Full-automatic middle plate continuous gear coupling vertical splicing machine

A fully automatic, tooth-joining technology, used in the joining of wooden veneers, wood processing appliances, adhesive application devices, etc., can solve the problems of unstable glue tooth temperature, large glue amount, uneven glue application, etc. The production efficiency and production quality, the high degree of coincidence of the synchronous comb teeth, and the effect of avoiding excessive seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

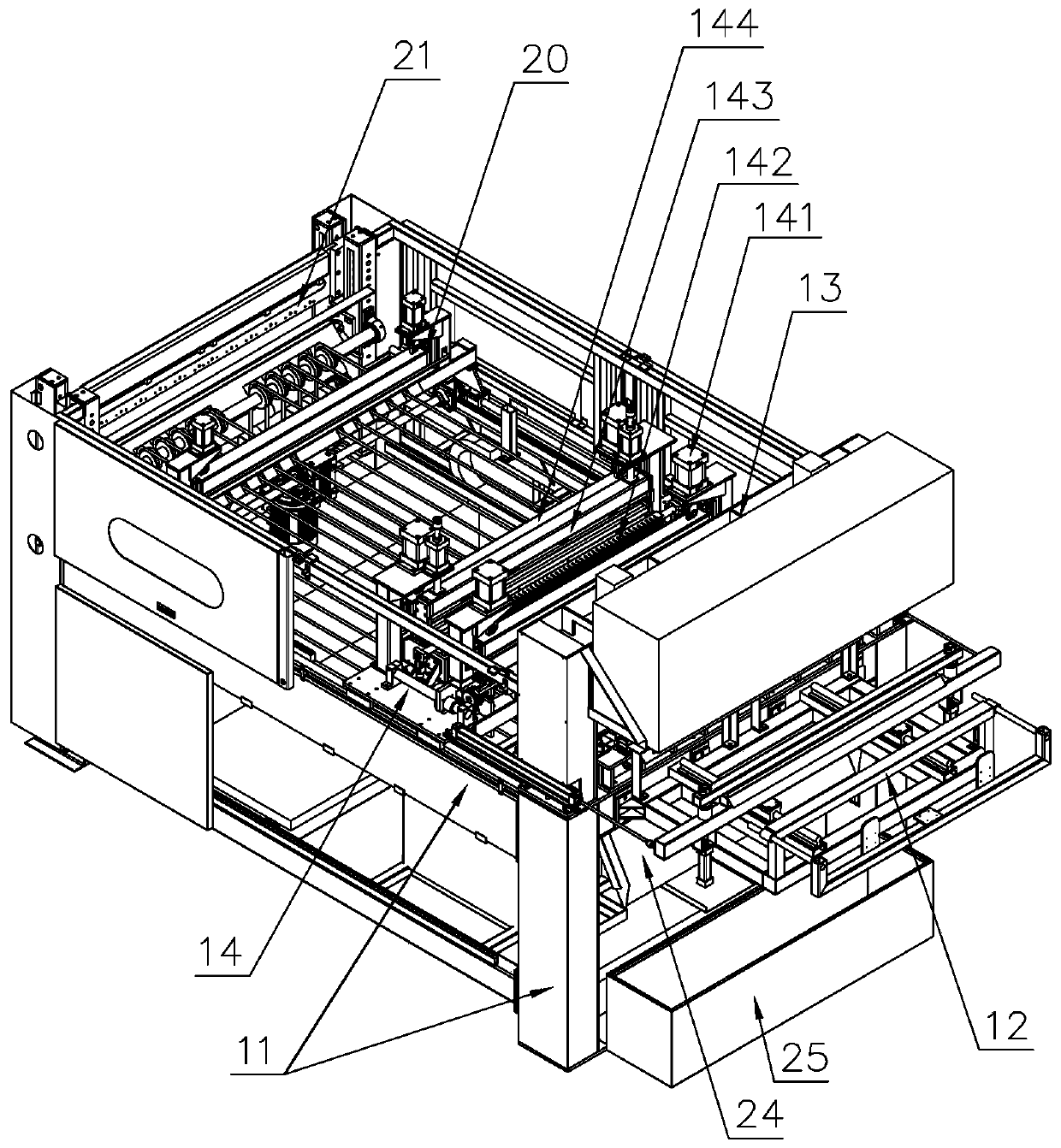

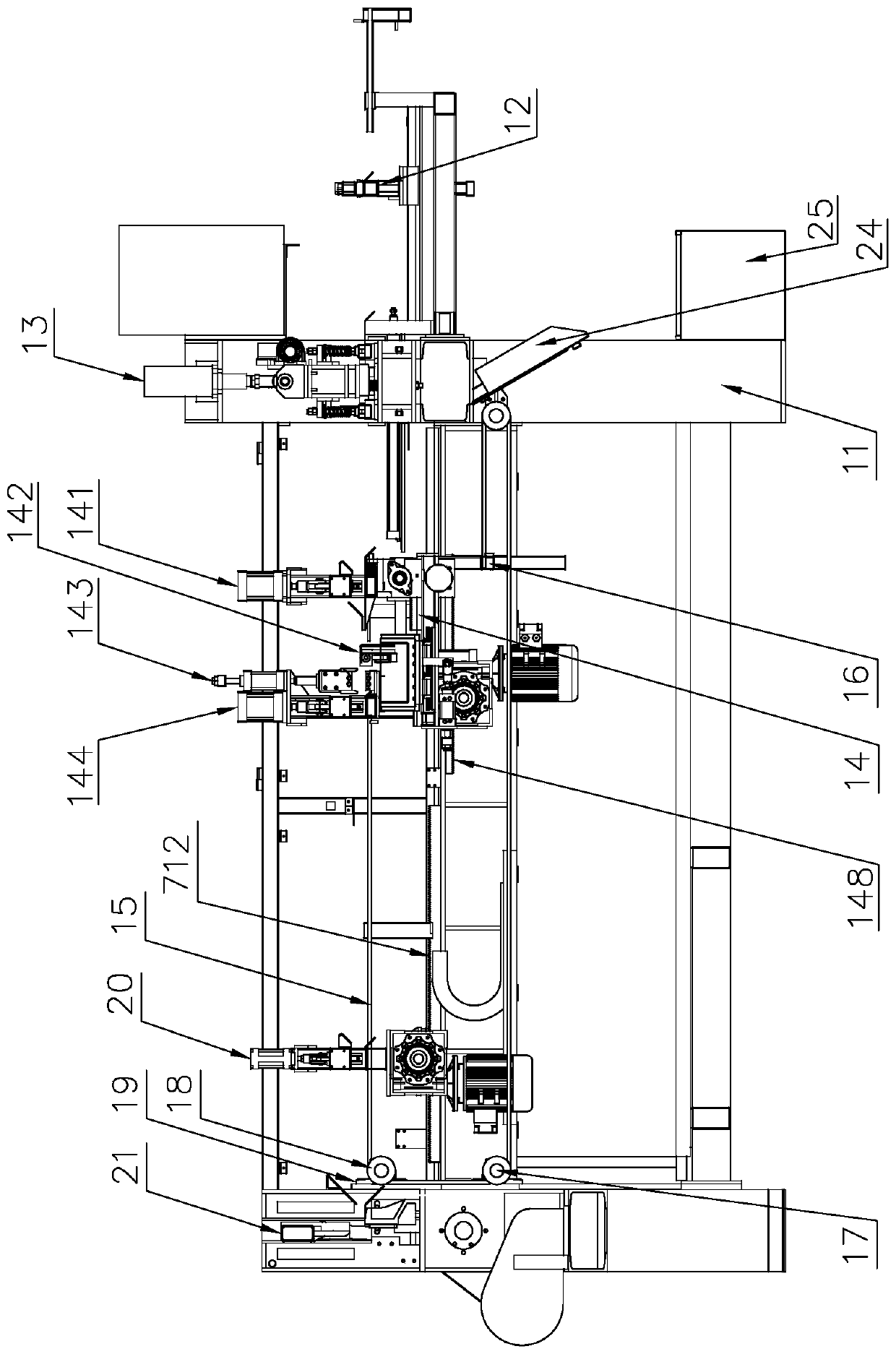

[0045] Example 1, such as Figure 1-9 as shown,

[0046] A fully automatic vertical splicing machine for continuous tooth splicing of middle plates, including a frame 11, a feeding mechanism I12, a comb mechanism 13, a moving splicing mechanism 14, a rear transmission mechanism 20, a length-setting mechanism 21, and a transfer mechanism; the frame 11 The front end is provided with a feeding mechanism I12, and one side of the feeding mechanism I12 is provided with a comb mechanism 13, and a transfer mechanism is provided on the frame 11, and the transfer mechanism includes a conveyor belt 15, a fixed frame 16, a transmission shaft I17, a transmission roller 18, Bearing seat I19, the mobile splicing mechanism 14 includes a front transmission mechanism 141, a glue applying mechanism I142, a docking mechanism 143, and a rear clamping mechanism 144. In the transfer mechanism, the conveyor belt 15 is connected end to end to the mobile splicing mechanism 14, and the conveyor belt 15 ...

