Environment-friendly EVA synthetic leather subjected to surface graft treatment and preparation method thereof

A surface grafting, environment-friendly technology, applied in the field of synthetic leather, can solve the problems of incompatibility, low adhesion strength, surface peeling, etc., and achieve the effects of good physical properties, elimination of organic pollution, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

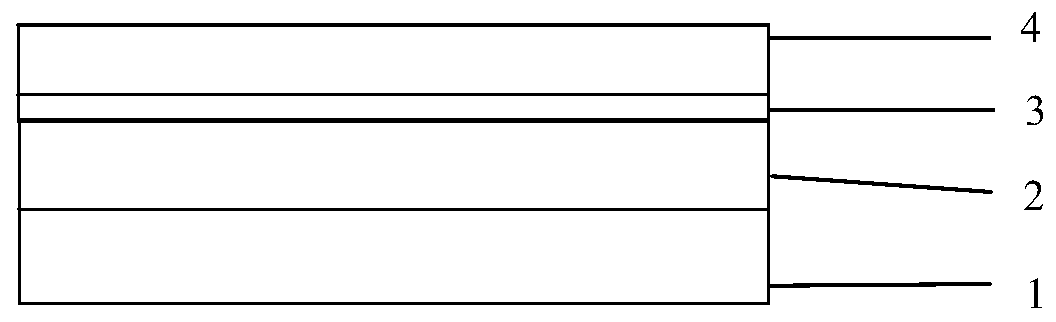

Image

Examples

Embodiment 1

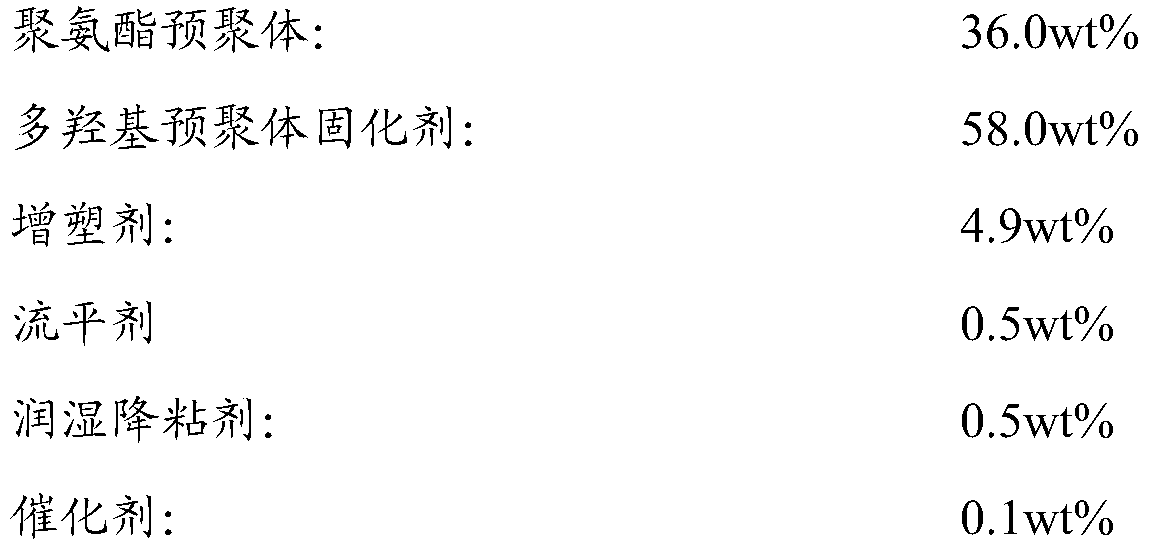

[0038] In the present embodiment, the surface graft treatment agent includes the following raw materials in terms of weight percentage:

[0039]

[0040] Wherein the isocyanate content of the polyurethane prepolymer is 14.5%, and the hydroxyl value of the curing agent is 80mgKOH / g;

[0041] The conventional formula of surface layer polyurethane slurry includes the following raw materials in terms of weight percentage:

[0042] Solvent-free polyurethane prepolymer: 60.0wt%

[0043] Curing agent: 39.9wt%

[0044] Catalyst: 0.1wt%

[0045] Wherein the isocyanate content of the polyurethane prepolymer is 2.3%, and the hydroxyl value of the curing agent is 40mgKOH / g;

[0046] The preparation of environment-friendly type through surface grafting treatment EVA synthetic leather comprises the following steps:

[0047] 1) prepare the relevant raw materials of EVA layer, wherein the content of EVA is 50wt%;

[0048] 2) After fully mixing the raw materials, add them into an extru...

