic plate type heat exchanger with a water inlet and a water outlet. The water inlet is connected with a low-temperature demineralized water feed pump. The water outlet s connected with a boiler system or a heating system. Compared with the prior art, the fluoroplastic waste heat recycling and ultra-low emission integrated device has good smoke waste heat recycling performance and dust and mist removing performance, and the purpose of integration of waste heat recycle and ultra-low emission is achieved. The fluoroplastic waste heat recycling and ultra-low emission integrated device has the beneficial effects of being resistant to corrosion, stable, reliable, low in water consumption and the like.

Owner:SHANGHAI HUAXIANG ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

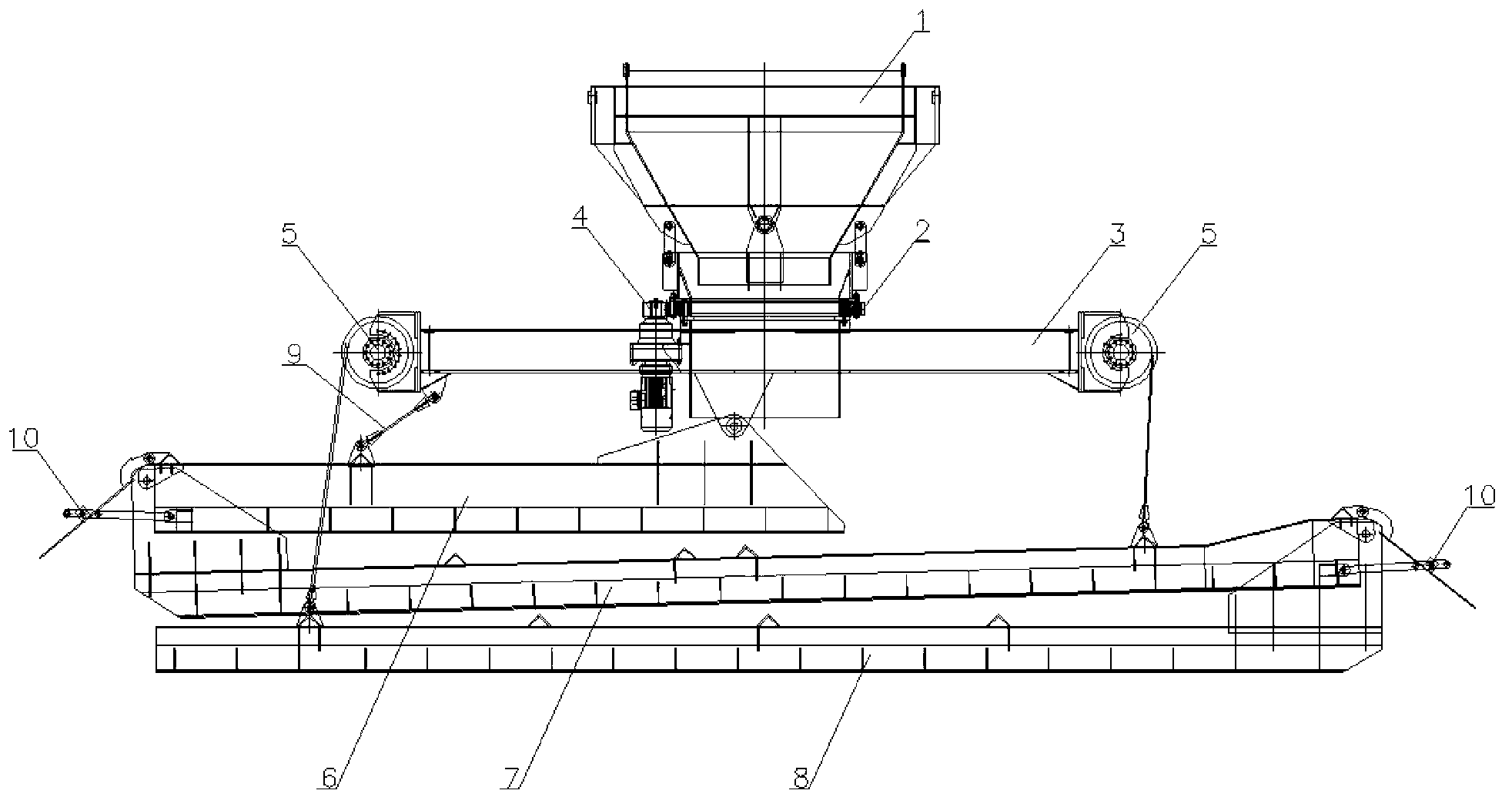

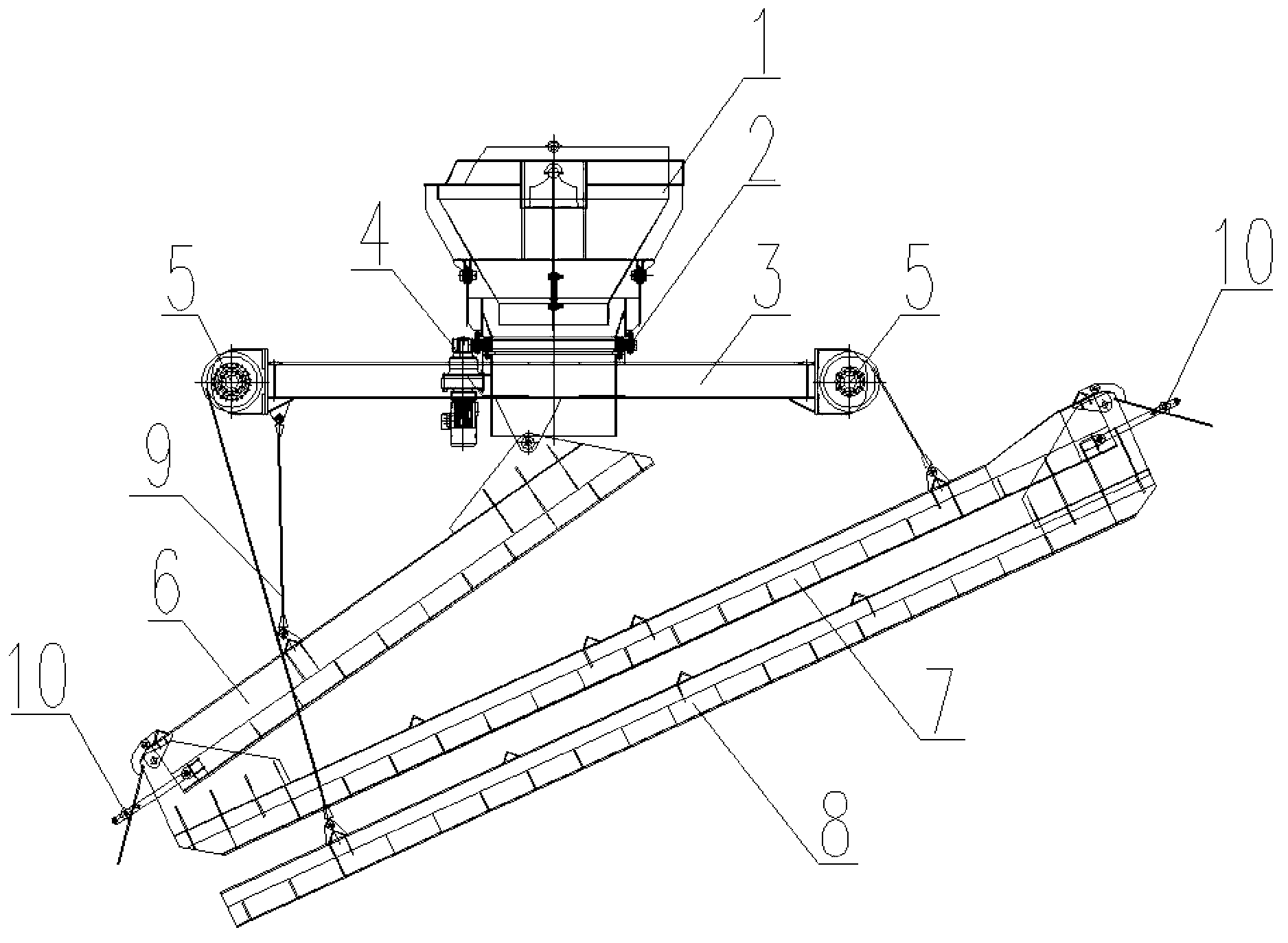

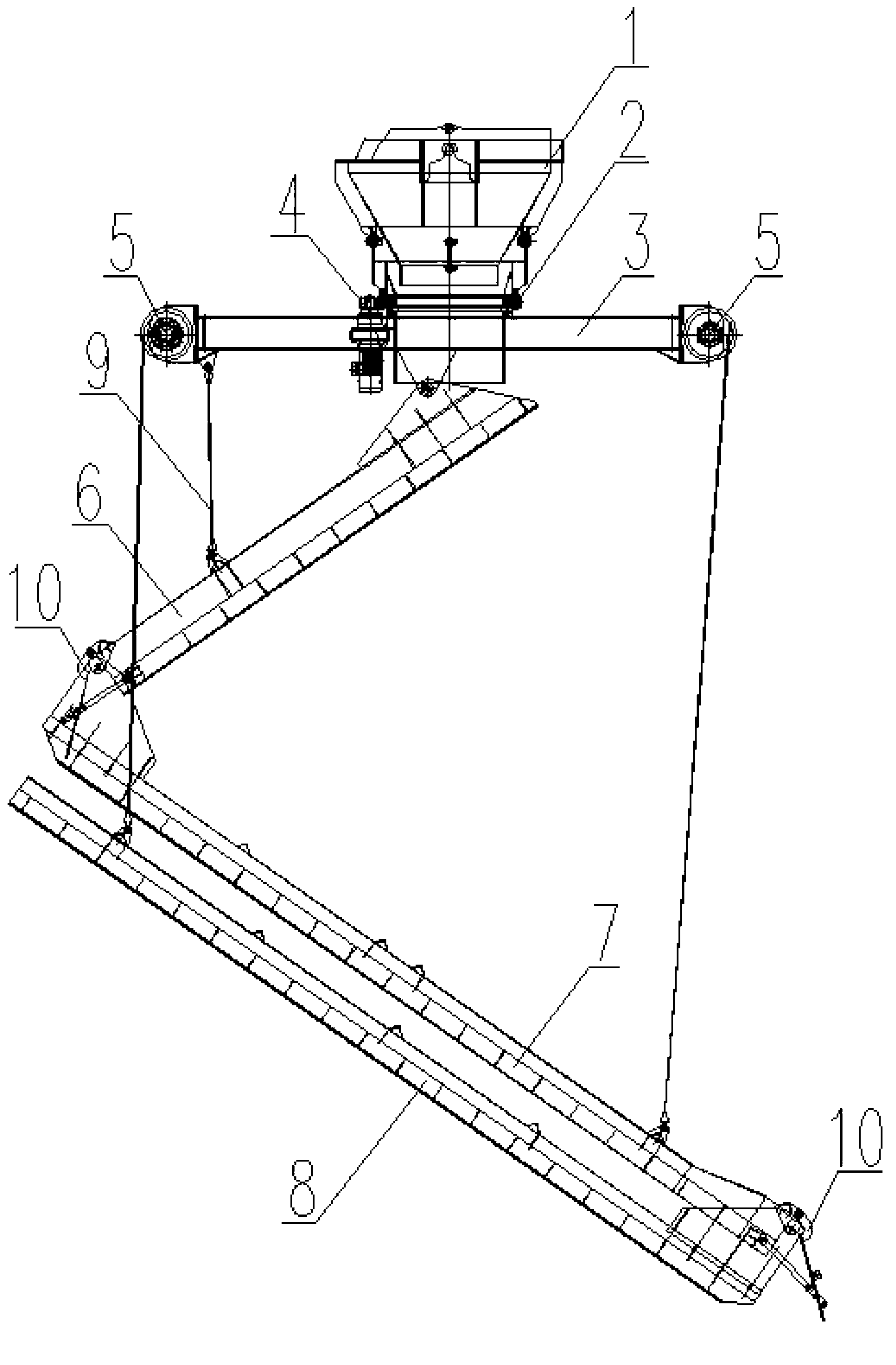

Z-shaped slow-descending chute discharging device

ActiveCN103224148AAchieve coveragePlay the role of linking the previous and the nextLoading/unloadingEngineeringWindlass

The invention provides a Z-shaped slow-descending chute discharging device and relates to a discharging device for bulk materials, particularly for bulk materials, such as bread iron, corn and wheat, which are suitable for loading and unloading by a ship loader. The discharging device adopts the structure that the lower end of a material guide cylinder is connected with a reversing frame through a pivotal bearing; a revolution drive mechanism is mounted on the reversing frame; a pinion wheel of the revolution drive mechanism is meshed with a bearing external gear ring of the pivotal bearing; material guide grooves are formed in the lower part of the reversing frame; two folding windlasses are symmetrically arranged on two ends of the reversing frame respectively; traction steel wire ropes of the two folding windlasses are connected with a secondary material guide groove and a tertiary material guide groove respectively; an iron chain is mounted between the reversing frame and a primary material guide groove of the material guide grooves; and baffles are mounted at the bottom ends of the primary and the secondary material guide grooves. The discharging device has the characteristics of novel structure, simplicity and convenience in processing, convenience in use, safety, reliability, high operating efficiency and the like.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

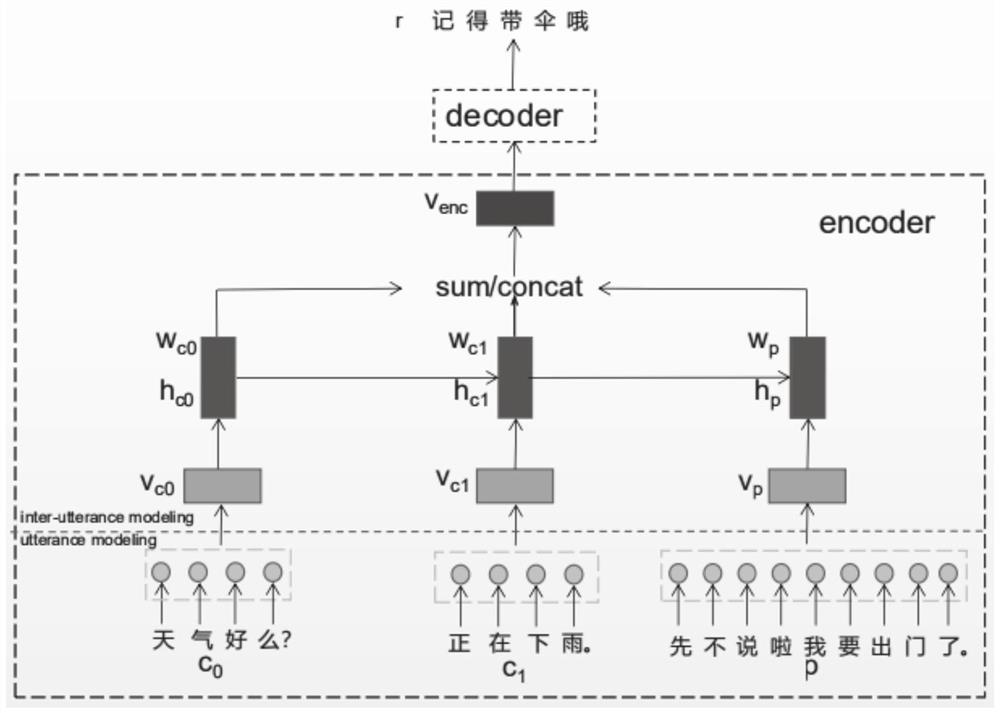

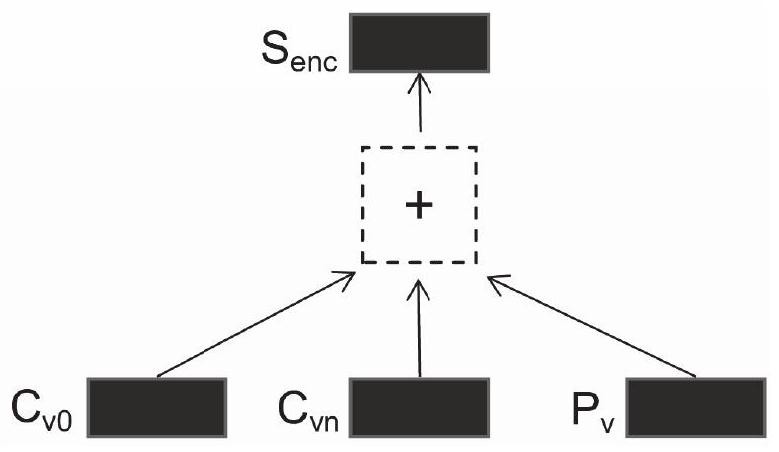

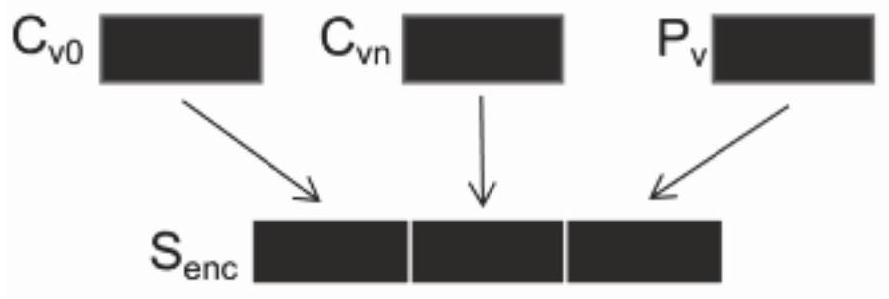

Context-based dialogue generation method and system

ActiveCN112328756AEasy to trainEmbody robustnessDigital data information retrievalCharacter and pattern recognitionEngineeringHuman–computer interaction

The invention discloses a context-based dialogue generation method and system. The method comprises the steps of obtaining a current dialogue statement, a previous statement of a current dialogue anda next statement of the current dialogue; and inputting the current dialogue statement, the previous statement of the current dialogue and the next statement of the current dialogue into a pre-trainedcodec, and outputting a predicted dialogue statement of the current dialogue statement by the codec. According to the method, the method can play a role in linking the previous part and the next part; the contextual information related to the current dialogue can be combined to generate more effective information, on one hand, the dialogue can be smoother, and the consistency and logicality of the dialogue before and after the dialogue are kept; on the other hand, more premise input information can be provided for the neural network, and research shows that the rich input information is beneficial for the neural network to generate more meaningful answers.

