Patents

Literature

59results about How to "Good anti-fog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

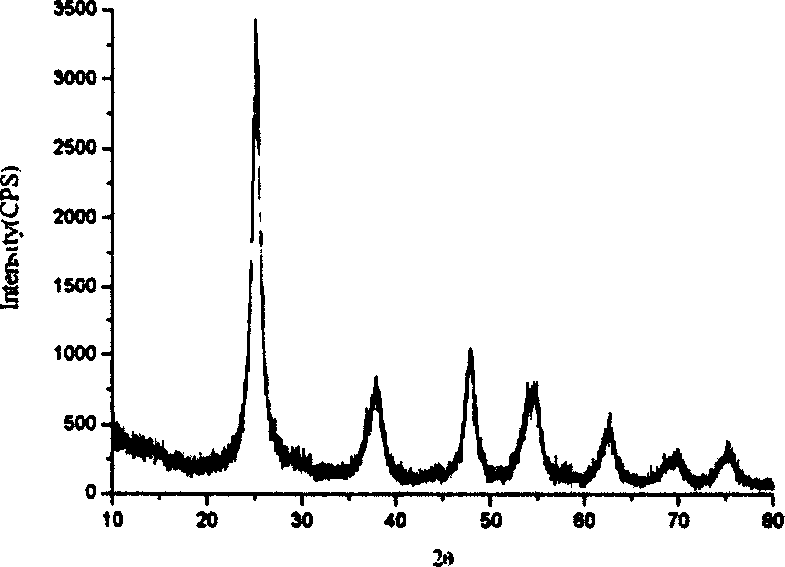

Preparation method of super-hydrophobic coating layer on aluminum surface

ActiveCN105521934AImprove hydrophobicityGood anti-fogPretreated surfacesLiquid/solution decomposition chemical coatingAcid etchingSilanes

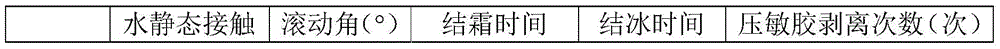

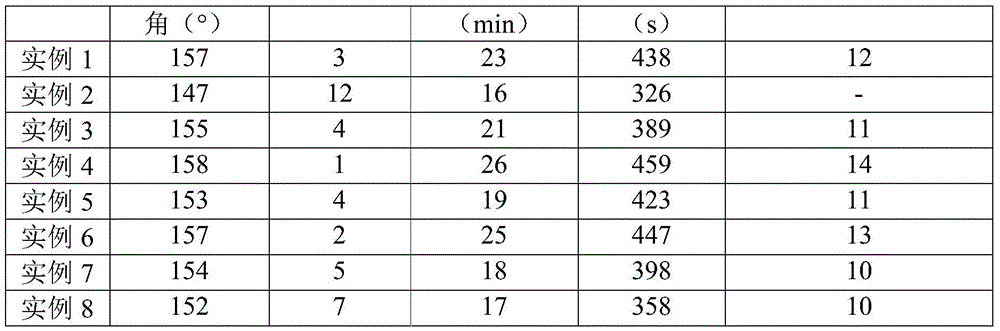

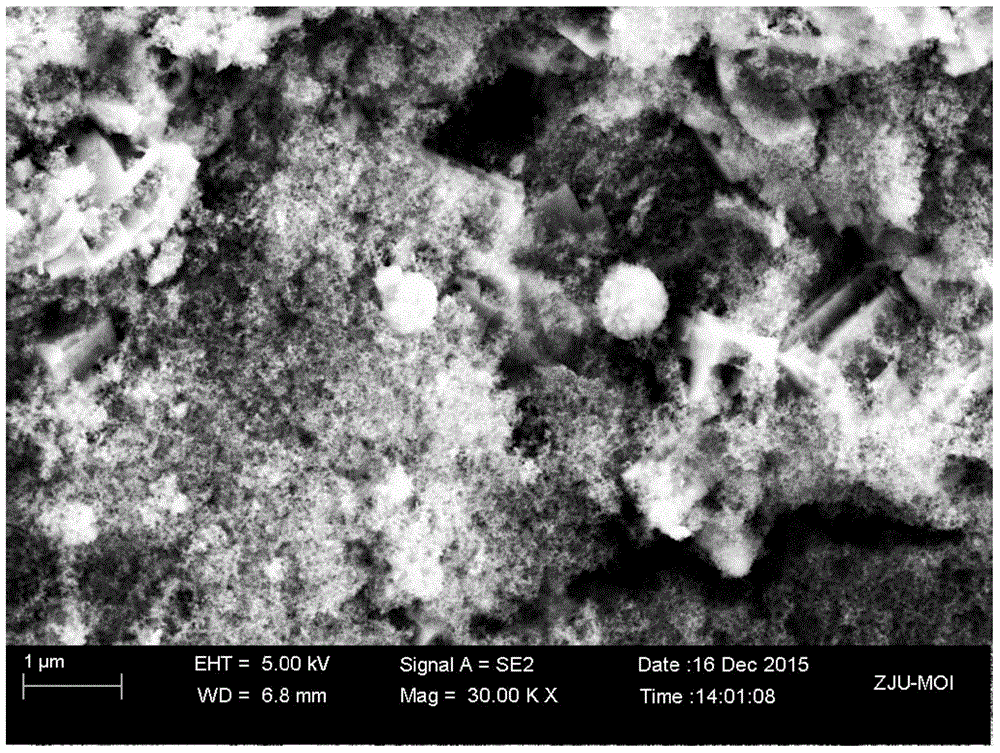

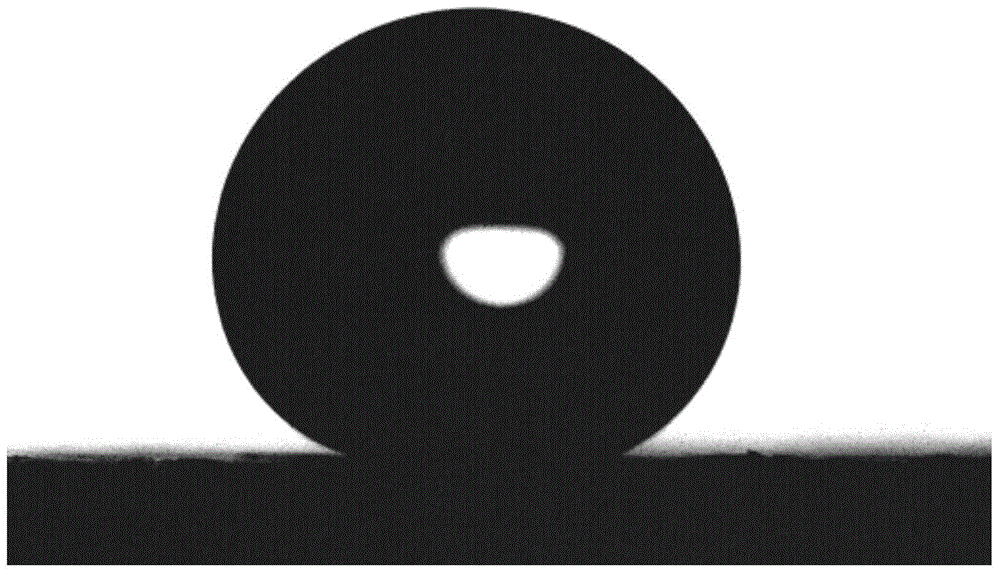

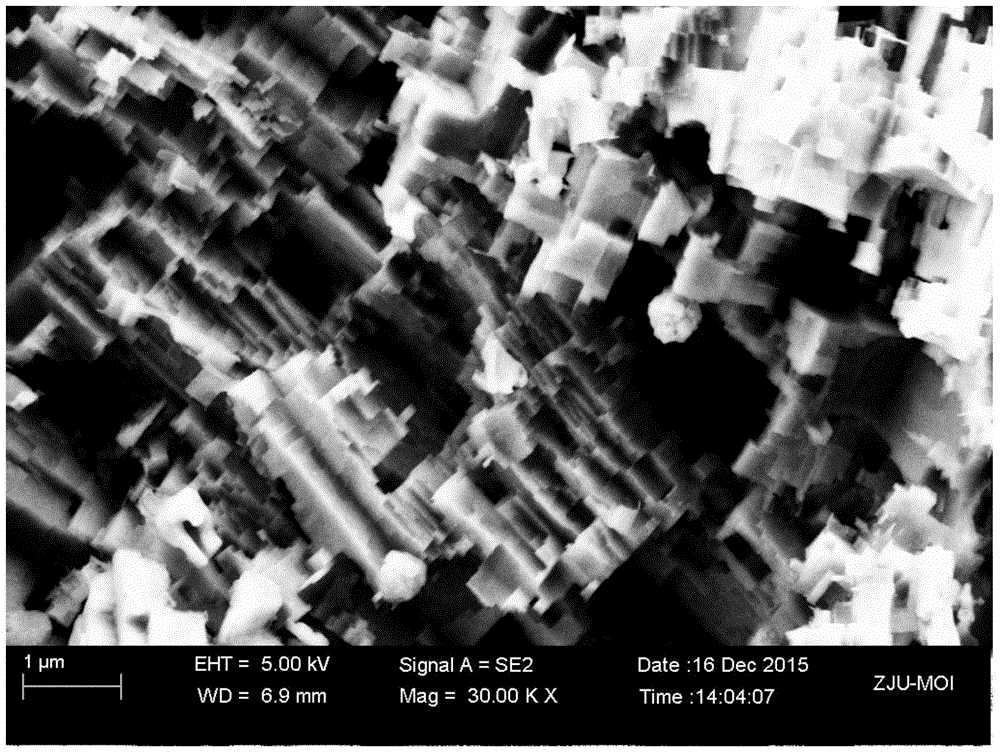

The invention discloses a preparation method of a super-hydrophobic coating layer on an aluminum surface. The preparation method mainly comprises the following steps: (1) an aluminum piece is polished by an abrasive paper, is ultrasonically cleaned for 10 minutes by acetone and ethanol, is washed by distilled water to remove oil stains on the surface, and is dried in an oven; (2) the aluminum piece is dip in an acid etching agent for etching to obtain the aluminum surface with a micron rough structure; (3) the micron rough aluminum piece is dip in nanometer TiO2 particle solution, and is treated at high temperature to obtain the aluminum surface with a micron-nanometer composite rough structure; and (4) the aluminum surface with the micron-nanometer composite rough structure is treated by fluorine silane with low surface energy to obtain the aluminum surface with super-hydrophobic performance. The prepared super-hydrophobic aluminum piece is excellent in self-cleaning performance, fog resistance and ice covering resistance, and can be applied to field of ice covering prevention.

Owner:ZHEJIANG UNIV

Normal temperature solidified titania sol

InactiveCN1530326ALow costNo operating temperatureTitanium dioxideColloidal chemistry detailsPhysical chemistryPeptization

A TiO2 sol able to be solidified at ordinary temp to become anatase crystal type TiO2 is prepared through hydrolyzing the compound of inorganic titanium to obtain spontaneous crystal seed, ordinary-pressure hydrolyzing inorganic titanium compound under the action of said crystal seed to obtain white deposit, and dissolving in inorganic acid. Its advantages are low cost, low operation temp, and no pollution.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparing method for aluminum surface super-hydrophobic coating with micro-nano composite structure

InactiveCN105689236AImprove hydrophobicityGood anti-fogPretreated surfacesSpecial surfacesAcid etchingMicro nano

The invention discloses a preparing method for an aluminum surface super-hydrophobic coating with a micro-nano composite structure. The method mainly comprises the steps that firstly, an aluminum sheet is ultrasonically cleaned for 10 min through acetone and methylbenzene and then flushed thoroughly through distilled water, and the aluminum sheet is dried in an oven at the temperature being 100 DEG C; secondly, the cleaned and dried aluminum sheet is immersed in an acid etching agent to be etched, and an aluminum surface with a micron rough structure is obtained; thirdly, after the etched aluminum sheet is ultrasonically cleaned thoroughly, the aluminum sheet is immersed in a nano particle solution, and after the aluminum sheet is treated at the high temperature, an aluminum surface with a micro-nano composite rough structure is obtained; and fourthly, after low-surface-energy fluorosilicone modified polyester resin is sprayed to the aluminum surface with the micro-nano composite rough structure, an aluminum surface with super-hydrophobic performance can be obtained. The super-hydrophobic aluminum sheet prepared through the preparing method has the superior icing preventing performance and very good mechanical strength and can be applied to an air conditioner heat exchange sheet, and frosting and icing of the heat exchange sheet are effectively restrained.

Owner:ZHEJIANG UNIV

Film and Bag specially for keeping fresh of Jinling jujube

InactiveCN101040631AEffective regulationStable best conditionFruits/vegetable preservation by coatingHigh pressureZiziphus jujuba

Disclosed are special-purpose films and bags for the fresh-keeping of jujubes, wherein the constituents of the raw materials include (by weight portions) linear polyvinyl resin (LLDPE) 100, high-tension polyvinyl resin (LDPE) 50-100, ethylene-vinyl acetate resin (EVA) 15-25, 10% antifog pellets (MD / PE) 5-10, 20% silver-containing antibiotic pellets (Ag / PE) 5-10, 20% calcium carbonate pellets (CaCO3 / PE) 5-15 and 2-ethylhexyl oleate 0.2-1.

