Patents

Literature

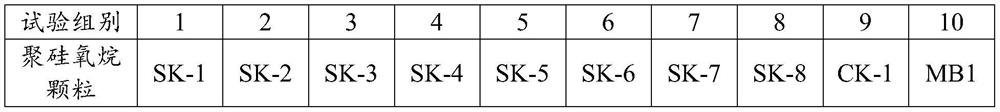

42results about How to "Good abrasion resistance and scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

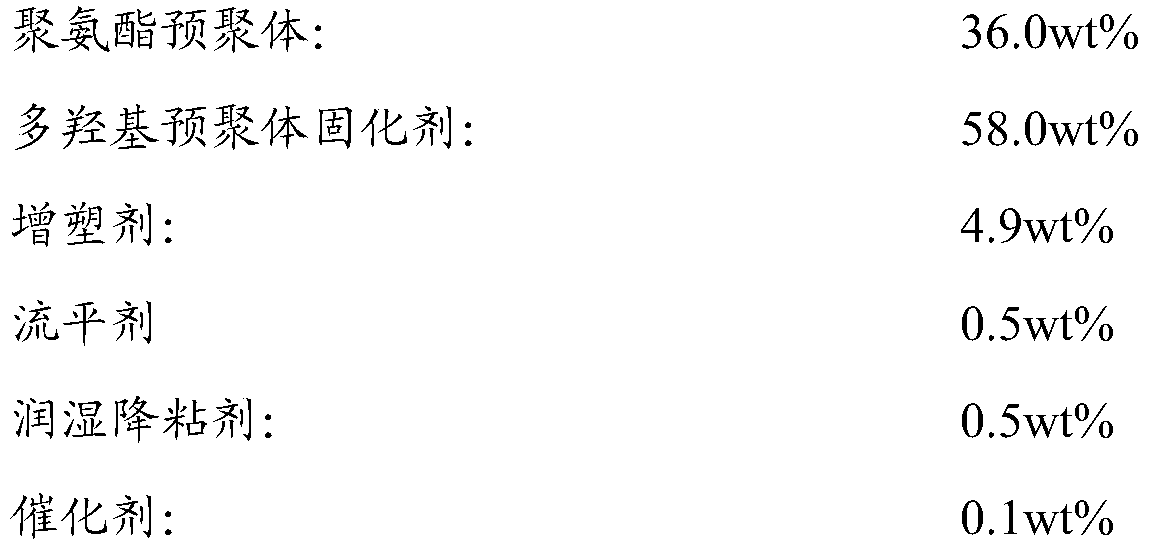

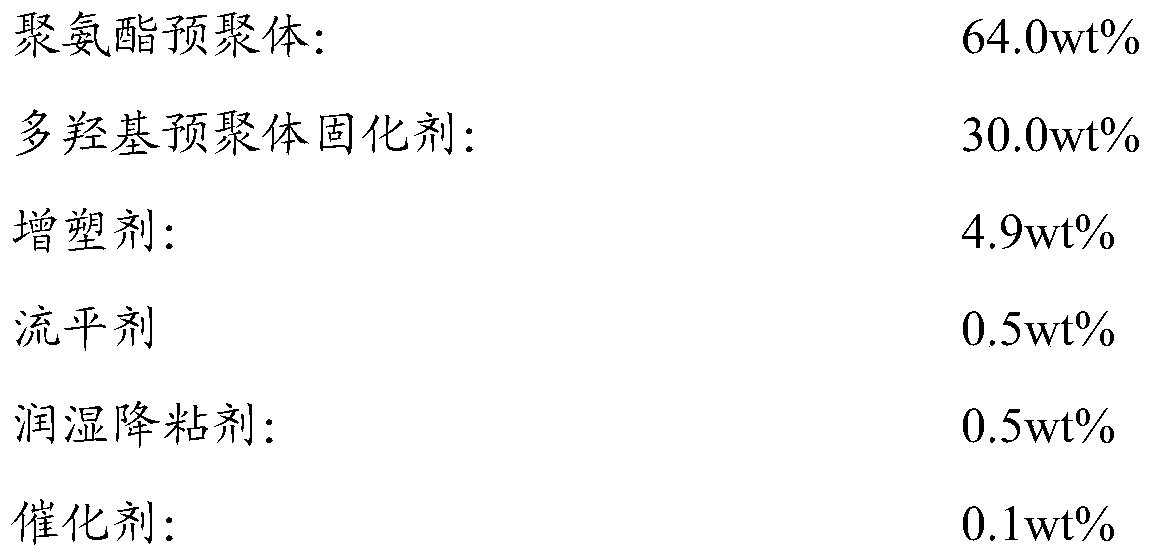

Method for preparing abrasion-resistance high-hydrolysis-resistance negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather

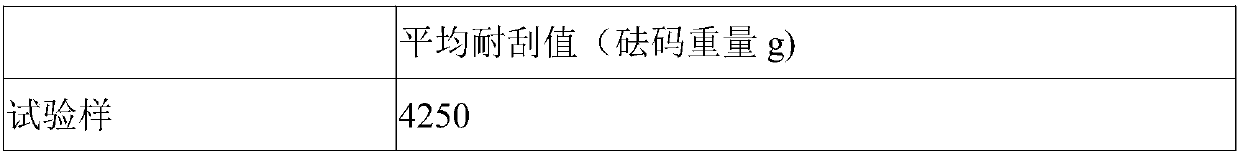

The invention discloses a method for preparing abrasion-resistance high-hydrolysis-resistance negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather. The synthetic leather is prepared by selecting abrasion-resistance scraping-resistance closed high-solid-content poly-carbon type polyurethane resin as a dry-method surface layer and high-hydrolysis-resistance solvent-free polyurethane resin as a foaming layer through low-pressure pouring equipment and adhering to a cloth base; and molding textures of the synthetic leather by adopting a negative pressure texture absorbing process. The negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather has the characteristics of efficient and environment-friendly preparation process, no DMF, strong texture solid feeling, plump and soft hand feeling, excellent genuine leather effect, abrasion resistance (Valspar is 0.3 million times), super hydrolysis resistance (8-12 years) and other highphysical performances.

Owner:ANHUI ANLI MATERIAL TECH

Waterborne extinction polyurethane resin and preparation method thereof

The invention discloses a water-based matting polyurethane resin and a preparation method thereof, comprising macromolecular polyols, hydrophilic diols, small molecule diols, diisocyanates, catalysts, salt-forming agents, amine chain extenders, and deionized water , Thickener. The preparation includes the following steps: step a: add macromolecular diol into the reaction kettle, and vacuum dehydrate at 100°C for 1 hour; step b: add co-solvent, diisocyanate, small molecular polyol and hydrophilic diol; step c: React at 70-90°C for 3-6 hours; Step d: After adding triethylamine to form a salt, add deionized water to emulsify into an emulsion while stirring; Step e: Add amine chain extender; Step f: Add thickener to adjust Viscosity: The prepared water-based polyurethane resin has a high matting degree, no additional matting powder is needed, and the obtained matting coating film is good in abrasion resistance and scratch resistance.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Formula of coating solution and preparation method and application of coating solution

InactiveCN107022295AGood antibacterialImprove mildew resistanceFireproof paintsAntifouling/underwater paintsFiberPolymer science

The invention relates to a formula of a coating solution and a preparation method and application of the coating solution. The coating solution comprises the following raw material ingredients: graphene, polyurethane resin and water, wherein the mass ratio of the graphene to the polyurethane resin to the water is (0.18 to 0.23): 100: (50 to 80). A specific application method comprises the step of coating leather-based fabrics with the coating solution, wherein the leather-based fabrics comprise one or more of knitted fabrics, woven fabrics, non-woven fabrics, ultra-fiber non-woven fabrics and true skin. By adopting the technical scheme provided by the invention, the graphene is compounded into a coating material, so that prepared leather products, particularly leather summer-sleeping mats have excellent functions such as wear resistance, scratch resistance, electrostatic resistance, wave absorbing, bacterial resistance, mildew proofing, UV aging resistance, flame retarding, smoke suppressing, electromagnetic shielding and far-infrared health care; the grade of leather can be comprehensively improved, and the performance of cowhide summer sleeping mats in our country in the aspects of comfortability, durability and mildew proofing and bacterial resistance is improved.

Owner:北欧牧风成都家居用品有限公司

Chloroethylene-butyl acrylate-hydroxypropyl acrylate copolymer emulsion and preparation method thereof

ActiveCN102977248AGood abrasion resistance and scratch resistanceHigh glossInksCoatingsPotassium persulfateWater based

The invention relates to chloroethylene-butyl acrylate-hydroxypropyl acrylate copolymer emulsion and a preparation method thereof, and mainly relates to a water-based industrial coating for water-based ink base materials, belonging to the technical field of industrial coatings. The copolymer emulsion is prepared by taking chloroethylene, butyl acrylate and hydroxypropyl acrylate as monomers, sodium dodecyl benzene sulfonate, sodium dodecyl sulfate and nonionic surfactants OP-100 and OP-4 as emulsifying agents, PVPK-30 as a colloid protecting agent and water-soluble potassium persulfate and ammonium persulfate as initiating agents to carry out polymerization. The copolymer emulsion has the advantages that compared with other water-based coatings, the copolymer emulsion, used as a water-based industrial coating, has better waterproofing property and acid, alkali and salt corrosion resistance, hard and tough film, good wear and scratching resistance, high gloss and relatively low cost, has qualified mechanical stability, calcium ion stability and heat stability and is free from demulsification and delamination after being stored for a year.

Owner:WUXI HONGHUI NEW MATERIALS TECH

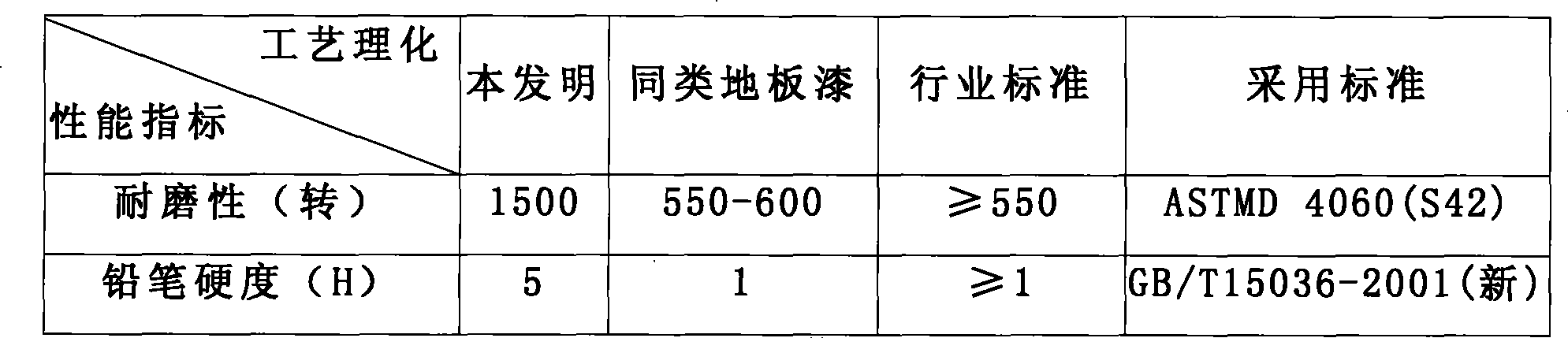

Floor paint

ActiveCN101412887AImprove wear resistanceExcellent abrasion resistance and scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsLacquerAcrylic resin

The invention discloses floor paint formed by aqueous primer and UV finishing coat. The solid content of aqueous polyurethane in the primer is between 25 and 45 percent, and is formed by oligomer polylol and isocyanate through hydrophilic chain extender by chain extension, wherein the ligomer polylol has molecular weight of between 500 and 3,000, and is selected from tetrahydrofuran polylol, polybutanediol adipate polylol and polycaprolactone polylol; and the hydrophilic chain extender is ethylenediamine with anionic sulphonate or anionic carboxylate groups. The finishing coat uses butanone as a solvent, and contains epoxy mondified acrylic resin, trifunctional monomer, 1,6-hexanediol diacrylate, silicon dioxide powder, light initiator, active amine assistant initiator, organic fluorine foam suppressor and aluminum oxide powder, wherein a diluent monomer is selected from trimethylolpropane triacrylate, trifunctional extractant acid ester, pentaerythritol triacrylate, and propoxylated propanetriol triacrylate. The floor paint has the advantages of good wear resisting property and scraping resisting property and splitting resisting property.