Embodiment 2

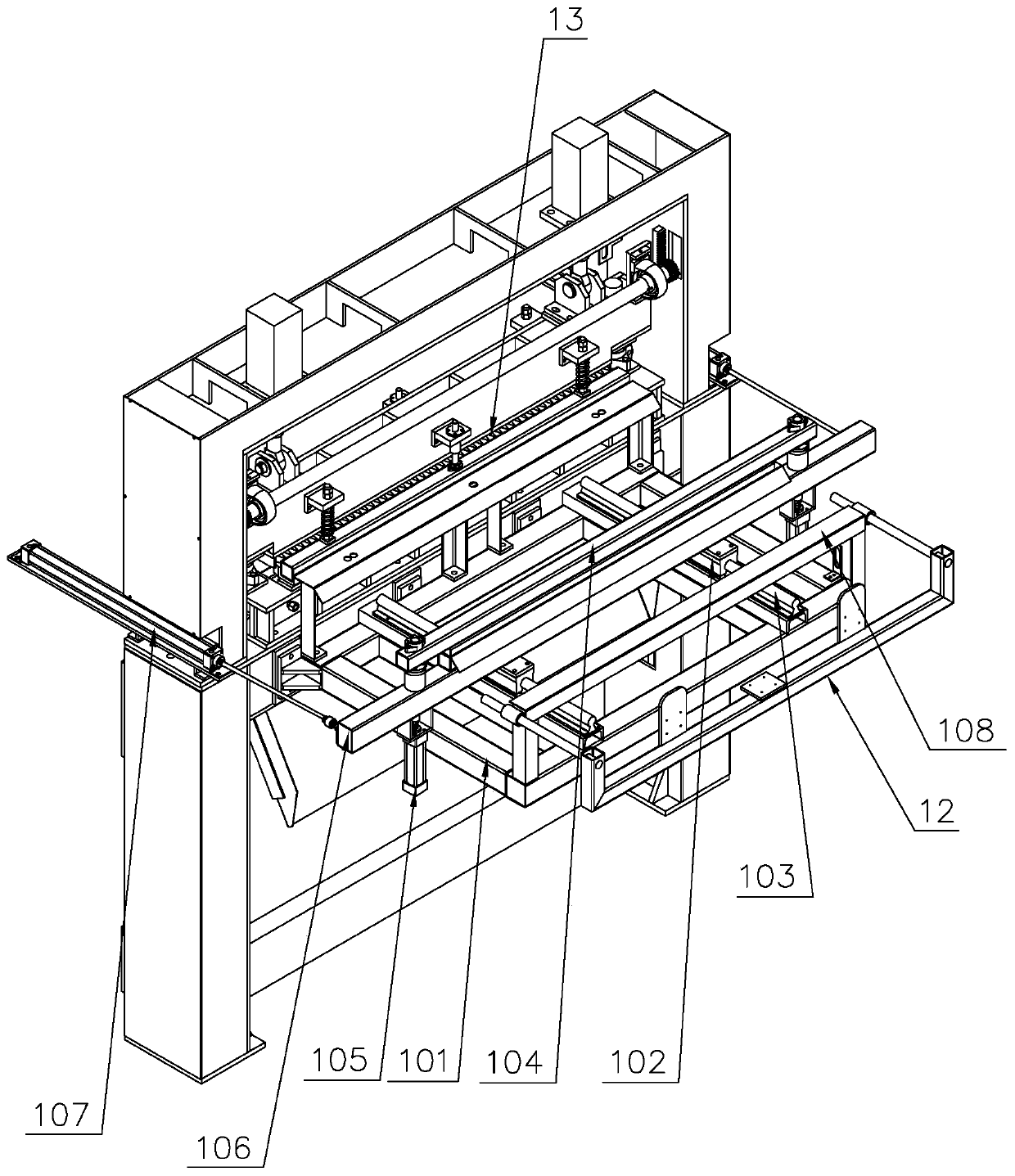

[0059] Example 2, such as image 3 , shown in 10

[0060] Compared with the embodiment, the difference is that the expansion and contraction of the cylinder II107 drives the lower pressure block I104 and the support block I106 to clamp the plate and feed it to the comb mechanism. The servo motor V110 drives the synchronous belt V112, and the synchronous belt V112 reciprocates, driving The lower pressing block Ⅰ104 and the supporting block Ⅰ106 clamp the sheet and feed it to the comb mechanism, the details are as follows:

[0061] The feeding mechanism I12 includes a feeding bracket I101, a slider I102, a guide rail I103, a lower pressure block I104, a cylinder I105, a support block I106, a support plate II109, a servo motor V110, a synchronous pulley V111, a synchronous belt V112, a fixed seat V113, Locking screw 114, a pair of guide rails I103 are provided on the feeding bracket I101, a slider I102 is provided on the guide rails I103, the top of the slider I102 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com