Owner:SHENYANG AGRI UNIV

Antiviral and antibacterial functional film and preparation method thereof

InactiveCN111732906AStrong antiviral and antibacterial effectExcellent anti-fingerprintAntifouling/underwater paintsFilm/foil adhesivesCombinatorial chemistryAnti bacterial

The invention discloses an antiviral and antibacterial functional film and a preparation method thereof, and relates to the technical field of functional films, the functional film comprises a base material, an antiviral and antibacterial coating fixed on the upper surface of the base material, and a low-viscosity organic adhesive layer fixed on the lower surface of the base material layer; the antiviral and antibacterial coating is obtained by coating a coating solution containing a nano inorganic / organic composite antiviral and antibacterial treatment agent and transparent resin on a base material. According to the invention, a reasonable process is adopted and formula raw materials such as transparent resin and the like are reasonably selected; therefore, the nano inorganic / organic composite antiviral and antibacterial treatment agent and the transparent resin are effectively mixed to prepare a composite material which can be used for coating liquid. The antiviral and antibacterialcoating forms phase separation, and the concentration of the nano inorganic / organic composite antiviral and antibacterial treatment agent gathered on the surface is high, so that a stronger antiviraland antibacterial effect is obtained, and the antiviral and antibacterial properties are uniform and long-acting.

Owner:TAIHU JINZHANG TECH CO LTD +1

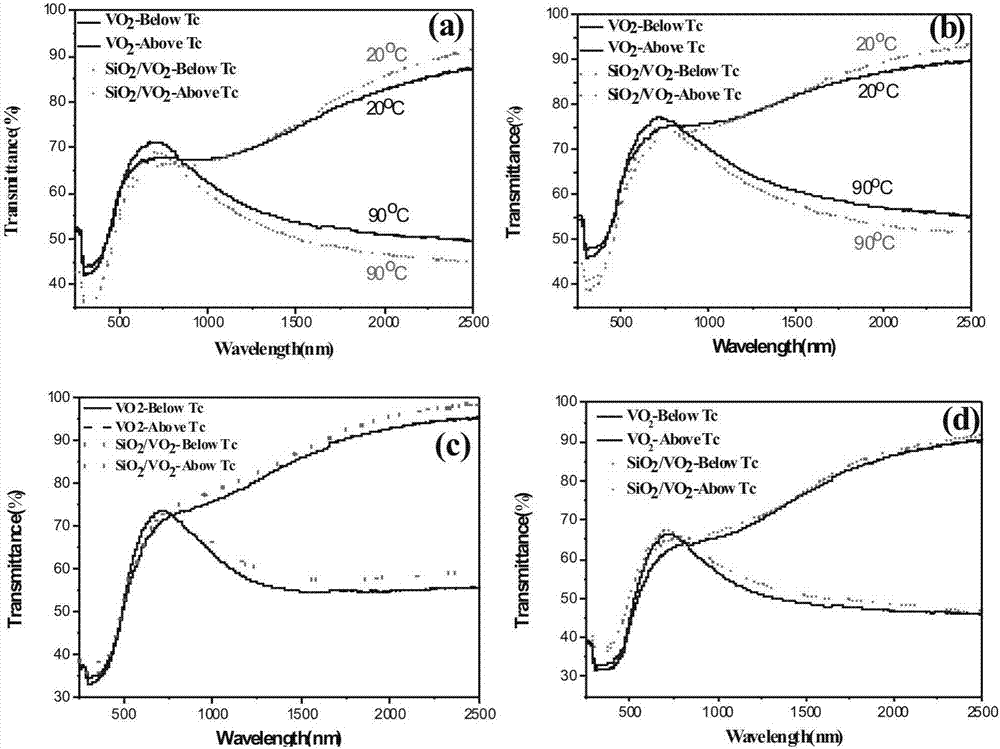

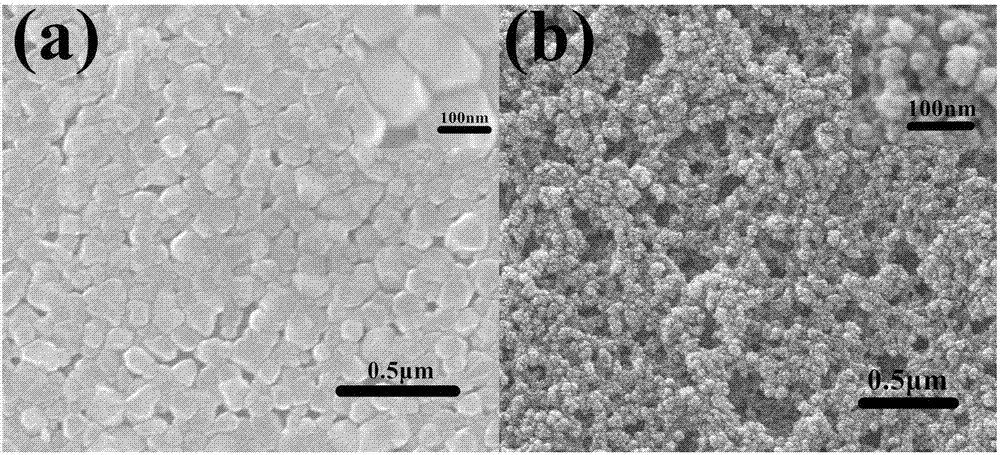

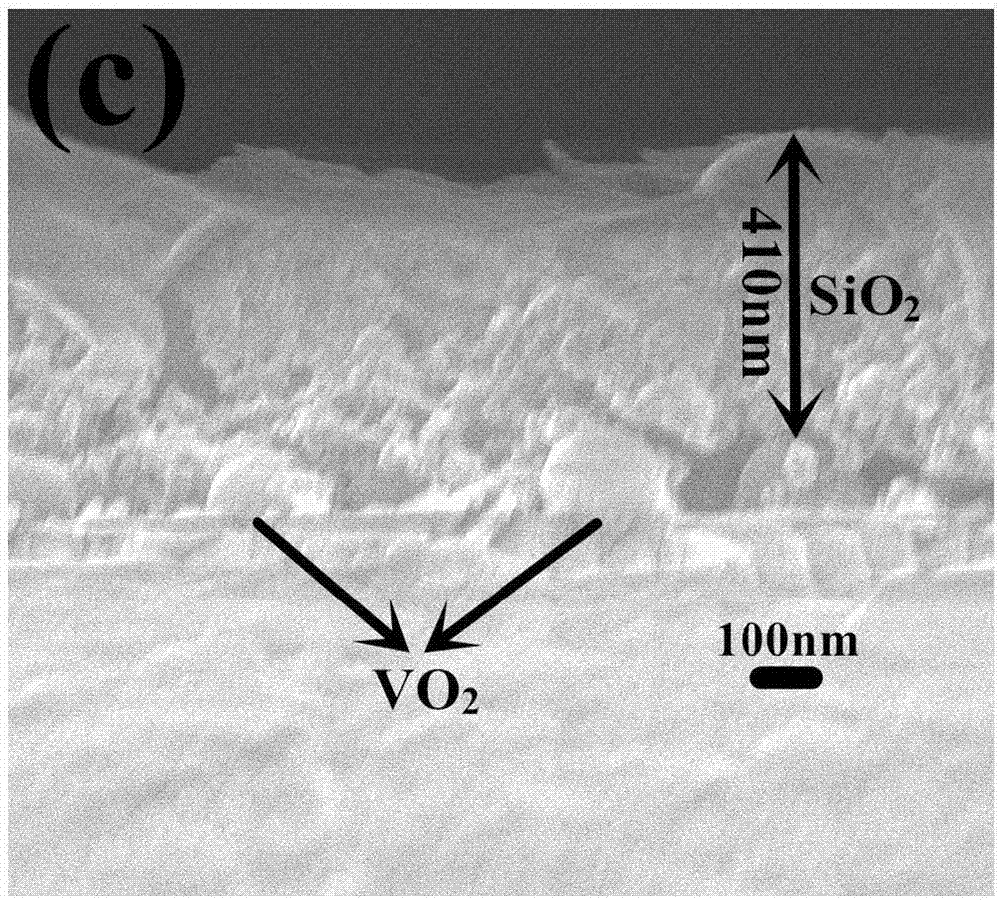

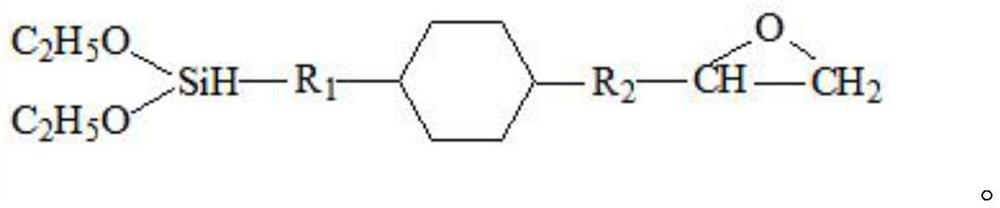

Intelligent temperature control vanadium dioxide composite film with enhanced infrared regulation capacity and preparation method thereof

InactiveCN107285640AExcellent Optical Switching CharacteristicsMeet the needs of lightingCoatingsVanadium dioxideTemperature control

The invention relates to an intelligent temperature control vanadium dioxide composite film with enhanced infrared regulation capacity. A vanadium dioxide film and a silicon dioxide film are compounded into the composite film; the silicon dioxide film is located on the surface layer; the silicon dioxide film has a nanometer porous structure which is formed by piling the SiO2 particles with hydrophobic groups on the surfaces; the grain size of the SiO2 particles is 10nm-50nm; the vanadium dioxide film is formed by irregular VO2 particle depositions; the grain size of the VO2 grain size is 20nm-150nm. According to the preparation method, the silicon dioxide gel is coated on the vanadium dioxide film surface and is annealed under an inert gas atmosphere. The intelligent temperature control vanadium dioxide composite film provided by the invention can keep excellent optical properties and self-cleaning function and meanwhile can greatly promote the infrared regulation capacity of the composite film.

Owner:HUBEI UNIV

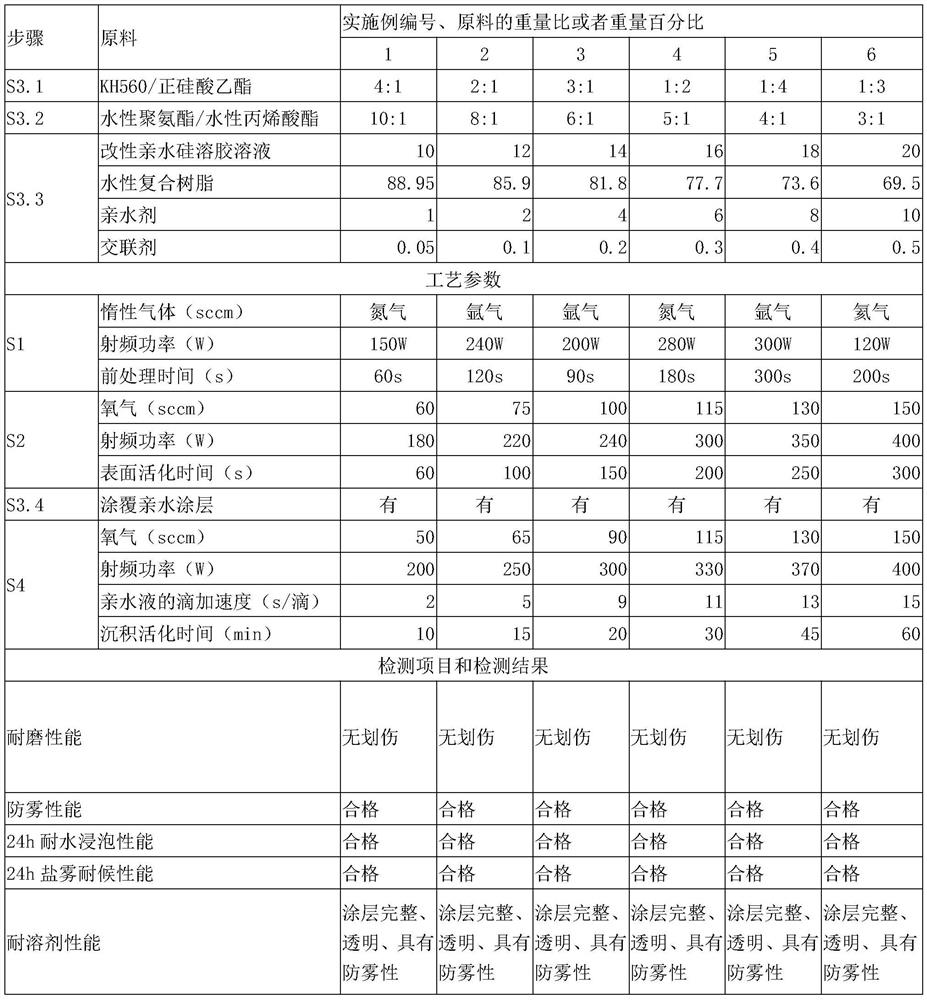

Plasma chemical vapor deposition nano super-hydrophilic anti-fog coating and preparation method thereof

PendingCN111992476AImprove hydrophilic effectImprove anti-fog performancePretreated surfacesAnti-corrosive paintsChemistryHydrophilic membrane

The invention relates to the technical field of chemical coatings, in particular to a plasma chemical vapor deposition nano super-hydrophilic anti-fog coating and a preparation method thereof. The method comprises the following steps that S1), cleaning is carried out on the surface of a base material; S2) activating is carried out on the surface of the base material; S3) a hydrophilic coating is prepared; and S4) a nano-deposition super-hydrophilic film is prepared; and deposition activation treatment is carried out on the hydrophilic coating, and the nano-deposition super-hydrophilic film isdeposited and adsorbed on the surface of the hydrophilic coating. The invention further provides the plasma chemical vapor deposition nano super-hydrophilic anti-fog coating prepared by the preparation method of the plasma chemical vapor deposition nano super-hydrophilic anti-fog coating, and the plasma chemical vapor deposition nano super-hydrophilic anti-fog coating has the characteristics of nopollution, safety and reliability, has excellent anti-fog, wear-resistant, water soaking-resistant, solvent-resistant and salt spray-resistant properties, and is long in service life. The nano-deposition super-hydrophilic film is a plasma chemical deposition nano hydrophilic film adsorbed on the outer surface of the hydrophilic coating.