Owner:SHANDONG NORMAL UNIV

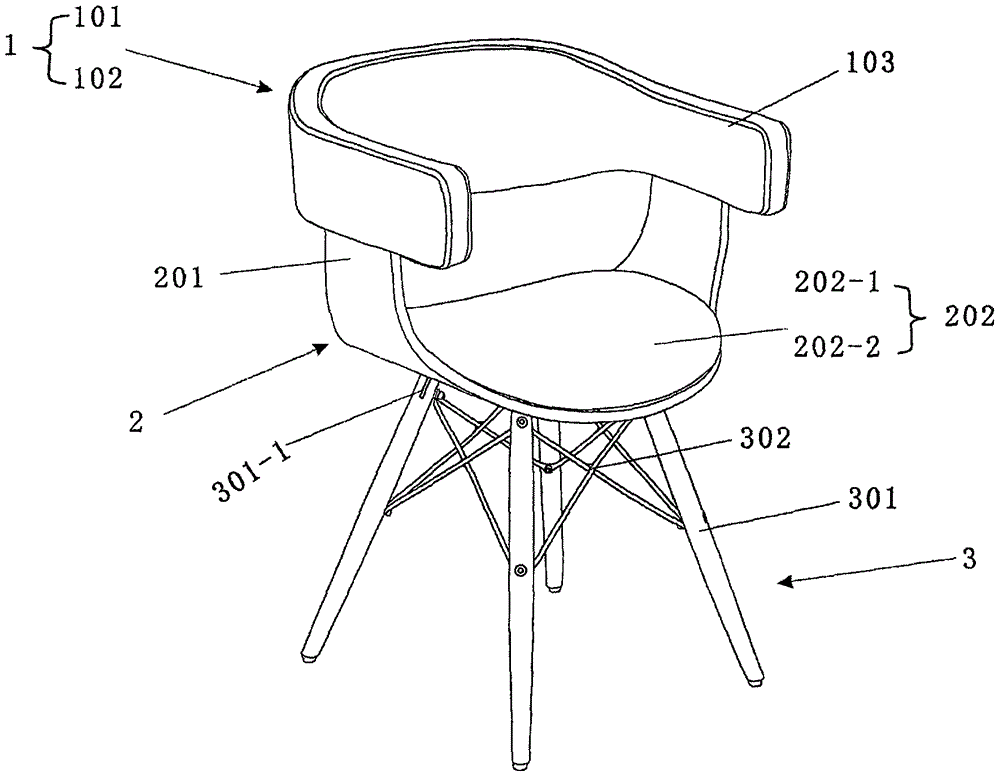

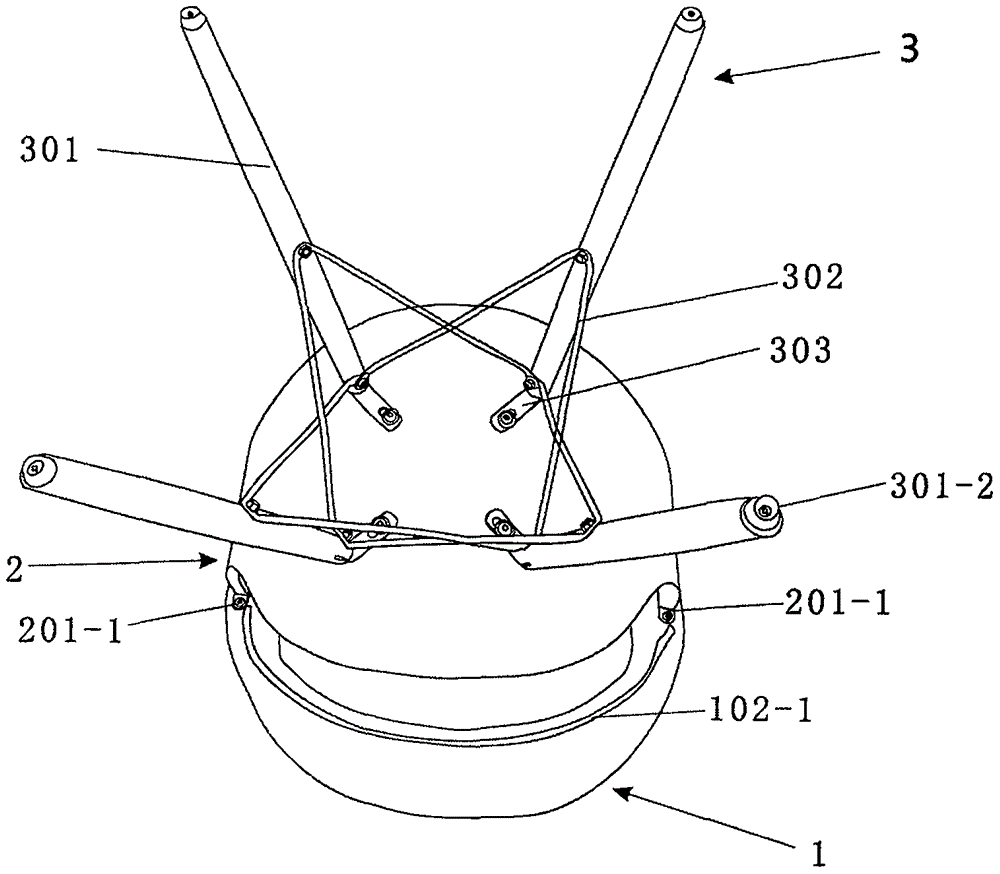

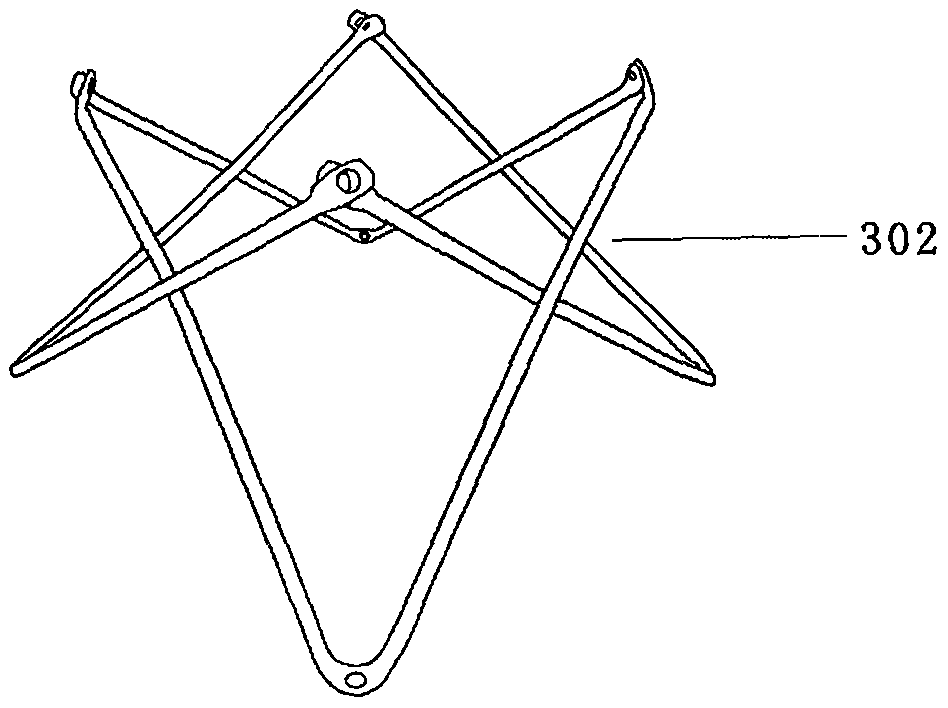

Novel bar chair

The invention relates to a novel bar chair. The novel bar chair comprises a backrest, a seat surface and chair legs. The backrest and armrest problem is solved through a U-type plate, placed flatly, of the backrest, the integrated structure is simple and elegant, cost is saved, and breakthrough and innovation are achieved. A double-layer plate structure (a plate inside a seat and a plate outside the seat) is adopted in the bar chair seat surface, ingenious use of concealed buckles is combined, and the inside and outside two-layer plate structure is novel in style and make the bar chair have stereoscopic sensation and fashion sensation. Connecting iron is reasonably used to serve as a connecting link. A leg net frame is used in cooperation, and stability and firmness of the whole bar chair are greatly improved.

Owner:ZHEJIANG CHAIRMENG FURNITURE

Aluminum automobile transmission shell

ActiveCN105714162AHigh strengthImprove toughnessLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingZinc

The invention discloses an aluminum automobile transmission shell. The transmission shell is composed of an aluminum alloy base material and outer electroplated layers. An aluminum alloy is prepared from, by weight percent, 7% to 9% of Zn, 12% to 14% of Si, 6% to 8% of Cu, 2% to 4% of Mn, 0.8% to 1.2% of Ti, 0.3% to 0.5% of Re, 3% to 5% of Mg, 1% to 3% of Zr, 0.6% to 0.8% of Ni and the balance Al and inevitable impurities. The electroplated layers sequentially comprise the zinc deposition layer, the electronickelling layer and the outermost nickel plating layer or chromium plating layer or copper plating layer from inside to outside. The zinc deposition layer is of a three-layer structure, and the thickness of each layer is about 1-2 micrometers. The thickness of the electronickelling layer is about 4-6 micrometers, and the thickness of the outermost nickel plating layer or chromium plating layer or copper plating layer is about 20-30 micrometers.

Owner:徐州超杰电动车配件有限公司

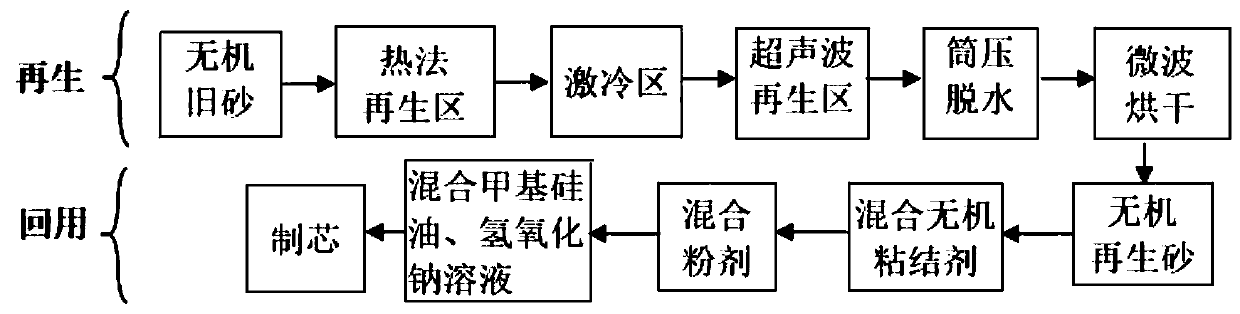

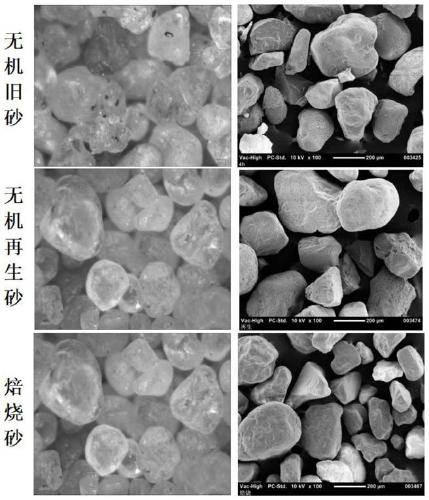

Cast aluminum inorganic used sand regeneration and reusing combined method

ActiveCN111496180AImprove regenerative abilityIncrease the effective contact areaFoundry mouldsMould handling/dressing devicesPhysical chemistryProcess engineering

The invention provides a cast aluminum inorganic used sand regeneration and reusing combined method. The solid waste environmental problem caused by inorganic used sand is solved, meanwhile, recyclingof the used sand is achieved, the production cost is reduced, and direct benefits are created for an enterprise. According to the technical scheme, the cast aluminum inorganic used sand regenerationand reusing combined method comprises regeneration of the inorganic used sand and reusing of the inorganic used sand, wherein regeneration of the inorganic used sand comprises the steps of crushing, hot-method regeneration, chilling, wet-method regeneration, dehydration, drying, sieving and the like; and the reusing method comprises the steps of adding, stirring and mixing inorganic powder, inorganic adhesives, methylsilicone oil, sodium hydroxide and the like.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

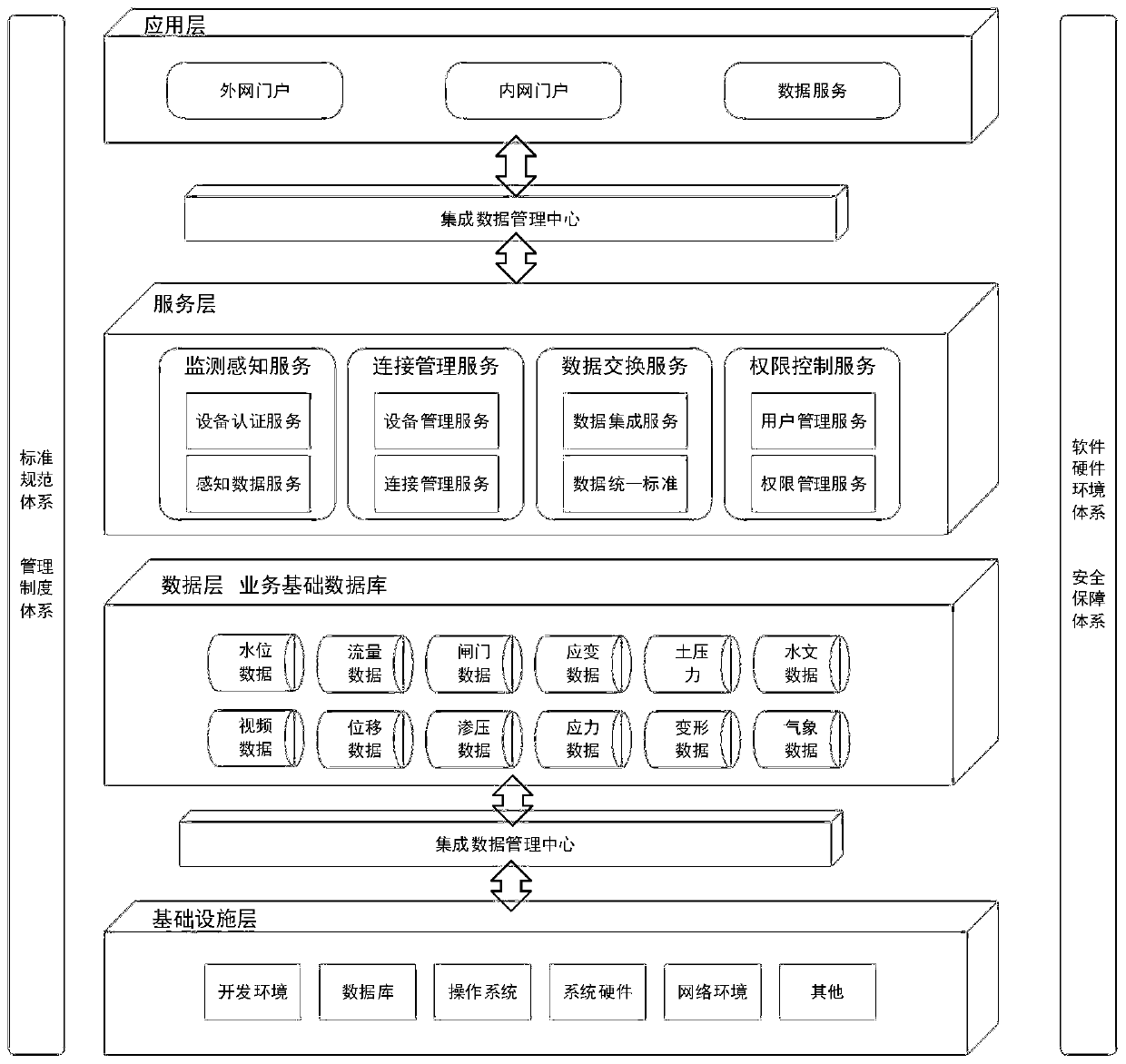

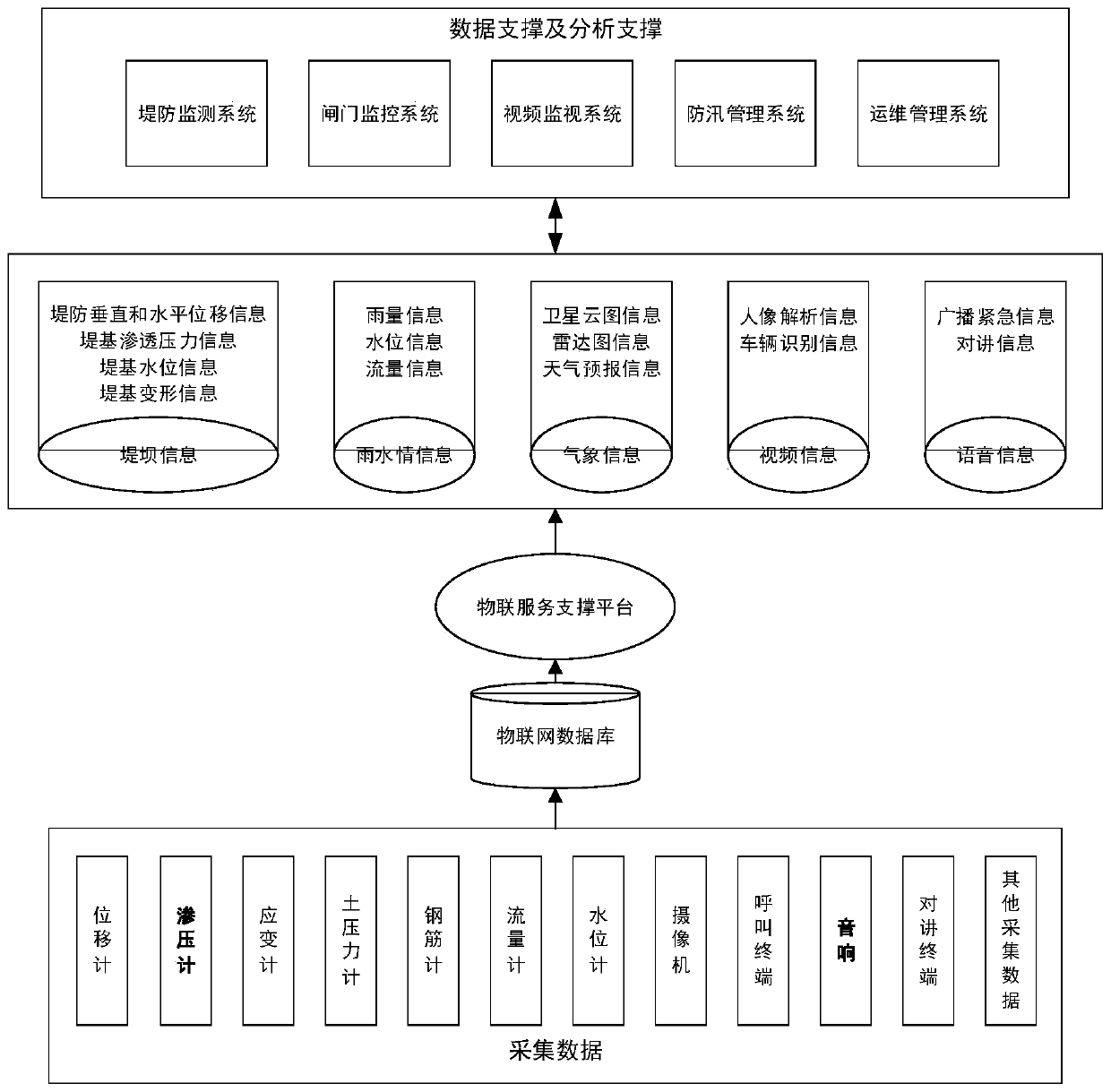

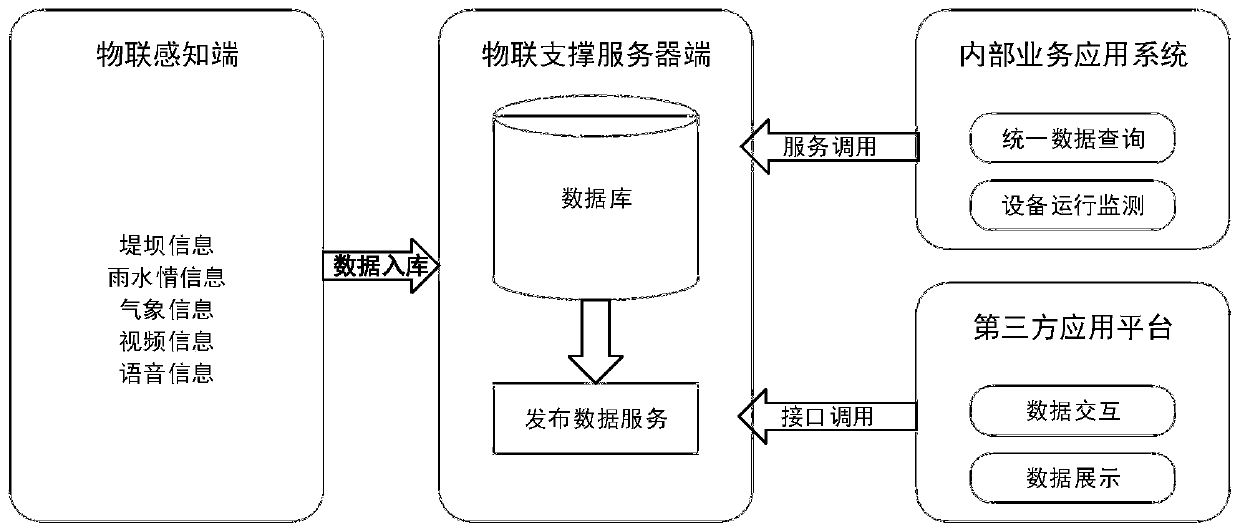

River channel intelligent management and control system

PendingCN110647315ARealize real-time controlRealize managementData processing applicationsSoftware designOperational systemNetwork communication

The invention discloses an intelligent riverway management and control system, which belongs to the technical field of intelligent riverway pipelines, and is characterized by comprising an infrastructure layer, a data layer, a service layer and an application layer, wherein the infrastructure layer comprises a development environment system, a database management system, an operating system, a network environment and hardware equipment; the infrastructure layer provides a server, a switch, a terminal, safe and stored software and hardware, a place and a network communication environment for the data layer, the service layer and the application layer, wherein the data layer is a service basic database and is used for storing basic data, and the data layer provides IoT data support for different application systems; the service layer comprises an equipment monitoring perception service, an equipment connection management service, a model and monitoring data exchange service and an authority control service; the application layer comprises an intranet portal website and an extranet portal website; and the infrastructure layer, the data layer, the service layer and the application layer perform data interaction in sequence through a data exchange system.