Owner:SINO MAPLE JIANGSU CO LTD

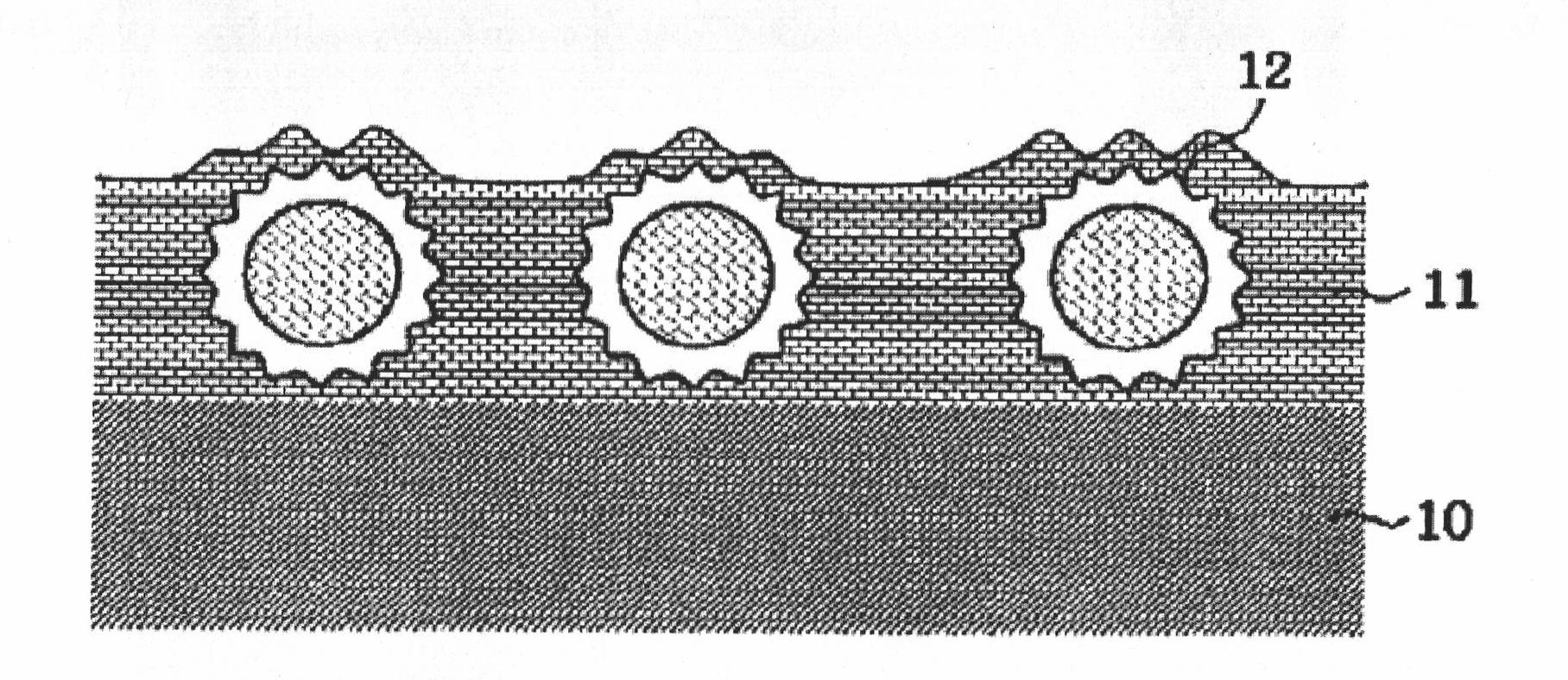

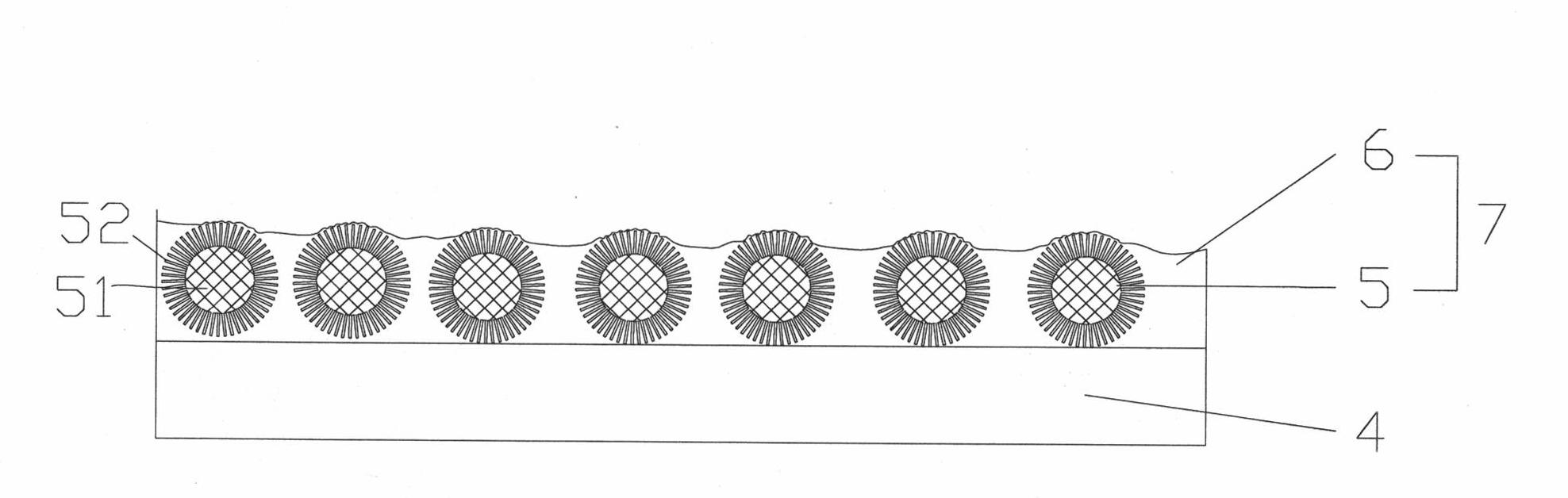

Anti-dazzling film, production method of anti-dazzling film, polarizing plate using anti-dazzling film and display device with polarizing plate

InactiveCN102375165AHigh light transmittanceHigh hardnessPolarising elementsCoatingsConvex structureCoated surface

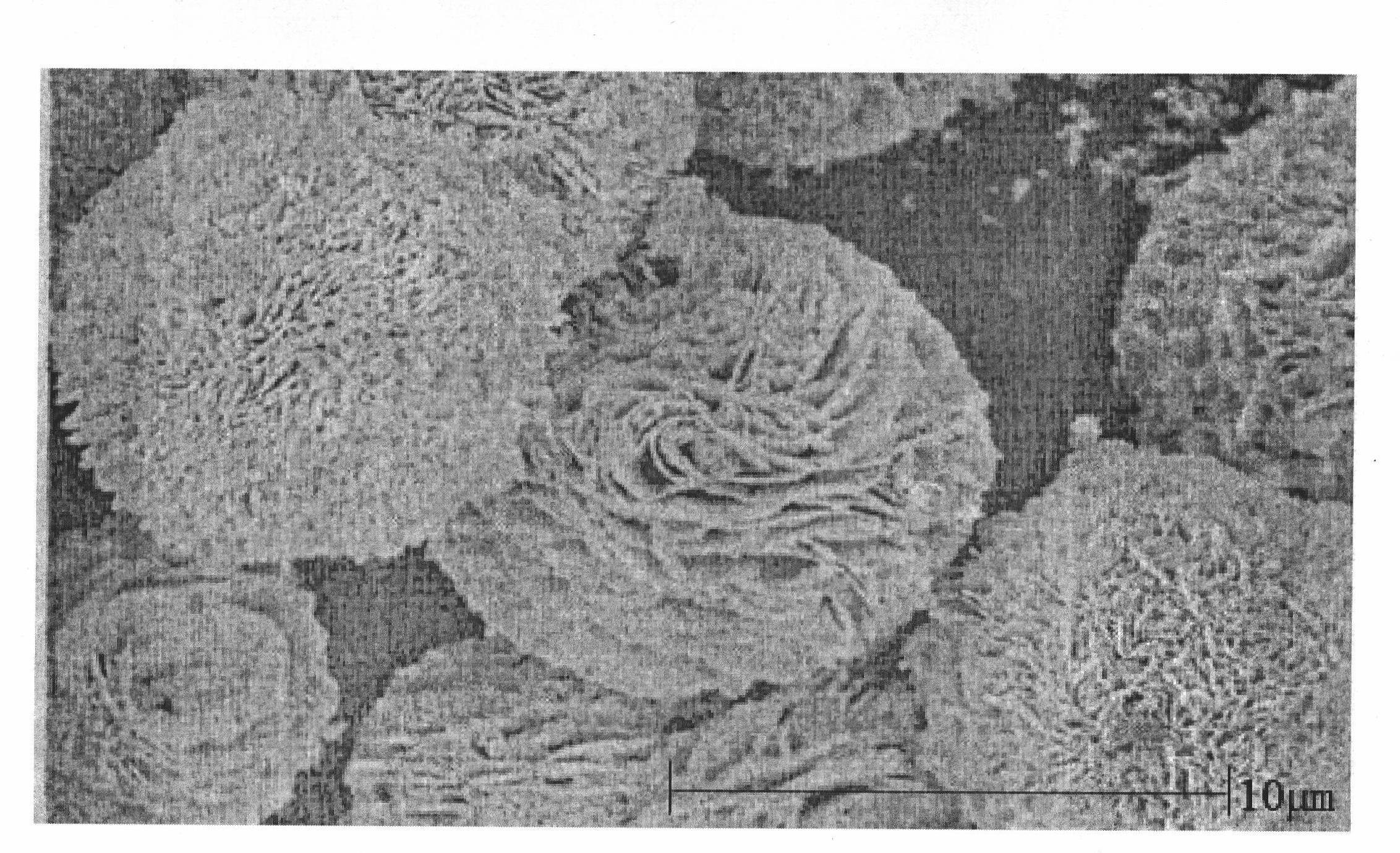

The invention provides an anti-dazzling film, which comprises a transparent substrate and an anti-dazzling coating layer which is arranged on at least one surface of the substrate. The anti-dazzling coating layer comprises resin adhesive and particles scattered in the resin adhesive. The surface of the anti-dazzling coating layer is provided with a concave and convex structure. The anti-dazzling film is characterized in that each particle is a ball-flower-shaped particle and comprises an internal part and a ball body which is of a reticular void structure on the surface, the external part of the ball body is of a petal-shaped structure, and the petal-shaped structure consists of a plurality of petals which integrally grow on the surface of the ball body and stretch outwards. The invention additionally discloses a production method of the anti-dazzling film. The anti-dazzling film provided by the invention has the advantages that the light transmittance is increased because of the reticular void structures of the ball-flower-shaped particles, the resin adhesive can seep into the voids and the anti-dazzling film has higher hardness and excellent wear and scratching resistance performance after the resin adhesive is solidified; and the petal-shaped structures of the ball-flower-shaped particles enable the concave and convex structure to be formed on the surface of the anti-dazzling film and therefore the anti-dazzling film has an anti-dazzling performance.