Owner:FOSHAN SPRING TECH CO LTD

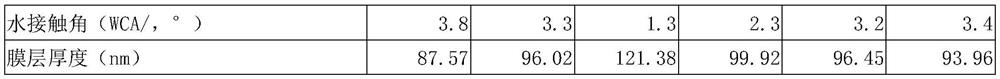

An aqueous antifogging resin, aqueous antifogging coating composition and preparation method thereof

ActiveUS20210071031A1Improve hydrophilicityGood hygroscopicityPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The present invention discloses an aqueous antifogging resin, introducing a molecular segment and a functional group with good hydrophilicity and hygroscopicity, which impart excellent antifogging performance, coating strength and transparent flow appearance to the aqueous antifogging resin and the cured coating has a water contact angle of up to 1˜10°. The present invention further discloses a coating composition including the aqueous antifogging resin, and the cured coating of the coating composition has good antifogging, wear-resistant, water-resistant, chemical resistant, stain-resistant and UV-resistant performance, and excellent adhesion to a substrate; and the coating is firm at the same time, and has excellent film-forming strength and flexual endurance. The coating composition can be used for antifogging surface treatment of the window of mobile phone, PC or PMMA transparent materials, automotive glass and bathroom mirrors and has good long-term stability.

Owner:HUNAN SOKAN NEW MATERIAL

Lens optical coating surface treatment process and lens obtained by process

InactiveCN110093587AExtended service lifeEasy to useVacuum evaporation coatingSputtering coatingOptical coatingEvaporation

The invention provides a lens optical coating surface treatment process and a lens obtained by the process. The process comprises the following steps of (1), performing plasma bombardment on the surface of the lens to activate a substrate; (2), preparing a coating material, specifically, ion-assisted plating is adopted; (3), performing electron beam evaporation plating to obtain a waterproof film;(4), preventing evaporation AF; and (5) standing. The process is simple, the properties of all aspects of the obtained lens are improved, and new technical requirements can be met. The obtained lens(such as a sunglass lens) is easy to clean, good in waterproof and antifogging performance and not likely to scratch, and the service time of the obtained lens is prolonged.

Owner:湖南宏泰新材料有限公司

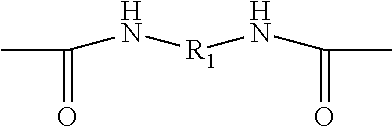

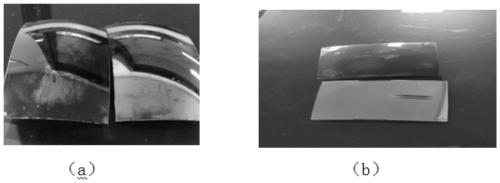

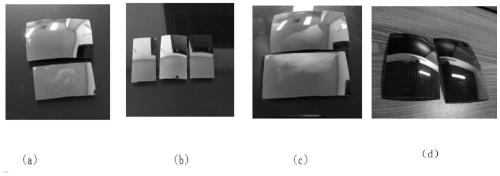

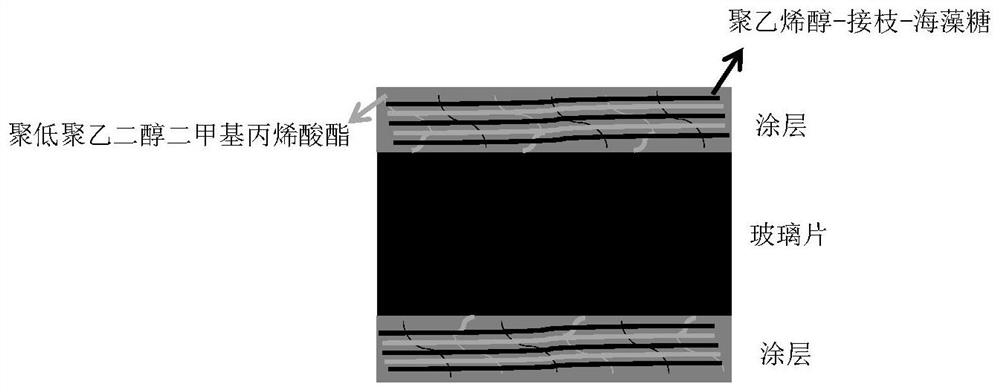

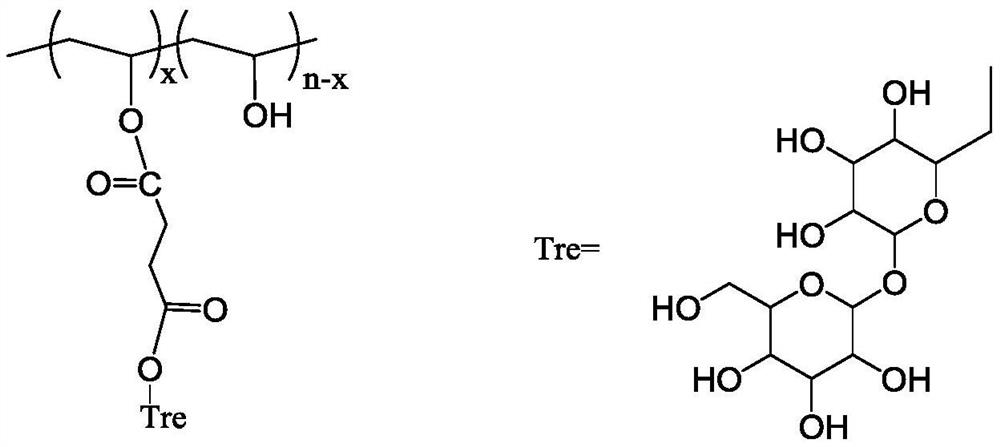

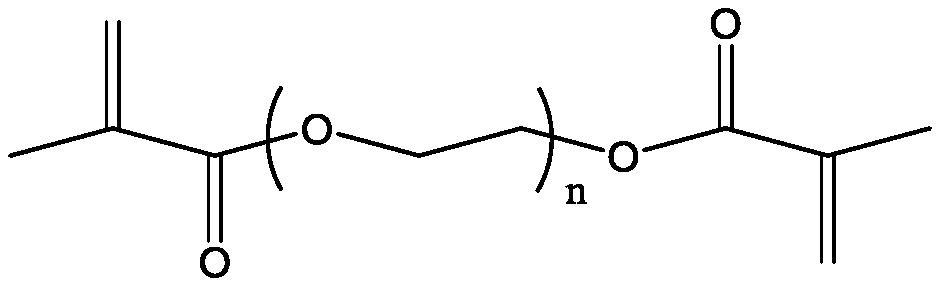

Trehalose modified polyvinyl alcohol anti-fog and anti-frost coating and preparation method thereof

ActiveCN113004730AGood anti-fogFast curingOther chemical processesCoatingsMethacrylatePolyvinyl alcohol

The invention relates to a trehalose modified polyvinyl alcohol anti-fog and anti-frost coating and a preparation method thereof. The coating is prepared from polyvinyl alcohol-grafted-trehalose, low polyethylene glycol dimethacrylate, benzoin dimethyl ether and deionized water; the materials are uniformly mixed and coated on a transparent glass sheet, and the mixture is irradiated and cured by ultraviolet light to form the hydrophilic graft polymer semi-interpenetrating network coating. According to the prepared anti-fog and anti-frost coating, the light transmittance can be kept at 89-90% in the anti-fog process, the anti-frost time can be prolonged by 9-31 min, and the light transmittance value of the glass sheet coated with the coating on the two sides at the wave band of 400-800 nm is calculated by using a visible spectrophotometer. Good anti-fog and anti-frost performance is realized. The preparation method is simple and convenient and mild in reaction, and has great application potential in the field of fog and frost prevention.

Owner:TIANJIN UNIV

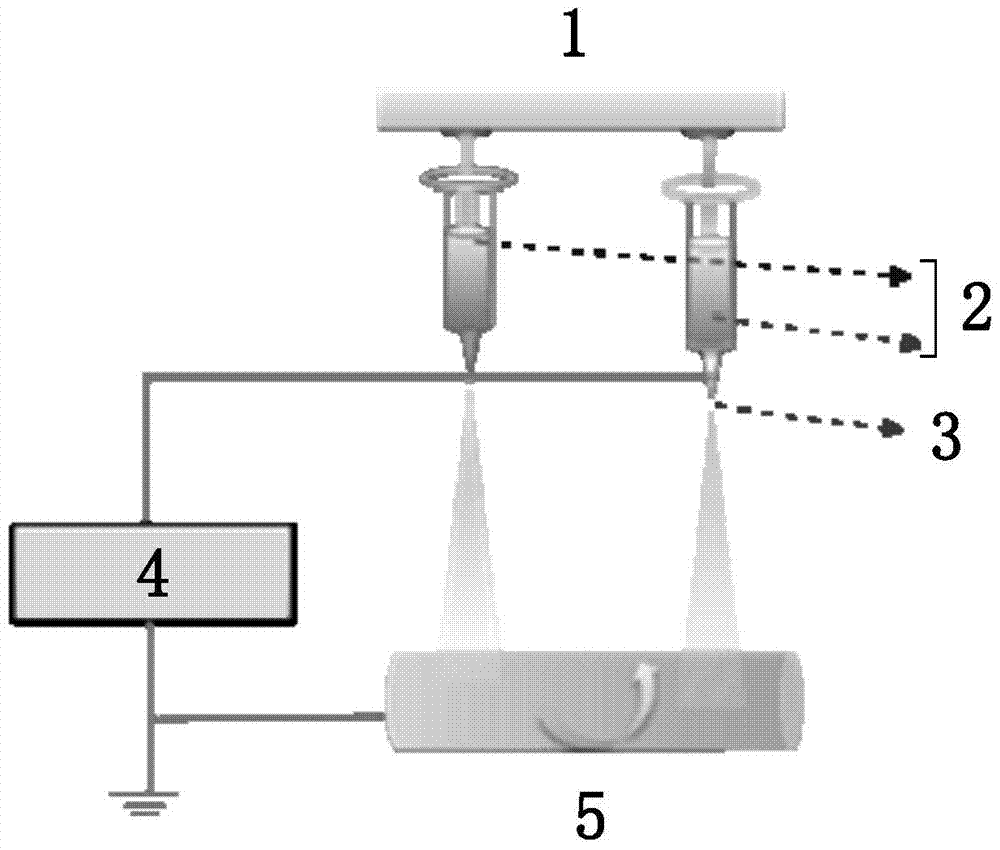

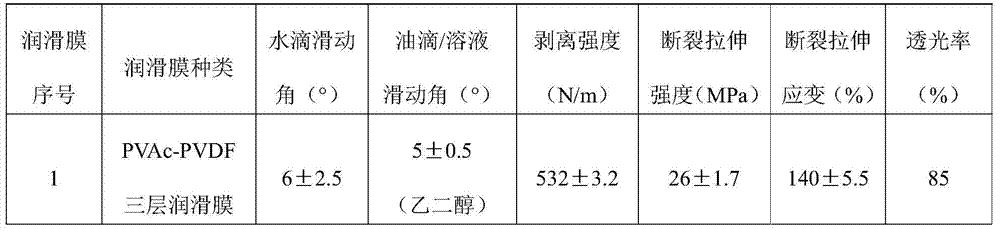

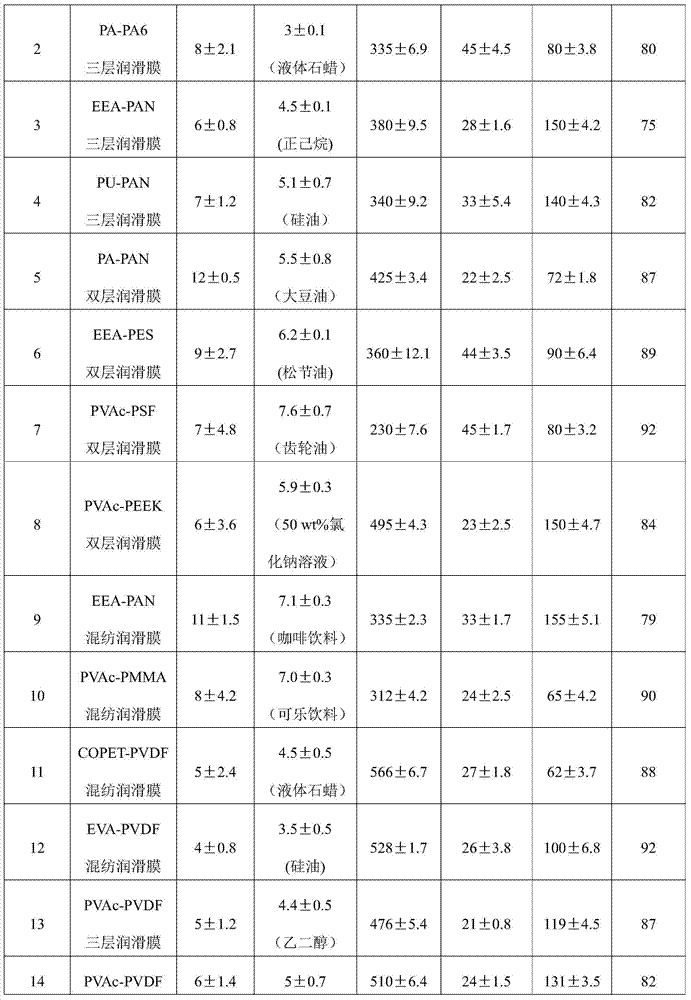

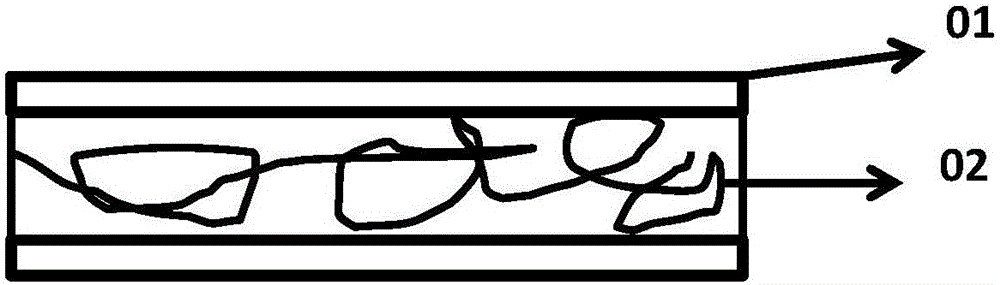

Lubricant film material, raw material composition, preparation method and applications