Owner:HEBEI RES INST OF INVESTIGATION & DESIGN OF WATER CONSERVANCY & HYDROPOWER

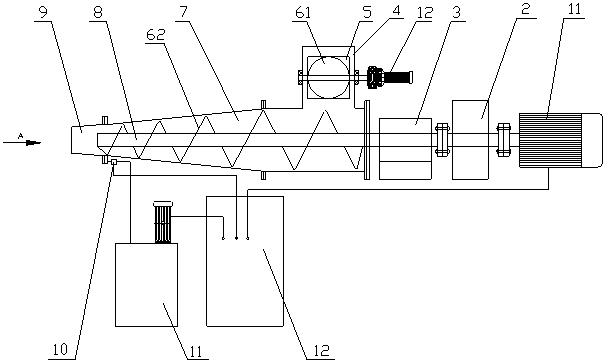

Novel straw compression forming equipment

The invention provides novel straw compression forming equipment, and relates to a compression forming device of fiber materials. The novel straw compression forming equipment comprises a main driving mechanism, a precompression mechanism and a compression mechanism. The precompression mechanism comprises a second motor, a feeding box, a precompression packing auger and a forced feeding turnover plate, a reinforcing compression cavity is formed in the outlet end of a compression cavity, and is of a left-and-right buckling structure, the two sides of the reinforcing compression cavity are connected with connecting rod mechanisms respectively, the connecting rod mechanisms are connected with a hydraulic station, the hydraulic station is controlled by an electric drive travel switch, and the hydraulic station and the electric drive travel switch are in linkage and automatic control through a PLC control cabinet. Based on the working principle that main machine volume variable physical extrusion and auxiliary machine forced feeding extrusion are combined, the materials are conveyed, extruded and dehydrated, the equipment is especially suitable for compression forming of straw type biomass, and the compressed materials are low in water content and small in density.

Owner:河南天冠纤维乙醇有限公司

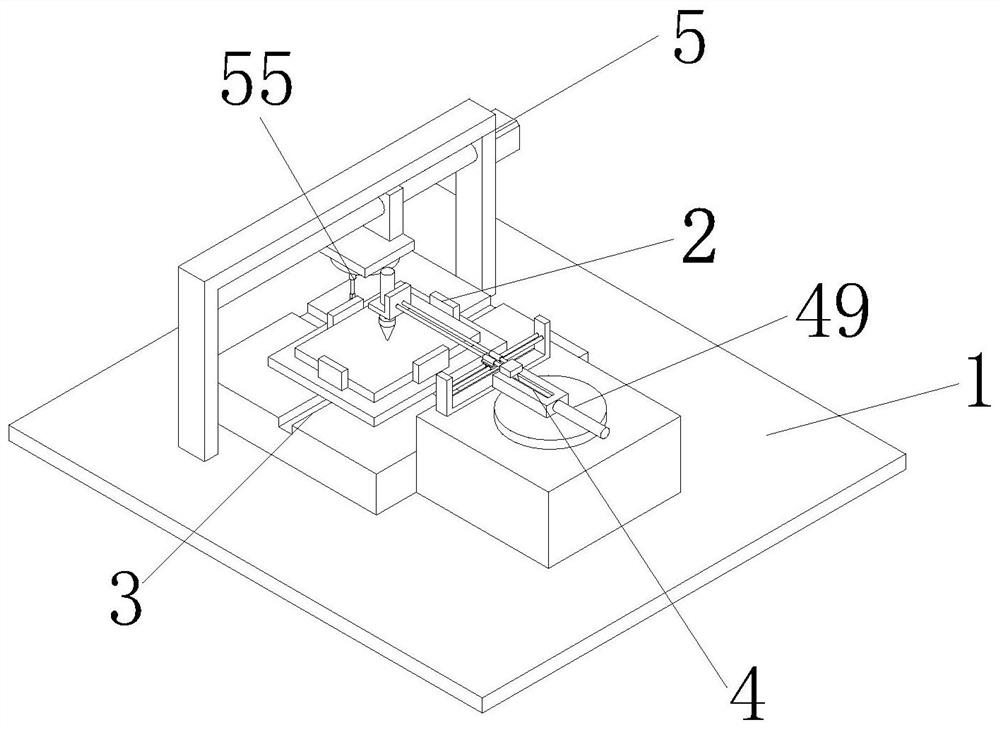

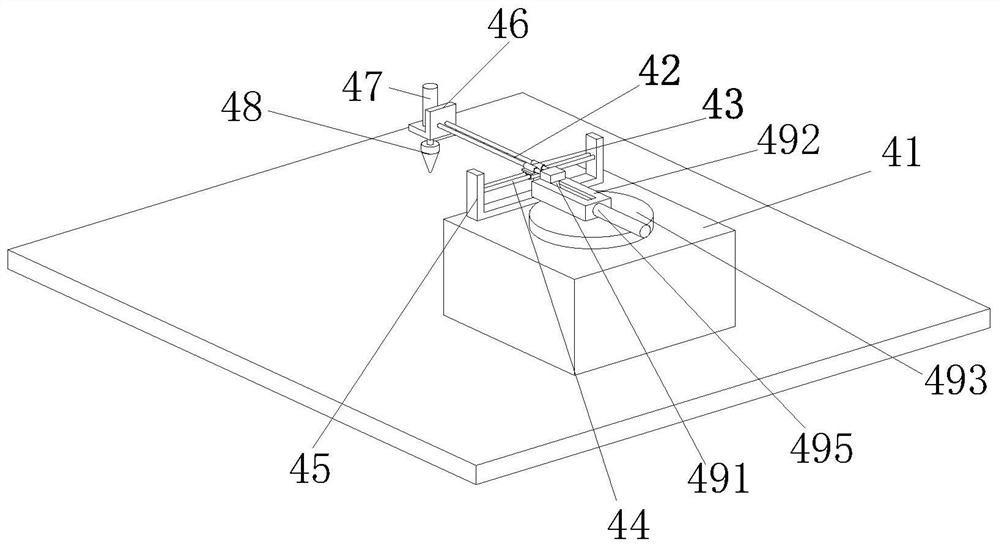

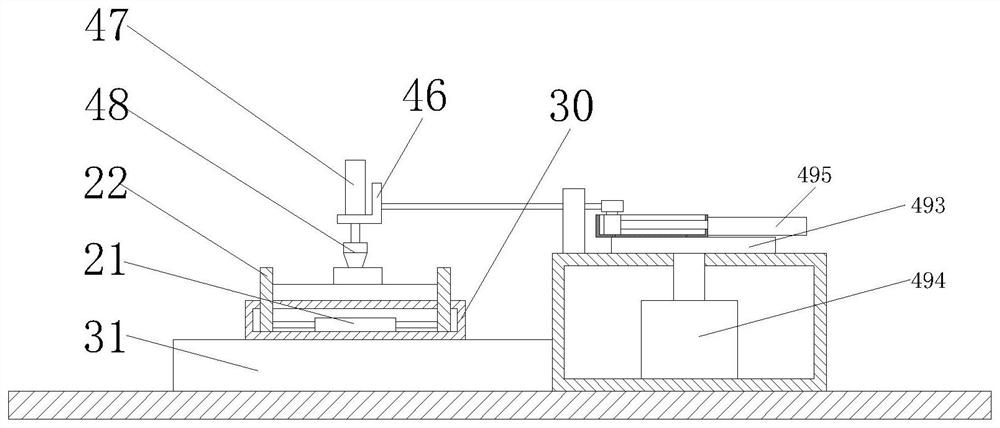

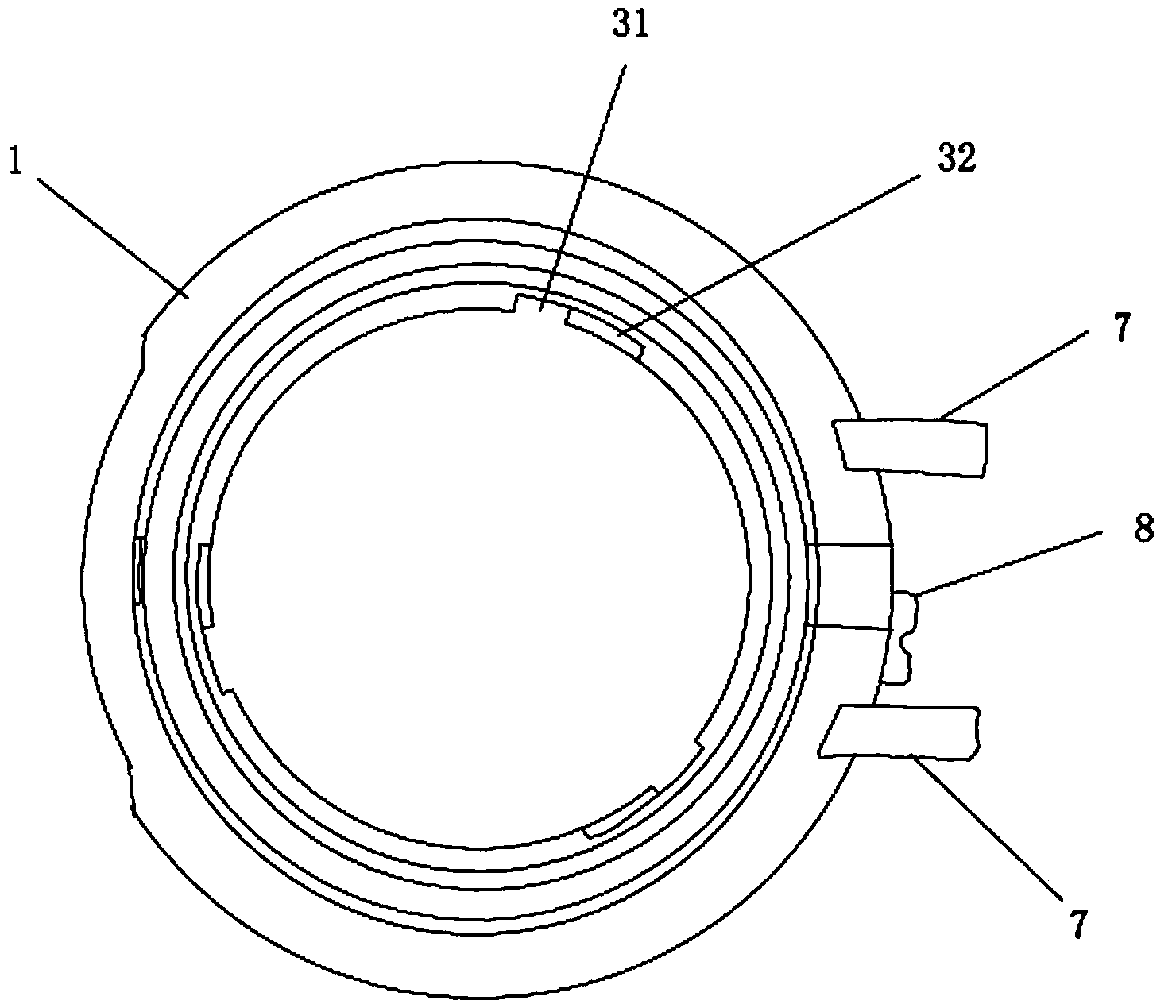

Automatic glass circle cutting machining machine and machining method

InactiveCN113149421AImprove stabilityImprove processing efficiencyGlass severing apparatusGlass productionMachineMachining

The invention provides an automatic glass circle cutting machining machine and method, and relates to the field of glass machining. The automatic glass circle cutting machining machine comprises a bottom plate, a clamping mechanism, a moving mechanism, a cutting mechanism and a knocking mechanism; the moving mechanism is fixedly installed on the bottom plate, the clamping mechanism is arranged on the moving mechanism, and the cutting mechanism is fixedly arranged on the bottom plate; the cutting mechanism is located on the right side of the moving mechanism, a knocking mechanism is fixedly installed on the bottom plate, and the knocking mechanism is located above the clamping mechanism. Automatic circle cutting machining can be achieved, the manual participation degree is reduced, the production efficiency is improved, meanwhile, the circle cutting diameter can be adjusted through the cutting mechanism, and the size of the tangent circle is adjusted according to different requirements, so the utilization rate of equipment is further improved.

Owner:卢纯珍

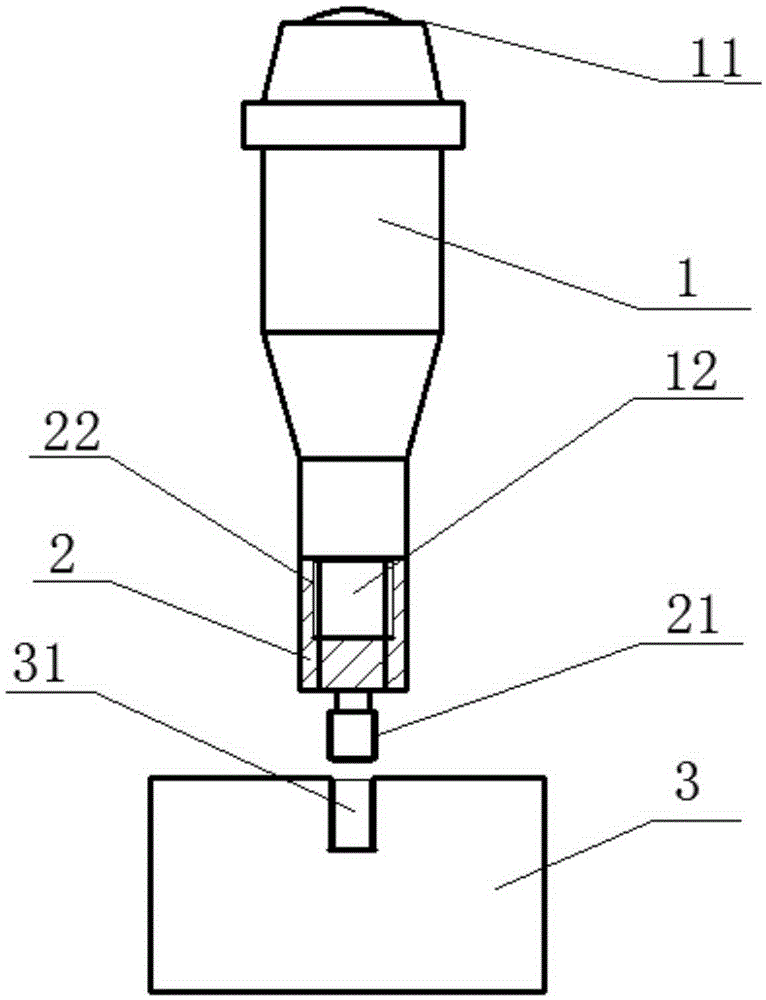

Measuring device for perpendicularity and planeness of vertical type rail and measuring method thereof

The invention discloses a measuring device for perpendicularity and planeness of a vertical type rail and a measuring method thereof, and belongs to the technical field of measurement of the perpendicularity and planeness. The measuring device for the perpendicularity and planeness of the vertical type rail comprises a measuring unit and a positioning unit. The measuring unit comprises a total station or a theodolite or a gradienter. The positioning unit comprises a measuring rod, a connecting piece and a magnetic base. The measuring rod is fixed to the upper surface of the magnetic base through the connecting piece. The planeness of the bottom face of the magnetic base is smaller than 0.005 mm. The measuring method includes the steps of assembling, absorbing, zero returning, measuring unit position selection, eyepiece observation, adjusting, measuring point replacement and rail debugging. According to the device and the method, the measuring unit and the positioning unit are arranged in a separated mode, the positioning unit achieves accurate positioning through the measuring rod and attraction by the magnetic, and the purpose of accurate measuring of the perpendicularity and planeness in any space without being affected by external factors can be achieved.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Electroplating method of high-strength aluminum alloy for die casting

ActiveCN105671377AHigh strengthImprove toughnessCopper platingSodium potassium tartrate tetrahydrate

The invention discloses an electroplating method of high-strength aluminum alloy for die casting. The electroplating method of the high-strength aluminum alloy for die casting is characterized in that the high-strength aluminum alloy comprises the following components in percentages by weight: 7-9% of Zn, 12-14% of Si, 6-8% of Cu, 2-4% of Mn, 0.8-1.2% of Ti, 0.3-0.5% of Re, 3-5% of Mg, 1-3% of Zr, 0.6-0.8% of Ni, and the balance Al and inevitable impurities. The electroplating method comprises the following steps: (1) pretreatment; (2) zinc depositing treatment: carrying out zinc depositing treatment for three times, wherein a zinc depositing treatment solution comprises the following components: 60-80 g / L of sodium hydroxide, 40-60 g / L of zinc oxide, 100-120 g / L of sodium potassium tartrate tetrahydrate, 3-5 g / L of ferric chloride and 3-5 g / L of sodium nitrate, zinc depositing temperature is 30-50 DEG C, and zinc depositing time is 20-40 seconds; (3) electronickelling treatment, wherein an electronickelling solution comprises the following components: 160-180 g / L of NiSO4.6H2O, 0.6-0.8 mol / L of F<->, 20-30 g / L of boric acid, 22-24 g / L of (NH4)3C6H5O7 and 1-3 g / L of sodium saccharin, and treatment conditions are as follows: pH value is 4.8-5.4, current density of a cathode is 2-4 A / d m<2>, temperature is 45-55 DEG C, and time is 20-30 minutes; and (4) surface layer nickel, chromium or copper plating.