Owner:BYD CO LTD

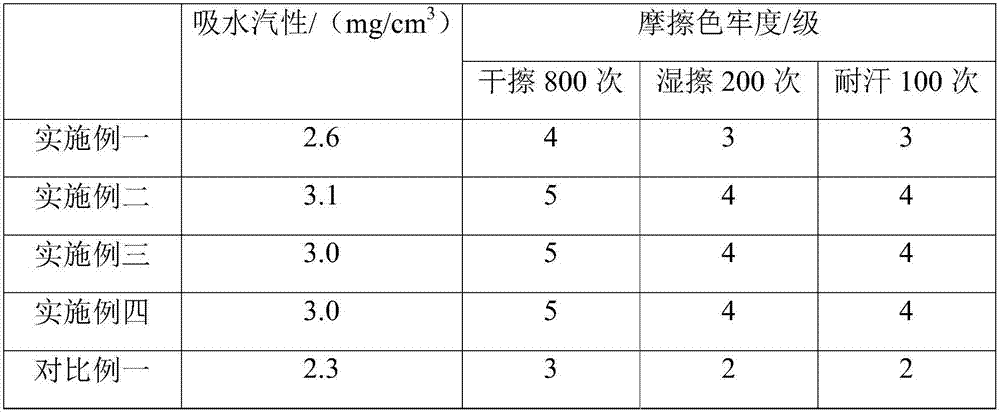

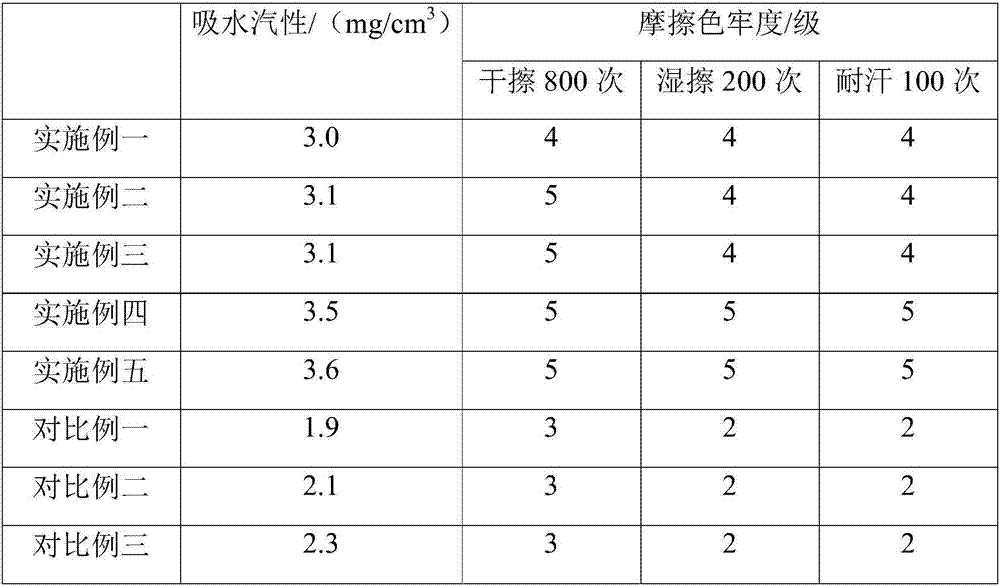

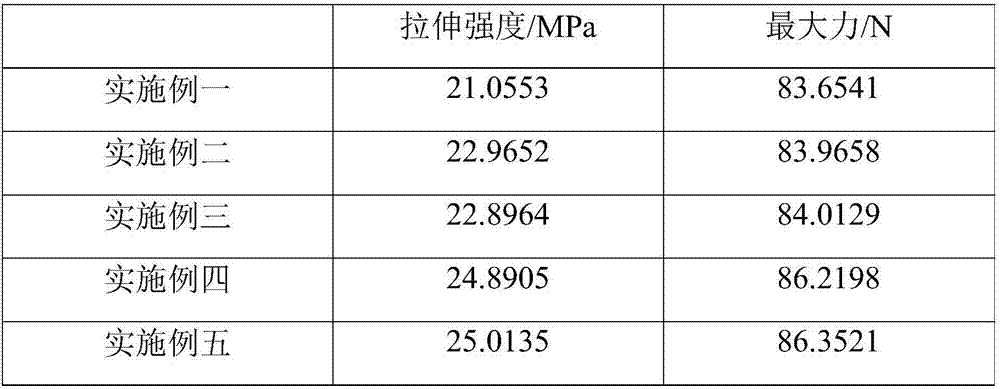

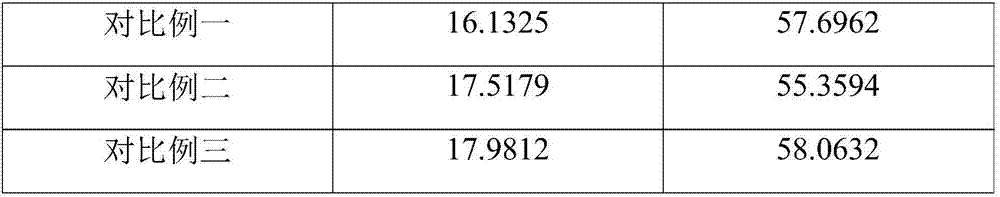

Leather preparation method and application

InactiveCN107164971AExcellent color fastness to rubbingExcellent water vapor absorptionTextiles and paperLeather surface finishingChemistryInfrared

The invention relates to a leather preparation method. The method comprises the following steps: S101, dissolving graphene in an acid solution; and heating for 3-5h under the temperature of 110-130 DEG C; S102, adding a polyethylene acrylate and tourmaline powder to the product obtained in S101; uniformly stirring, and regulating the pH of the product to be 5.8-6.3; S103, adding polyurethane resin and polyvinyl alcohol to the product obtained in S102; uniformly stirring; S104, coating a base leather with the product obtained in S103, so as to obtain the leather. According to the method, the graphene is used as the additive to be applied to the leather preparation process, so that the obtained leather product, in particular a leather bad mat, is outstanding in abrasion and scratching resisting functions, antistatic function, wave absorbing function, bacteria resisting function, mould preventing performance, UV ageing resisting performance, flame resisting and smoke inhibiting performance, electromagnetic shielding function, infrared healthcare function and other function. Therefore, the level of the leather can be comprehensively increased; the comfort, the durability, the mould resistance and the bacteria resistance of national cattlehide bed mats can be improved.

Owner:北欧牧风成都家居用品有限公司

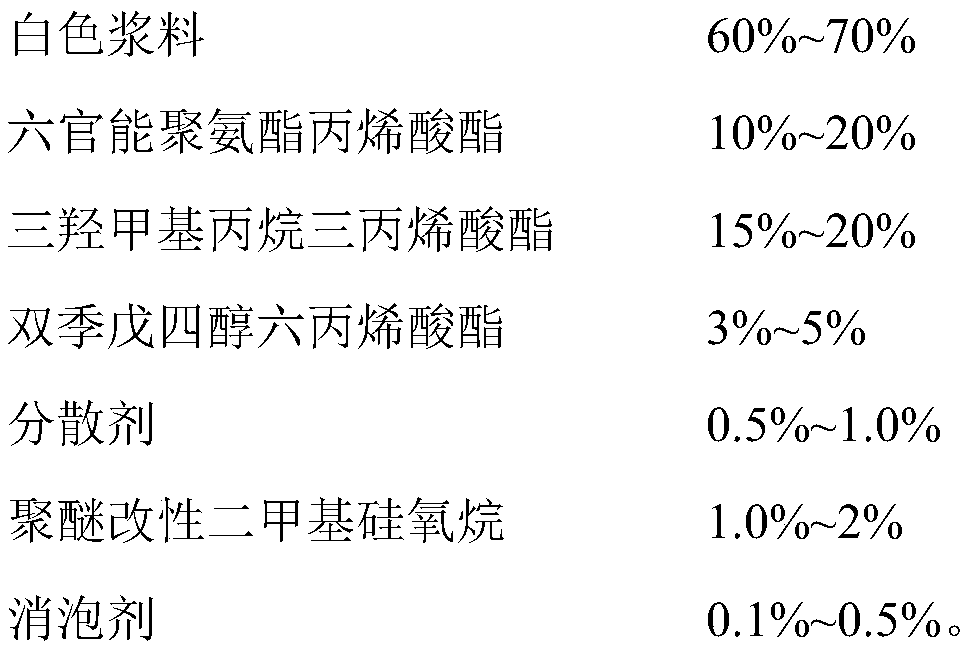

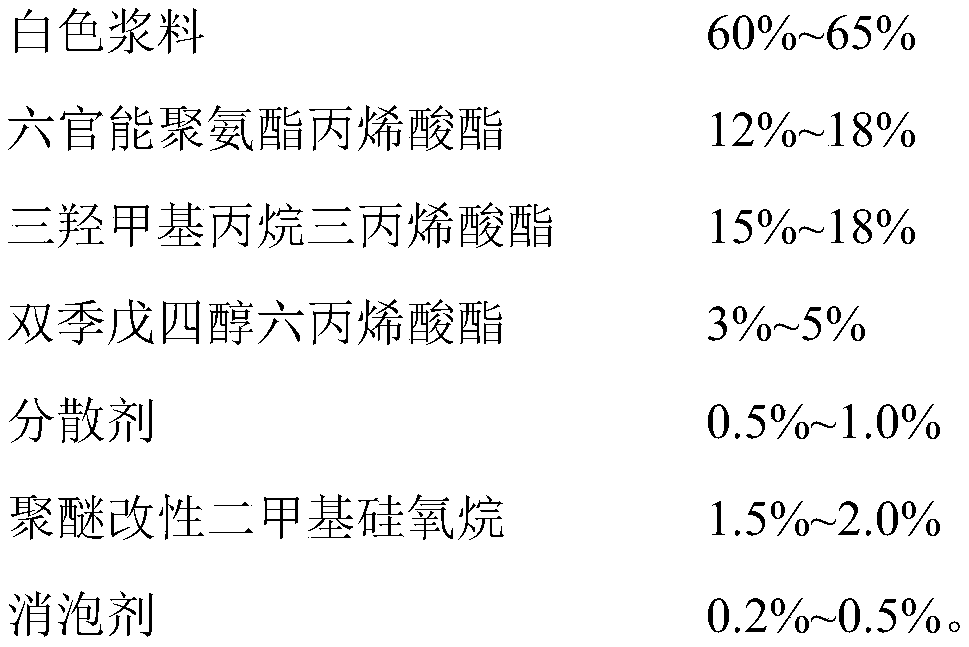

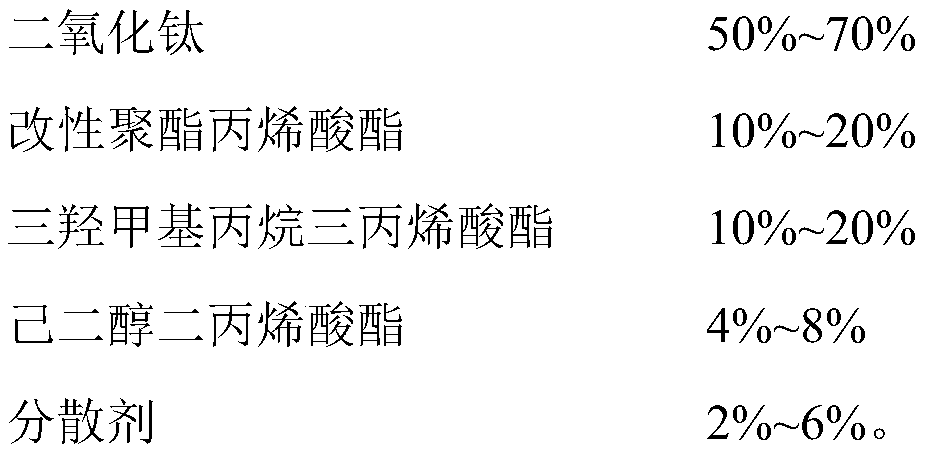

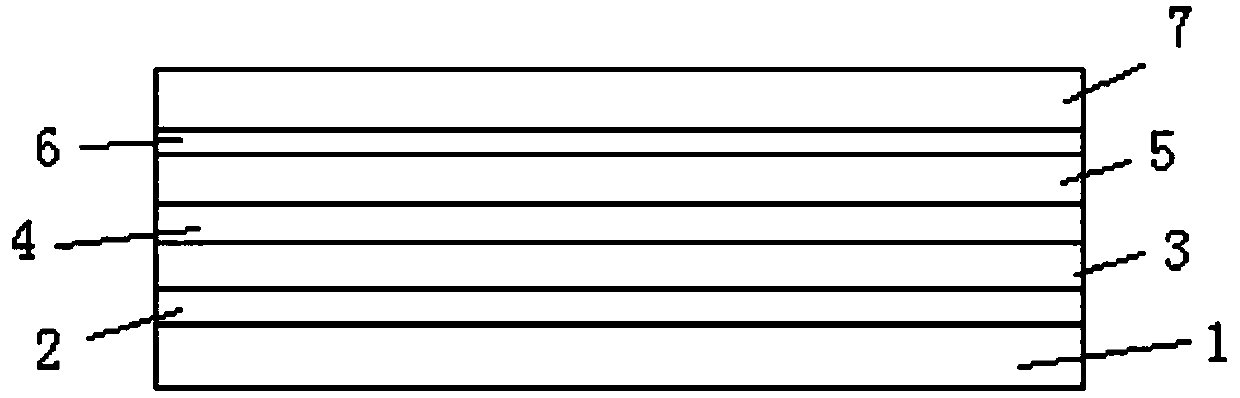

Electron beam cured high-wear-resistant scratch-resistant white coating and preparation method and construction method thereof

ActiveCN109897530AHigh concentration of color pasteStrong covering powerPretreated surfacesPolyurea/polyurethane coatingsChemistryDefoaming Agents

The invention relates to the technical field of coatings, in particular to an electron beam cured high-wear-resistant scratch-resistant white coating and a preparation method and a construction methodthereof. The electron beam cured high-wear-resistant scratch-resistant white coating comprises white slurry, urethane acrylate with six functional groups, trimethylolpropane triacrylate, dipentaerythritol hexaacrylate, a dispersing agent, polyether modified dimethyl siloxane and a defoaming agent. The preparation method of the electron beam cured high-wear-resistant scratch-resistant white coating comprises the following steps: first step, preparing white slurry; and second step, preparing the white coating. The electron beam cured high-wear-resistant scratch-resistant white coating has the characteristics of being high in color paste concentration, excellent in hiding power, capable of avoiding the fact that a white primer coats for many times and is combined to a white finish paint or varnish to achieve a good hiding power effect, capable of enabling a cured white coating layer to be better in yellowing property, high in hardness, wear-resistant, scratch-resistant, good in yellowingproperty, good in adhesive force, good in leveling property and the like.