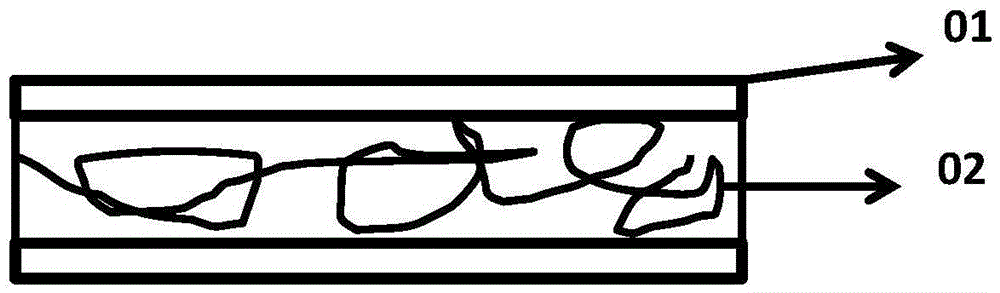

ActiveCN107022848ASimple film making processLow costSynthetic resin layered productsLaminationElectrospinningFilm material

The invention discloses a lubricant film material, a raw material composition, a preparation method and applications. The preparation method comprises following steps: electrostatic spinning films are prepared from spinning liquid A and spinning liquid B through electrostatic spinning; lubrication is performed on the electrostatic spinning films with lubricant; the spinning liquid A is obtained by solving hot melt adhesive in an organic solvent; the spinning liquid B is obtained by solving a hydrophobic polymer in an organic solvent; the melting point of the hot melt adhesive is lower than that of the hydrophobic polymer; the concentration of the hot melt adhesive in the spinning liquid A is 5 wt% to 30 wt%; the concentration of the hydrophobic polymer in the spinning liquid B is 5 wt% to 30 wt% The preparation method has simple process, mild preparation condition, low cost and high production efficiency and is suitable for industrial production; the produced lubricant film material is transparent, has excellent waterproof and oil-proof performance, high mechanical strength and can be used repeatedly, and is especially suitable for water resistance, fog resistance, freezing resistance and oil resistance of glass surface.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Normal temperature solidified titania sol

InactiveCN1218878CLow costNo operating temperatureTitanium dioxideColloidal chemistry detailsPhysical chemistryPeptization

Owner:INST OF CHEM CHINESE ACAD OF SCI

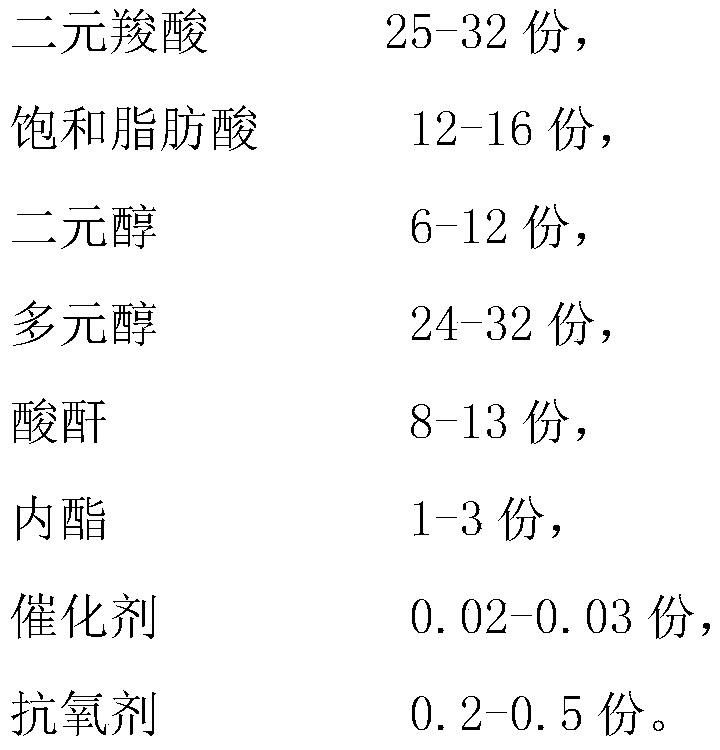

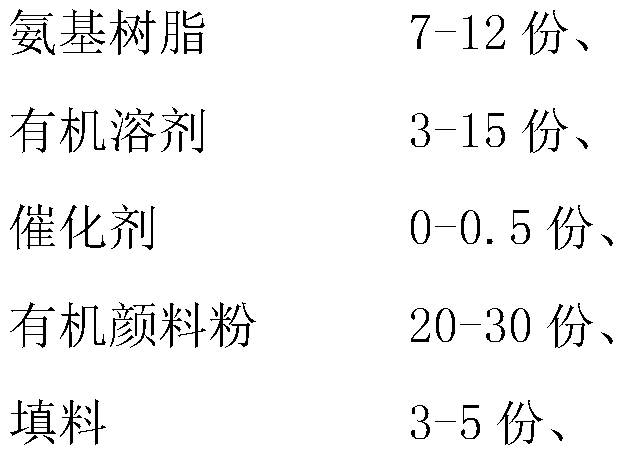

Polyester resin for two-piece can printing ink, two-piece can printing ink and preparation method thereof

InactiveCN111205443AGood viscoelastic thixotropyGood pigment wettingInksPolymer sciencePtru catalyst

The invention provides polyester resin for two-piece can printing ink. The polyester resin is prepared from the following raw materials in parts by weight: 25-32 parts of dicarboxylic acid, 12-16 parts of saturated fatty acid, 6-12 parts of dihydric alcohol, 24-32 parts of polyhydric alcohol, 8-13 parts of anhydride, 1-3 parts of lactone, 0.02-0.03 parts of a catalyst and 0.2-0.5 parts of an antioxidant. The invention further provides a preparation method of the polyester resin for the two-piece can printing ink. The invention further provides the two-piece can printing ink. The two-piece canprinting ink is prepared from the polyester resin for the two-piece can printing ink, amino resin, an organic solvent, a catalyst, organic pigment powder, filler and auxiliaries. Meanwhile, the invention further discloses a method for preparing the two-piece can printing ink from the polyester resin. The two-piece can printing ink prepared by the invention has the advantages of better viscoelasticthixotropy, pigment wettability, scratch resistance, ink flying resistance and the like, particularly, the pencil hardness can reach 7H, and the ink flying test reaches level 5.

Owner:上海超彩油墨有限公司

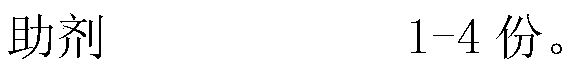

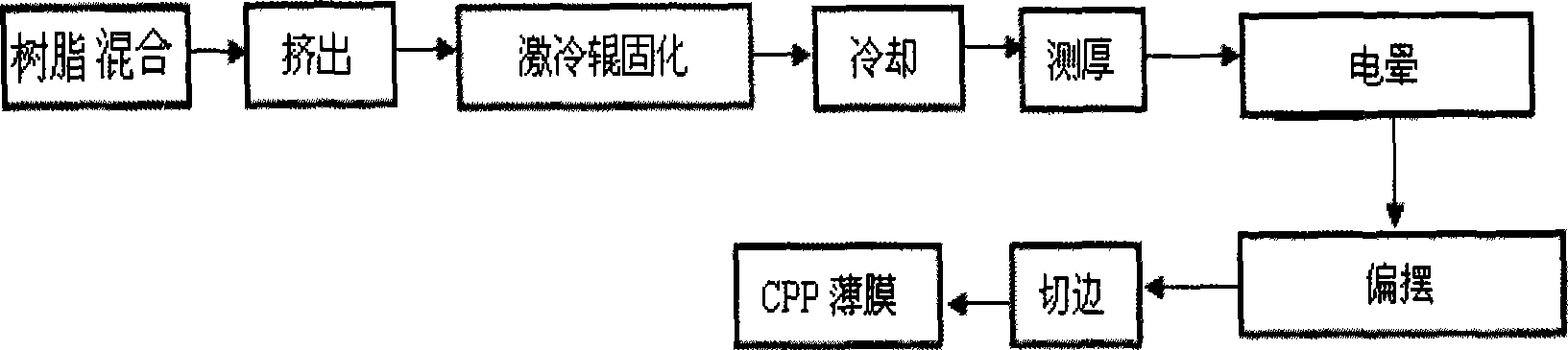

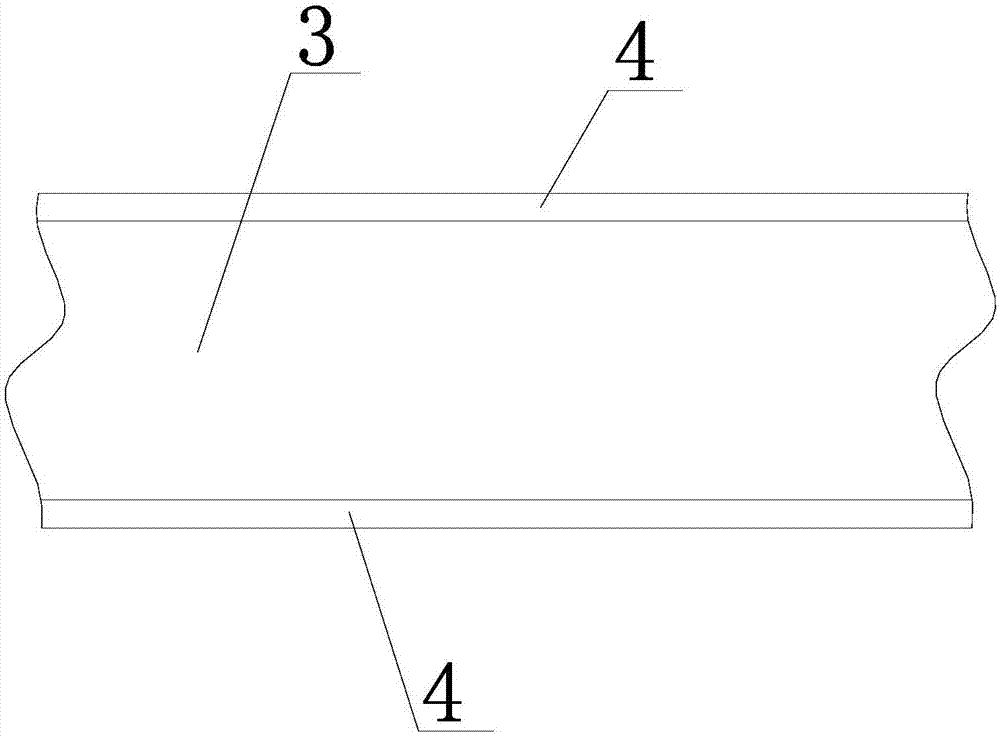

Antifog polypropylene film and preparation method thereof

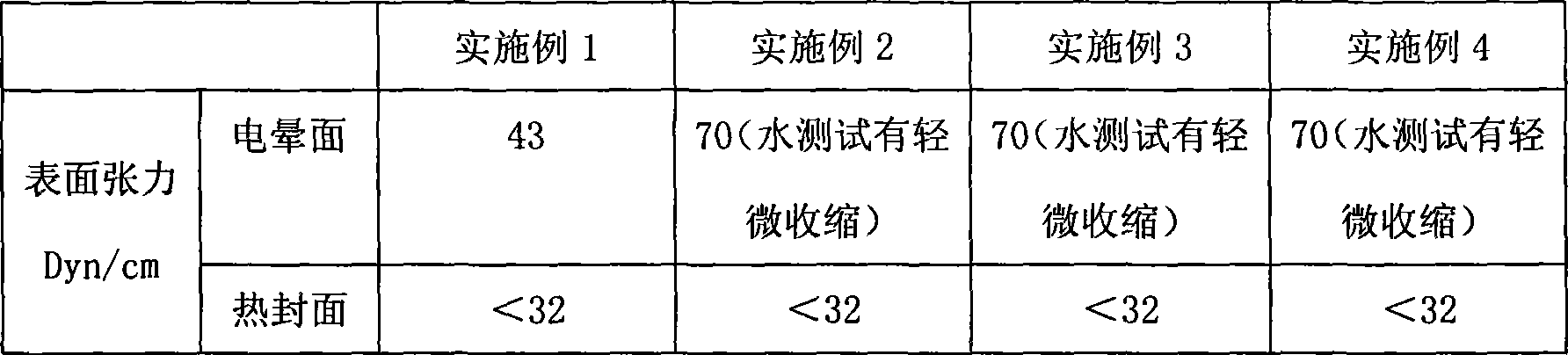

ActiveCN101367282AIncrease wetting tensionGood anti-fogSynthetic resin layered productsPolypropyleneWetting

The invention discloses an antifog polypropylene film and a preparation method thereof. The film consists of a corona layer, an intermediate layer and a heat-sealing layer, and is characterized in that the intermediate layer comprises polypropylene resin and antifog master batches, and the weight ratio of the polypropylene resin to the antifog master batches is between 6 and 15 to 1. The preparation method comprises the following steps in turn: a step of extrusion, a step of cooling setting of a flow casting station, a step of thickness measurement, a step of swing, a step of corona and a step of edge cutting. Compared with the prior art, the surface wetting tension of the antifog polypropylene film can be greatly improved, so that a layer of water film can be formed on the inner surface of the film by vapor emitted by garden stuff to achieve good antifog effect. The polypropylene film is suitable for cold storage packaging below an ambient temperature of between 4 and 10 DEG C.