Owner:瑞晟通金属(广东)有限公司

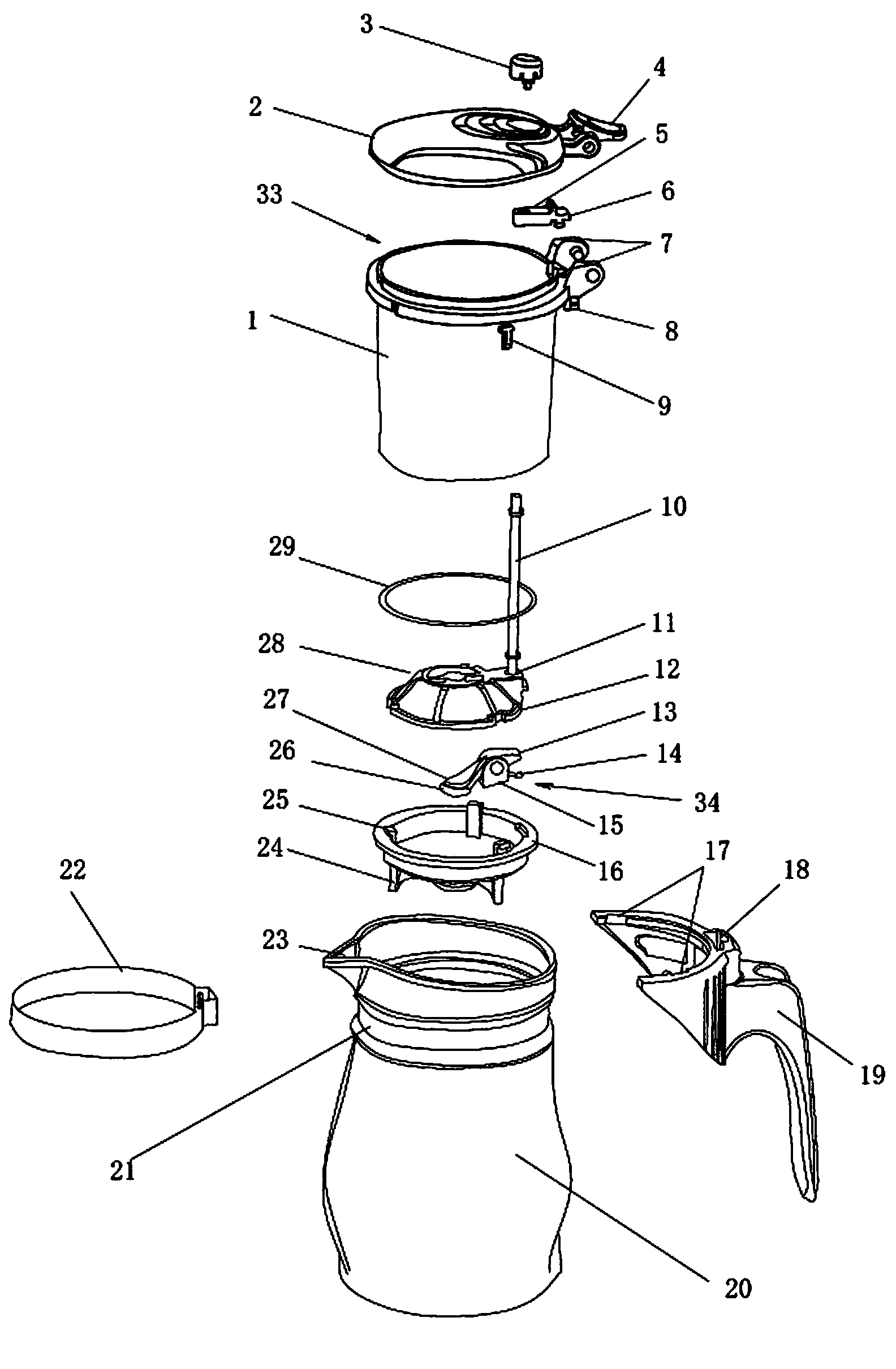

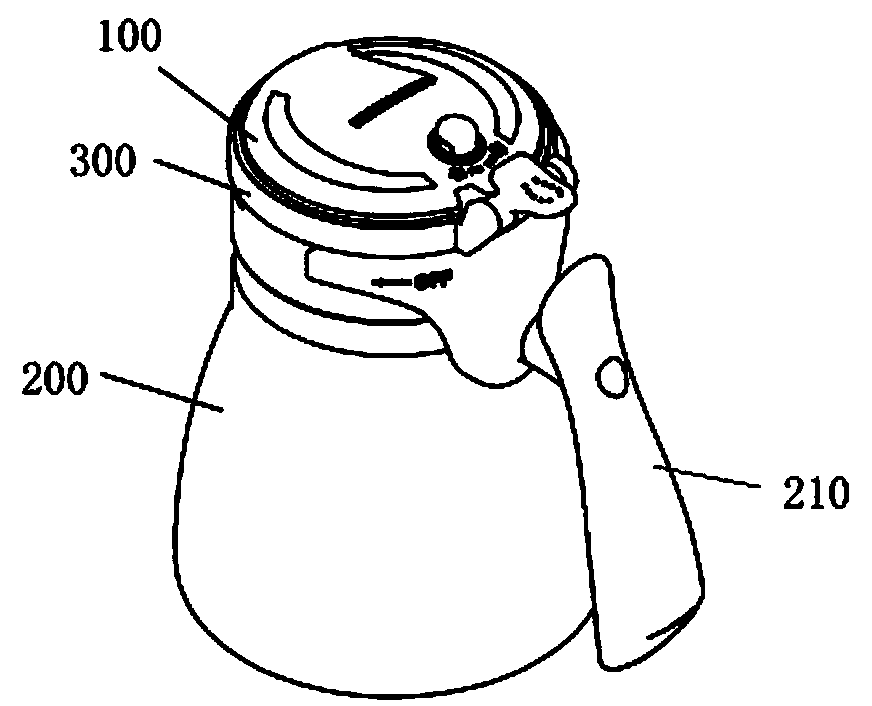

Novel teapot

ActiveCN104000446APlay the role of linking the previous and the nextEasy to implementDomestic vesselsEngineeringStructural barrier

The invention discloses a novel teapot and relates to the field of the tea set. The novel teapot comprises a pot body and an inner cup. The inner cup comprises a cup body, a filter screen and a cup base. The filter screen comprises a filter screen body and a cylindrical fixing seat. The filter screen body is disposed at the upper end of the fixing seat, and the filter screen body and the fixing seat form a concentric integral structure. The filter screen comprises a mounting structure which can be taken down to be mounted on the cup base and a mounting structure which can be taken down to be mounted at the lower end of the cup body, so that the filter screen has a filter function and a mounting function enabling the cup body, the filter screen and the cup base to be assembled and disassembled from the top to the bottom successively. According to the novel teapot, the structure and the functions of the filter screen are improved greatly, so that snapping protrusions are not needed to be manufactured in the lower end of the cup body, and structural barriers are removed for cup fabrication through glass. A slope groove is formed in the fixing seat of the filter screen, so that the filter screen and the cup base are effort-saving and convenient to assemble and disassemble, the friction is small, and the teapot is durable and long lasting.

Owner:东莞市唯成节能科技有限公司

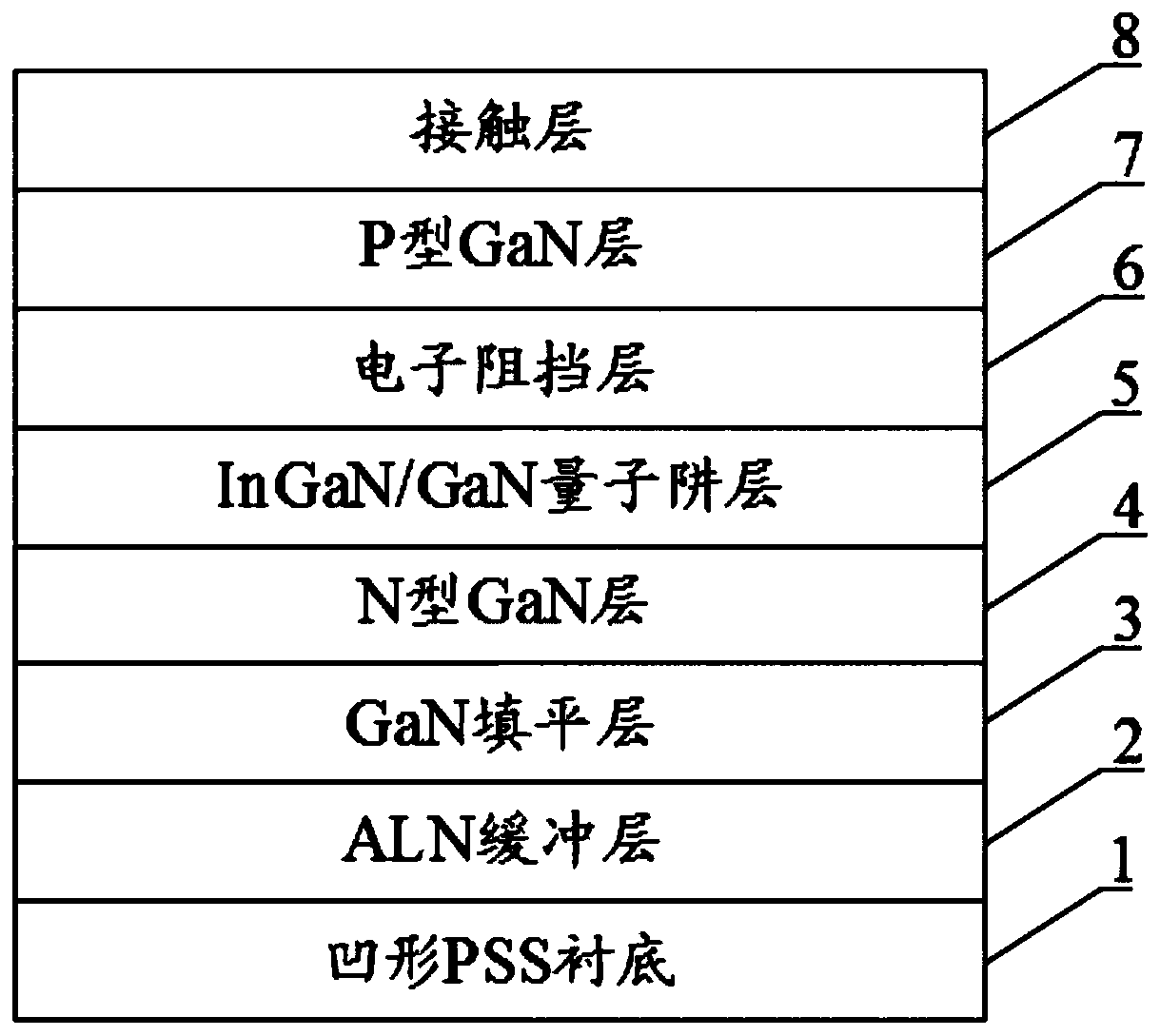

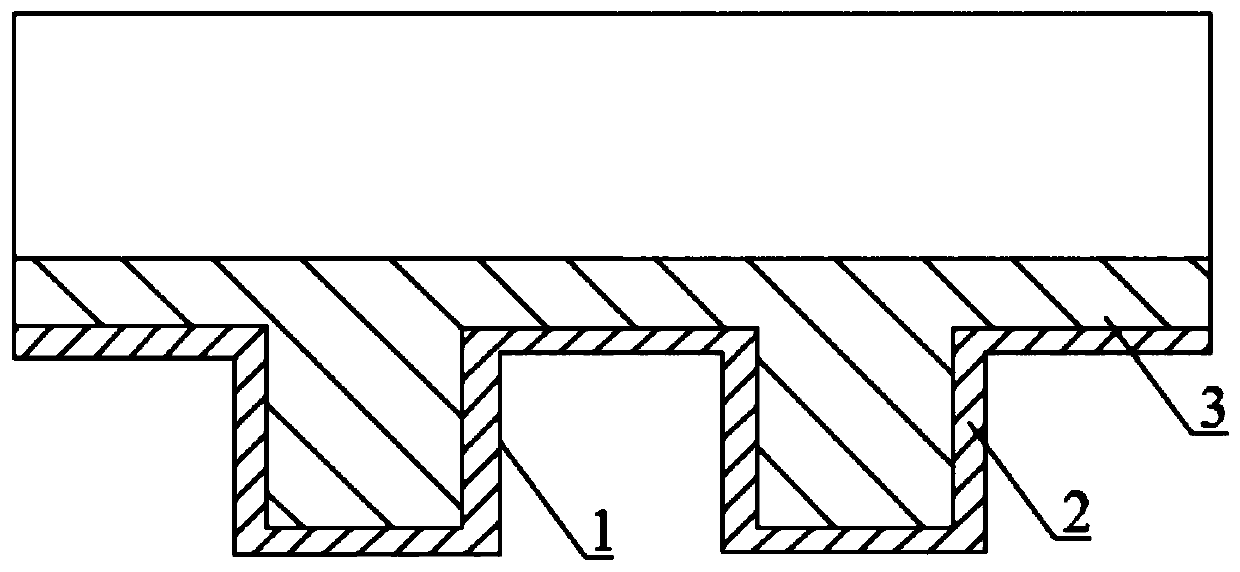

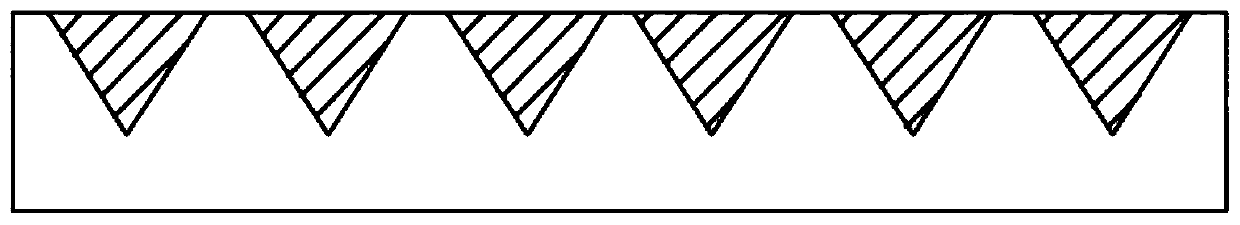

Preparation method of epitaxial wafer for improving brightness of flip chip

InactiveCN111029445AImprove the quality of growing crystalsPlay the role of linking the previous and the nextSemiconductor devicesSputteringPhysical chemistry

The invention discloses a preparation method of an epitaxial wafer for improving the brightness of a flip chip. The method comprises the steps: carrying out the sputtering of an ALN buffer layer on aconcave PSS substrate, and growing a GaN filling layer on the ALN buffer layer through a high-low pressure environment so as to fill the concave PSS substrate. According to the method, the ALN bufferlayer grows between the GaN filling layer and an Al2O3 sapphire substrate, the ALN buffer layer plays a role of connecting an upper part and a lower part to improve the growth rate of a crystal, therefore, the surface and the quality of the crystal rapidly grown on the concave PSS substrate can reach the same level as those of a crystal grown on a convex PSS substrate; on the basis, due to growthin the concave PSS substrate, light is emitted from the concave PSS substrate during light emission, and secondary light emission is easy to form through continuous refraction, so that the light emission efficiency can be effectively improved.