Owner:中山易必固电子束科技有限公司

Special washing branding discoloration resin for synthetic leather and preparation method thereof

ActiveCN103214821AThe branding part is clearIntense anxietyTextiles and paperPolymer scienceDimethylformamide

The invention relates to a special washing branding discoloration resin for synthetic leather. The branding discoloration resin comprises the following components: polyurethane resin, silicon dioxide extinction powder, micronization wax powder, a plasticizing agent, an organosilicon feeling agent, butyl acetate and N, N-dimethylformamide. The method comprises the following steps: 1, adding the polyurethane resin, the N, N-dimethylformamide and the butyl acetate into a reactor, and mixing uniformly; 2, adding the plasticizing agent, the silicon dioxide extinction powder and the micronization wax powder while stirring, and stirring for 20-40 minutes so as to completely dispersing the plasticizing agent, the silicon dioxide extinction powder and the micronization wax powder; and 3, testing the viscosity of a product, filtering and discharging after qualification. The branding discoloration resin is good in physical property, good in wear resistance and scratch resistance and good in visual effect, and can be widely used in occasions such as shoes and bags with high performance requirements on the synthetic leather.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

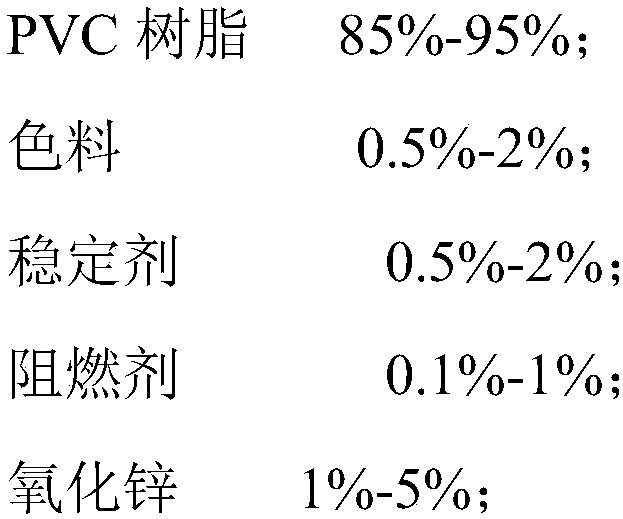

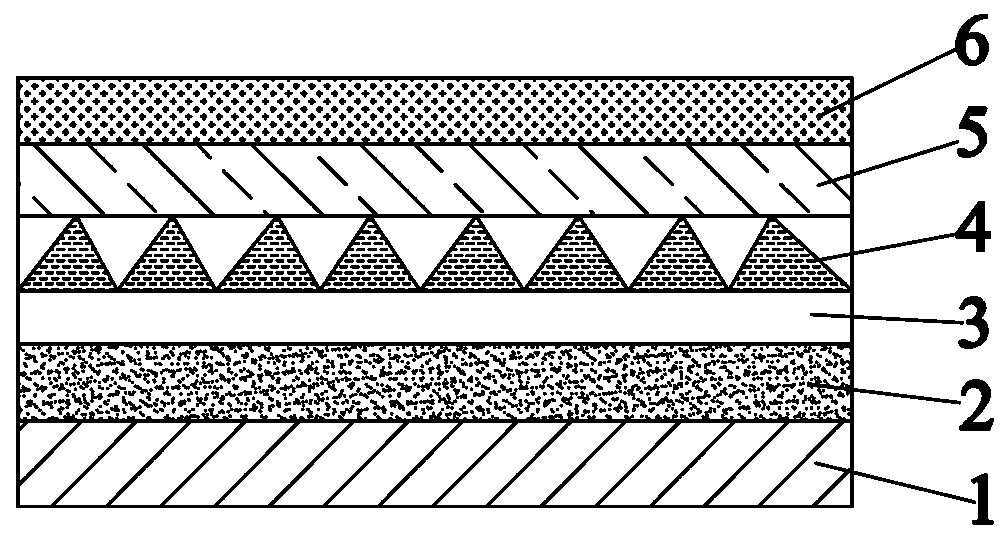

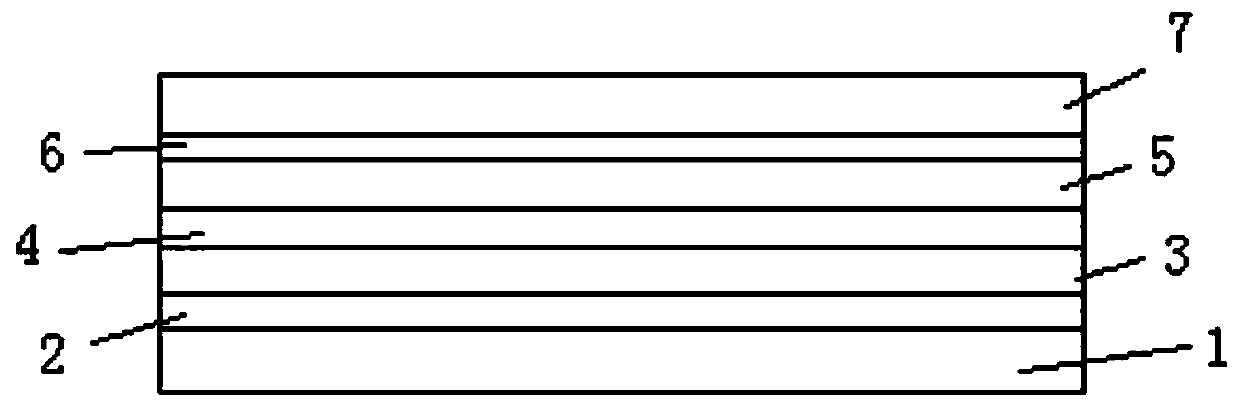

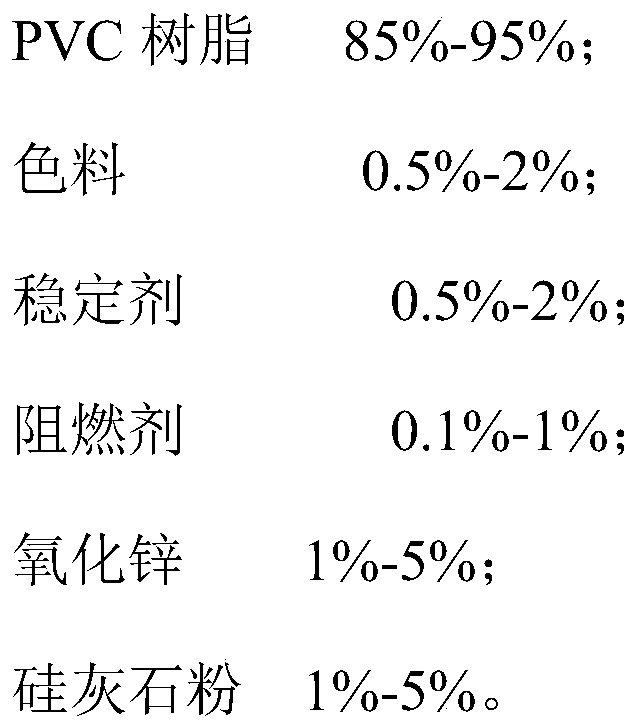

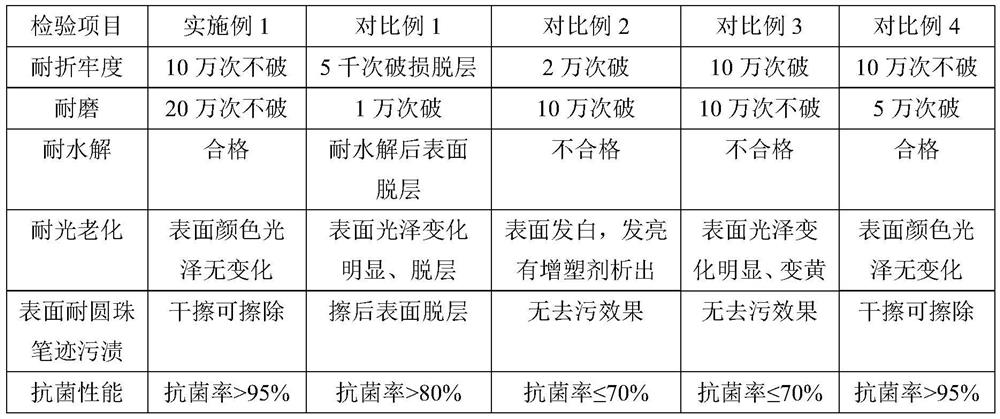

PVC synthetic leather for automotive interior

ActiveCN108016102AImproves UV resistanceImprove anti-aging functionSynthetic resin layered productsSuperstructure subunitsWear resistantUltraviolet

The invention belongs to the technical field of leather and more specifically relates to PVC synthetic leather for automotive interior. The PVC synthetic leather comprises a PVC base layer, a first adhesion layer, an antibacterial layer, a second adhesion layer, an ultraviolet-proof layer, a third adhesion layer and a wear-resistant layer sequentially, wherein the antibacterial layer comprises thecomponents by weight as follows: 90%-98% of PVC resin, 0.1%-5% of chitosan and 0.1%-5% of a nano-silver antibacterial agent, the degree of deacetylation of the chitosan is 85%-95%, and the molecularweight of the chitosan is 0.1-0.2 million. Compared with the prior art, the PVC synthetic leather can have a good antibacterial effect by means of the antibacterial layer. Meanwhile, the ultraviolet-proof layer is arranged, so that the ultraviolet resistance of the synthetic leather can be improved, and the aging resistance of the synthetic leather can be improved; the PVC synthetic leather is endowed with good wear resistance and scratch resistance by means of the wear-resistant layer.

Owner:雄进塑料制品(东莞)有限公司

Coating used for expressway guardrails and preparation method thereof

ActiveCN108610846AConvenient spraying operationAdjustable drying speedFireproof paintsAnti-corrosive paintsWear resistantSpray coating

The invention discloses a coating used for expressway guardrails and a preparation method thereof. The coating includes a resin base material, a dispersant, a leveling agent, a cosolvent, a solvent, anano-material, an anti-flash rust agent, and a defoamer. The preparation method includes the steps of: mixing and dispersing the dispersant, the leveling agent, the cosolvent, the solvent, the nano-material and the anti-flash rust agent to prepare a dispersion liquid; adding the resin base material into the dispersion liquid with stirring, and adding a defoaming agent and continuously stirring the mixture to obtain the coating. The preparation method is simple and is free of special large-size equipment. The coating can reach more than 9H in hardness, is wearing resistant and anti-scratching,has excellent electrical insulation property and is high temperature-resistant and ultraviolet aging-resistant, can prevent and resist fouling, and is convenient to clean. The coating is simple in spray coating operation and is free of detachment of the expressway guardrails. The coating is low in cost and is adjustable in drying speed after the spray coating operation.

Owner:BEIJING FAIRVIEW NEW TECH CO LTD

VCM (Vinyl Chloride Monomer)-2-EHA (ethylhexyl acrylate)-organosilicone copolymerization emulsion and preparation method thereof

ActiveCN102993849AGood abrasion resistance and scratch resistanceHigh hardnessAnti-corrosive paintsIsooctyl acrylateWater based

The invention relates to a VCM (Vinyl Chloride Monomer)-2-EHA (ethylhexyl acrylate)-organosilicone copolymerization emulsion and a preparation method thereof, and mainly relates to a production method of an emulsion used in a water-based industrial coating stock, belonging to the technical field of industrial coatings. According to the preparation method, with vinyl chloride, 2-ethylhexyl acrylate and vinyl trimethoxy silane as monomers and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, lauryl sodium sulfate and OP-4 as emulsifying agents and water-soluble ammonium persulfate as an initiating agent, the VCM-2-EHA-organosilicone copolymerization emulsion is prepared by a polymerization reaction. Compared with other water-based coatings, the VCM-2-EHA-organosilicone copolymerization emulsion has better water resisting property, acid-base salt corrosion resisting property, low cost and high performance cost ratio when used as a water-based industrial coating; in addition, a coating film is high and has wear and scratching resistance properties,. The VCM-2-EHA-organosilicone copolymerization emulsion is qualified in mechanical stability, calcium ion stability and heat stability, and is stored for one year without demulsification and demixing.

