Floor paint

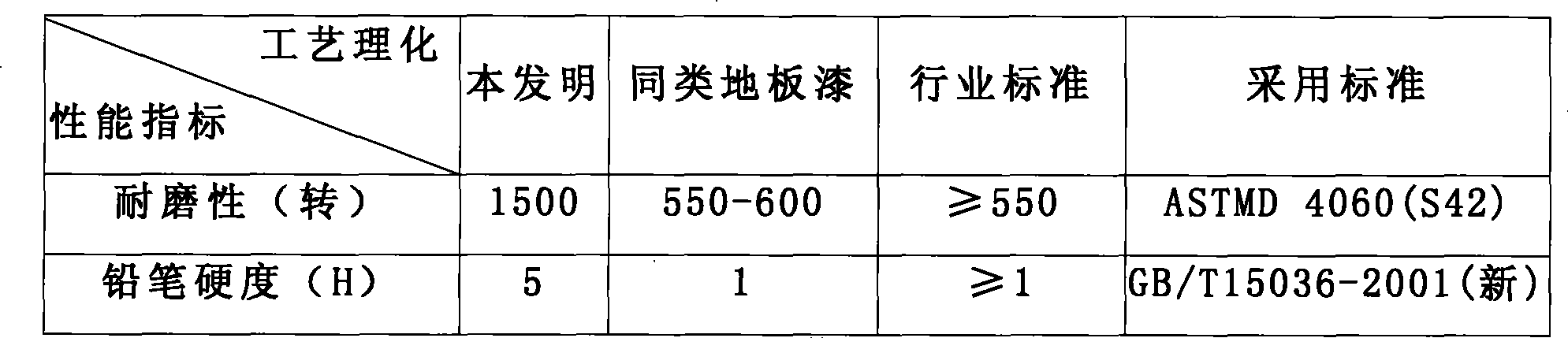

A technology of floor paint and topcoat, applied in the field of floor paint, which can solve problems such as floor cracking, poor environmental protection, and high cost, and achieve the effects of reducing viscosity, increasing resistance, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 57% water-based polyurethane with a solid content of 40%;

[0043] Ethylene glycol 0.8%;

[0044] Polysiloxane dispersant 1%;

[0045] Isocyanate crosslinking agent 7.5%;

[0047] The rest is water.

[0048] Water-based polyurethane is made of polytetrahydrofuran polyol and isocyanate through chain extension of ethylenediamine with anionic sulfonate group, and its molecular weight is 10,000-10,000.

[0049] The polysiloxane dispersant is an addition modified product of polydimethylsiloxane and polyethylene oxide, with a molecular weight of 1000-5000.

[0050] The isocyanate crosslinking agent is an addition modified product of hexamethylene diisocyanate (HDI trimer) and polyalkylene oxide, and the content of isocyanate group (NCO) is 23%.

[0051] About 1% thickener can also be added in the formula of the primer.

[0052] The isocyanate crosslinking agent and water are added before the primer is used. After adding, mix the primer ev...

Embodiment 2

[0054] 75% water-based polyurethane with a solid content of 45%;

[0055] Ethylene glycol 0.5%;

[0056] Polysiloxane dispersant 0.8%;

[0057] Isocyanate crosslinking agent 7.5%;

[0058] Silicone defoamer 1.2%;

[0059] The rest is water.

[0060] Water-based polyurethane is made of polybutylene adipate polyol and isocyanate through chain extension of ethylenediamine with anionic carboxylate group, and its molecular weight is 10,000-100,000.

[0061] The polysiloxane dispersant is an addition modified product of polydimethylsiloxane and polyethylene oxide, with a molecular weight of 1000-5000.

[0062] The isocyanate crosslinking agent is an addition modified product of isophorone diisocyanate (IPDI) trimer and polyalkylene oxide, and the content of isocyanate group (NCO) is 15%.

Embodiment 3

[0064] 57% water-based polyurethane with a solid content of 40%;

[0065] Ethylene glycol 0.8%;

[0066] Polysiloxane dispersant 1%;

[0067] Isocyanate crosslinking agent 7.5%;

[0069] The rest is water.

[0070] Water-based polyurethane is made of polycaprolactone polyol and isocyanate through chain extension of ethylenediamine with anionic sulfonate group, and its molecular weight is 10,000-100,000.

[0071] The polysiloxane dispersant is an addition modified product of polydimethylsiloxane and polyethylene oxide, with a molecular weight of 1000-5000.

[0072] The isocyanate crosslinking agent is an addition modified product of hexamethylene diisocyanate (HDI trimer) and polyalkylene oxide, and the content of isocyanate group (NCO) is 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com