Owner:FUJIAN PRIMA OPTOELECTRONICS CO LTD

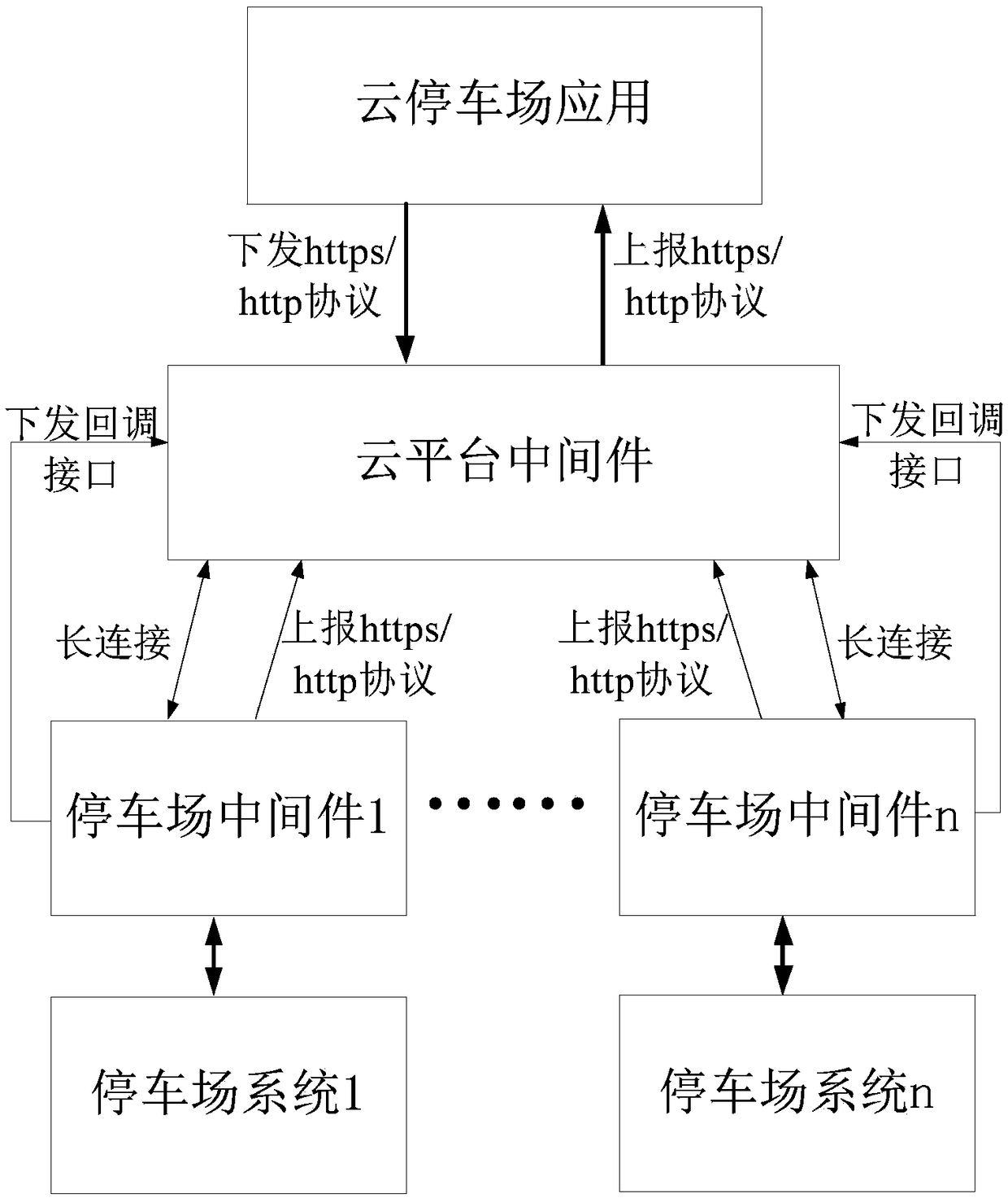

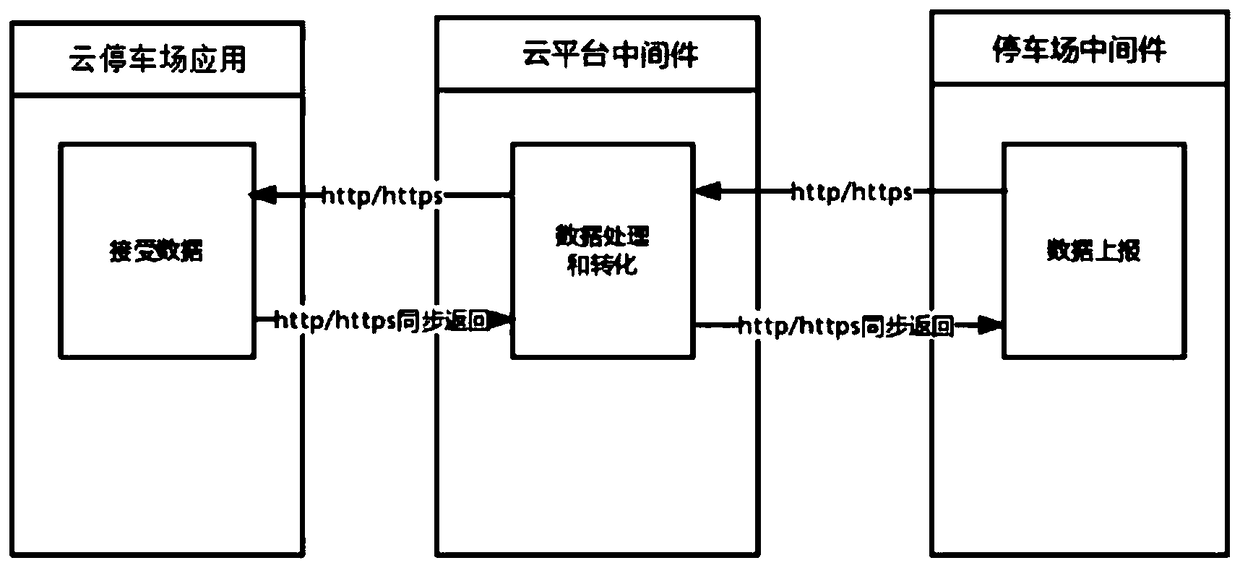

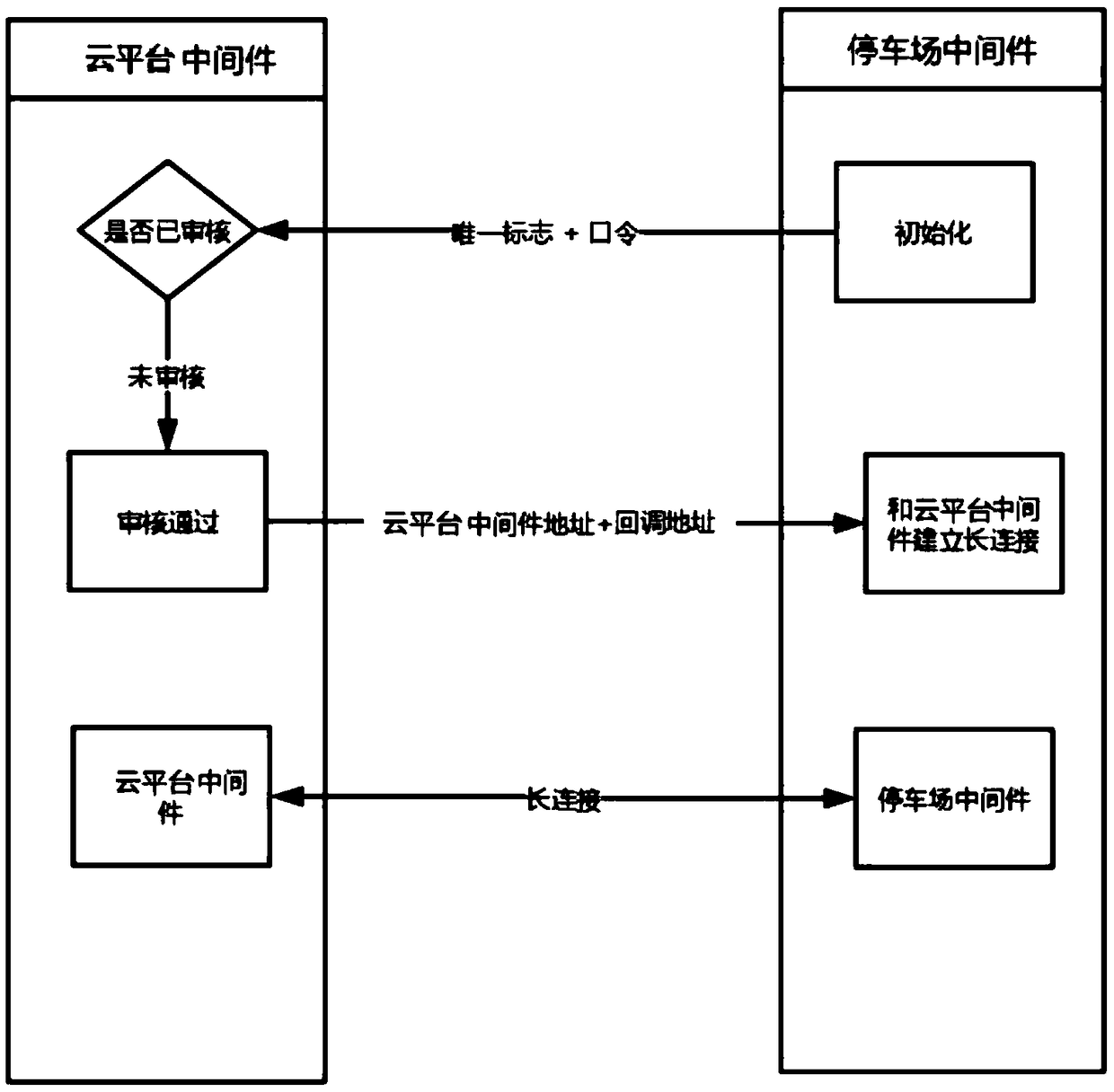

Cloud parking lot management system

ActiveCN109166352AAvoid dependencePlay the role of linking the previous and the nextIndication of parksing free spacesTransmissionParking areaMiddleware

The invention provides a cloud parking lot management system. The cloud parking lot management system comprises a parking lot system, a parking lot middleware, a cloud parking lot application and a cloud platform middleware, wherein the parking lot middleware transmits parking lot identification and reported data to the corresponding cloud platform middleware based on a https / http protocol after receiving the reported data of the parking lot system; the cloud platform middleware determines a corresponding key value key according to the identification of the parking lot, and transmits the key and the reported data to the cloud parking lot application based on the https / http protocol; the cloud platform middleware is in long connection with the parking lot middleware, wherein after the issued data and the key are received from the cloud parking lot application based on the https / http protocol, a corresponding long connection link is determined according to the key; the long connection link transmits the issued data to the corresponding parking lot middleware; and then the parking lot middleware transfers the issued data to the parking lot system. The cloud parking lot management system is relatively low in building cost and simple in structure.

Owner:重庆惠家通信息技术有限公司

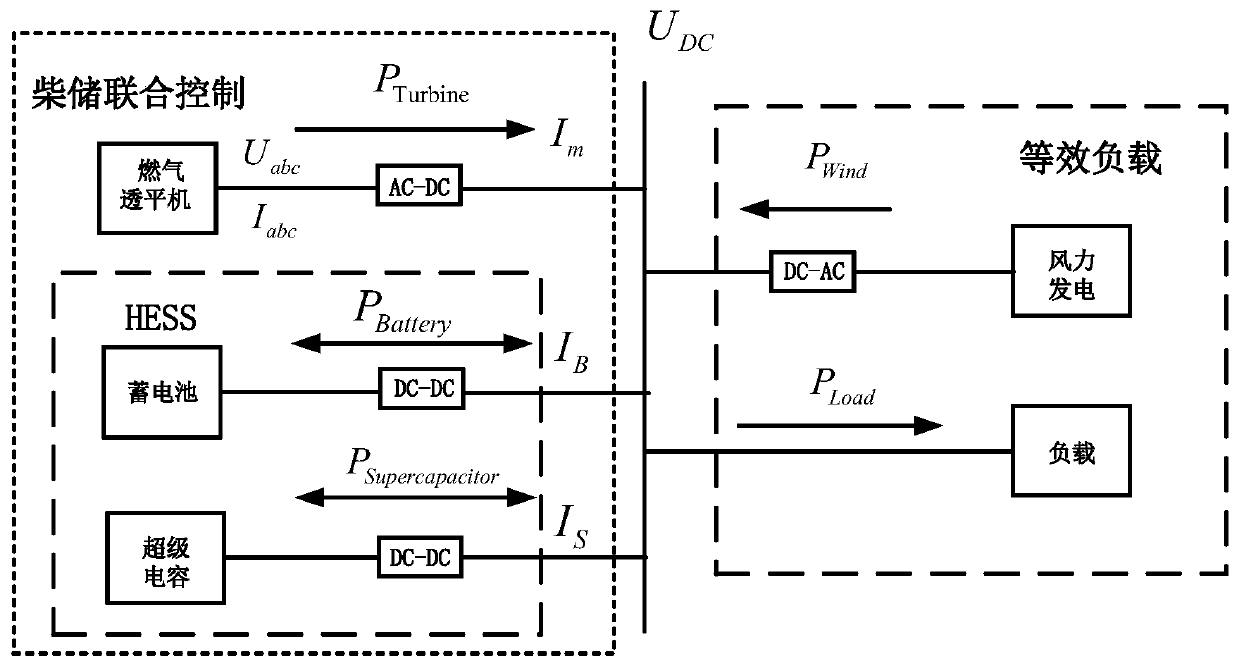

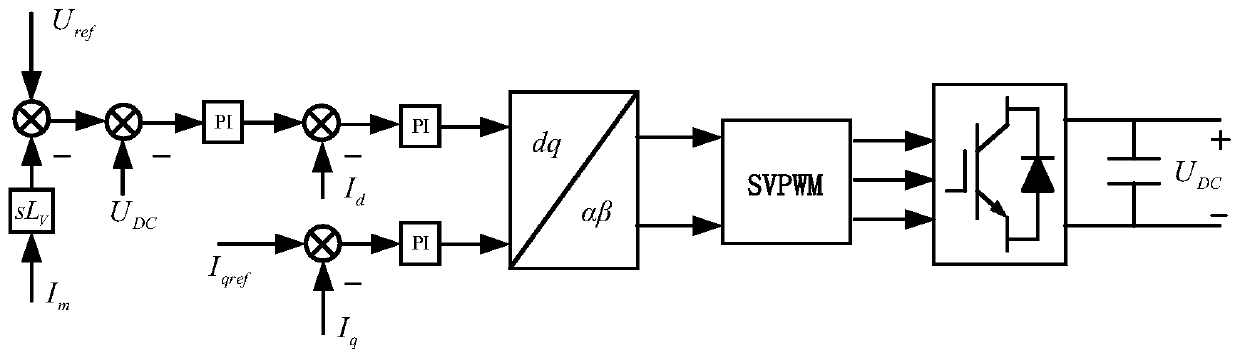

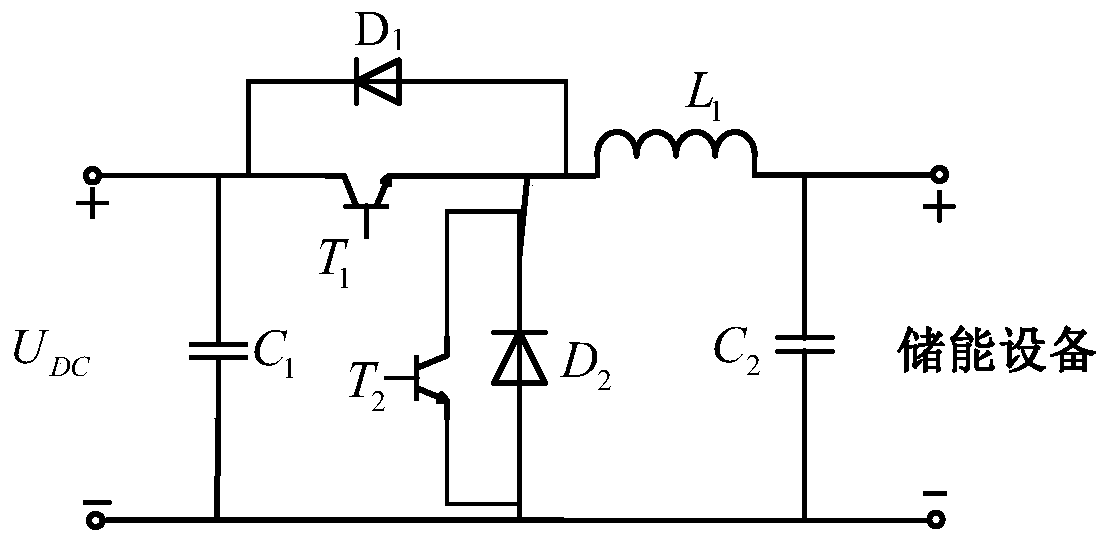

Multi-energy complementary power supply system for offshore oil drilling platform and control method thereof

ActiveCN110905661AReduce dependencyReasonable distributionGas turbine plantsEnergy storageIntermediate frequencyVirtual impedance

The invention discloses a multi-energy complementary power supply system for an offshore oil drilling platform and a control method thereof. According to the method, the load power fluctuation is divided into three parts through virtual impedance, namely a rapid dynamic part, a intermediate frequency transition part, and a low frequency dynamic part, wherein the power of the rapid dynamic part isregulated by power-type energy storage equipment, the power of the intermediate frequency transition part is regulated by energy-type energy storage equipment, the power of the low frequency dynamic part is regulated by a gas turbine, and the gas turbine provides the power support during the steady state at the same time. According to the control method, the gas turbine is added into the energy storage management and is used for managing the steady state part in the load power fluctuation while the advantages of the energy-type energy storage equipment and the power-type energy storage equipment are fully exerted, the charging and discharging times of a storage battery and the required capacity of the battery are effectively reduced; when a distributed power generation system fails or cannot work by the natural environment constraint, the gas turbine with the leading function increases the output power at the moment, the problem that in a traditional method, due to the fact that the energy-type energy storage equipment works for a long time, the state of charge is lower than a lower limit value, then partial load can only be cut off is solved, and the system reliability is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