Embodiment 2

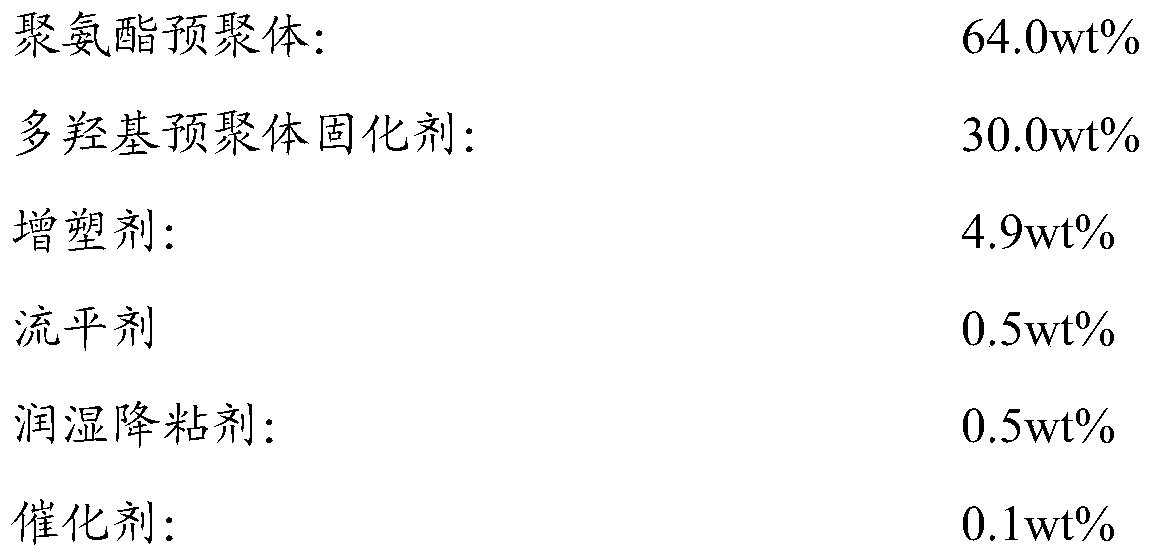

[0053] In the present embodiment, the surface graft treatment agent includes the following raw materials in terms of weight percentage:

[0054]

[0055] Wherein the isocyanate content of the polyurethane prepolymer is 15.0%, and the hydroxyl value of the curing agent is 210mgKOH / g;

[0056] The preparation of environment-friendly type through surface grafting treatment EVA synthetic leather comprises the following steps:

[0057] 1) prepare the relevant raw materials of EVA layer, wherein the content of EVA is 60wt%;

[0058] 2) After fully mixing the raw materials, add them into an extruder, extrude them into a film, cast them on the base cloth, flatten them and wind them up;

[0059] 3) Carry out radiation crosslinking, the crosslinking degree of EVA layer is 72%, obtains environment-friendly EVA synthetic leather Base;

[0060] 4) Pre-treat a layer of environmentally friendly surface graft treatment agent on the surface of the environmentally friendly EVA synthetic le...

Embodiment 3

[0063] In the present embodiment, the surface graft treatment agent includes the following raw materials in terms of weight percentage:

[0064]

[0065] Wherein the isocyanate content of the polyurethane prepolymer is 10.5%, and the hydroxyl value of the curing agent is 400mgKOH / g;

[0066] The preparation of environment-friendly type through surface grafting treatment EVA synthetic leather comprises the following steps:

[0067] 1) prepare the relevant raw materials of EVA layer, wherein the content of EVA is 78wt%;

[0068] 2) After fully mixing the raw materials, add them into an extruder, extrude them into a film, cast them on the base cloth, flatten them and wind them up;

[0069] 3) Carry out radiation cross-linking, the cross-linking degree of EVA layer is 90%, obtains environment-friendly EVA synthetic leather Base;

[0070] 4) Pre-treat a layer of environmentally friendly surface graft treatment agent on the surface of the environmentally friendly EVA synthetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com