Owner:HUANGSHAN NOVEL

Anti-electromagnetic interference socket device assembly

InactiveCN105552624AImprove shielding effectGuaranteed purityCouplings bases/casesPermalloyLow frequency band

The invention discloses an anti-electromagnetic interference socket device assembly. An electromagnetic shielding cover body covers the socket device assembly; the electromagnetic shielding cover body which is of a sandwich structure specifically comprises two layers of permalloy plates and a layer of foamed aluminum-copper-nickel alloy sandwiched between the two layers of the permalloy plates and can realize a good shielding effect for electromagnetic waves at a low frequency band and a high frequency band; meanwhile, pollution from electromagnetic radiation of the socket device assembly to the environment is prevented, and interference from outer electromagnetic waves to the socket device assembly is also reduced; furthermore, a nanosheet super-hydrophobic structure is formed after the surface of the permalloy plate of the cover body is subjected to a hydrochloric acid treatment, so that a self-cleaning, anti-fogging, anti-icing and erosion-resisting protective effect is played, and the service life of the socket device assembly can be prolonged.

Owner:邱炎新

Core-shell toughened and anti-fogging preservation master batch for PET film

The invention discloses a core-shell toughened and anti-fogging preservation master batch for a PET film. The master batch comprises the following components in percentage by mass: 10-30 percent of a PET resin, 20-40 percent of nano calcium carbonate, 20-40 percent of an elastomer, 2-6 percent of methylacrylic acid, 1-3 percent of diethyl azodicarboxylate, 3-10 percent of a dripping agent, 3-10 percent of an antifogging agent, 1-3 percent of a stabilizer, 0.5-2 percent of a nucleating agent, 0.5-3 percent of a coupling agent and 0.1-2 percent of an antioxidant. The nano calcium carbonate is treated and interacts with the elastomer so as to carry out a grafting reaction, a core-shell structure in which the elastomer is chemically coated with nano calcium carbonate is formed, and the synergistic toughening effect is enhanced. Meanwhile, the prepared master batch has the characteristics of anti-fogging performance, aging resistance, heat resistance, chemical resistance and the like and can be directly added and used in production of PET films, the process is simple, the operation is convenient, the product quality can be improved, and the master batch has high practical values and application prospects.

Owner:QINGDAO JIAYIYANG IND & TRADE

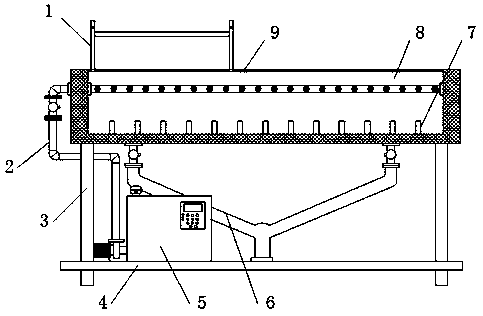

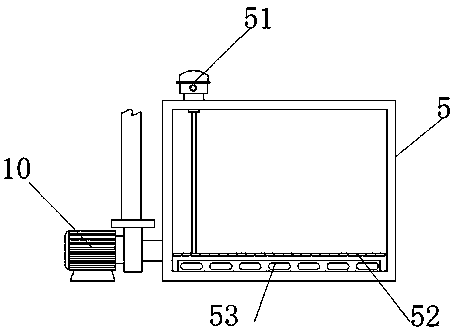

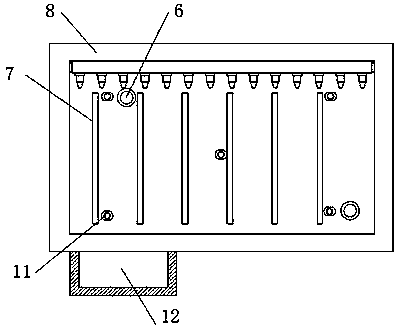

Wet power leakage testing device of photovoltaic module

InactiveCN108259005AReduce the risk of accidentsConstant water temperaturePhotovoltaic monitoringPhotovoltaic energy generationElectricityEngineering

The invention discloses a wet power leakage testing device of a photovoltaic module, which comprises a wet power leakage testing water tank and a protecting plate; the wet power leakage testing watertank is fixed through a supporting rod, and a supporting base in parallel to the wet power leakage testing water tank is installed on the supporting rod closing to the bottom end; the upper part of the supporting base is equipped with a water box, and the water box is fixedly connected with the wet power leakage testing water tank through a water transmission pipe; the water transmission pipe is fixedly connected with the water box through a water circulating pump, and the inner bottom part of the wet power leakage testing water tank is provided with draining pipes distributed in a diagonal line form. The invention designs the wet power leakage testing device of the photovoltaic module, which can keep constant water temperature and reduce accident risk level, and is prepared with a protecting mechanism capable of keeping far from water mist and resisting reflection; the device is made of epoxy resin electric insulation material, the safety performance is high; a convex strip erected atthe bottom part can guarantee that both faces of the photovoltaic module contact with water, the detecting accuracy is improved.

Owner:吴燕

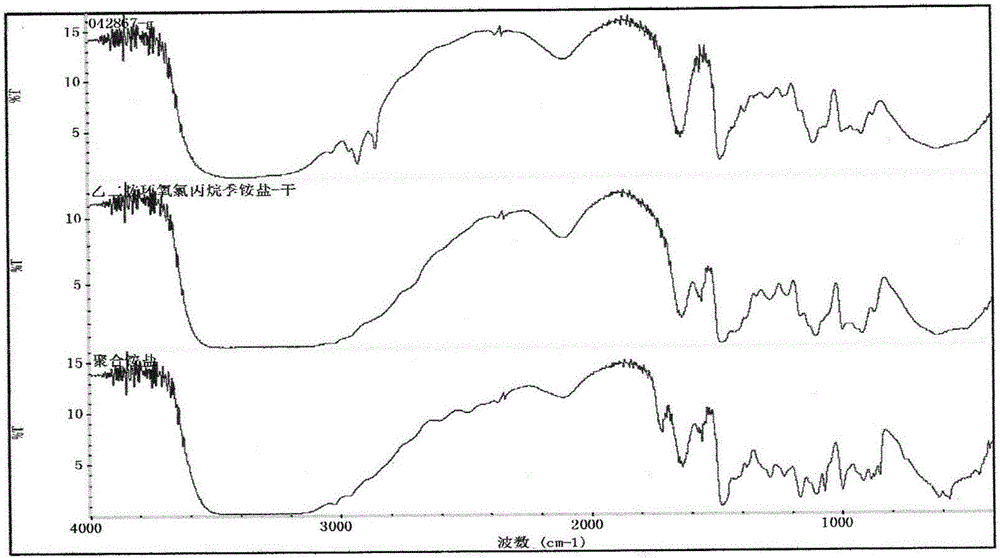

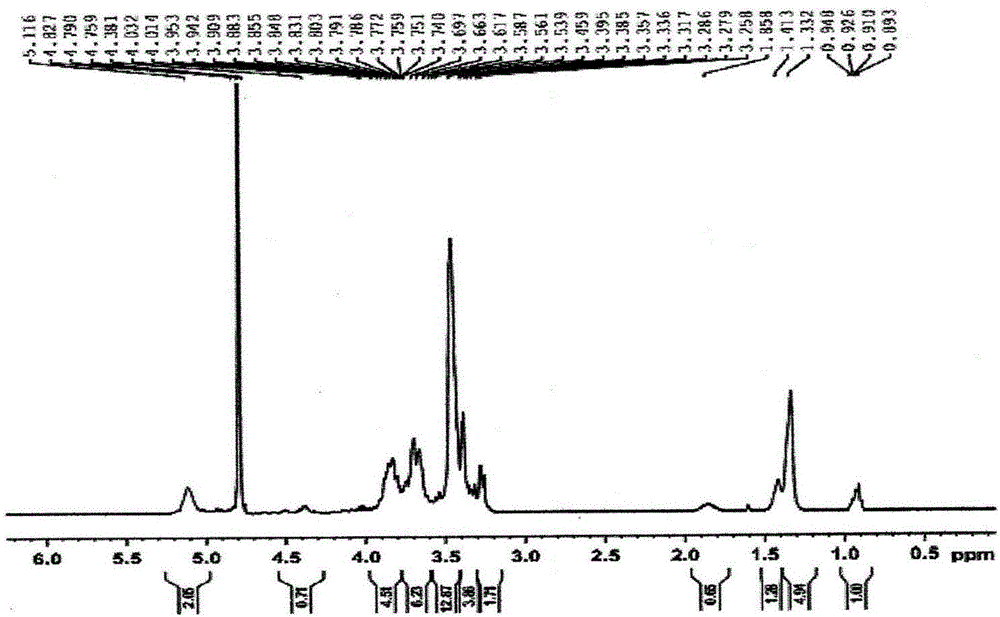

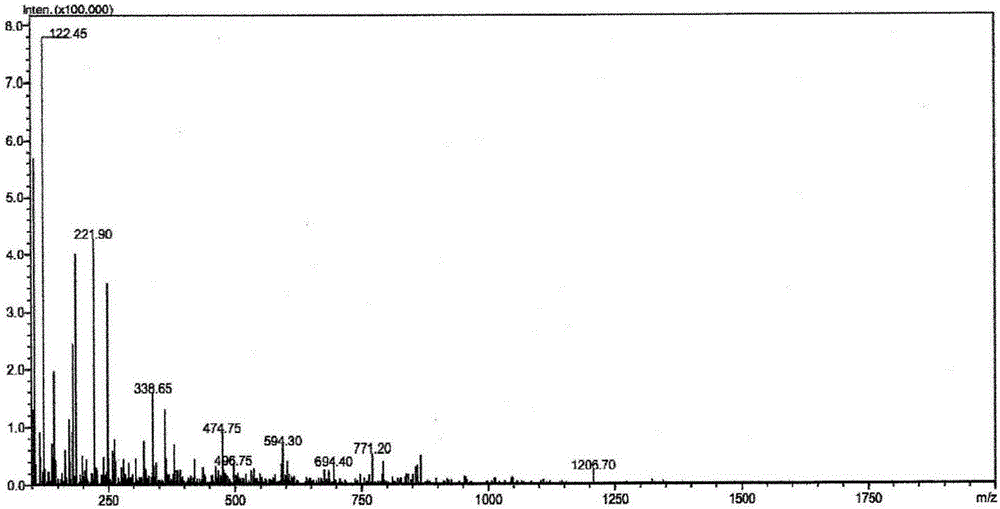

Quaternary ammonium salt cationic surfactant and preparation method thereof

InactiveCN106279680AGood water solubilityGood effectBiocideTransportation and packagingSolubilityHigh pressure

The invention discloses a quaternary ammonium salt cationic surfactant and a preparation method thereof. The preparation method comprises the following steps: adding a dimethylamine aqueous solution and linear chain dimethyl alkyl tertiary amine selected from 10 to 18 carbon atoms into 1-chlorine-2,3-epoxypropane, wherein the molar ratio of the linear chain dimethyl alkyl tertiary amine to the 1-chlorine-2,3-epoxypropane to the dimethylamine is 1.0:(4.0 to 20.0):(3.01 to 20.01); heating to 70 to 90 DEG C and reacting; and finally removing non-reacted materials to obtain the surfactant. The method does not need high pressure and high temperature and avoids three wastes, so the method has the characteristics of environmental friendliness, and safe and simple process. The cationic surfactant obtained by the method has low ecotoxicity, no irritation to a human body and good water solubility, has high charge density, has cleaning, foaming, sterilizing, algae-control, anti-static and anti-fog functions, particularly embodies good cost performance on space disinfection and water sterilization, and has the characteristics that the surfactant is non-toxic and harmless to a human body, is easy to decompose and has good anti-fog and anti-static effects.

Owner:贯硕磉

Environment-friendly and all-purpose windshield washer fluid

InactiveCN106701371AClear visionNo pollution in the processOther chemical processesSurface-active non-soap compounds and soap mixture detergentsSnow meltingStain

The invention provides an environment-friendly and all-purpose windshield washer fluid. The environment-friendly and all-purpose windshield washer fluid is characterized by comprising raw materials in parts by weight as follows: 10-30 parts of methanol, 5-8 parts of calcium chloride dihydrate, 3-6 parts of a surfactant, 4-7 parts of sorbitan monopalmitate, 2-6 parts of water soluble silicone oil and 30-60 parts of deionized water. The environment-friendly and all-purpose windshield washer fluid has the beneficial effects as follows: a freezing point of the prepared windshield washer fluid is subzero 47 DEG C or lower, a boiling point is 73 DEG C or higher, and the environment-friendly and all-purpose windshield washer fluid has good freeze-proofing, anti-fogging and snow-melting effects as well as strong stain and oil removing effects. With the adoption of the environment-friendly and all-purpose windshield washer fluid, clear sight of a driver and driving safety can be guaranteed, and besides, the windshield washer fluid has no pollution to environment and is safe and environment-friendly.

