Lower shell structure for refrigerator compressor

A refrigerator compressor and shell structure technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve problems such as weak connections, loose bolts, and waste of manpower and material resources, and achieves simple and reasonable structural design. Easy to install and remove, improve the effect of fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

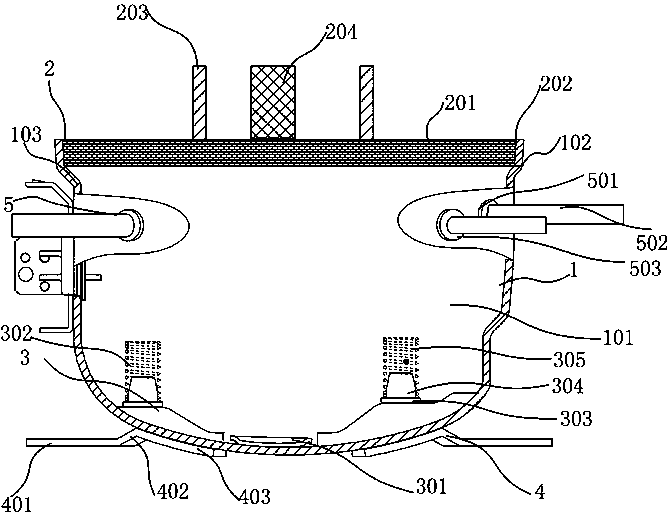

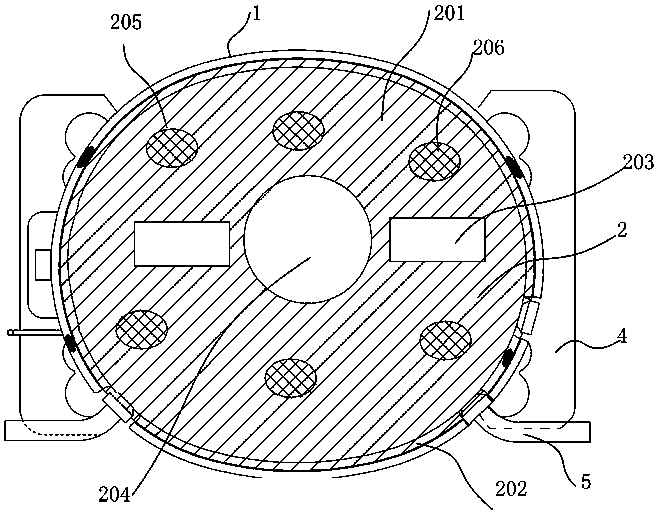

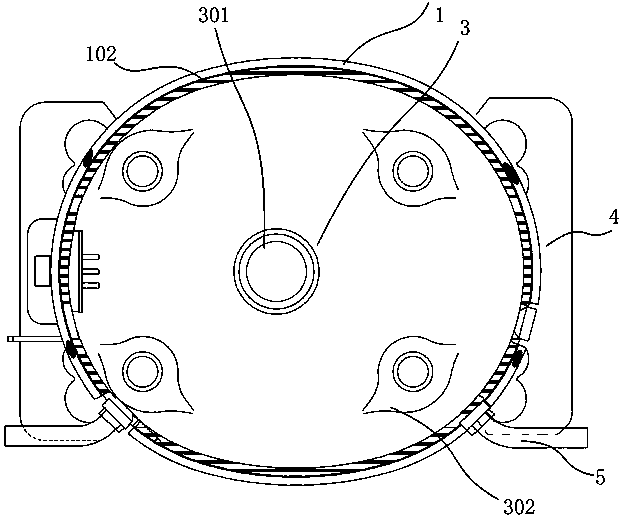

[0018] A lower shell shell structure for a refrigerator compressor, comprising a lower shell body assembly 1, a limit top plate assembly 2, a compressor body positioning assembly 3, a positioning support assembly 4 and a line source positioning unit 5, the lower shell body The inner side of the top of the component 1 is provided with a limiting top plate component 2 and is connected in a rotationally separated manner. The bottom end of the inner side of the lower shell body component 1 is equipped with a compressor body positioning component 3, and the outer bottom end of the lower shell body component 1 is set. There is a positioning support assembly 4 and is connected by welding. The side end of the lower shell body assembly 1 is provided with a line source positioning unit 5, and the line source positioning unit 5 communicates with the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com