A kind of photocuring hydrophilic polyurea nanoparticle and its preparation method and application

A nanoparticle and hydrophilic technology, applied in the field of photocurable hydrophilic polyurea nanoparticle and its preparation, can solve the problems of easy precipitation, coating extinction, affecting the transparency of the coating, etc. Good optical performance, good wear resistance and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

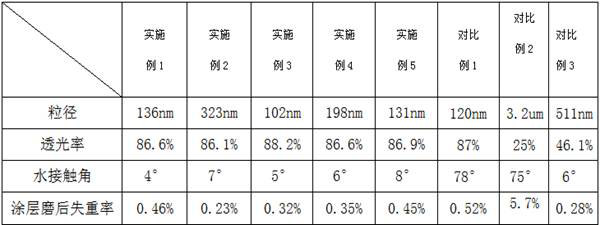

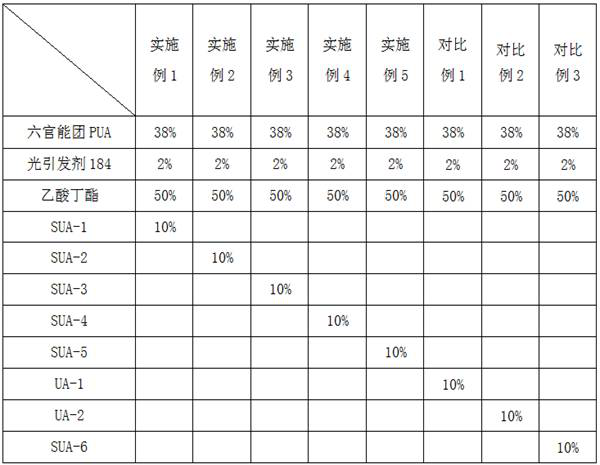

Examples

Embodiment 1

[0034] Add 100 parts of toluene / butanone (weight ratio 1:2) into the reactor, then add 30 parts of isophorone diisocyanate, stir and disperse while cooling down to -10°C, add 18.2 parts of isophorone diisocyanate dropwise Amine, control the temperature below 10°C, after the dropwise addition, keep warm, and disperse at high speed for 2 hours; add 0.2 parts of p-hydroxyanisole, 0.1 part of organotin catalyst, 3 parts of hydroxyethyl acrylate, heat up to 70°C, and keep warm for 2 hours ; Add 3.2 parts of 4-hydroxybutyl sulfonic acid, heat up to 90°C, and keep warm for 2 hours; cool down to room temperature, filter, add 50 parts of toluene / butanone (weight ratio 1:2) to the filter cake, ultrasonically disperse, filter, Dry to obtain light-cured hydrophilic polyurea nanoparticles SUA-1.

Embodiment 2

[0036] Add 100 parts of methylcyclohexane / butyl acetate (weight ratio 1:1) into the reactor, then add 36 parts of dicyclohexylmethane diisocyanate, stir and disperse while cooling down to -10°C, dropwise add 16.1 part of isophorone diamine, control the temperature to less than 10°C, after the dropwise addition, keep warm, and disperse at high speed for 2 hours; add 0.2 part of p-hydroxyanisole, 0.1 part of organic tin catalyst, 3.5 parts of hydroxybutyl acrylate, and heat to 70°C, keep warm for 2 hours; add 5 parts of sodium cyclamate, keep warm at 70°C for 2 hours; cool down to room temperature, filter, add 50 parts of methylcyclohexane / butyl acetate (total ratio 1 : 2), ultrasonically dispersed, filtered, and dried to obtain light-cured hydrophilic polyurea nanoparticles SUA-2.

Embodiment 3

[0038] Add 125 parts of toluene / butyl acetate (mass ratio 1:2) into the reactor, then add 25 parts of hexamethylene diisocyanate, stir and disperse while cooling down to 0°C, add 26.8 parts of dodecane binary Amine, control the temperature below 15°C, after the dropwise addition, keep warm, and disperse at high speed for 1.5 hours; add 0.2 parts of p-hydroxyanisole, 0.1 part of organotin catalyst, 4 parts of caprolactone acrylate, heat up to 80°C, and keep warm for 2 hours ; Add 5 parts of sodium hexamethylenediaminohexacarboxylate, keep warm at 80°C for 2 hours; cool down to room temperature, filter, add 50 parts of toluene / butyl acetate (mass ratio 1:2) to the filter cake, ultrasonically disperse, filter, and dry Dry to obtain photocurable hydrophilic polyurea nanoparticles SUA-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com