Owner:TIANCHANG EARTHQUAKE OFFICE

Anti-electromagnetic interference type vacuum circuit breaker

InactiveCN105513883AImprove shielding effectGuaranteed purityLamination ancillary operationsLaminationLow frequency bandPermalloy

The invention discloses an anti-electromagnetic interference type vacuum circuit breaker. A shield with an electromagnetic shielding function covers the vacuum circuit breaker body and is of a sandwich structure, and particularly, the sandwich structure is formed by sandwiching a foamed aluminum-copper-nickel alloy layer between two permalloy layers. The anti-electromagnetic interference type vacuum circuit breaker has the advantages that low-frequency-band and high-frequency-band electromagnetic waves can be well shielded, environmental pollution caused by electromagnetic radiation of the vacuum circuit breaker is prevented, and interference of external electromagnetic waves on the vacuum circuit breaker is weakened; further, the permalloy surface of the shield is subjected to hydrochloric acid treatment to form a nanosheet super-hydrophobic structure, so that self-cleaning, antifog, anti-freezing and anticorrosive protection effects are achieved, and service life of the vacuum circuit breaker can be prolonged.

Owner:邱炎新

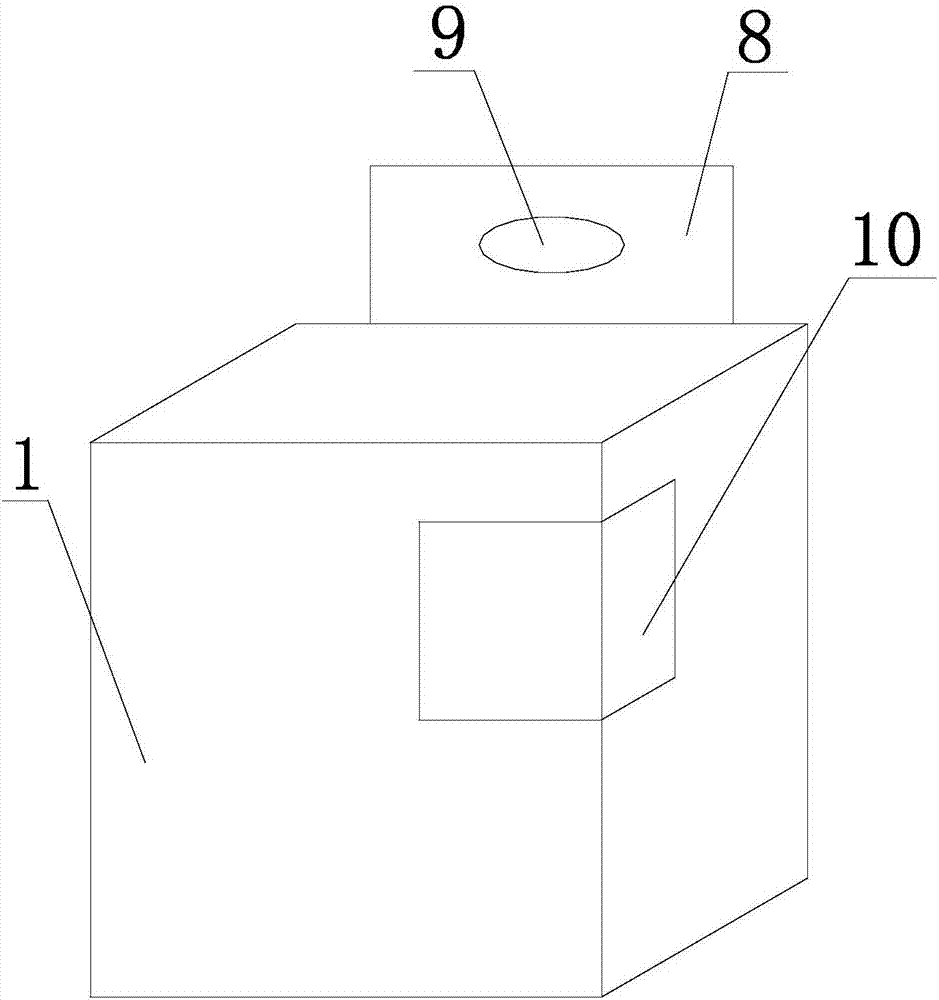

Color printing packaging box

InactiveCN107380603AFast molding speedSimple structurePaper/cardboard layered productsCoatingsSurface layerColor printing

The invention discloses a color printing packaging box, which solves the problems that the prior art does not have waterproof, anti-fog, oil-proof, insect-proof and unsatisfactory physical strength. The packaging box of the present invention is square, and is made of degradable stone cardboard folded and pasted according to the fold marks on it. The front and back of the stone cardboard are printed with a layer of color pattern surface layer and monochrome inner layer respectively, and the color pattern surface layer is heated. Pressed with a layer of transparent waterproof and dustproof film, the stone cardboard includes the main body of the stone cardboard and the coating layer. The top of the packaging box is provided with square top ears that are opened inwardly and connected to the oval hole, and the box body of the packaging box is provided with a transparent window. The invention has simple structure, scientific and reasonable design, convenient use, effective waterproof, anti-fog, oil-proof and insect-proof, good sealing performance, high physical strength, beautiful appearance, fast forming speed of the packaging box, and internal product identification function, which greatly improves the The scope of application of the present invention is expanded.

Owner:中山市中正包装印刷有限公司

Building external wall with good anti-electromagnetic radiation performance

InactiveCN105735591AImprove shielding effectGuaranteed purityCovering/liningsLaminationPermalloyLow frequency band

The invention discloses a building external wall with the good anti-electromagnetic radiation performance. An electromagnetic shielding material is pasted on the outer surface of the building external wall. The electromagnetic shielding material is of a sandwich structure, and specifically formed by sandwiching a layer of foamed aluminum-copper-nickel alloy between two layers of permalloy plates. The electromagnetic shielding material has good shielding effects on low-frequency-band and high-frequency-band electromagnetic waves, avoids indoor electromagnetic information leakage and reduces interference of outside electromagnetic waves on the indoor environment. Further, the surfaces of the permalloy plates of the material are subjected to hydrochloric acid treatment to form nanosheet super-hydrophobic structures, so that the self-cleaning, anti-foggy, anti-frozen and anti-corrosive protective effects are achieved, and the service life of the building external wall can be prolonged.

Owner:邱炎新

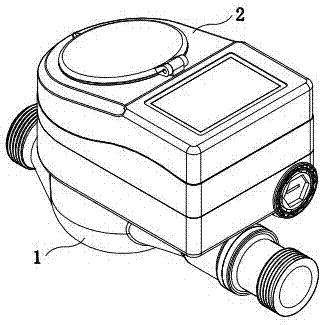

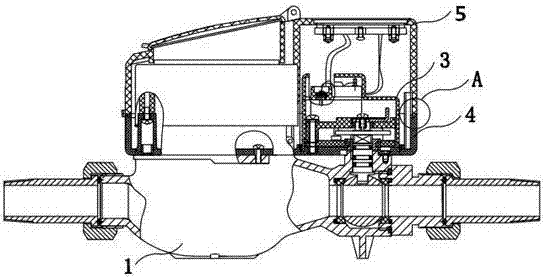

Intelligent valve control water meter control box

The invention relates to an intelligent valve control water meter control box, and belongs to the technical field of an intelligent valve control water meter. The intelligent valve control water meter control box is composed of an upper box body, a lower box body, a meter cover and a sealing element; the upper and lower box bodies are fastened and connected by a screw through a positioning sealing device at the binding face part; a metering and sampling path of the water meter is introduced by sealing a specific sealing cabin in the lower box body by means of glue body; a battery cabin is matched with an O-shaped sealing ring so as to seal the battery cabin end; sealing and protection of an intelligent water meter main control element, an executor part and a power battery are realized; the intelligent valve control water meter control box is applicable to the technical improvement of the like intelligent product, and also meaningful to popularize and apply.