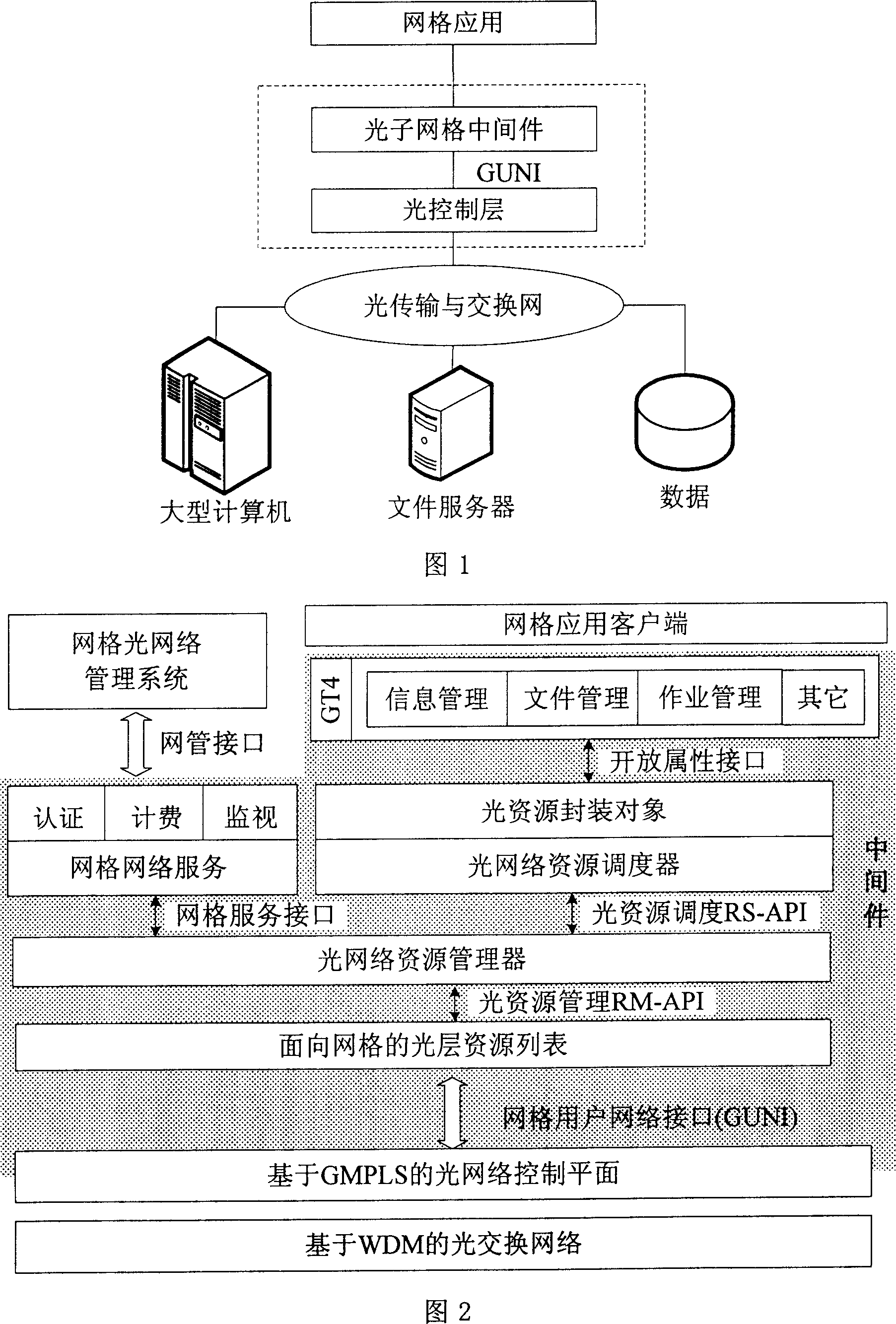

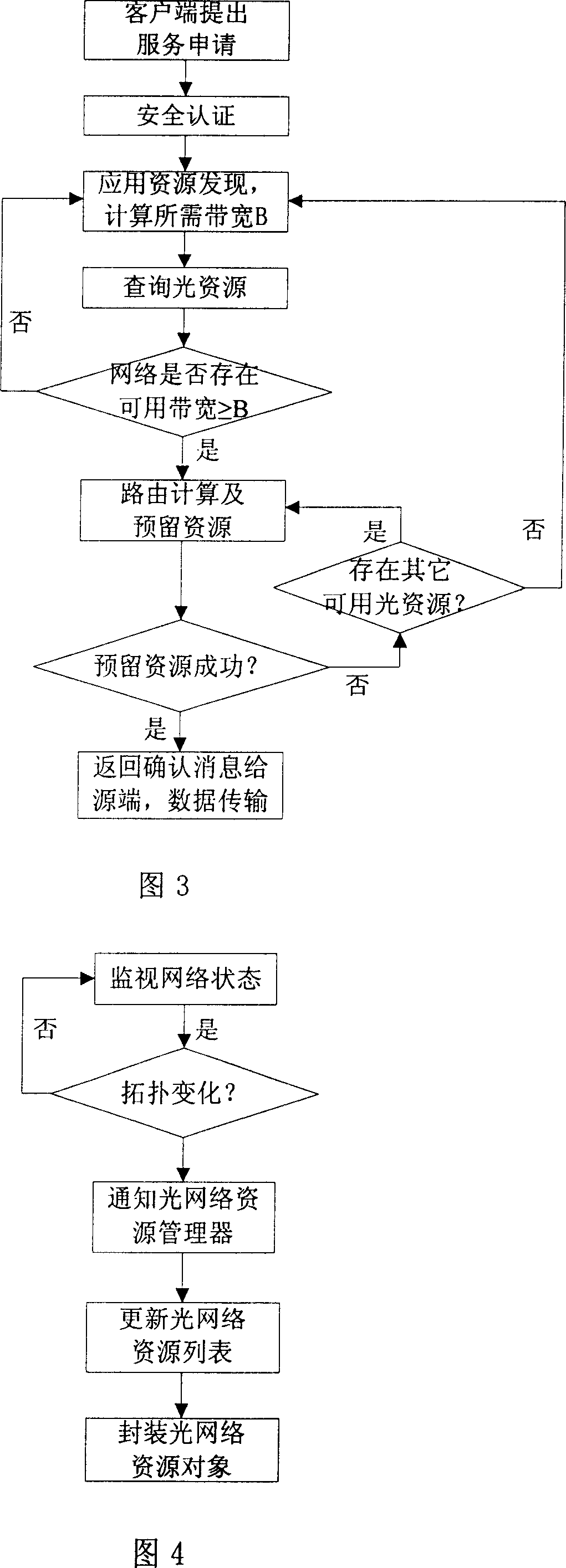

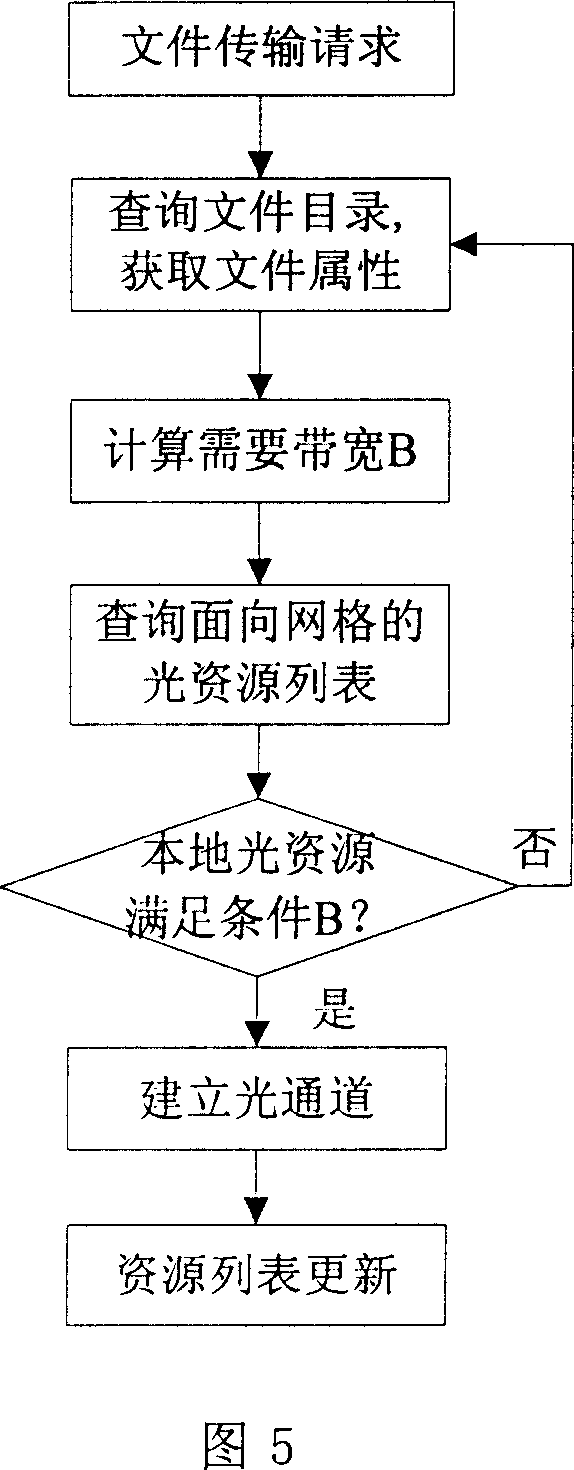

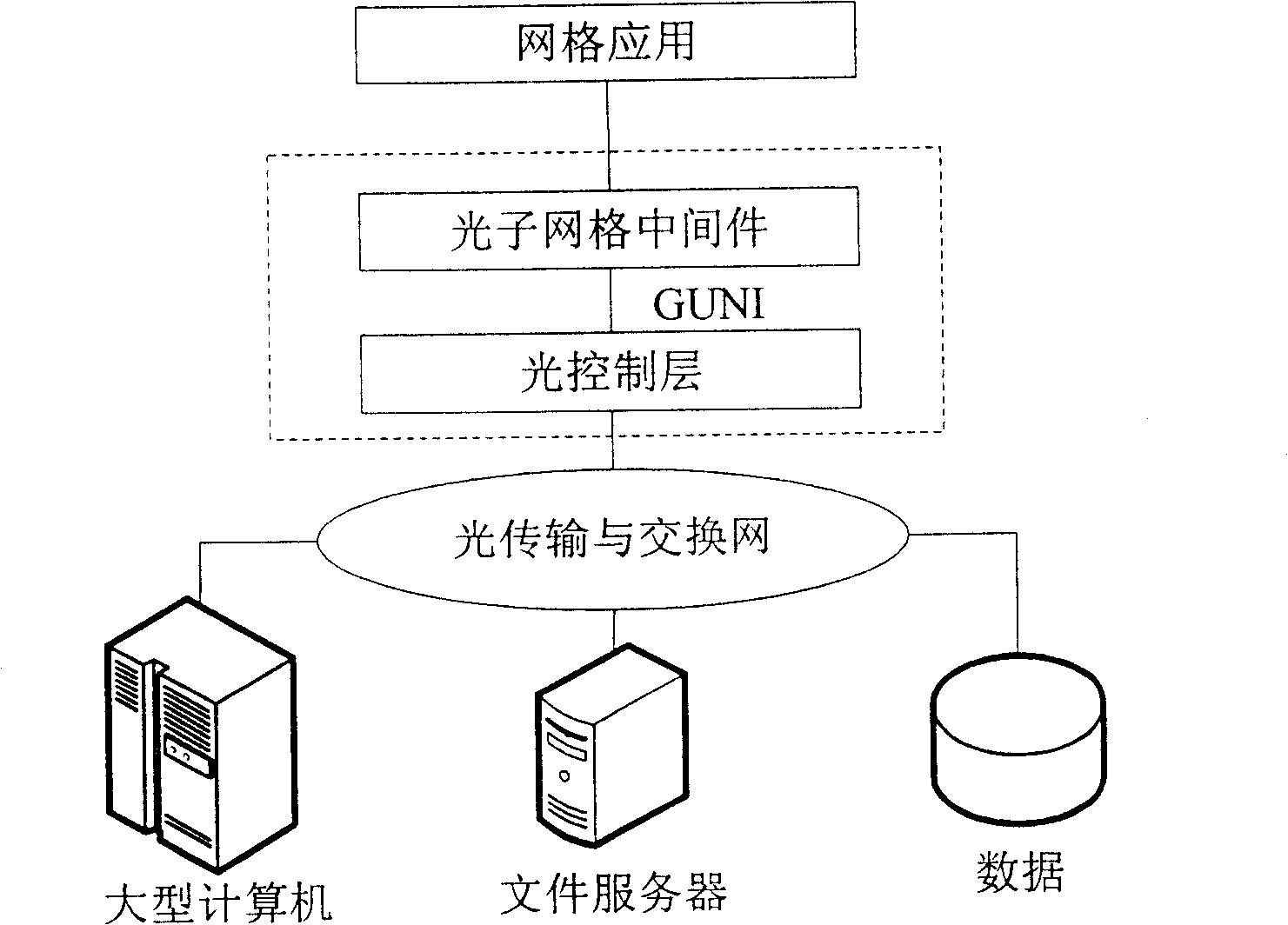

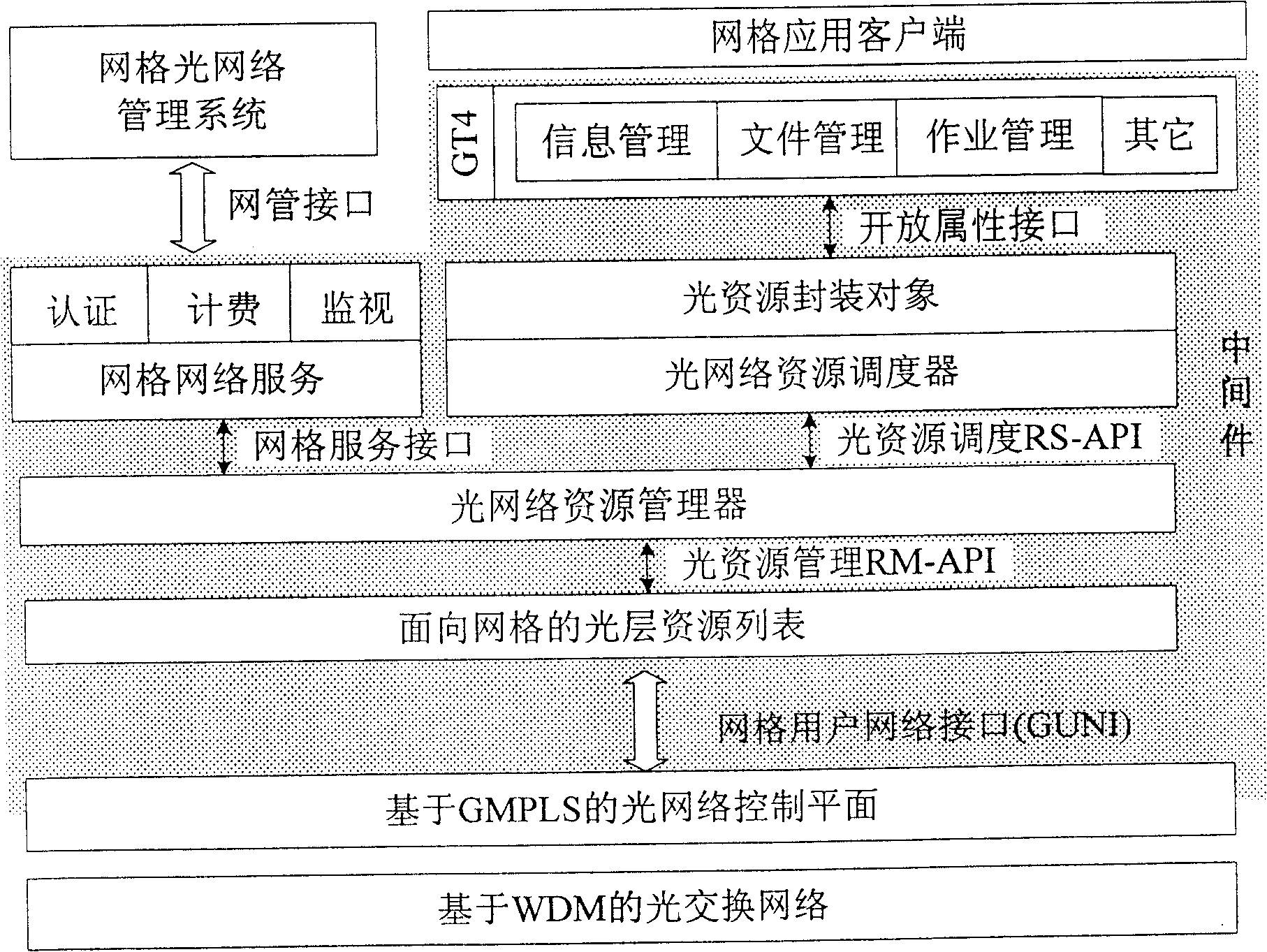

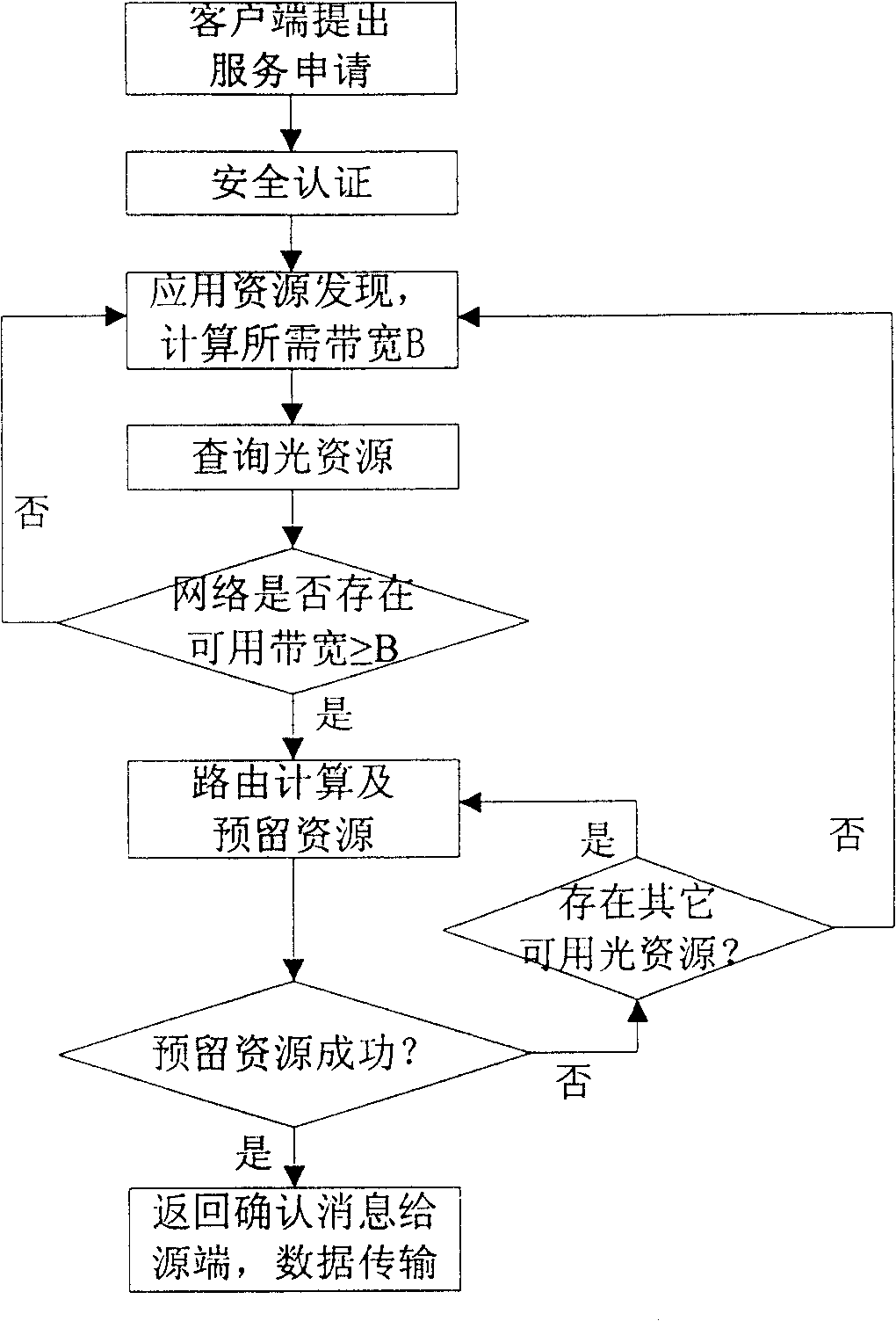

Photon grid middleware and its control based on optical network resource allocation on demand

InactiveCN1984007ARealize optimal schedulingRealize intelligent controlData switching by path configurationElectromagnetic network arrangementsNetwork resource managementMiddleware

This invention discloses photon grid middleware which is based on optical network demand allocation and its resource control method. In the middleware, grid service terminal send the resource application to photon grid middleware; G4 application resource management carries on grid-oriented 's resource control and application resource scheduling; middleware packages optical network resource object, according to application resource attribute drive the network resource operation; optical network resource dispatcher uses optical resource scheduling interface to operate grid service-oriented optical resource scheduling, it realizes optical resource's inquiry and scheduling for the grid application and provides the control optical channel for top service; optical network resource supervisor carries on grid-oriented optical resource list management; optical control layer provides the establishment of the signaling mechanism, based on routing algorithm choose the suitable routing, and realize the optical access control through GUNI. This invention can realize dynamic bandwidth allocation of grid application data transmission based on the grid service's driving to optical network.