Owner:WUXI HONGHUI NEW MATERIALS TECH

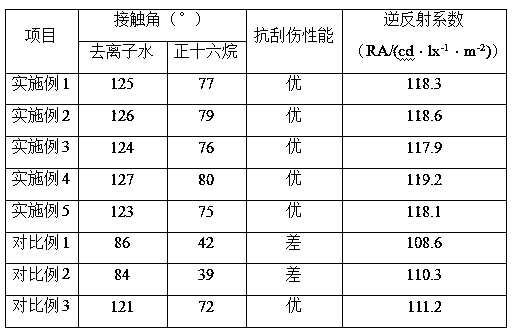

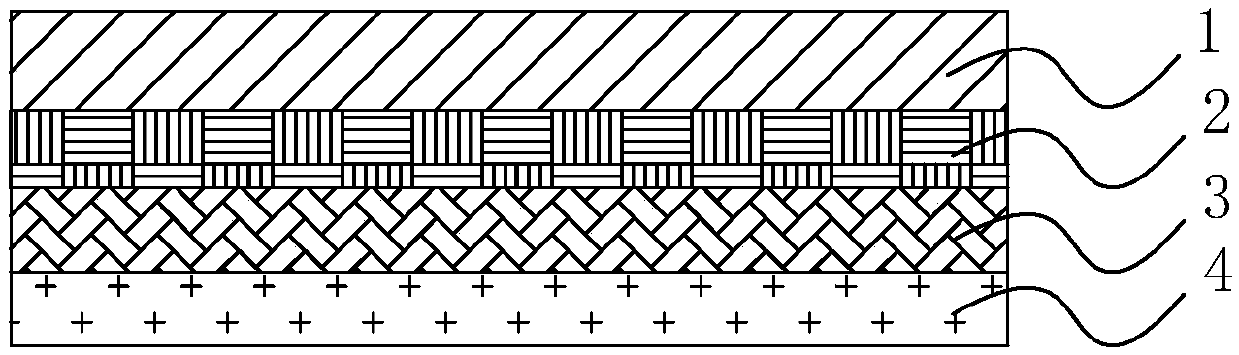

High-brightness PET reflective film

InactiveCN111308594AReduce condensationAlleviate problems such as dirt absorptionMirrorsAntifouling/underwater paintsPolyethylene terephthalate glycolAdhesive

The invention belongs to the technical field of films, in particular to a high-brightness PET reflective film. The reflective film comprises a release layer, a pressure-sensitive adhesive layer, a reflective layer, a microprism layer, a carrier layer and an antifouling scratch-resistant anti-reflection layer which are stacked in sequence, the carrier layer contains polyethylene glycol terephthalate, the antifouling scratch-resistant anti-reflection layer is formed by coating and curing high-hardness organic silicon resin added with inorganic nano powder, and the inorganic nano powder comprisesat least one of nano zirconium oxide, nano magnesium fluoride, nano magnesium nitride, nano titanium dioxide, nano aluminum oxide and nano silicon dioxide. Compared with the prior art, the high-brightness PET reflective film has the advantages that the film has excellent reflective brightness and long service life, can replace previous glass, can be applied to reflective glass or previous mirrorglass, can prevent breakage, can also be used as a decoration, and is convenient and practical.

Owner:瑞年新材料(广东)有限公司

Composite reinforced plastic floor and production process thereof

The invention discloses a composite reinforced plastic floor and a production process thereof. The composite reinforced plastic floor comprises a wear-resistant layer, a decorative layer, a stone-plastic base material layer and a balance layer which are formed by hot pressing from top to bottom, and the stone-plastic base material layer comprises polyvinyl chloride. The stone-plastic base materiallayer is prepared from the following raw materials in parts by weight: 50-65 parts of polyvinyl chloride, 150-190 parts of stone powder, 6-8 parts of calcium zinc stabilizer, 0.35-0.65 part of stearic acid, 5-8 parts of PVC modifier, 0.2-0.4 part of carbon black and 0.6-0.8 part of polyethylene wax. The production process comprises the working procedures of batching, stirring, preliminary forming, thickness fixing, cooling, cutting, hot pressing, slicing, grooving and the like. The invention provides the composite reinforced plastic floor which is high in dimensional stability, low in production cost and excellent in scratch resistance and the production process of the composite reinforced plastic floor.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Antistatic wear-resistant floor coating and preparation method thereof

InactiveCN111808464AEasy to operateReduce dosagePolyurea/polyurethane coatingsElectrically-conductive paintsWaxPolyol

The invention discloses an antistatic wear-resistant floor coating and a preparation method thereof. The coating comprises a component A, a component B and a component C, wherein the component A comprises 30-40 parts by weight of grease polyol; 15 to 20 parts by weight of a conductive material, 20 to 25 parts by weight of a filler, 0.1 to 2 parts by weight of a dispersant, 0.1 to 1 part by weightof an antifoaming agent, 0.1 to 1 part by weight of a wetting agent, 0.1 to 1 part by weight of a leveling agent, 3 to 8 parts by weight of zeolite powder, 10 to 15 parts by weight of a pigment and 2to 5 parts by weight of polytetrafluoroethylene wax powder; the component B comprises the following components in parts by weight: 5-20 parts of grease polyol and 70-95 parts of polyisocyanate; and the component C is 100 parts by weight of quartz sand or corundum powder. The floor coating is convenient to operate and low in consumption, and can meet the requirements of production plants, assemblyworkshops and the like on anti-static performance.

Owner:MIANYANG HUILI EPOXY ENG

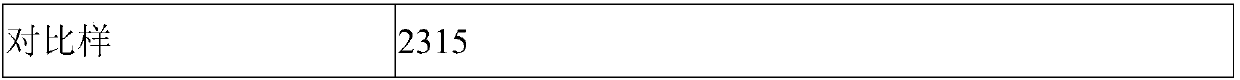

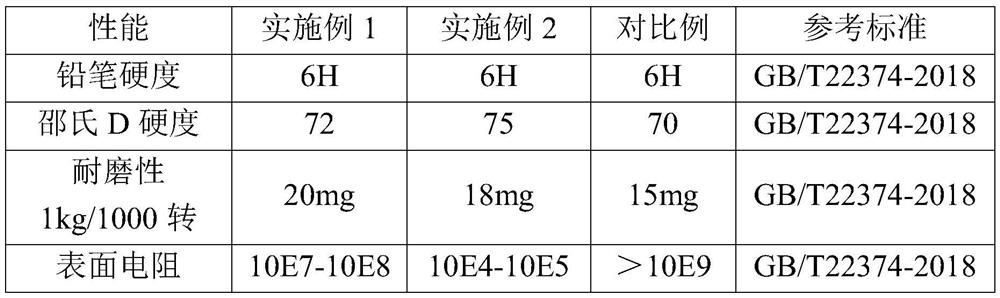

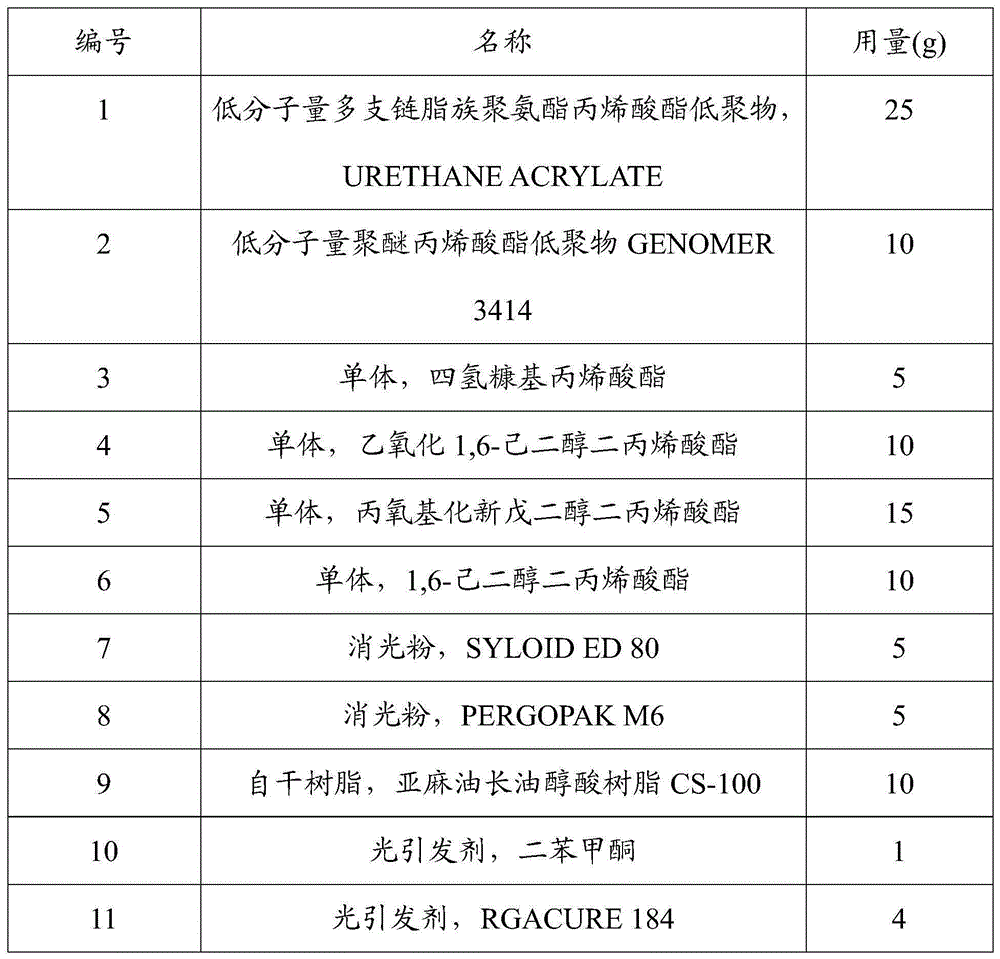

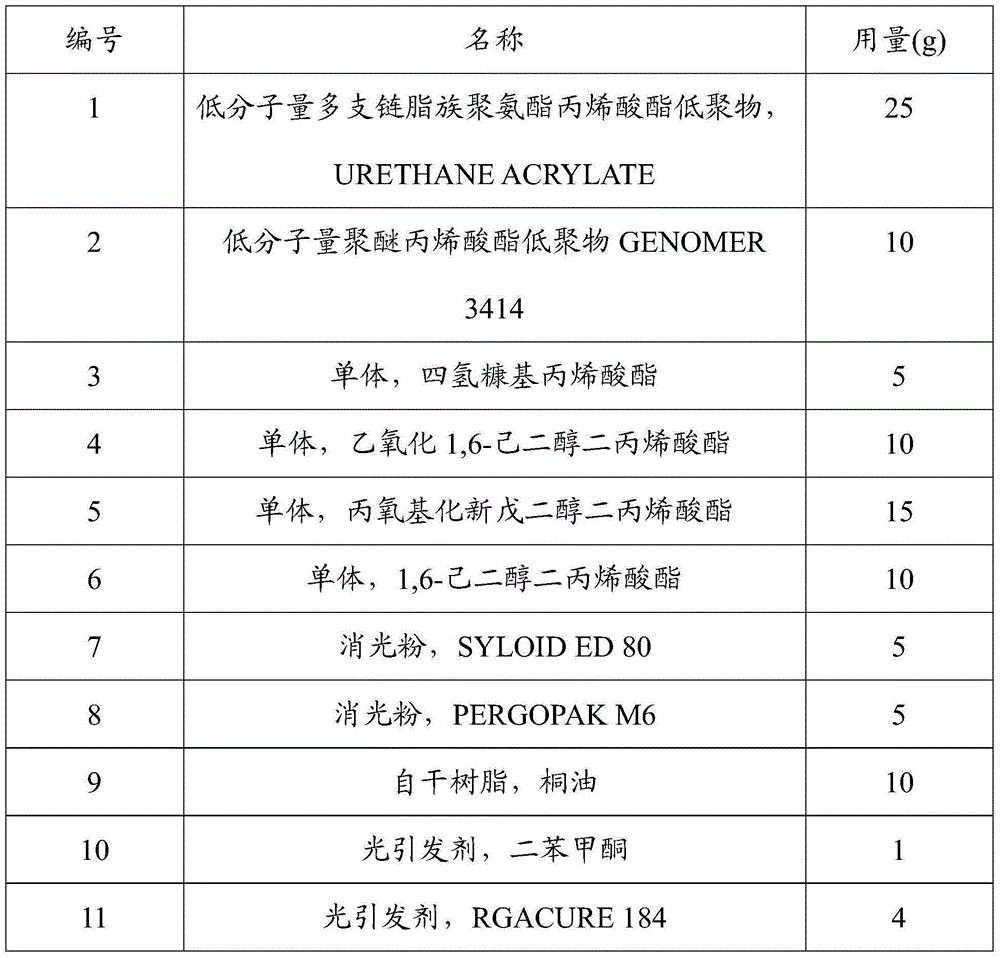

Dual-cured matte paint system

ActiveCN105907286AReduce glossNatural Matte AppearancePolyurea/polyurethane coatingsPolyether coatingsDual cureOligomer

The invention discloses a dual-cured matte paint composition. The composition comprises an irradiation curing component, an air drying component and a delustering agent. The irradiation curing component comprises one or more oligomers, one or more monomers and a photoinitiator. The air drying component comprises long oil alkyd resin and / or natural drying oil and / or polymerized natural oil. The invention discloses a method for preparing the dual-cured matte paint composition and a base at least partially coated with the dual-cured matte paint composition.