Owner:臧艳丽

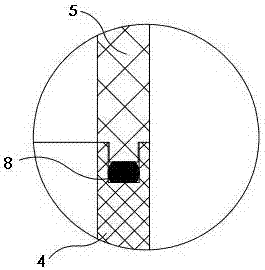

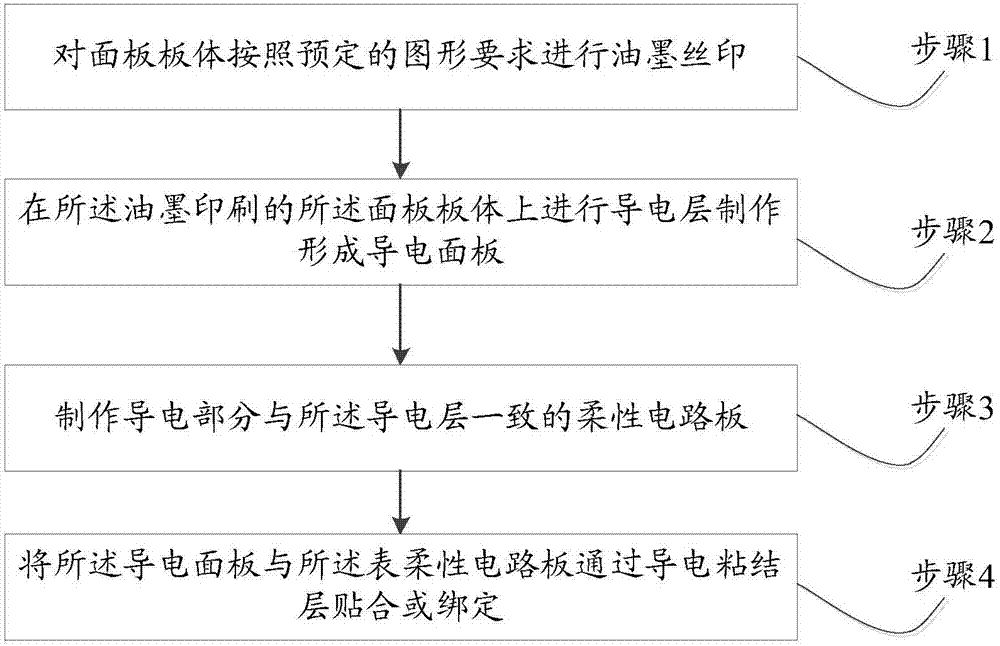

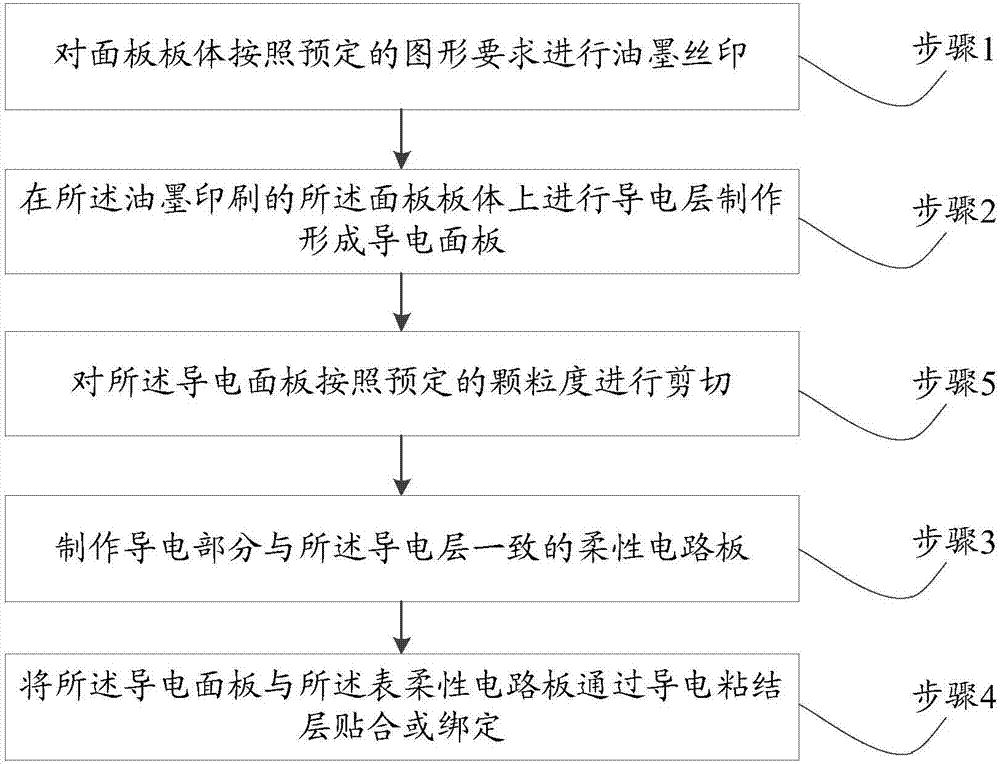

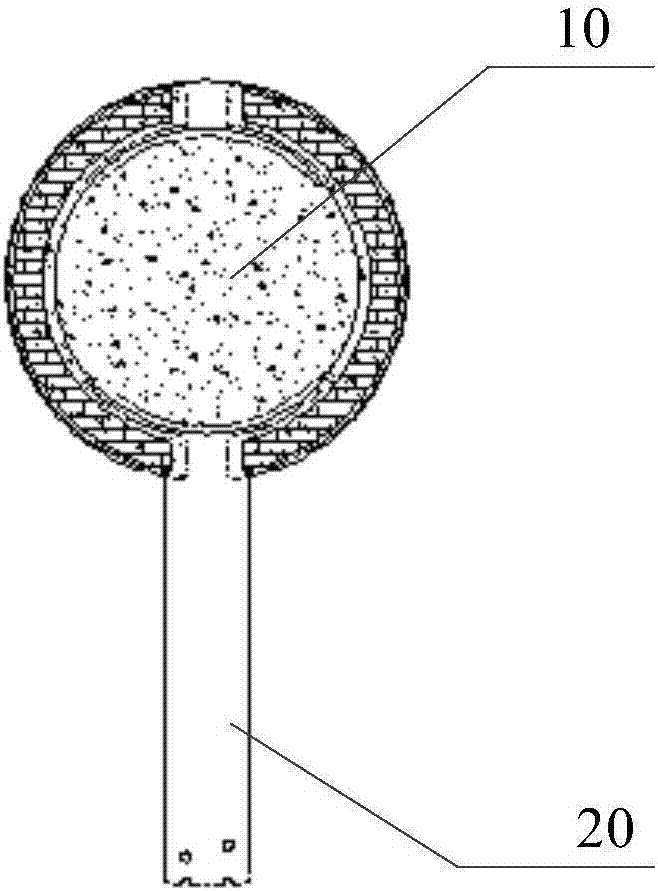

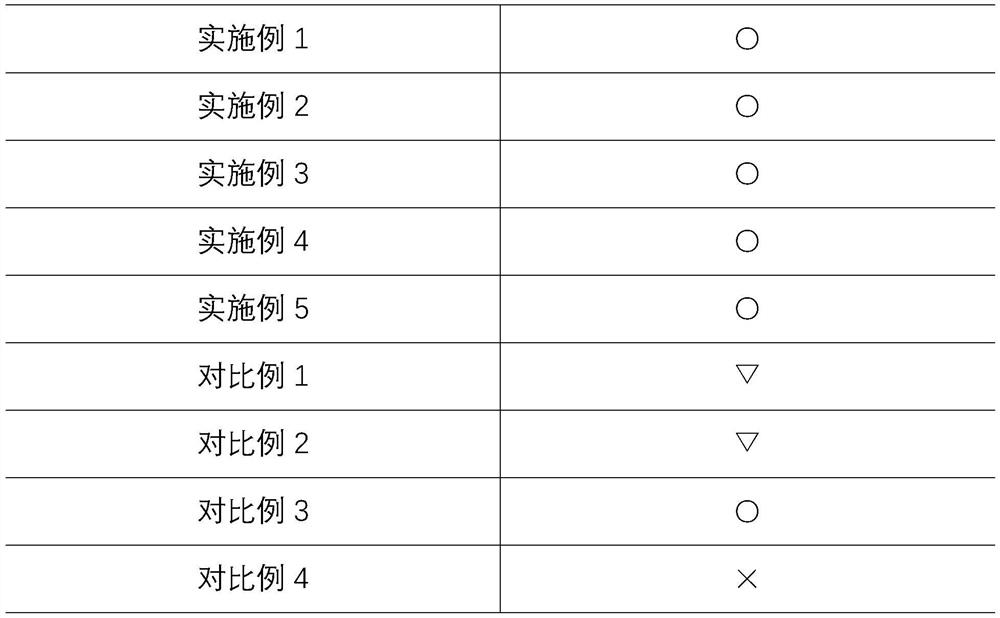

Electrical heating panel device and manufacturing method thereof

InactiveCN107071944AGood anti-fogImprove defogging effectTransparent/reflecting heating arrangementsHeating element materialsScreen printingFlexible circuits

The invention discloses an electrical heating panel device and a manufacturing method thereof. The manufacturing method comprises the following steps: step one, carrying out printing ink screen printing on a panel body according to predetermined graphic requirements; step two, carrying out conducting layer manufacturing on the panel body through the printing ink screen printing to form a conducting panel; step three, manufacturing a flexible circuit board, of which the conducting part is consistent with a conducting layer; and step four, gluing or binding the conducting panel with the flexible circuit board through a conducting bonding layer. The panel or a cover plate is glued or bond with the flexible circuit board by adopting the conducting bonding layer, and the connection is conducted, so that the production process is simplified, the process difficulty is reduced, the manufacturing efficiency is improved, and the manufacturing cost is reduced.

Owner:TRULY OPTO ELECTRONICS

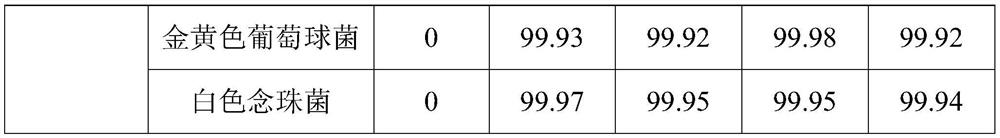

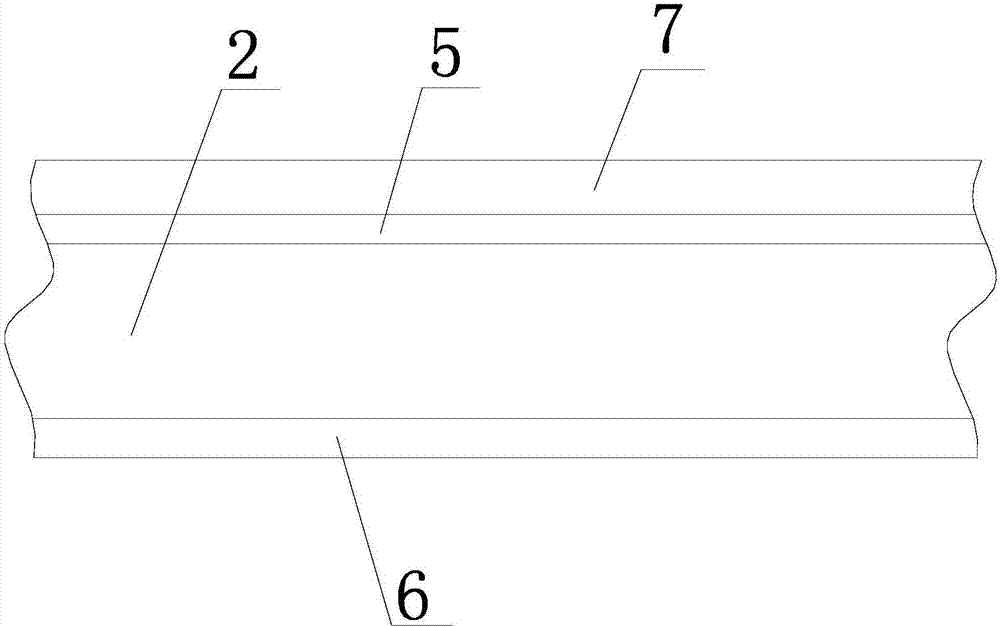

A kind of anti-fog antibacterial BOPP film and preparation method thereof

ActiveCN109094159BEasy to heat sealHigh tensile strengthSynthetic resin layered productsMasterbatchAnti-Adhesion Agent

The invention provides an anti-fog antibacterial BOPP film and a preparation method thereof. The film is prepared by sequentially and biaxially stretching an upper surface layer, a core layer and a lower surface layer, wherein the upper surface layer is an anti-fog layer composed of the following components by weight: 3-4 parts of anti-fog master batch, 2-3 parts of organic anti-adhesive agent and93-95 parts of heat sealing material; the core layer is homo-polypropylene; the lower layer is an anti-fog antibacterial layer composed of the following components by weight: 1-2 parts of antibacterial master batch, 2-3 parts of organic anti-adhesive agent, 4-5 parts of anti-fog master batch and 90-93 parts of heat sealing material. According to the preparation method, the anti-fog antibacterialBOPP film can be produced by direct co-extrusion in the biaxial stretching production line. Compared with the traditional coating anti-fog antibacterial film, the BOPP film can save the investment ofa coating machine and avoid pollution and energy loss caused by the later coating. At the same time, the film is more excellent and stable in anti-fog performance, and has long-term antibacterial capability.

Owner:ANHUI GUOFENG PLASTIC

Long-acting anti-fog dripping coating liquid for agricultural plastic greenhouse film and preparation method of long-acting anti-fog dripping coating liquid

ActiveCN112961519AGood anti-fogGood dripping double effectAlkali metal silicate coatingsClimate change adaptationEmulsionCoconut diethanolamide

The invention discloses long-acting transparent anti-fog dripping coating liquid for an agricultural plastic greenhouse film and a preparation method of the long-acting transparent anti-fog dripping coating liquid. The transparent long-acting anti-fog dripping coating liquid for the agricultural plastic greenhouse film comprises 10%-20% of silicate, 1%-10% of a modified latex binder, 1%-10% of coconut diethanolamide and 60%-88% of water. The silicate is a compound of metal silicate, and the modified latex is a modified acrylate series emulsion. The externally-smeared anti-fog dripping coating for the agricultural plastic greenhouse film has good anti-fog and dripping dual effects, the initial dripping time and the ten dripping time are both superior to national standard values, and the externally-smeared anti-fog dripping coating for the agricultural plastic greenhouse film has the advantages of long anti-fog dripping lasting time, biodegradability, no pollution to the environment, capability of enabling the greenhouse film to have self-repairing performance and the like.

Owner:山东齐舜新材料有限公司

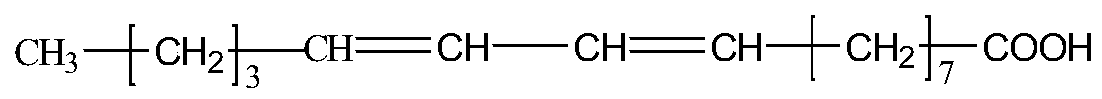

Tung oil modified organosilicon multifunctional coating and preparation method thereof

InactiveCN111393991AReduce surface tensionExpand the scope of influenceFireproof paintsAntifouling/underwater paintsTriethoxysilaneAcid catalyzed

The invention discloses tung oil modified organic silicon multifunctional coating and a preparation method thereof. The coating is prepared by or the preparation method comprises the following steps:firstly preparing resin and then preparing the coating. The preparation method of the resin comprises the following steps: adding dodecene and triethoxysilane into a four-neck flask, starting mechanical stirring, with a condensate being orange non-transparent liquid at this moment, heating with an oil bath, removing moisture in raw materials, feeding high-purity nitrogen, heating, adding a chloroplatinic acid isopropanol solution, reacting, adding tung oil, reacting, removing small molecules, performing vacuum release, cooling and discharging to obtain resin; sealing and storing the coating. The resin for the coating is prepared by selecting one of four preparation methods. The coating is obtained by reacting dodecene, triethoxysilane and tung oil under the catalysis of chloroplatinic acid. Due to the excellent molecular structure, the adhesive force is good. The multifunctional coating has the advantages of low surface tension, favorable corrosion resistance, favorable rust resistance, favorable fog resistance and favorable water resistance, has wide application range, and can be widely used in severe environments.

Owner:刘翠芬

Heating type anti-fog mask and heating type anti-fog helmet

PendingCN111772288AWith heating functionImprove defogging effectHelmetsHelmet coversThermodynamicsEngineering

The invention provides a heating type anti-fog mask and a heating type anti-fog helmet, and relates to the field of safety protection articles. According to the heating type anti-fog mask, the transparent heating element is arranged in the heating type anti-fog mask or the transparent heating layer is arranged in the mask body, so that the heating type anti-fog mask has a heating function, and therefore, the heating type anti-fog mask has a relatively good demisting effect when the air temperature is cold. Furthermore, the electrodes on the two sides of the same face of the transparent heatinglayer are designed to be strip-shaped electrodes, and sight is not affected. The heating type anti-fog helmet comprises the heating type anti-fog mask and has excellent anti-fog and defogging effects. Furthermore, an electric heating film can be further arranged in the interlayer of the helmet body of the heating type anti-fog helmet, the head can be kept warm in a cold environment, and the wearing comfort is improved.

Owner:深圳烯旺先进材料技术有限公司

Production method of suede fabric material with strong water absorption

InactiveCN103882695AReduce manufacturing costSimple processHeating/cooling textile fabricsAnimal fibresDyeingEngineering

The invention discloses a production method of a suede fabric material with strong water absorption, after initial shaping, teasing, shearing, splitting, dyeing, heat shaping and sanding treatment of warp knitted suede, an obtained suede fabric material is soaked in a strong hygroscopic liquid for soaking, and then is dried in air to obtain the final product suede fabric material with strong water absorption. The initial shaping temperature is 155-160 DEG C, the heat shaping temperature is 185-190 DEG C, the dyeing temperature is 120-130 DEG C; the splitting is performed in an alkaline solution, the alkaline solution temperature is 145-150 DEG C. The strong hygroscopic liquid comprises the components of lauryl sodium sulfate, an emulsifier, a penetrant, glycerin and water. The suede fabric material with strong water absorption has good anti-fog, decontaminating and mildew-proof effects, is low in production cost, simple in process, and good in use effect, and can be widely used in daily life.