Owner:BEIJING UNIV OF POSTS & TELECOMM

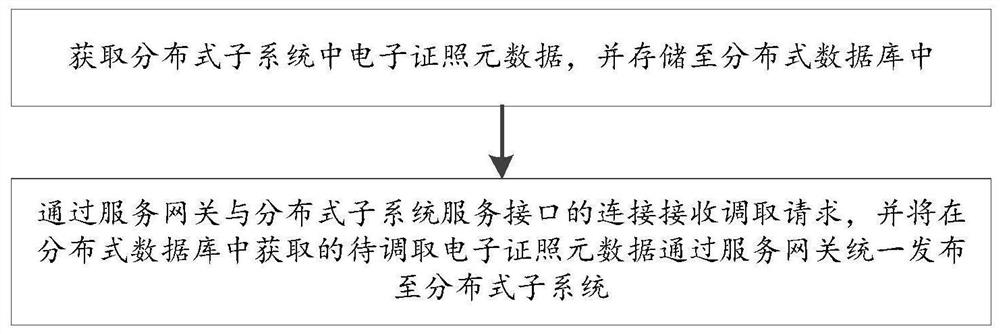

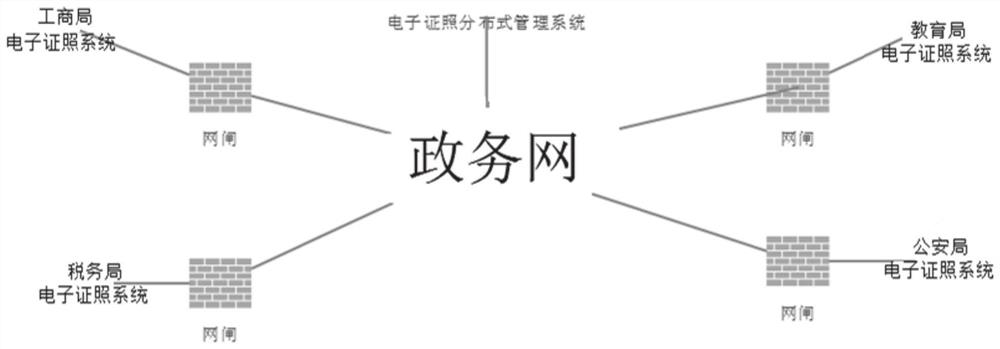

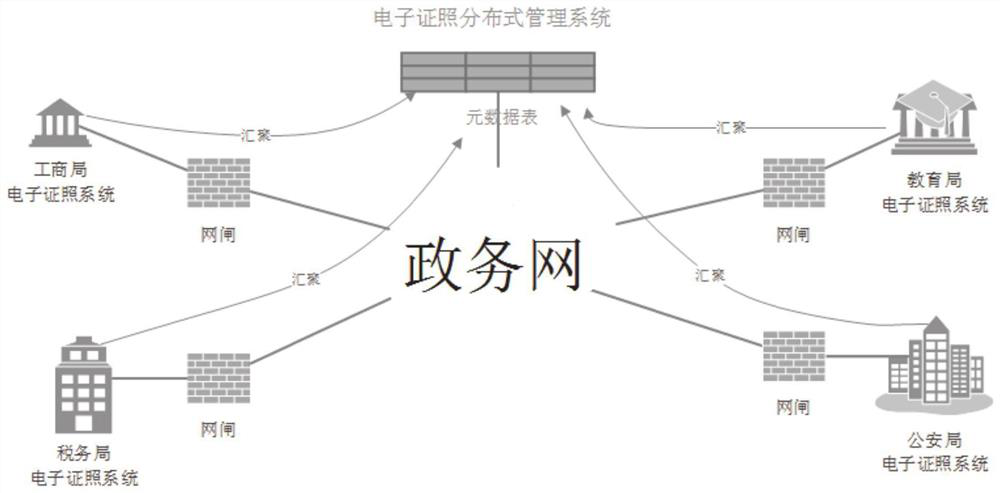

Electronic certificate distributed management method and system based on micro-service

InactiveCN111953799AImprove the efficiency of sharing electronic certificatesSave storage spaceDatabase management systemsTransmissionEngineeringService gateway

The invention discloses an electronic certificate distributed management method and system based on micro-service, and the method comprises the steps: obtaining electronic certificate metadata in a distributed subsystem, and storing the electronic certificate metadata in a distributed database; and receiving a calling request through the connection between the service gateway and the service interface of the distributed subsystem, and uniformly publishing the to-be-called electronic certificate metadata acquired in the distributed database to the distributed subsystem through the service gateway. The distributed management system centralizes scattered electronic certificate data of subsystems, each subsystem is in butt joint with the service gateway through a service interface in an independent API mode, the service calling method is micro-service, and the service gateway achieves service unified calling.

Owner:山东合天智汇信息技术有限公司

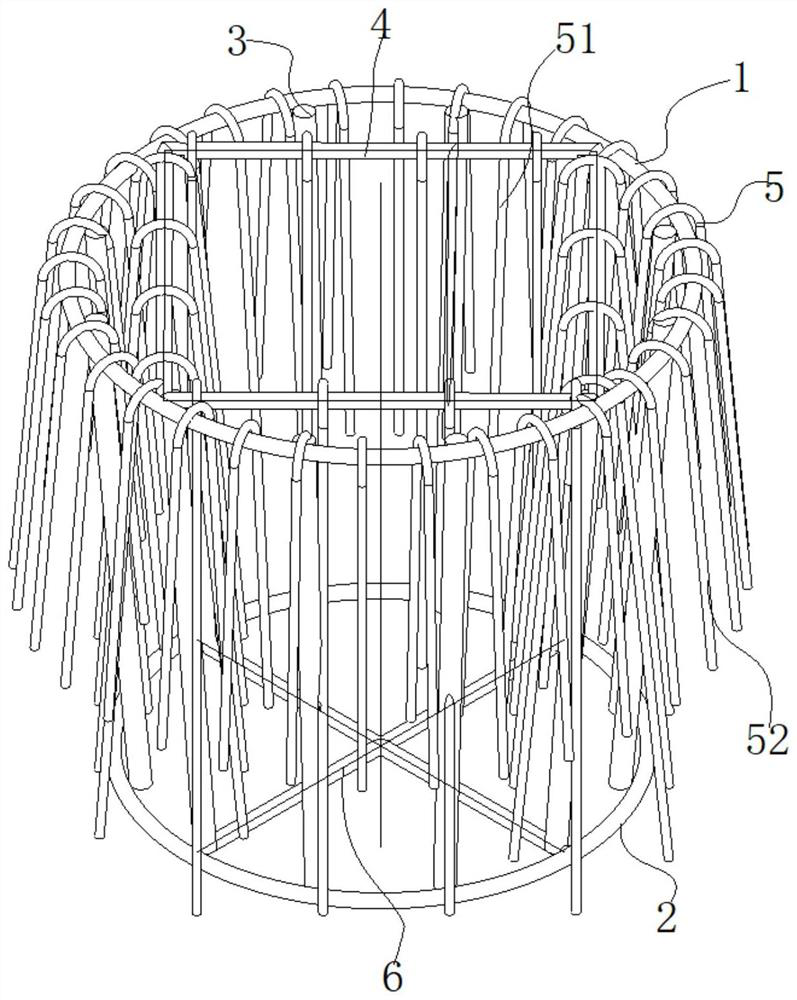

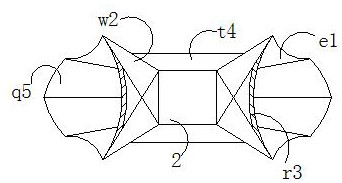

Continuous casting round billet quick-change connecting piece and application thereof

PendingCN114799101AReduce head cuttingPlay the role of linking the previous and the nextEngineeringSteel quality

The invention discloses a continuous casting round billet quick-change connecting piece and application thereof, and belongs to the technical field of molten steel smelting equipment. The continuous casting round billet quick-change connecting piece comprises a lacing wire frame and a hook-shaped lacing wire, and the lacing wire is fixedly connected to the lacing wire frame in a hooking mode; the lacing wire frame and the lacing wire are made of steel materials, the round billet connecting piece is rapidly placed on the liquid level of a round billet crystallizer in the replacement gap of the tundish, the lacing wire plays a role in connecting the upper part and the lower part, and the whole round billet connecting piece is melted in molten steel, and the molten steel is solidified in the crystallizer. Molten steel casting blanks in the tundish crystallizer in front of and behind the round blank connecting piece are integrated, so that the head cutting of the round casting blanks is reduced. Therefore, the problem that in the molten steel continuous casting process in the prior art, the cropping ratio of a casting blank is high is solved.

Owner:马鞍山江润冶金有限责任公司

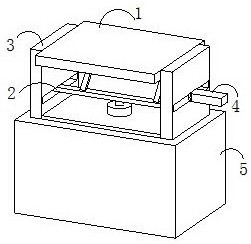

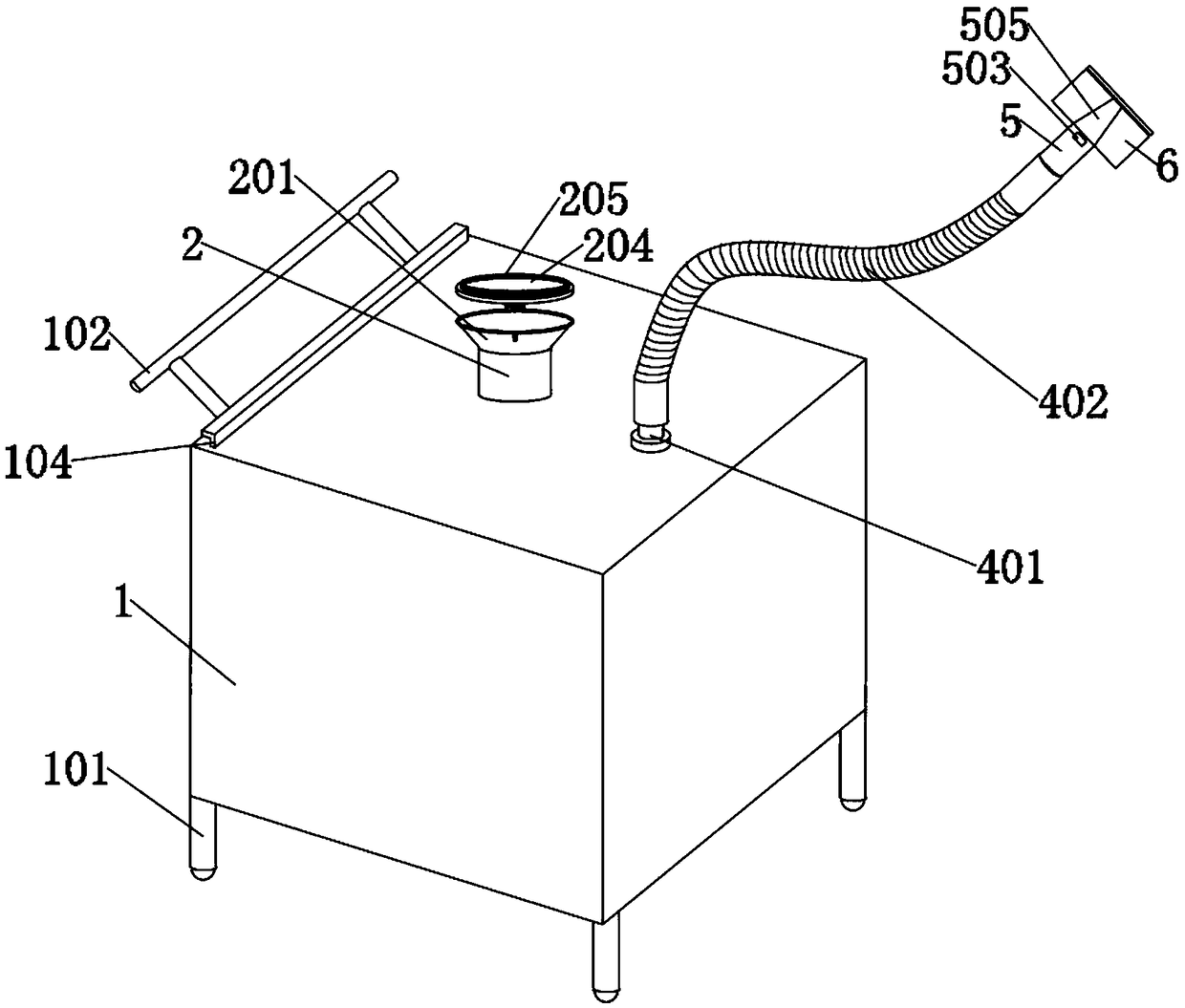

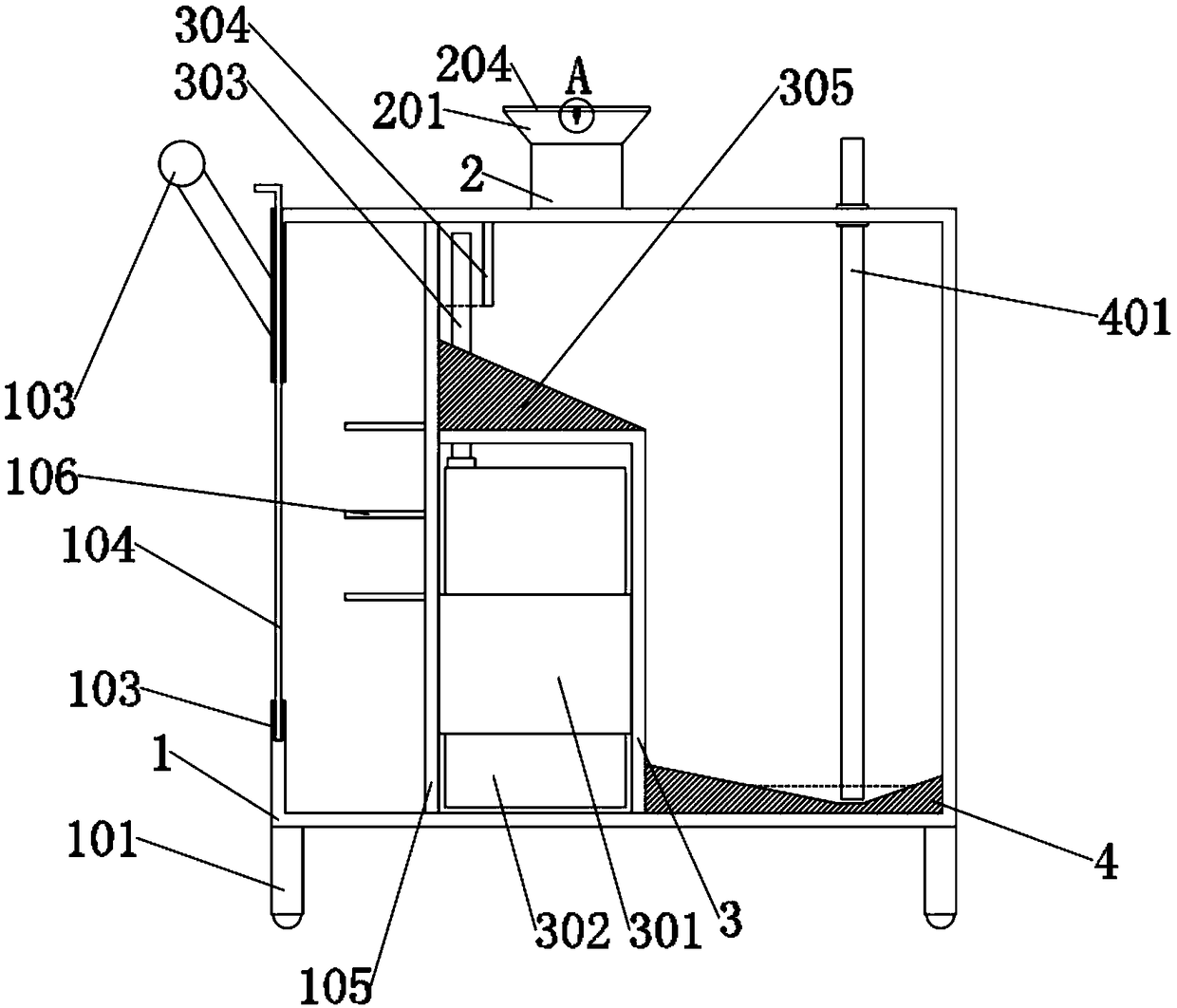

Multifunctional workbench for art design

InactiveCN114771145AEasy to containStrengthen the direction of forceOther artistic work equipmentsLap jointEngineering

The invention discloses a multifunctional workbench for art design, which structurally comprises a sliding plate, a drawing board, a connecting rod, a grip and a base, the sliding plate is connected to the base and is in sliding fit with the connecting rod through the grip, the connecting rod is connected with the drawing board, the grip comprises an opening and closing plate, a bandage, a lap joint piece, a power assisting body and a main rod, and the opening and closing plate is in sliding fit with the sliding plate through the lap joint piece. The opening and closing plate is arranged in the supporting groove and connected into the main rod through the bandage, the main rod is connected to the connecting rod, the power assisting body is arranged in the bandage, the partition structure and the limiting device are arranged in the power assisting body, and the partition structure and the limiting device are matched on the supporting groove. When the opening and closing plate is opened, the bandage is pulled to approach the limiting device through the buckle pad, so that the limiting device slides upwards below the supporting groove, the supporting groove is pushed to swing downwards along the two sides of the partition structure, the partition structure is conveniently guided to hold the opening and closing plate on the swing seat, and the opening and closing plate is ensured to slide upwards on the sliding plate on the two sides of the main rod in the unified direction.

Owner:NINGBO DAHONGYING UNIV

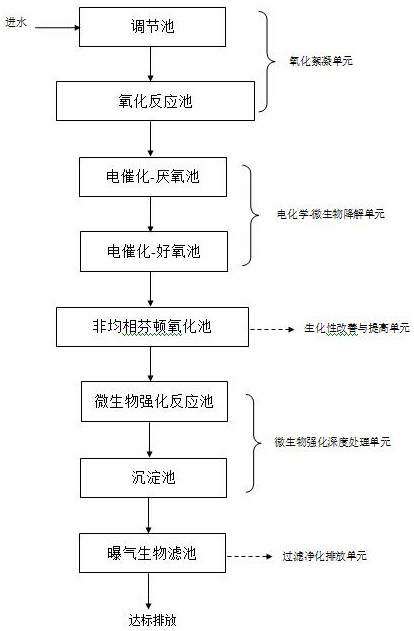

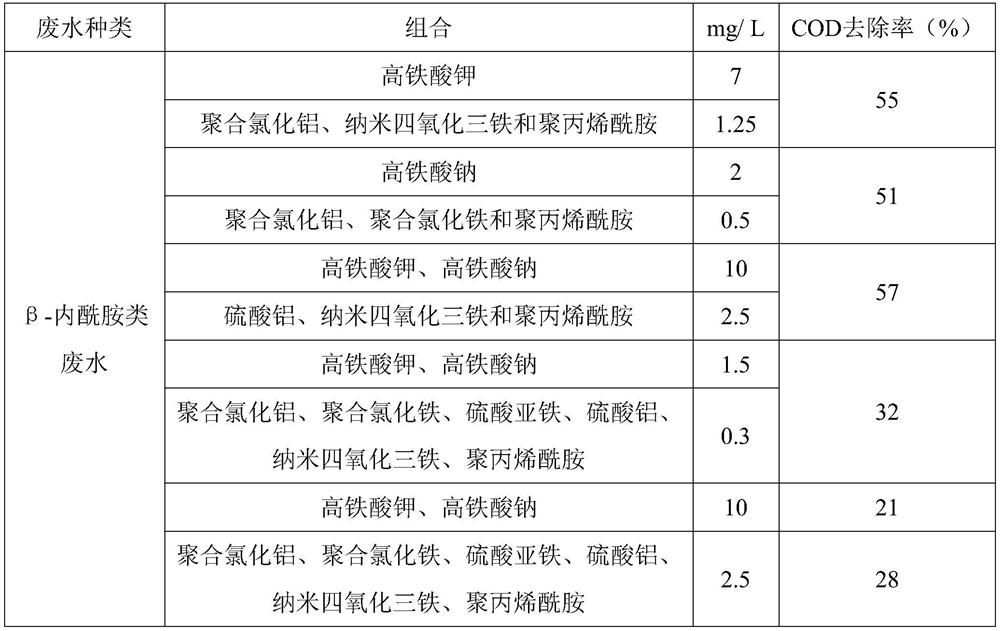

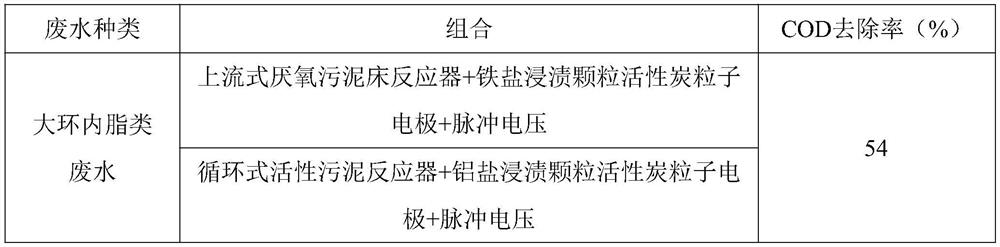

Treatment method of antibiotic pharmaceutical wastewater

ActiveCN114409196ABroad-spectrum applicabilityCombination settings are reasonableTreatment by combined electrochemical biological processesWater treatment compoundsChemical synthesisMicroorganism

The invention discloses a treatment method of antibiotic pharmaceutical wastewater, and belongs to the technical field of wastewater treatment environmental protection. The treatment method is a combined process of a plurality of units, and mainly comprises an oxidation flocculation precipitation unit, an electrochemical-microorganism synergistic degradation unit, a biochemical improvement and enhancement unit, a microorganism enhanced deep treatment unit and a filtration purification discharge unit. The method is reasonable in process combination, low in energy consumption, high in efficiency, stable in operation effect and suitable for treating wastewater generated in the biological fermentation type and chemical synthesis type antibiotic pharmaceutical process.