Owner:PPG COATINGS TIANJIN

Cloth-grain-imitated PVC mat and preparation method thereof

InactiveCN112318982ARaise the gradeDense surfaceSynthetic resin layered productsFlat articlesComposite materialCeramic materials

The invention discloses a cloth-grain-imitated PVC mat and a preparation method thereof. The cloth-grain-imitated PVC mat comprises a base layer and a printed surface layer, wherein the base layer comprises a PVC foamed layer and base cloth embedded in the PVC foamed layer, wherein the printed surface layer is attached to the PVC foamed layer, the printed surface layer comprises a PVC surface layer body and a printed layer body, the PVC surface layer body is prepared through calendaring molding, and the printed layer is a cloth-grain-imitated printed layer. The preparation method comprises thesteps of preparation of the printed surface layer, preparation of the base layer and composite foaming. According to the cloth-grain-imitated PVC mat and the preparation method thereof, the purpose of printing special grains and patterns on the PVC mat is achieved by arranging the printed surface layer and the base layer which are made of PVC materials; the PVC surface layer is prepared through acalendering forming process, so curling and pattern printing are facilitated; a calendered PVC film is good in binding force with the base layer and ink and does not fall off; and the printed surfacelayer obtained after printing not only has excellent wear resistance and scratch resistance, but also has an ornamental effect, so the grade of the PVC mat is greatly improved.

Owner:广东远华新材料股份有限公司

Chloroethylene-butyl acrylate-hydroxypropyl acrylate copolymer emulsion and preparation method thereof

ActiveCN102977248BGood abrasion resistance and scratch resistanceHigh glossInksCoatingsWater basedPotassium persulfate

The invention relates to chloroethylene-butyl acrylate-hydroxypropyl acrylate copolymer emulsion and a preparation method thereof, and mainly relates to a water-based industrial coating for water-based ink base materials, belonging to the technical field of industrial coatings. The copolymer emulsion is prepared by taking chloroethylene, butyl acrylate and hydroxypropyl acrylate as monomers, sodium dodecyl benzene sulfonate, sodium dodecyl sulfate and nonionic surfactants OP-100 and OP-4 as emulsifying agents, PVPK-30 as a colloid protecting agent and water-soluble potassium persulfate and ammonium persulfate as initiating agents to carry out polymerization. The copolymer emulsion has the advantages that compared with other water-based coatings, the copolymer emulsion, used as a water-based industrial coating, has better waterproofing property and acid, alkali and salt corrosion resistance, hard and tough film, good wear and scratching resistance, high gloss and relatively low cost, has qualified mechanical stability, calcium ion stability and heat stability and is free from demulsification and delamination after being stored for a year.

Owner:WUXI HONGHUI NEW MATERIALS TECH

Method for manufacturing wear-resisting corrosion-resistant inner surface of wall of integrated bathroom

The invention discloses a method for manufacturing a wear-resisting corrosion-resistant inner surface of a wall of an integrated bathroom. The method comprises the following steps that the surface of the inner wall is cleaned up; a layer of UV photocuring shadow-less glue is evenly smeared on the board surface of the inner wall; a surface-course high-transmittance acrylic hard sheet or high-transmittance hard and half-hard PVC wear-resisting sheet is attached to the glue, squeezing is conducted till no bubble exists in the middle, and attaching is conducted smoothly; irradiation is conducted by utilizing an ultraviolet photocuring lamp for 10 s, so that photocuring is conducted on the UV photocuring shadow-less glue. According to the method for manufacturing the wear-resisting corrosion-resistant inner surface of the wall of the integrated bathroom, compared with an original surface-high-transmittance surface layer, the texture of an original surface course can be well improved. Excellent wear-resisting, scratch-resistant and corrosion-resistant properties are achieved, meanwhile an adopted surface material is stain resistant, microbial resistant and easy to clean, and yellowing does not occur after long-term using; equipment and a technology used by the method are simple, the minimum time needed by curing of the adopted UV photocuring shadow-less glue is only 10 seconds, and the production efficiency is high; and the method can be applied to different walls, and promotion in the market is easy.

Owner:丰县正标卫浴有限公司

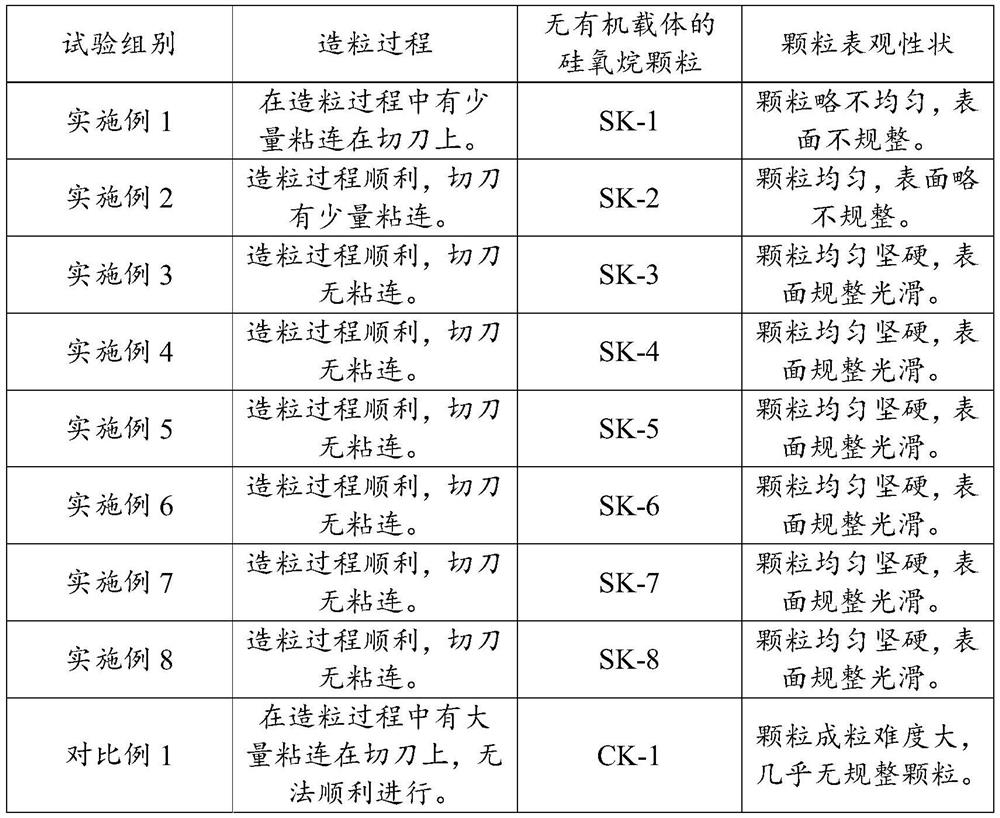

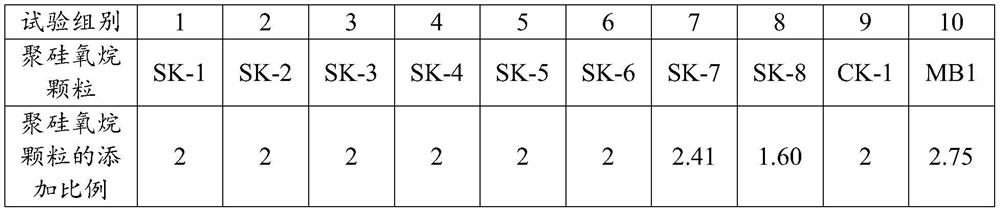

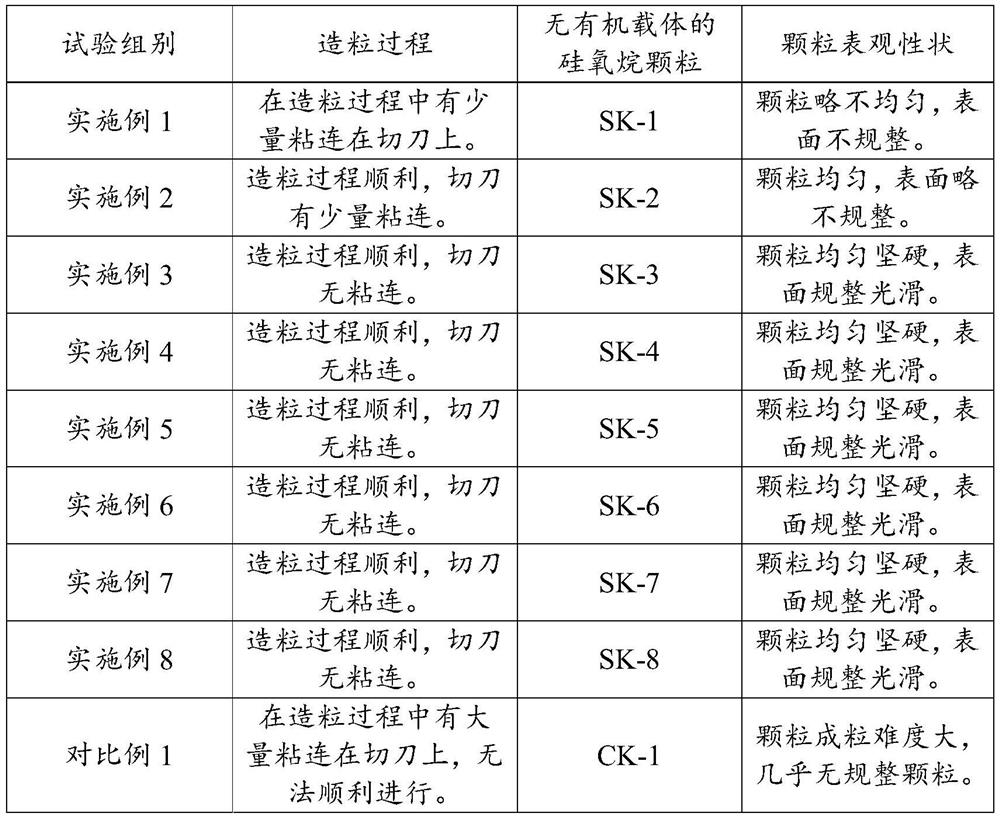

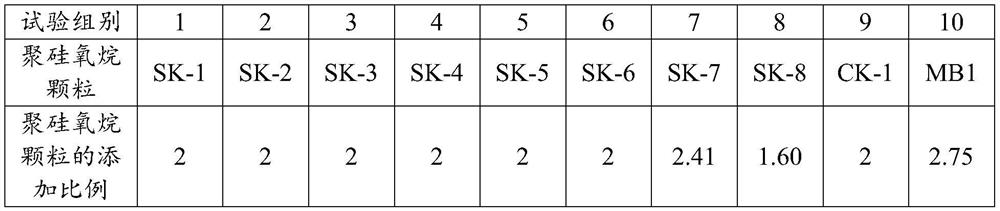

Inorganic-organic carrier polysiloxane particle and preparation method thereof

The invention belongs to the field of high polymer materials, and provides a preparation method of inorganic-organic carrier polysiloxane particles. The preparation method comprises the steps of S1, reacting and mixing polysiloxane, white carbon black, a grafting agent and a catalyst A in a kneading machine or an internal mixer to prepare a high viscosity polysiloxane composition, wherein the polysiloxane contains 0.02% to 0.2% of vinyl; and S2, mixing the high-viscosity polysiloxane composition prepared in the step S1 with a filler in the kneading machine or the internal mixer, and carrying out extrusion granulation to prepare the inorganic-organic carrier polysiloxane particles. The method is simple in technological process, safe and easy in raw material production and excellent in product performance, and has good application and popularization prospects. The invention also provides the inorganic-organic carrier polysiloxane particles prepared by the method, which are almost suitable for processing all thermoplastic resins, can improve the processing fluidity of the thermoplastic resins, and can improve the surface smoothness of products, reduce the surface friction coefficient,improve the wear resistance and scratch resistance and the like.