Owner:QINGDAO TONGGUANWANG IND

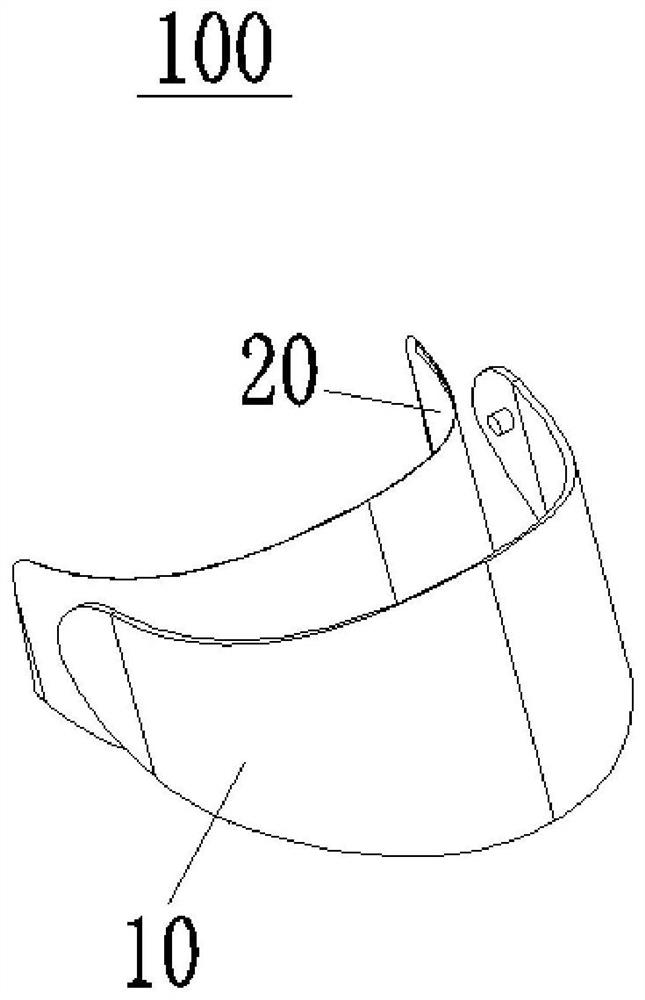

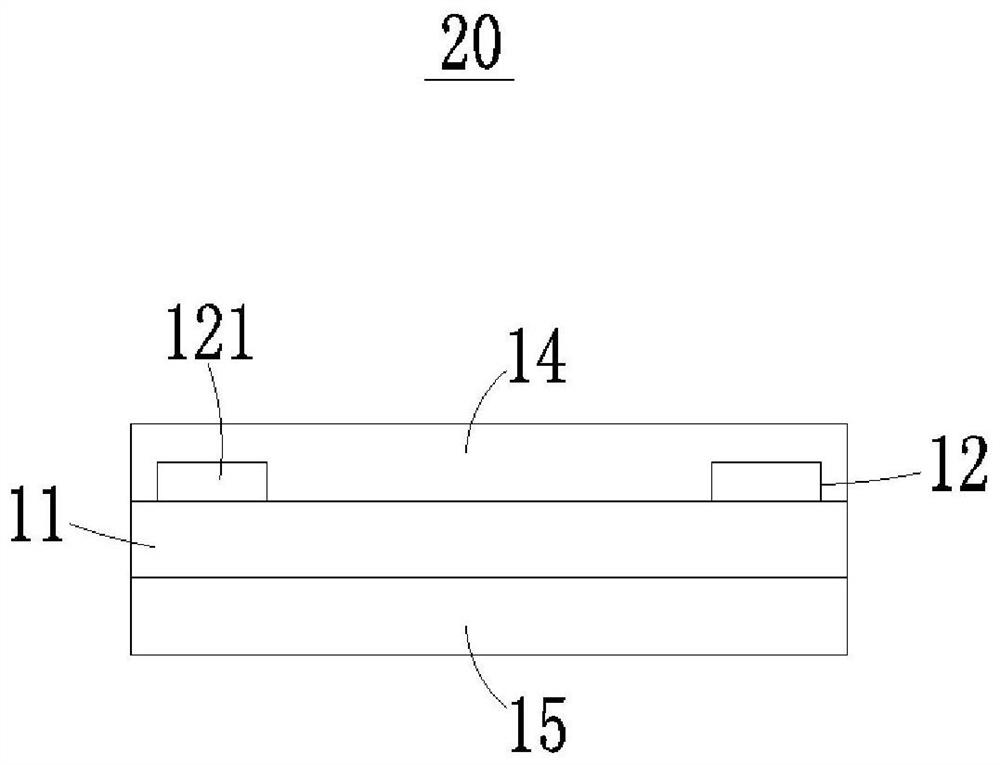

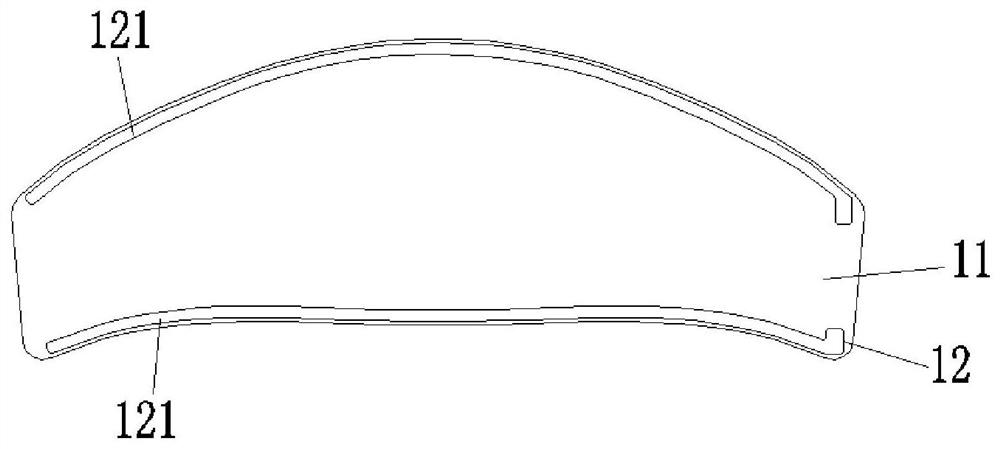

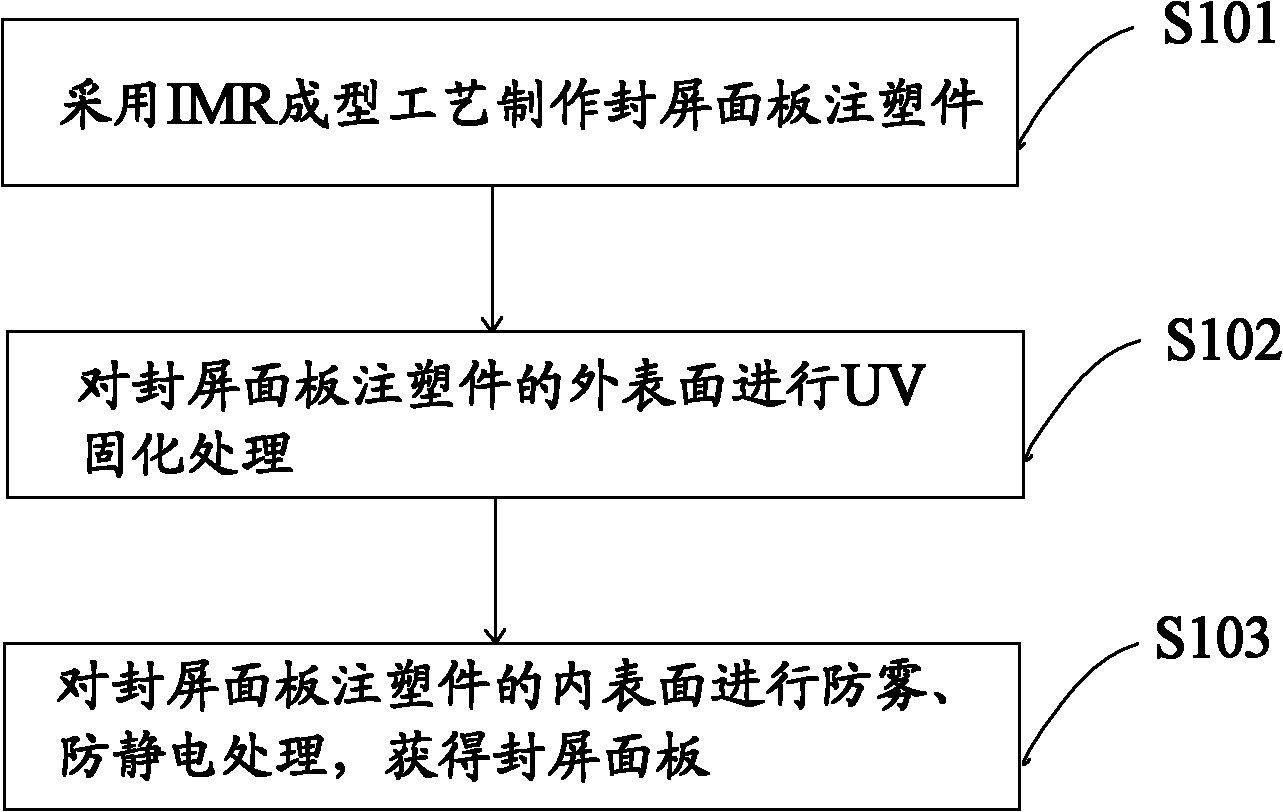

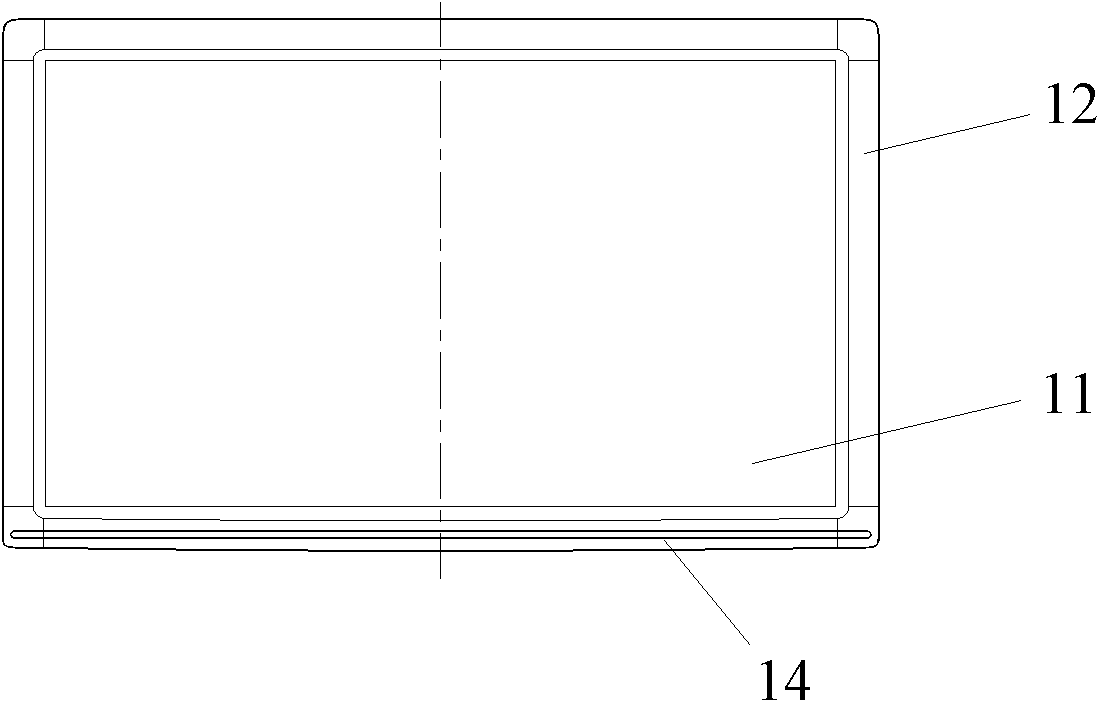

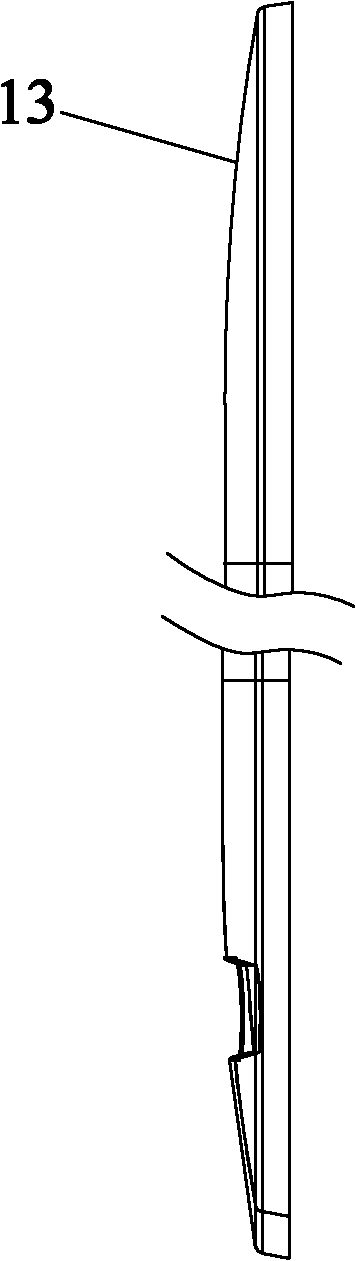

Method for manufacturing screen sealing panel, screen sealing panel and television

ActiveCN102179897AReduce post-processing linksSimplified and shortened manufacturing processTelevision system detailsColor television detailsUV curingEngineering

The invention is applied in the field of display electronic products, and provides a method for manufacturing a screen sealing panel, the screen sealing panel and a television. The method comprises the following steps of: manufacturing a screen sealing panel injection molding piece by adopting an in-molding roller (IMR) forming process; performing ultraviolet (UV) curing treatment on the outer surface of the screen sealing panel injection molding piece; and performing anti-fog and antistatic treatment on the inner surface of the screen sealing panel injection molding piece to obtain the screen sealing panel. Because the injection molding piece of the screen sealing panel is manufactured by adopting the IMR forming process, the automation degree of the production is high, and the mass production cost is low. By the UV curing treatment on the outer surface of the injection molding piece, the problems of poor surface quality, low yield and the like caused by the traditional UV coating method can be avoided. By the anti-fog and antistatic treatment on the inner surface of the injection molding piece, the quality of the screen sealing panel is further improved. Because the anti-fog and antistatic treatment step is carried out after the UV curing step, the hardened injection molding piece is subjected to anti-fog and antistatic treatment so that the product can be protected from being scratched.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com