Owner:郑琪豫

Photon grid middleware and its control based on optical network resource allocation on demand

InactiveCN100438472CRealize intelligent controlIncrease communication resource control capabilityData switching by path configurationElectromagnetic network arrangementsNetwork resource managementMiddleware

This invention discloses photon grid middleware which is based on optical network demand allocation and its resource control method. In the middleware, grid service terminal send the resource application to photon grid middleware; G4 application resource management carries on grid-oriented 's resource control and application resource scheduling; middleware packages optical network resource object, according to application resource attribute drive the network resource operation; optical network resource dispatcher uses optical resource scheduling interface to operate grid service-oriented optical resource scheduling, it realizes optical resource's inquiry and scheduling for the grid application and provides the control optical channel for top service; optical network resource supervisor carries on grid-oriented optical resource list management; optical control layer provides the establishment of the signaling mechanism, based on routing algorithm choose the suitable routing, and realize the optical access control through GUNI. This invention can realize dynamic bandwidth allocation of grid application data transmission based on the grid service's driving to optical network.

Owner:BEIJING UNIV OF POSTS & TELECOMM

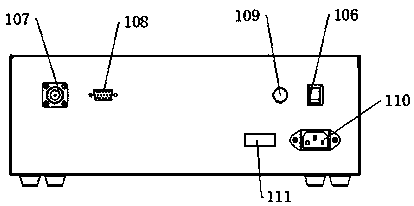

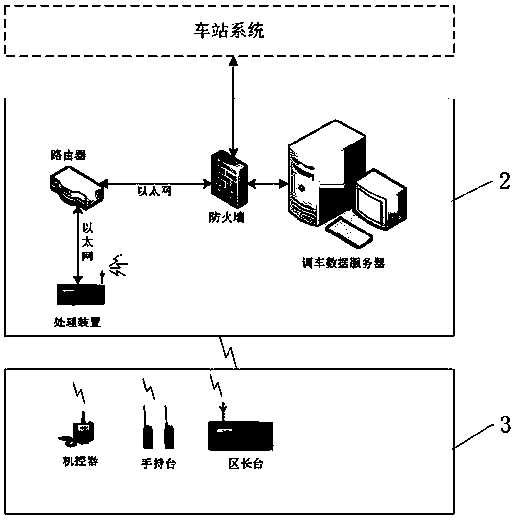

Railway shunting data processing device

InactiveCN110509962AEnsure safetyRealize integrationRailway traffic control systemsSignal boxes station blockingCommunication interfaceDigital radio

The invention discloses a railway shunting data processing device. The railway shunting data processing device includes a main machine, the main machine includes a power supply unit, a digital radio station unit, a digital radio station control unit and an industrial personal computer unit, wherein the power supply unit is used for providing power supply for the whole shunting data processing device, the digital radio station unit is used for sending electronic shunting orders and receiving information such as shunting group voice and signaling, the digital radio station control unit is used for controlling a radio station to transmit and receive and forward voice and signaling, one end of the industrial personal computer unit is connected with a superior server through a network interface, and the other end of the industrial personal computer unit is connected with the digital radio station control unit through a communication interface for forwarding data and voice. The railway shunting data processing device has the beneficial effects that the processing device can receive the shunting order data from a shunting data server, and send the shunting orders to a mechanical control machine and a hand-held platform of railway wireless shunting lamp display equipment; the processing device can receive shunting operation data sent from the mechanical control machine and the hand-held platform and analyze and compress the data; and the processing device can transmit the collected shunting operation data to the shunting data server.

Owner:沈阳铁道科学技术研究所有限公司

Scale formation cleaning device for condenser in thermal power plant

InactiveCN109237995APlay the role of linking the previous and the nextCleaning heat-transfer devicesCamEngineering

The invention provides a scale formation cleaning device for a condenser in a thermal power plant, which comprises a cam, a mounting plate, a movable spring, a chute, a grinding part, a fixed groove and fixed rods. An installation silo is a rectangular internal hollow structure, and the inner part of the installation silo is provided with a motor through a fixed block; the left side of a brush isinstalled in the inner part of a movable part through an embedded head of a T-shaped structure, and the bottom of a lower pressure bar is inserted into a slot in an insertion way; the right side of the brush is provided with a bush head; and the fixed groove is arranged on the right side of the grinding part; the threaded holes on the two ends of the grinding part are provided with fixed rods with threads. The movable part acts as a connecting link between the upper and the lower parts, thereby the motor and the cam being received by the movable part.

Owner:张皓

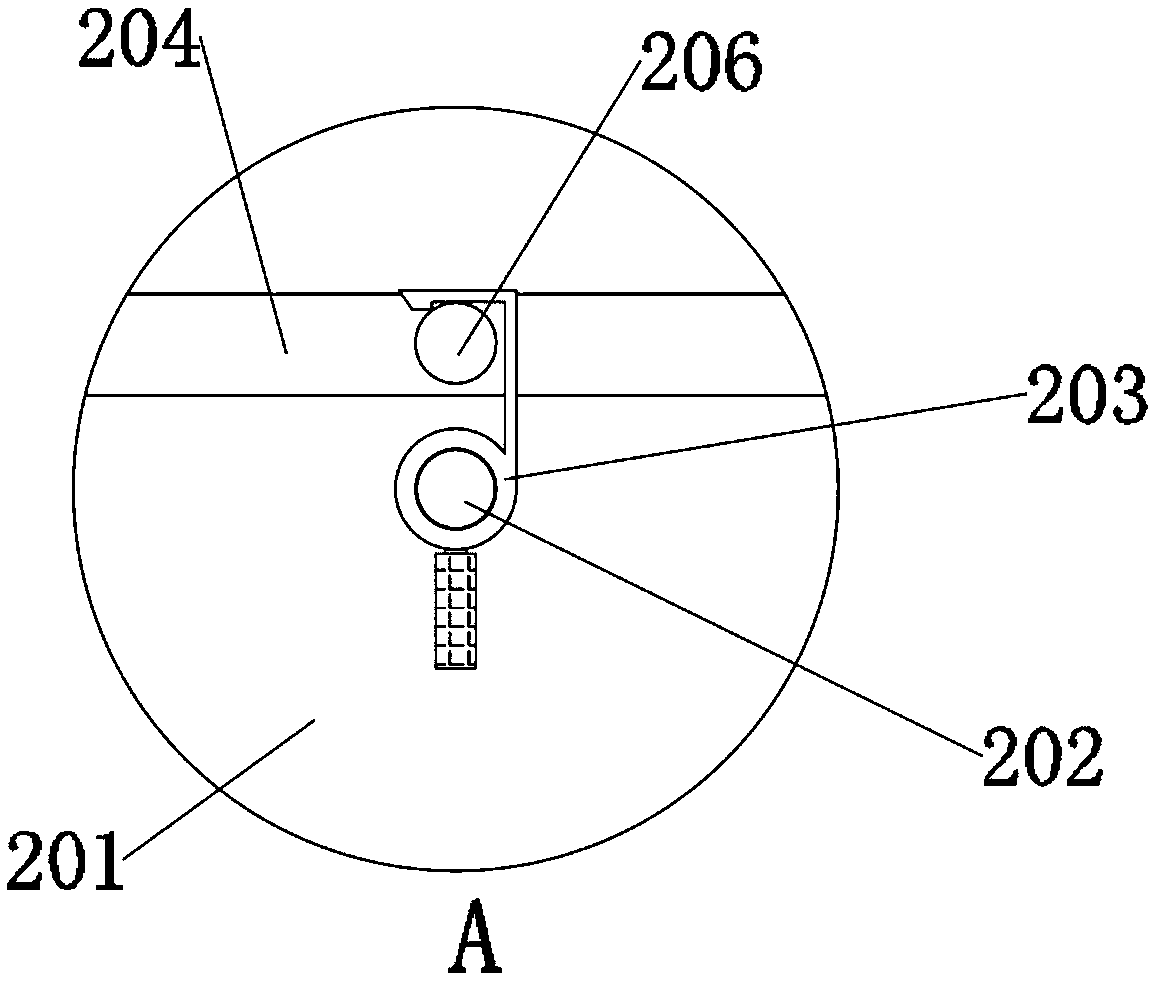

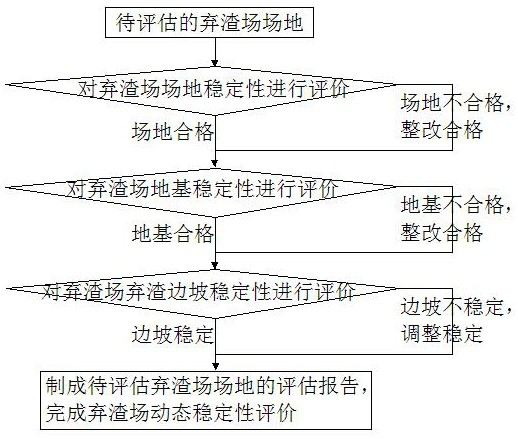

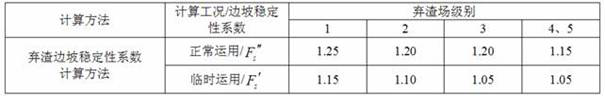

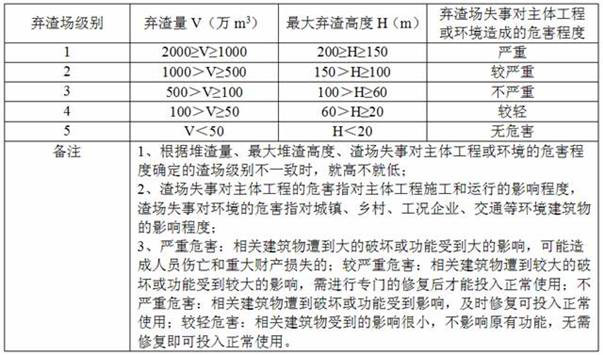

A Method for Dynamic Stability Evaluation of Spoil Fields in Mountainous Highway

ActiveCN113807748BRich qualitative assessment contentPlay the role of linking the previous and the nextResourcesSlagEnvironmental engineering

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

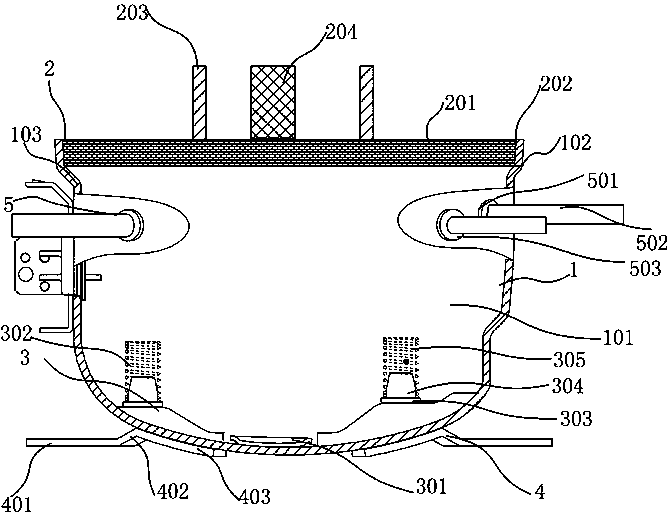

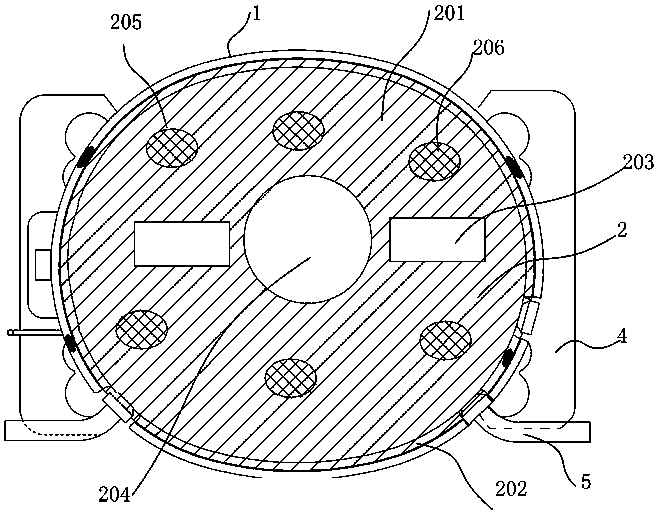

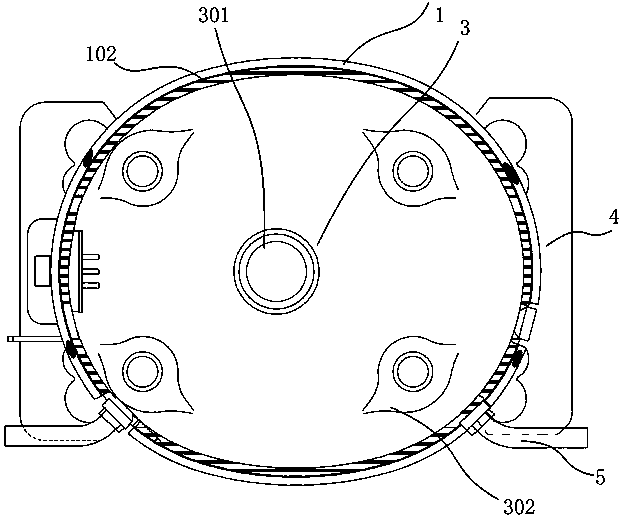

Lower shell structure for refrigerator compressor

InactiveCN111102171AGuaranteed fixed effectEasy to fixPositive displacement pump componentsPositive-displacement liquid enginesIceboxEngineering

The invention discloses a lower shell structure for a refrigerator compressor. The lower shell structure comprises a lower shell body assembly, a limiting top plate assembly, a compressor body positioning assembly, a positioning supporting assembly and a line source positioning unit, the limiting top plate assembly is arranged on the inner side of the top end of the lower shell body assembly and is in rotatable separation connection with the inner side of the top end of the lower shell body assembly, the compressor body positioning assembly is mounted at the bottom end of the inner side of thelower shell body assembly, and the positioning supporting assembly is arranged at the bottom end of the outer side of the lower shell body assembly and connected with the bottom end of the outer sideof the lower shell body assembly through welding. The limiting top plate assembly can be fixedly and rotatably connected with an upper shell structure and the lower shell structure to achieve the effect of a connecting link between the preceding and the following, and fixity of the compressor in a lower shell assembly is further improved; and heat dissipating through holes are formed in a limiting top plate, thus a compressor body can dissipate heat through the heat dissipating through holes in the upper shell structure and the lower shell structure, filter nets are mounted in the heat dissipating through holes, the hole diameters of the filter nets are each 0.3-0.55 mm, impurities can be effectively prevented from entering the compressor through the shell structures, and overall operation of the structure is ensured.

Owner:何俊

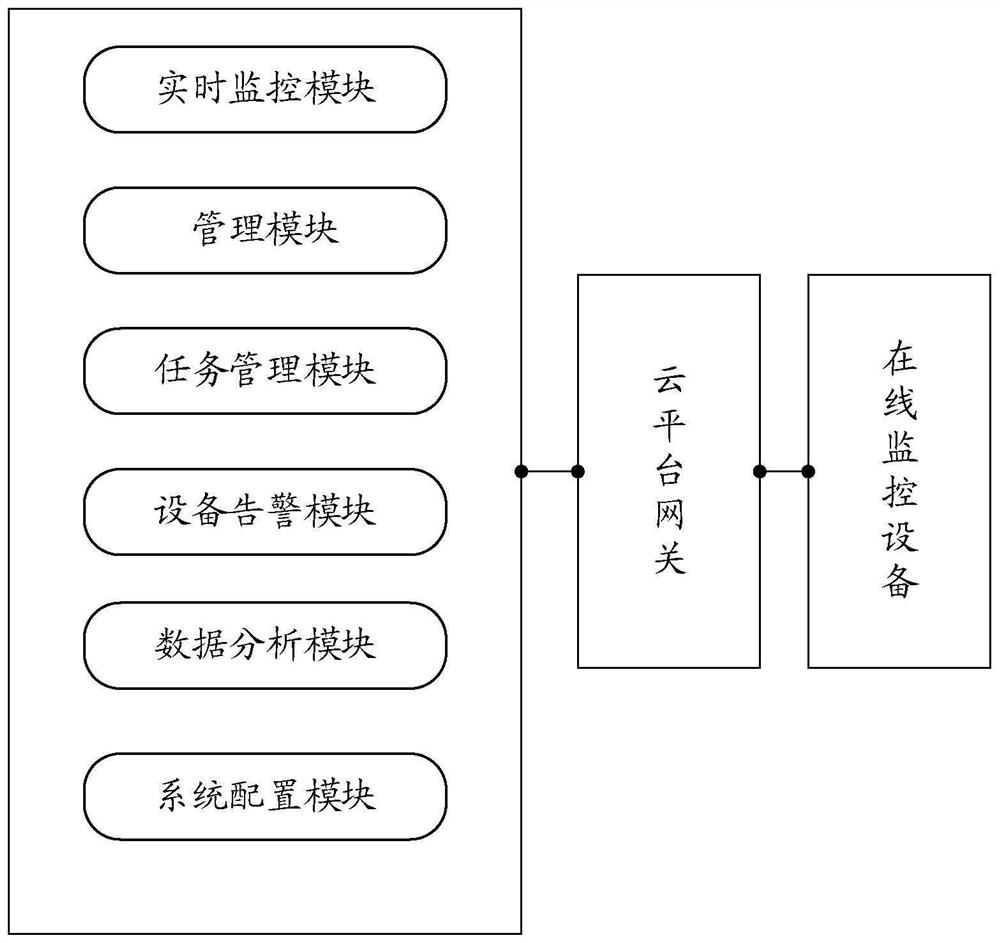

Centralized management system and method for on-line monitoring equipment of transformer substation

PendingCN114256978AMeet access needsPlay the role of linking the previous and the nextCircuit arrangementsManagement efficiencyMonitor equipment

The invention discloses a centralized management system and method for on-line monitoring equipment of a transformer substation, and the system comprises the steps: generalizing an interface function, so as to meet the access demands of different on-line monitoring equipment; the problem that different online monitoring devices have different processing methods for the same processing object is solved by adopting a method of adding a platform gateway intermediate agent program, namely, an instruction issued by a cloud platform system is forwarded through the intermediate agent program of a cloud platform gateway; when the management system works, the cloud platform gateway is used for being in butt joint with various types of online monitoring equipment, the cloud platform system is used for processing data transmitted by the cloud platform gateway and interacting with a user or a superior system, an instruction is issued to the online monitoring equipment through the cloud platform gateway, and the platform gateway plays a role in connecting the top and the bottom. And the consistency of the interface and the function of the cloud platform system and the diversity and the expandability of the access equipment are ensured. Therefore, the technical problem that an existing management method is high in learning cost and low in management efficiency is solved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com