Owner:CHENGDU SILIKE TECH

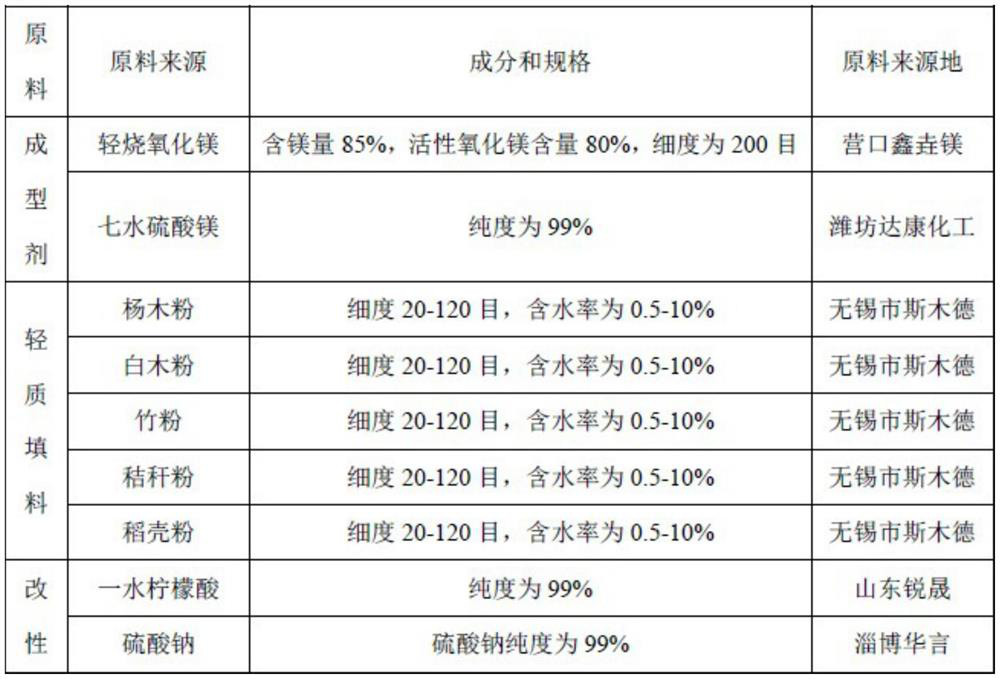

A kind of high whiteness mgo substrate, preparation method and decorative board with the substrate

ActiveCN111302757BReduce generationImprove internal bond strengthCovering/liningsSolid waste managementO-Phosphoric AcidPolyvinyl alcohol

The invention discloses a high-whiteness MGO substrate, a preparation method and a decorative plate with the substrate. A high-whiteness MGO substrate includes a surface layer and a substrate, and the substrate is composed of a forming agent, a lightweight filler, a modifier and water, and the parts by mass of each component are as follows: 40-49 parts of light-burned magnesium oxide powder, seven 18-25 parts of magnesium sulfate water, 16-25 parts of polyvinyl alcohol solution, 16-20 parts of plant powder, 0.5-2 parts of modifier; the modifier is citric acid: phosphoric acid: sodium sulfate by mass ratio The ratio of 10:3:6 is mixed; it has the advantages of high internal bonding strength and is not easy to peel and crack; the preparation method of this substrate has the advantages of simple preparation process, effectively improving the internal bonding strength of the substrate, and not easy to peel and crack; the decorative board It has the advantages of wide application range and good practicability.

Owner:JIANGSU LANGYUE NEW MATERIALS TECH CO LTD

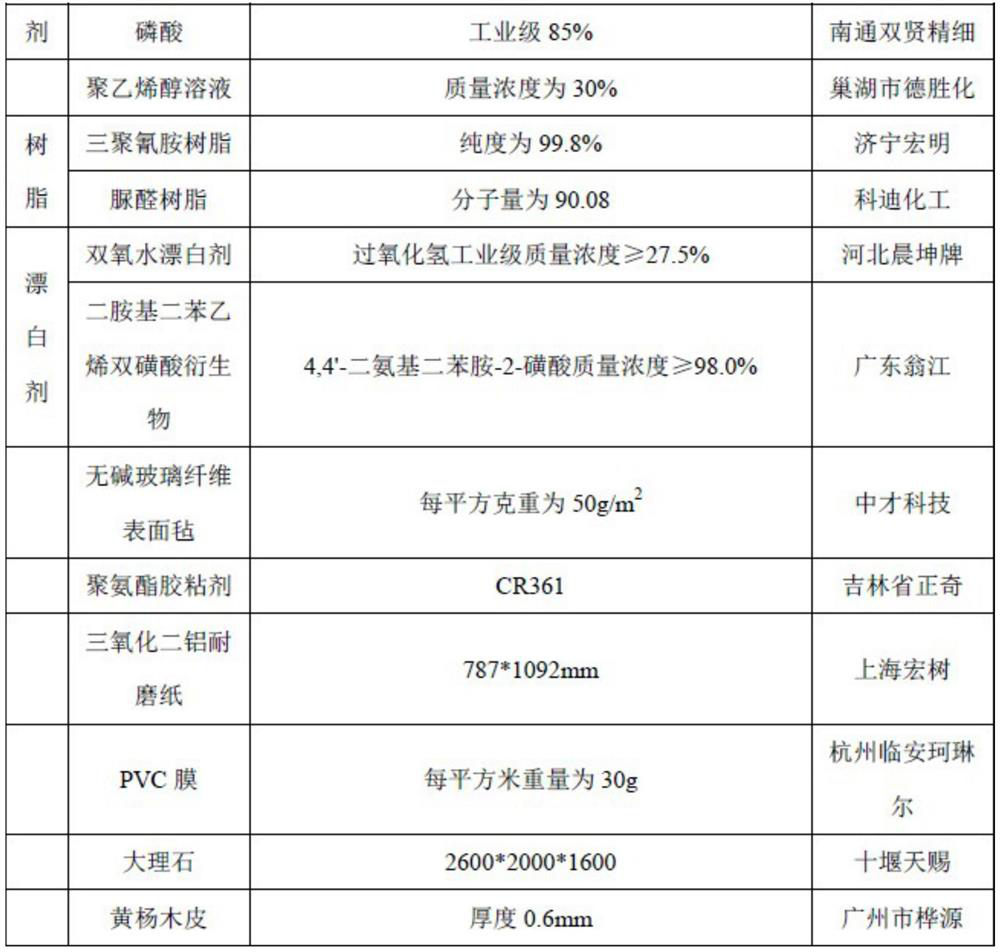

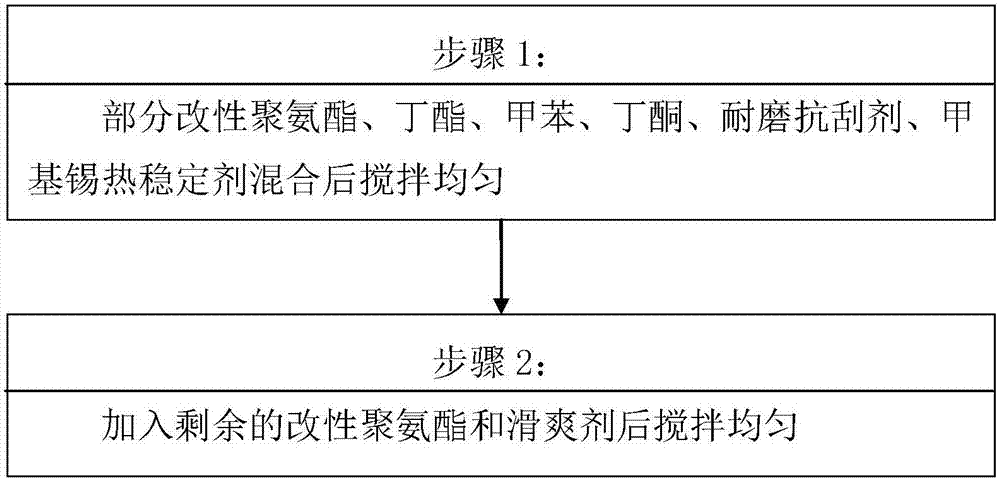

Injection molding wear-resisting and scratch-resisting glossy surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an injection molding wear-resisting and scratch-resisting glossy surface treatment agent for synthetic leather. The injection molding wear-resisting and scratch-resisting glossy surface treatment agent is used for an after-section printing technology and is prepared from the following components: modified polyurethane, butyl acrylate, methylbenzene, butanone, a wear-resisting and scratch-resisting agent, a tin methyl heat stabilizer and a slip agent. The invention further discloses a preparation method of the injection molding wear-resisting and scratch-resisting glossy surface treatment agent for the synthetic leather. All the components for forming the injection molding wear-resisting and scratch-resisting glossy surface treatment agent are mutually coordinated and interact; the leather prepared from the treatment agent has the advantages of natural luster, clear color, excellent injection molding effect, bright and transparent color, strong crystal feeling, excellent layering feeling, good touch effect of a treated leather surface, dry and cool hand feeling of the leather surface, good wear resistance and scratch resistance and excellent integrative effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

A kind of pvc synthetic leather for automotive interior

ActiveCN108016102BImproves UV resistanceImprove anti-aging functionSynthetic resin layered productsSuperstructure subunitsWear resistantAging resistance

The invention belongs to the technical field of leather and more specifically relates to PVC synthetic leather for automotive interior. The PVC synthetic leather comprises a PVC base layer, a first adhesion layer, an antibacterial layer, a second adhesion layer, an ultraviolet-proof layer, a third adhesion layer and a wear-resistant layer sequentially, wherein the antibacterial layer comprises thecomponents by weight as follows: 90%-98% of PVC resin, 0.1%-5% of chitosan and 0.1%-5% of a nano-silver antibacterial agent, the degree of deacetylation of the chitosan is 85%-95%, and the molecularweight of the chitosan is 0.1-0.2 million. Compared with the prior art, the PVC synthetic leather can have a good antibacterial effect by means of the antibacterial layer. Meanwhile, the ultraviolet-proof layer is arranged, so that the ultraviolet resistance of the synthetic leather can be improved, and the aging resistance of the synthetic leather can be improved; the PVC synthetic leather is endowed with good wear resistance and scratch resistance by means of the wear-resistant layer.

Owner:雄进塑料制品(东莞)有限公司

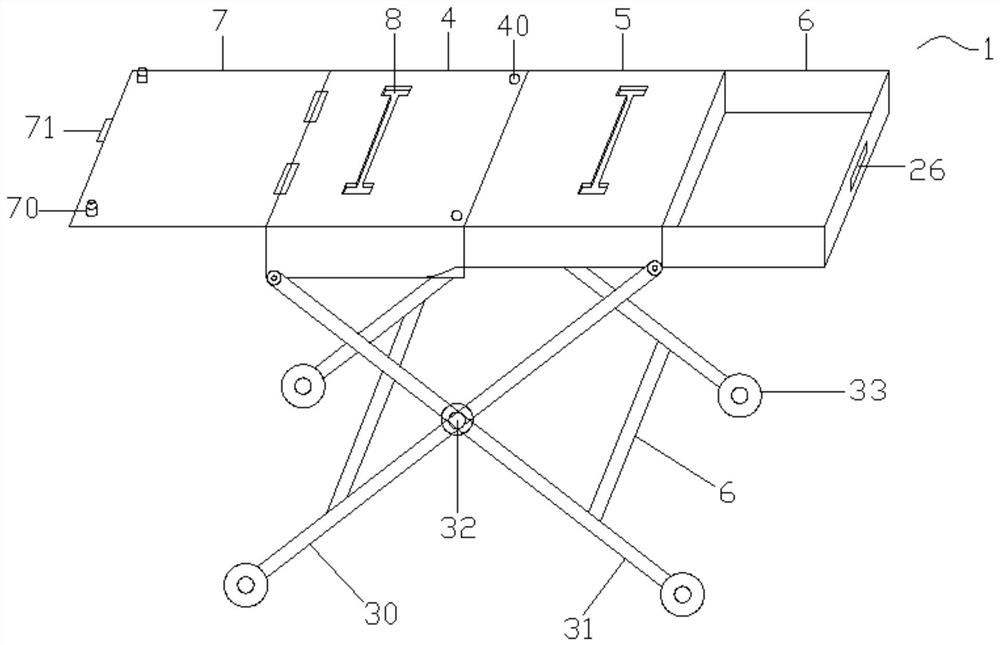

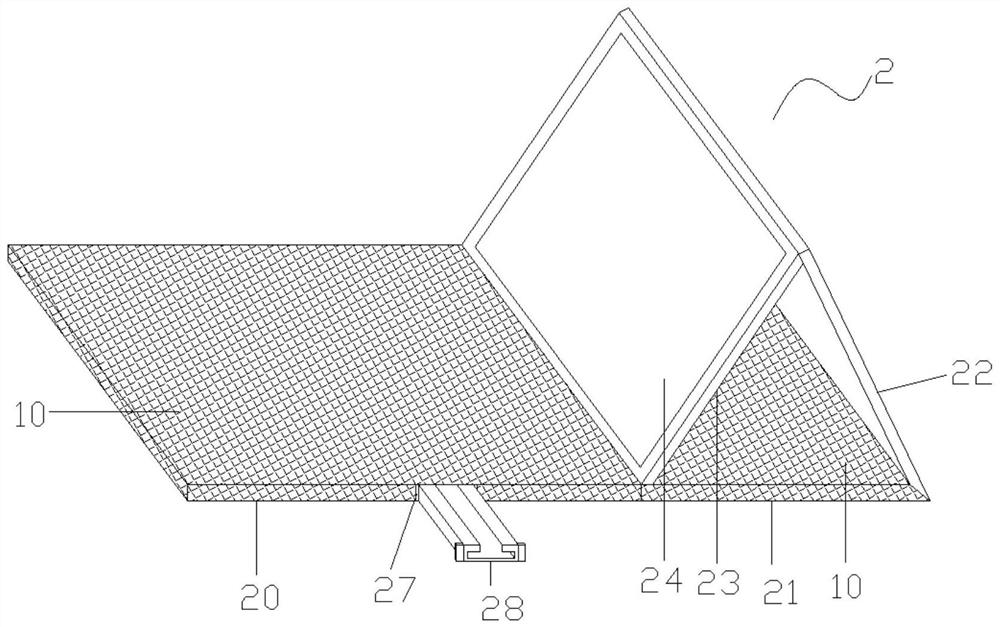

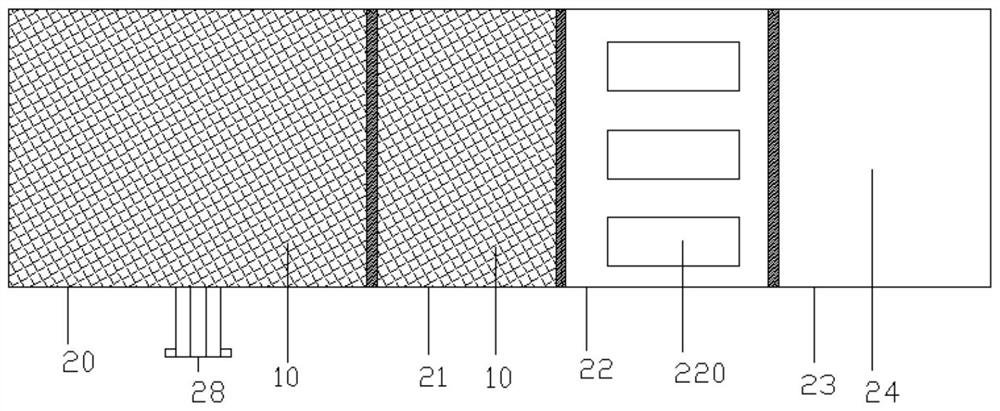

Vehicle-mounted mirror therapy device

InactiveCN108905081BHigh strengthImprove wear resistanceGymnastic exercisingEngineeringTreatment Vehicle

The invention discloses a vehicular mirror image treatment device which comprises a treatment cart body and a mirror image treatment instrument. The mirror image treatment instrument comprises a handrest plate, a first connecting plate, a second connecting plate and a protection sleeve plate which are sequentially connected in a folded manner, a plane mirror is arranged on the protection sleeve plate, multifunctional protection coating layers are arranged on the outer surfaces of the hand rest plate and the first connecting plate, and multifunctional protection coatings are sprayed on the outer surfaces of the hand rest plate and the first connecting plate and dried to obtain the multifunctional protection coating layers. According to the vehicular mirror image treatment device, the mirror image treatment instrument and the treatment cart body are combined, the device can be conveniently moved, outdoor mirror image treatment is facilitated, and rehabilitation training and treatment ofa patient can be conveniently achieved by the mirror image treatment instrument. The vehicular mirror image treatment device is reasonable in structure and convenient to use, mirror image treatment of the patient is facilitated, rehabilitation is accelerated, and the device has high popularization and application values.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

VCM (Vinyl Chloride Monomer)-2-EHA (ethylhexyl acrylate)-organosilicone copolymerization emulsion and preparation method thereof

ActiveCN102993849BGood abrasion resistance and scratch resistanceHigh hardnessAnti-corrosive paintsIsooctyl acrylateWater based

The invention relates to a VCM (Vinyl Chloride Monomer)-2-EHA (ethylhexyl acrylate)-organosilicone copolymerization emulsion and a preparation method thereof, and mainly relates to a production method of an emulsion used in a water-based industrial coating stock, belonging to the technical field of industrial coatings. According to the preparation method, with vinyl chloride, 2-ethylhexyl acrylate and vinyl trimethoxy silane as monomers and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, lauryl sodium sulfate and OP-4 as emulsifying agents and water-soluble ammonium persulfate as an initiating agent, the VCM-2-EHA-organosilicone copolymerization emulsion is prepared by a polymerization reaction. Compared with other water-based coatings, the VCM-2-EHA-organosilicone copolymerization emulsion has better water resisting property, acid-base salt corrosion resisting property, low cost and high performance cost ratio when used as a water-based industrial coating; in addition, a coating film is high and has wear and scratching resistance properties,. The VCM-2-EHA-organosilicone copolymerization emulsion is qualified in mechanical stability, calcium ion stability and heat stability, and is stored for one year without demulsification and demixing.

Owner:WUXI HONGHUI NEW MATERIALS TECH

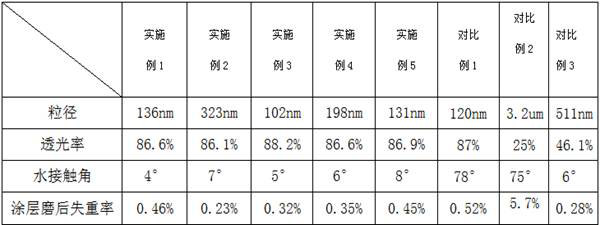

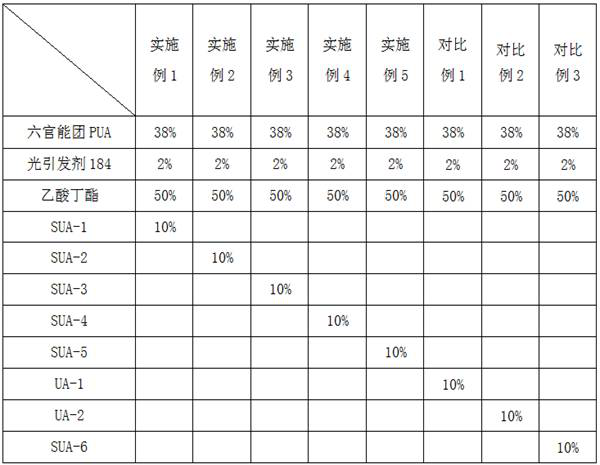

A kind of photocuring hydrophilic polyurea nanoparticle and its preparation method and application

ActiveCN112266457BSmall particle sizeOvercome optical performance effectsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a photocurable hydrophilic polyurea nanoparticle and its preparation method and application, comprising components: 10-43 parts of diamine, 13-40 parts of isocyanate, 50-150 parts of solvent, and acrylate with hydroxyl 2-15 parts, 2-15 parts of hydrophilic agent, 0.02-0.5 parts of catalyst, 0.02-0.5 parts of polymerization inhibitor. The present invention forms polyurea by reacting diamine and isocyanate, and then adds hydroxyl acrylate end cap and hydrophilic agent, thereby prepares a kind of polyurea nanoparticle with photocuring function, overcomes the organic microsphere widely used at present and the influence of inorganic nanoparticles on the optical properties of the coating. The coating made of the light-cured hydrophilic polyurea nanoparticles not only has good optical properties, but also can provide better wear and scratch resistance for the coating. Wipe and hydrophilic, anti-fog function.

Owner:SUMDA MATERIAL TECH CO LTD

Special washing branding discoloration resin for synthetic leather and preparation method thereof

ActiveCN103214821BThe branding part is clearIntense anxietyTextiles and paperPolymer scienceDimethylformamide

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Environment-friendly EVA synthetic leather subjected to surface graft treatment and preparation method thereof

PendingCN111593574AGood abrasion resistance and scratch resistanceEliminate organic pollutionTextiles and paperBonding strengthEthylene-vinyl acetate

The invention discloses environment-friendly EVA synthetic leather subjected to surface grafting treatment. The environment-friendly EVA synthetic leather sequentially comprises base cloth, an ethylene vinyl acetate copolymer (EVA) layer, a surface grafting treatment layer and a polyurethane lay from bottom to top. The invention also provides a corresponding preparation method of the environment-friendly EVA synthetic leather. The preparation method comprises the steps that firstly, raw materials of resin with EVA as a main body are cast onto the base cloth, and subjected to radiation crosslinking to obtain an environment-friendly EVA synthetic leather Base; secondly, an environment-friendly surface grafting treatment agent is applied to the surface of the Base for treatment; and finally,the surface of the grafting treatment layer is coated with polyurethane slurry, and after drying and curing, the environment-friendly EVA synthetic leather with high bonding strength, good wear resistance and scratch resistance and other physical properties can be prepared. According to the synthetic leather produced by the preparation method of the invention, harmful chemicals such as organic solvents which are not friendly to the environment are not used in production processes of EVA raw material film casting, surface grafting treatment, polyurethane coating and the like, and organic pollution is eliminated from the source.

Owner:SHANGHAI HIUV APLLIED MATERIALS CO LTD

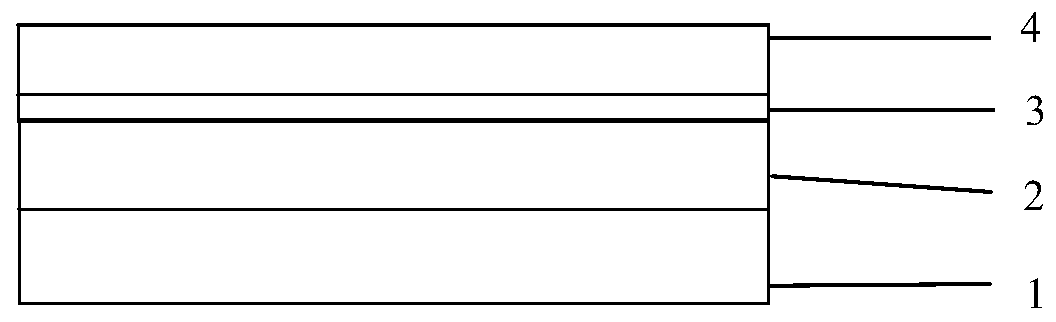

Silicon-based ecological functional polyurethane composite material and preparation method thereof

PendingCN114318891AAddressing limitations of standalone useSolve the problem of interface combinationTextiles and paperSports equipmentSolvent free

The invention discloses a silicon-based ecological functional polyurethane composite material and a preparation method thereof. The silicon-based ecological functional polyurethane composite material is sequentially composed of an organic silicon resin surface layer, a water-based PU middle layer, a solvent-free foaming bonding layer and base cloth from top to bottom. Wherein the organic silicon resin surface layer endows the surface of the material with natural anti-fouling performance and skin-friendly touch, and has high temperature resistance and ultraviolet aging resistance; the water-based PU middle layer has higher strength and toughness than those of a silicon-based material, so that the material is endowed with better wear resistance and scratch resistance; the solvent-free foaming bonding layer is small in density, good in rebound resilience and soft and plump in hand feeling after being combined with a cloth base, and the combination of the three layers endows the material with excellent comprehensive performance. According to the preparation method, the limitation of independent use of an organic silicon material and a polyurethane material is solved, the problem of interface bonding of the organic silicon and the polyurethane material is also solved, and the prepared product can be widely applied to the fields of engineering decoration, home furnishing, medical treatment, electronics, sports equipment and the like.

Owner:ANHUI ANLI MATERIAL TECH

A kind of organic carrier-free polysiloxane particle and preparation method thereof

The invention belongs to the field of polymer materials, and provides a method for preparing polysiloxane particles without an organic carrier, comprising the following steps: S1. putting polysiloxane, white carbon black, grafting agent and catalyst A in a kneader or Reaction and mixing in an internal mixer to prepare a high-viscosity polysiloxane composition; the polysiloxane contains 0.02%-0.2% vinyl; S2. The high-viscosity polysiloxane composition prepared in step S1 The compound and the filler are mixed in a kneader or an internal mixer, extruded and granulated to prepare organic carrier-free polysiloxane granules. The method has the advantages of simple technological process, safe raw materials and easy production, excellent product performance, and good application and popularization prospects. The present invention also provides organic carrier-free polysiloxane particles prepared by the above method, which are suitable for processing almost all thermoplastic resins, can improve the processing fluidity of thermoplastic resins, and can improve the surface smoothness of products and reduce the surface Friction coefficient and improved wear resistance and scratch resistance, etc.

Owner:CHENGDU SILIKE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com